An Investigation to Study the Effect of Process Parameters on the Strength and Fatigue Behavior of 3D-Printed PLA-Graphene

Abstract

:1. Introduction

2. Material Description and Experimental Methods

2.1. PLA-Graphene Filament

2.2. 3D Printer Device

2.3. Characterization Methods and Experimental Procedure

2.3.1. Microscopic Observation

2.3.2. Quasi-Static Tensile Test

2.3.3. Fatigue Test

2.4. Condition of Printing

3. Results and Discussion

3.1. Quasi-Static Tensile Test

3.1.1. PLA-Graphene Filament

3.1.2. Influence of Process Parameters on the Tensile Behavior of Printed Vertical Walls

- The influence of Tplatform on ultimate strength is limited. When platform temperature is increased, the ultimate strength varies around 24%, whereas the increase in print speed causes approximately a 38% variation.

- Average failure strain occurs around 6% by variation of platform temperature, which is around 7% in the case of changing of print speed.

- In general, the variation of Young’s modulus in the case of the samples printed at different platform temperature is higher than that of a different print speed.

- Overall, print speed has more influence on the enhancement of the bonding and strength of the deposited filaments.

3.1.3. Influence of Process Parameters on the Tensile Behavior of Printed Tensile Samples

- By increasing the print speed in the range of 20 mm/s–40 mm/s (e.g., conditions I-1 and III-1), the tensile strength of the PLA-Graphene increased by 5%.

- By increasing the print speed in the range of 20 mm/s–40 mm/s (e.g., conditions I-3 and III-3), the failure strain increased by 20%.

- By increasing the platform temperature from 40 °C to 60 °C in each condition group (e.g., condition I), Young’s modulus and tensile strength increased by 17% and 5%, respectively.

- By increasing the platform temperature from 40 °C to 60 °C in each condition group (e.g., condition II), the failure strain increased by 12%.

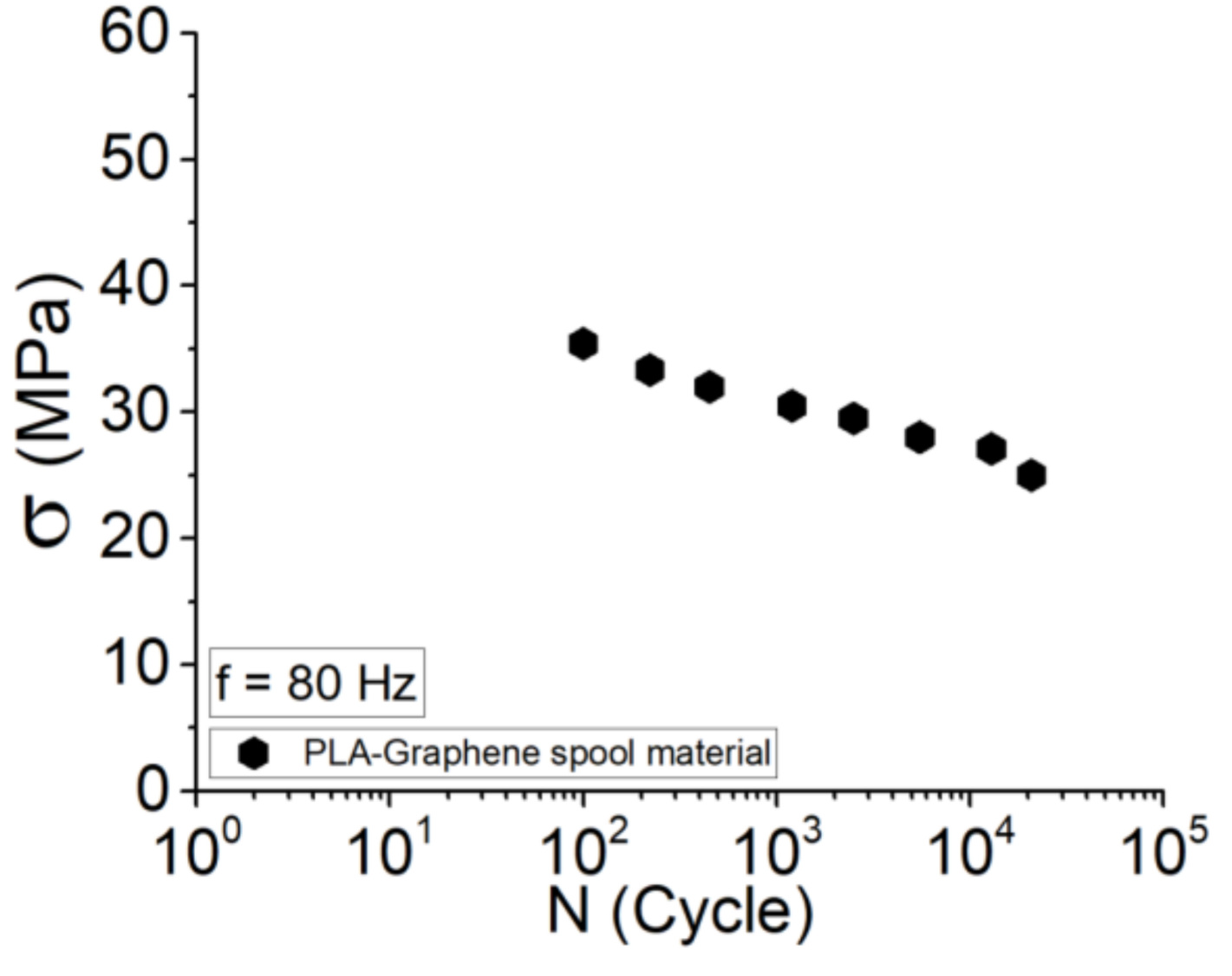

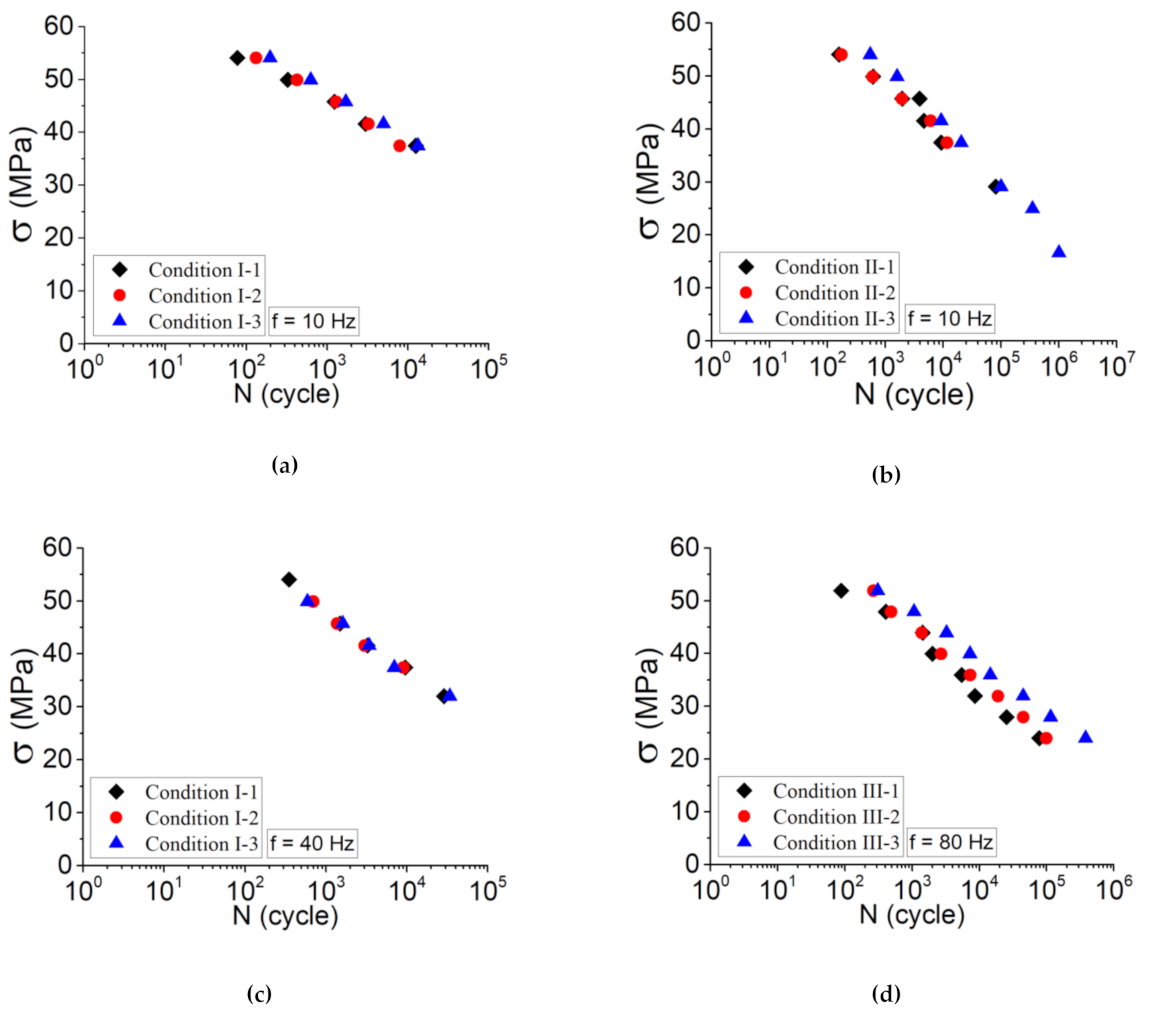

3.2. Fatigue Behavior Analysis

3.2.1. Influence of Process Parameters

3.2.2. Relative Young’s Modulus Evolution

- The higher the platform temperature, the lower the damage caused during fatigue test.

- The significance of kinetic damage is observed for the samples printed with the lowest platform temperature and print speed (in a same frequency).

- The higher the applied frequency, the higher the damage appeared during the fatigue test.

3.2.3. Self-Heating Phenomenon

- The fracture surface observed in the case of low frequency (Figure 13a,b) shows that the enhancement of the induced temperature until glass transition temperature at low amplitude tends to increase the ductility of the sample, whereas the brittle fracture is more obvious at a high amplitude.

- SEM observations on the samples tested at 80 Hz highlight ductile fracture (Figure 13c,d). In fact, self-heating provides more deformation at low amplitude; however, the influence of high frequency and the ductile behavior of the sample is inevitable.

- In general, the higher the self-heating, the more the ductility of the material.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- el Magri, A.; Vaudreuil, S.; el Mabrouk, K.; Touhami, M.E. Printing temperature effects on the structural and mechanical performances of 3D printed Poly-(phenylene sulfide) material. IOP Conf. Ser. Mater. Sci. Eng. 2020, 783, 012001. [Google Scholar] [CrossRef]

- Sohrabian, M.; Vaseghi, M.; Khaleghi, H.; Dehrooyeh, S.; Kohan, M.S.A. Structural Investigation of Delicate-Geometry Fused Deposition Modeling Additive Manufacturing Scaffolds: Experiment and Analytics. J. Mater. Eng. Perform. 2021, 1–13. [Google Scholar]

- Vanaei, S.; Parizi, M.; Salemizadehparizi, F.; Vanaei, H.R. An overview on materials and techniques in 3d bioprinting toward biomedical application. Eng. Regen. 2021, 2, 1–18. [Google Scholar]

- Iftikhar, A.; Khan, M.; Alam, K.; Imran Jaffery, S.H.; Ali, L.; Ayaz, Y.; Khan, A. Turbine blade manufacturing through rapid tooling (RT) process and its quality inspection. Mater. Manuf. Process. 2013, 28, 534–538. [Google Scholar] [CrossRef]

- Noorani, R. Rapid Prototyping: Principles and Applications; John Wiley & Sons Incorporated: Hoboken, NJ, USA, 2006. [Google Scholar]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. Int. Sch. Res. Not. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- el Magri, A.; el Mabrouk, K.; Vaudreuil, S.; Chibane, H.; Touhami, M.E. Optimization of printing parameters for improvement of mechanical and thermal performances of 3D printed poly (ether ether ketone) parts. J. Appl. Polym. Sci. 2020, 137, 49087. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Shirinbayan, M.; Costa, S.F.; Duarte, F.M.; Covas, J.A.; Deligant, M.; Khelladi, S.; Tcharkhtchi, A. Experimental study of PLA thermal behavior during fused filament fabrication. J. Appl. Polym. Sci. 2021, 138, 49747. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Deligant, M.; Shirinbayan, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. A comparative in-process monitoring of temperature profile in fused filament fabrication. Polym. Eng. Sci. 2021, 61, 68–76. [Google Scholar] [CrossRef]

- el Magri, A.; el Mabrouk, K.; Vaudreuil, S.; Touhami, M.E. Experimental investigation and optimization of printing parameters of 3D printed polyphenylene sulfide through response surface methodology. J. Appl. Polym. Sci. 2021, 138, 49625. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Shirinbayan, M.; Deligant, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Influence of process parameters on thermal and mechanical properties of polylactic acid fabricated by fused filament fabrication. Polym. Eng. Sci. 2020, 60, 1822–1831. [Google Scholar] [CrossRef]

- Lyu, Y.; Yin, H.; Chen, Y.; Zhang, Q.; Shi, X. Structure and evolution of multiphase composites for 3D printing. J. Mater. Sci. 2020, 55, 6861–6874. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.; Bellehumeur, C.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Torres, J.; Cotelo, J.; Karl, J.; Gordon, A.P. Mechanical property optimization of FDM PLA in shear with multiple objectives. JOM 2015, 67, 1183–1193. [Google Scholar] [CrossRef]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Magri, A.E.; el Mabrouk, K.; Vaudreuil, S.; Touhami, M.E. Mechanical properties of CF-reinforced PLA parts manufactured by fused deposition modeling. J. Thermoplast. Compos. Mater. 2021, 34, 581–595. [Google Scholar] [CrossRef]

- Raissi, H.R.V.K.; Deligant, M.; Shirinbayan, M.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Toward the understanding of temperature effect on bonding strength, dimensions and geometry of 3D-printed parts. J. Mater. Sci. 2020, 55, 14677–14689. [Google Scholar]

- Vanaei, H.R.; Shirinbayan, M.; Vanaei, S.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Multi-scale damage analysis and fatigue behavior of PLA manufactured by fused deposition modeling (FDM). Rapid Prototyp. J. 2021, 27, 371–378. [Google Scholar] [CrossRef]

- Khayamian, M.A.; Shalileh, S.; Vanaei, S.; Parizi, M.S. Electrochemical generation of microbubbles by carbon nanotube interdigital electrodes to increase the permeability and material uptakes of cancer cells. Drug Deliv. 2019, 26, 928–934. [Google Scholar] [CrossRef] [Green Version]

- Terekhina, S.; Tarasova, T.; Egorov, S.; Skornyakov, I.; Guillaumat, L.; Hattali, M. The effect of build orientation on both flexural quasi-static and fatigue behaviours of filament deposited PA6 polymer. Int. J. Fatigue 2020, 140, 105825. [Google Scholar] [CrossRef]

- el Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021. [Google Scholar] [CrossRef]

- el Magri, A.; el Mabrouk, K.; Vaudreuil, S. Preparation and characterization of poly (ether ether ketone)/poly (ether imide)[PEEK/PEI] blends for fused filament fabrication. J. Mater. Sci. 2021, 56, 14348–14367. [Google Scholar] [CrossRef]

- Alhubail, M.; Alenezi, D.; Aldousiri, B. Taguchi-based optimisation of process parameters of fused deposition modelling for improved part quality. Int. J. Eng. Res. Technol. 2013, 2, 2519. [Google Scholar]

- Masood, S.H.; Mau, K.; Song, W. Tensile properties of processed FDM polycarbonate material. Mater. Sci. Forum 2010, 654, 2556–2559. [Google Scholar] [CrossRef]

- Blattmeier, M.; Witt, G.; Wortberg, J.; Eggert, J.; Toepker, J. Influence of surface characteristics on fatigue behaviour of laser sintered plastics. Rapid Prototyp. J. 2012, 18, 161–171. [Google Scholar] [CrossRef]

- Ezeh, O.; Susmel, L. On the notch fatigue strength of additively manufactured polylactide (PLA). Int. J. Fatigue 2020, 136, 105583. [Google Scholar] [CrossRef]

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- Jap, N.S.; Pearce, G.M.; Hellier, A.K.; Russell, N.; Parr, W.C.; Walsh, W.R. The effect of raster orientation on the static and fatigue properties of filament deposited ABS polymer. Int. J. Fatigue 2019, 124, 328–337. [Google Scholar] [CrossRef]

- Stephens, B.; Azimi, P.; el Orch, Z.; Ramos, T. Ultrafine particle emissions from desktop 3D printers. Atmos. Environ. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Dong, Y.; Milentis, J.; Pramanik, A. Additive manufacturing of mechanical testing samples based on virgin poly (lactic acid)(PLA) and PLA/wood fibre composites. Adv. Manuf. 2018, 6, 71–82. [Google Scholar] [CrossRef]

- Kasuga, T.; Ota, Y.; Nogami, M.; Abe, Y. Preparation and mechanical properties of polylactic acid composites containing hydroxyapatite fibers. Biomaterials 2000, 22, 19–23. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Llumà-Fuentes, J.; Gomez-Gras, G.; Puig, D. Fatigue lifespan study of PLA parts obtained by additive manufacturing. Procedia Manuf. 2017, 13, 872–879. [Google Scholar] [CrossRef] [Green Version]

- Mirkhalaf, S.; Fagerström, M. The mechanical behavior of polylactic acid (PLA) films: Fabrication, experiments and modelling. Mech. Time-Depend. Mater. 2019, 25, 119–131. [Google Scholar] [CrossRef] [Green Version]

- Letcher, T.; Waytashek, M. Material property testing of 3D-printed specimen in PLA on an entry-level 3D printer. ASME Int. Mech. Eng. Congr. Expo. 2014, 46438, V02AT02A014. [Google Scholar]

- Afrose, M.F.; Masood, S.; Iovenitti, P.; Nikzad, M.; Sbarski, I. Effects of part build orientations on fatigue behaviour of FDM-processed PLA material. Prog. Addit. Manuf. 2016, 1, 21–28. [Google Scholar] [CrossRef]

- Ezeh, O.; Susmel, L. Fatigue strength of additively manufactured polylactide (PLA): Effect of raster angle and non-zero mean stresses. Int. J. Fatigue 2019, 126, 319–326. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive manufacturing of PLA-based composites using fused filament fabrication: Effect of graphene nanoplatelet reinforcement on mechanical properties, dimensional accuracy and texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [Green Version]

- Plaza, E.G.; López, P.J.N.; Torija, M.Á.C.; Muñoz, J.M.C. Analysis of PLA geometric properties processed by FFF additive manufacturing: Effects of process parameters and plate-extruder precision motion. Polymers 2019, 11, 1581. [Google Scholar] [CrossRef] [Green Version]

- Camargo, J.C.; Machado, Á.R.; Almeida, E.C.; Sousa, S.E.F.M. Mechanical properties of PLA-graphene filament for FDM 3D printing. Int. J. Adv. Manuf. Technol. 2019, 103, 2423–2443. [Google Scholar] [CrossRef]

- Shirinbayan, M.; Fitoussi, J.; Meraghni, F.; Surowiec, B.; Laribi, M.; Tcharkhtchi, A. Coupled effect of loading frequency and amplitude on the fatigue behavior of advanced sheet molding compound (A-SMC). J. Reinf. Plast. Compos. 2017, 36, 271–282. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef] [Green Version]

| Properties | Typical Value |

|---|---|

| Material Density | 1.24 g/cm3 |

| Diameter (Tolerance) | 1.75 mm (± 0.01 mm) |

| Glass Transition Temperature | 72 °C |

| Melting Temperature | 158 °C |

| Printing Parameters | Value |

|---|---|

| Nozzle temperature (°C) | 200 |

| Platform temperature (°C) | 40–50–60 |

| Chamber temperature (°C) | 30 |

| Print speed (mm/s) | 20–30–40 |

| Layer height (mm) | 0.15 |

| Infill density (%) | 100 |

| Infill pattern | line |

| Number of bottom/top layers | 2/2 |

| Number of contours (wall) | 2 |

| Infill line directions (relative to the long axis of the test bar) (°) | (45/−45) |

| Condition | Liquefier Temperature (°C) | Platform Temperature (°C) | Print Speed (mm/s) | |

|---|---|---|---|---|

| I | 1 | 200 | 40 | 20 |

| 2 | 50 | |||

| 3 | 60 | |||

| II | 1 | 200 | 40 | 30 |

| 2 | 50 | |||

| 3 | 60 | |||

| III | 1 | 200 | 40 | 40 |

| 2 | 50 | |||

| 3 | 60 | |||

| Condition | E (GPa) | |||

|---|---|---|---|---|

| I | 1 | 1.8 ± 0.1 | 59 ± 1 | 3.8 ± 0.2 |

| 2 | 2.1 ± 0.1 | 60 ± 1 | 3.9 ± 0.2 | |

| 3 | 2.1 ± 0.1 | 62 ± 1 | 4 ± 0.2 | |

| II | 1 | 2.1 ± 0.1 | 61 ± 1 | 3.9 ± 0.2 |

| 2 | 2.2 ± 0.1 | 61 ± 1 | 3.9 ± 0.2 | |

| 3 | 2.2 ± 0.1 | 63 ± 1 | 4.2 ± 0.2 | |

| III | 1 | 2.2 ± 0.1 | 62 ± 1 | 4.1 ± 0.2 |

| 2 | 2.3 ± 0.1 | 63 ± 1 | 4.2 ± 0.2 | |

| 3 | 2.4 ± 0.1 | 65 ± 1 | 4.4 ± 0.2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

EL MAGRI, A.; VANAEI, S.; SHIRINBAYAN, M.; Vaudreuil, S.; TCHARKHTCHI, A. An Investigation to Study the Effect of Process Parameters on the Strength and Fatigue Behavior of 3D-Printed PLA-Graphene. Polymers 2021, 13, 3218. https://doi.org/10.3390/polym13193218

EL MAGRI A, VANAEI S, SHIRINBAYAN M, Vaudreuil S, TCHARKHTCHI A. An Investigation to Study the Effect of Process Parameters on the Strength and Fatigue Behavior of 3D-Printed PLA-Graphene. Polymers. 2021; 13(19):3218. https://doi.org/10.3390/polym13193218

Chicago/Turabian StyleEL MAGRI, Anouar, Saeedeh VANAEI, Mohammadali SHIRINBAYAN, Sébastien Vaudreuil, and Abbas TCHARKHTCHI. 2021. "An Investigation to Study the Effect of Process Parameters on the Strength and Fatigue Behavior of 3D-Printed PLA-Graphene" Polymers 13, no. 19: 3218. https://doi.org/10.3390/polym13193218

APA StyleEL MAGRI, A., VANAEI, S., SHIRINBAYAN, M., Vaudreuil, S., & TCHARKHTCHI, A. (2021). An Investigation to Study the Effect of Process Parameters on the Strength and Fatigue Behavior of 3D-Printed PLA-Graphene. Polymers, 13(19), 3218. https://doi.org/10.3390/polym13193218