The Extent of Interlayer Bond Strength during Fused Filament Fabrication of Nylon Copolymers: An Interplay between Thermal History and Crystalline Morphology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Filament Feedstock and Characterization

2.2. Thermal History, Crystallinity and the Equivalent Isothermal Weld Time

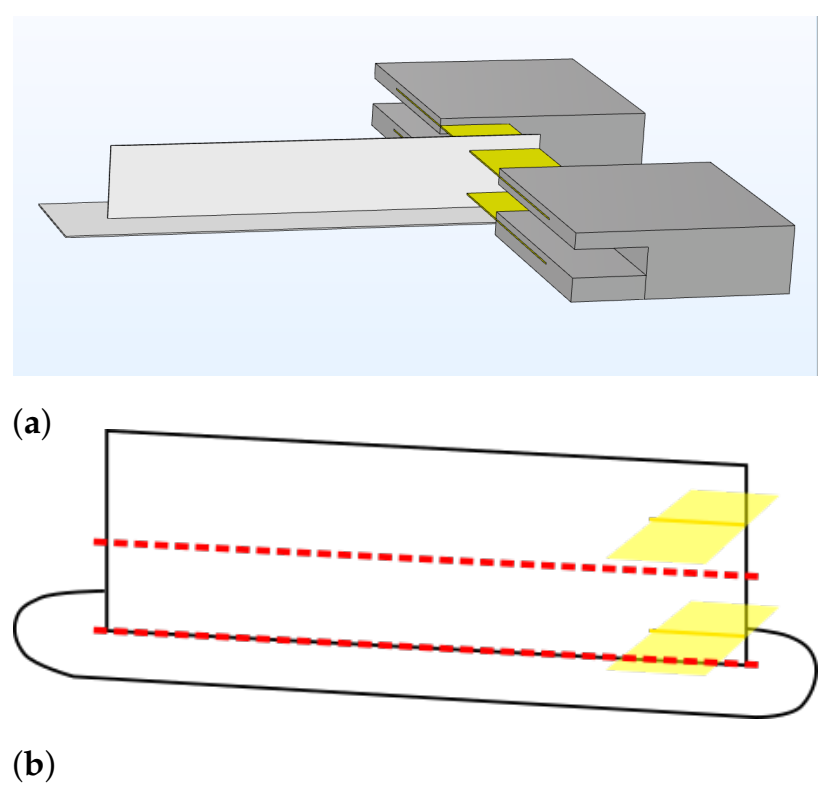

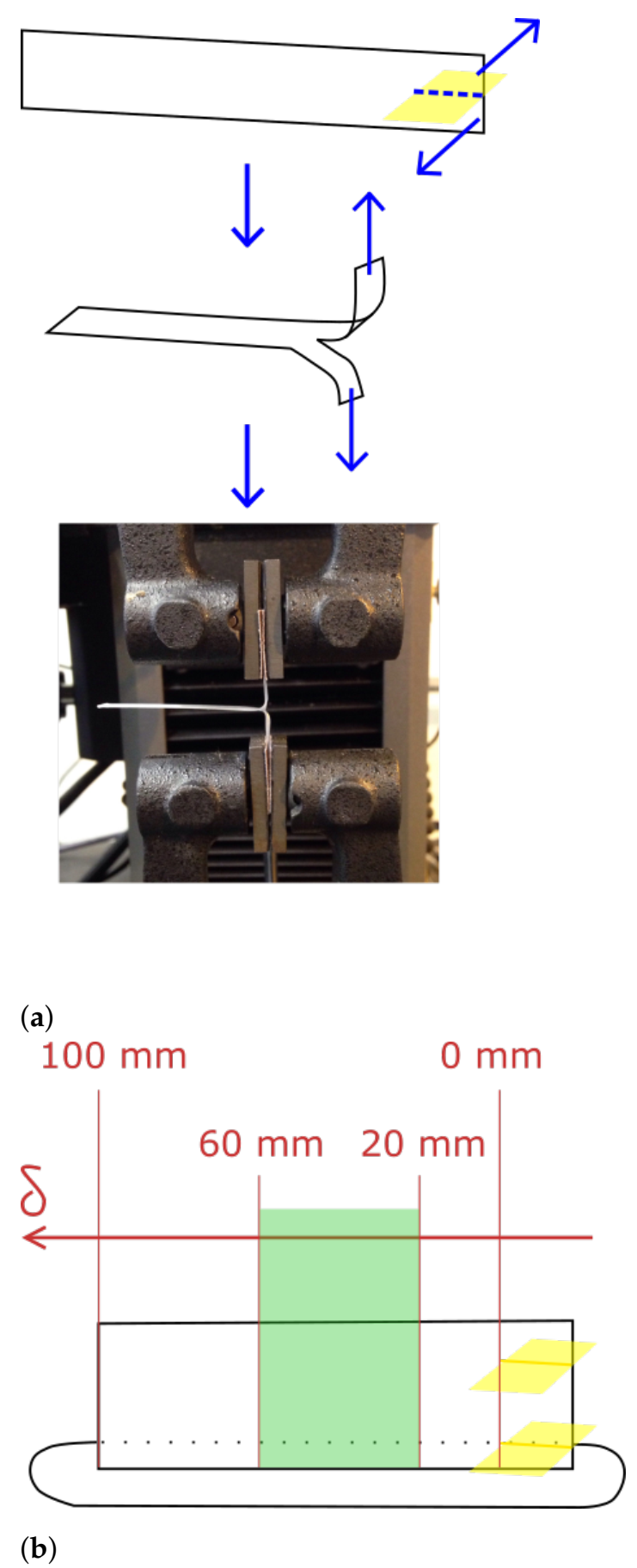

2.3. Fracture Tests

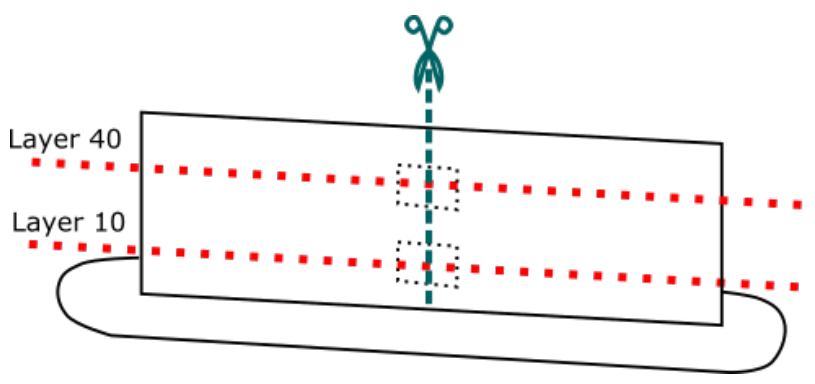

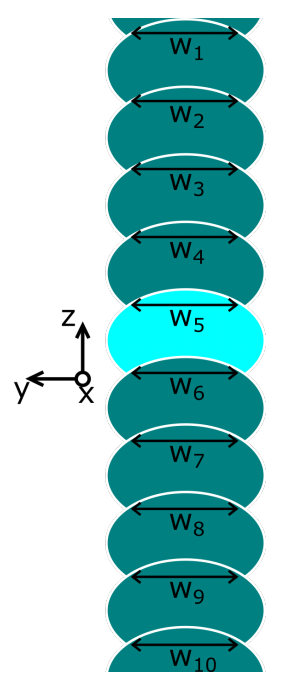

2.4. Sectioning and Visualization

3. Results and Discussion

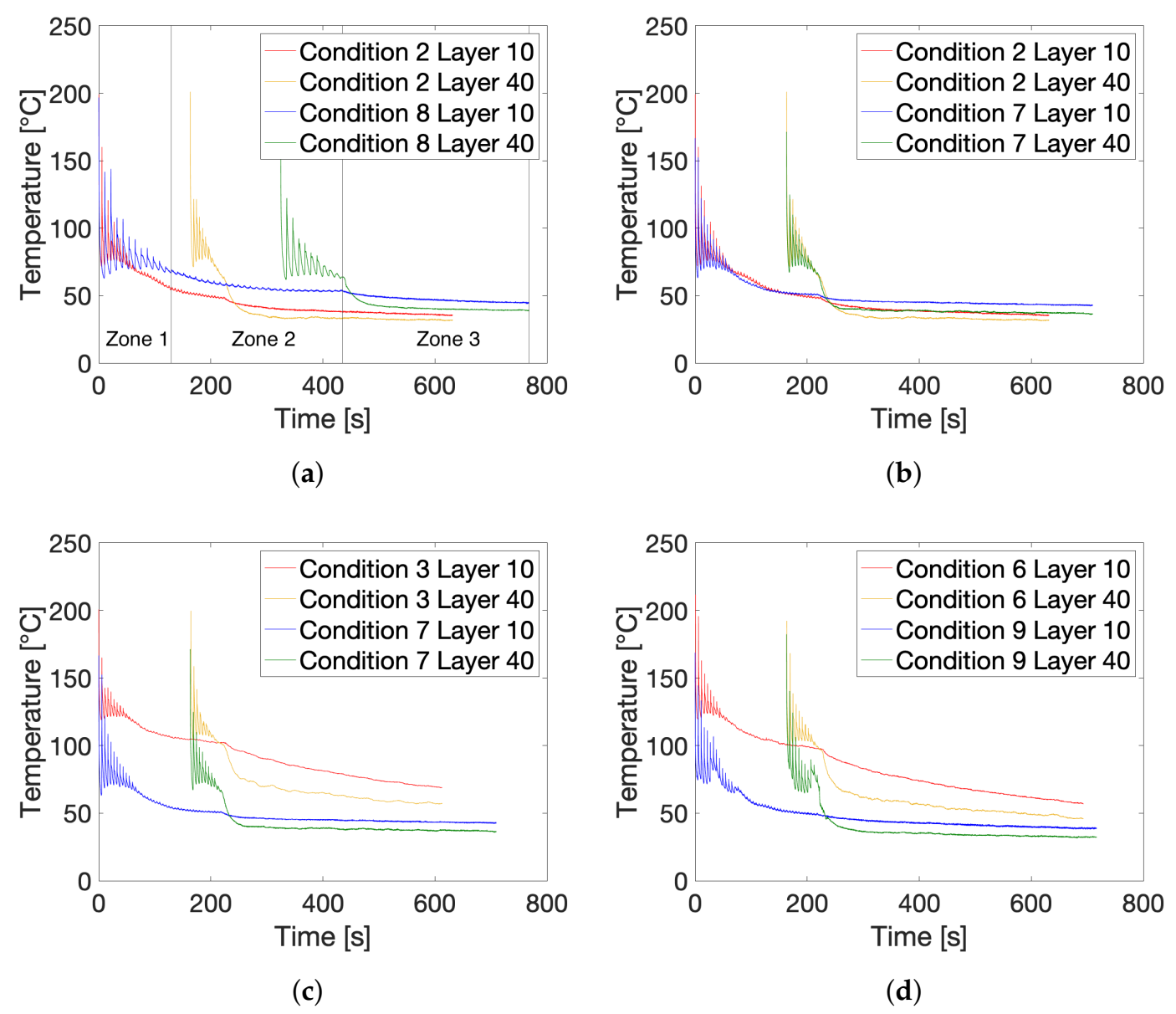

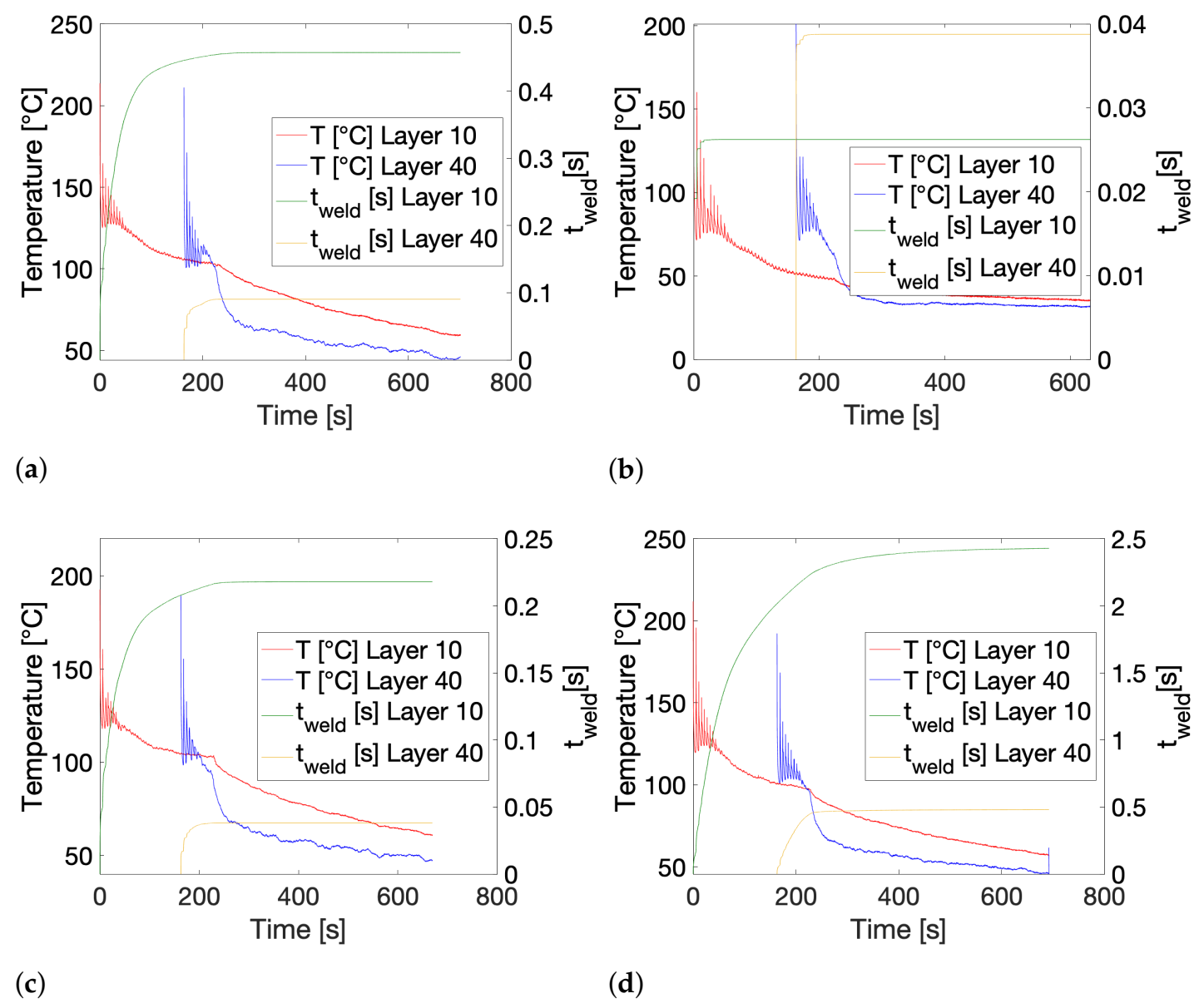

3.1. Thermal History

3.2. Crystallinity

3.3. Weld Time as a Predictive Tool for Interlayer Bond Strength

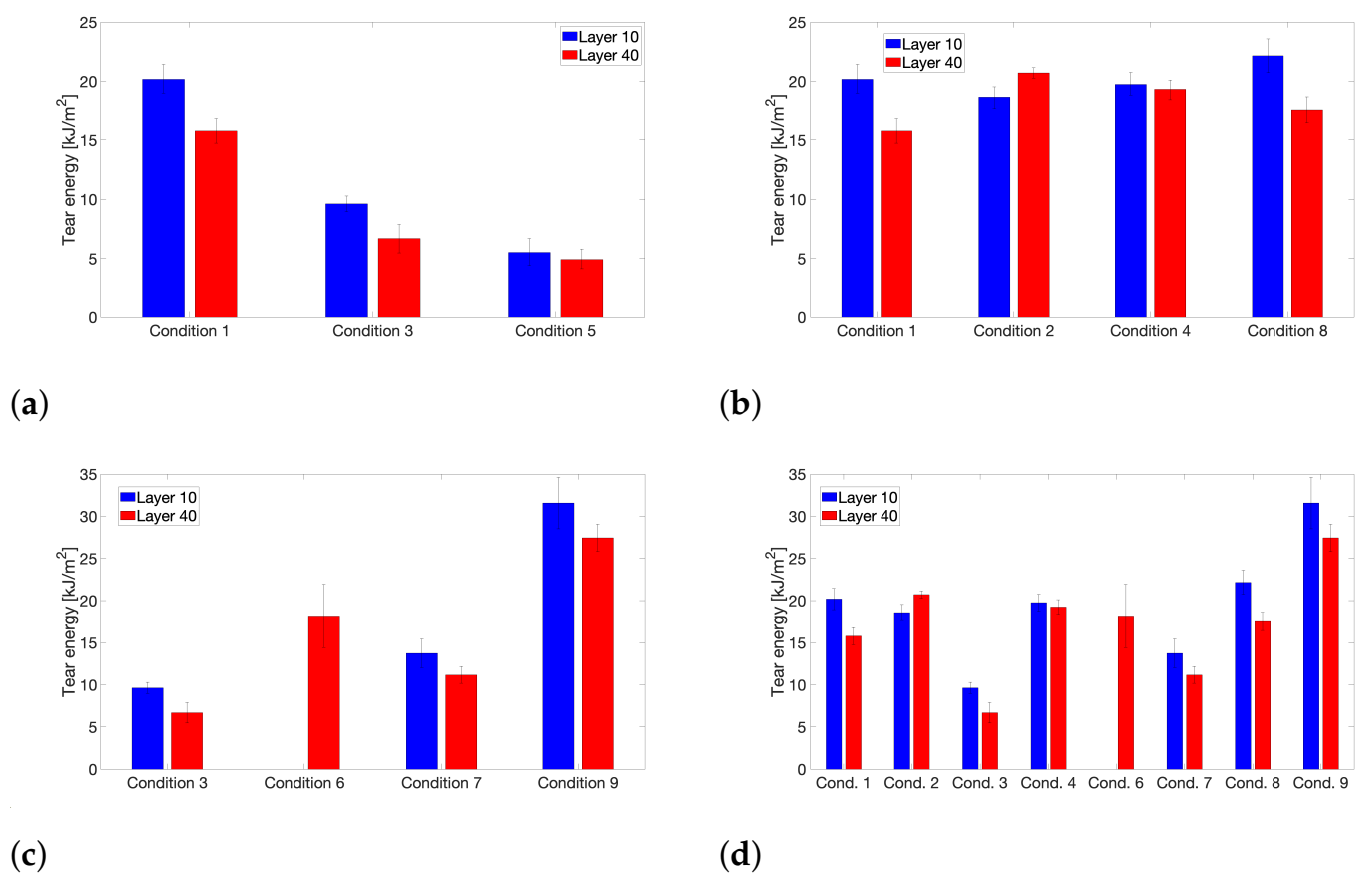

3.4. Interlayer Bond Strength

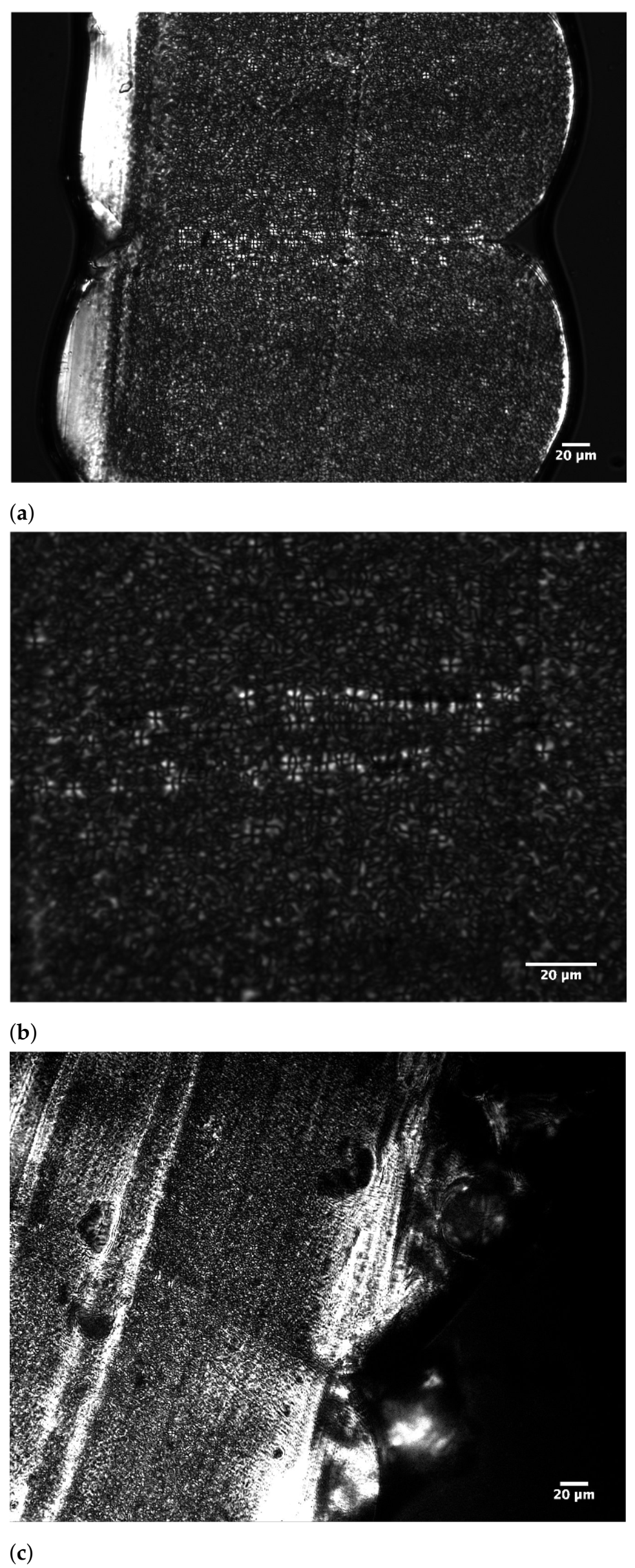

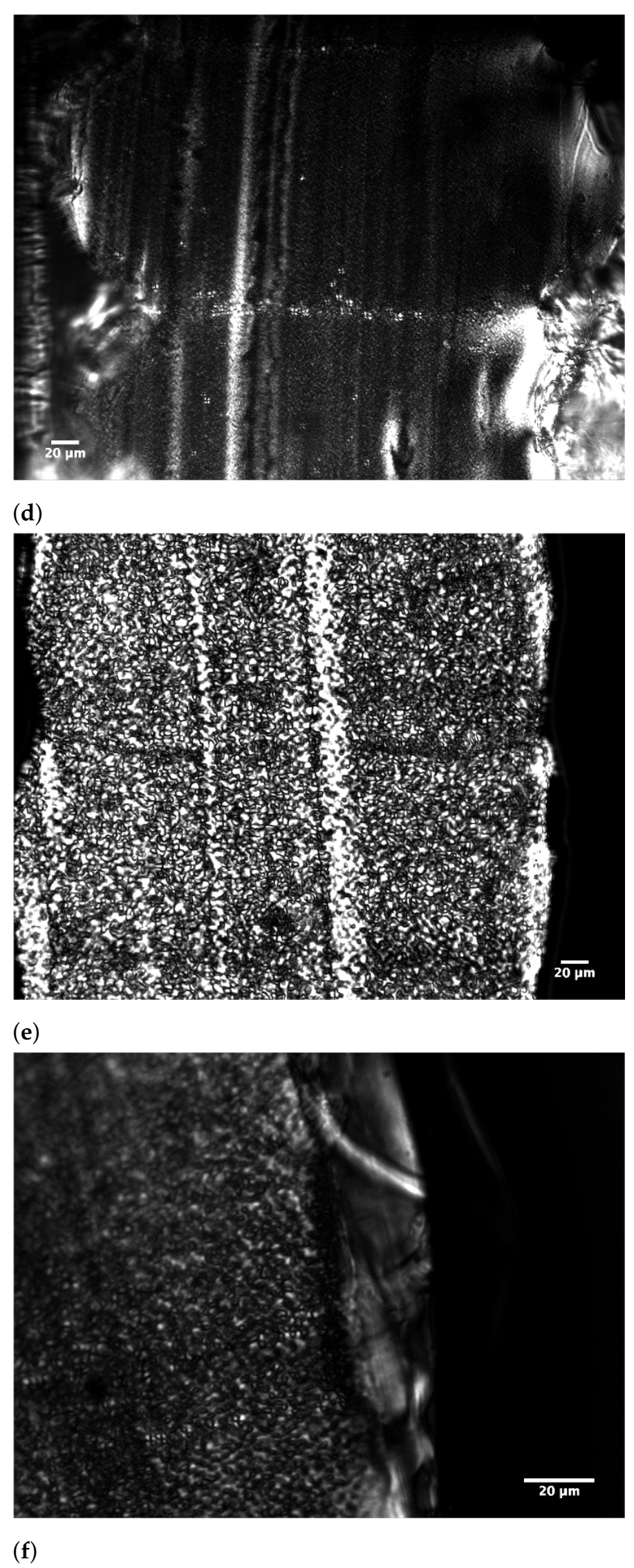

3.5. Crystalline Morphology at the Weld Interface

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

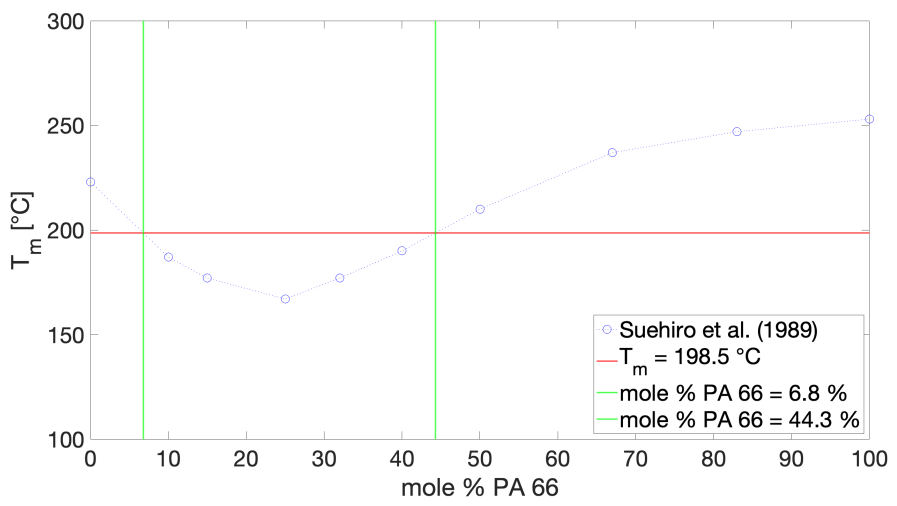

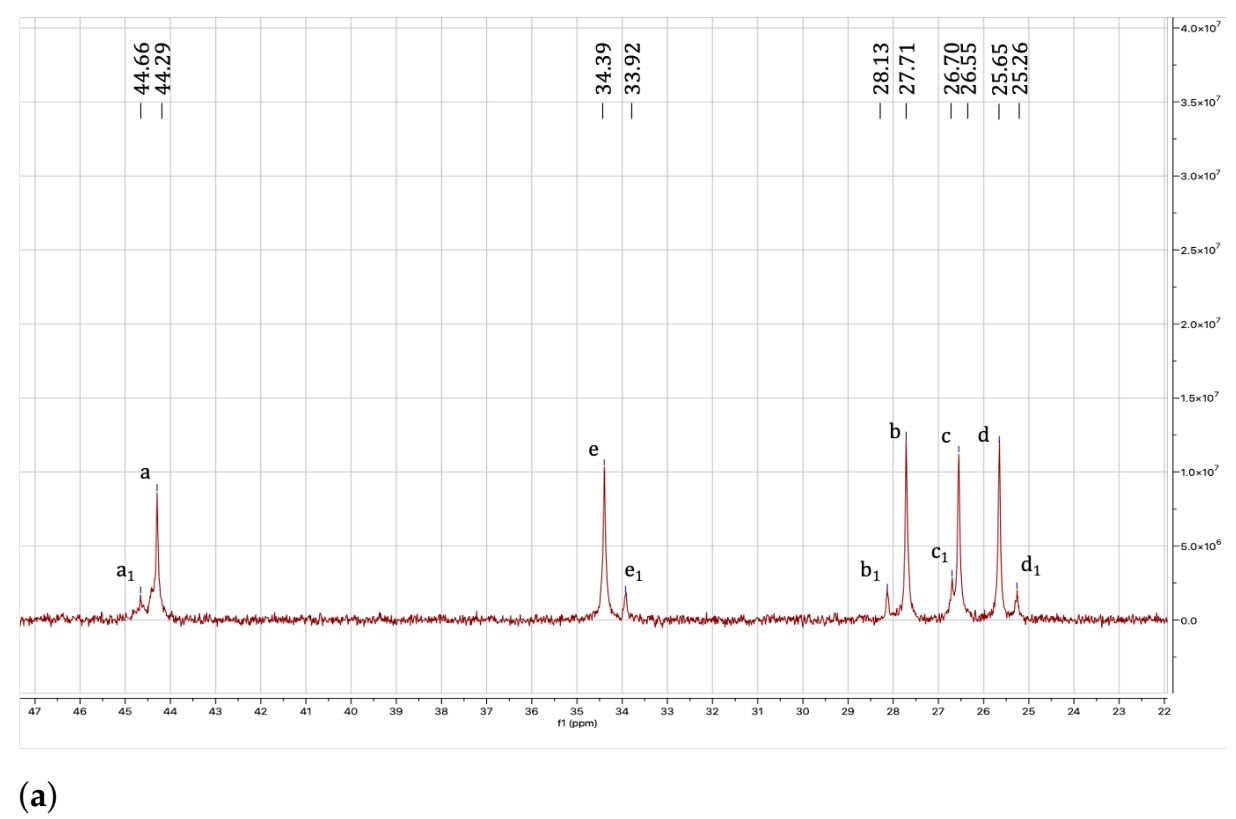

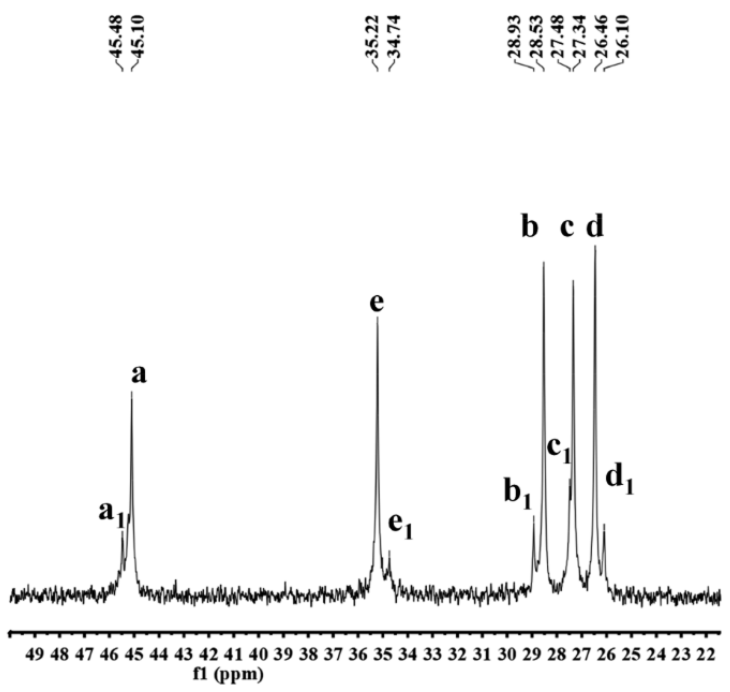

Appendix A. Determination of the Comonomer Content

| Peak | Peak Position [ppm] | Peak Position [ppm] from [77] |

|---|---|---|

| f1 | 179.96 | 180.80 |

| f2 | 179.69 | 180.54 |

| f3 | 179.20 | 180.04 |

| f4 | 178.93 | 179.77 |

| a1 | 44.66 | 45.48 |

| a | 44.29 | 45.10 |

| e | 34.39 | 35.22 |

| e1 | 33.92 | 34.74 |

| b1 | 28.13 | 28.93 |

| b | 27.71 | 28.53 |

| c1 | 26.70 | 27.48 |

| c | 26.55 | 27.34 |

| d | 25.65 | 26.46 |

| d1 | 25.26 | 26.10 |

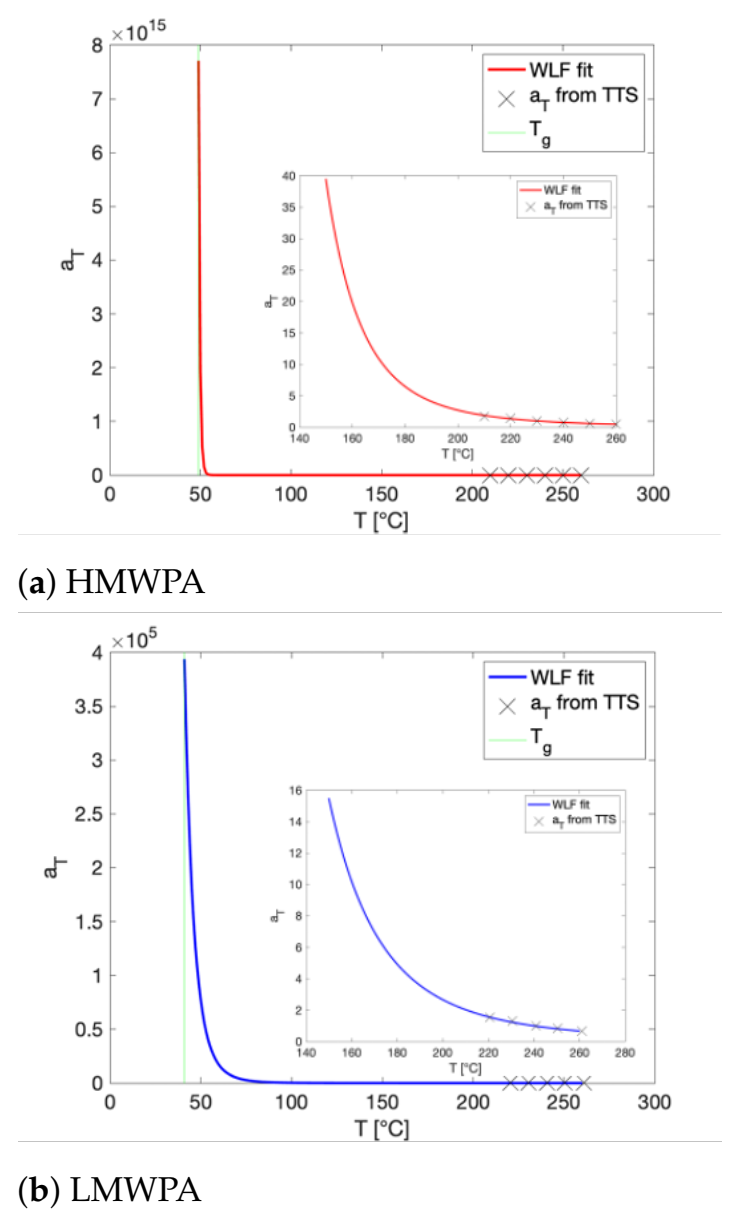

Appendix B. Rheological Characterization

Appendix C. Degree of Crystallinity for Printing Conditions 1 to 6

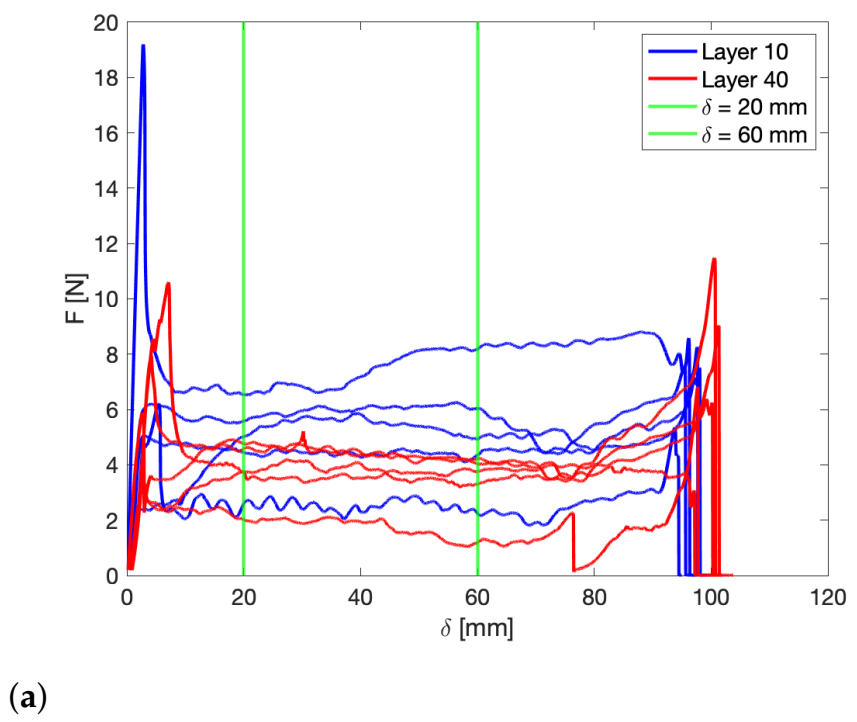

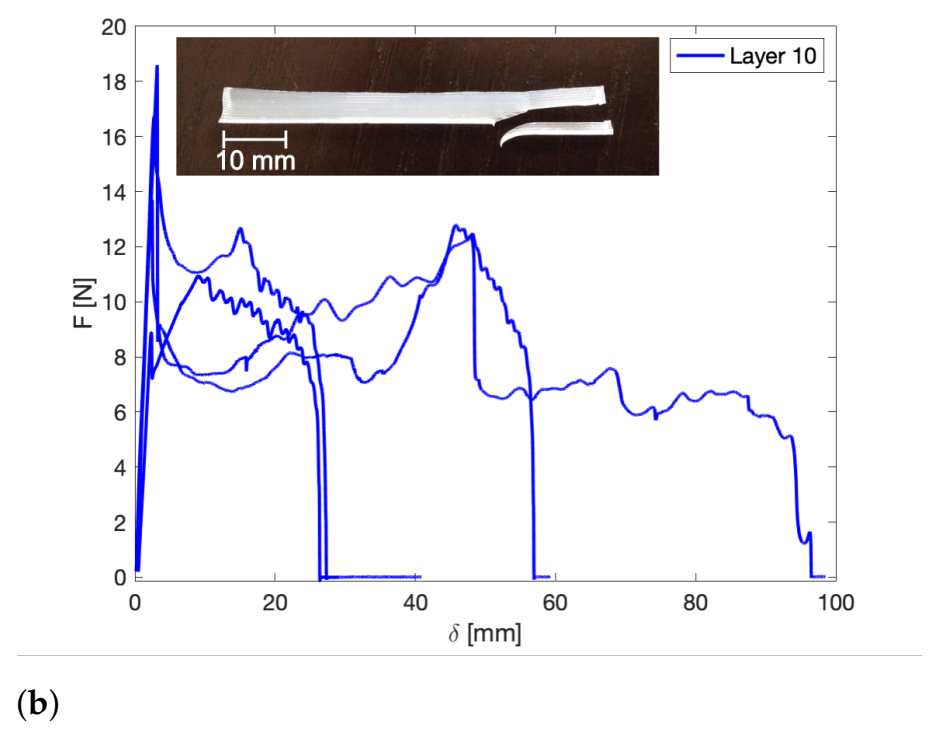

Appendix D. Load Data from Fracture Tests

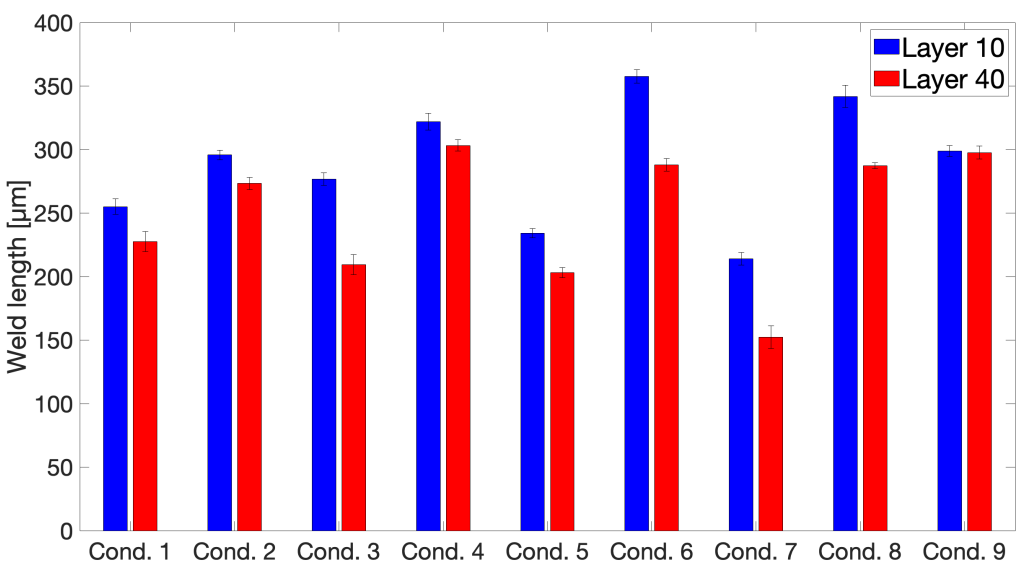

Appendix E. Weld Length Determination

References

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. CAD Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Singh, R.; Garg, H.K. Fused Deposition Modeling–A State of Art Review and Future Applications. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Wohlers, T. Wohlers Report 2020: 3D Printing and Additive Manufacturing Global State of the Industry; Technical Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2020. [Google Scholar]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [Green Version]

- Peterson, A.M. Review of acrylonitrile butadiene styrene in fused filament fabrication: A plastics engineering-focused perspective. Addit. Manuf. 2019, 27, 363–371. [Google Scholar] [CrossRef]

- Rubinstein, M.; Colby, R.H. Polymer Physics; Oxford University Press: Oxford, UK, 2003. [Google Scholar]

- Gofman, I.V.; Yudin, V.E.; Orell, O.; Vuorinen, J.; Grigoriev, A.Y.; Svetlichnyi, V.M. Influence of the degree of crystallinity on the mechanical and tribological properties of high-performance thermoplastics over a wide range of temperatures: From room temperature up to 250 °C. J. Macromol. Sci. Part B Phys. 2013, 52, 1848–1860. [Google Scholar] [CrossRef]

- Kutz, M. (Ed.) Applied Plastics Engineering Handbook, 2nd ed.; William Andrew: Norwich, NY, USA, 2017. [Google Scholar] [CrossRef]

- Piorkowska, E.; Rutledge, G.C. Handbook of Polymer Crystallization; Wiley: Hoboken, NJ, USA, 2013; pp. 1–481. [Google Scholar] [CrossRef]

- Mark, J.E. (Ed.) Physical Properties of Polymers Handbook, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Li, D.; Guo, G.; Fan, R.; Liang, J.; Deng, X.; Luo, F.; Qian, Z. PLA/F68/Dexamethasone implants prepared by hot-melt extrusion for controlled release of anti-inflammatory drug to implantable medical devices: I. Preparation, characterization and hydrolytic degradation study. Int. J. Pharm. 2013, 441, 365–372. [Google Scholar] [CrossRef]

- Patrício, T.; Domingos, M.; Gloria, A.; D’Amora, U.; Coelho, J.F.; Bártolo, P.J. Fabrication and characterisation of PCL and PCL/PLA scaffolds for tissue engineering. Rapid Prototyp. J. 2014, 20, 145–156. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Zadorozhnyy, M.Y.; Maksimkin, A.V.; Kaloshkin, S.D.; Estrin, Y.Z. Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 2016, 57, 139–148. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C.; Ramakrishna, S. 3D printing of polyether-ether-ketone for biomedical applications. Eur. Polym. J. 2019, 114, 234–248. [Google Scholar] [CrossRef]

- Katschnig, M.; Arbeiter, F.; Haar, B.; van Campe, G.; Holzer, C. Cranial Polypropylene Implants by Fused Filament Fabrication. Adv. Eng. Mater. 2017, 19, 1–5. [Google Scholar] [CrossRef]

- Sacco, E.; Moon, S.K. Additive manufacturing for space: Status and promises. Int. J. Adv. Manuf. Technol. 2019, 105, 4123–4146. [Google Scholar] [CrossRef]

- Reyes, C.; Somogyi, R.; Niu, S.; Cruz, M.A.; Yang, F.; Catenacci, M.J.; Rhodes, C.P.; Wiley, B.J. Three-Dimensional Printing of a Complete Lithium Ion Battery with Fused Filament Fabrication. ACS Appl. Energy Mater. 2018, 1, 5268–5279. [Google Scholar] [CrossRef]

- Aslanzadeh, S.; Saghlatoon, H.; Honari, M.M.; Mirzavand, R.; Montemagno, C.; Mousavi, P. Investigation on electrical and mechanical properties of 3D printed nylon 6 for RF/microwave electronics applications. Addit. Manuf. 2018, 21, 69–75. [Google Scholar] [CrossRef]

- Tichy, T.; Sefl, O.; Vesely, P.; Capal, T. Application Possibilities of Fused Filament Fabrication Technology for High-Voltage and Medium-Voltage Insulation Systems. In Proceedings of the International Spring Seminar on Electronics Technology, Wroclaw, Poland, 15–19 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Gao, X.; Qi, S.; Kuang, X.; Su, Y.; Li, J.; Wang, D. Fused filament fabrication of polymer materials: A review of interlayer bond. Addit. Manuf. 2021, 37, 101658. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Tan, H.K.J.; Sing, S.L.; Goh, G.L.; Yeong, W.Y. Process–Structure–Properties in Polymer Additive Manufacturing via Material Extrusion: A Review. Crit. Rev. Solid State Mater. Sci. 2020, 45, 113–133. [Google Scholar] [CrossRef]

- Wang, L.; Gardner, D.J. Effect of fused layer modeling (FLM) processing parameters on impact strength of cellular polypropylene. Polymer 2017, 113, 74–80. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P.D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef] [Green Version]

- Abbott, A.C.; Tandon, G.P.; Bradford, R.L.; Koerner, H.; Baur, J.W. Process-structure-property effects on ABS bond strength in fused filament fabrication. Addit. Manuf. 2018, 19, 29–38. [Google Scholar] [CrossRef]

- Seppala, J.E.; Hoon Han, S.; Hillgartner, K.E.; Davis, C.S.; Migler, K.B. Weld formation during material extrusion additive manufacturing. Soft Matter 2017, 13, 6761–6769. [Google Scholar] [CrossRef]

- Bähr, F.; Westkämper, E. Correlations between Influencing Parameters and Quality Properties of Components Produced by Fused Deposition Modeling. Procedia CIRP 2018, 72, 1214–1219. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical strength of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef]

- Aliheidari, N.; Christ, J.; Tripuraneni, R.; Nadimpalli, S.; Ameli, A. Interlayer adhesion and fracture resistance of polymers printed through melt extrusion additive manufacturing process. Mater. Des. 2018, 156, 351–361. [Google Scholar] [CrossRef]

- Bellehumeur, C.; Li, L.; Sun, Q.; Gu, P. Modeling of bond formation between polymer filaments in the fused deposition modeling process. J. Manuf. Process. 2004, 6, 170–178. [Google Scholar] [CrossRef]

- Bartolai, J.; Simpson, T.W.; Xie, R. Predicting strength of additively manufactured thermoplastic polymer parts produced using material extrusion. Rapid Prototyp. J. 2018, 24, 321–332. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Healing simulation for bond strength prediction of FDM. Rapid Prototyp. J. 2017, 23, 551–561. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Prediction of interlayer strength in material extrusion additive manufacturing. Addit. Manuf. 2020, 35, 101368. [Google Scholar] [CrossRef]

- Mackay, M.E. The importance of rheological behavior in the additive manufacturing technique material extrusion. J. Rheol. 2018, 62, 1549–1561. [Google Scholar] [CrossRef]

- Firas, A. Autohesion of polymers. Polymer 2016, 97, 387–407. [Google Scholar] [CrossRef]

- Jarrousse, G. Self Adhesion of Semi-Crystalline Polymers between Their Glass Transition Temperature and Their Melting Temperature. Ph.D. Thesis, Université Paris VI, Paris, France, 2005. [Google Scholar]

- Barocio Vaca, E. Fusion Bonding of Fiber Reinforced Semi-Crystalline Polymers in Extrusion Deposition Additive Manufacturing. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2018. [Google Scholar]

- Srinivas, V.; van Hooy-Corstjens, C.S.J.; Harings, J.A.W. Correlating molecular and crystallization dynamics to macroscopic fusion and thermodynamic stability in fused deposition modeling; a model study on polylactides. Polymer 2018, 142, 348–355. [Google Scholar] [CrossRef]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Hertle, S.; Drexler, M.; Drummer, D. Additive Manufacturing of Poly(propylene) by Means of Melt Extrusion. Macromol. Mater. Eng. 2016, 301, 1482–1493. [Google Scholar] [CrossRef]

- Xue, Y.Q.; Tervoort, T.A.; Rastogi, S.; Lemstra, P.J. Welding behavior of semicrystalline polymers. 2. Effect of cocrystallization on autoadhesion. Macromolecules 2000, 33, 7084–7087. [Google Scholar] [CrossRef]

- Li, H.; Zhang, S.; Yi, Z.; Li, J.; Sun, A.; Guo, J.; Xu, G. Bonding quality and fracture analysis of polyamide 12 parts fabricated by fused deposition modeling. Rapid Prototyp. J. 2017, 23, 973–982. [Google Scholar] [CrossRef]

- Shmueli, Y.; Jiang, J.; Zhou, Y.; Xue, Y.; Chang, C.C.; Yuan, G.; Satija, S.K.; Lee, S.; Nam, C.Y.; Kim, T.; et al. Simultaneous in Situ X-ray Scattering and Infrared Imaging of Polymer Extrusion in Additive Manufacturing. ACS Appl. Polym. Mater. 2019, 1, 1559–1567. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Cajner, H.; Sapkota, J.; Holzer, C. Parametric optimization of intra- and inter-layer strengths in parts produced by extrusion-based additive manufacturing of poly(lactic acid). J. Appl. Polym. Sci. 2017, 134, 1–15. [Google Scholar] [CrossRef]

- Qi, S.; Gao, X.; Su, Y.; Dong, X.; Cavallo, D.; Wang, D. Correlation between welding behavior and mechanical anisotropy of long chain polyamide 12 manufactured with fused filament fabrication. Polymer 2021, 213, 123318. [Google Scholar] [CrossRef]

- Costanzo, A.; Croce, U.; Spotorno, R.; Fenni, S.E.; Cavallo, D. Fused deposition modeling of polyamides: Crystallization and weld formation. Polymers 2020, 12, 2980. [Google Scholar] [CrossRef]

- Costanzo, A.; Spotorno, R.; Candal, M.V.; Fernández, M.M.; Müller, A.J.; Graham, R.S.; Cavallo, D.; McIlroy, C. Residual alignment and its effect on weld strength in material-extrusion 3D-printing of polylactic acid. Addit. Manuf. 2020, 36, 101415. [Google Scholar] [CrossRef]

- McIlroy, C.; Seppala, J.E.; Kotula, A.P. Combining Modeling and Measurements to Predict Crystal Morphology in Material Extrusion. ACS Symp. Ser. 2019, 1315, 85–113. [Google Scholar] [CrossRef]

- Wang, L.; Gramlich, W.M.; Gardner, D.J. Improving the impact strength of Poly(lactic acid) (PLA) in fused layer modeling (FLM). Polymer 2017, 114, 242–248. [Google Scholar] [CrossRef]

- Vaes, D.; Coppens, M.; Goderis, B.; Zoetelief, W.; Van Puyvelde, P. Assessment of crystallinity development during fused filament fabrication through Fast Scanning Chip Calorimetry. Appl. Sci. 2019, 9, 2676. [Google Scholar] [CrossRef] [Green Version]

- Wunderlich, B. Macromolecular Physics, Vol. 3, Chap. 8: Crystal Melting; Academic Press: New York, NY, USA, 1971. [Google Scholar]

- Telen, L.; Van Puyvelde, P.; Goderis, B. Random Copolymers from Polyamide 11 and Polyamide 12 by Reactive Extrusion: Synthesis, Eutectic Phase Behavior, and Polymorphism. Macromolecules 2016, 49, 876–890. [Google Scholar] [CrossRef]

- El Magri, A.; El Mabrouk, K.; Vaudreuil, S.; Chibane, H.; Touhami, M.E. Optimization of printing parameters for improvement of mechanical and thermal performances of 3D printed poly(ether ether ketone) parts. J. Appl. Polym. Sci. 2020, 137, 49087. [Google Scholar] [CrossRef]

- Lodge, T.P. Reconciliation of the molecular weight dependence of diffusion and viscosity in entangled polymers. Phys. Rev. Lett. 1999, 83, 3218–3221. [Google Scholar] [CrossRef]

- Wolszczak, P.; Lygas, K.; Paszko, M.; Wach, R.A. Heat distribution in material during fused deposition modelling. Rapid Prototyp. J. 2018, 24, 615–622. [Google Scholar] [CrossRef]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef]

- Vanaei, H.; Shirinbayan, M.; Deligant, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Influence of process parameters on thermal and mechanical properties of polylactic acid fabricated by fused filament fabrication. Polym. Eng. Sci. 2020, 60, 1822–1831. [Google Scholar] [CrossRef]

- Akhoundi, B.; Nabipour, M.; Hajami, F.; Shakoori, D. An Experimental Study of Nozzle Temperature and Heat Treatment (Annealing) Effects on Mechanical Properties of High-Temperature Polylactic Acid in Fused Deposition Modeling. Polym. Eng. Sci. 2020, 60, 1–9. [Google Scholar] [CrossRef]

- Wang, L.; Sanders, J.E.; Gardner, D.J.; Han, Y. Effect of fused deposition modeling process parameters on the mechanical properties of a filled polypropylene. Prog. Addit. Manuf. 2018, 3, 205–214. [Google Scholar] [CrossRef]

- Petersmann, S.; Spoerk-Erdely, P.; Feuchter, M.; Wieme, T.; Arbeiter, F.; Spoerk, M. Process-induced morphological features in material extrusion-based additive manufacturing of polypropylene. Addit. Manuf. 2020, 35, 101384. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, D.; Wen, X.; Qi, S.; Su, Y.; Dong, X. Fused deposition modeling with polyamide 1012. Rapid Prototyp. J. 2019, 25, 1145–1154. [Google Scholar] [CrossRef]

- Levenhagen, N.P.; Dadmun, M.D. Bimodal molecular weight samples improve the isotropy of 3D printed polymeric samples. Polymer 2017, 122, 232–241. [Google Scholar] [CrossRef]

- Verbeeten, W.M.H.; Lorenzo-Bañuelos, M.; Arribas-Subiñas, P.J. Anisotropic rate-dependent mechanical behavior of Poly(Lactic Acid) processed by Material Extrusion Additive Manufacturing. Addit. Manuf. 2020, 31, 100968. [Google Scholar] [CrossRef]

- Wang, L.; Gardner, D.J. Contribution of printing parameters to the interfacial strength of polylactic acid (PLA) in material extrusion additive manufacturing. Prog. Addit. Manuf. 2018, 3, 165–171. [Google Scholar] [CrossRef]

- Peeters, M.; Goderis, B.; Vonk, C.; Reynaers, H.; Mathot, V. Morphology of homogeneous copolymers of ethene and 1-octene. I. Influence of thermal history on morphology. J. Polym. Sci. Part Polym. Phys. 1997, 35, 2689–2713. [Google Scholar] [CrossRef]

- Huo, H.; Yao, X.; Zhang, Y.; Li, J.; Shang, Y.; Jiang, S. In Situ Studies on the Temperature-Related Deformation Behavior of Isotactic Polypropylene Spherulites with Uniaxial Stretching: The Effect of Crystallization Conditions. Polym. Eng. Sci. 2013, 53, 125–133. [Google Scholar] [CrossRef]

- Turska, E.; Gogolewski, S. Study on crystallization of nylon-6 (polycaproamide). II. Effect of molecular weight on isothermal crystallization kinetics. Polymer 1971, 12, 629–641. [Google Scholar] [CrossRef]

- Shang, Y.; Ning, P.; Zhang, Y.; Xue, F.; Cai, Z.; Li, J.; Ma, G.; Song, J.; Wu, Z.; Jiang, S. Study on structure and property relations of α-iPP during uniaxial deformation via in situ synchrotron SAXS/WAXS and POM investigations. Polym. Eng. Sci. 2018, 58, 160–169. [Google Scholar] [CrossRef]

- McDermott, A.G.; Deslauriers, P.J.; Fodor, J.S.; Jones, R.L.; Snyder, C.R. Measuring Tie Chains and Trapped Entanglements in Semicrystalline Polymers. Macromolecules 2020, 53, 5614–5626. [Google Scholar] [CrossRef]

- Thomas, C.; Seguela, R.; Detrez, F.; Miri, V.; Vanmansart, C. Plastic deformation of spherulitic semi-crystalline polymers: An in situ AFM study of polybutene under tensile drawing. Polymer 2009, 50, 3714–3723. [Google Scholar] [CrossRef]

- Harvey, E.D.; Hybart, F.J. Rates of crystallization of copolyamides. II. Random copolymers of nylons 66 and 6. J. Appl. Polym. Sci. 1970, 14, 2133–2143. [Google Scholar] [CrossRef]

- Suehiro, K.; Egashira, T.; Imamura, K.; Nagano, Y. Structural studies on 6-66 and 6-68 copolyamides. Acta Polym. 1989, 40, 4–8. [Google Scholar] [CrossRef]

- Tang, J.; Xu, B.; Xi, Z.; Pan, X.; Zhao, L. Controllable Crystallization Behavior of Nylon-6/66 Copolymers Based on Regulating Sequence Distribution. Ind. Eng. Chem. Res. 2018, 57, 15008–15019. [Google Scholar] [CrossRef]

- Shangguan, Y.; Chen, F.; Jia, E.; Lin, Y.; Hu, J.; Zheng, Q. New insight into Time-Temperature correlation for polymer relaxations ranging from secondary relaxation to terminal flow: Application of a Universal and developed WLF equation. Polymers 2017, 9, 567. [Google Scholar] [CrossRef] [Green Version]

| Material | Mw [kg/mol] | Tg [°C] | Tm [°C] |

|---|---|---|---|

| HMWPA | 58 | 49 | 199 |

| LMWPA | 24 | 41 | 198 |

| Condition | Material | Tliquefier [°C] | Tbuild plate [°C] | vprint [mm/s] |

|---|---|---|---|---|

| 1 | HMWPA | 260 | 110 | 11 |

| 2 | HMWPA | 260 | 40 | 11 |

| 3 | HMWPA | 240 | 110 | 11 |

| 4 | HMWPA | 260 | 110 | 5.5 |

| 5 | HMWPA | 220 | 110 | 11 |

| 6 | LMWPA | 240 | 110 | 11 |

| 7 | HMWPA | 240 | 40 | 11 |

| 8 | HMWPA | 260 | 40 | 5.5 |

| 9 | LMWPA | 240 | 40 | 11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaes, D.; Coppens, M.; Goderis, B.; Zoetelief, W.; Van Puyvelde, P. The Extent of Interlayer Bond Strength during Fused Filament Fabrication of Nylon Copolymers: An Interplay between Thermal History and Crystalline Morphology. Polymers 2021, 13, 2677. https://doi.org/10.3390/polym13162677

Vaes D, Coppens M, Goderis B, Zoetelief W, Van Puyvelde P. The Extent of Interlayer Bond Strength during Fused Filament Fabrication of Nylon Copolymers: An Interplay between Thermal History and Crystalline Morphology. Polymers. 2021; 13(16):2677. https://doi.org/10.3390/polym13162677

Chicago/Turabian StyleVaes, Dries, Margot Coppens, Bart Goderis, Wim Zoetelief, and Peter Van Puyvelde. 2021. "The Extent of Interlayer Bond Strength during Fused Filament Fabrication of Nylon Copolymers: An Interplay between Thermal History and Crystalline Morphology" Polymers 13, no. 16: 2677. https://doi.org/10.3390/polym13162677

APA StyleVaes, D., Coppens, M., Goderis, B., Zoetelief, W., & Van Puyvelde, P. (2021). The Extent of Interlayer Bond Strength during Fused Filament Fabrication of Nylon Copolymers: An Interplay between Thermal History and Crystalline Morphology. Polymers, 13(16), 2677. https://doi.org/10.3390/polym13162677