Comparison of the Physico-Mechanical and Weathering Properties of Wood–Plastic Composites Made of Wood Fibers from Discarded Parts of Pomelo Trees and Polypropylene

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of the Composite Panels

2.3. Xenon Arc Accelerated Weathering Test

2.4. Characterizations of Composite Properties

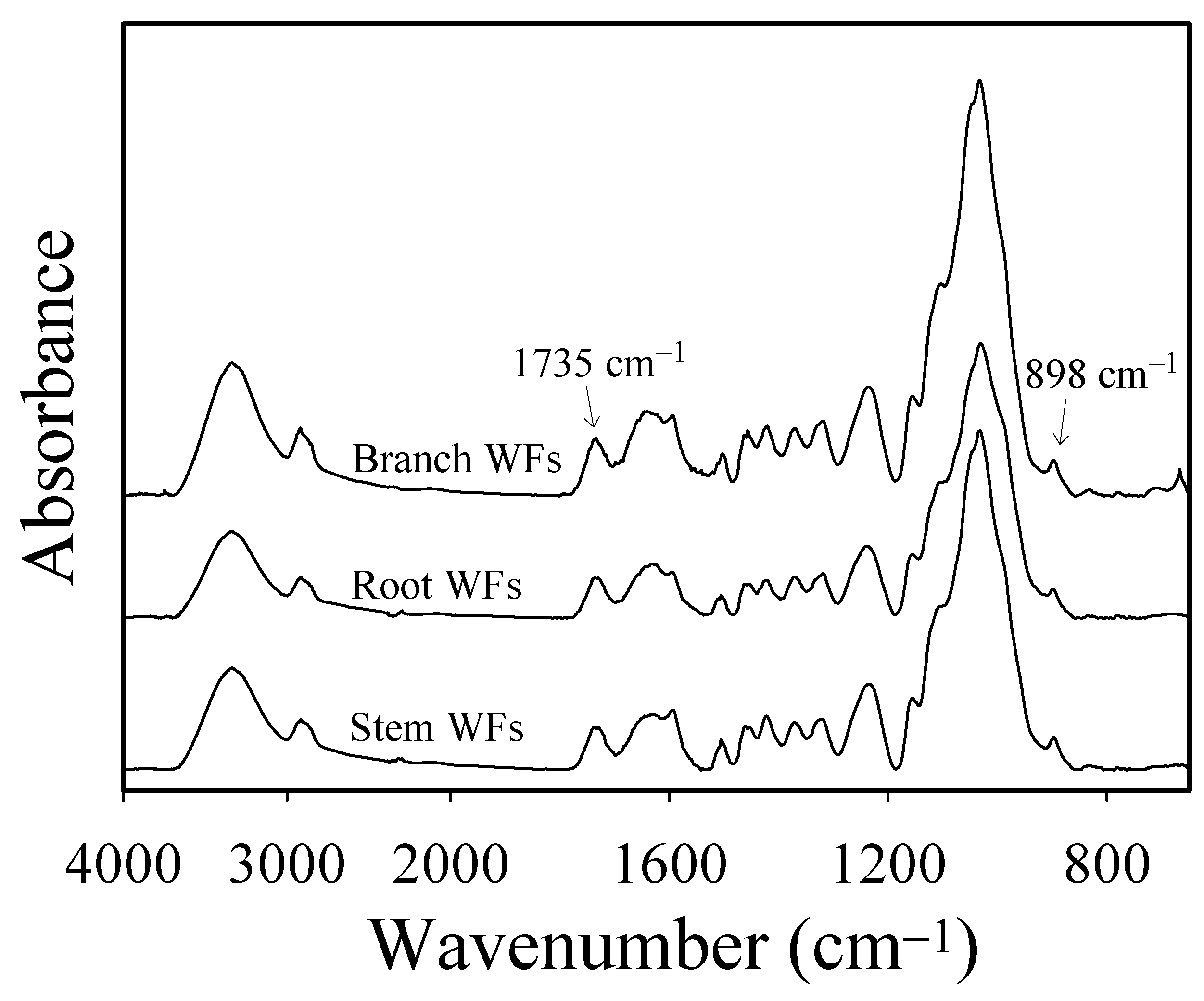

2.5. ATR-FTIR Spectral Measurement

2.6. Measurement of Surface Color

2.7. Scanning Electron Microscopy

2.8. Analysis of Variance

3. Results and Discussion

3.1. The Physical and Flexural Properties of the WPCs

3.2. Characteristics of the WPCs during Xenon Arc Accelerated Weathering

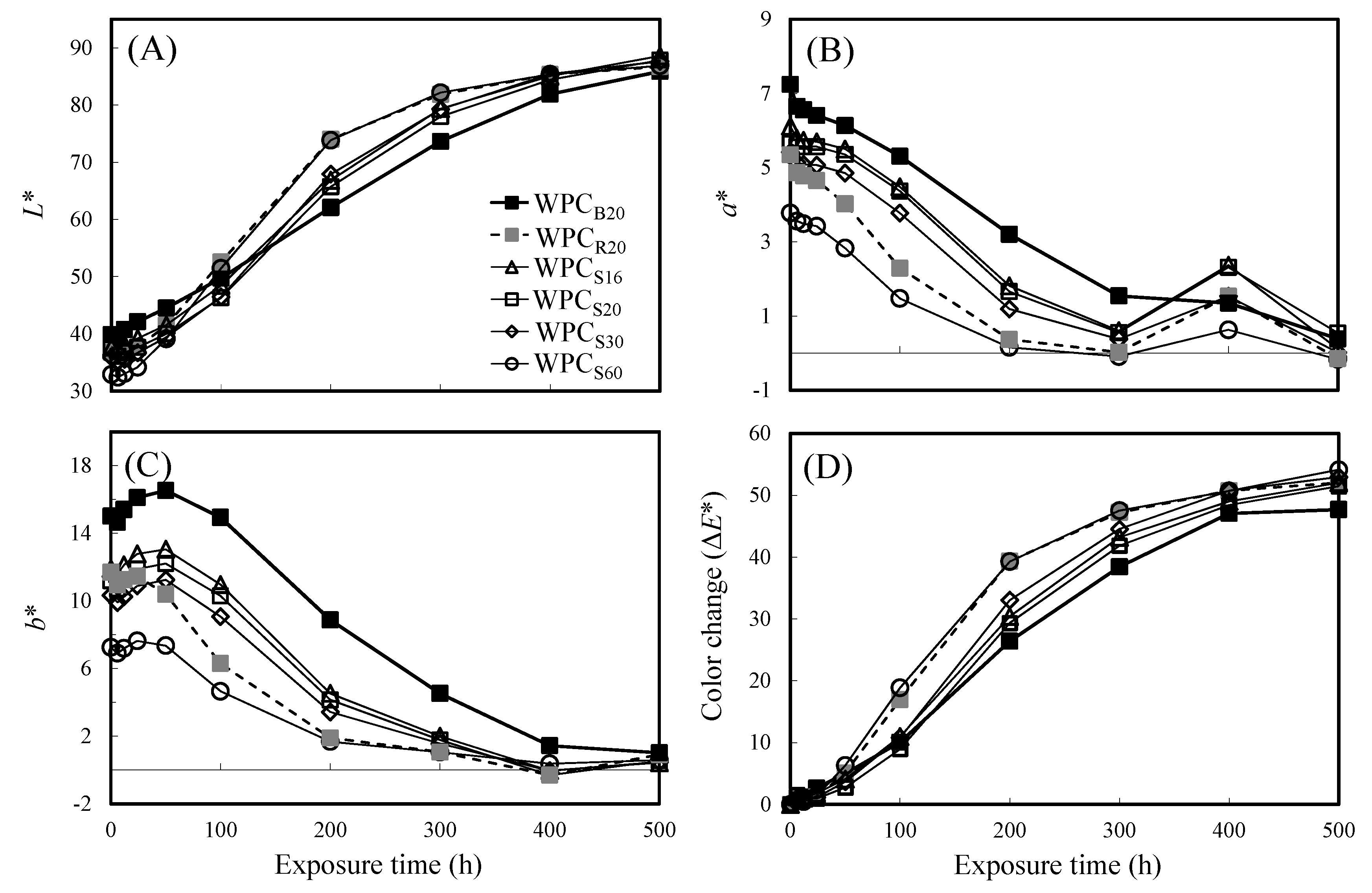

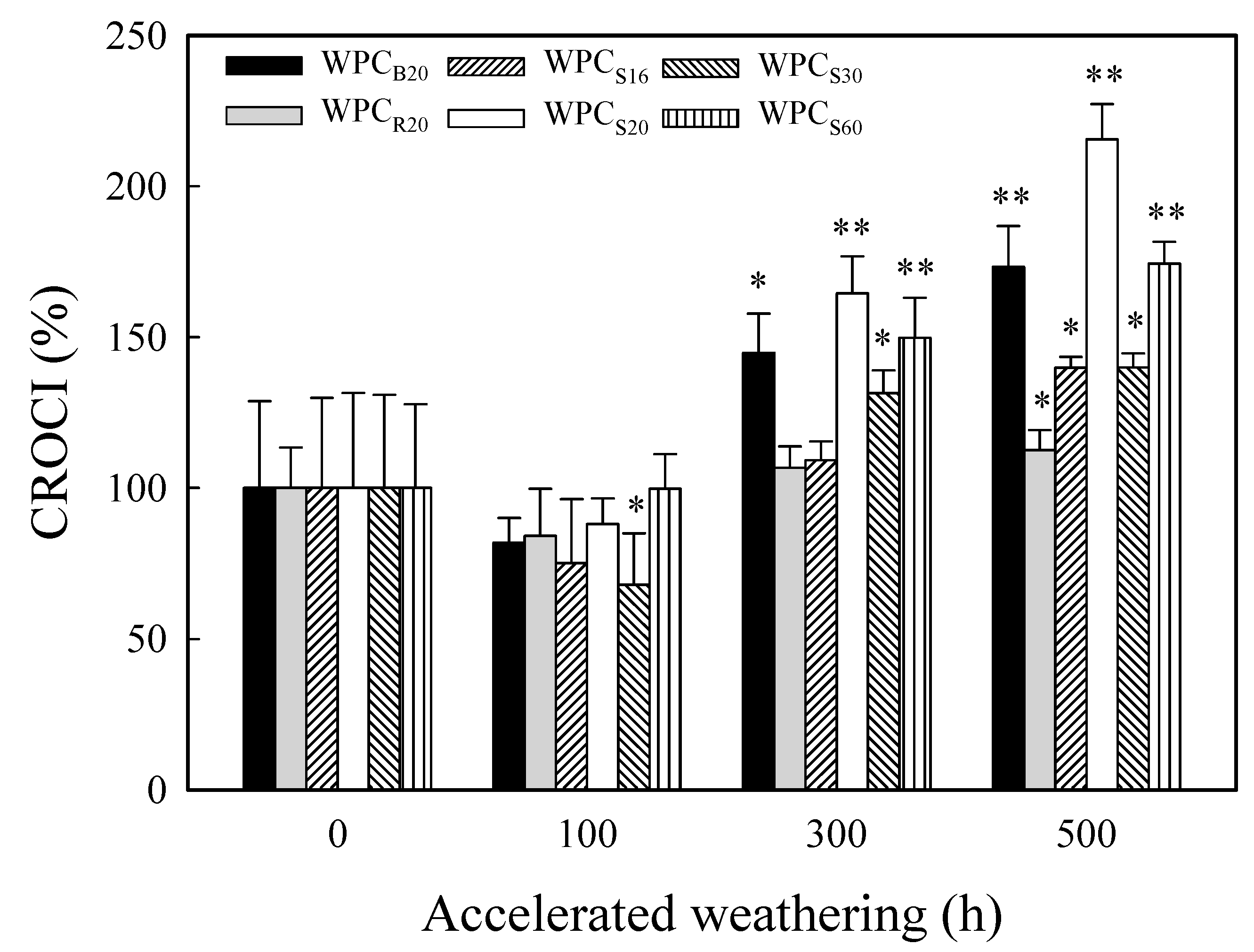

3.2.1. Color Changes of the WPCs during Accelerated Weathering

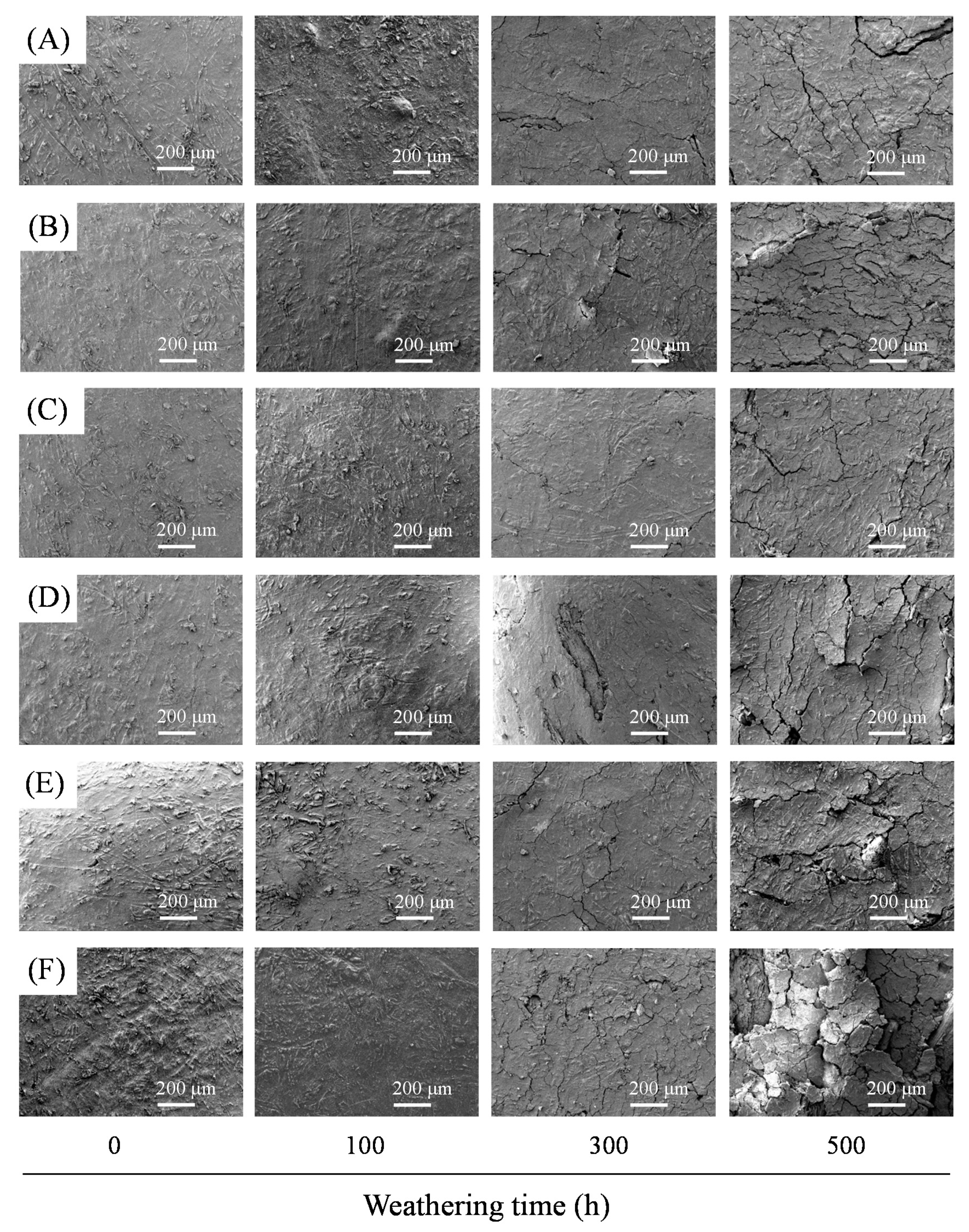

3.2.2. Surface and Flexural Properties of the WPCs during Accelerated Weathering

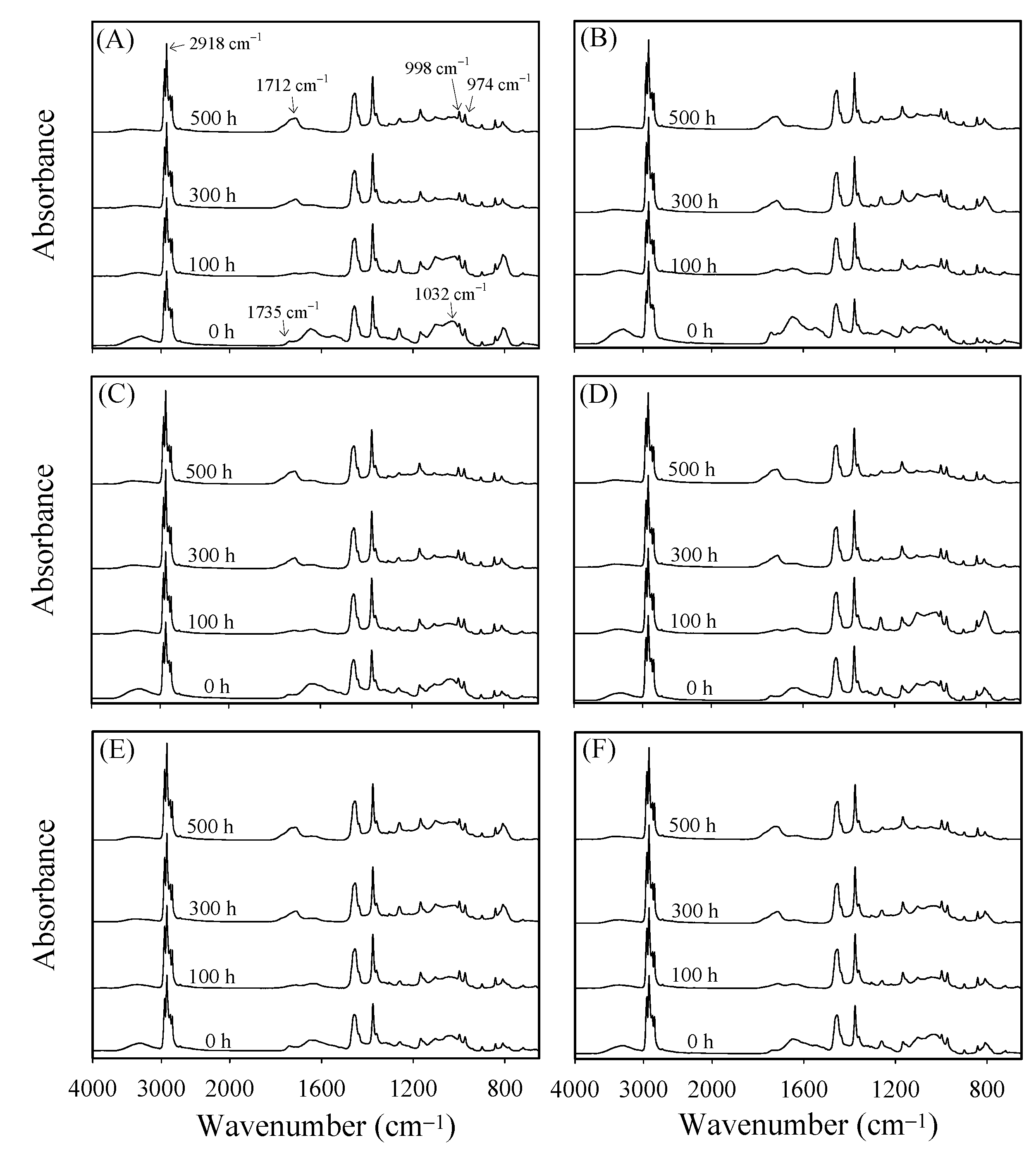

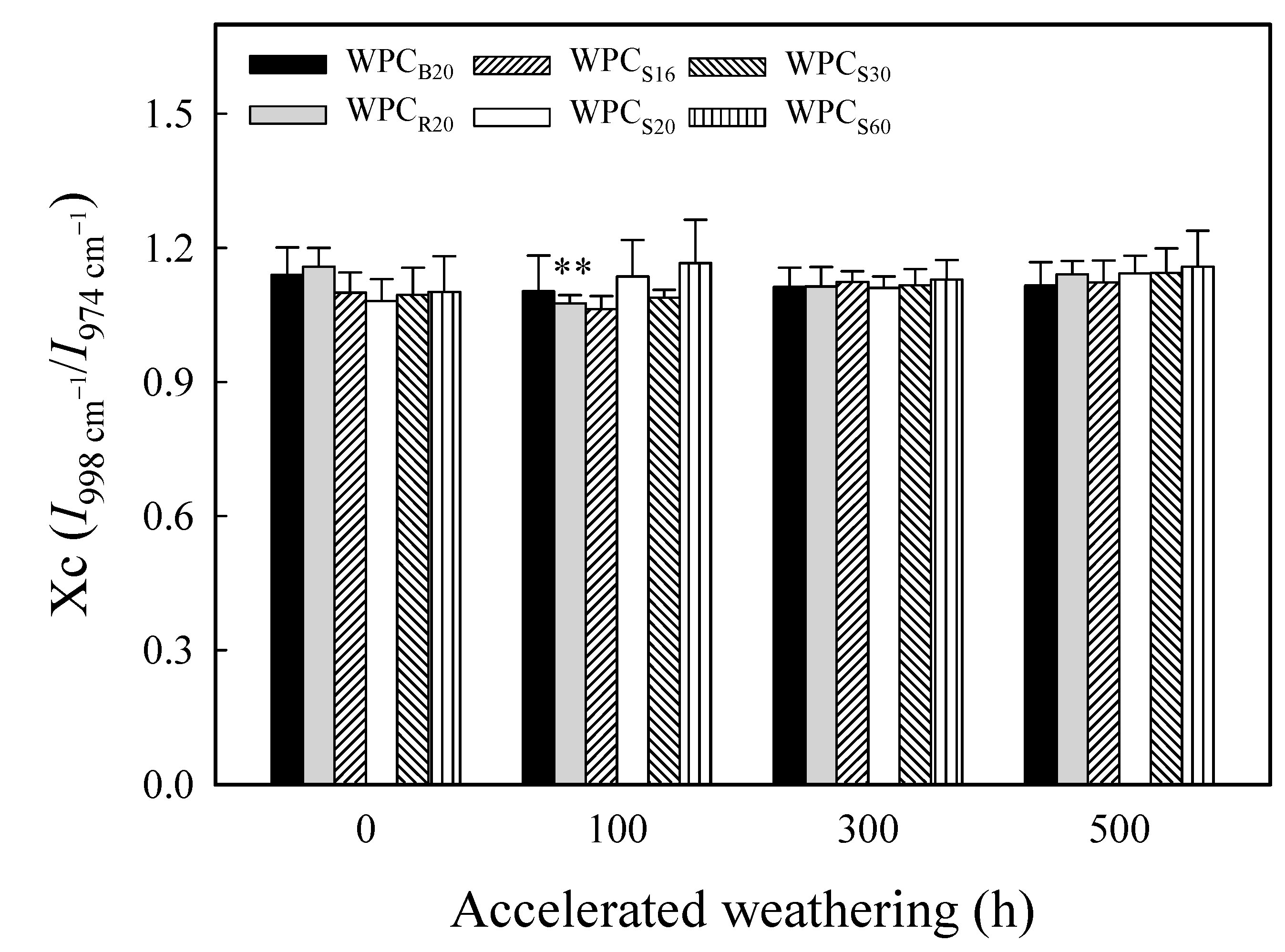

3.2.3. ATR-FTIR Analysis of the WPCs during Accelerated Weathering

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, Z.; Zhang, Z.; Wu, H.; Zhou, Z.; Yu, J. Phenolic composition and antioxidant capacities of Chinese local pummelo cultivars’ peel. Hortic. Plant J. 2016, 2, 133–140. [Google Scholar] [CrossRef]

- Tocmo, R.; Pena-Fronteras, J.; Calumba, K.F.; Mendoza, M.; Johnson, J.J. Valorization of pomelo (Citrus grandis Osbeck) peel: A review of current utilization, phytochemistry, bioactivities, and mechanisms of action. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1969–2012. [Google Scholar] [CrossRef]

- Lin, L.-Y.; Huang, C.-Y.; Chen, K.-C.; Peng, R.Y. Pomelo fruit wastes are potentially valuable antioxidants, anti-inflammatories, antihypertensives, and antihyperglycemics. Hortic. Environ. Biotechnol. 2021, 62, 377–395. [Google Scholar] [CrossRef]

- Tsai, M.-L.; Lin, C.-D.; Khoo, K.A.; Wang, M.-Y.; Kuan, T.-K.; Lin, W.-C.; Zhang, Y.-N.; Wang, Y.-Y. Composition and bioactivity of essential oil from Citrus grandis (L.) Osbeck ‘Mato peiyu’ leaf. Molecules 2017, 22, 2514. [Google Scholar] [CrossRef]

- Kiguchi, M.; Kataoka, Y.; Matsunaga, H.; Yamamoto, K.; Evans, P.D. Surface deterioration of wood-flour polypropylene composites by weathering trials. J. Wood Sci. 2007, 53, 234–238. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Characterization of weathered wood-plastic composite surfaces using FTIR spectroscopy, contact angle, and XPS. Polym. Degrad. Stabil. 2007, 92, 1883–1890. [Google Scholar] [CrossRef]

- Ashori, A. Wood-plastic composites as promising green-composites for automotive industries. Bioresource Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohyd. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood plastic composites technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef]

- Chao, Y.-Y.; Hung, K.-C.; Xu, J.-W.; Wu, T.-L.; Wu, J.-H. Effects of acetylated veneer on the natural weathering properties of adhesive-free veneer overlaid wood-plastic composites. Polymers 2020, 72, 513. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Ochi, S. Development of high strength biodegradable composites using Manila hemp fiber and starch-based biodegradable resin. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1879–1883. [Google Scholar] [CrossRef]

- Wibowo, A.C.; Misra, M.; Park, H.-M.; Drzal, L.T.; Schalek, R.; Mohanty, A.K. Biodegradable nanocomposites from cellulose acetate: Mechanical, morphological, and thermal properties. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1428–1433. [Google Scholar] [CrossRef]

- Rao, K.M.M.; Rao, K.M. Extraction and tensile properties of natural fibers: Vakka, date and bamboo. Compos. Struct. 2007, 77, 288–295. [Google Scholar] [CrossRef]

- Alsaeed, T.; Yousif, B.F.; Ku, H. The potential of using date palm fibres as reinforcement for polymeric composites. Mater. Des. 2013, 43, 177–184. [Google Scholar] [CrossRef]

- Hung, K.-C.; Yeh, H.; Yang, T.-C.; Wu, T.-L.; Xu, J.-W.; Wu, J.-H. Characterization of wood-plastic composites made with different lignocellulosic materials that vary in their morphology, chemical composition and thermal stability. Polymers 2017, 9, 726. [Google Scholar] [CrossRef]

- Yang, T.-C.; Chien, Y.-C.; Wu, T.-L.; Hung, K.-C.; Wu, J.-H. Effects of heat-treated wood particles on the physico-mechanical properties and extended creep behavior of wood/recycled-HDPE composites using the time–temperature superposition principle. Materials 2017, 10, 365. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Yang, T.-C.; Wu, T.-L.; Hung, K.-C.; Wu, J.-H. Effects of a layered structure on the physicomechanical properties and extended creep behavior of bamboo polypropylene composites (BPCs) determined by the stepped isostress method. Holzforschung 2018, 72, 589–597. [Google Scholar] [CrossRef]

- Huang, C.-W.; Yang, T.-C.; Wu, T.-L.; Hung, K.-C.; Wu, J.-H. Effects of maleated polypropylene content on the extended creep behavior of wood‒polypropylene composites using the stepped isothermal method and the stepped isostress method. Wood Sci. Technol. 2018, 52, 1313–1330. [Google Scholar] [CrossRef]

- Homami, S.S.; Seydei, M.K.; Moradi, S. Preparation of wood plastic composite from polyethylene and bagasse. Middle East J. Sci. Res. 2013, 14, 453–455. [Google Scholar] [CrossRef]

- Lazarini, R.G.; Marconcini, J.M. Sugarcane bagasse fibers at high contents in thermoplastic composites: A novel approach using agro-industrial residue via thermokinetic mixing. Polym. Compos. 2021, 1–12. [Google Scholar] [CrossRef]

- Ling, S.L.; Koay, S.C.; Chan, M.Y.; Tshai, K.Y.; Chantara, T.R.; Pang, M.M. Wood plastic composites produced from postconsumer recycled polystyrene and coconut shell: Effect of coupling agent and processing aid on tensile, thermal, and morphological properties. Polym. Eng. Sci. 2020, 60, 202–210. [Google Scholar] [CrossRef]

- Bernard, M.; Khalina, A.; Ali, A.; Janius, R.; Faizal, M.; Hasnah, K.S.; Sanuddin, A.B. The effect of processing parameters on the mechanical properties of kenaf fibre plastic composite. Mater. Des. 2011, 32, 1039–1043. [Google Scholar] [CrossRef]

- Nordin, M.N.A.; Sakamoto, K.; Azhari, H.; Goda, K.; Okamoto, M.; Ito, H.; Endo, T. Tensile and impact properties of pulverized oil palm fiber reinforced polypropylene composites: A comparison study with wood fiber reinforced polypropylene composites. J. Mech. Eng. Sci. 2018, 12, 4191–4202. [Google Scholar] [CrossRef]

- Yang, H.S.; Kim, H.J.; Park, H.J.; Lee, B.J.; Hwang, T.S. Effect of compatibilizing agents on rice-husk flour reinforced polypropylene composites. Compos. Struct. 2007, 77, 45–55. [Google Scholar] [CrossRef]

- Özdemir, F.; Serin, Z.O.; Mengeloğlu, F. Utilization of red pepper fruit stem as reinforcing filler in plastic composites. Bioresources 2013, 8, 5299–5308. [Google Scholar] [CrossRef][Green Version]

- Sain, M.; Panthapulakkal, S. Bioprocess preparation of wheat straw fibers and their characterization. Ind. Crops Prod. 2006, 23, 1–8. [Google Scholar] [CrossRef]

- Lee, C.-H.; Wu, T.-L.; Chen, Y.-L.; Wu, J.-H. Characteristics and discrimination of five types of wood-plastic composites by FTIR spectroscopy combined with principal component analysis. Holzforschung 2010, 64, 699–704. [Google Scholar] [CrossRef]

- Lee, C.-H.; Hung, K.-C.; Chen, Y.-L.; Wu, T.-L.; Chien, Y.-C.; Wu, J.-H. Effects of polymeric matrix on accelerated UV weathering properties of wood–plastic composites. Holzforschung 2012, 66, 981–987. [Google Scholar] [CrossRef]

- Ghasem, J.M. Economic model assessment of wood–polymer composites production from agricultural wastes. Ann. Biol. Res. 2013, 4, 169–174. [Google Scholar]

- Hung, K.-C.; Wu, J.-H. Mechanical and interfacial properties of plastic composite panels made from esterified bamboo particles. J. Wood Sci. 2010, 56, 216–221. [Google Scholar] [CrossRef]

- Hung, K.-C.; Chen, Y.-L.; Wu, J.-H. Natural weathering properties of acetylated bamboo plastic composites. Polym. Degrad. Stab. 2012, 97, 1680–1685. [Google Scholar] [CrossRef]

- Wu, T.-L.; Chien, Y.-C.; Chen, T.-Y.; Wu, J.-H. The influence of hot-press temperature and cooling rate on thermal and physicomechanical properties of bamboo particle-polylactic acid composites. Holzforschung 2013, 67, 325–331. [Google Scholar] [CrossRef]

- Hung, K.-C.; Wu, T.-L.; Chen, Y.-L.; Wu, J.-H. Assessing the effect of wood acetylation on mechanical properties and extended creep behavior of wood/recycled-polypropylene composites. Constr. Build. Mater. 2016, 108, 139–145. [Google Scholar] [CrossRef]

- Chen, Y.-L.; Lin, C.-Y.; Wu, T.-L.; Chung, M.-J.; Chen, T.-Y.; Yang, T.-H.; Chen, H.-C.; Wu, J.-H. Evaluation and application of the invasive weed Mikania micrantha as an alternative reinforcement in recycled high density polyethylene. Bioresources 2012, 7, 2403–2417. [Google Scholar] [CrossRef]

- ASTM. Standard Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials; ASTM G155-13; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM. Standard Test Methods for Specific Gravity of Wood and Wood-Based Materials; ASTM D2395-07a; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM. Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials; ASTM D4442-07a; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM D790-09; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM. Standard Test Methods for Tensile Properties of Plastic; ASTM D638-08; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Stark, N.M.; Matuana, L.M.; Clemons, C.M. Effect of processing method on surface and weathering characteristics of wood-flour/HDPE composites. J. Appl. Polym. Sci. 2004, 93, 1021–1030. [Google Scholar] [CrossRef]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005; 487p. [Google Scholar]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; 698p. [Google Scholar]

- CNS. Wood-Plastic Recyeled Composite; Chinese National Standard CNS 15730; Bureau of Standards, Metrology and Inspection: Taipei, Taiwan, 2014. [Google Scholar]

- Rahman, K.-S.; Islam, M.N.; Ratul, S.B.; Dana, N.H.; Musa, S.M.; Hannan, M.O. Properties of flat-pressed wood plastic composites as a function of particle size and mixing ratio. J. Wood Sci. 2018, 64, 279–286. [Google Scholar] [CrossRef]

- Chen, H.C.; Chen, T.Y.; Hsu, C.H. Effects of wood particle size and mixing ratios of HDPE on the properties of the composites. Eur. J. Wood Wood Prod. 2006, 64, 172–177. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Reinforced polypropylene composites: Effects of chemical compositions and particle size. Bioresour. Technol. 2010, 101, 2515–2519. [Google Scholar] [CrossRef]

- Feng, A.; Wu, G.; Wang, Y.; Pan, C. Synthesis, preparation and mechanical property of wood fiber-reinforced poly(vinyl chloride) composites. J. Nanosci. Nanotechnol. 2017, 17, 3859–3863. [Google Scholar] [CrossRef]

- Onuoha, C.; Onyemaobi, O.O.; Anyakwo, C.N.; Onuegbu, G.C. Effect of filler loading and particle size on the mechanical properties of periwinkle shell-filled recycled polypropylene composites. Am. J. Eng. Res. 2017, 6, 72–79. [Google Scholar]

- Stark, N.M. Effect of weathering cycle and manufacturing method on performance of wood flour and high-density polyethylene composites. J. Appl. Polym. Sci. 2006, 100, 3131–3140. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Influence of photostabilizers on wood floure-HDPE composites exposed to xenon-arc radiation with and without water spray. Polym. Degrad. Stab. 2006, 91, 3048–3056. [Google Scholar] [CrossRef]

- Kanbayashi, T.; Matsunaga, M.; Kobayashi, M. Cellular-level chemical changes in Japanese beech (Fagus crenata Blume) during artificial weathering. Holzforschung 2021. published online. [Google Scholar] [CrossRef]

- Fayolle, B.; Richaud, E.; Verdu, J.; Farcas, F. Embrittlement of polypropylene fiber during thermal oxidation. J. Mater. Sci. 2008, 43, 1026–1032. [Google Scholar] [CrossRef]

- Li, R. Environmental degradation of wood-HDPE composite. Polym. Degrad. Stabil. 2000, 70, 135–145. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; McDonald, A.G.; Wolcott, M.P.; Griffiths, P.R. Wood plastic composites weathering: Visual appearance and chemical changes. Polym. Degrad. Stabil. 2008, 93, 1405–1414. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; McDonald, A.G. Effect of wood species on property and weathering performance of wood plastic composites. Compos. Part A Appl. S. 2010, 41, 1434–1440. [Google Scholar] [CrossRef]

- Turku, I.; Kärki, T.; Puurtinen, A. Durability of wood plastic composites manufactured from recycled plastic. Heliyon 2018, 4, e00559. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L. Accelerated weathering of unbleached and bleached kraft wood fibre reinforced polypropylene composites. Polym. Degrad. Stab. 2008, 93, 1939–1946. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Surface chemistry and mechanical property changes of wood-flour/high-density-polyethylene composites after accelerated weathering. J. Appl. Polym. Sci. 2004, 94, 2263–2273. [Google Scholar] [CrossRef]

- Ndiaye, D.; Fanton, E.; Morlat-Therias, S.; Vidal, L.; Tidjani, A.; Gardette, J.L. Durability of wood polymer composites: Part 1. Influence of wood on the photochemical properties. Compos. Sci. Technol. 2008, 68, 2779–2784. [Google Scholar] [CrossRef]

- Jabarin, S.A.; Lofgren, E.A. Photooxidative effects on properties and structure of high-density polyethylene. J. Appl. Polym. Sci. 1994, 53, 411–423. [Google Scholar] [CrossRef]

- Zou, P.; Xiong, H.; Tang, S. Natural weathering of rape straw flour (RSF)/HDPE and nano-SiO2/RSF/HDPE composites. Carbohyd. Polym. 2008, 73, 378–383. [Google Scholar] [CrossRef]

- Lanyi, F.J.; Wenzke, N.; Kaschta, J.; Schubert, D.W. A method to reveal bulk and surface crystallinity of Polypropylene by FTIR spectroscopy–Suitable for fibers and nonwovens. Polym. Test. 2018, 71, 49–55. [Google Scholar] [CrossRef]

| Code | Part | WF Size (mesh) | Density (kg/m3) | Moisture Content (%) | Flexural Properties | Tensile Properties | |||

|---|---|---|---|---|---|---|---|---|---|

| MOR (MPa) | MOE (GPa) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation at Break (%) | |||||

| WPCB20 | Branch | 20–30 | 1067 ± 10 A | 2.77 ± 0.08 A | 39 ± 2 B | 2.2 ± 0.1 C | 23.0 ± 0.5 B | 2.38 ± 0.05 A | 1.9 ± 0.1 A |

| WPCR20 | Root | 20–30 | 1070 ± 13 A | 1.00 ± 0.08 B | 43 ± 3 A | 2.7 ± 0.2 A | 20.1 ± 0.5 C | 2.22 ± 0.08 C | 1.3 ± 0.1 B |

| WPCS16 | Stem | 16–20 | 1078 ± 17 a | 1.01 ± 0.05 a | 43 ± 3 a | 2.5 ± 0.2 ab | 21.9 ± 1.0 c | 2.27 ± 0.08 b | 1.6 ± 0.2 c |

| WPCS20 | Stem | 20–30 | 1076 ± 14 aA | 1.01 ± 0.04 aB | 42 ± 3 aA | 2.4 ± 0.2 bB | 23.4 ± 0.4 bA | 2.30 ± 0.09 abB | 1.9 ± 0.1 bA |

| WPCS30 | Stem | 30–60 | 1073 ± 16 a | 0.96 ± 0.04 ab | 44 ± 2 a | 2.6 ± 0.1 a | 24.1 ± 0.2 a | 2.35 ± 0.08 a | 2.1 ± 0.2 a |

| WPCS60 | Stem | <60 | 1082 ± 14 a | 0.90 ± 0.14 b | 39 ± 3 b | 2.3 ± 0.1 b | 23.3 ± 0.4 b | 2.28 ± 0.07 ab | 2.0 ± 0.2 ab |

| Code | Part | WF Size (mesh) | MOR (MPa) | MOE (GPa) | ||||

|---|---|---|---|---|---|---|---|---|

| 100 h | 300 h | 500 h | 100 h | 300 h | 500 h | |||

| WPCB20 | Branch | 20–30 | 42 ± 1 B | 42 ± 3 A | 43 ± 3 A | 2.6 ± 0.2 A | 2.6 ± 0.2 A | 2.5 ± 0.2 AB |

| WPCR20 | Root | 20–30 | 47 ± 1 A | 45 ± 2 A | 45 ± 3 A | 2.9 ± 0.2 A | 2.8 ± 0.2 A | 2.8 ± 0.3 A |

| WPCS16 | Stem | 16–20 | 47 ± 2 a | 45 ± 2 a | 42 ± 4 a | 2.8 ± 0.1 a | 2.6 ± 0.2 a | 2.4 ± 0.2 a |

| WPCS20 | Stem | 20–30 | 48 ± 1 aA | 44 ± 1 aA | 41 ± 2 aA | 2.8 ± 0.1 aA | 2.6 ± 0.1 aA | 2.4 ± 0.2 aB |

| WPCS30 | Stem | 30–60 | 44 ± 3 a | 42 ± 2 a | 44 ± 2 a | 2.8 ± 0.1 a | 2.6 ± 0.1 a | 2.5 ± 0.2 a |

| WPCS60 | Stem | <60 | 45 ± 4 a | 44 ± 2 a | 45 ± 1 a | 2.8 ± 0.3 a | 2.7 ± 0.1 a | 2.7 ± 0.1 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, K.-C.; Chang, W.-C.; Xu, J.-W.; Wu, T.-L.; Wu, J.-H. Comparison of the Physico-Mechanical and Weathering Properties of Wood–Plastic Composites Made of Wood Fibers from Discarded Parts of Pomelo Trees and Polypropylene. Polymers 2021, 13, 2681. https://doi.org/10.3390/polym13162681

Hung K-C, Chang W-C, Xu J-W, Wu T-L, Wu J-H. Comparison of the Physico-Mechanical and Weathering Properties of Wood–Plastic Composites Made of Wood Fibers from Discarded Parts of Pomelo Trees and Polypropylene. Polymers. 2021; 13(16):2681. https://doi.org/10.3390/polym13162681

Chicago/Turabian StyleHung, Ke-Chang, Wen-Chao Chang, Jin-Wei Xu, Tung-Lin Wu, and Jyh-Horng Wu. 2021. "Comparison of the Physico-Mechanical and Weathering Properties of Wood–Plastic Composites Made of Wood Fibers from Discarded Parts of Pomelo Trees and Polypropylene" Polymers 13, no. 16: 2681. https://doi.org/10.3390/polym13162681

APA StyleHung, K.-C., Chang, W.-C., Xu, J.-W., Wu, T.-L., & Wu, J.-H. (2021). Comparison of the Physico-Mechanical and Weathering Properties of Wood–Plastic Composites Made of Wood Fibers from Discarded Parts of Pomelo Trees and Polypropylene. Polymers, 13(16), 2681. https://doi.org/10.3390/polym13162681