Fully Bio-Based Elastomer Nanocomposites Comprising Polyfarnesene Reinforced with Plasma-Modified Cellulose Nanocrystals

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Surface Modification of CNCs

2.2.2. In-Situ Polymerizations

2.3. Characterization

2.3.1. Surface Modification of CNC

2.3.2. Elastomeric Nanocomposites

3. Results and Discussion

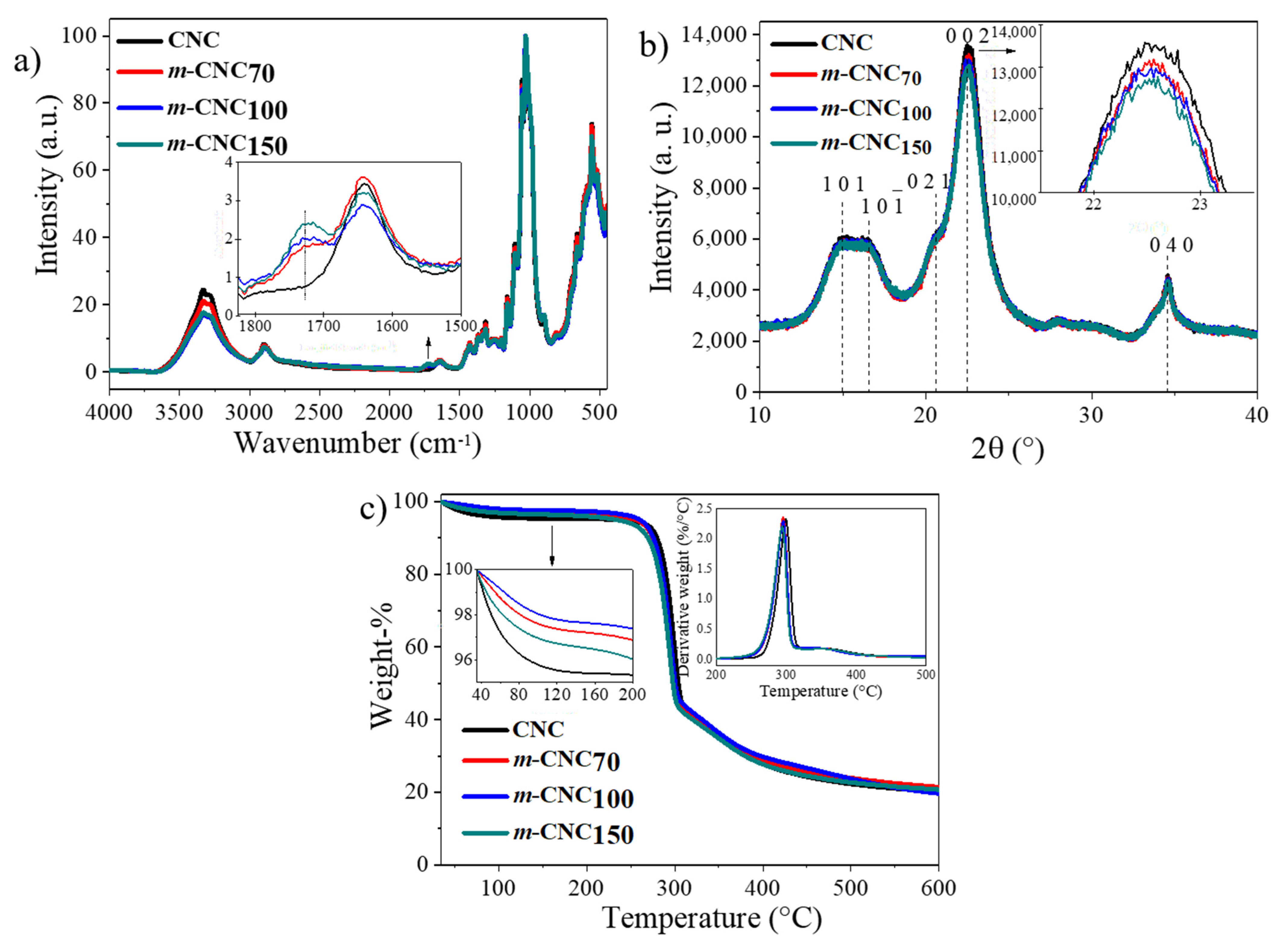

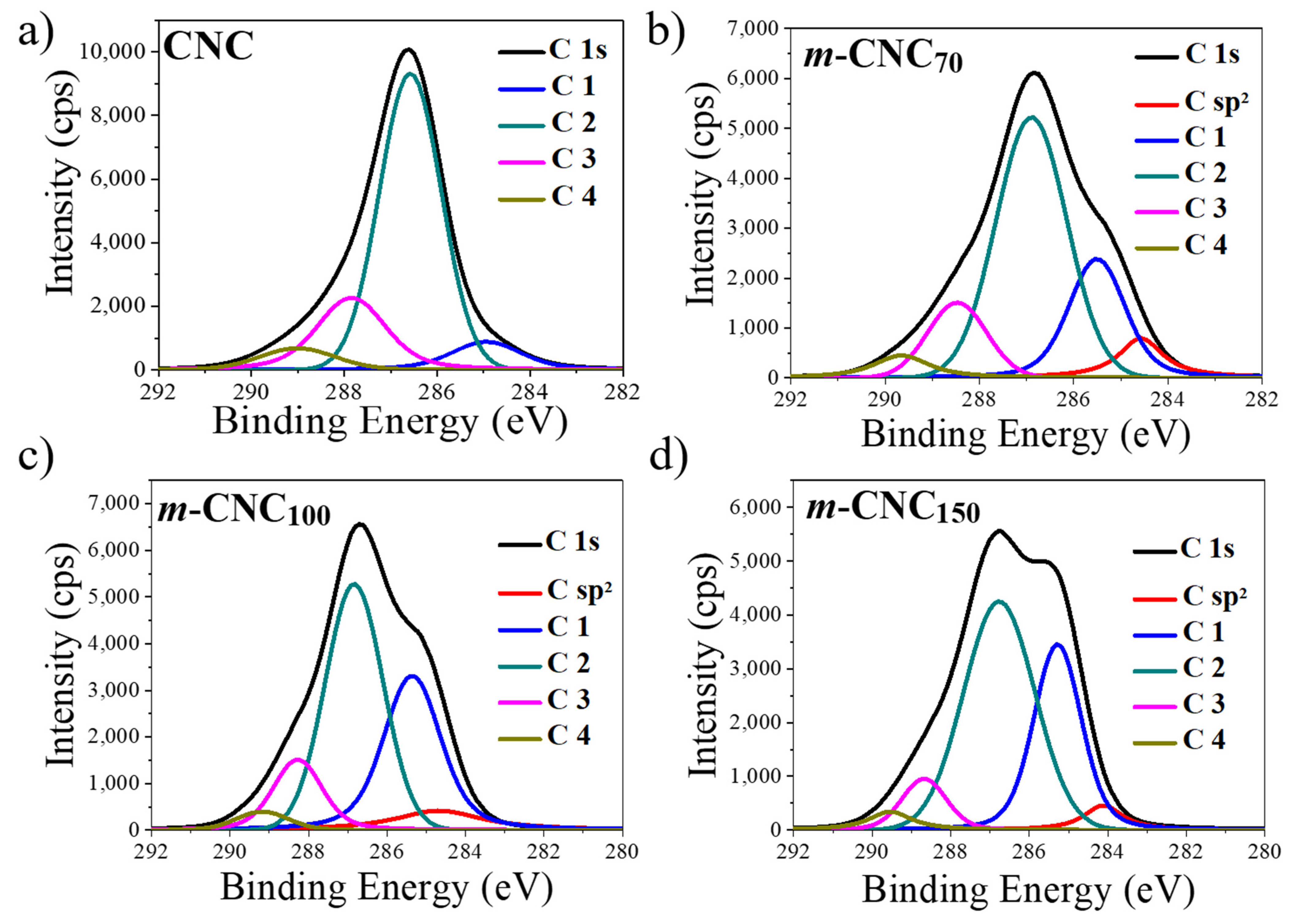

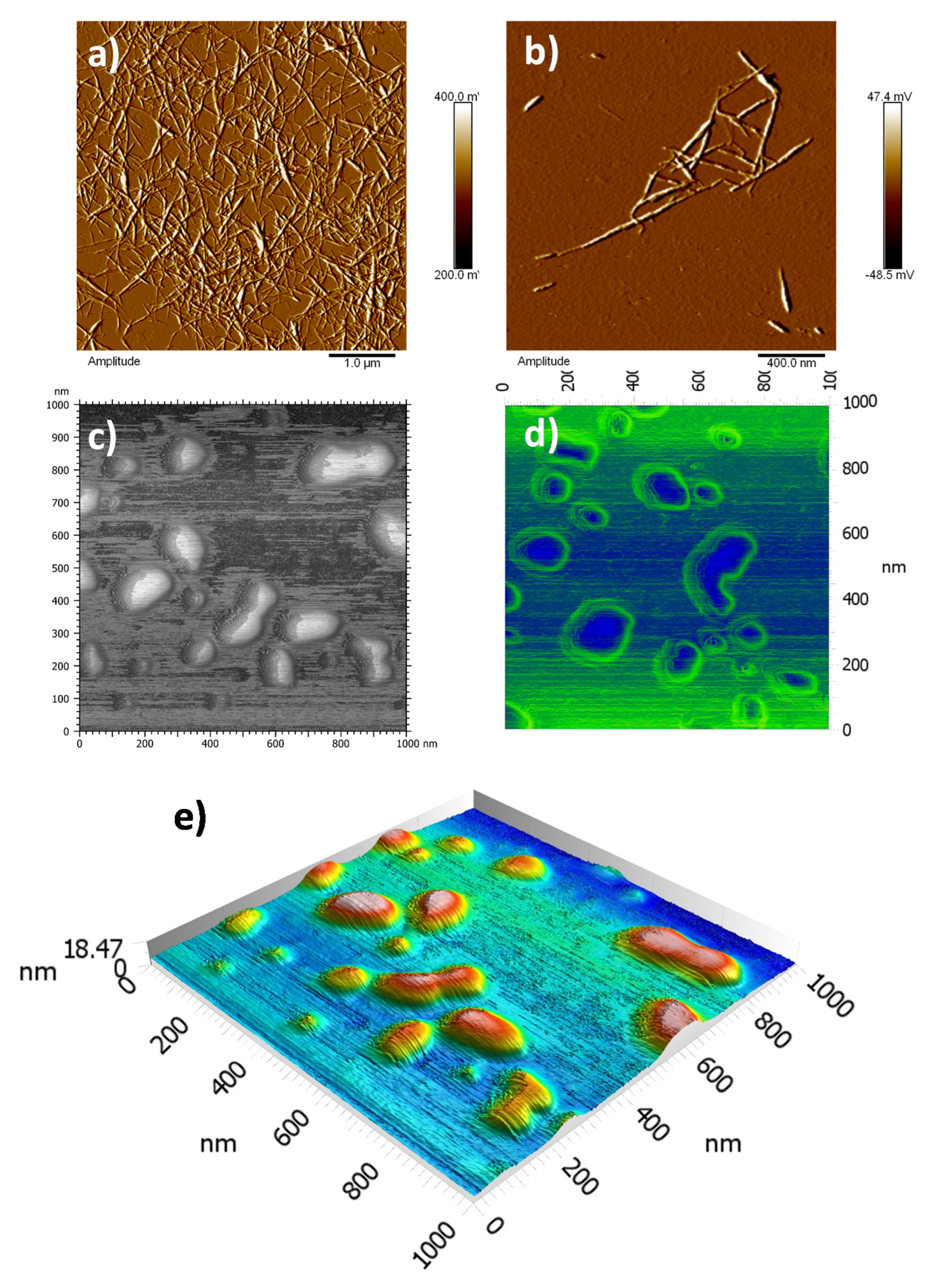

3.1. Modified Cellulose Nanocrystals

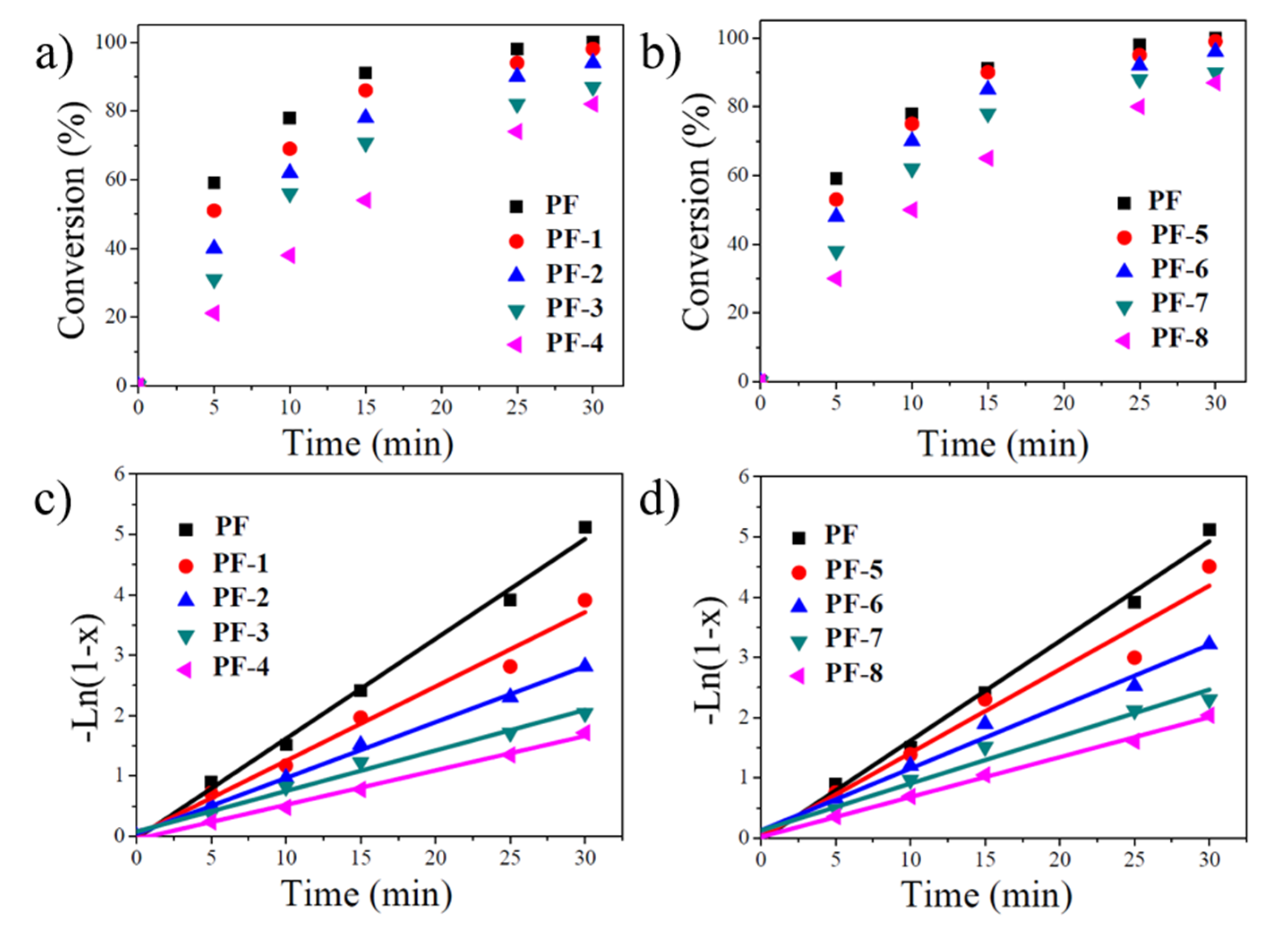

3.2. Synthesis of Nanocomposites

3.3. Rheological Properties of the Elastomer Nanocomposites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fortman, D.J.; Brutman, J.P.; De Hoe, G.X.; Snyder, R.; Dichtel, W.R.; Hillmyer, M.A. Approaches to Sustainable and Continually Recyclable Cross-Linked Polymers. ACS Sustain. Chem. Eng. 2018, 6, 11145–11159. [Google Scholar] [CrossRef] [Green Version]

- Wilbon, P.A.; Chu, F.; Tang, C. Progress in Renewable Polymers from Natural Terpenes, Terpenoids, and Rosin. Macromol. Rapid Commun. 2013, 34, 8–37. [Google Scholar] [CrossRef] [PubMed]

- Sahu, P.; Bhowmick, A.K. Redox Emulsion Polymerization of Terpenes: Mapping the Effect of the System, Structure, and Reactivity. Ind. Eng. Chem. Res. 2019, 58, 20946–20960. [Google Scholar] [CrossRef]

- Imhof, P.; van der Waal, J.C. Catalytic Process Development for Renewable Materials. In Catalytic Process Development for Renewable Materials; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013. [Google Scholar] [CrossRef]

- Díaz de León Gómez, R.E.; Enríquez-Medrano, F.J.; Maldonado Textle, H.; Mendoza Carrizales, R.; Reyes Acosta, K.; Lopez Gonzalez, H.R.; Olivares Romero, J.L.; Lugo Uribe, L.E. Synthesis and characterization of high cis-polymyrcene using neodymium-based catalysts. Can. J. Chem. Eng. 2016, 94, 823–832. [Google Scholar] [CrossRef]

- Díaz de León, R.; López, R.; Valencia, L.; Mendoza, R.; Cabello, J.; Enríquez, J. Towards Bioelastomers via Coordination Polymerization of Renewable Terpenes Using Neodymium-Based Catalyst Systems. Key Eng. Mater. 2018, 779, 115–121. [Google Scholar] [CrossRef]

- Gazzotti, S.; Farina, H.; Lesma, G.; Rampazzo, R.; Piergiovanni, L.; Ortenzi, M.A.; Silvani, A. Polylactide/cellulose nanocrystals: The in situ polymerization approach to improved nanocomposites. Eur. Polym. J. 2017, 94, 173–184. [Google Scholar] [CrossRef]

- Miao, C.; Hamad, W.Y. In-situ polymerized cellulose nanocrystals (CNC)—poly(l-lactide) (PLLA) nanomaterials and applications in nanocomposite processing. Carbohydr. Polym. 2016, 153, 549–558. [Google Scholar] [CrossRef]

- Geng, S.; Wei, J.; Aitomäki, Y.; Noël, M.; Oksman, K. Well-dispersed cellulose nanocrystals in hydrophobic polymers by in situ polymerization for synthesizing highly reinforced bio-nanocomposites. Nanoscale 2018, 10, 11797–11807. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Wang, C.; Wang, J.; Chu, F. In situ development of self-reinforced cellulose nanocrystals based thermoplastic elastomers by atom transfer radical polymerization. Carbohydr. Polym. 2016, 141, 143–150. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, D.; Xu, C.; Chen, Y. Biobased, self-healable, high strength rubber with tunicate cellulose nanocrystals. Nanoscale 2017, 9, 15696–15706. [Google Scholar] [CrossRef]

- Cao, X.; Xu, C.; Liu, Y.; Chen, Y. Preparation and properties of carboxylated styrene-butadiene rubber/cellulose nanocrystals composites. Carbohydr. Polym. 2013, 92, 69–76. [Google Scholar] [CrossRef]

- Cao, X.; Xu, C.; Wang, Y.; Liu, Y.; Liu, Y.; Chen, Y. New nanocomposite materials reinforced with cellulose nanocrystals in nitrile rubber. Polym. Test. 2013, 32, 819–826. [Google Scholar] [CrossRef]

- Visakh, P.; Thomas, S.; Oksman, K.; Mathew, A.P. Crosslinked natural rubber nanocomposites reinforced with cellulose whiskers isolated from bamboo waste: Processing and mechanical/thermal properties. Compos. Part A Appl. Sci. Manuf. 2012, 43, 735–741. [Google Scholar] [CrossRef]

- Yin, B.; Li, G.; Wang, D.; Wang, L.; Wang, J.; Jia, H.; Ding, L.; Sun, D. Enhanced mechanical properties of styrene-butadiene rubber with low content of bacterial cellulose nanowhiskers. Adv. Polym. Technol. 2016, 37, 1323–1334. [Google Scholar] [CrossRef]

- Alanis, A.; Valdés, J.H.; Guadalupe, N.-V.M.; López, L.A.V.; Mendoza, R.; Mathew, A.P.; de León, R.D.; Valencia, L. Plasma surface-modification of cellulose nanocrystals: A green alternative towards mechanical reinforcement of ABS. RSC Adv. 2019, 9, 17417–17424. [Google Scholar] [CrossRef] [Green Version]

- Al Zoubi, W.; Kamil, M.P.; Fatimah, S.; Nashrah, N.; Ko, Y.G. Recent advances in hybrid organic-inorganic materials with spatial architecture for state-of-the-art applications. Prog. Mater. Sci. 2020, 112, 100663. [Google Scholar] [CrossRef]

- Al Zoubi, W.; Kim, M.J.; Kim, Y.G.; Ko, Y.G. Dual-functional crosslinked polymer-inorganic materials for robust electrochemical performance and antibacterial activity. Chem. Eng. J. 2020, 392, 123654. [Google Scholar] [CrossRef]

- Van Os, M.T. Surface modification by plasma polymerization: Film deposition, tailoring of surface properties and biocompatibility. Film 2000. [Google Scholar]

- Shi, D.; He, P.; Lian, J.; Wang, L.; van Ooij, W.J. Plasma deposition and characterization of acrylic acid thin film on ZnO nanoparticles. J. Mater. Res. 2002, 17, 2555–2560. [Google Scholar] [CrossRef] [Green Version]

- Sidorina, A.I.; Gunyaeva, A.G. Modification of Surface of Reinforcing Carbon Fillers for Polymeric Composite Materials by Plasma Treatment (Review). Fibre Chem. 2017, 49, 24–27. [Google Scholar] [CrossRef]

- Tsai, G.; Montero, J.; Calle, W.; Quinde, M.; Sarmiento, P. Plasma: Una tecnología de gran potencial para la industria y la ciencia. Ingenius 2010, 4, 66–72. [Google Scholar] [CrossRef]

- Guadalupe, N.-V.M.; Valle, L.F.R.-D.; Hernández-Hernández, E.; Zapata-González, I. Surface modification of carbon nanofibers (CNFs) by plasma polymerization of methylmethacrylate and its effect on the properties of PMMA/CNF nanocomposites. e-Polymers 2008, 8, 1855–1865. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aguayo, M.G.; Pérez, A.F.; Reyes, G.; Oviedo, C.; Gacitúa, W.; Gonzalez, R.; Uyarte, O. Isolation and Characterization of Cellulose Nanocrystals from Rejected Fibers Originated in the Kraft Pulping Process. Polymers 2018, 10, 1145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nagarajan, K.J.; Balaji, A.N.; Ramanujam, N.R. Isolation and characterization of cellulose nanocrystals from Saharan aloe vera cactus fibers. Int. J. Polym. Anal. Charact. 2018, 25, 51–64. [Google Scholar] [CrossRef]

- Trilokesh, C.; Uppuluri, K.B. Isolation and characterization of cellulose nanocrystals from jackfruit peel. Sci. Rep. 2019, 9, 16709. [Google Scholar] [CrossRef]

- Peng, Y.; Gardner, D.J.; Han, Y.; Kiziltas, A.; Cai, Z.; Tshabalala, M.A. Influence of drying method on the material properties of nanocellulose I: Thermostability and crystallinity. Cellulose 2013, 20, 2379–2392. [Google Scholar] [CrossRef]

- Inari, G.N.; Petrissans, M.; Lambert, J.; Ehrhardt, J.J.; Gérardin, P. XPS characterization of wood chemical composition after heat-treatment. Surf. Interface Anal. 2006, 38, 1336–1342. [Google Scholar] [CrossRef]

- Pan, M.; Zhou, X.; Chen, M. Cellulose Nanowhiskers Isolation and Properties from Acid Hydrolysis Combined with High Pressure Homogenization. BioResources 2012, 8, 933–943. [Google Scholar] [CrossRef] [Green Version]

- Valencia, L.; Kumar, S.; Jalvo, B.; Mautner, A.; Salazar-Alvarez, G.; Mathew, A.P. Fully bio-based zwitterionic membranes with superior antifouling and antibacterial properties prepared via surface-initiated free-radical polymerization of poly(cysteine methacrylate). J. Mater. Chem. A 2018, 6, 16361–16370. [Google Scholar] [CrossRef] [Green Version]

- Valencia, L.; Kumar, S.; Nomena, E.M.; Salazar-Alvarez, G.; Mathew, A.P. In-Situ Growth of Metal Oxide Nanoparticles on Cellulose Nanofibrils for Dye Removal and Antimicrobial Applications. ACS Appl. Nano Mater. 2020, 3, 7172–7181. [Google Scholar] [CrossRef]

- Wistara, N.; Zhang, X.; Young, R.A. Properties and treatments of pulps from recycled paper. Part II. Surface properties and crystallinity of fibers and fines. Cellulose 1999, 6, 325–348. [Google Scholar] [CrossRef]

- González-Zapata, J.L.; Enríquez-Medrano, F.J.; González, H.R.L.; Revilla-Vázquez, J.; Carrizales, R.M.; Georgouvelas, D.; Valencia, L.; Gómez, R.E.D.D.L. Introducing random bio-terpene segments to high cis-polybutadiene: Making elastomeric materials more sustainable. RSC Adv. 2020, 10, 44096–44102. [Google Scholar] [CrossRef]

- Herrera-Ordonez, J.; Leon, R.D.D.; de Santiago-Rodriguez, Y.A. Kinetic Modeling of 1, 3-Diene Polymerization Using a Neodymium-Based Catalytic System: A New Approach for Calculating the Molecular Weight Distribution. Macromol. Symp 2013, 325, 125–131. [Google Scholar] [CrossRef]

- Valencia, L.; Enríquez-Medrano, F.J.; González, H.R.L.; Handa, R.; Caballero, H.S.; Carrizales, R.M.; Olivares-Romero, J.L.; Gómez, R.E.D.D.L. Bio-elastomers based on polyocimene synthesized via coordination polymerization using neodymium-based catalytic systems. RSC Adv. 2020, 10, 36539–36545. [Google Scholar] [CrossRef]

- Bahena, A.; Magaña, I.; González, H.R.L.; Handa, R.; Enríquez-Medrano, F.J.; Kumar, S.; Carrizales, R.M.; Fernandez, S.; Valencia, L.; Gómez, R.E.D.D.L. Bio-elastomer nanocomposites reinforced with surface-modified graphene oxide prepared via in situ coordination polymerization. RSC Adv. 2020, 10, 36531–36538. [Google Scholar] [CrossRef]

- Friebe, L.; Windisch, H.; Nuyken, O.; Obrecht, W. Polymerization of 1,3-Butadiene Initiated by Neodymium Versatate/Triisobutylaluminum/Ethylaluminum Sesquichloride: Impact of the Alkylaluminum Cocatalyst Component. J. Macromol. Sci. Part A 2004, 41, 245–256. [Google Scholar] [CrossRef]

- Manuiko, G.V.; Salakhov, I.; Aminova, G.A.; Akhmetov, I.G.; Dyakonov, G.S.; Bronskaya, V.V.; Demidova, E.V. Mathematical modeling of 1,3-butadiene polymerization over a neodymium-based catalyst in a batch reactor with account taken of the multisite nature of the catalyst and chain transfer to the polymer. Theor. Found. Chem. Eng. 2010, 44, 139–149. [Google Scholar] [CrossRef]

- Valente, A.; Mortreux, A.; Visseaux, M.; Zinck, P. Coordinative Chain Transfer Polymerization. Chem. Rev. 2013, 113, 3836–3857. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Liu, H.; Zheng, W.; Guo, J.; Zhang, C.; Zhao, L.; Zhang, H.; Hu, Y.; Bai, C.; Zhang, X. Fully-reversible and semi-reversible coordinative chain transfer polymerizations of 1,3-butadiene with neodymium-based catalytic systems. Polymer 2013, 54, 6716–6724. [Google Scholar] [CrossRef]

- Friebe, L.; Nuyken, O.; Windisch, H.; Obrecht, W. Polymerization of 1,3-Butadiene Initiated by Neodymium Versatate/Diisobutylaluminium Hydride/Ethylaluminium Sesquichloride: Kinetics and Conclusions About the Reaction Mechanism. Macromol. Chem. Phys. 2002, 203, 1055–1064. [Google Scholar] [CrossRef]

- Fan, C.; Bai, C.; Cai, H.; Dai, Q.; Zhang, X.; Wang, F. Preparation of high cis-1,4 polyisoprene with narrow molecular weight distribution via coordinative chain transfer polymerization. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 4768–4774. [Google Scholar] [CrossRef]

- López, L.A.V.; Enríquez-Medrano, F.J.; Textle, H.M.; Corral, F.S.; González, H.R.L.; Thomas, C.S.; Gámez, F.H.; Romero, J.L.O.; Gómez, R.E.D.D.L. The Influence of co-catalyst in the Polymerization of 1,3-butadiene Catalyzed by Neodymium Chloride Tripentanolate. J. Mex. Chem. Soc. 2017, 60, 141–147. [Google Scholar] [CrossRef]

- Anderson, B.J.; Zukoski, C.F. Rheology and Microstructure of Entangled Polymer Nanocomposite Melts. Macromolecules 2009, 42, 8370–8384. [Google Scholar] [CrossRef]

- Chen, D.T.; Wen, Q.; Janmey, P.A.; Crocker, J.C.; Yodh, A.G. Rheology of Soft Materials. Annu. Rev. Condens. Matter Phys. 2010, 1, 301–322. [Google Scholar] [CrossRef] [Green Version]

- Hassanabadi, H.M.; Abbasi, M.; Wilhelm, M.; Rodrigue, D. Validity of the modified molecular stress function theory to predict the rheological properties of polymer nanocomposites. J. Rheol. 2013, 57, 881–899. [Google Scholar] [CrossRef]

- Kabanemi, K.K.; Hétu, J.-F. Reptation Model for the Dynamics and Rheology of Particle Reinforced Polymer Chains. In Modeling and Prediction of Polymer Nanocomposite Properties; Wiley: Hoboken, NJ, USA, 2013; pp. 63–94. [Google Scholar]

- Krishnamoorti, R.; Giannelis, E.P. Rheology of End-Tethered Polymer Layered Silicate Nanocomposites. Macromolecules 1997, 30, 4097–4102. [Google Scholar] [CrossRef]

- Manitiu, M.; Horsch, S.; Gulari, E.; Kannan, R.M. Role of polymer–clay interactions and nano-clay dispersion on the viscoelastic response of supercritical CO2 dispersed polyvinylmethylether (PVME)–Clay nanocomposites. Polymer 2009, 50, 3786–3796. [Google Scholar] [CrossRef]

- Mobuchon, C.; Carreau, P.J.; Heuzey, M.-C. Structural analysis of non-aqueous layered silicate suspensions subjected to shear flow. J. Rheol. 2009, 53, 1025–1048. [Google Scholar] [CrossRef] [Green Version]

- Utracki, L.A.; Sepehr, M.M. Rheology of polymers with nanofillers. In Polymers Physics: From Suspensions to Nanocomposites and Beyond; Wiley: Hoboken, NJ, USA, 2010; pp. 639–708. [Google Scholar]

- Doi, M.; Edwards, S.F. The Theory of Polymer Dynamics; Oxford University Press Inc.: Oxford, UK, 1989. [Google Scholar]

- Mahi, H.; Rodrigue, D. Linear and non-linear viscoelastic properties of ethylene vinyl acetate/nano-crystalline cellulose composites. Rheol. Acta 2012, 51, 127–142. [Google Scholar] [CrossRef]

- Rubinstein, M.; Colby, R.H. Polymer Physics; Oxford University Press Inc.: Oxford, UK, 2003. [Google Scholar]

- Fontaine, A.; Guntzburger, Y.; Bertrand, F.; Fradette, L.; Heuzey, M.-C. Experimental investigation of the flow dynamics of rheologically complex fluids in a Maxblend impeller system using PIV. Chem. Eng. Res. Des. 2013, 91, 7–17. [Google Scholar] [CrossRef]

- Hassanabadi, H.M.; Wilhelm, M.; Rodrigue, D. A rheological criterion to determine the percolation threshold in polymer nano-composites. Rheol. Acta 2014, 53, 869–882. [Google Scholar] [CrossRef]

- Zohrevand, A.; Ajji, A.; Mighri, F. Relationship between rheological and electrical percolation in a polymer nanocomposite with semiconductor inclusions. Rheol. Acta 2014, 53, 235–254. [Google Scholar] [CrossRef]

| Sample | C/O | C 1 (%) | C 2 (%) | C 3 (%) | C 4 (%) | C sp2 (%) |

|---|---|---|---|---|---|---|

| 0.47 | 8.2 | 70.3 | 15.3 | 6.1 | - | |

| m- | 0.54 | 19.6 | 54.5 | 12.5 | 5.0 | 8.4 |

| m- | 0.62 | 26.4 | 53.5 | 9.3 | 3.2 | 7.5 |

| m- | 0.78 | 36.2 | 46.9 | 8.1 | 4.2 | 4.5 |

| Run | Additive | wt% | Yield a | Kb | A c | (kDa) | Ð d | 1,4-Content e (%) | 1,4-Cis f(%) | Tg g (°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| PF | - | 0 | ~100 | 109 | 204.1 | 107 | 3.8 | 97.7 | 94 | −76.6 |

| PF-1 | CNC | 0.5 | 98 | 81 | 200 | 137 | 3.9 | 97.6 | N.D. | −76.6 |

| PF-2 | CNC | 1.5 | 94 | 61 | 191.8 | 281 | 4.4 | 97.5 | N.D. | −76.8 |

| PF-3 | CNC | 3.0 | 87 | 44 | 177.6 | 1443 | 3.5 | 97.4 | 93.3 | −79.4 |

| PF-4 | CNC | 5.0 | 82 | 37 | 167.4 | 2622 | 5.5 | 97.1 | N.D. | N.D. |

| PF-5 | m-CNC150 | 0.5 | 99 | 91 | 202 | 175 | 4.0 | 97.5 | N.D. | −76.8 |

| PF-6 | m-CNC150 | 1.5 | 96 | 68 | 195.9 | 267 | 4.1 | 97.3 | N.D. | −76.1 |

| PF-7 | m-CNC150 | 3.0 | 90 | 51 | 183.7 | 1304 | 3.4 | 97.6 | 93.0 | −76.1 |

| PF-8 | m-CNC150 | 5.0 | 87 | 44 | 177.6 | 2296 | 4.8 | 97.4 | N.D. | −76.8 |

| Sample | Filler | wt% | (kDa) | Ð |

|---|---|---|---|---|

| PF | - | 0 | 28 | 3.8 |

| PF-1 | CNC | 0.5 | 35 | 3.9 |

| PF-9 | CNC | 1.5 | 39 | 4.3 |

| PF-10 | CNC | 3.0 | 19 | 4.8 |

| PF-5 | m-CNC150 | 0.5 | 43 | 4.0 |

| PF-6 | m-CNC150 | 1.5 | 65 | 4.1 |

| PF-11 | m-CNC150 | 3.0 | 30 | 4.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magaña, I.; Georgouvelas, D.; Handa, R.; Neira Velázquez, M.G.; López González, H.R.; Enríquez Medrano, F.J.; Díaz de León, R.; Valencia, L. Fully Bio-Based Elastomer Nanocomposites Comprising Polyfarnesene Reinforced with Plasma-Modified Cellulose Nanocrystals. Polymers 2021, 13, 2810. https://doi.org/10.3390/polym13162810

Magaña I, Georgouvelas D, Handa R, Neira Velázquez MG, López González HR, Enríquez Medrano FJ, Díaz de León R, Valencia L. Fully Bio-Based Elastomer Nanocomposites Comprising Polyfarnesene Reinforced with Plasma-Modified Cellulose Nanocrystals. Polymers. 2021; 13(16):2810. https://doi.org/10.3390/polym13162810

Chicago/Turabian StyleMagaña, Ilse, Dimitrios Georgouvelas, Rishab Handa, María Guadalupe Neira Velázquez, Héctor Ricardo López González, Francisco Javier Enríquez Medrano, Ramón Díaz de León, and Luis Valencia. 2021. "Fully Bio-Based Elastomer Nanocomposites Comprising Polyfarnesene Reinforced with Plasma-Modified Cellulose Nanocrystals" Polymers 13, no. 16: 2810. https://doi.org/10.3390/polym13162810

APA StyleMagaña, I., Georgouvelas, D., Handa, R., Neira Velázquez, M. G., López González, H. R., Enríquez Medrano, F. J., Díaz de León, R., & Valencia, L. (2021). Fully Bio-Based Elastomer Nanocomposites Comprising Polyfarnesene Reinforced with Plasma-Modified Cellulose Nanocrystals. Polymers, 13(16), 2810. https://doi.org/10.3390/polym13162810