Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review

Abstract

:1. Introduction

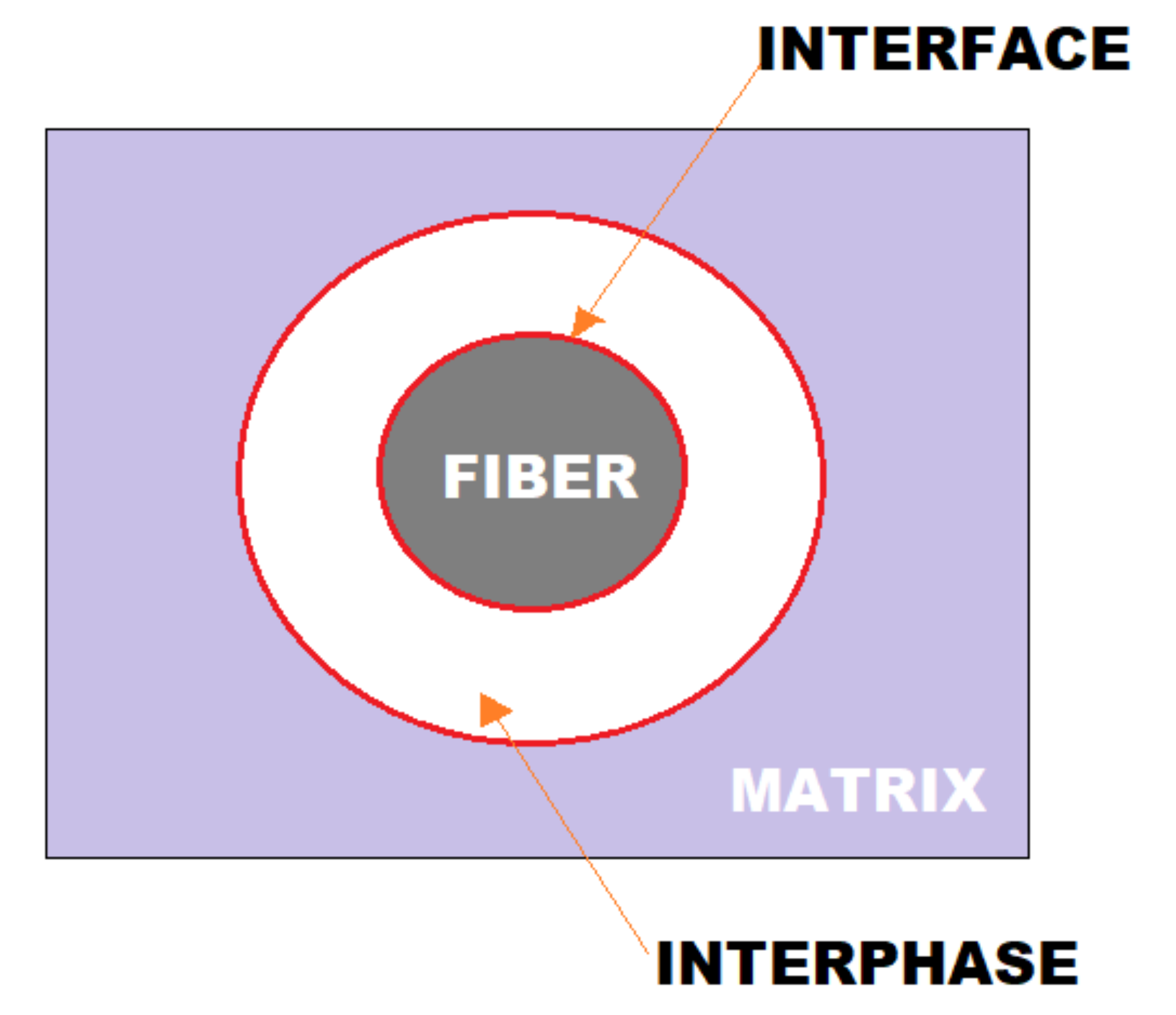

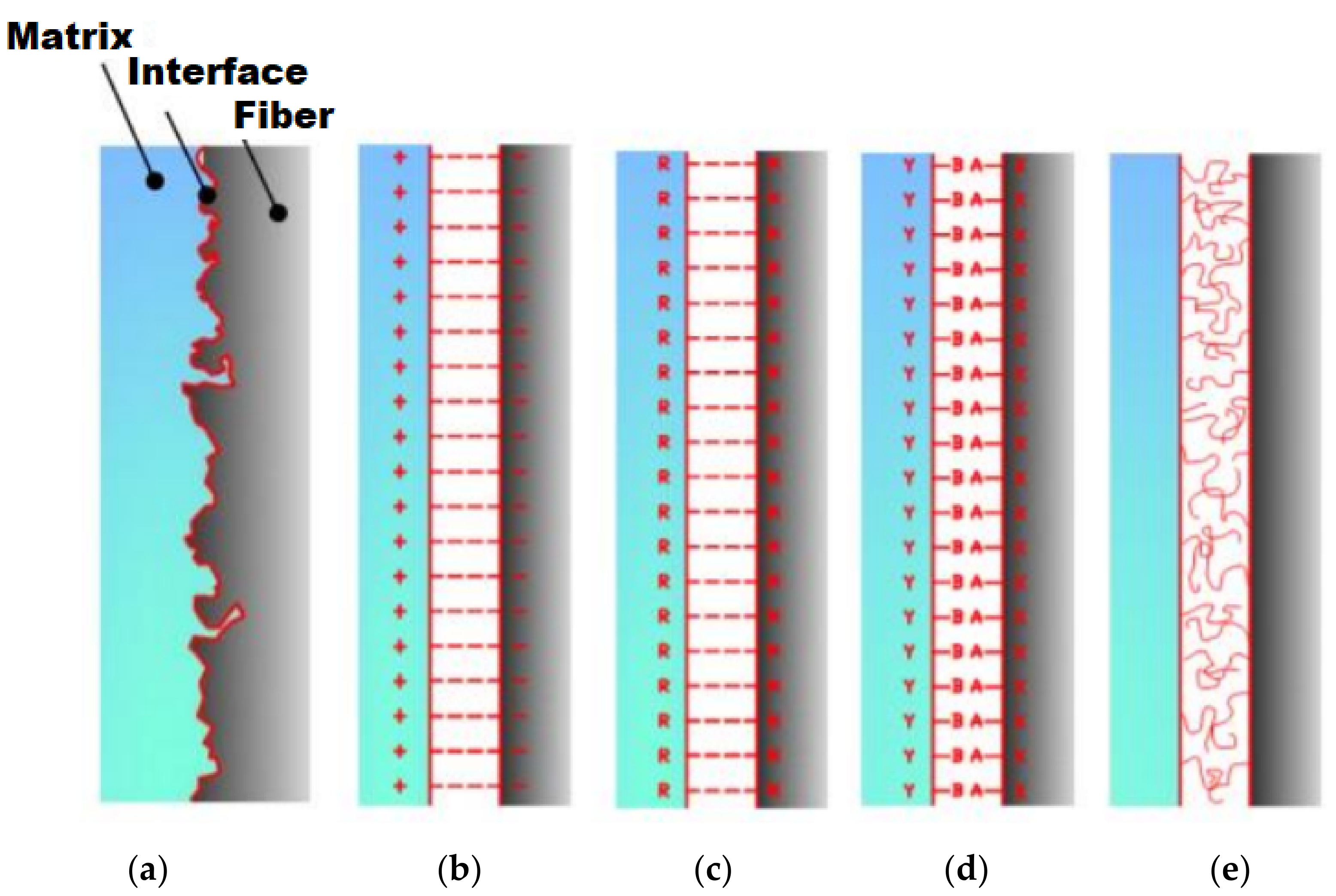

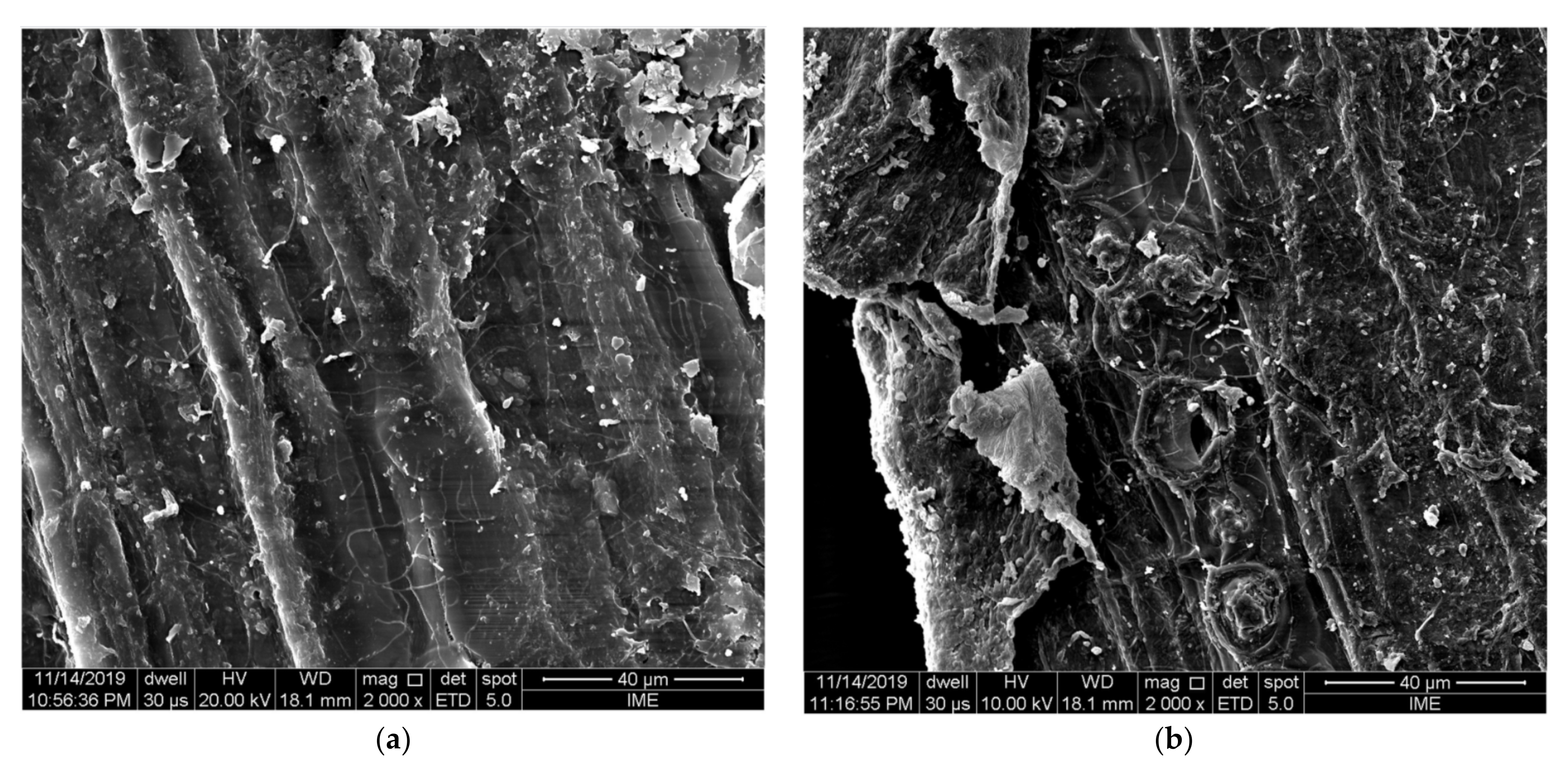

2. Interface between Fiber-Matrix

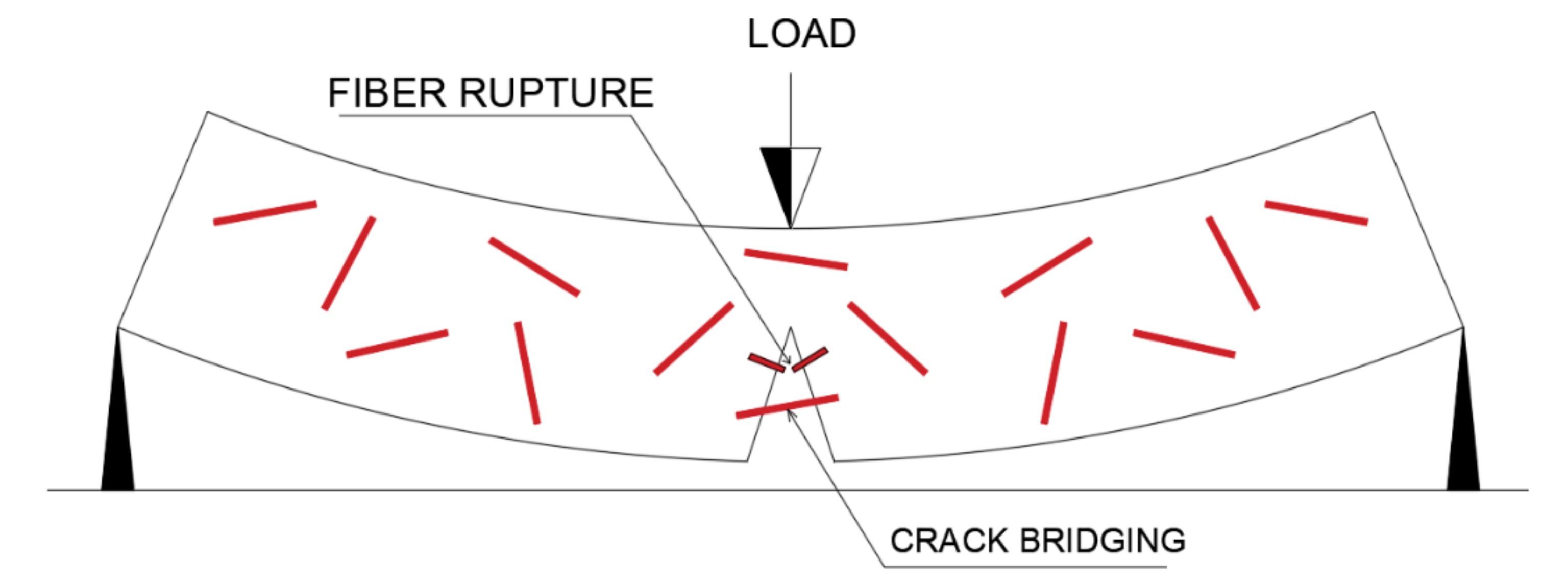

3. Surface Treatment of Natural Fibers

4. Mechanical Performance of Fiber Reinforced Geopolymer Composites

5. Discussion Section

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Cornelis Metselaar, H.S.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Khieng, T.K.; Debnath, S.; Ting Chaw Liang, E.; Anwar, M.; Pramanik, A.; Basak, A.K. A review on mechanical properties of natural fibre reinforced polymer composites under various strain rates. J. Compos. Sci. 2021, 5, 130. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Valencia-Saavedra, W.; Ramírez-Benavides, S.; Gutiérrez, R.M.; Orobio, A. Eco-house prototype constructed with alkali-activated blocks: Material production, characterization, design, construction, and environmental impact. Materials 2021, 14, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Marvila, M.T.; De Azevedo, A.R.G.; Vieira, C.M.F. Reaction mechanisms of alkali-activated materials. Rev. IBRACON Estruturas e Mater. 2021, 14. [Google Scholar] [CrossRef]

- Santana, H.A.; Amorim Júnior, N.S.; Ribeiro, D.V.; Cilla, M.S.; Dias, C.M.R. 3D printed mesh reinforced geopolymer: Notched prism bending. Cem. Concr. Compos. 2021, 116, 103892. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Teixeira Marvila, M.; Barbosa de Oliveira, L.; Macario Ferreira, W.; Colorado, H.; Rainho Teixeira, S.; Mauricio Fontes Vieira, C. Circular economy and durability in geopolymers ceramics pieces obtained from glass polishing waste. Int. J. Appl. Ceram. Technol. 2021. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Pordsari, A.J.; Mehrali, M.; Alengaram, U.J.; Jumaat, M.Z. A comprehensive study of the polypropylene fiber reinforced fly ash based geopolymer. PLoS ONE 2016, 11, e0147546. [Google Scholar] [CrossRef] [Green Version]

- Marvila, M.T.; Azevedo, A.R.G.; Delaqua, G.C.G.; Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F. Performance of geopolymer tiles in high temperature and saturation conditions. Constr. Build. Mater. 2021, 286, 122994. [Google Scholar] [CrossRef]

- Abu Alfoul, B.; Al Hattamleh, O.; Aldeeky, H. Investigating the effects of disc shaped thumb tacks as a “fiber” reinforcement on various concrete properties. Case Stud. Constr. Mater. 2019, 11, e00257. [Google Scholar] [CrossRef]

- Ajouguim, S.; Page, J.; Djelal, C.; Waqif, M.; Saâdi, L. Investigation on the use of ground alfa fibres as reinforcement of cement mortars. Proc. Inst. Civ. Eng. Constr. Mater. 2021, 174, 161–171. [Google Scholar] [CrossRef]

- Korniejenko, K.; Frączek, E.; Pytlak, E.; Adamski, M. Mechanical Properties of Geopolymer Composites Reinforced with Natural Fibers. Proc. Eng. 2016, 151, 388–393. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Impact of fiber reinforcements on properties of geopolymer composites: A review. J. Build. Eng. 2021, 44, 102628. [Google Scholar] [CrossRef]

- Ahmad, J.; Ali, S.; Yu, T.; Sheikh, M.N.; Hadi, M.N.S. Analytical investigation on the load-moment interaction behavior of the FRP reinforced geopolymer concrete filled FRP tube circular columns. J. Build. Eng. 2021, 42, 102818. [Google Scholar] [CrossRef]

- Ahmad, J.; Yu, T.; Hadi, M.N.S. Behavior of GFRP bar reinforced geopolymer concrete filled GFRP tube columns under different loading conditions. Structures 2021, 33, 1633–1644. [Google Scholar] [CrossRef]

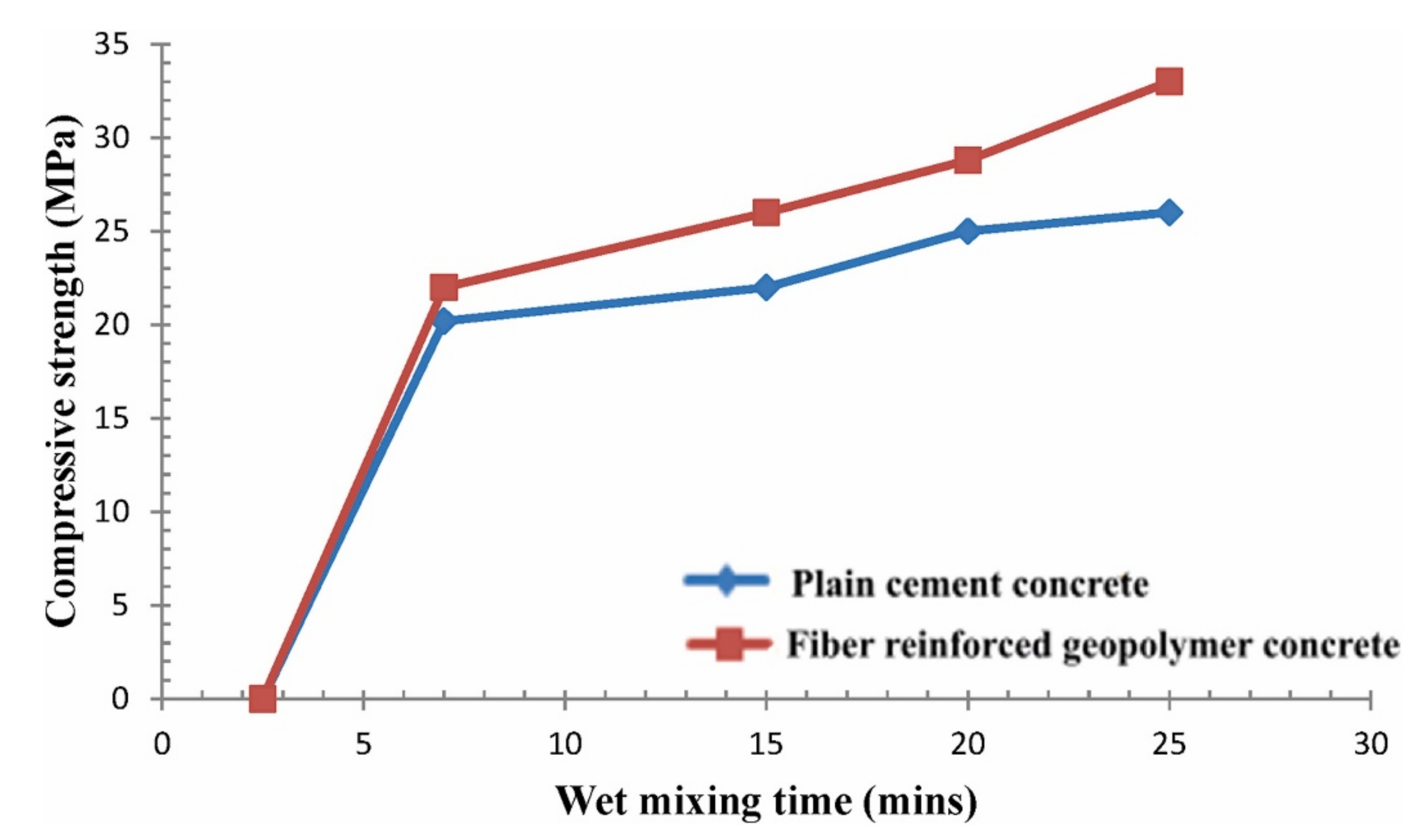

- Sabu, A.; Karthi, L. Experimental study on hybrid fibre reinforced geopolymer concrete. In Proceedings of the National Conference on Structural Engineering and Construction Management, Angamaly, India, 14–15 May 2020; Volume 46, pp. 213–220. [Google Scholar]

- Maras, M.M.; Kose, M.M. Mechanical and microstructural properties of polypropylene fiber-reinforced geopolymer composites. J. Fiber Sci. Technol. 2019, 75, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Lesovik, V.; Voronov, V.; Glagolev, E.; Fediuk, R.; Alaskhanov, A.; Amran, Y.H.M.; Murali, G.; Baranov, A. Improving the behaviors of foam concrete through the use of composite binder. J. Build. Eng. 2020, 31, 101414. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Yavna, V.; Mischinenko, V.; Kukharskii, A.; Kruglikov, A.; Kolodina, A.; Yalovega, G. Effect of pre-treatment of flax tows on mechanical properties and microstructure of natural fiber reinforced geopolymer composites. Environ. Technol. Innov. 2020, 20, 101105. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Lee, Y.H.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-reinforced foamed concretes: A review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Fediuk, R. High-strength fibrous concrete of Russian Far East natural materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tomsk, Russia, 9–11 November 2015; Volume 116. [Google Scholar]

- Martins, R.O.G.; Alvarenga, R.D.C.S.S.; Pedroti, L.G.; De Oliveira, A.F.; Mendes, B.C.; De Azevedo, A.R.G. Assessment of the durability of grout submitted to accelerated carbonation test. Constr. Build. Mater. 2018, 159, 261–268. [Google Scholar] [CrossRef]

- Bindiganavile, V.; Goncalves, J.R.A.; Boluk, Y. Crack growth resistance in fibre reinforced geopolymer concrete exposed to sustained extreme temperatures. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2016; Volume 711, pp. 511–518. ISBN 9783035710441. [Google Scholar]

- Areias, I.O.R.; Vieira, C.M.F.; Colorado, H.A.; Delaqua, G.C.G.; Monteiro, S.N.; Azevedo, A.R.G. Could city sewage sludge be directly used into clay bricks for building construction? A comprehensive case study from Brazil. J. Build. Eng. 2020, 31, 101374. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- De Azevedo, A.G.S.; Strecker, K.; Lombardi, C.T. Produção de geopolímeros à base de metacaulim e cerâmica vermelha. Cerâmica 2018, 64, 388–396. [Google Scholar] [CrossRef] [Green Version]

- Haruna, S.; Mohammed, B.S.; Wahab, M.M.A.; Liew, M.S. Effect of paste aggregate ratio and curing methods on the performance of one-part alkali-activated concrete. Constr. Build. Mater. 2020, 261, 120024. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Neuba, L.M.; Pereira Junio, R.F.; Ribeiro, M.P.; Souza, A.T.; Lima, E.S.; Filho, F.C.G.; Figueiredo, A.B.-H.S.; Braga, F.O.; De Azevedo, A.R.G.; Monteiro, S.N. Promising mechanical, thermal, and ballistic properties of novel epoxy composites reinforced with Cyperus malaccensis sedge fiber. Polymers 2020, 12, 1776. [Google Scholar] [CrossRef] [PubMed]

- Baloyi, R.B.; Ncube, S.; Moyo, M.; Nkiwane, L.; Dzingai, P. Analysis of the properties of a glass/sisal/polyester composite. Sci. Rep. 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Fei, W.; Yutong, Y.; Shiping, Y. Thermal and moisture performance parameters of high toughness engineered cementitious Composite(ECC) with PVA fibers. J. Build. Eng. 2021, 43, 102905. [Google Scholar] [CrossRef]

- Shen, H.; Li, Y.; Yao, W.; Yang, S.; Yang, L.; Pan, F.; Chen, Z.; Yin, X. Solvent-free cellulose nanocrystal fluids for simultaneous enhancement of mechanical properties, thermal conductivity, moisture permeability and antibacterial properties of polylactic acid fibrous membrane. Compos. Part B Eng. 2021, 222, 109042. [Google Scholar] [CrossRef]

- Johnson, R.D.J.; Arumugaprabu, V.; Ko, T.J. Mechanical Property, Wear Characteristics, Machining and Moisture Absorption Studies on Vinyl Ester Composites—A Review. Silicon 2019, 11, 2455–2470. [Google Scholar] [CrossRef]

- Johnson, R.D.J.; Arumugaprabu, V.; Rajasekar, E.; Santhosh, G.; Saravanakumar, M. Mechanical Property Studies on Environmental Friendly Bio Epoxy Resin. Mater. Today Proc. 2018, 5, 6815–6820. [Google Scholar] [CrossRef]

- Fidan, I.; Imeri, A.; Gupta, A.; Hasanov, S.; Nasirov, A.; Elliott, A.; Alifui-Segbaya, F.; Nanami, N. The trends and challenges of fiber reinforced additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 102, 1801–1818. [Google Scholar] [CrossRef]

- Azevedo, A.R.; Marvila, M.T.; Zanelato, E.B.; Alexandre, J.; Xavier, G.C.; Cecchin, D. Development of mortar for laying and coating with pineapple fiber. Rev. Bras. Eng. Agric. Ambient. 2020, 24, 187–193. [Google Scholar] [CrossRef]

- Zhan, J.; Wang, G.; Li, J.; Guan, Y.; Zhao, G.; Naceur, H.; Coutellier, D.; Lin, J. Effect of the compatilizer and chemical treatments on the performance of poly(lactic acid)/ramie fiber composites. Compos. Commun. 2021, 27, 100843. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Marvila, M.T.; Antunes, M.L.P.; Rangel, E.C.; Fediuk, R. Technological Perspective for Use the Natural Pineapple Fiber in Mortar to Repair Structures. Waste Biomass Valorization 2021, 1–15. [Google Scholar] [CrossRef]

- Viscusi, G.; Pantani, R.; Gorrasi, G. Transport properties of water vapor through hemp fibers modified with a sustainable process: Effect of surface morphology on the thermodynamic and kinetic phenomena. Appl. Surf. Sci. 2021, 541, 148433. [Google Scholar] [CrossRef]

- Chen, F.; Sawada, D.; Hummel, M.; Sixta, H.; Budtova, T. Swelling and dissolution kinetics of natural and man-made cellulose fibers in solvent power tuned ionic liquid. Cellulose 2020, 27, 7399–7415. [Google Scholar] [CrossRef]

- Nouri, M.; Tahlaiti, M.; Grondin, F.; Belarbi, R. The Influence of Chemical and Thermal Treatments on the Diss Fiber Hygroscopic Behaviors. J. Nat. Fibers 2020, 1–14. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Hebdowska-Krupa, M.; Mikuła, J. Impact of Flax Fiber Reinforcement on Mechanical Properties of Solid and Foamed Geopolymer Concrete. Adv. Technol. Innov. 2021, 6, 11–20. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.; Cecchin, D.; Costa, J.M.; Xavier, G.C.; De Fátima do Carmo, D.; Monteiro, S.N. Durability of coating mortars containing açaí fibers. Case Stud. Constr. Mater. 2020, 13, e00406. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Teng, L. Fiber alignment and its effect on mechanical properties of UHPC: An overview. Constr. Build. Mater. 2021, 296, 123741. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Khayat, K.H.; Su, A. Influence of fiber alignment and length on flexural properties of UHPC. Constr. Build. Mater. 2021, 290, 122863. [Google Scholar] [CrossRef]

- Sakuratani, A.; Matsuoka, T.; Hirayama, T. Influence of cyclic stress on interfacial debonding in natural fiber reinforced composite. In Proceedings of the 8th Asian-Australasian Conference on Composite Materials 2012, ACCM 2012—Composites: Enabling Tomorrow’s Industry Today, Kuala Lumpur, Malaysia, 6–8 November 2012; Volume 1, pp. 191–196. [Google Scholar]

- Ortega, Z.; Romero, F.; Su, L.; Nizardo, A. Valorization of Invasive Plants from Macaronesia as Filler Materials in the Production of Natural Fiber Composites by Rotational Molding. Polymers 2021, 13, 2220. [Google Scholar] [CrossRef] [PubMed]

- Beckman, I.P.; Lozano, C.; Freeman, E.; Riveros, G. Fiber Selection for Reinforced Additive Manufacturing. Polymers 2021, 13, 2231. [Google Scholar] [CrossRef] [PubMed]

- Salih, C.; Manalo, A.; Ferdous, W.; Yu, P.; Abousnina, R.; Heyer, T.; Schubel, P. Effect of bending and compressive modulus of elasticity on the behaviour of timber-alternative railway sleepers supported by ballast. Case Stud. Constr. Mater. 2021, 15, e00597. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of landfill wastes (tyres, plastics and glass) in construction—A review on global waste generation, performance, application and future opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Manalo, A.C.; Schubel, P.; Ferdous, W. Composite railway sleepers—New developments and opportunities. In Proceedings of the 9th International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, CICE, Perth, Australia, 21–24 June 2015; Volume 2018, pp. 904–910. [Google Scholar]

- Manalo, A.; Maranan, G.; Benmokrane, B.; Cousin, P.; Alajarmeh, O.; Ferdous, W.; Liang, R.; Hota, G. Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments. Cem. Concr. Compos. 2020, 109, 103564. [Google Scholar] [CrossRef]

- Todkar, S.S.; Patil, S.A. Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos. Part B Eng. 2019, 174, 106927. [Google Scholar] [CrossRef]

- Loginov, P.A.; Sidorenko, D.A.; Orekhov, A.S.; Levashov, E.A. A novel method for in situ TEM measurements of adhesion at the diamond–metal interface. Sci. Rep. 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Fugolin, A.P.P.; Costa, A.R.; Correr-Sobrinho, L.; Crystal Chaw, R.; Lewis, S.; Ferracane, J.L.; Pfeifer, C.S. Toughening and polymerization stress control in composites using thiourethane-treated fillers. Sci. Rep. 2021, 11, 1–12. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2021, 33, 101675. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, W.; Yan, Z.; Zhang, J. Interfacial Morphology and Bonding Mechanism of Explosive Weld Joints. Chinese J. Mech. Eng. English Ed. 2021, 34, 1–12. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Haque, M.A.; Saleem Kazmi, S.M.; Munir, M.J. Development of plant-concrete composites containing pretreated corn stalk bio-aggregates and different type of binders. Cem. Concr. Compos. 2021, 121, 104054. [Google Scholar] [CrossRef]

- Lyu, B.-C.; Ding, C.; Guo, L.-P.; Chen, B.; Wang, A.-G. Basic performances and potential research problems of strain hardening geopolymer composites: A critical review. Constr. Build. Mater. 2021, 287, 123030. [Google Scholar] [CrossRef]

- El Alouani, M.; Saufi, H.; Moutaoukil, G.; Alehyen, S.; Nematollahi, B.; Belmaghraoui, W.; Taibi, M. Application of geopolymers for treatment of water contaminated with organic and inorganic pollutants: State-of-the-art review. J. Environ. Chem. Eng. 2021, 9, 105095. [Google Scholar] [CrossRef]

- Trindade, A.C.C.; De Andrade Silva, F.; Kriven, W.M. Mechanical behavior of K-geopolymers reinforced with silane-coated basalt fibers. J. Am. Ceram. Soc. 2021, 104, 437–447. [Google Scholar] [CrossRef]

- Gassan, J. A study of fibre and interface parameters affecting the fatigue behaviour of natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 369–374. [Google Scholar] [CrossRef]

- Nogueira, A.; De Barros, S.; Amaral Alves, L. Fiber–matrix adhesion on industrial geopolymer. Iran. J. Mater. Sci. Eng. 2020, 17, 95–101. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Kruglikov, A.; Mischinenko, V.; Yavna, V. Sustainable geopolymer composites reinforced with flax tows. Ceram. Int. 2020, 46, 12870–12875. [Google Scholar] [CrossRef]

- Arslan, A.A.; Uysal, M.; Yılmaz, A.; Al-mashhadani, M.M.; Canpolat, O.; Şahin, F.; Aygörmez, Y. Influence of wetting-drying curing system on the performance of fiber reinforced metakaolin-based geopolymer composites. Constr. Build. Mater. 2019, 225, 909–926. [Google Scholar] [CrossRef]

- De Nossa, T.S. Comparative Study of the Stresses at the Interface of Epoxy Resin Composites Reinforced with Carbon, Aramid And Glass Fibers; Federal University of São Carlos: São Carlos, Brazil, 2011. [Google Scholar]

- Bołtryk, M.; Granatyr, K.; Stankiewicz, N. Ecological aspects in the application of geopolymer composites on road surfaces. Ekon. Sr. 2019, 193–202. [Google Scholar] [CrossRef]

- Liu, Z.-H.; Pang, X.-Q.; Wang, K.-T.; Lv, X.-S.; Cui, X.-M. Superhydrophobic Coatings Prepared by the in Situ Growth of Silicone Nanofilaments on Alkali-Activated Geopolymers Surface. ACS Appl. Mater. Interfaces 2019, 11, 22809–22816. [Google Scholar] [CrossRef] [PubMed]

- Kolínová, M.; Bakalova, T.; Voleský, L.; Kejzlar, P.; Kovačíč, V. Non-destructive evaluation of pore size and structural change in geopolymer composite materials with added fibres. Manuf. Technol. 2019, 19, 71–76. [Google Scholar] [CrossRef]

- Kovářík, T.; Křenek, T.; Rieger, D.; Pola, M.; Říha, J.; Svoboda, M.; Beneš, J.; Šutta, P.; Bělský, P.; Kadlec, J. Synthesis of open-cell ceramic foam derived from geopolymer precursor via replica technique. Mater. Lett. 2017, 209, 497–500. [Google Scholar] [CrossRef]

- Jianqiang Wei, C.M. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar]

- Ye, H.; Zhang, Y.; Yu, Z.; Mu, J. Effects of cellulose, hemicellulose, and lignin on the morphology and mechanical properties of metakaolin-based geopolymer. Constr. Build. Mater. 2018, 173, 10–16. [Google Scholar] [CrossRef]

- Haddaji, Y.; Majdoubi, H.; Mansouri, S.; Tamraoui, Y.; El bouchti, M.; Manoun, B.; Oumam, M.; Hannache, H. Effect of synthetic fibers on the properties of geopolymers based on non-heat treated phosphate mine tailing. Mater. Chem. Phys. 2021, 260, 124147. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.; Barroso, L.S.; Barbosa, M.Z.; De Brito, J. Gypsum plaster using rock waste: A proposal to repair the renderings of historical buildings in brazil. Constr. Buil. Mat. 2020, 250, 118786. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef] [Green Version]

- Shah, I.; Jing, L.; Fei, Z.M.; Yuan, Y.S.; Farooq, M.U.; Kanjana, N. A Review on Chemical Modification by using Sodium Hydroxide (NaOH) to Investigate the Mechanical Properties of Sisal, Coir and Hemp Fiber Reinforced Concrete Composites. J. Nat. Fibers 2021, 1–19. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. Part B Eng. 2019, 176, 107305. [Google Scholar] [CrossRef]

- Ozerkan, N.G.; Ahsan, B.; Mansour, S.; Iyengar, S.R. Mechanical performance and durability of treated palm fiber reinforced mortars. Int. J. Sustain. Built Environ. 2013, 2, 131–142. [Google Scholar] [CrossRef] [Green Version]

- Haridharan, M.K.; Matheswaran, S.; Murali, G.; Abid, S.R.; Fediuk, R.; Mugahed Amran, Y.H.; Abdelgader, H.S. Impact response of two-layered grouted aggregate fibrous concrete composite under falling mass impact. Constr. Build. Mater. 2020, 263, 120628. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Lakshmi Narayana, V.; Bhaskara Rao, L. A brief review on the effect of alkali treatment on mechanical properties of various natural fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 1988–1994. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Sultan, M.T.H.; Ariffin, A.H.; Shah, A.U.M. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [Google Scholar] [CrossRef]

- Tragoonwichian, S.; Yanumet, N.; Ishida, H. Effect of fiber surface modification on the mechanical properties of sisal fiber-reinforced benzoxazine/epoxy composites based on aliphatic diamine benzoxazine. J. Appl. Polym. Sci. 2007, 106, 2925–2935. [Google Scholar] [CrossRef]

- Chernysheva, N.V.; Lesovik, V.S.; Drebezgova, M.Y.; Shatalova, S.V.; Alaskhanov, A.H. Composite Gypsum Binders with Silica-containing Additives. Proc. IOP Conf. Series Mater. Sci. Eng. 2018, 327, 032015. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Ibragimov, R.A.; Lesovik, V.S.; Pak, A.A.; Krylov, V.V.; Poleschuk, M.M.; Stoyushko, N.Y.; Gladkova, N.A. Processing equipment for grinding of building powders. Proc. IOP Conf. Series Mater. Sci. Eng. 2018, 327, 042029. [Google Scholar] [CrossRef]

- Lesovik, V.S.; Zagorodnyuk, L.Kh.; Babaev, Z.K.; Dzhumaniyazov, Z.B. Analysis of the Causes of Brickwork Efflorescence in the Aral Sea Region. Glas. Ceram. 2020, 77, 277–279. [Google Scholar] [CrossRef]

- Lesovik, V.S. The reducing effect of argon in the plasma treatment of high-melting nonmetallic materials (a review). Glas. Ceram. 2001, 58, 362–364. [Google Scholar]

- De Azevedo, A.R.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; De Lima, T.E.; Roman Fediuk, A.O. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 1–13. [Google Scholar] [CrossRef]

- Chernysheva, N.; Lesovik, V.; Fediuk, R.; Vatin, N. Improvement of Performances of the Gypsum-Cement Fiber Reinforced Composite (GCFRC). Materials 2020, 13, 3847. [Google Scholar] [CrossRef] [PubMed]

- Teo, S.C. Oil Palm Biomass: Reinforced Palm Oil Based Polyurethane Composite Foam and Structural Sandwich. Ph.D. Thesis, School of Materials Engineering, Paris, France, 2016. [Google Scholar]

- Batista dos Santos, G.Z.; Passos de Oliveira, D.; De Almeida Melo Filho, J.; Marques da Silva, N. Sustainable geopolymer composite reinforced with sisal fiber: Durability to wetting and drying cycles. J. Build. Eng. 2021, 43, 102568. [Google Scholar] [CrossRef]

- Santos, E.B.C.; Moreno, C.G.; Barros, J.J.P.; De Moura, D.A.; De Carvalho Fim, F.; Ries, A.; Wellen, R.M.R.; Da Silva, L.B. Effect of alkaline and hot water treatments on the structure and morphology of piassava fibers. Mater. Res. 2018, 21. [Google Scholar] [CrossRef]

- Nuaklong, P.; Wongsa, A.; Boonserm, K.; Ngohpok, C.; Jongvivatsakul, P.; Sata, V.; Sukontasukkul, P.; Chindaprasirt, P. Enhancement of mechanical properties of fly ash geopolymer containing fine recycled concrete aggregate with micro carbon fiber. J. Build. Eng. 2021, 41, 102403. [Google Scholar] [CrossRef]

- Zhao, J.; Tong, L.; Li, B.; Chen, T.; Wang, C.; Yang, G.; Zheng, Y. Eco-friendly geopolymer materials: A review of performance improvement, potential application and sustainability assessment. J. Clean. Prod. 2021, 307, 127085. [Google Scholar] [CrossRef]

- Moghaddam, M.K.; Mortazavi, S.M. Physical and Chemical Properties of Natural Fibers Extracted from Typha Australis Leaves. J. Nat. Fibers 2016, 13, 353–361. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. Effect of the state of conservation of the hemp used in geopolymer and hydraulic lime concretes. Constr. Build. Mater. 2021, 285, 122853. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, R.; Zeng, X.; Jia, W.; Jin, H.; Li, F. Reinforced Geopolymer Materials with Natural Fibers: A Review|用自然纤维增强地聚物材料: 综述. Mater. Rep. 2021, 35, 7107–7113. [Google Scholar] [CrossRef]

- Camargo, M.M.; Taye, E.A.; Roether, J.A.; Redda, D.T.; Boccaccini, A.R. A review on natural fiber-reinforced geopolymer and cement-based composites. Materials 2020, 13, 1–29. [Google Scholar] [CrossRef]

- Alshaaer, M. Synthesis and characterization of self-healing geopolymer composite. Constr. Build. Mater. 2020, 245, 118432. [Google Scholar] [CrossRef]

- Wongsa, A.; Kunthawatwong, R.; Naenudon, S.; Sata, V.; Chindaprasirt, P. Natural fiber reinforced high calcium fly ash geopolymer mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar] [CrossRef]

- Trindade, A.C.C.; Borges, P.H.R.; De Andrade Silva, F. Mechanical behavior of strain-hardening geopolymer composites reinforced with natural and PVA fibers. Mater. Today Proc. 2019, 8, 753–759. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Hao, H. Experimental and analytical investigation on flexural behaviour of ambient cured geopolymer concrete beams reinforced with steel fibers. Eng. Struct. 2019, 200, 109707. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Characterisation of cotton fibre-reinforced geopolymer composites. Compos. Part B Eng. 2013, 50, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Noushini, A.; Hastings, M.; Castel, A.; Aslani, F. Mechanical and flexural performance of synthetic fibre reinforced geopolymer concrete. Constr. Build. Mater. 2018, 186, 454–475. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Characterization of cotton fabric reinforced geopolymer composites modified with Portland cement. Design, Development, and Applications of Structural Ceramics, Composites, and Nanomaterials 2014, 244, 155–167. [Google Scholar]

- Rahier, H.; Esaifan, M.; Wastiels, J.; Slatyi, F.; Aldabsheh, I.; Khoury, H. Alkali activation of kaolinite for production of bricks and tiles. In Proceedings of the 4th International Conference, Non-Traditional Cement and Concrete Conference (NTCC), Brno, Czech Republic, 19–22 June 2011. [Google Scholar]

- Marvila, M.T.; De Azevedo, A.R.G.; De Matos, P.R.; Monteiro, S.N.; Vieira, C.M.F. Rheological and the fresh state properties of alkali-activated mortars by blast furnace slag. Materials 2021, 14, 2069. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.; Vieira, C.M.F.; Ferreira, W.M.; Faria, K.C.P.; Pedroti, L.G.; Mendes, B.C. Potential use of ceramic waste as precursor in the geopolymerization reaction for the production of ceramic roof tiles. J. Build. Eng. 2020, 29, 101156. [Google Scholar] [CrossRef]

- Bhutta, A.; Borges, P.H.R.; Zanotti, C.; Farooq, M.; Banthia, N. Flexural behavior of geopolymer composites reinforced with steel and polypropylene macro fibers. Cem. Concr. Compos. 2017, 80, 31–40. [Google Scholar] [CrossRef]

- Bai, T.; Liu, B.; Wu, Y.; Huang, W.; Wang, H.; Xia, Z. Mechanical properties of metakaolin-based geopolymer with glass fiber reinforcement and vibration preparation. J. Non. Cryst. Solids 2020, 544, 120173. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Fawzy, A.M. Experimental investigation on permeability indices and strength of modified pervious concrete with recycled concrete aggregate. Constr. Build. Mater. 2018, 193, 105–127. [Google Scholar] [CrossRef]

- Benyahia, A.; Ghrici, M.; Choucha, S.; Omran, A. Characterization of Fiber Reinforced Self-Consolidating Mortars for Use in Patching Damaged Concrete. Lat. Am. J. Solids Struct. 2017, 14, 1124–1142. [Google Scholar] [CrossRef]

- Saeli, M.; Tobaldi, D.M.; Seabra, M.P.; Labrincha, J.A. Mix design and mechanical performance of geopolymeric binders and mortars using biomass fly ash and alkaline effluent from paper-pulp industry. J. Clean. Prod. 2019, 208, 1188–1197. [Google Scholar] [CrossRef]

- Marvila, M.T.; De Azevedo, A.R.G.; Alexandre, J.; Colorado, H.; Pereira Antunes, M.L.; Vieira, C.M.F. Circular economy in cementitious ceramics: Replacement of hydrated lime with a stoichiometric balanced combination of clay and marble waste. Int. J. Appl. Ceram. Technol. 2021, 18, 192–202. [Google Scholar] [CrossRef]

- Alomayri, T.; Low, I.M. Synthesis and characterization of mechanical properties in cotton fiber-reinforced geopolymer composites. J. Asian Ceram. Soc. 2013, 1, 30–34. [Google Scholar] [CrossRef] [Green Version]

- Bhutta, A.; Farooq, M.; Banthia, N. Performance characteristics of micro fiber-reinforced geopolymer mortars for repair. Constr. Build. Mater. 2019, 215, 605–612. [Google Scholar] [CrossRef]

- Al-mashhadani, M.M.; Canpolat, O.; Aygörmez, Y.; Uysal, M.; Erdem, S. Mechanical and microstructural characterization of fiber reinforced fly ash based geopolymer composites. Constr. Build. Mater. 2018, 167, 505–513. [Google Scholar] [CrossRef]

- Ilamvazhuthi, S.S. and D.G.V.T.G. Performance of Geopolymer Concrete with Polypropylene Fibres. Int. J. Innov. Eng. Technol. 2013, 3, 148–156. [Google Scholar]

- Sukontasukkul, P.; Pongsopha, P.; Chindaprasirt, P.; Songpiriyakij, S. Flexural performance and toughness of hybrid steel and polypropylene fibre reinforced geopolymer. Constr. Build. Mater. 2018, 161, 37–44. [Google Scholar] [CrossRef]

- Alomayri, T.; Vickers, L.; Shaikh, F.U.A.; Low, I.-M. Mechanical properties of cotton fabric reinforced geopolymer composites at 200–1000 °C. J. Adv. Ceram. 2014, 3, 184–193. [Google Scholar] [CrossRef] [Green Version]

- Riahi, S.; Nemati, A.; Khodabandeh, A.R.; Baghshahi, S. Investigation of interfacial and mechanical properties of alumina-coated steel fiber reinforced geopolymer composites. Constr. Build. Mater. 2021, 288, 123118. [Google Scholar] [CrossRef]

- Chu, S.H.; Ye, H.; Huang, L.; Li, L.G. Carbon fiber reinforced geopolymer (FRG) mix design based on liquid film thickness. Constr. Build. Mater. 2021, 269, 121278. [Google Scholar] [CrossRef]

- França, B.R.; Azevedo, A.R.G.; Monteiro, S.N.; Da Costa, F.; Filho, G.; Marvila, M.T.; Alexandre, J.; Zanelato, E.B. Durability of soil-Cement blocks with the incorporation of limestone residues from the processing of marble. Mater. Res. 2018, 21, 125–138. [Google Scholar] [CrossRef] [Green Version]

- Teixeira de Freitas, S.; Banea, M.D.; Budhe, S.; De Barros, S. Interface adhesion assessment of composite-to-metal bonded joints under salt spray conditions using peel tests. Compos. Struct. 2017, 164, 68–75. [Google Scholar] [CrossRef]

- Marvila, M.T.; Rocha, H.A.; De Azevedo, A.R.G.; Colorado, H.A.; Zapata, J.F.; Vieira, C.M.F. Use of natural vegetable fibers in cementitious composites: Concepts and applications. Innov. Infrastruct. Solut. 2021, 6, 1–24. [Google Scholar] [CrossRef]

| Natural Fiber | Cellulose (%) | Semi Cellulose (%) | Lignin (%) | Total (%) |

|---|---|---|---|---|

| Cotton | 89.7 | 1.0 | 2.7 | 93.4 |

| Linen | 80.0 | 13.0 | 2.0 | 95.0 |

| Hemp | 74.1 | 7.6 | 2.2 | 83.9 |

| Sugar cane | 51.8 | 27.6 | 10.7 | 90.1 |

| Bamboo | 54.6 | 11.4 | 21.7 | 87.7 |

| Coconut | 51.3 | 11.7 | 30.7 | 93.7 |

| Wheat Straw | 38.0 | 36.0 | 22.0 | 96.0 |

| Parameters | Natural Fibers | Synthetic Fibers | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jute [42] | Sisal [42] | Cotton [120] | Alumina-coated Steel [121] | Polypropylene and Steel fibers [1] | Carbon Fiber [122] | |||||||

| wt.% Fibers | Result | wt.% Fibers | Result | wt.% Fibers | Result | wt.% Fibers | Result | wt.% Fibers | Result | wt.% Fibers | Result | |

| Compressive strength (MPa) | 0 | 12.80 | 0 | 12.80 | 0 | 19.0 | 0 | 67.50 | 0 | 30.00 | 0 | 23.40 |

| 0.50 | 16.10 | 0.50 | 16.70 | 0.30 | 27.2 | 0.50 | 69.00 | 0.50 | 40.50 | 0.50 | 26.50 | |

| 1.00 | 17.20 | 1.00 | 17.50 | 0.50 | 46.5 | 0.75 | 72.00 | 1.00 | 42.10 | - | - | |

| 1.50 | 21.20 | 1.50 | 18.40 | 0.70 | 35.0 | 1.00 | 69.50 | 2.00 | 51.60 | - | - | |

| 2.00 | 18.50 | 2.00 | 18.60 | 1.00 | 28.1 | 1.50 | 69.00 | 3.00 | 54.70 | - | - | |

| Flexural strength (MPa) | 0 | 0.85 | 0 | 0.85 | 0 | 0.72 | 0 | 66.50 | 0 | 3.50 | 0 | 4.40 |

| 0.50 | 1.54 | 0.50 | 1.30 | 0.30 | 1.20 | 0.50 | 67.50 | 0.50 | 7.80 | 0.50 | 5.50 | |

| 1.00 | 2.10 | 1.00 | 1.74 | 0.50 | 1.30 | 0.75 | 69.50 | 1.00 | 11.00 | - | - | |

| 1.50 | 2.50 | 1.50 | 2.40 | 0.70 | 1.50 | 1.00 | 70.00 | 2.00 | 18.40 | - | - | |

| 2.00 | 3.30 | 2.00 | 2.58 | 1.00 | 2.10 | 1.50 | 71.50 | 3.00 | 23.45 | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Azevedo, A.R.G.; Cruz, A.S.A.; Marvila, M.T.; de Oliveira, L.B.; Monteiro, S.N.; Vieira, C.M.F.; Fediuk, R.; Timokhin, R.; Vatin, N.; Daironas, M. Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review. Polymers 2021, 13, 2493. https://doi.org/10.3390/polym13152493

de Azevedo ARG, Cruz ASA, Marvila MT, de Oliveira LB, Monteiro SN, Vieira CMF, Fediuk R, Timokhin R, Vatin N, Daironas M. Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review. Polymers. 2021; 13(15):2493. https://doi.org/10.3390/polym13152493

Chicago/Turabian Stylede Azevedo, Afonso R. G., Ariana S. A. Cruz, Markssuel T. Marvila, Leandro B. de Oliveira, Sergio N. Monteiro, Carlos Mauricio F. Vieira, Roman Fediuk, Roman Timokhin, Nikolai Vatin, and Marina Daironas. 2021. "Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review" Polymers 13, no. 15: 2493. https://doi.org/10.3390/polym13152493

APA Stylede Azevedo, A. R. G., Cruz, A. S. A., Marvila, M. T., de Oliveira, L. B., Monteiro, S. N., Vieira, C. M. F., Fediuk, R., Timokhin, R., Vatin, N., & Daironas, M. (2021). Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review. Polymers, 13(15), 2493. https://doi.org/10.3390/polym13152493