Prediction Models of Shear Parameters and Dynamic Creep Instability for Asphalt Mixture under Different High Temperatures

Abstract

:1. Introduction

1.1. Test Methods of High-Temperature Deformation

1.2. Instability Mechanism of High-Temperature Deformation

2. Objective

- (1)

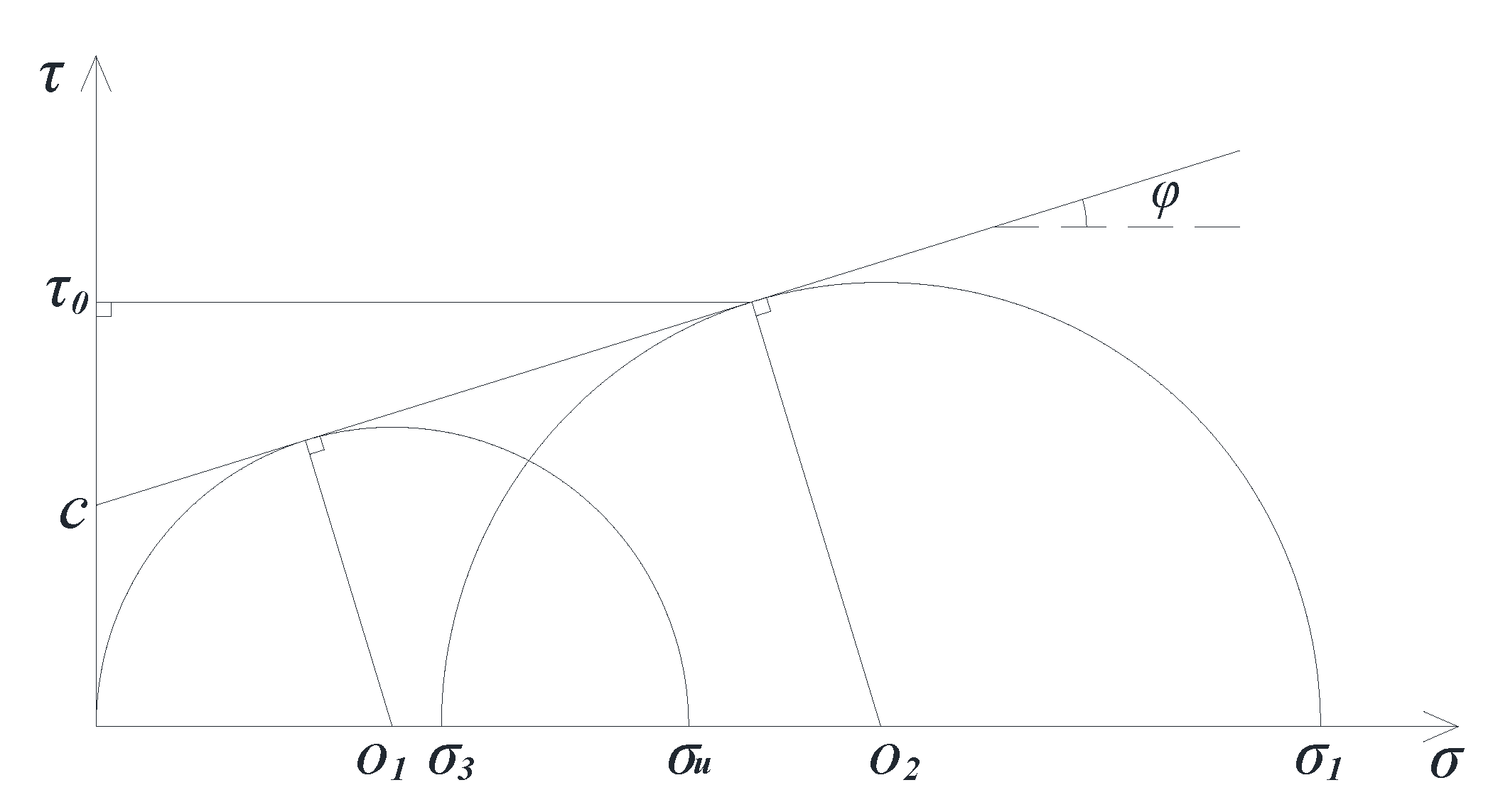

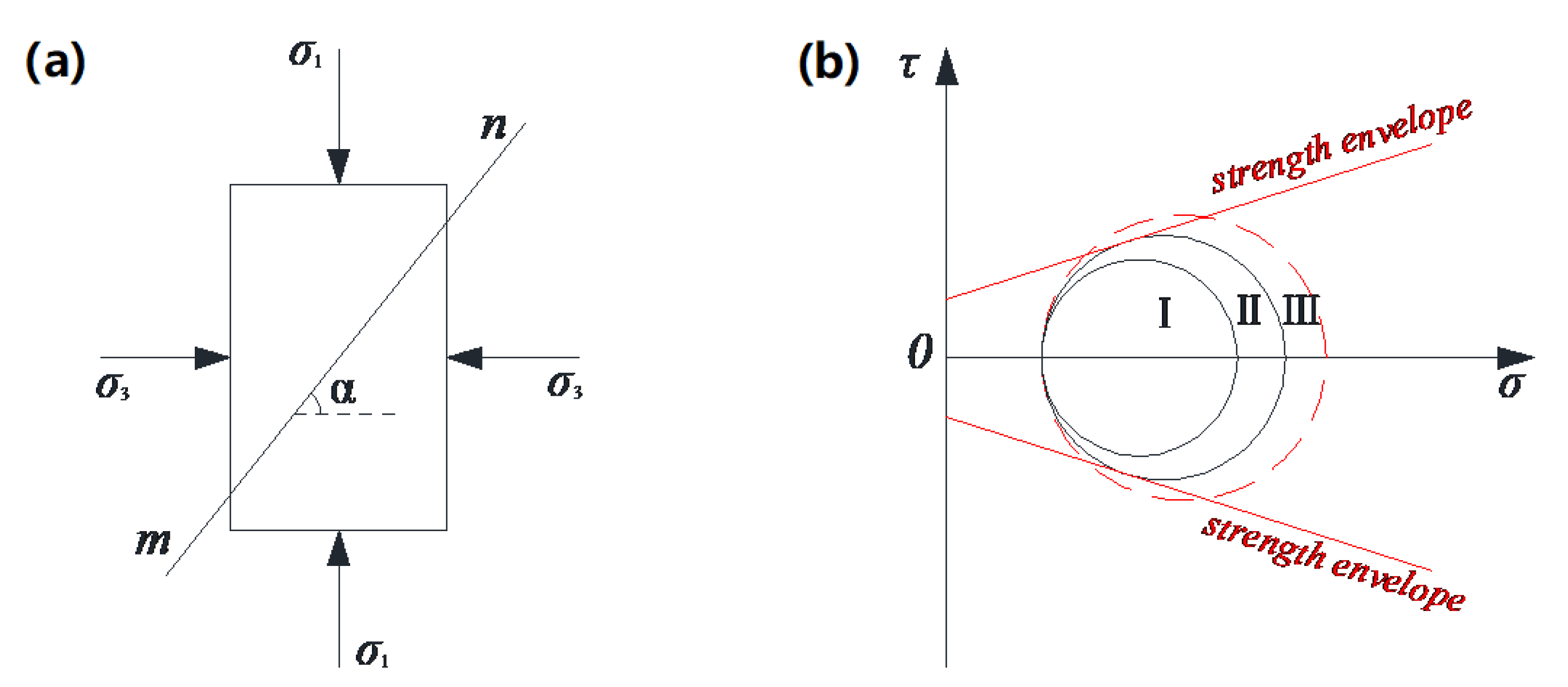

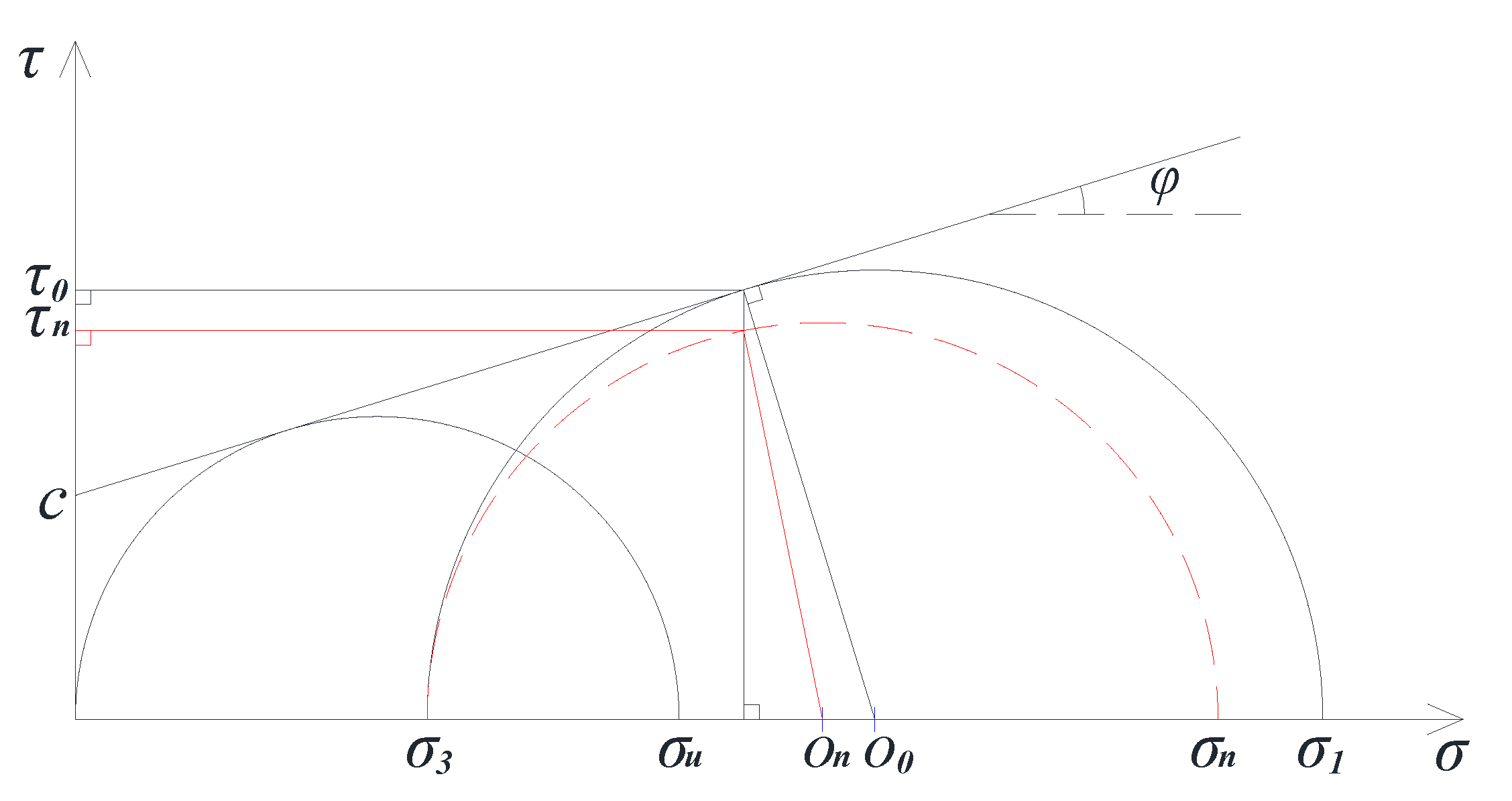

- To establish the prediction model of shear strength parameters, triaxial compressive strength tests (TCST) that measure strength of asphalt mixture under different confining pressures are used to obtain shear strength parameters for a given temperature based on the Mohr–Coulomb strength theory. Then, the influence of different temperatures is considered to identify the relationship between shear strength parameters of asphalt mixture and temperature. Meanwhile, the influence of the additive on shear strength parameters of asphalt mixture is explored. Furthermore, the prediction model of shear stress level in the failure surface under cyclic loading is developed through geometric analysis.

- (2)

- The effects of the confining pressure and compressive load level on the test results are considered to establish the instability prediction model under triaxial dynamic creep tests (TDCT), and the prediction model of the dynamic creep cycle times is developed by fitting analysis at 60 °C. Moreover, the influence of temperature on the shear strength is comprehensively considered to obtain the predicted equation of cyclic times for the mixture in the entire temperature range and to build and verify the instability prediction model in the laboratory test.

3. Raw Materials and Testing Methods

3.1. Raw Materials

3.2. Testing Methods

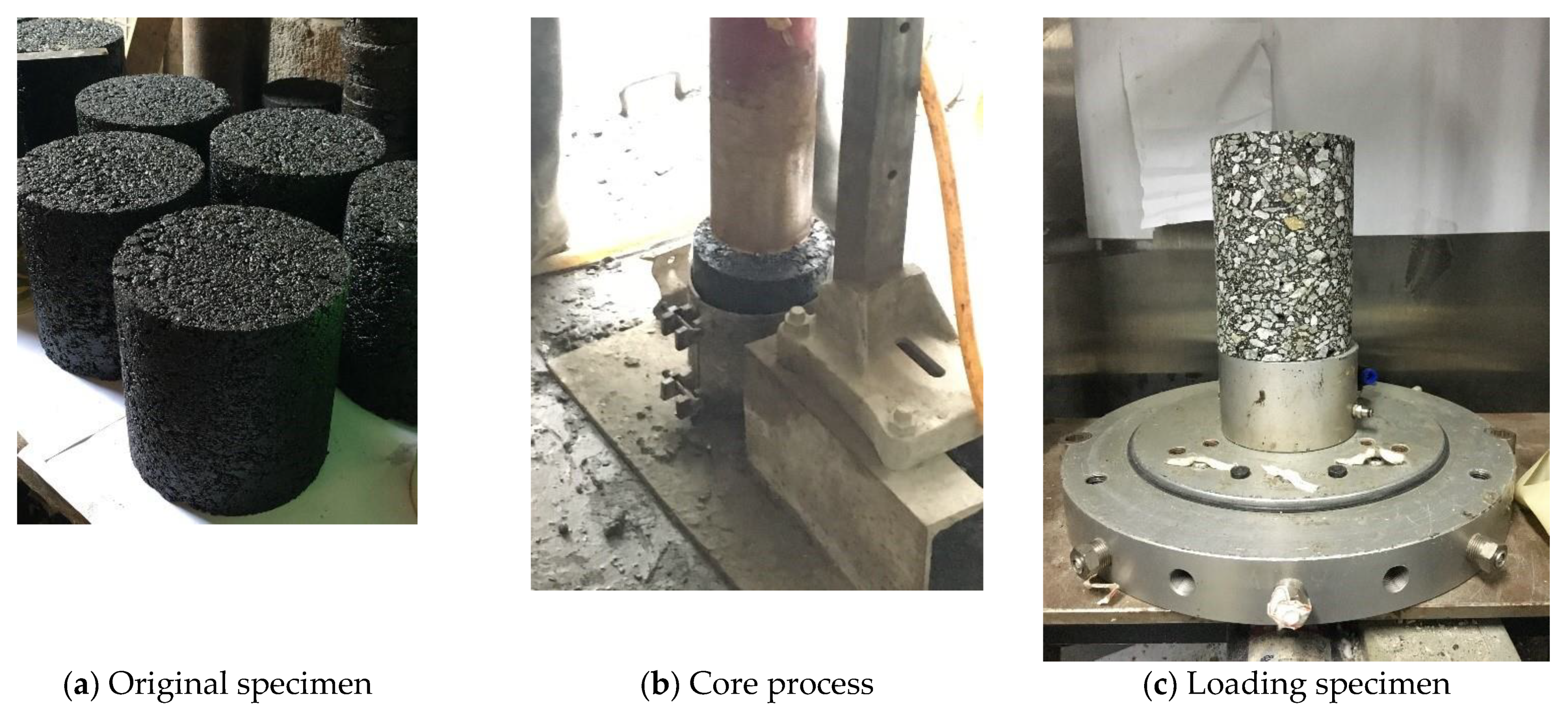

3.2.1. Specimen Preparation and Loading

3.2.2. Scheme of the TCST

- (a)

- The specimens were set to 70 °C, 60 °C, 50 °C, and 40 °C in the UTM-25 testing machine, respectively, and the shear strength parameters under three different confining pressures were obtained at each same temperature.

- (b)

- The relationship between shear strength parameters and high temperature was established and analyzed. Then, the change rule of shear strength parameters in asphalt mixture after adding fiber additives at a specific temperature was investigated.

3.2.3. Scheme of the TDCT

- (1)

- initial compaction stage, in this stage the internal structure of the mixture is eadjusted, and the strain gradually increases and the corresponding strain rate decreases;

- (2)

- in the stable growth stage, the viscoplastic deformation of the mixture is accumulated continuously, the internal aggregate begins to break, the strain increases steadily, and the strain rate remains unchanged;

- (3)

- in the accelerated instability stage, the instability of the mixture structure occurs, and the strain and the strain rate increases rapidly.

- (a)

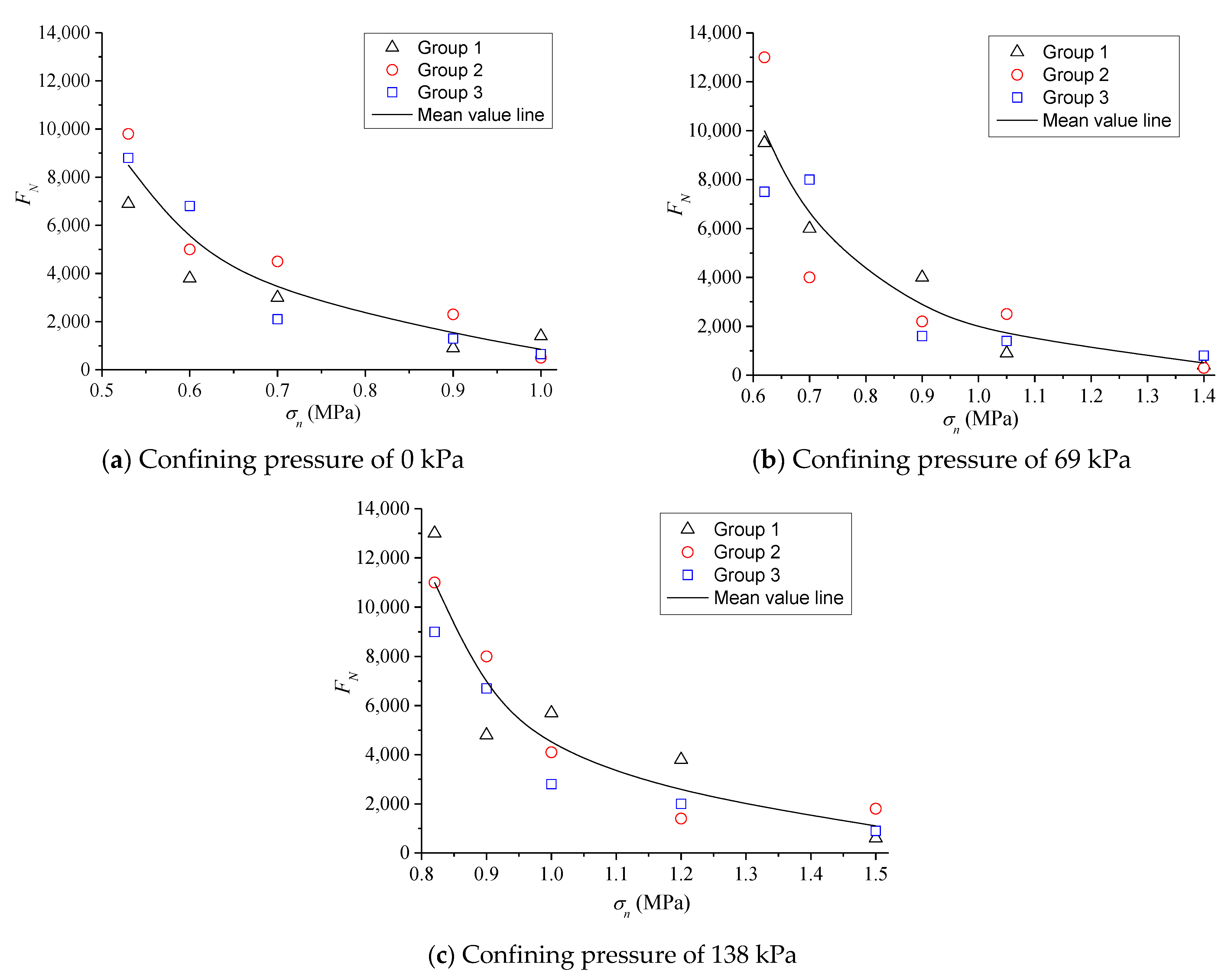

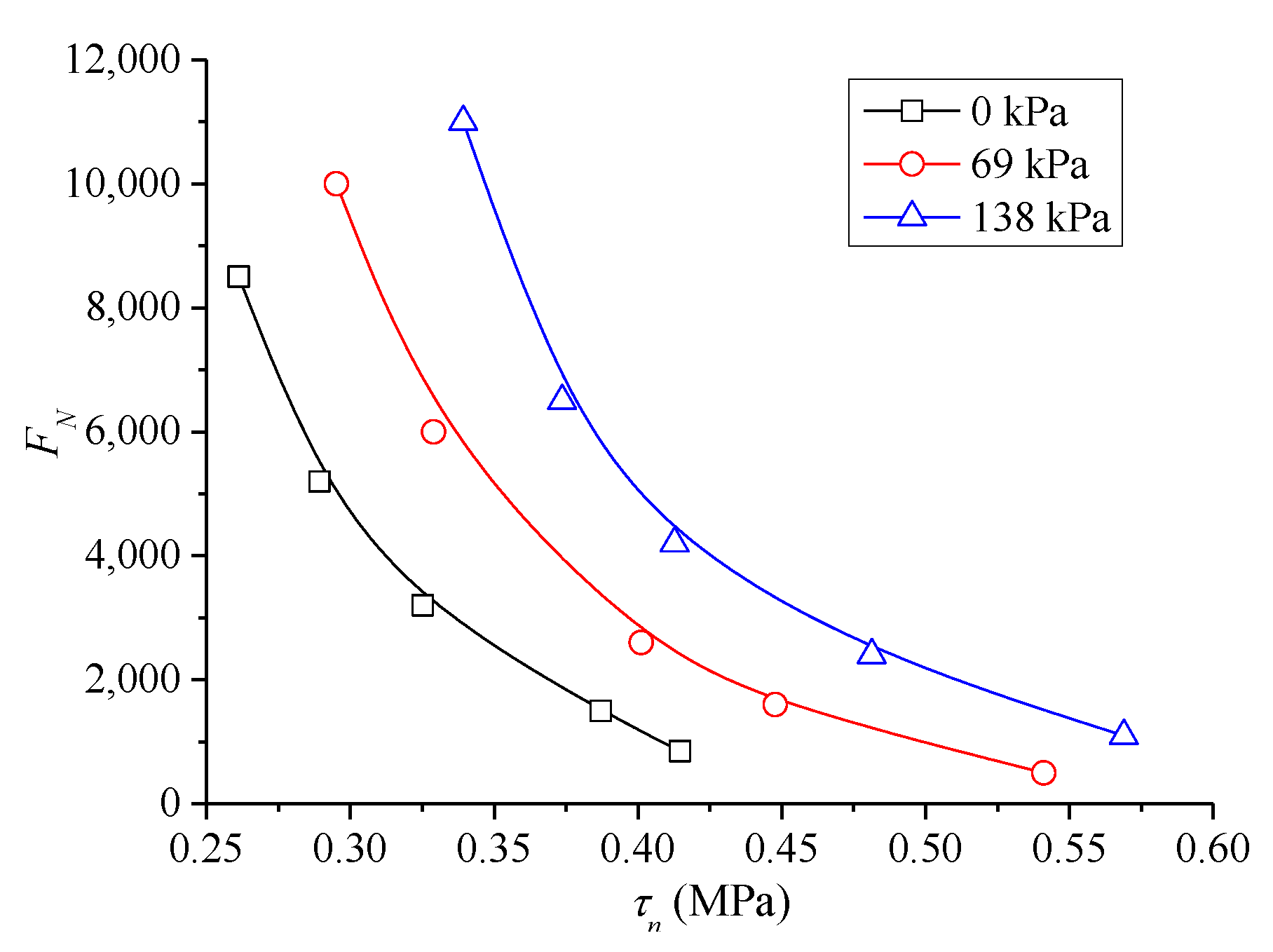

- TDCT was conducted by setting different confining pressures, including 0, 69, and 138 kPa at a high temperature of 60 °C to obtain the curve changes with confining pressures as the only variable, and then establish an instability prediction model.

- (b)

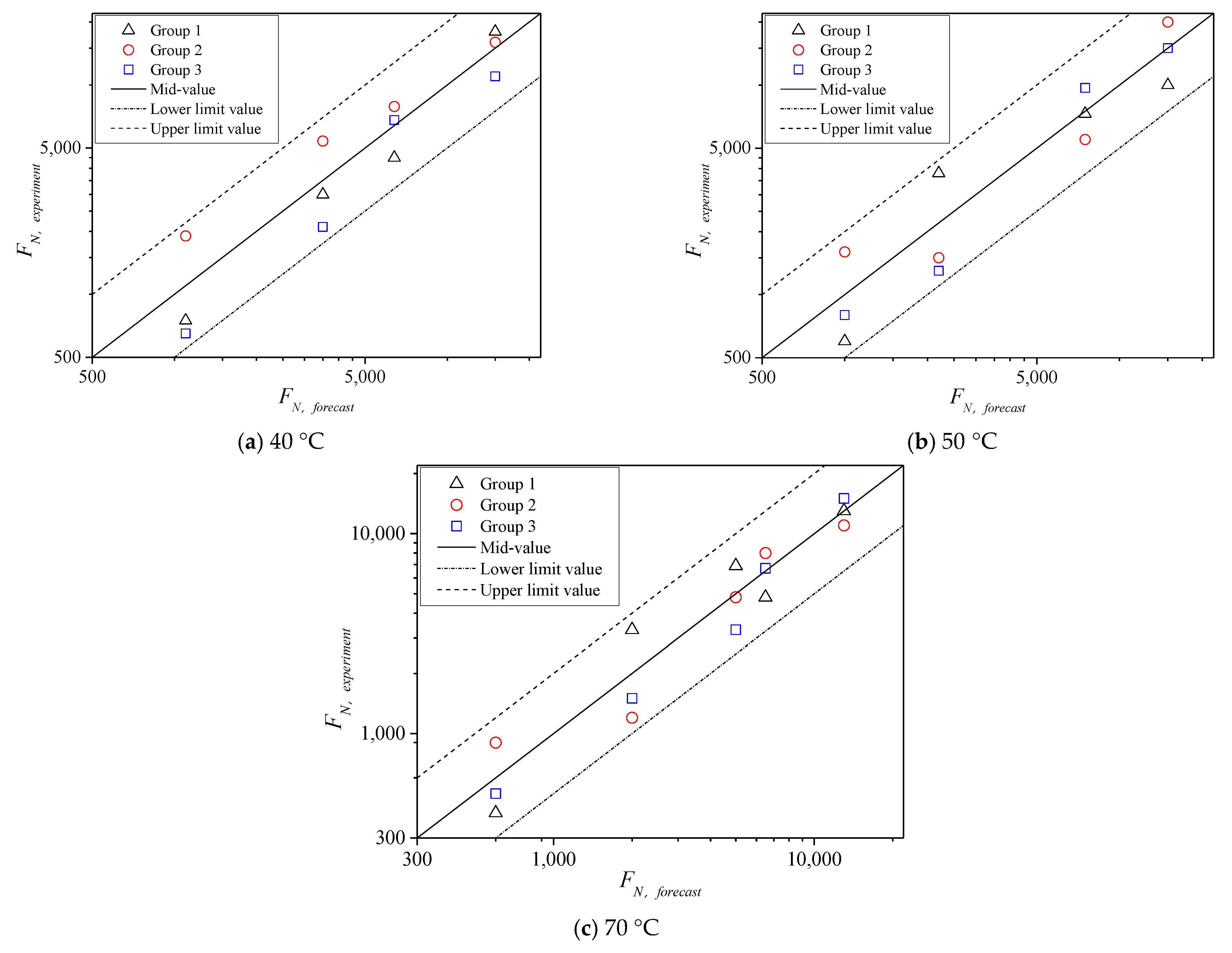

- TDCT was carried out on asphalt mixture at different temperatures to obtain the change in the instability prediction model with temperature as the only variable.

4. Discuss and Analysis

4.1. Influence Factors and Prediction Model of Shear Parameters in Asphalt Mixture

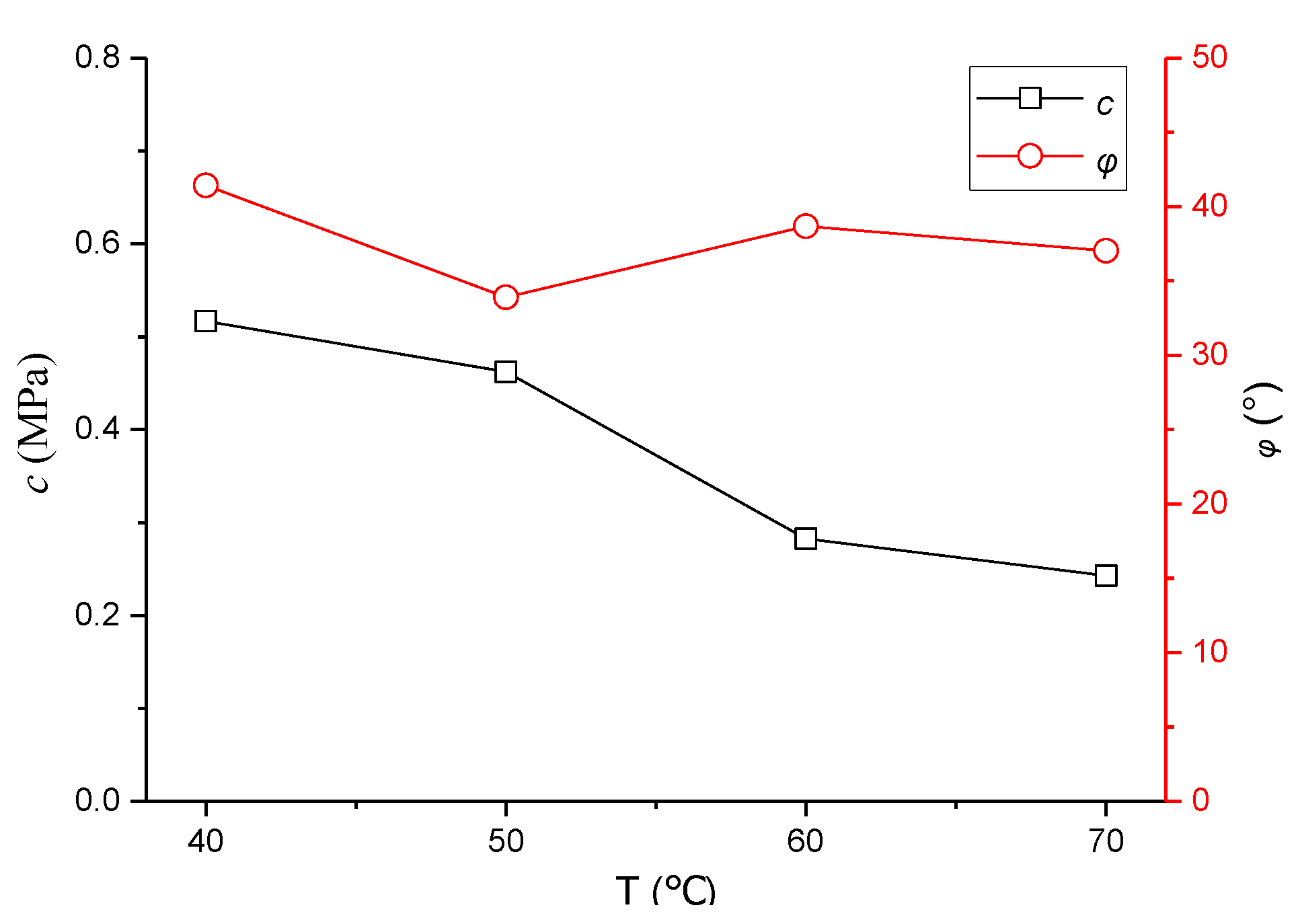

4.1.1. Effect of Temperature on Shear Strength Parameters

4.1.2. Effect of Fiber on Shear Strength Parameters

4.1.3. Establishment of Prediction Models of Shear Parameters

- (i)

- Prediction Models of c and φ

- (ii)

- Prediction Model of Shear Stress on the Failure Surface

4.2. Creep Instability Life and Its Prediction Model of Asphalt Mixture

4.2.1. TDCT Results of Asphalt Mixture at 60 °C

4.2.2. Instability Prediction Model and its Verification of Asphalt Mixture at 60 °C

- (i)

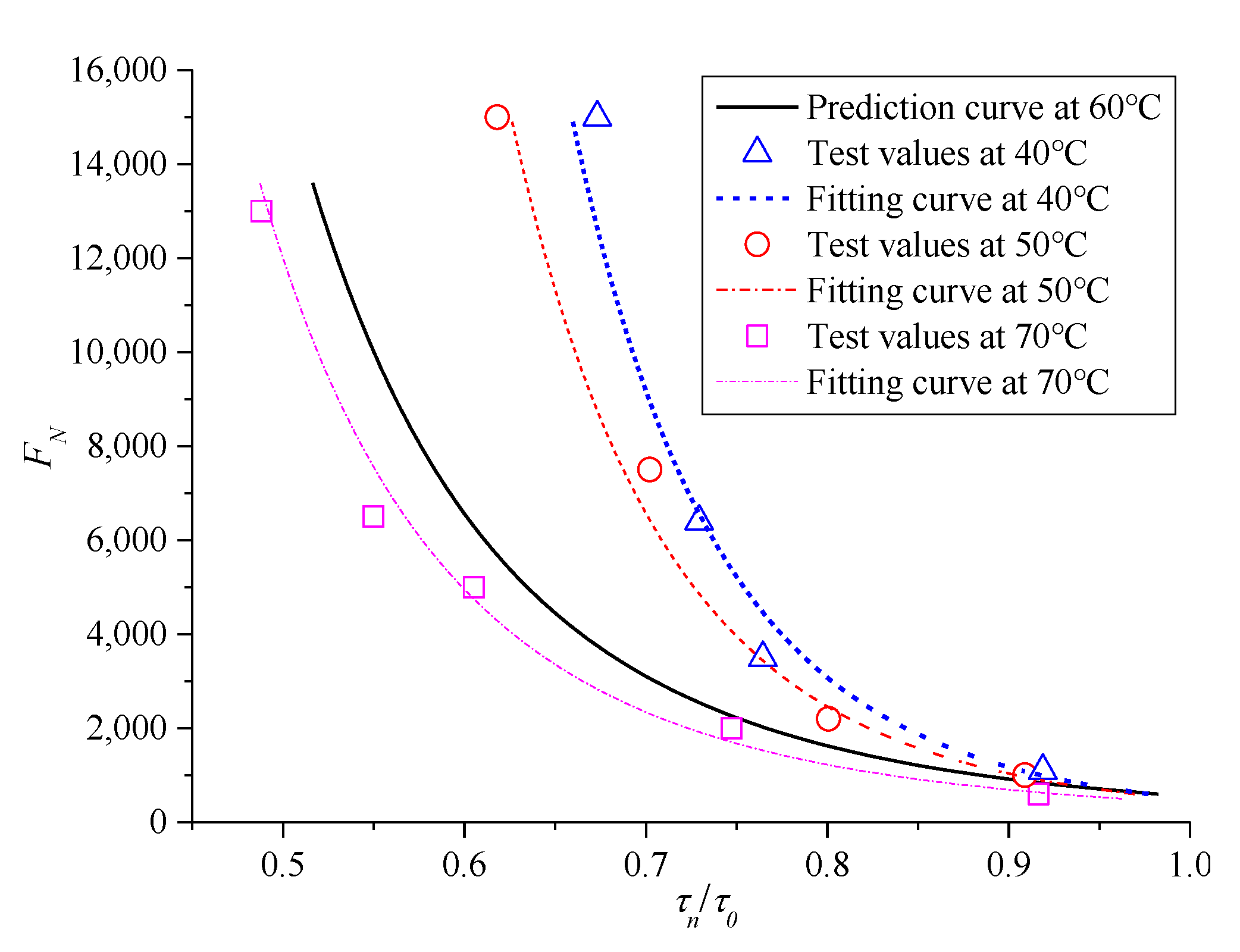

- Presentation of the Instability Prediction Model

- (ii)

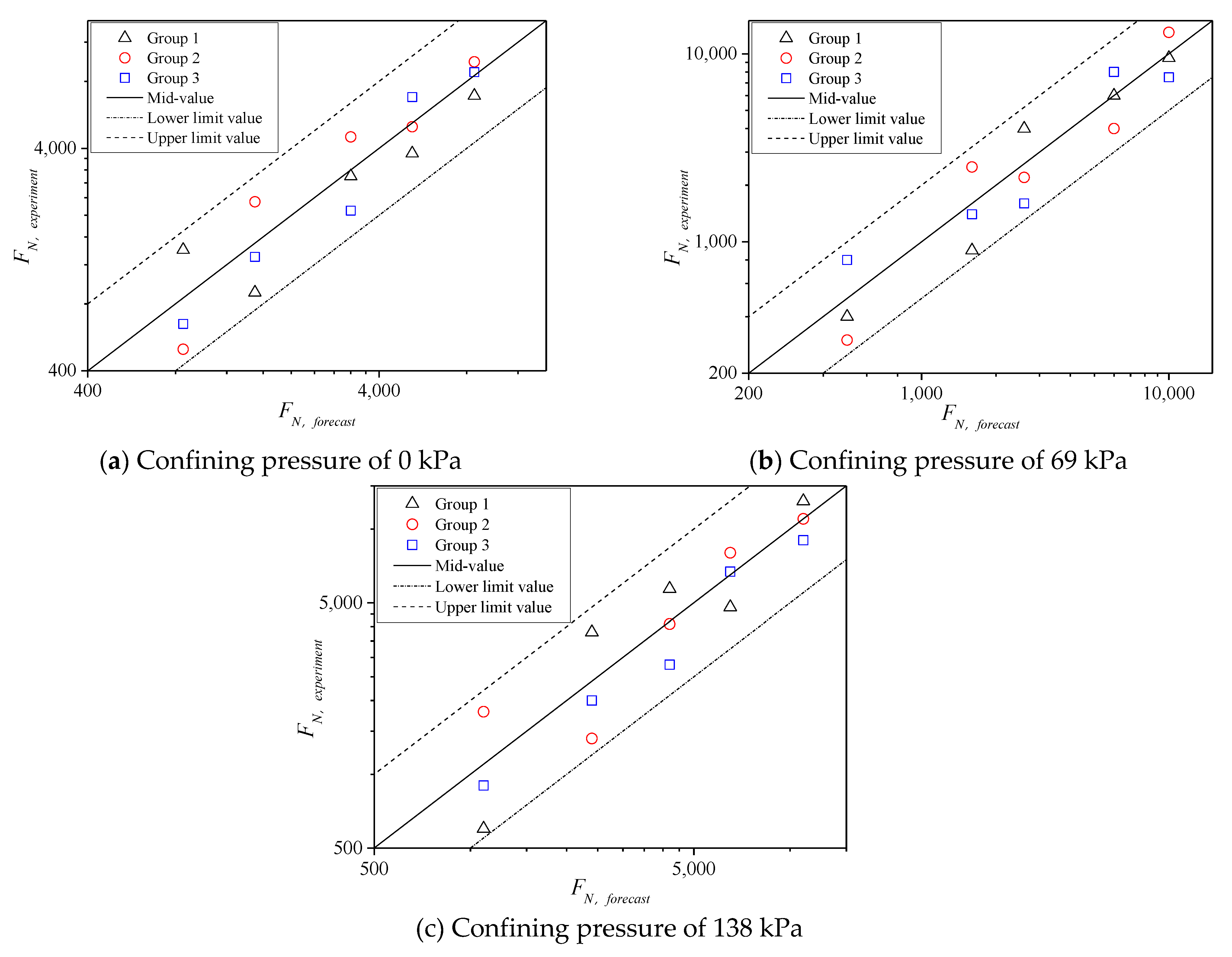

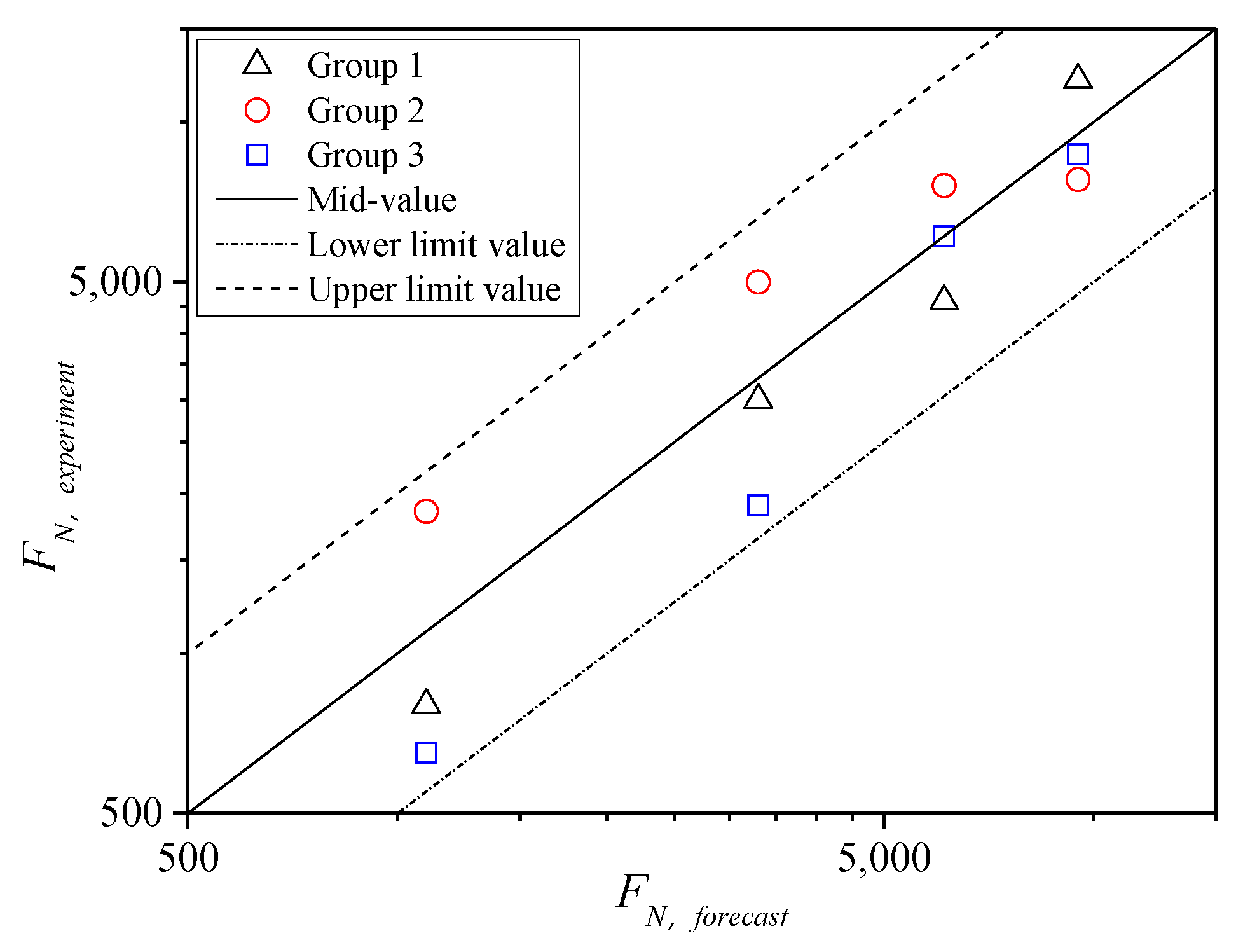

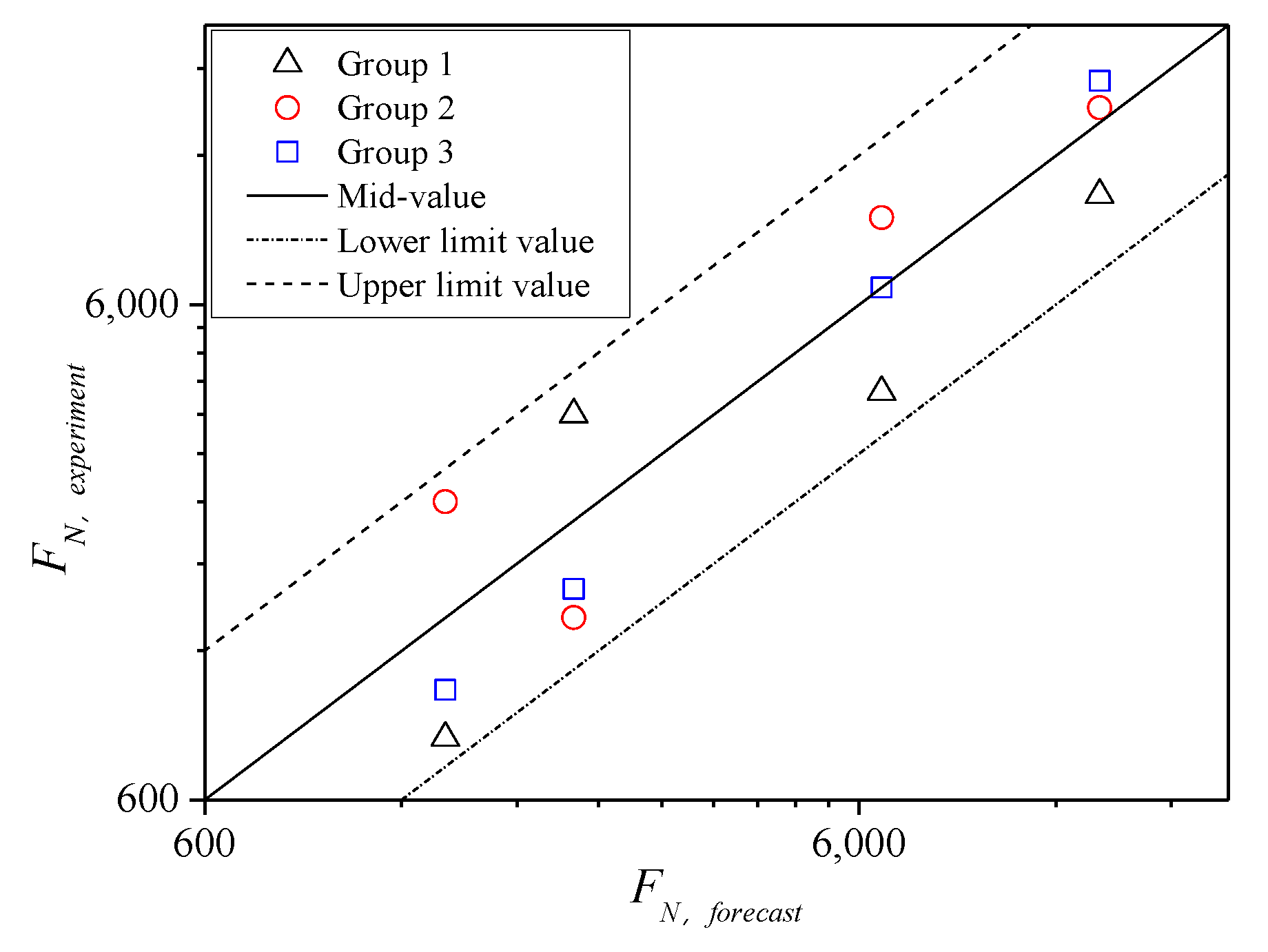

- Verification of the instability prediction model

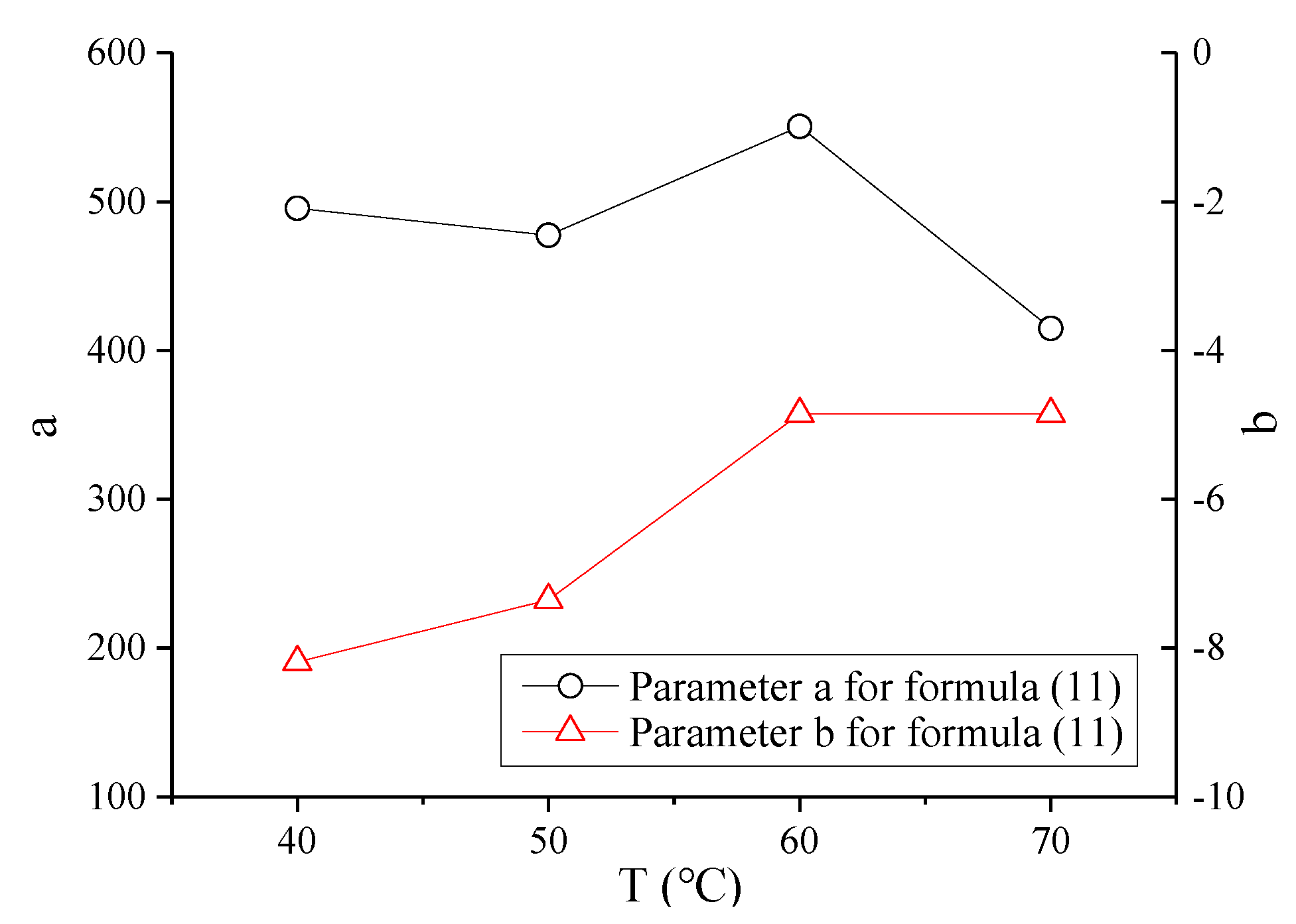

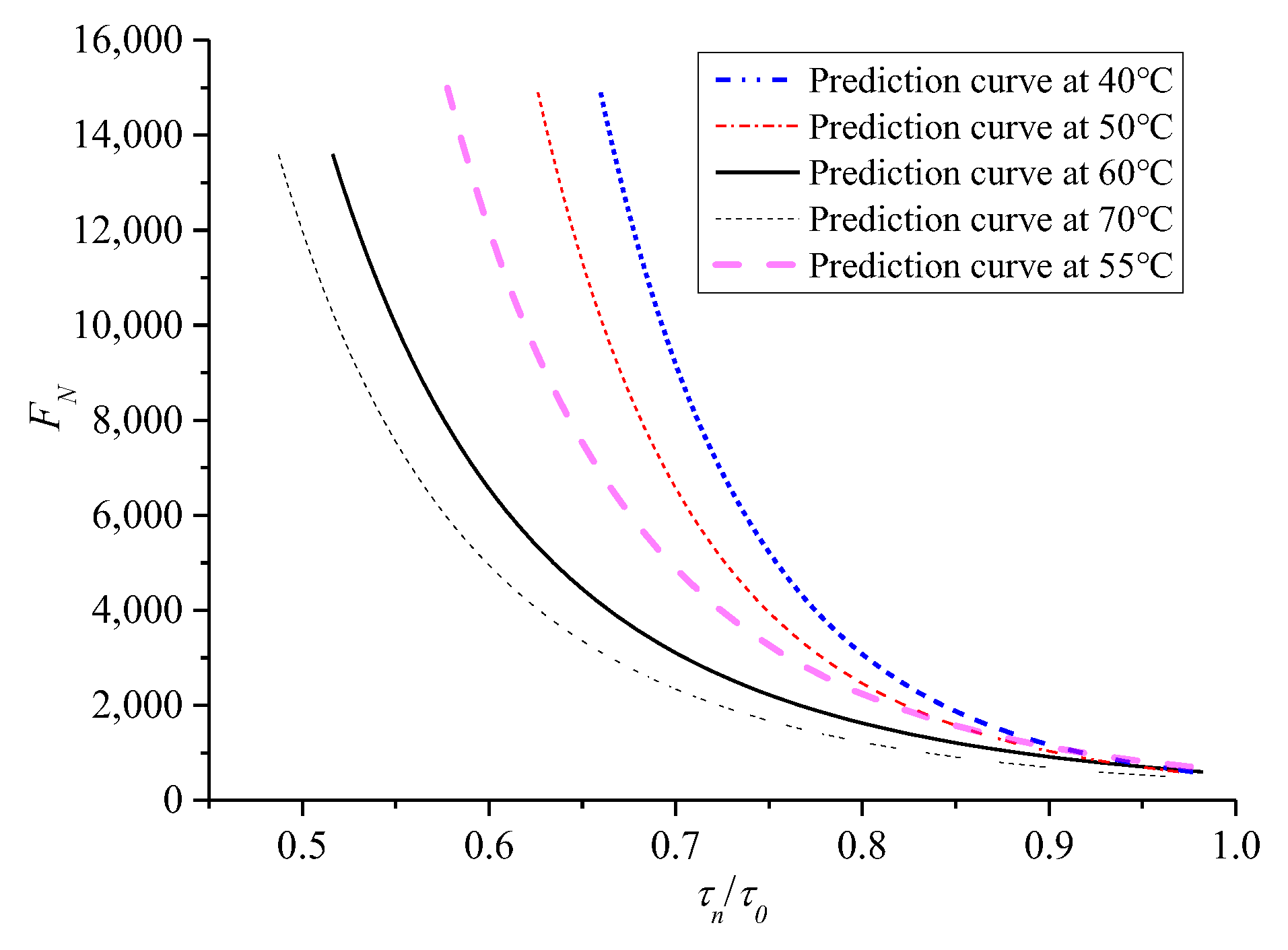

4.2.3. Instability Prediction Model of Asphalt Mixture in the Entire Temperature Range

5. Conclusions

- (1)

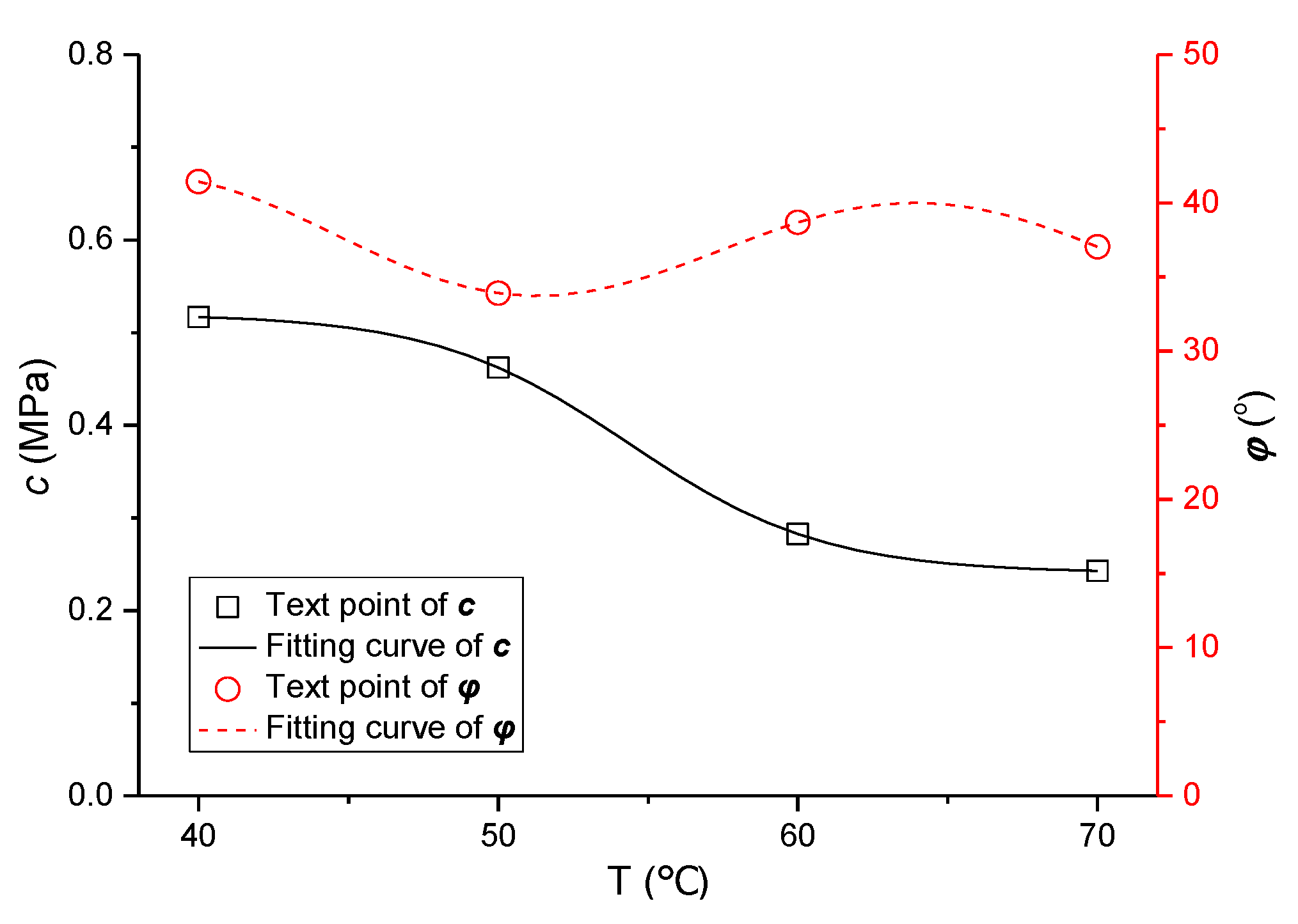

- TCSTs show that the cohesive force c value of the asphalt mixture decreases with the increase in temperature, and the internal friction angle φ value fluctuates with the increase in temperature, where compared with c value at 40 °C, the result at 70 °C decreased by 53.0%. When 0.3% basalt fiber is added into the mixture, the parameters c and φ of the mixture are improved by 7.9% and 4.6% at 60 °C, respectively. Furthermore, the prediction model of the parameters c and φ with temperature is put forward, and the prediction models of the shear stress strength and shear stress level on the failure surface with confining pressure are further obtained.

- (2)

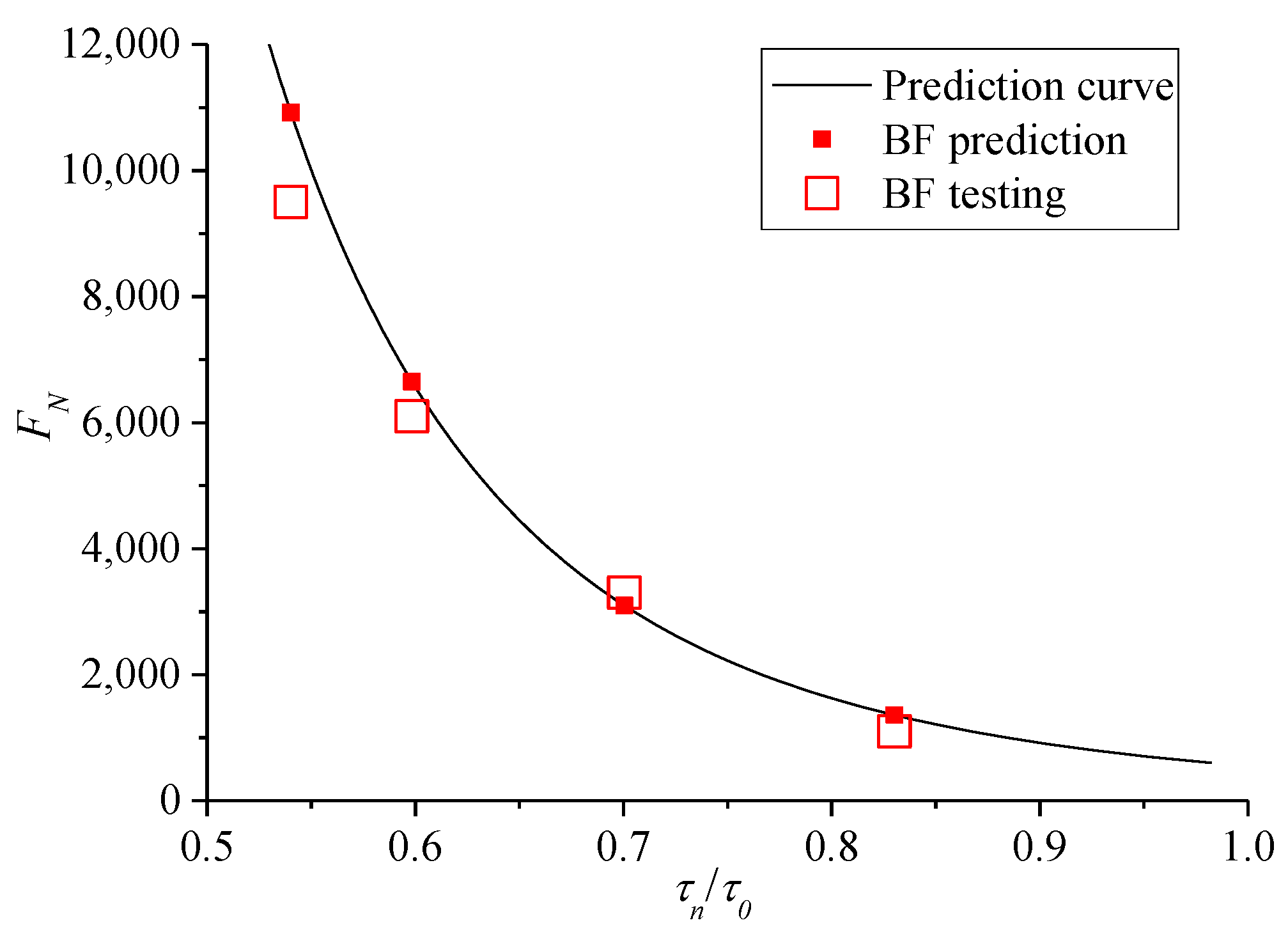

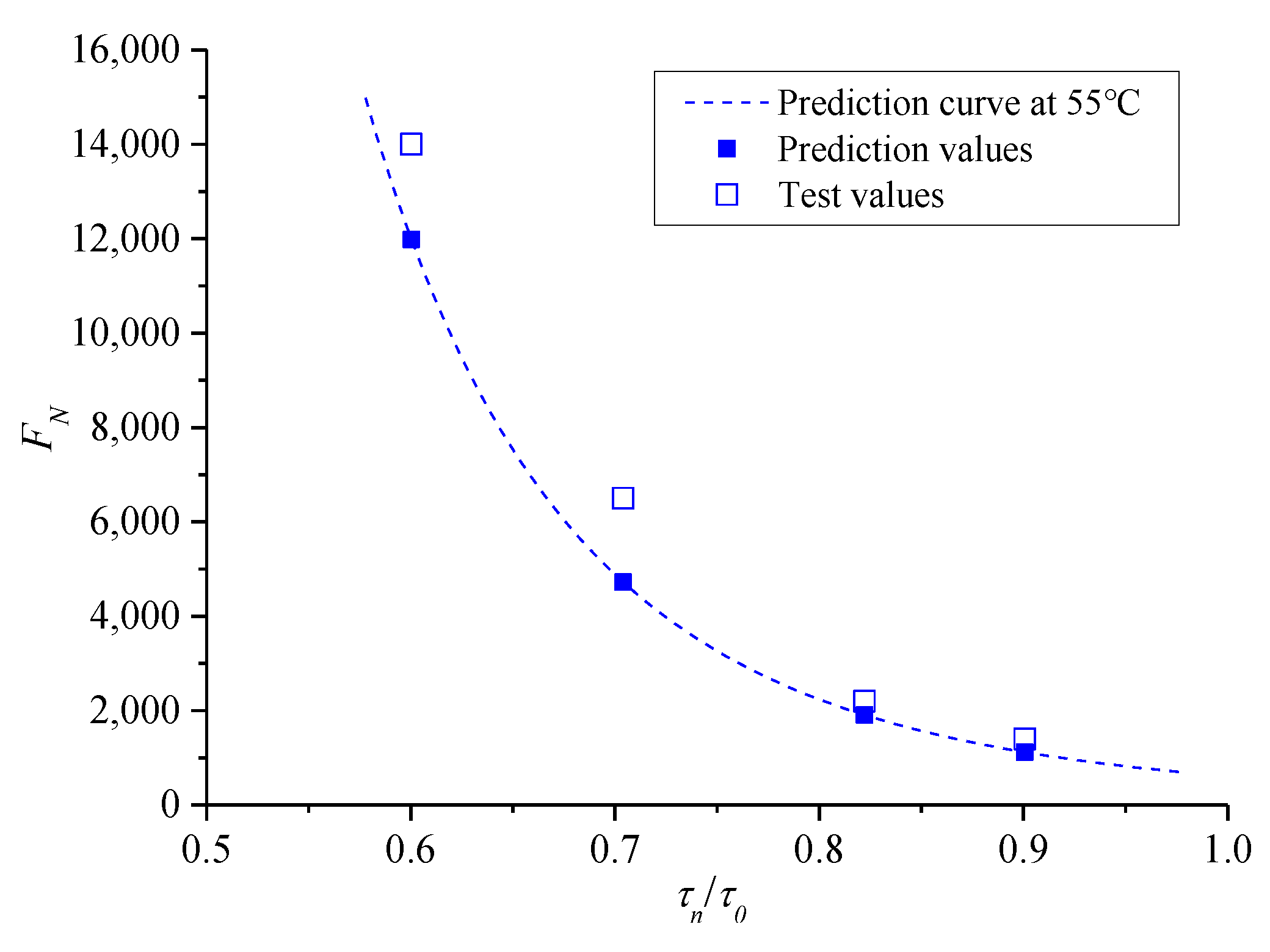

- TDCTs indicate that the instability cyclic times FN of the asphalt mixture decreases exponentially with the increase in the vertical pressure stress levels under the same confining pressure and increases gradually with the increase in confining pressure. Moreover, through analyzing the rules of FN with shear stress ratio at 60 °C, a uniform instability prediction model for the mixture is obtained to eliminate the effect of different confining pressures. Meanwhile, the reliability of the prediction model is verified by the experimental research and forecast analysis for shear strength parameters of fiber mixture addition.

- (3)

- TDCTs under different temperatures show that the instability life of the asphalt mixture decreases with the increase in temperature, and temperature greatly influences the parameters of the mixture in the instability prediction model. The prediction model parameter values can be calculated using an interpolation method for a given temperature, that is, the instability cyclic times FN of the same gradation mixture in the entire temperature range can be predicted. Moreover, the reliability of the prediction model in the entire temperature range is further proved by the corresponding TDCT study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, X.; Tang, B.; Zhu, H.; Zhang, A.; Chen, S. Cooling Principle Analyses and Performance Evaluation of Heat-Reflective Coating for Asphalt Pavement. J. Mater. Civ. Eng. 2011, 23, 1067–1075. [Google Scholar] [CrossRef]

- Gu, X.; Lv, J.; Zhang, X.; Zou, X. Prediction models of creep instability points for asphalt mixture at high temperature and parameters effects on model. J. Southeast Univ. (Nat. Sci. Ed.) 2017, 47, 1013–1019. [Google Scholar]

- Huang, X.; Zhang, Y. A test design for high-temperature performance of asphalt mixtures. J. Highw. Transp. Res. Dev. 2008, 25, 1–7. [Google Scholar]

- Peng, B.; Yuan, W.; Chen, Z. Evaluation of anti wheel rutting performance of asphalt mixture by using wheel rutting index. J. South China Univ. Technol. (Nat. Sci. Ed.) 2005, 33, 84–86. [Google Scholar]

- Gandomi, A.; Alavi, A.H.; MirzaHosseini, M.R.; Nejad, F.M. Nonlinear Genetic-Based Models for Prediction of Flow Number of Asphalt Mixtures. J. Mater. Civ. Eng. 2011, 23, 248–263. [Google Scholar] [CrossRef]

- Fwa, T.F.; Pasindu, H.R.; Ong, G.P. Critical Rut Depth for Pavement Maintenance Based on Vehicle Skidding and Hydro-planing Consideration. J. Transp. Eng. 2012, 138, 423–429. [Google Scholar] [CrossRef]

- Fan, T.; He, Z. Static and dynamic response of creep stiffness modulus of asphalt mixtures. J. Build. Mater. 2008, 11, 736–740. [Google Scholar]

- Goh, S.W.; You, Z. A simple stepwise method to determine and evaluate the initiation of tertiary flow for asphalt mixtures under dynamic creep test. Constr. Build. Mater. 2009, 23, 3398–3405. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, X. Triaxial repeated load creep tests and research on deformation property of asphalt mixture at high temperature and heavy load. Highway 2006, 12, 151–156. [Google Scholar]

- Zhu, H.; Sun, L. A viscoelastic–viscoplastic damage constitutive model for asphalt mixtures based on thermodynamics. Int. J. Plast. 2013, 40, 81–100. [Google Scholar] [CrossRef]

- Peng, Y.; Sun, L.; Shi, Y.; Wang, Y. Influence factors of shear resistance of asphalt mixture. J. Southeast Univ. (Nat. Sci. Ed.) 2007, 37, 330–333. [Google Scholar]

- Cao, Y.; Zeng, H.; Zhang, D. Research on influencing factors on asphalt mixture shear strength. J. Highw. Transp. Res. Dev. 2009, 26, 28–32. [Google Scholar]

- Ziari, H.; Babagoli, R.; Akbari, A. Investigation of fatigue and rutting performance of hot mix asphalt mixtures prepared by bentonite-modified bitumen. Road Mater. Pavement Des. 2014, 16, 101–118. [Google Scholar] [CrossRef]

- Ren, R.; Geng, L.; An, H.; Wang, X. Experimental research on shear fatigue characteristics of asphalt mixture based on repeated uniaxial penetrating test. Road Mater. Pavement Des. 2014, 16, 459–468. [Google Scholar] [CrossRef]

- Fwa, T.F.; Tan, S.A.; Zhu, L.Y. Rutting prediction of asphalt pavement layer using C-φ model. J. Transp. Eng. 2004, 130, 675–683. [Google Scholar] [CrossRef]

- Yuan, J.; Jia, L.; Sun, L. Accumulation model of shear fatigue deformation for asphalt mixture with changing temperature. J. Build. Mater. 2008, 11, 435–440. [Google Scholar]

- Zhang, Y.; Luo, R.; Lytton, R.L. Characterizing Permanent Deformation and Fracture of Asphalt Mixtures by Using Compressive Dynamic Modulus Tests. J. Mater. Civ. Eng. 2012, 24, 898–906. [Google Scholar] [CrossRef]

- Fontes, L.P.; Trichês, G.; Pais, J.C.; Pereira, P.A. Evaluating permanent deformation in asphalt rubber mixtures. Constr. Build. Mater. 2010, 24, 1193–1200. [Google Scholar] [CrossRef]

- Standard JTG E20-2011. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; China Communications Press: Beijing, China, 2011; pp. 186–356. [Google Scholar]

- Standard JTG F40-2004. Technical Specifications for Construction of Highway Asphalt Pavements; China Communications Press: Beijing, China, 2004; pp. 23–39. [Google Scholar]

- Zhang, X.; Xu, L.; Lv, J. Investigation on the Flexural–Tensile Rheological Behavior and Its Influence Factors of Fiber-reinforced Asphalt Mortar. Polymers 2020, 12, 1970. [Google Scholar] [CrossRef]

- Li, Q.; Yang, H.; Ni, F.; Ma, X.; Luo, L. Cause analysis on permanent deformation for asphalt pavements using field cores. Constr. Build. Mater. 2015, 100, 40–51. [Google Scholar] [CrossRef]

- Wang, H.; Al-Qadi, I. Near-Surface Pavement Failure under Multiaxial Stress State in Thick Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2010, 2154, 91–99. [Google Scholar] [CrossRef]

- Zhu, S.; Fu, Q.; Cai, C.; Spanos, P.D. Damage evolution and dynamic response of cement asphalt mortar layer of slab track under vehicle dynamic load. Sci. China Ser. E Technol. Sci. 2014, 57, 1883–1894. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. Application of extended Mohr–Coulomb criterion to ductile fracture. Int. J. Fract. 2009, 161, 1–20. [Google Scholar] [CrossRef]

- Gu, X.; Zhang, X.; Lv, J. Establishment and verification of prediction models of creep instability points of asphalt mixtures at high temperatures. Constr. Build. Mater. 2018, 171, 303–311. [Google Scholar] [CrossRef]

- Miao, Y.; Wang, T.; Wang, L. Influences of Interface Properties on the Performance of Fiber-Reinforced Asphalt Binder. Polymers 2019, 11, 542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, W.; Cheng, Y.; Zhou, P.; Tan, G.; Wang, H.; Liu, H. Performance Evaluation of Styrene-Butadiene-Styrene-Modified Stone Mastic Asphalt with Basalt Fiber Using Different Compaction Methods. Polymers 2019, 11, 1006. [Google Scholar] [CrossRef] [Green Version]

| Temperature/°C | Vertical Pressure Strength/MPa | c/MPa | φ/° | ||

|---|---|---|---|---|---|

| Confining Pressure 0 kPa | Confining Pressure 69 kPa | Confining Pressure 138 kPa | |||

| 40 | 2.291 | 2.630 | 2.969 | 0.5168 | 41.43 |

| 50 | 1.735 | 1.978 | 2.221 | 0.4623 | 33.90 |

| 60 | 1.176 | 1.475 | 1.774 | 0.2825 | 38.68 |

| 70 | 0.975 | 1.253 | 1.531 | 0.2429 | 37.04 |

| Materials | Vertical Pressure Strength/MPa | c/MPa | φ/° | ||

|---|---|---|---|---|---|

| Confining Pressure 0 kPa | Confining Pressure 69 kPa | Confining Pressure 138 kPa | |||

| BF | 1.321 | 1.645 | 1.969 | 0.3048 | 40.46 |

| σ0 (MPa) | τ0 (MPa) | σn (MPa) | τn (MPa) | τn/τ0 | FN (times) | ||

|---|---|---|---|---|---|---|---|

| Group Ⅰ | Group Ⅱ | Group Ⅲ | |||||

| 1.969 | 0.6966 | 0.9 | 0.3763 | 0.5402 | 12,060 | 7820 | 8710 |

| 1.0 | 0.4169 | 0.5984 | 4620 | 7610 | 6110 | ||

| 1.2 | 0.4879 | 0.7004 | 3030 | 5020 | 1910 | ||

| 1.5 | 0.5784 | 0.8302 | 810 | 1850 | 650 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, J.; Zhang, X. Prediction Models of Shear Parameters and Dynamic Creep Instability for Asphalt Mixture under Different High Temperatures. Polymers 2021, 13, 2542. https://doi.org/10.3390/polym13152542

Lv J, Zhang X. Prediction Models of Shear Parameters and Dynamic Creep Instability for Asphalt Mixture under Different High Temperatures. Polymers. 2021; 13(15):2542. https://doi.org/10.3390/polym13152542

Chicago/Turabian StyleLv, Junxiu, and Xiaoyuan Zhang. 2021. "Prediction Models of Shear Parameters and Dynamic Creep Instability for Asphalt Mixture under Different High Temperatures" Polymers 13, no. 15: 2542. https://doi.org/10.3390/polym13152542

APA StyleLv, J., & Zhang, X. (2021). Prediction Models of Shear Parameters and Dynamic Creep Instability for Asphalt Mixture under Different High Temperatures. Polymers, 13(15), 2542. https://doi.org/10.3390/polym13152542