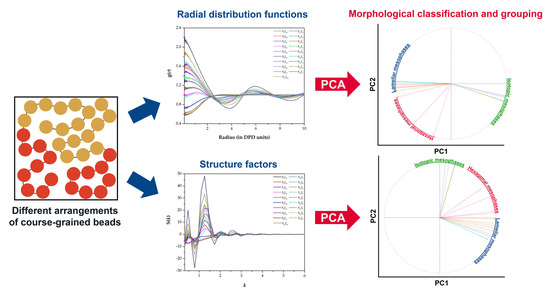

Characteristic Structural Knowledge for Morphological Identification and Classification in Meso-Scale Simulations Using Principal Component Analysis

Abstract

:1. Introduction

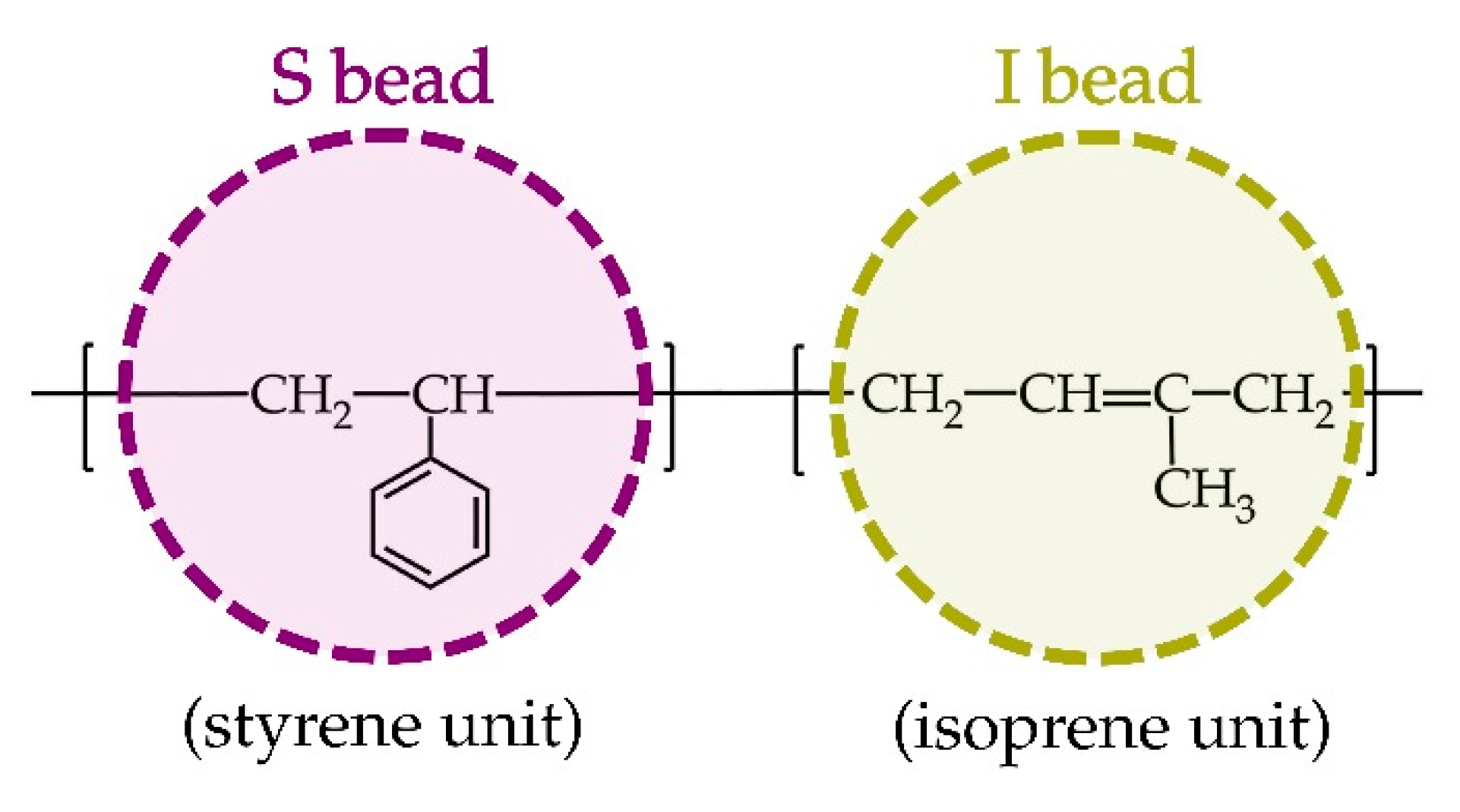

2. Methods

2.1. Dissipative Particle Dynamics (DPD) Simulation and the Analysis of an Apparent Morphology at an Equilibrium and Its Related Order Parameters

2.2. Principal Component Analysis (PCA)

3. Results

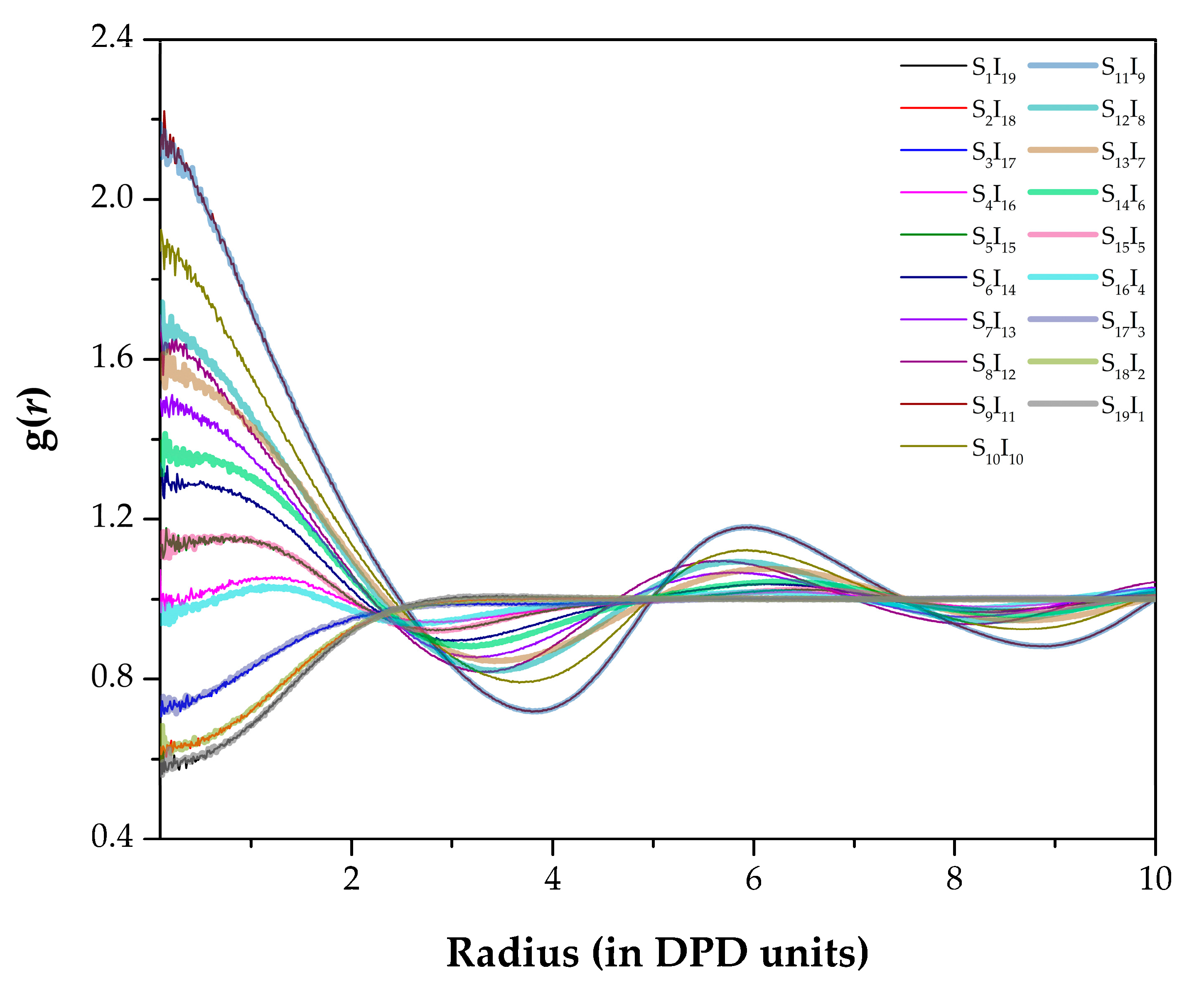

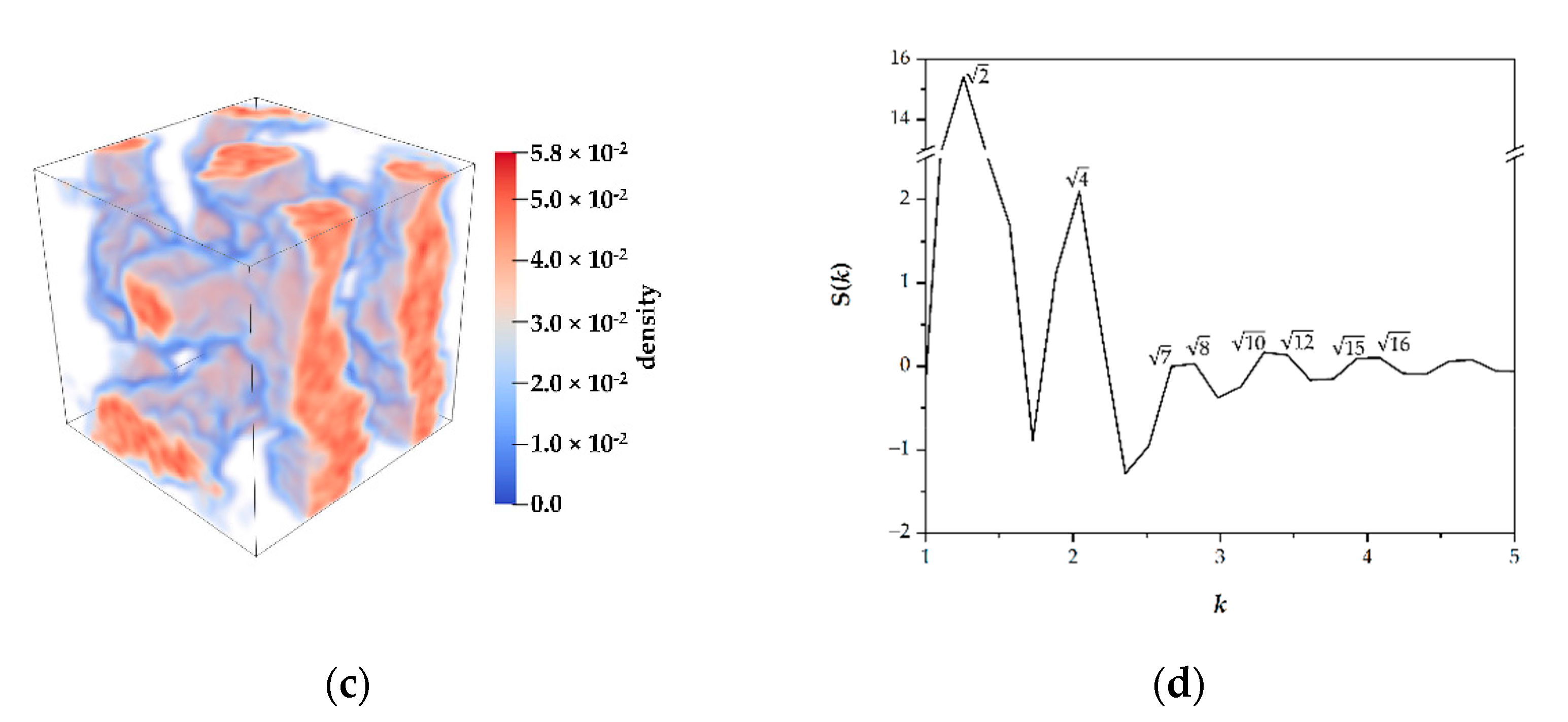

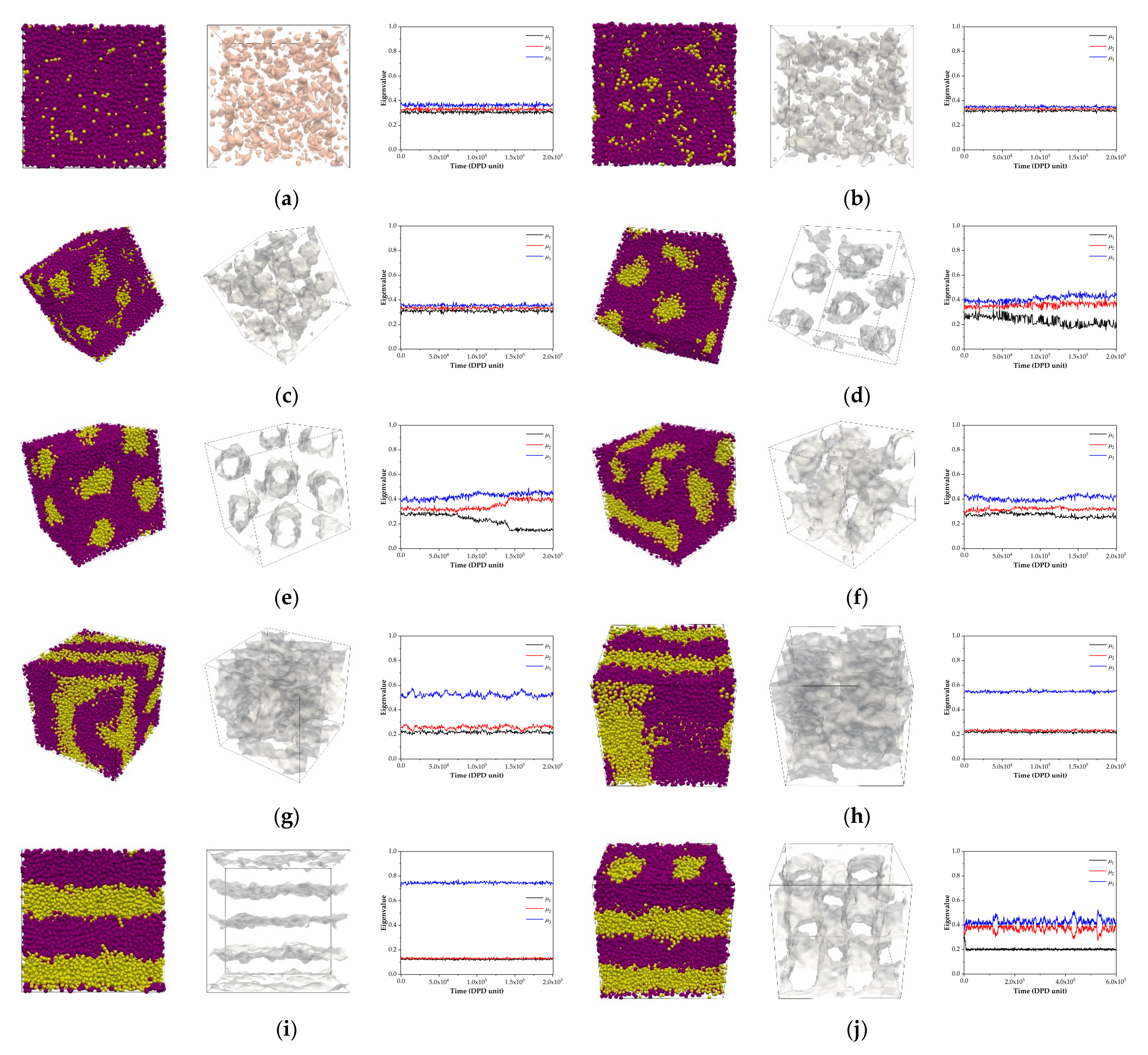

3.1. Radial Distribution Function (RDF) and Structure Factor (S(k)) Analysis of Coarse-Grained Structures

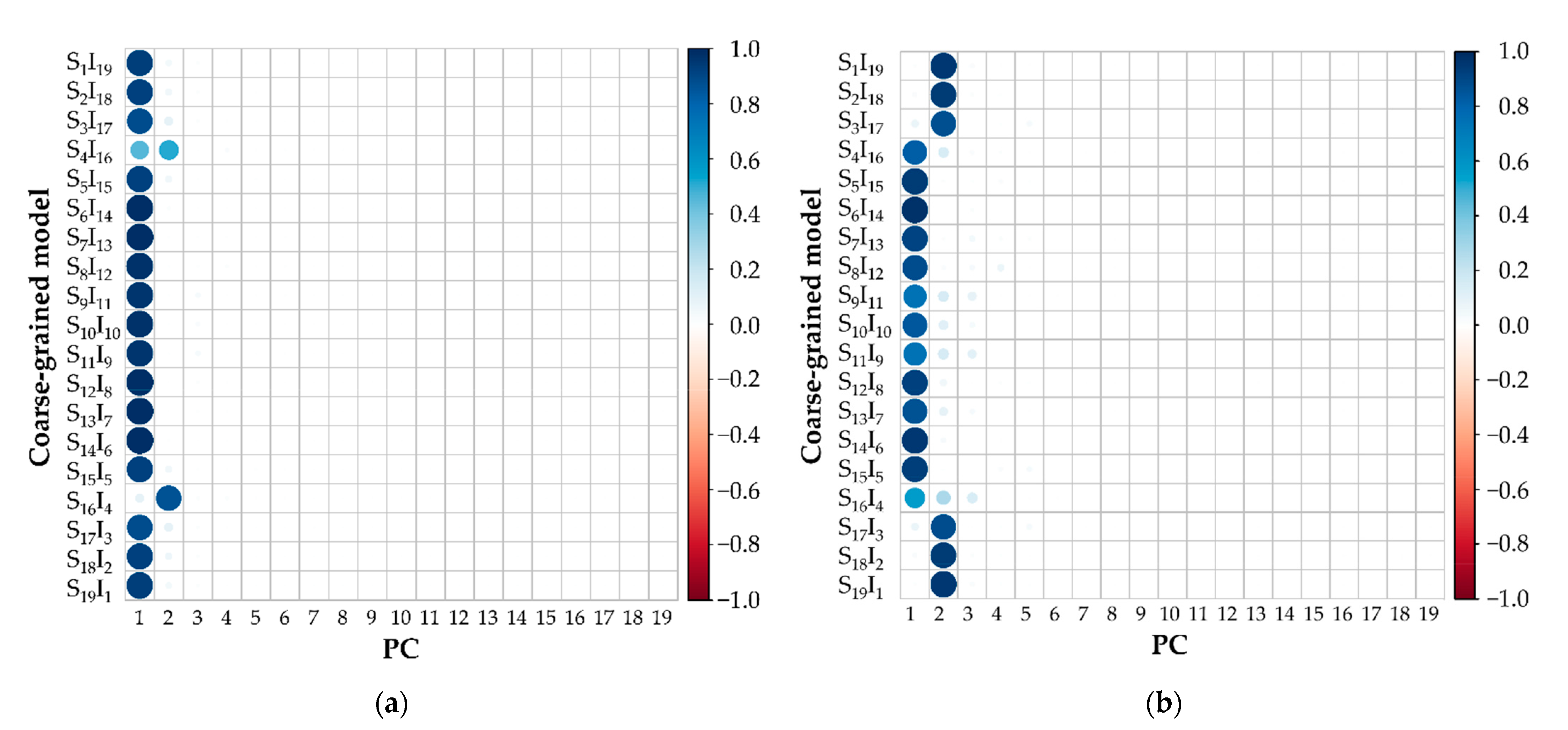

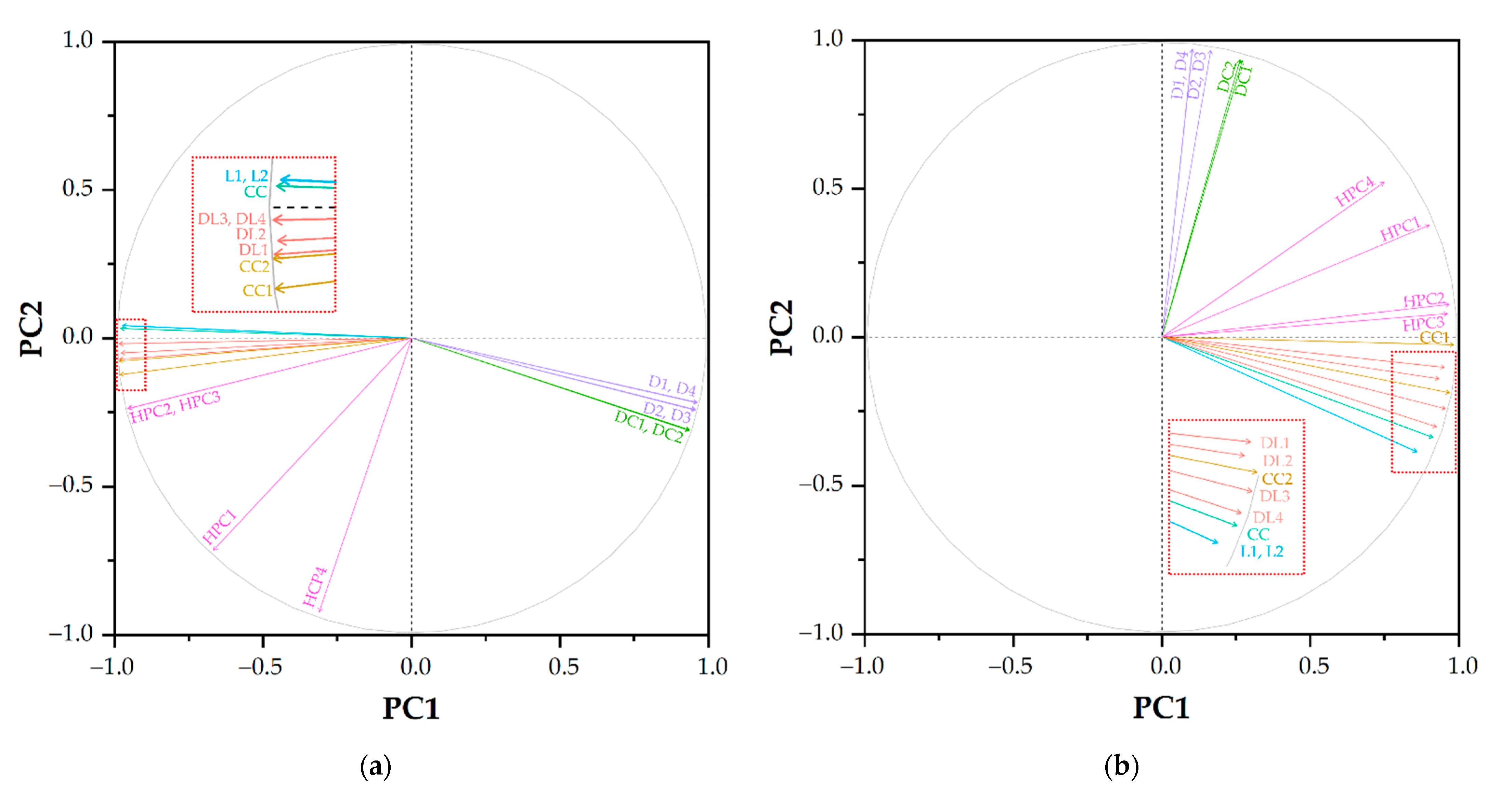

3.2. Principal Component Analysis (PCA) for Classification of Morphologies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schacher, F.H.; Rupar, P.A.; Manners, I. Functional block copolymers: Nanostructured materials with emerging applications. Angew. Chem. Int. Ed. 2012, 51, 7898–7921. [Google Scholar] [CrossRef] [PubMed]

- Orilall, M.C.; Wiesner, U. Block copolymer based composition and morphology control in nanostructured hybrid materials for energy conversion and storage: Solar cells, batteries, and fuel cells. Chem. Soc. Rev. 2011, 40, 520–535. [Google Scholar] [CrossRef]

- Khandpur, A.K.; Foerster, S.; Bates, F.S.; Hamley, I.W.; Ryan, A.J.; Bras, W.; Almdal, K.; Mortensen, K. Polyisoprene-polystyrene diblock copolymer phase diagram near the order-disorder transition. Macromolecules 1995, 28, 8796–8806. [Google Scholar] [CrossRef]

- Förster, S.; Khandpur, A.K.; Zhao, J.; Bates, F.S.; Hamley, I.W.; Ryan, A.J.; Bras, W. Complex phase behavior of polyisoprene-polystyrene diblock copolymers near the order-tisorder transition. Macromolecules 1994, 27, 6922–6935. [Google Scholar] [CrossRef]

- Chiangraeng, N.; Keyen, U.; Yoshida, N.; Nimmanpipug, P. Temperature-responsive morphology formation of PS-b-PI copolymer: A dissipative particle dynamics simulation study. Soft Matter 2021, 17, 6248–6258. [Google Scholar] [CrossRef]

- Chiangraeng, N.; Lee, V.S.; Nimmanpipug, P. Coarse-grained modelling and temperature effect on the morphology of PS-b-PI copolymer. Polymers 2019, 11, 1008. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Weiyu, C.; Tashiro, K.; Hanesaka, M.; Takeda, S.; Masunaga, H.; Sasaki, S.; Takata, M. First detection of lamella-gyroid-cylinder phase transition of neat polyethylene-poly(ethylene oxide) diblock copolymers on the basis of synchrotron WAXD/SAXS and infrared/Raman spectral measurements. J. Phys. Conf. Ser. 2009, 184. [Google Scholar] [CrossRef]

- Jain, S.; Dyrdahl, M.H.E.; Gong, X.; Scriven, L.E.; Bates, F.S. Lyotropic Phase Behavior of Poly(ethylene oxide)−Poly(butadiene) Diblock Copolymers: Evolution of the Random Network Morphology. Macromolecules 2008, 41, 3305–3316. [Google Scholar] [CrossRef]

- Weiyu, C.; Tashiro, K.; Hanesaka, M.; Takeda, S.; Masunaga, H.; Sasaki, S.; Takata, M. Relationship between morphological change and crystalline phase transitions of polyethylene-poly(ethylene oxide) diblock copolymers, revealed by the temperature-dependent synchrotron WAXD/SAXS and infrared/raman spectral measurements. J. Phys. Chem. B 2009, 113, 2338–2346. [Google Scholar] [CrossRef]

- Cochran, E.W.; Garcia-Cervera, C.J.; Fredrickson, G.H. Stability of the gyroid phase in diblock copolymers at strong segregation. Macromolecules 2006, 39, 2449–2451. [Google Scholar] [CrossRef]

- Fraaije, J.G.E.M.; van Vlimmeren, B.A.C.; Maurits, N.M.; Postma, M.; Evers, O.A.; Hoffmann, C.; Altevogt, P.; Goldbeck-Wood, G. The dynamic mean-field density functional method and its application to the mesoscopic dynamics of quenched block copolymer melts. J. Chem. Phys. 1997, 106, 4260–4269. [Google Scholar] [CrossRef] [Green Version]

- Fraaije, J.G.E.M. Dynamic density functional theory for microphase separation kinetics of block copolymer melts. J. Chem. Phys. 1993, 99, 9202–9212. [Google Scholar] [CrossRef]

- Chiangraeng, N.; Lee, V.S.; Nimmanpipug, P. Phase separation dynamics and morphologies prediction of PEO-b-PMMA copolymer by atomistic and mesoscopic simulations. J. Met. Mater. Miner. 2018, 28, 18–26. [Google Scholar] [CrossRef]

- Seaton, M.A.; Anderson, R.L.; Metz, S.; Smith, W. DL_MESO: Highly scalable mesoscale simulations. Mol. Simul. 2013, 39, 796–821. [Google Scholar] [CrossRef]

- Prinsen, P.; Warren, P.B.; Michels, M.A.J. Mesoscale Simulations of Surfactant Dissolution and Mesophase Formation. Phys. Rev. Lett. 2002, 89, 148302. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Warren, P.B.; Prinsen, P.; Michels, M.A.J. The physics of surfactant dissolution. Philos. Trans. R. Soc. Lond. Ser. A 2003, 361, 665–676. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Principal Component Analysis, 2nd ed.; Springer: New York, NY, USA, 2002; ISBN 0-387-95442-2. [Google Scholar]

- Abdi, H.; Williams, L.J. Principal component analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Kar, R.K.; Bhunia, A. Will it be beneficial to simulate the antifreeze proteins at ice freezing condition or at lower temperature? J. Phys. Chem. B 2015, 119, 11485–11495. [Google Scholar] [CrossRef]

- Fernandez, M.; Trefiak, N.R.; Woo, T.K. Atomic property weighted radial distribution functions descriptors of metal−organic frameworks for the prediction of gas uptake capacity. J. Phys. Chem. C 2013, 117, 14095–14105. [Google Scholar] [CrossRef]

- Humphrey, W.; Dalke, A.; Schulten, K. VMD: Visual molecular dynamics. J. Mol. Graph. 1996, 14, 33–38. [Google Scholar] [CrossRef]

- Ayachit, U. The ParaView Guide: A Parallel Visualization Application; Kitware Inc.: New York, NY, USA, 2015; ISBN 978-1930934306. [Google Scholar]

- R Core Team. A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021; Available online: http://www.r-project.org/ (accessed on 13 June 2021).

- Kassambara, A.; Mundt, F. Factoextra: Extract and Visualize the Results of Multivariate Data Analyses. R Package Version 1.4.1717. 2021. Available online: https://cran.r-project.org/package=factoextra (accessed on 15 June 2021).

- R Package “Corrplot”: Visualization of a Correlation Matrix. (Version 0.89). Available online: https://github.com/taiyun/corrplot (accessed on 15 June 2021).

- Li, X.; Guo, J.; Liu, Y.; Liang, H. Microphase separation of diblock copolymer poly(styrene-b-isoprene): A dissipative particle dynamics simulation study. J. Chem. Phys. 2009, 130, 074908. [Google Scholar] [CrossRef] [PubMed]

- Hajduk, D.A.; Harper, P.E.; Gruner, S.M.; Honeker, C.C.; Kim, G.; Thomas, E.L.; Fetters, L.J. The gyroid: A new equilibrium morphology in weakly segregated diblock copolymers. Macromolecules 1994, 27, 4063–4075. [Google Scholar] [CrossRef]

- Lodge, T.P.; Pudil, B.; Hanley, K.J. The full phase behavior for block copolymers in solvents of varying selectivity. Macromolecules 2002, 35, 4707–4717. [Google Scholar] [CrossRef]

| PC No. | RDFs | S(k) | ||||

|---|---|---|---|---|---|---|

| Eigenvalue | Variance Percent(%) | Accumulated Variance Percent (%) | Eigenvalue | Variance Percent (%) | Accumulated Variance Percent (%) | |

| 1 | 1.67 × 101 | 87.94 | 87.94 | 1.13 × 101 | 59.69 | 59.69 |

| 2 | 1.94 | 10.23 | 98.17 | 6.63 | 34.89 | 94.59 |

| 3 | 2.15 × 10−1 | 1.13 | 99.30 | 6.27 × 10−1 | 3.30 | 97.88 |

| 4 | 6.93 × 10−2 | 0.36 | 99.67 | 2.14 × 10−1 | 1.13 | 99.01 |

| 5 | 3.05 × 10−2 | 0.16 | 99.83 | 1.61 × 10−1 | 0.85 | 99.86 |

| 6 | 1.52 × 10−2 | 0.08 | 99.91 | 2.36 × 10−2 | 0.12 | 99.99 |

| 7 | 6.31 × 10−3 | 0.03 | 99.94 | 1.90 × 10−3 | 0.01 | 100.00 |

| 8 | 2.71 × 10−3 | 0.01 | 99.95 | 5.77 × 10−4 | 0.00 | 100.00 |

| 9 | 2.33 × 10−3 | 0.01 | 99.97 | 2.66 × 10−4 | 0.00 | 100.00 |

| 10 | 2.15 × 10−3 | 0.01 | 99.98 | 2.55 × 10−5 | 0.00 | 100.00 |

| 11 | 1.13 × 10−3 | 0.01 | 99.98 | 6.06 × 10−6 | 0.00 | 100.00 |

| 12 | 8.03 × 10−4 | 0.00 | 99.99 | 4.77 × 10−6 | 0.00 | 100.00 |

| 13 | 6.66 × 10−4 | 0.00 | 99.99 | 1.28 × 10−6 | 0.00 | 100.00 |

| 14 | 4.80 × 10−4 | 0.00 | 99.99 | 8.82 × 10−7 | 0.00 | 100.00 |

| 15 | 3.11 × 10−4 | 0.00 | 100.00 | 5.52 × 10−7 | 0.00 | 100.00 |

| 16 | 2.92 × 10−4 | 0.00 | 100.00 | 4.21 × 10−7 | 0.00 | 100.00 |

| 17 | 2.39 × 10−4 | 0.00 | 100.00 | 2.44 × 10−7 | 0.00 | 100.00 |

| 18 | 1.90 × 10−4 | 0.00 | 100.00 | 2.05 × 10−7 | 0.00 | 100.00 |

| 19 | 1.26 × 10−4 | 0.00 | 100.00 | 2.64 × 10−8 | 0.00 | 100.00 |

| Volume Fraction of Styrene | Coarse-Grained Model | Morphology (Its Abbreviation) |

|---|---|---|

| 0.05 | S1I19 | Disorder (D1) |

| 0.10 | S2I18 | Disorder (D2) |

| 0.15 | S3I17 | Discrete clusters (DC1) |

| 0.20 | S4I16 | Hexagonally packed cylinders (HPC1) |

| 0.25 | S5I15 | Hexagonally packed cylinders (HPC2) |

| 0.30 | S6I14 | Connected clusters (CC1) |

| 0.35 | S7I13 | Defected lamellae (DL1) |

| 0.40 | S8I12 | Defected lamellae (DL2) |

| 0.45 | S9I11 | Lamellae (L1) |

| 0.50 | S10I10 | Connected cylinders (CC) |

| 0.55 | S11I9 | Lamellae (L2) |

| 0.60 | S12I8 | Defected lamellae (DL3) |

| 0.65 | S13I7 | Defected lamellae (DL4) |

| 0.70 | S14I6 | Connected clusters (CC2) |

| 0.75 | S15I5 | Hexagonally packed cylinders (HPC3) |

| 0.80 | S16I4 | Hexagonally packed cylinders (HPC4) |

| 0.85 | S17I3 | Discrete clusters (DC2) |

| 0.90 | S18I2 | Disorder (D3) |

| 0.95 | S19I1 | Disorder (D4) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiangraeng, N.; Armstrong, M.; Manokruang, K.; Lee, V.S.; Jiranusornkul, S.; Nimmanpipug, P. Characteristic Structural Knowledge for Morphological Identification and Classification in Meso-Scale Simulations Using Principal Component Analysis. Polymers 2021, 13, 2581. https://doi.org/10.3390/polym13162581

Chiangraeng N, Armstrong M, Manokruang K, Lee VS, Jiranusornkul S, Nimmanpipug P. Characteristic Structural Knowledge for Morphological Identification and Classification in Meso-Scale Simulations Using Principal Component Analysis. Polymers. 2021; 13(16):2581. https://doi.org/10.3390/polym13162581

Chicago/Turabian StyleChiangraeng, Natthiti, Michael Armstrong, Kiattikhun Manokruang, Vannajan Sanghiran Lee, Supat Jiranusornkul, and Piyarat Nimmanpipug. 2021. "Characteristic Structural Knowledge for Morphological Identification and Classification in Meso-Scale Simulations Using Principal Component Analysis" Polymers 13, no. 16: 2581. https://doi.org/10.3390/polym13162581

APA StyleChiangraeng, N., Armstrong, M., Manokruang, K., Lee, V. S., Jiranusornkul, S., & Nimmanpipug, P. (2021). Characteristic Structural Knowledge for Morphological Identification and Classification in Meso-Scale Simulations Using Principal Component Analysis. Polymers, 13(16), 2581. https://doi.org/10.3390/polym13162581