An Ultrastretchable Electrical Switch Fiber with a Magnetic Liquid Metal Core for Remote Magnetic Actuation

Abstract

:1. Introduction

2. Materials and Methods

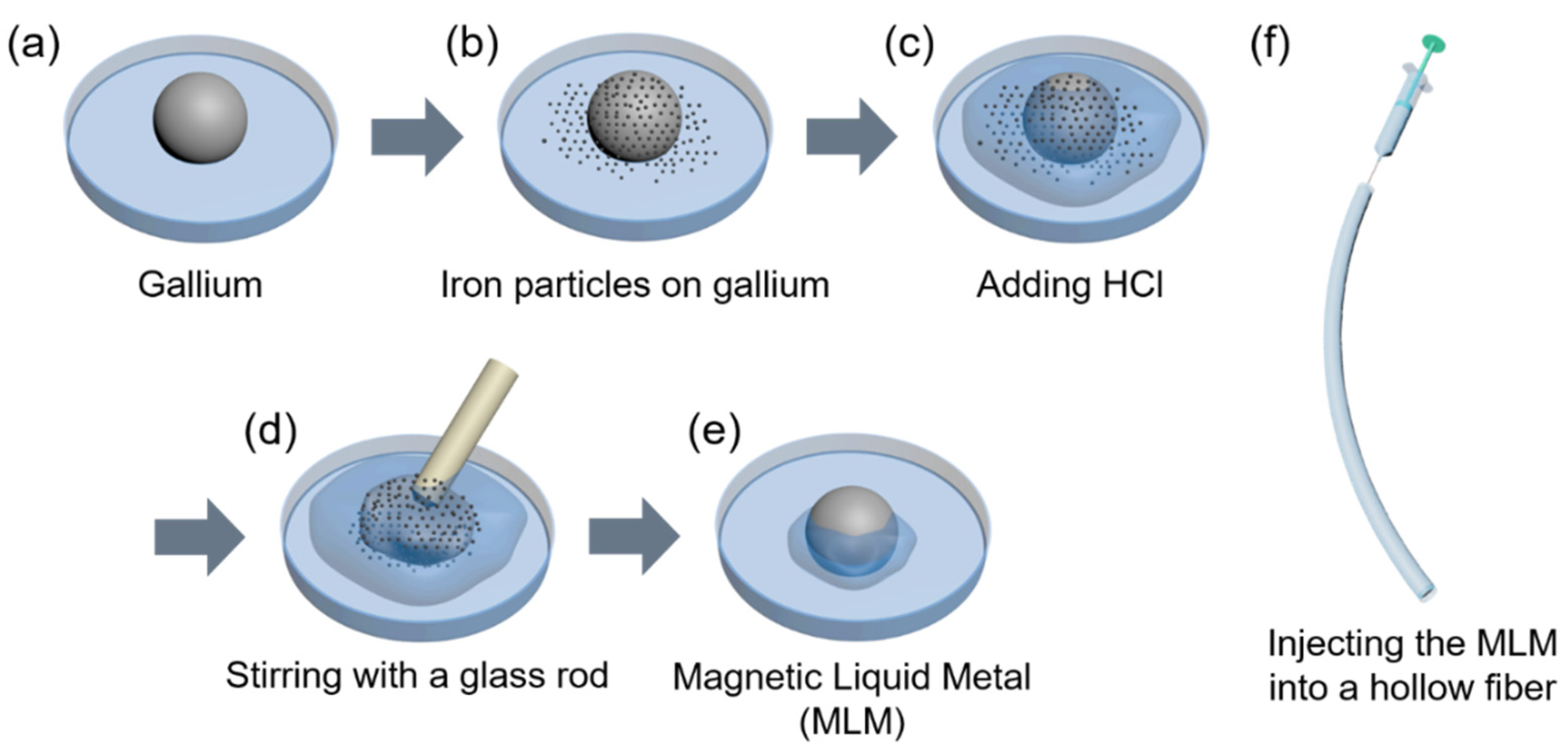

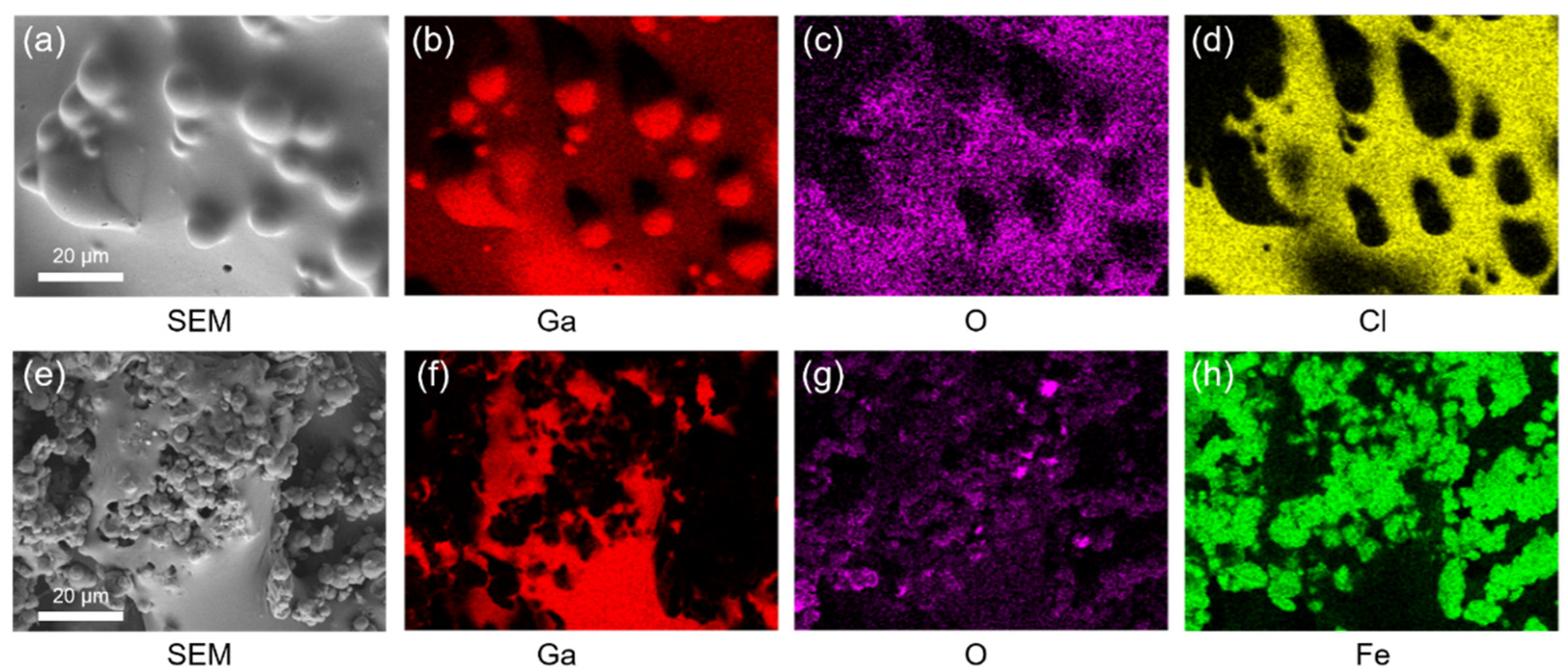

2.1. Preparation of Magnetic Liquid Metal (MLM)

2.2. Fabrication of Ultrastretchable and Elastic Hollow Fiber with MLM Core

2.3. Characterization

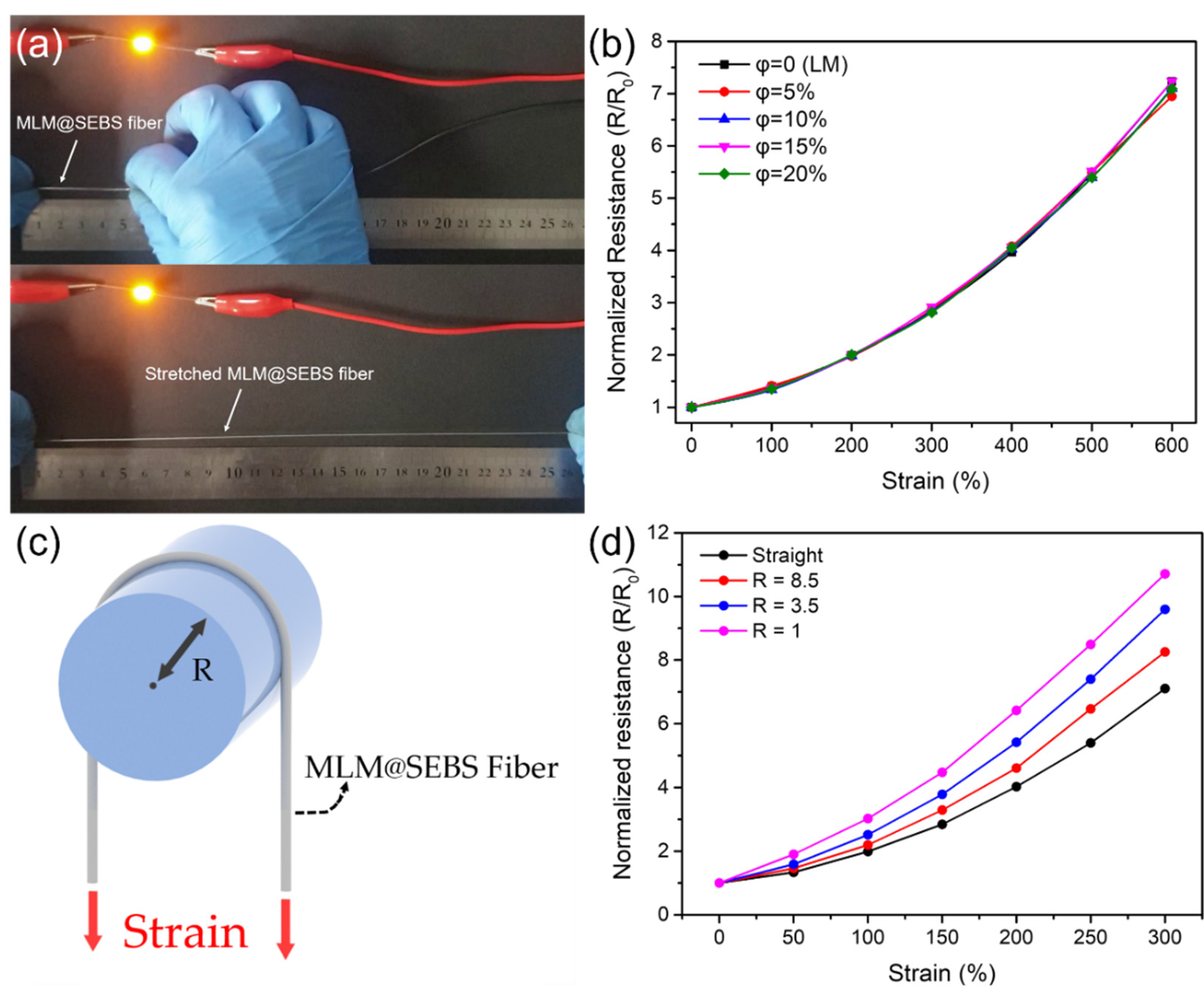

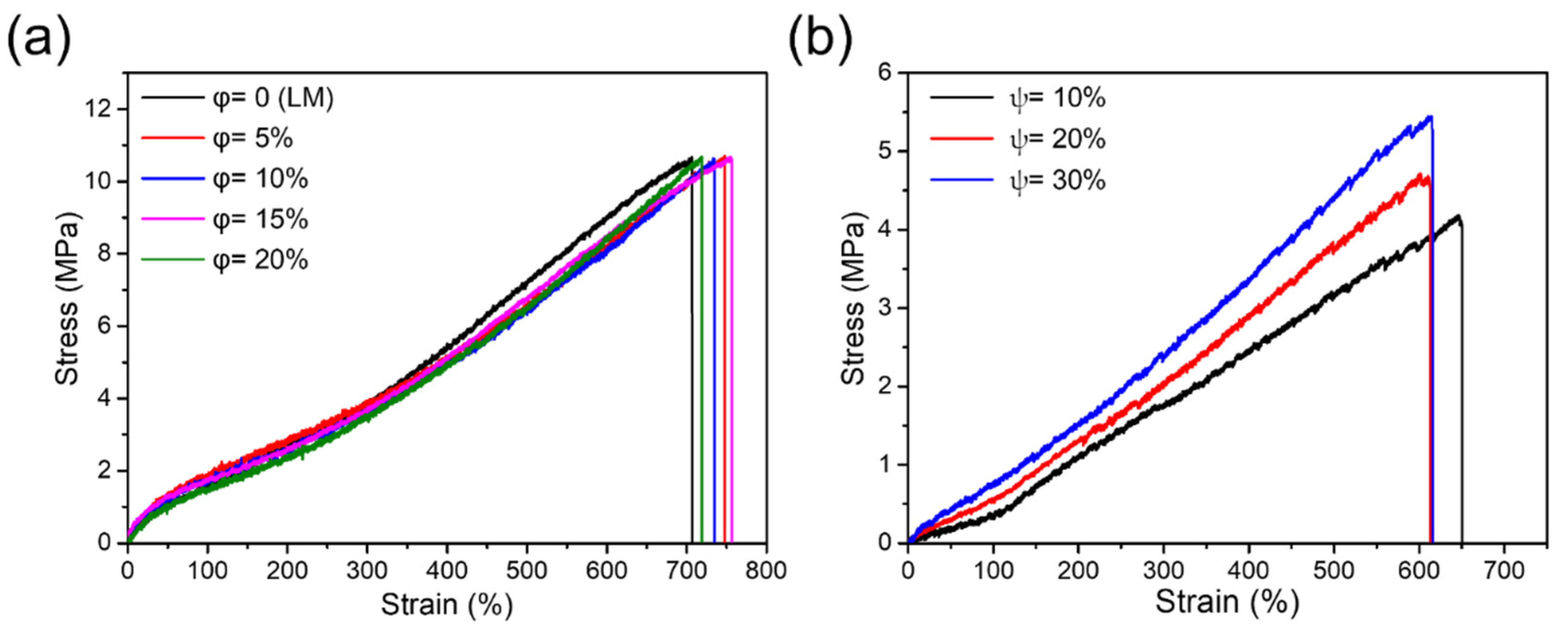

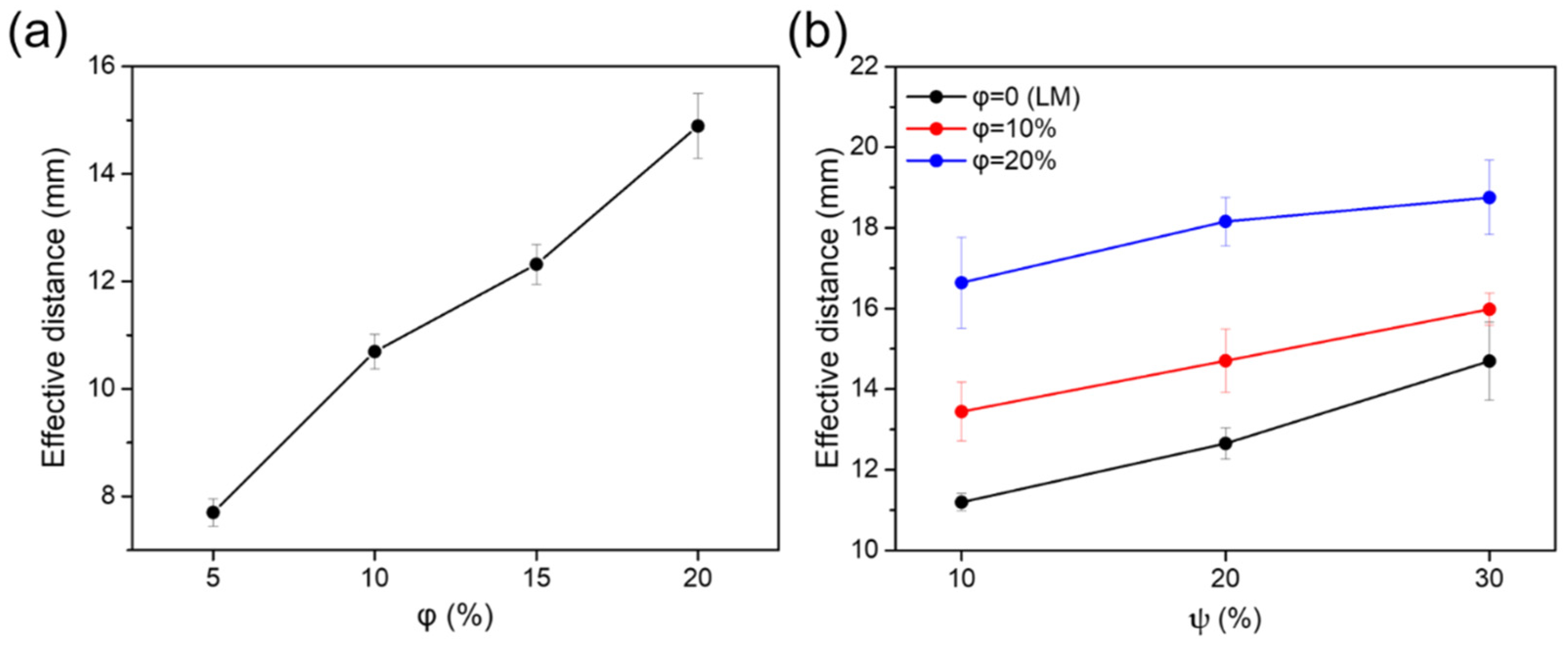

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Ashuri, T.; Armani, A.; Jalilzadeh Hamidi, R.; Reasnor, T.; Ahmadi, S.; Iqbal, K. Biomedical Soft Robots: Current Status and Perspective. Biomed. Eng. Lett. 2020, 10, 369–385. [Google Scholar] [CrossRef]

- Wang, J.; Gao, D.; Lee, P.S. Recent Progress in Artificial Muscles for Interactive Soft Robotics. Adv. Mater. 2020, 2003088. [Google Scholar] [CrossRef]

- Wang, X.; Guo, R.; Liu, J. Liquid Metal Based Soft Robotics: Materials, Designs, and Applications. Adv. Mater. Technol. 2018, 1800549. [Google Scholar] [CrossRef] [Green Version]

- Polygerinos, P.; Correll, N.; Morin, S.A.; Mosadegh, B.; Onal, C.D.; Petersen, K.; Cianchetti, M.; Tolley, M.T.; Shepherd, R.F. Soft Robotics: Review of Fluid-Driven Intrinsically Soft Devices; Manufacturing, Sensing, Control, and Applications in Human-Robot Interaction. Adv. Eng. Mater. 2017, 19, 1700016. [Google Scholar] [CrossRef]

- Qi, D.; Zhang, K.; Tian, G.; Jiang, B.; Huang, Y. Stretchable Electronics Based on PDMS Substrates. Adv. Mater. 2021, 33, 2003155. [Google Scholar] [CrossRef] [PubMed]

- Song, J.-K.; Do, K.; Koo, J.H.; Son, D.; Kim, D.-H. Nanomaterials-Based Flexible and Stretchable Bioelectronics. MRS Bull. 2019, 44, 643–656. [Google Scholar] [CrossRef]

- Dickey, M.D. Liquid Metals for Soft and Stretchable Electronics. In Stretchable Bioelectronics for Medical Devices and Systems; Rogers, J.A., Ghaffari, R., Kim, D.-H., Eds.; Microsystems and Nanosystems; Springer International Publishing: Cham, Switzerland, 2016; pp. 3–30. ISBN 978-3-319-28692-1. [Google Scholar]

- Heo, J.S.; Eom, J.; Kim, Y.-H.; Park, S.K. Recent Progress of Textile-Based Wearable Electronics: A Comprehensive Review of Materials, Devices, and Applications. Small 2018, 14, 1703034. [Google Scholar] [CrossRef]

- Rajan, K.; Garofalo, E.; Chiolerio, A. Wearable Intrinsically Soft, Stretchable, Flexible Devices for Memories and Computing. Sensors 2018, 18, 367. [Google Scholar] [CrossRef] [Green Version]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-Based Wearable Electronics: A Review of Materials, Fabrication, Devices, and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef]

- Borgne, B.L.; Liu, S.; Morvan, X.; Crand, S.; Sporea, R.A.; Lu, N.; Harnois, M. Water Transfer Printing Enhanced by Water-Induced Pattern Expansion: Toward Large-Area 3D Electronics. Adv. Mater. Technol. 2019, 4, 1800600. [Google Scholar] [CrossRef]

- Jahanshahi, A.; Gonzalez, M.; van den Brand, J.; Bossuyt, F.; Vervust, T.; Verplancke, R.; Vanfleteren, J.; Baets, J.D. Stretchable Circuits with Horseshoe Shaped Conductors Embedded in Elastic Polymers. Jpn. J. Appl. Phys. 2013, 52, 05DA18. [Google Scholar] [CrossRef]

- Webb, R.C.; Bonifas, A.P.; Behnaz, A.; Zhang, Y.; Yu, K.J.; Cheng, H.; Shi, M.; Bian, Z.; Liu, Z.; Kim, Y.-S.; et al. Ultrathin Conformal Devices for Precise and Continuous Thermal Characterization of Human Skin. Nat. Mater. 2013, 12, 938–944. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, H.; Xiao, L.; Duan, Y.; Zhu, H.; Bian, J.; Ye, D.; Yin, Z. Assembly and Applications of 3D Conformal Electronics on Curvilinear Surfaces. Mater. Horiz. 2019, 6, 642–683. [Google Scholar] [CrossRef]

- Dickey, M.D. Stretchable and Soft Electronics Using Liquid Metals. Adv. Mater. 2017, 29, 1606425. [Google Scholar] [CrossRef]

- Dickey, M.D. Emerging Applications of Liquid Metals Featuring Surface Oxides. ACS Appl. Mater. Interfaces 2014, 6, 18369–18379. [Google Scholar] [CrossRef] [Green Version]

- Dickey, M.D.; Chiechi, R.C.; Larsen, R.J.; Weiss, E.A.; Weitz, D.A.; Whitesides, G.M. Eutectic Gallium-Indium (EGaIn): A Liquid Metal Alloy for the Formation of Stable Structures in Microchannels at Room Temperature. Adv. Funct. Mater. 2008, 18, 1097–1104. [Google Scholar] [CrossRef]

- Guo, R.; Tang, J.; Dong, S.; Lin, J.; Wang, H.; Liu, J.; Rao, W. One-Step Liquid Metal Transfer Printing: Toward Fabrication of Flexible Electronics on Wide Range of Substrates. Adv. Mater. Technol. 2018, 3, 1800265. [Google Scholar] [CrossRef]

- Lin, Y.; Gordon, O.; Khan, M.R.; Vasquez, N.; Genzer, J.; Dickey, M.D. Vacuum Filling of Complex Microchannels with Liquid Metal. Lab Chip 2017, 17, 3043–3050. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, Y.; Shang, W.; Handschuh-Wang, S.; Zhou, X.; Gan, T.; Wu, Q.; Liu, Y.; Zhou, X. Anisotropic Liquid Metal–Elastomer Composites. J. Mater. Chem. C 2019, 7, 10166–10172. [Google Scholar] [CrossRef]

- Yang, J.; Tang, D.; Ao, J.; Ghosh, T.; Neumann, T.V.; Zhang, D.; Piskarev, E.; Yu, T.; Truong, V.K.; Xie, K.; et al. Ultrasoft Liquid Metal Elastomer Foams with Positive and Negative Piezopermittivity for Tactile Sensing. Adv. Funct. Mater. 2020, 30, 2002611. [Google Scholar] [CrossRef]

- Ford, M.J.; Ambulo, C.P.; Kent, T.A.; Markvicka, E.J.; Pan, C.; Malen, J.; Ware, T.H.; Majidi, C. A Multifunctional Shape-Morphing Elastomer with Liquid Metal Inclusions. Proc. Natl. Acad. Sci. USA 2019, 116, 21438–21444. [Google Scholar] [CrossRef] [Green Version]

- Tahidul Haque, A.B.M.; Tutika, R.; Gao, M.; Martinez, A.; Mills, J.; Arul Clement, J.; Gao, J.; Tabrizi, M.; Ravi Shankar, M.; Pei, Q.; et al. Conductive Liquid Metal Elastomer Thin Films with Multifunctional Electro-Mechanical Properties. Multifunct. Mater. 2020, 3, 044001. [Google Scholar] [CrossRef]

- Barron, E.J.; Peterson, R.S.; Lazarus, N.; Bartlett, M.D. Mechanically Cloaked Multiphase Magnetic Elastomer Soft Composites for Wearable Wireless Power Transfer. ACS Appl. Mater. Interfaces 2020, 12, 50909–50917. [Google Scholar] [CrossRef]

- Malakooti, M.H.; Bockstaller, M.R.; Matyjaszewski, K.; Majidi, C. Liquid Metal Nanocomposites. Nanoscale Adv. 2020, 2, 2668–2677. [Google Scholar] [CrossRef]

- Pan, C.; Markvicka, E.J.; Malakooti, M.H.; Yan, J.; Hu, L.; Matyjaszewski, K.; Majidi, C. A Liquid-Metal–Elastomer Nanocomposite for Stretchable Dielectric Materials. Adv. Mater. 2019, 31, 1900663. [Google Scholar] [CrossRef]

- Li, Y.; Feng, S.; Cao, S.; Zhang, J.; Kong, D. Printable Liquid Metal Microparticle Ink for Ultrastretchable Electronics. ACS Appl. Mater. Interfaces 2020, 12, 50852–50859. [Google Scholar] [CrossRef]

- Carle, F.; Bai, K.; Casara, J.; Vanderlick, K.; Brown, E. Development of Magnetic Liquid Metal Suspensions for Magnetohydrodynamics. Phys. Rev. Fluids 2017, 2, 013301. [Google Scholar] [CrossRef]

- Parekh, D.P.; Fancher, C.M.; Mohammed, M.G.; Neumann, T.V.; Saini, D.; Guerrier, J.; Ladd, C.; Hubbard, E.; Jones, J.L.; Dickey, M.D. Liquid–Solid Mixtures of Ga Metal Infused with Cu Microparticles and Nanoparticles for Microscale and Nanoscale Patterning of Solid Metals at Room Temperature. ACS Appl. Nano Mater. 2020, 3, 12064–12070. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, J.-B.; Chung, S.K.; Kim, D. On-Demand Magnetic Manipulation of Liquid Metal in Microfluidic Channels for Electrical Switching Applications. Lab Chip 2017, 17, 128–133. [Google Scholar] [CrossRef]

- Jeong, J.; Lee, J.-B.; Chung, S.K.; Kim, D. Electromagnetic Three Dimensional Liquid Metal Manipulation. Lab Chip 2019, 19, 3261–3267. [Google Scholar] [CrossRef]

- Guo, R.; Sun, X.; Yuan, B.; Wang, H.; Liu, J. Magnetic Liquid Metal (Fe-EGaIn) Based Multifunctional Electronics for Remote Self-Healing Materials, Degradable Electronics, and Thermal Transfer Printing. Adv. Sci. 2019, 6, 1901478. [Google Scholar] [CrossRef] [Green Version]

- Tutika, R.; Zhou, S.H.; Napolitano, R.E.; Bartlett, M.D. Mechanical and Functional Tradeoffs in Multiphase Liquid Metal, Solid Particle Soft Composites. Adv. Funct. Mater. 2018, 28, 1804336. [Google Scholar] [CrossRef]

- Merhebi, S.; Mayyas, M.; Abbasi, R.; Christoe, M.J.; Han, J.; Tang, J.; Rahim, M.A.; Yang, J.; Tan, T.T.; Chu, D.; et al. Magnetic and Conductive Liquid Metal Gels. ACS Appl. Mater. Interfaces 2020, 12, 20119–20128. [Google Scholar] [CrossRef]

- Hu, L.; Wang, H.; Wang, X.; Liu, X.; Guo, J.; Liu, J. Magnetic Liquid Metals Manipulated in the Three-Dimensional Free Space. ACS Appl. Mater. Interfaces 2019, 11, 8685–8692. [Google Scholar] [CrossRef]

- Li, X.; Li, S.; Lu, Y.; Liu, M.; Li, F.; Yang, H.; Tang, S.-Y.; Zhang, S.; Li, W.; Sun, L. Programmable Digital Liquid Metal Droplets in Reconfigurable Magnetic Fields. ACS Appl. Mater. Interfaces 2020, 12, 37670–37679. [Google Scholar] [CrossRef]

- Jeong, J.; Seo, J.; Chung, S.K.; Lee, J.-B.; Kim, D. Reversible On-Demand Magnetic Liquid Metal Marble Manipulation by Magnetowetting: Split and Merge, Deformation and Recovery. In Proceedings of the 2019 IEEE 32nd International Conference on Micro Electro Mechanical Systems (MEMS), Seoul, Korea, 27–31 January 2019; pp. 409–411. [Google Scholar]

- Zhu, S.; So, J.-H.; Mays, R.; Desai, S.; Barnes, W.R.; Pourdeyhimi, B.; Dickey, M.D. Ultrastretchable Fibers with Metallic Conductivity Using a Liquid Metal Alloy Core. Adv. Funct. Mater. 2013, 23, 2308–2314. [Google Scholar] [CrossRef]

- Park, S.; Baugh, N.; Shah, H.K.; Parekh, D.P.; Joshipura, I.D.; Dickey, M.D. Ultrastretchable Elastic Shape Memory Fibers with Electrical Conductivity. Adv. Sci. 2019, 6, 1901579. [Google Scholar] [CrossRef]

- Cooper, C.B.; Joshipura, I.D.; Parekh, D.P.; Norkett, J.; Mailen, R.; Miller, V.M.; Genzer, J.; Dickey, M.D. Toughening Stretchable Fibers via Serial Fracturing of a Metallic Core. Sci. Adv. 2019, 5, eaat4600. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, G.; Liu, L.; Zhao, Y.; Ning, F.; Jiang, M.; Wu, C. Self-Assembly of Carboxylated Poly(Styrene- b -Ethylene- c o -Butylene- b -Styrene) Triblock Copolymer Chains in Water via a Microphase Inversion. Macromolecules 2000, 33, 6340–6343. [Google Scholar] [CrossRef] [Green Version]

- Dai, P.; Mo, Z.-H.; Xu, R.-W.; Zhang, S.; Wu, Y.-X. Cross-Linked Quaternized Poly(Styrene- b -(Ethylene- Co -Butylene)- b -Styrene) for Anion Exchange Membrane: Synthesis, Characterization and Properties. ACS Appl. Mater. Interfaces 2016, 8, 20329–20341. [Google Scholar] [CrossRef]

- Sierra, C.A.; Galán, C.; Fatou, J.G.; Parellada, M.D.; Barrio, J.A. Thermal and Mechanical Properties of Poly (Styrene-b-Ethylene-Co-Butylene-b-Styrene) Triblock Copolymers. Polymer 1997, 38, 4325–4335. [Google Scholar] [CrossRef]

- Wang, H.; Yuan, B.; Liang, S.; Guo, R.; Rao, W.; Wang, X.; Chang, H.; Ding, Y.; Liu, J.; Wang, L. PLUS-M: A Porous Liquid-Metal Enabled Ubiquitous Soft Material. Mater. Horiz. 2018, 5, 222–229. [Google Scholar] [CrossRef]

- Sin, D.; Singh, V.K.; Bhuyan, P.; Wei, Y.; Lee, H.-M.; Kim, B.-J.; Park, S. Ultrastretchable Thermo- and Mechanochromic Fiber with Healable Metallic Conductivity. Adv. Electron. Mater. 2021, 2100146. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, K.; Choe, M.; Kim, S.; Lee, H.-M.; Kim, B.-J.; Park, S. An Ultrastretchable Electrical Switch Fiber with a Magnetic Liquid Metal Core for Remote Magnetic Actuation. Polymers 2021, 13, 2407. https://doi.org/10.3390/polym13152407

Hong K, Choe M, Kim S, Lee H-M, Kim B-J, Park S. An Ultrastretchable Electrical Switch Fiber with a Magnetic Liquid Metal Core for Remote Magnetic Actuation. Polymers. 2021; 13(15):2407. https://doi.org/10.3390/polym13152407

Chicago/Turabian StyleHong, Kyeongmin, Minjae Choe, Seoyeon Kim, Hye-Min Lee, Byung-Joo Kim, and Sungjune Park. 2021. "An Ultrastretchable Electrical Switch Fiber with a Magnetic Liquid Metal Core for Remote Magnetic Actuation" Polymers 13, no. 15: 2407. https://doi.org/10.3390/polym13152407

APA StyleHong, K., Choe, M., Kim, S., Lee, H.-M., Kim, B.-J., & Park, S. (2021). An Ultrastretchable Electrical Switch Fiber with a Magnetic Liquid Metal Core for Remote Magnetic Actuation. Polymers, 13(15), 2407. https://doi.org/10.3390/polym13152407