Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering

Abstract

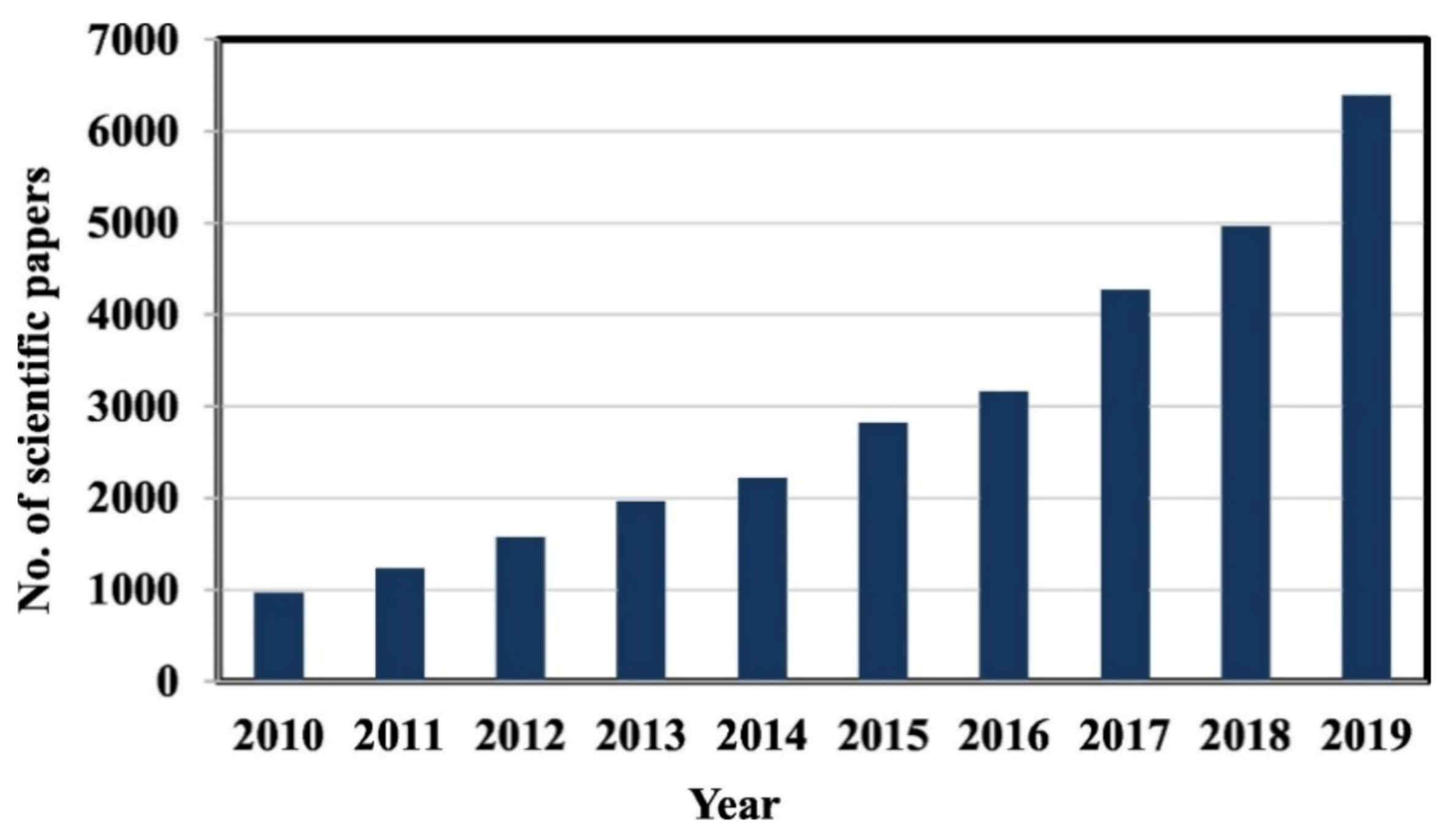

:1. Introduction

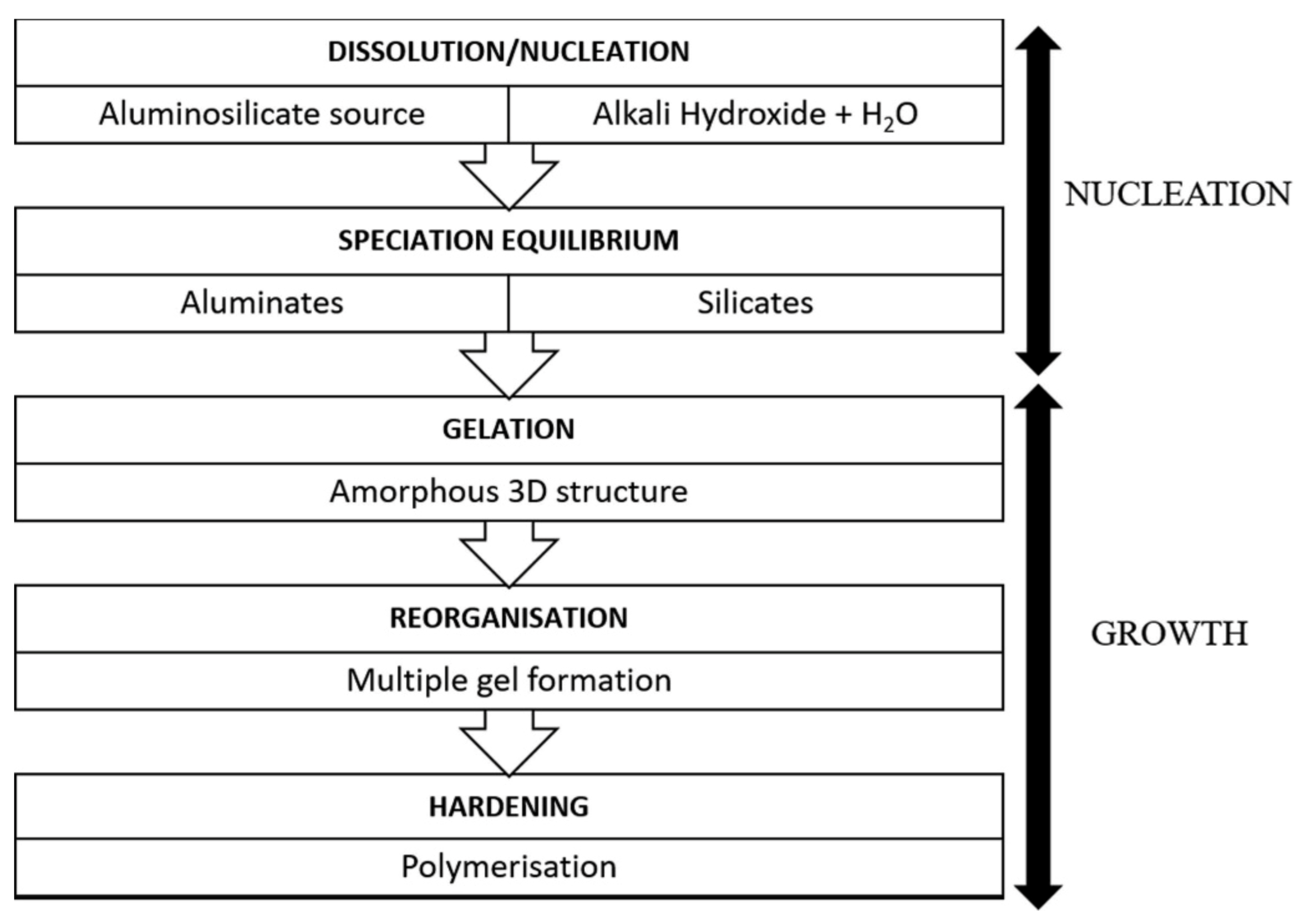

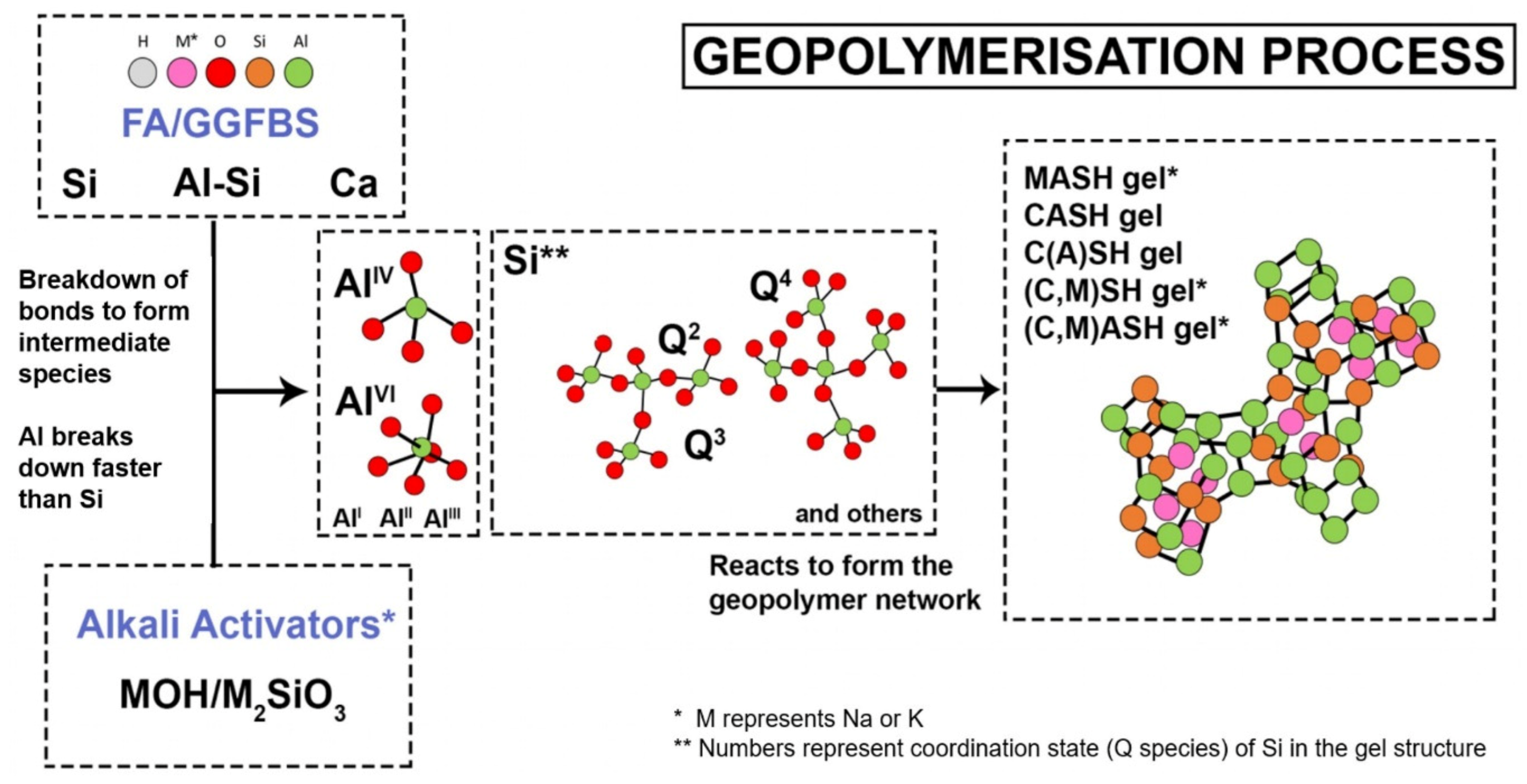

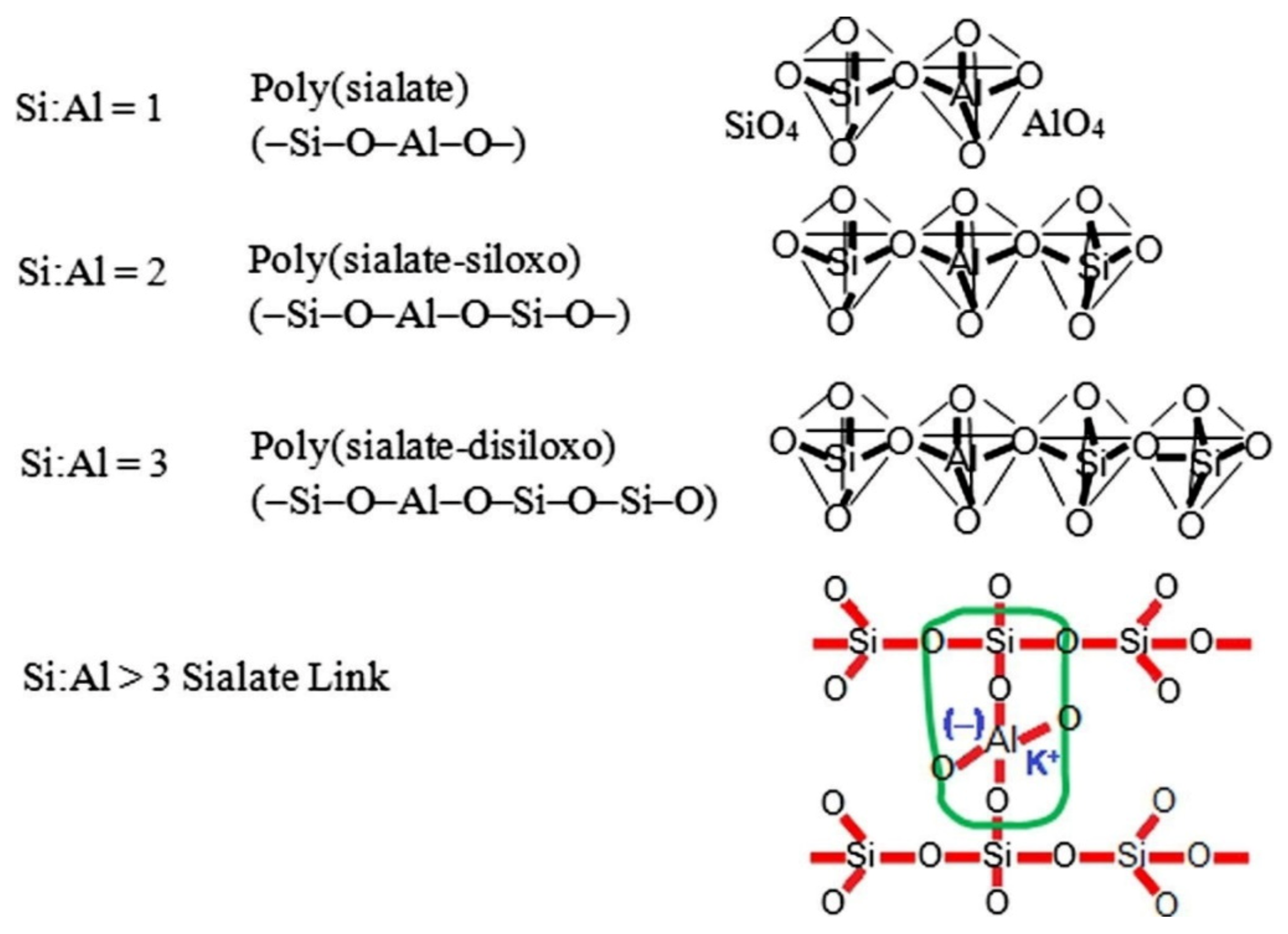

2. Geopolymers

2.1. Factors Affecting on Geopolymers

2.2. Cementitious Materials for Geopolymers

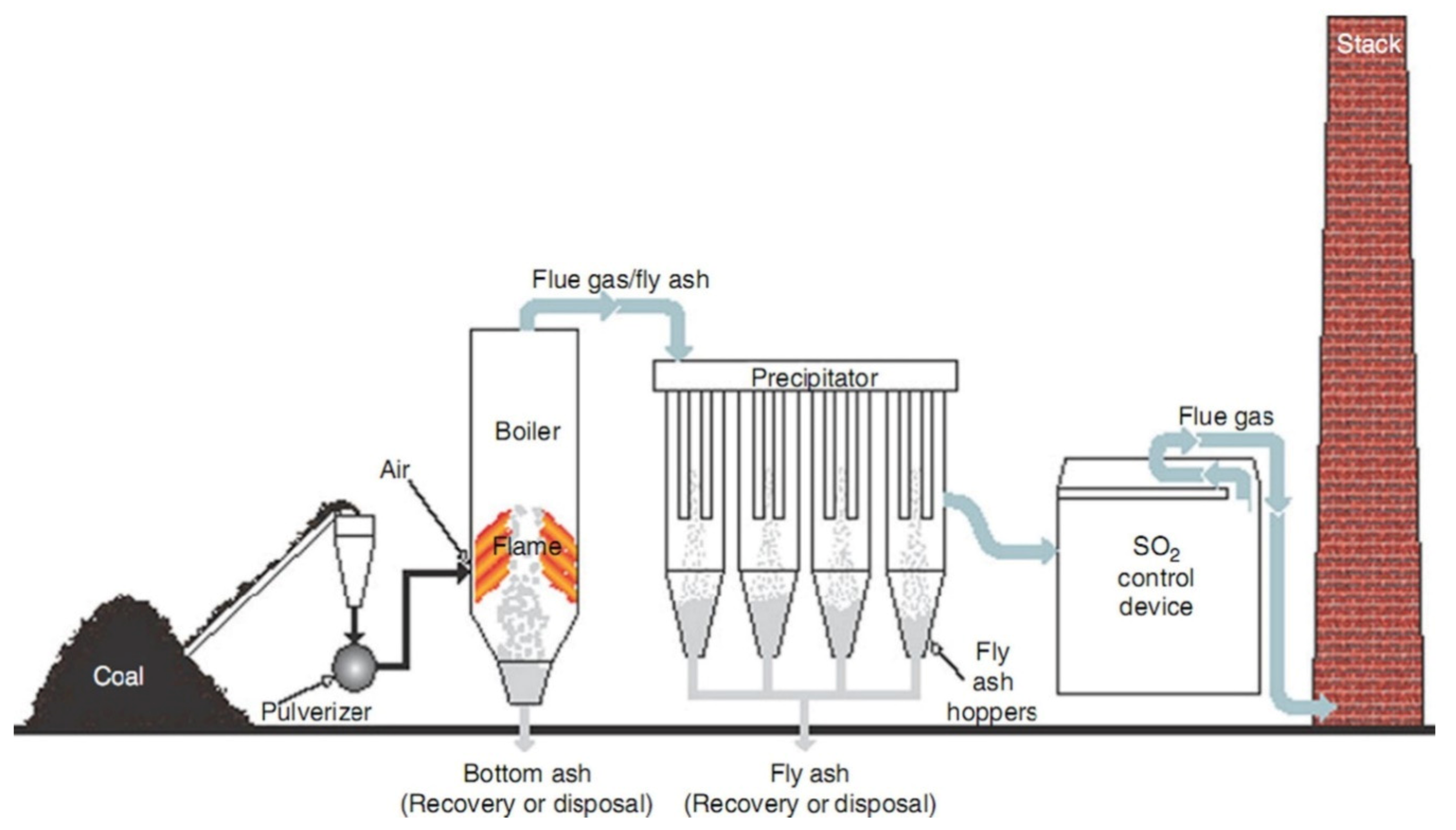

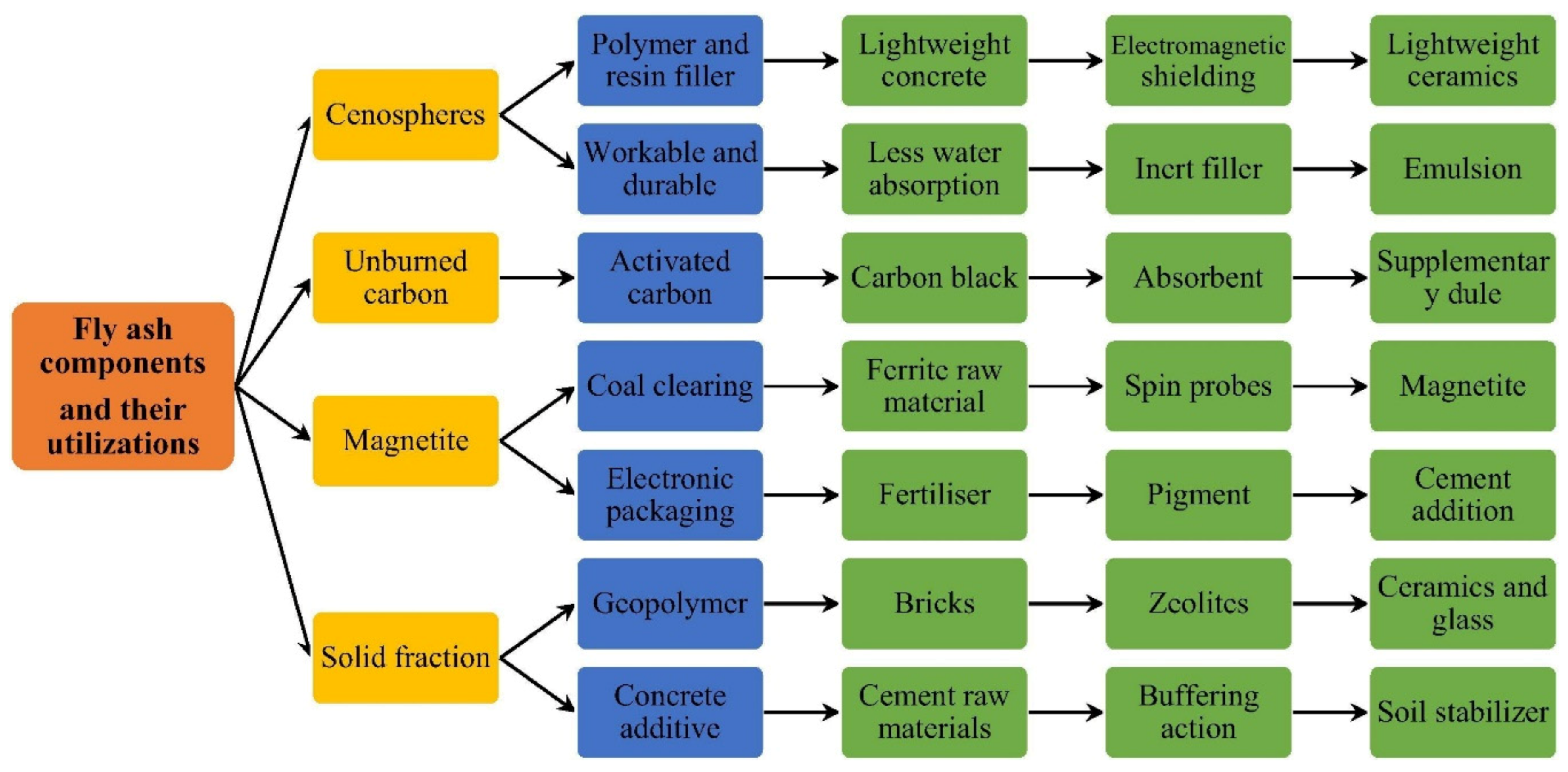

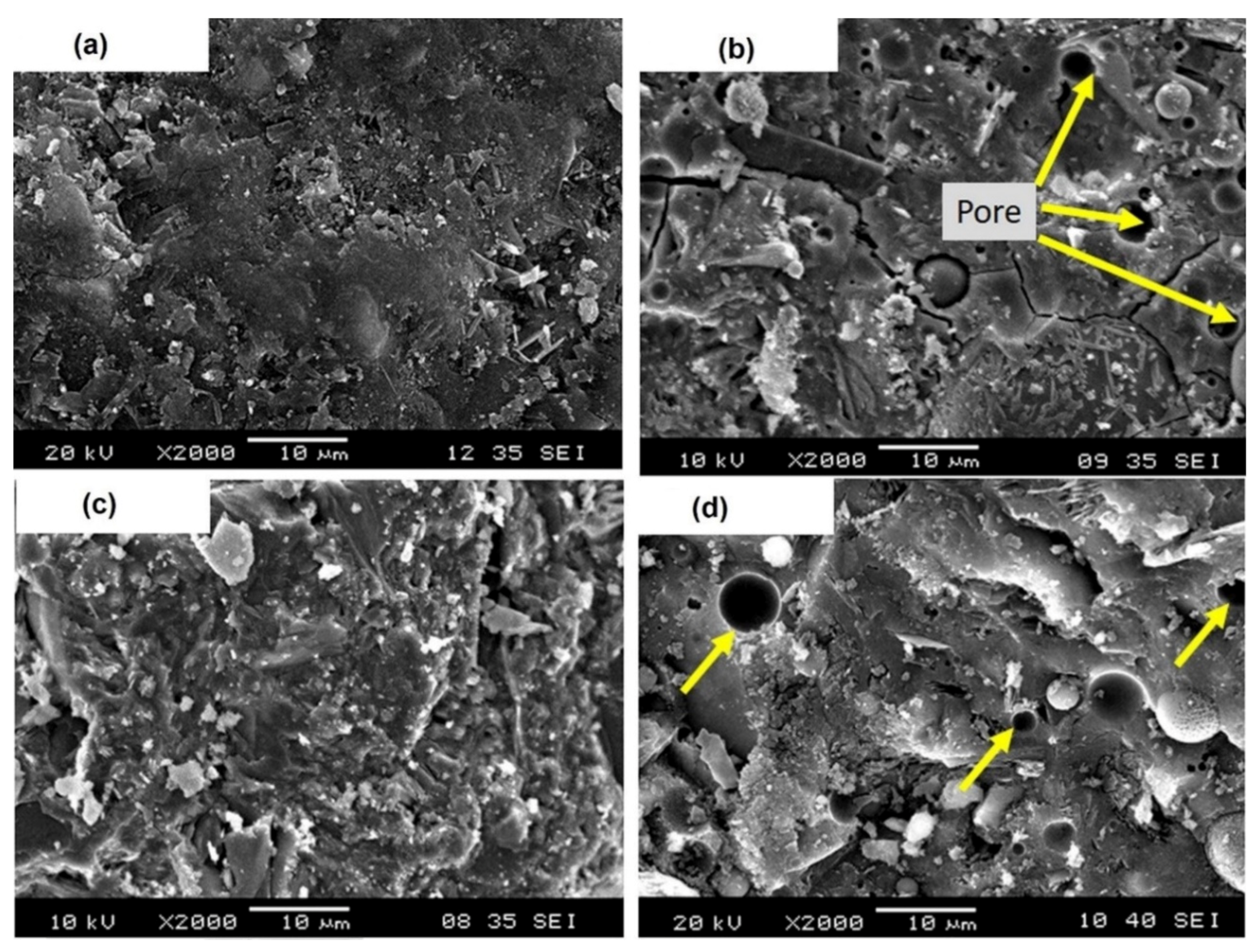

2.2.1. Fly Ash

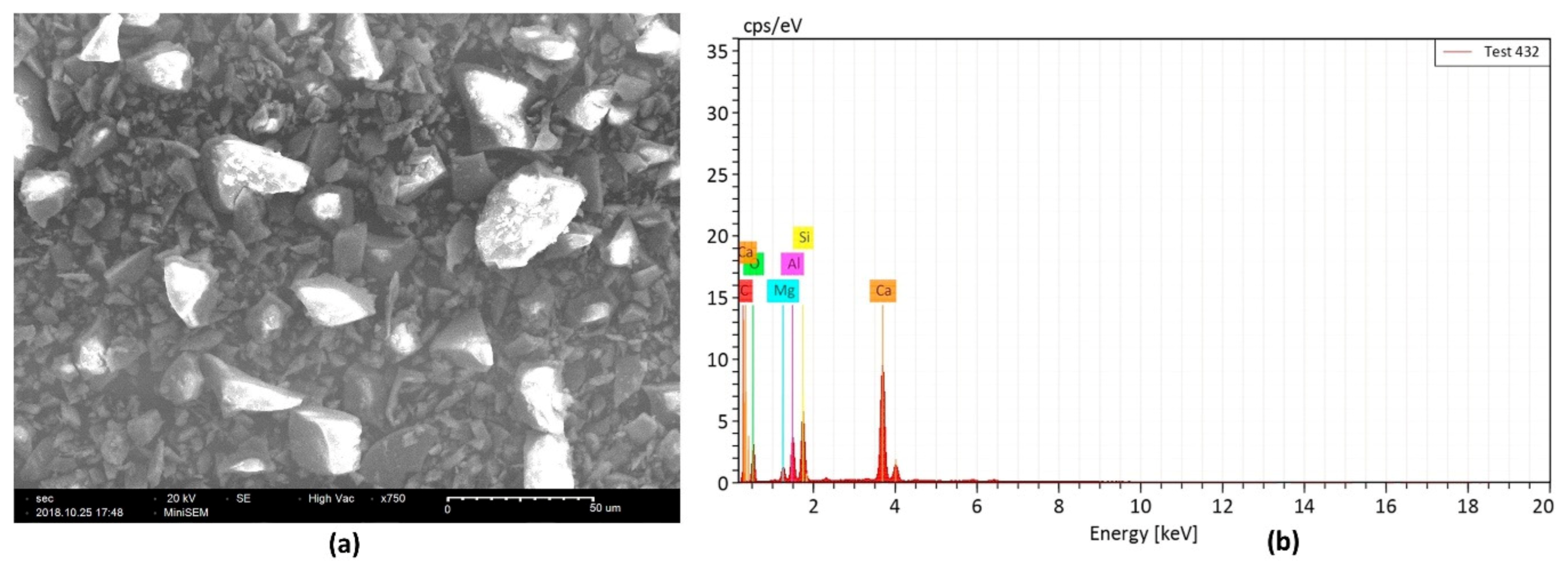

2.2.2. Ground-Granulated Blast Furnace Slag (GGBFS)

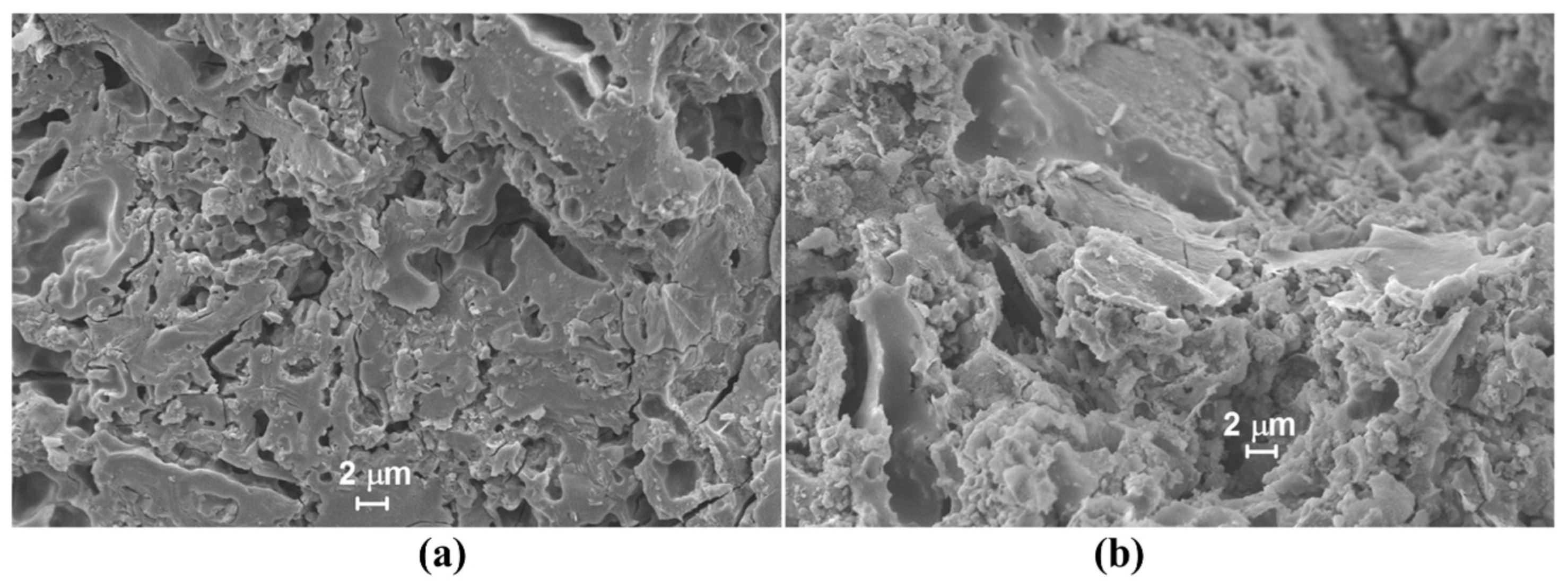

2.2.3. Metakaolin

2.3. Activating Chemical Solutions for Geopolymers

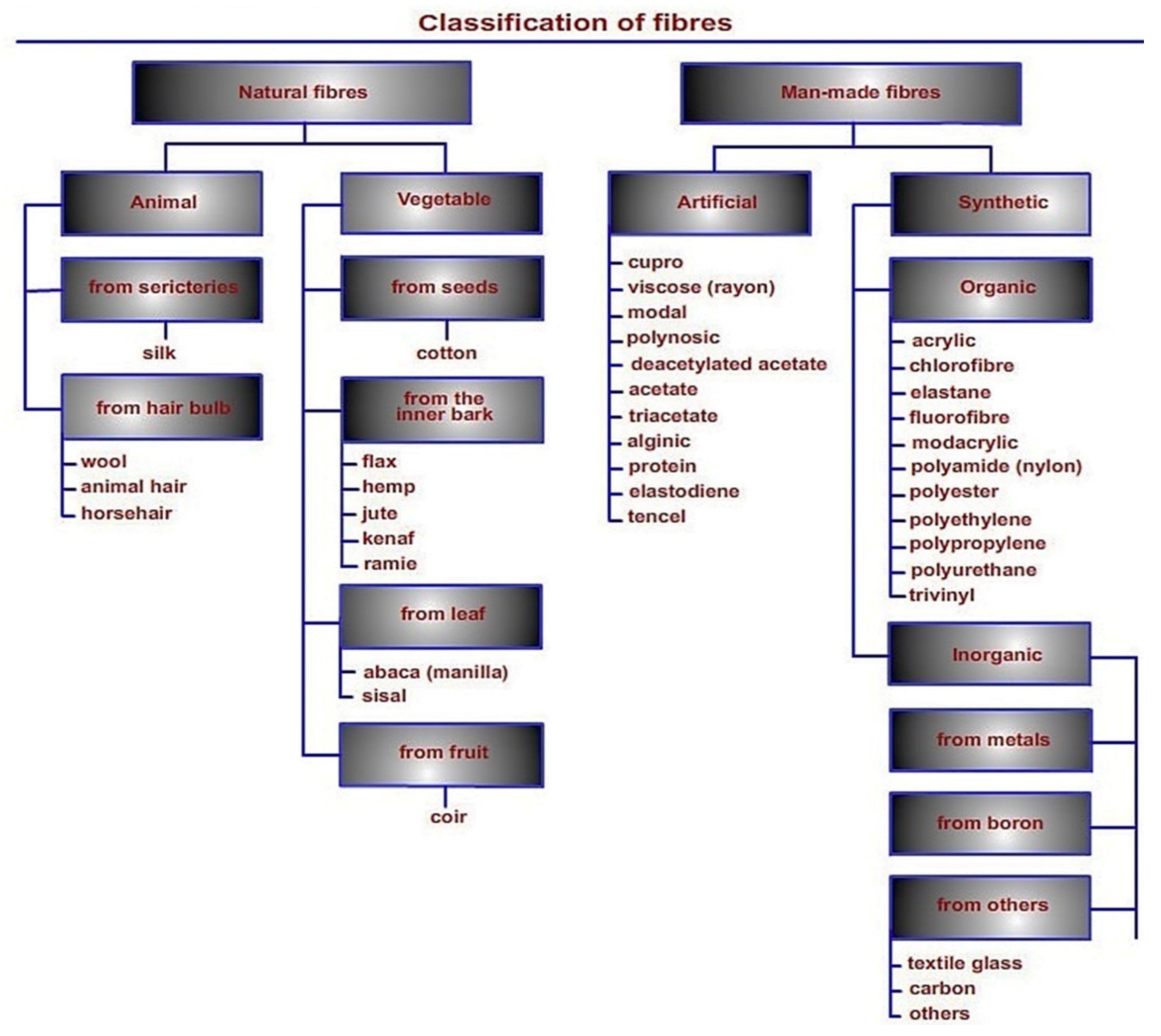

3. Geopolymers and Natural Fiber-Reinforced Composites

3.1. Cellulosic Fiber Reinforced Geopolymer Composites

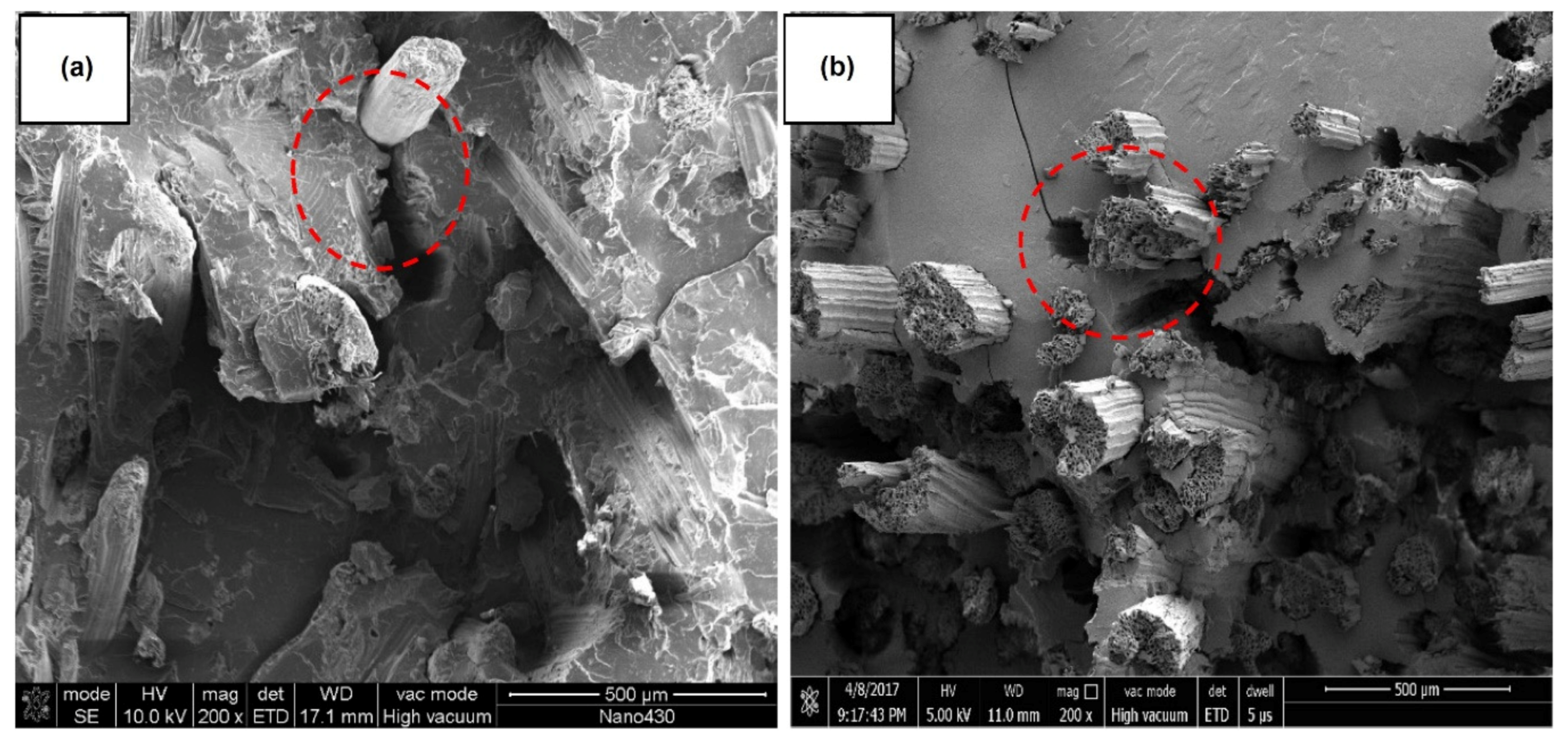

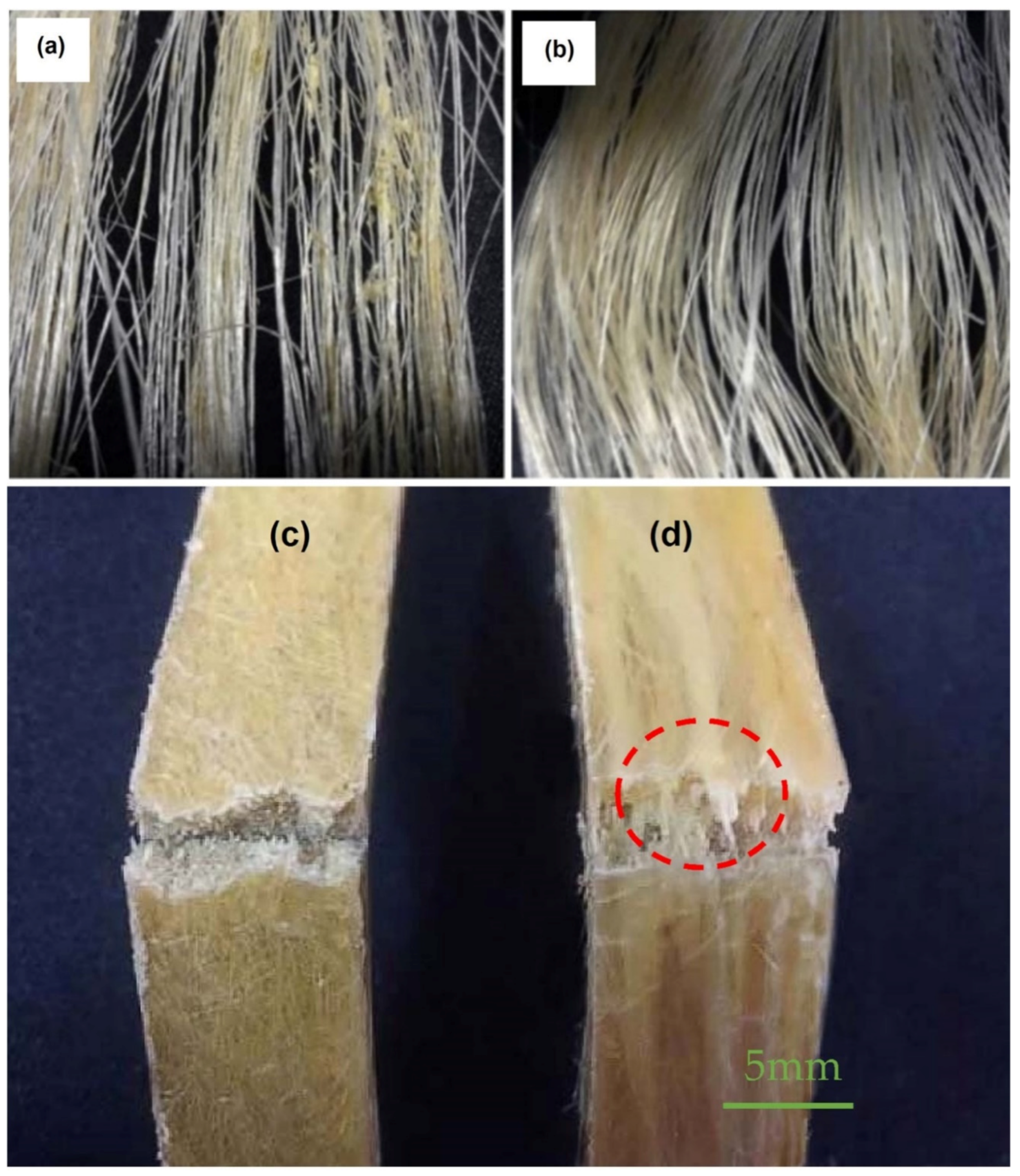

3.1.1. Sisal and Its Composite

3.1.2. Jute and Its Composites

3.2. Inorganic Fiber-Reinforced Geopolymer Composites

3.2.1. Basalt and Its Composites

3.2.2. Glass and Its Composites

4. Summary and Future Direction

- This paper represents the inclusion of selective cellulosic and non-cellulosic fibers in geopolymers-based, fiber-reinforced concrete composites from a construction and civil engineering perspective. Geopolymers are the relatively new materials being employed in the construction industry to replace the use of traditional concrete materials. Due to a number of advantages, interest in developing, characterizing and implementing the use of geopolymers in the construction industry is growing.

- Geopolymer cement-based materials are developed using alumina silicate sources, with fly ash, metakaolin and GGBFS being the most-used ones. First, the properties and uses of these alumino-silicate materials were briefly discussed and represented in this paper. Moreover, the second part discussed the inclusion of fibers as a reinforcement in concrete composites. It is well-known that geopolymers alone cannot respond adequately to certain mechanical properties and hence need to be employed in combination with other suitable materials.

- As discussed in this paper, geopolymers are weak in tension and possess brittle behavior that represents poor tensile/flexural properties. To overcome this problem, one such solution is the inclusion of fibers in geopolymers-based composites. Natural fibers are gaining attention regarding their use in composites due to a number of reasons, including their relatively low density, excellent strength and environmental friendliness.

- This paper examines the use of cellulosic and non-cellulosic fibers in composites for the construction industry. A brief description of sisal, jute, basalt and glass fibers are discussed in this context and represent some recent works conducted in the area.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Shehata, N.; Sayed, E.T.; Abdelkareem, M.A. Recent progress in environmentally friendly geopolymers: A review. Sci. Total Environ. 2020, 762, 143166. [Google Scholar] [CrossRef]

- El-Salamony, A.-H.R.; Mahmoud, H.M.; Shehata, N. Enhancing the efficiency of a cement plant kiln using modified alternative fuel. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100310. [Google Scholar]

- Hasanbeigi, A.; Morrow, W.; Masanet, E.; Sathaye, J.; Xu, T. Energy efficiency improvement and CO2 emission reduction opportunities in the cement industry in China. Energy Policy 2013, 57, 287–297. [Google Scholar] [CrossRef]

- Shafeek, A.M.; Khedr, M.H.; El-Dek, S.I.; Shehata, N. Influence of ZnO nanoparticle ratio and size on mechanical properties and whiteness of White Portland Cement. Appl. Nanosci. 2020, 10, 3603–3615. [Google Scholar] [CrossRef]

- Bajpai, R.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Singh, M. Environmental impact assessment of fly ash and silica fume based geopolymer concrete. J. Clean. Prod. 2020, 254, 120147. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N. Effect of ground granulated blast furnace slag and fly ash ratio and the curing conditions on the mechanical properties of geopolymer concrete. Struct. Concr. 2021. [Google Scholar] [CrossRef]

- Shekhawat, P.; Sharma, G.; Singh, R.M. Microstructural and morphological development of eggshell powder and flyash-based geopolymers. Constr. Build. Mater. 2020, 260, 119886. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Kathirvel, P.; Sreekumaran, S. Sustainable development of ultra high performance concrete using geopolymer technology. J. Build. Eng. 2021, 39, 102267. [Google Scholar] [CrossRef]

- Matalkah, F.; Ababneh, A.; Aqel, R. Efflorescence Control in Calcined Kaolin-Based Geopolymer Using Silica Fume and OPC. J. Mater. Civ. Eng. 2021, 33, 04021119. [Google Scholar] [CrossRef]

- Tchadjie, L.N.; Ekolu, S.O. Enhancing the reactivity of aluminosilicate materials toward geopolymer synthesis. J. Mater. Sci. 2018, 53, 4709–4733. [Google Scholar] [CrossRef]

- Ribeiro, R.A.S.; Ribeiro, M.S.; Kriven, W.M. A review of particle-and fiber-reinforced metakaolin-based geopolymer composites. J. Ceram. Sci. Technol. 2017, 8, 307. [Google Scholar]

- Ali, A.; Sattar, M.; Riaz, T.; Alam Khan, B.; Awais, M.; Militky, J.; Noman, M.T. Highly stretchable durable electro-thermal conductive yarns made by deposition of carbon nanotubes. J. Text. Inst. 2021, 1–10. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Wiener, J.; Farooq, A.; Saskova, J.; Noman, M.T. Development of Maghemite Glass Fibre Nanocomposite for Adsorptive Removal of Methylene Blue. Fibers Polym. 2018, 19, 1735–1746. [Google Scholar] [CrossRef]

- Behera, P.; Noman, M.T.; Petrů, M. Enhanced Mechanical Properties of Eucalyptus-Basalt-Based Hybrid-Reinforced Cement Composites. Polymers 2020, 12, 2837. [Google Scholar] [CrossRef]

- Noman, M.T.; Amor, N.; Petru, M. Synthesis and applications of ZnO nanostructures (ZONSs): A review. Crit. Rev. Solid State Mater. Sci. 2021, 1–43. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Nawaz, M.; Heitor, A.; Sivakumar, M. Geopolymers in construction—Recent developments. Constr. Build. Mater. 2020, 260, 120472. [Google Scholar] [CrossRef]

- Wong, V.; Jervis, W.; Fishburn, B.; Numata, T.; Joe, W.; Rawal, A.; Sorrell, C.C.; Koshy, P. Long-Term Strength Evolution in Ambient-Cured Solid-Activator Geopolymer Compositions. Minerals 2021, 11, 143. [Google Scholar] [CrossRef]

- Ng, C.; Alengaram, U.J.; Wong, L.S.; Mo, K.H.; Jumaat, M.Z.; Ramesh, S. A review on microstructural study and compressive strength of geopolymer mortar, paste and concrete. Constr. Build. Mater. 2018, 186, 550–576. [Google Scholar] [CrossRef]

- Liew, Y.-M.; Heah, C.-Y.; Mustafa, A.B.M.; Kamarudin, H. Structure and properties of clay-based geopolymer cements: A review. Prog. Mater. Sci. 2016, 83, 595–629. [Google Scholar] [CrossRef]

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Sammak, M. Strength and chloride ion penetration resistance of ultra-high-performance fiber reinforced geopolymer concrete. Structures 2021, 32, 1420–1427. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Noman, M.; Petrů, M. Functional Properties of Sonochemically Synthesized Zinc Oxide Nanoparticles and Cotton Composites. Nanomaterials 2020, 10, 1661. [Google Scholar] [CrossRef] [PubMed]

- Noman, M.T.; Petru, M.; Amor, N.; Louda, P. Thermophysiological comfort of zinc oxide nanoparticles coated woven fabrics. Sci. Rep. 2020, 10, 21080. [Google Scholar] [CrossRef] [PubMed]

- Sturm, P.; Gluth, G.; Jäger, C.; Brouwers, H.; Kühne, H.-C. Sulfuric acid resistance of one-part alkali-activated mortars. Cem. Concr. Res. 2018, 109, 54–63. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Li, Y.; Hu, T.; Ni, H.; Zhang, H. Coupling effect of steel slag in preparation of calcium-containing geopolymers with spent fluid catalytic cracking (FCC) catalyst. Constr. Build. Mater. 2021, 290, 123194. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Kriven, W.M.; Bell, J.L.; Gordon, M. Microstructure and Microchemistry of Fully-Reacted Geopolymers and Geopolymer Matrix Composites. Ceram. Transact. 2003, 153, 1994. [Google Scholar]

- Peng, X.; Shuai, Q.; Li, H.; Ding, Q.; Gu, Y.; Cheng, C.; Xu, Z. Fabrication and Fireproofing Performance of the Coal Fly Ash-Metakaolin-Based Geopolymer Foams. Materials 2020, 13, 1750. [Google Scholar] [CrossRef] [Green Version]

- Değirmenci, F.N. Utilization of Natural and Waste Pozzolans as an Alternative Resource of Geopolymer Mortar. Int. J. Civ. Eng. 2018, 16, 179–188. [Google Scholar] [CrossRef]

- Król, M.; Rożek, P.; Mozgawa, W. Synthesis of the Sodalite by Geopolymerization Process Using Coal Fly Ash. Pol. J. Environ. Stud. 2017, 26, 2611–2617. [Google Scholar] [CrossRef]

- Andini, S.; Cioffi, R.; Colangelo, F.; Grieco, T.; Montagnaro, F.; Santoro, L. Coal fly ash as raw material for the manufacture of geopolymer-based products. Waste Manag. 2008, 28, 416–423. [Google Scholar] [CrossRef]

- Zafar, I.; Rashid, K.; Ju, M. Synthesis and characterization of lightweight aggregates through geopolymerization and microwave irradiation curing. J. Build. Eng. 2021, 42, 102454. [Google Scholar] [CrossRef]

- Nuaklong, P.; Wongsa, A.; Boonserm, K.; Ngohpok, C.; Jongvivatsakul, P.; Sata, V.; Sukontasukkul, P.; Chindaprasirt, P. Enhancement of mechanical properties of fly ash geopolymer containing fine recycled concrete aggregate with micro carbon fiber. J. Build. Eng. 2021, 41, 102403. [Google Scholar] [CrossRef]

- Muraleedharan, M.; Nadir, Y. Factors affecting the mechanical properties and microstructure of geopolymers from red mud and granite waste powder: A review. Ceram. Int. 2021, 47, 13257–13279. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Simão, L.; De Rossi, A.; Hotza, D.; Ribeiro, M.J.; Novais, R.M.; Montedo, O.R.K.; Raupp-Pereira, F. Zeolites-containing geopolymers obtained from biomass fly ash: Influence of temperature, composition, and porosity. J. Am. Ceram. Soc. 2020, 104, 803–815. [Google Scholar] [CrossRef]

- Yip, C.K.; Van Deventer, J.S.J. Microanalysis of calcium silicate hydrate gel formed within a geopolymeric binder. J. Mater. Sci. 2003, 38, 3851–3860. [Google Scholar] [CrossRef]

- van Jaarsveld, J.; van Deventer, J.; Lukey, G. The effect of composition and temperature on the properties of fly ash- and kaolinite-based geopolymers. Chem. Eng. J. 2002, 89, 63–73. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Goodier, C.I.; Austin, S.A. Factors affecting the slump and strength development of geopolymer concrete. Constr. Build. Mater. 2020, 261, 119945. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Sarker, P.K.; Long, T.; Shi, X.; Wang, Q.; Cai, G. Investigating Various Factors Affecting the Long-Term Compressive Strength of Heat-Cured Fly Ash Geopolymer Concrete and the Use of Orthogonal Experimental Design Method. Int. J. Concr. Struct. Mater. 2019, 13, 63. [Google Scholar] [CrossRef]

- Zhang, B.; MacKenzie, K.J.D.; Brown, I.W.M. Crystalline phase formation in metakaolinite geopolymers activated with NaOH and sodium silicate. J. Mater. Sci. 2009, 44, 4668–4676. [Google Scholar] [CrossRef]

- De Vargas, A.S.; Molin, D.C.D.; Vilela, A.; da Silva, F.J.; Pavão, B.; Veit, H.M. The effects of Na2O/SiO2molar ratio, curing temperature and age on compressive strength, morphology and microstructure of alkali-activated fly ash-based geopolymers. Cem. Concr. Compos. 2011, 33, 653–660. [Google Scholar] [CrossRef]

- Noman, M.T.; Petru, M.; Militký, J.; Azeem, M.; Ashraf, M.A. One-Pot Sonochemical Synthesis of ZnO Nanoparticles for Photocatalytic Applications, Modelling and Optimization. Materials 2019, 13, 14. [Google Scholar] [CrossRef] [Green Version]

- Phair, J.; Van Deventer, J. Effect of the silicate activator pH on the microstructural characteristics of waste-based geopolymers. Int. J. Miner. Process. 2002, 66, 121–143. [Google Scholar] [CrossRef]

- Kusbiantoro, A.; Ibrahim, M.S.; Muthusamy, K.; Alias, A. Development of Sucrose and Citric Acid as the Natural based Admixture for Fly Ash based Geopolymer. Proc. Environ. Sci. 2013, 17, 596–602. [Google Scholar] [CrossRef] [Green Version]

- Nematollahi, B.; Sanjayan, J. Effect of different superplasticizers and activator combinations on workability and strength of fly ash based geopolymer. Mater. Des. 2014, 57, 667–672. [Google Scholar] [CrossRef]

- Jang, J.; Lee, N.; Lee, H. Fresh and hardened properties of alkali-activated fly ash/slag pastes with superplasticizers. Constr. Build. Mater. 2014, 50, 169–176. [Google Scholar] [CrossRef]

- Palomo, A.; Grutzeck, M.; Blanco-Varela, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Heah, C.; Kamarudin, H.; Al Bakri, A.M.; Binhussain, M.; Luqman, M.; Nizar, I.K.; Ruzaidi, C.; Liew, Y. Effect of Curing Profile on Kaolin-based Geopolymers. Phys. Proc. 2011, 22, 305–311. [Google Scholar] [CrossRef] [Green Version]

- Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Zuhua, Z.; Xiao, Y.; Huajun, Z.; Yue, C. Role of water in the synthesis of calcined kaolin-based geopolymer. Appl. Clay Sci. 2009, 43, 218–223. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.; van Deventer, J.; Lukey, G. The characterisation of source materials in fly ash-based geopolymers. Mater. Lett. 2003, 57, 1272–1280. [Google Scholar] [CrossRef]

- Isaia, G.C.; Gastaldini, A.L.G. Concrete sustainability with very high amount of fly ash and slag. Rev. IBRACON Estrut. Mater. 2009, 2, 244–253. [Google Scholar] [CrossRef] [Green Version]

- Panias, D.; Giannopoulou, I.P.; Perraki, T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 301, 246–254. [Google Scholar] [CrossRef]

- Belviso, C. State-of-the-art applications of fly ash from coal and biomass: A focus on zeolite synthesis processes and issues. Prog. Energy Combust. Sci. 2018, 65, 109–135. [Google Scholar] [CrossRef]

- Yao, Z.; Ji, X.; Sarker, P.; Tang, J.; Ge, L.; Xia, M.; Xi, Y. A comprehensive review on the applications of coal fly ash. Earth Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of chemical composition of fly ash on compressive strength of fly ash cement mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Temuujin, J.; Van Riessen, A.; Williams, R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J. Hazard. Mater. 2009, 167, 82–88. [Google Scholar] [CrossRef]

- Sarkar, A.; Rano, R.; Udaybhanu, G.; Basu, A. A comprehensive characterisation of fly ash from a thermal power plant in Eastern India. Fuel Process. Technol. 2006, 87, 259–277. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of fly ash on Portland cement systems: Part II. High-calcium fly ash. Cem. Concr. Res. 2000, 30, 1647–1654. [Google Scholar] [CrossRef]

- Çiçek, T.; Çinçin, Y. Use of fly ash in production of light-weight building bricks. Constr. Build. Mater. 2015, 94, 521–527. [Google Scholar] [CrossRef]

- Bendapudi, S.C.K.; Saha, P. Contribution of fly ash to the properties of mortar and concrete. Int. J. Earth Sci. Eng. 2011, 4, 1017–1023. [Google Scholar]

- Malhotra, V. Durability of concrete incorporating high-volume of low-calcium (ASTM Class F) fly ash. Cem. Concr. Compos. 1990, 12, 271–277. [Google Scholar] [CrossRef]

- Johari, M.A.M.; Brooks, J.; Kabir, S.; Rivard, P. Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr. Build. Mater. 2011, 25, 2639–2648. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Cheah, C.B.; Tan, L.E.; Ramli, M. Recent advances in slag-based binder and chemical activators derived from industrial by-products—A review. Constr. Build. Mater. 2020, 272, 121657. [Google Scholar] [CrossRef]

- Kumar, V.P.; Gunasekaran, K.; Shyamala, T. Characterization study on coconut shell concrete with partial replacement of cement by GGBS. J. Build. Eng. 2019, 26, 100830. [Google Scholar] [CrossRef]

- Siddique, R.; Bennacer, R. Use of iron and steel industry by-product (GGBS) in cement paste and mortar. Resour. Conserv. Recycl. 2012, 69, 29–34. [Google Scholar] [CrossRef]

- Pal, S.; Mukherjee, A.; Pathak, S. Investigation of hydraulic activity of ground granulated blast furnace slag in concrete. Cem. Concr. Res. 2003, 33, 1481–1486. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Barnett, S.; Soutsos, M.; Millard, S.; Bungey, J. Strength development of mortars containing ground granulated blast-furnace slag: Effect of curing temperature and determination of apparent activation energies. Cem. Concr. Res. 2006, 36, 434–440. [Google Scholar] [CrossRef]

- Oner, A.; Akyuz, S. An experimental study on optimum usage of GGBS for the compressive strength of concrete. Cem. Concr. Compos. 2007, 29, 505–514. [Google Scholar] [CrossRef]

- Sabir, B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Murray, H.H. Traditional and new applications for kaolin, smectite, and palygorskite: A general overview. Appl. Clay Sci. 2000, 17, 207–221. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Zulkifly, K.; Cheng-Yong, H.; Yun-Ming, L.; Abdullah, M.M.A.B.; Shee-Ween, O.; Bin Khalid, M.S. Effect of phosphate addition on room-temperature-cured fly ash-metakaolin blend geopolymers. Constr. Build. Mater. 2021, 270, 121486. [Google Scholar] [CrossRef]

- Cai, R.; He, Z.; Tang, S.; Wu, T.; Chen, E. The early hydration of metakaolin blended cements by non-contact impedance measurement. Cem. Concr. Compos. 2018, 92, 70–81. [Google Scholar] [CrossRef]

- Rashad, A.M. Metakaolin as cementitious material: History, scours, production and composition—A comprehensive overview. Constr. Build. Mater. 2013, 41, 303–318. [Google Scholar] [CrossRef]

- Paiva, H.; Yliniemi, J.; Illikainen, M.; Rocha, F.; Ferreira, V.M. Mine Tailings Geopolymers as a Waste Management Solution for A More Sustainable Habitat. Sustainability 2019, 11, 995. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.-R.; Jia, D.-C.; He, P.-G.; Zhou, Y. Microstructural and mechanical characterization of fly ash cenosphere/metakaolin-based geopolymeric composites. Ceram. Int. 2011, 37, 1661–1666. [Google Scholar] [CrossRef]

- Poon, C.-S.; Azhar, S.; Anson, M.; Wong, Y.-L. Performance of metakaolin concrete at elevated temperatures. Cem. Concr. Compos. 2003, 25, 83–89. [Google Scholar] [CrossRef]

- Khatib, J.; Wild, S. Sulphate Resistance of Metakaolin Mortar. Cem. Concr. Res. 1998, 28, 83–92. [Google Scholar] [CrossRef]

- Khatib, J.; Hibbert, J. Selected engineering properties of concrete incorporating slag and metakaolin. Constr. Build. Mater. 2005, 19, 460–472. [Google Scholar] [CrossRef]

- Neupane, K. Fly ash and GGBFS based powder-activated geopolymer binders: A viable sustainable alternative of portland cement in concrete industry. Mech. Mater. 2016, 103, 110–122. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of availability of source materials for geopolymer/sustainable concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Görhan, G.; Kürklü, G. The influence of the NaOH solution on the properties of the fly ash-based geopolymer mortar cured at different temperatures. Compos. Part. B Eng. 2014, 58, 371–377. [Google Scholar] [CrossRef]

- Sanchindapong, S.; Narattha, C.; Piyaworapaiboon, M.; Sinthupinyo, S.; Chindaprasirt, P.; Chaipanich, A. Microstructure and phase characterizations of fly ash cements by alkali activation. J. Therm. Anal. Calorim. 2020, 142, 1–8. [Google Scholar] [CrossRef]

- Rahim, R.A.; Rahmiati, T.; Azizli, K.A.; Man, Z.; Nuruddin, M.F.; Ismail, L. Comparison of Using NaOH and KOH Activated Fly Ash-Based Geopolymer on the Mechanical Properties. Mater. Sci. Forum 2014, 803, 179–184. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, L.; Liu, M.; Mu, C.; Liang, Y.N.; Hu, X. Role of alkali cation in compressive strength of metakaolin based geopolymers. Ceram. Int. 2017, 43, 3811–3817. [Google Scholar] [CrossRef]

- Fu, C.; Ye, H.; Zhu, K.; Fang, D.; Zhou, J. Alkali cation effects on chloride binding of alkali-activated fly ash and metakaolin geopolymers. Cem. Concr. Compos. 2020, 114, 103721. [Google Scholar] [CrossRef]

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Metselaar, H.S.C.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Bertolotti, B.; Nakamatsu, J.; Aguilar, R. Optimization of a reinforced geopolymer composite using natural fibers and construction wastes. Constr. Build. Mater. 2020, 258, 119697. [Google Scholar] [CrossRef]

- Amor, N.; Noman, M.T.; Petru, M. Prediction of functional properties of nano TiO2 coated cotton composites by artificial neural network. Sci. Rep. 2021, 11, 1–11. [Google Scholar] [CrossRef]

- Noman, M.T.; Petru, M.; Louda, P.; Kejzlar, P. Woven textiles coated with zinc oxide nanoparticles and their thermophysiological comfort properties. J. Nat. Fiber 2021, 18, 1–14. [Google Scholar] [CrossRef]

- Arisoy, B.; Wu, H.-C. Material characteristics of high performance lightweight concrete reinforced with PVA. Constr. Build. Mater. 2008, 22, 635–645. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Review of mechanical properties of short fibre reinforced geopolymer composites. Constr. Build. Mater. 2013, 43, 37–49. [Google Scholar] [CrossRef] [Green Version]

- Jamshaid, H.; Mishra, R.; Militký, J.; Noman, M.T. Interfacial performance and durability of textile reinforced concrete. J. Text. Inst. 2017, 109, 879–890. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R.; Militky, J.; Pechociakova, M.; Noman, M.T. Mechanical, thermal and interfacial properties of green composites from basalt and hybrid woven fabrics. Fibers Polym. 2016, 17, 1675–1686. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Noman, M.T.; Ashraf, M.A.; Ali, A. Synthesis and applications of nano-TiO2: A review. Environ. Sci. Pollut. Res. 2019, 26, 3262–3291. [Google Scholar] [CrossRef]

- Noman, M.T.; Ashraf, M.A.; Jamshaid, H.; Ali, A. A Novel Green Stabilization of TiO2 Nanoparticles onto Cotton. Fibers Polym. 2018, 19, 2268–2277. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part. B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Savastano, H., Jr.; Warden, P.G.; Coutts, R. Mechanically pulped sisal as reinforcement in cementitious matrices. Cem. Concr. Compos. 2003, 25, 311–319. [Google Scholar] [CrossRef]

- Morton, J.; Cooke, T.; Akers, S. Performance of slash pine fibers in fiber cement products. Constr. Build. Mater. 2010, 24, 165–170. [Google Scholar] [CrossRef]

- Noman, M.; Amor, N.; Petru, M.; Mahmood, A.; Kejzlar, P. Photocatalytic Behaviour of Zinc Oxide Nanostructures on Surface Activation of Polymeric Fibres. Polymers 2021, 13, 1227. [Google Scholar] [CrossRef]

- Azwa, Z.; Yousif, B.; Manalo, A.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef] [Green Version]

- Ardanuy, M.; Claramunt, J.; Filho, R.T. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Al-Oraimi, S.; Seibi, A. Mechanical characterisation and impact behaviour of concrete reinforced with natural fibres. Compos. Struct. 1995, 32, 165–171. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Impact strength of a few natural fibre reinforced cement mortar slabs: A comparative study. Cem. Concr. Compos. 2005, 27, 547–553. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Amuthakkannan, P.; Chandrasekar, M. Mechanical and physical properties of sisal and hybrid sisal fiber-reinforced polymer composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier BV: Amsterdam, The Netherlands, 2019; pp. 427–440. [Google Scholar]

- Kumre, A.; Rana, R.; Purohit, R. A Review on mechanical property of sisal glass fiber reinforced polymer composites. Mater. Today Proc. 2017, 4, 3466–3476. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites–A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Kumar, P.S.S.; Allamraju, K.V. A Review of Natural Fiber Composites [Jute, Sisal, Kenaf]. Mater. Today Proc. 2019, 18, 2556–2562. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Idicula, M.; Neelakantan, N.R.; Oommen, Z.; Joseph, K.; Thomas, S. A study of the mechanical properties of randomly oriented short banana and sisal hybrid fiber reinforced polyester composites. J. Appl. Polym. Sci. 2005, 96, 1699–1709. [Google Scholar] [CrossRef]

- Liang, Z.; Wu, H.; Liu, R.; Wu, C. Preparation of Long Sisal Fiber-Reinforced Polylactic Acid Biocomposites with Highly Improved Mechanical Performance. Polymers 2021, 13, 1124. [Google Scholar] [CrossRef]

- Prasad, A.R.; Rao, K.M. Mechanical properties of natural fibre reinforced polyester composites: Jowar, sisal and bamboo. Mater. Des. 2011, 32, 4658–4663. [Google Scholar] [CrossRef]

- Hashmi, S.; Rajput, R.S.; Naik, A.; Chand, N.; Singh, R. Investigations on weld joining of sisal CSM-thermoplastic composites. Polym. Compos. 2014, 36, 214–220. [Google Scholar] [CrossRef]

- De Castro, B.D.; Fotouhi, M.; Vieira, L.M.G.; De Faria, P.E.; Rubio, J.C.C. Mechanical Behaviour of a Green Composite from Biopolymers Reinforced with Sisal Fibres. J. Polym. Environ. 2021, 29, 429–440. [Google Scholar] [CrossRef]

- Rajesh, G.; Prasad, A.R.; Gupta, A. Mechanical and degradation properties of successive alkali treated completely biodegradable sisal fiber reinforced poly lactic acid composites. J. Reinf. Plast. Compos. 2015, 34, 951–961. [Google Scholar] [CrossRef]

- Savastano, H., Jr.; Warden, P.; Coutts, R. Brazilian waste fibres as reinforcement for cement-based composites. Cem. Concr. Compos. 2000, 22, 379–384. [Google Scholar] [CrossRef]

- Baloyi, R.B.; Ncube, S.; Moyo, M.; Nkiwane, L.; Dzingai, P. Analysis of the properties of a glass/sisal/polyester composite. Sci. Rep. 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Bahja, B.; Elouafi, A.; Tizliouine, A.; Omari, L. Morphological and structural analysis of treated sisal fibers and their impact on mechanical properties in cementitious composites. J. Build. Eng. 2021, 34, 102025. [Google Scholar] [CrossRef]

- Ren, G.; Yao, B.; Huang, H.; Gao, X. Influence of sisal fibers on the mechanical performance of ultra-high performance concretes. Constr. Build. Mater. 2021, 286, 122958. [Google Scholar] [CrossRef]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of Steel and Macro-Synthetic Fibers on Concrete Properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef] [Green Version]

- Chalioris, C.E.; Panagiotopoulos, T.A. Flexural analysis of steel fibre-reinforced concrete members. Comput. Concr. 2018, 22, 11–25. [Google Scholar]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G. Analysis of Residual Flexural Stiffness of Steel Fiber-Reinforced Concrete Beams with Steel Reinforcement. Materials 2020, 13, 2698. [Google Scholar] [CrossRef]

- Choi, S.-W.; Choi, J.; Lee, S.-C. Probabilistic Analysis for Strain-Hardening Behavior of High-Performance Fiber-Reinforced Concrete. Materials 2019, 12, 2399. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, K.; Pan, L.; Li, J.; Lin, C. What is the mechanism of the fiber effect on the rheological behavior of cement paste with polycarboxylate superplasticizer? Constr. Build. Mater. 2021, 281, 122542. [Google Scholar] [CrossRef]

- Okeola, A.A.; Mwero, J.; Bello, A. Behavior of sisal fiber-reinforced concrete in exterior beam-column joint under monotonic loading. Asian J. Civ. Eng. 2021, 22, 627–636. [Google Scholar] [CrossRef]

- De Andrare Silva, F.; Toledo Filho, R.D.; de Almeida Melo Filho, J.; Fairbairn, E.D.M.R. Physical and mechanical properties of durable sisal fiber–cement composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Sever, K.; Sarikanat, M.; Seki, Y.; Erkan, G.; Erdogan, U.H.; Erden, S. Surface treatments of jute fabric: The influence of surface characteristics on jute fabrics and mechanical properties of jute/polyester composites. Ind. Crops Prod. 2012, 35, 22–30. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A Review of Natural Fibers Used in Biocomposites: Plant, Animal and Regenerated Cellulose Fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Noman, M.T.; Wiener, J.; Saskova, J.; Ashraf, M.A.; Vikova, M.; Jamshaid, H.; Kejzlar, P. In-situ development of highly photocatalytic multifunctional nanocomposites by ultrasonic acoustic method. Ultrason. Sonochem. 2018, 40, 41–56. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A review on natural fiber reinforced composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Alshaaer, M. Synthesis, Characterization, and Recyclability of a Functional Jute-Based Geopolymer Composite. Front. Built Environ. 2021, 7, 38. [Google Scholar] [CrossRef]

- Khondker, O.; Ishiaku, U.; Nakai, A.; Hamada, H. A novel processing technique for thermoplastic manufacturing of unidirectional composites reinforced with jute yarns. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2274–2284. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Krishnamurthy, K.; Rajeshkumar, G.; Asim, M. Dynamic Mechanical Properties and Free Vibration Characteristics of Surface Modified Jute Fiber/Nano-Clay Reinforced Epoxy Composites. J. Polym. Environ. 2021, 29, 1076–1088. [Google Scholar] [CrossRef]

- Yao, X.; Liu, K.; Huang, G.; Wang, M.; Dong, X. Mechanical Properties and Durability of Deep Soil–Cement Column Reinforced by Jute and PVA Fiber. J. Mater. Civ. Eng. 2021, 33, 04021021. [Google Scholar] [CrossRef]

- Da Fonseca, R.P.; Rocha, J.C.; Cheriaf, M. Mechanical Properties of Mortars Reinforced with Amazon Rainforest Natural Fibers. Materials 2020, 14, 155. [Google Scholar] [CrossRef]

- Sankar, K.; Kriven, W.M. Sodium geopolymer reinforced with jute weave. In Developments in Strategic Materials and Computational Design V; Kriven, W.M., Zhou, D., Moon, K., Hwang, T., Wang, J., Lewinssohn, C., Zhou, Y., Eds.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2015; pp. 39–60. [Google Scholar]

- Trindade, A.C.; Arêas, I.O.; Almeida, D.C.; Alcamand, H.A.; Borges, P.H.; Silva, F.A. Mechanical behavior of geopolymeric composites reinforced with natural fibers. In Proceedings of the International Conference on Strain-Hardening Cement-Based Composites, Dresden, Germany, 18–20 September 2017; pp. 383–391. [Google Scholar]

- Bheel, N.; Sohu, S.; Awoyera, P.; Kumar, A.; Abbasi, S.A.; Olalusi, O.B. Effect of Wheat Straw Ash on Fresh and Hardened Concrete Reinforced with Jute Fiber. Adv. Civ. Eng. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Fonseca, C.S.; Scatolino, M.V.; Silva, L.E.; Martins, M.A.; Júnior, M.G.; Tonoli, G.H.D. Valorization of Jute Biomass: Performance of Fiber–Cement Composites Extruded with Hybrid Reinforcement (Fibers and Nanofibrils). Waste Biomass Valorizat 2021, 19. [Google Scholar] [CrossRef]

- Bernal, S.A.; Bejarano, J.; Garzón, C.; de Gutiérrez, R.M.; Delvasto, S.; Rodríguez, E.D. Performance of refractory aluminosilicate particle/fiber-reinforced geopolymer composites. Compos. Part B Eng. 2012, 43, 1919–1928. [Google Scholar] [CrossRef]

- Welter, M.; Schmücker, M.; MacKenzie, K. Evolution of the fibre-matrix interactions in basalt-fibre-reinforced geopolymer-matrix composites after heating. J. Ceram. Sci. Technol. 2015, 6, 17–24. [Google Scholar]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L.; Burman, M. Static and fatigue characterisation of new basalt fibre reinforced composites. Compos. Struct. 2012, 94, 1165–1174. [Google Scholar] [CrossRef]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Dehkordi, M.T.; Nosraty, H.; Shokrieh, M.M.; Minak, G.; Ghelli, D. The influence of hybridization on impact damage behavior and residual compression strength of intraply basalt/nylon hybrid composites. Mater. Des. 2013, 43, 283–290. [Google Scholar] [CrossRef]

- Noman, M.T.; Petru, M.; Amor, N.; Yang, T.; Mansoor, T. Thermophysiological comfort of sonochemically synthesized nano TiO2 coated woven fabrics. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Tensile behavior contrast of basalt and glass fibers after chemical treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Masi, G.; Rickard, W.; Bignozzi, M.C.; van Riessen, A. The effect of organic and inorganic fibres on the mechanical and thermal properties of aluminate activated geopolymers. Compos. Part B Eng. 2015, 76, 218–228. [Google Scholar] [CrossRef]

- Hou, X.; Yao, S.; Wang, Z.; Fang, C.; Li, T. Enhancement of the mechanical properties of polylactic acid/basalt fiber composites via in-situ assembling silica nanospheres on the interface. J. Mater. Sci. Technol. 2021, 84, 182–190. [Google Scholar] [CrossRef]

- Le, C.; Louda, P.; Buczkowska, K.E.; Dufkova, I. Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite. Polymers 2021, 13, 751. [Google Scholar] [CrossRef]

- Kim, M.; Rhee, K.; Park, S.; Hui, D. Effects of silane-modified carbon nanotubes on flexural and fracture behaviors of carbon nanotube-modified epoxy/basalt composites. Compos. Part B Eng. 2012, 43, 2298–2302. [Google Scholar] [CrossRef]

- Szabó, J.; Czigány, T. Static fracture and failure behavior of aligned discontinuous mineral fiber reinforced polypropylene composites. Polym. Test. 2003, 22, 711–719. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, C.; Chu, P.K.; Lv, F.; Zhang, C.; Ji, J.; Zhang, R.; Wang, H. Mechanical and thermal properties of basalt fiber reinforced poly(butylene succinate) composites. Mater. Chem. Phys. 2012, 133, 845–849. [Google Scholar] [CrossRef]

- Punurai, W.; Kroehong, W.; Saptamongkol, A.; Chindaprasirt, P. Mechanical properties, microstructure and drying shrinkage of hybrid fly ash-basalt fiber geopolymer paste. Constr. Build. Mater. 2018, 186, 62–70. [Google Scholar] [CrossRef]

- Li, W.; Xu, J. Mechanical properties of basalt fiber reinforced geopolymeric concrete under impact loading. Mater. Sci. Eng. A 2009, 505, 178–186. [Google Scholar] [CrossRef]

- Yang, L.; Xie, H.; Fang, S.; Huang, C.; Chao, Y.J. Experimental study on mechanical properties and damage mechanism of basalt fiber reinforced concrete under uniaxial compression. Structures 2021, 31, 330–340. [Google Scholar] [CrossRef]

- Shen, D.; Li, M.; Kang, J.; Liu, C.; Li, C. Experimental studies on the seismic behavior of reinforced concrete beam-column joints strengthened with basalt fiber-reinforced polymer sheets. Constr. Build. Mater. 2021, 287, 122901. [Google Scholar] [CrossRef]

- Ashik, K.P.; Sharma, R.S. A Review on Mechanical Properties of Natural Fiber Reinforced Hybrid Polymer Composites. J. Miner. Mater. Charact. Eng. 2015, 3, 420–426. [Google Scholar] [CrossRef]

- Noman, M.T.; Militky, J.; Wiener, J.; Saskova, J.; Ashraf, M.A.; Jamshaid, H.; Azeem, M. Sonochemical synthesis of highly crystalline photocatalyst for industrial applications. Ultrasonics 2018, 83, 203–213. [Google Scholar] [CrossRef]

- Noman, M.T.; Petru, M. Effect of Sonication and Nano TiO2 on Thermophysiological Comfort Properties of Woven Fabrics. ACS Omega 2020, 5, 11481–11490. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinforc. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Zhang, M.; Matinlinna, J.P. E-Glass Fiber Reinforced Composites in Dental Applications. Silicon 2012, 4, 73–78. [Google Scholar] [CrossRef] [Green Version]

- XiaoChun, Q.; Xiaoming, L.; Xiaopei, C. The applicability of alkaline-resistant glass fiber in cement mortar of road pavement: Corrosion mechanism and performance analysis. Int. J. Pavement Res. Technol. 2017, 10, 536–544. [Google Scholar] [CrossRef]

- Arslan, M.E.; Aykanat, B.; Subaşı, S.; Maraşlı, M. Cyclic behavior of autoclaved aerated concrete block infill walls strengthened by basalt and glass fiber composites. Eng. Struct. 2021, 240, 112431. [Google Scholar] [CrossRef]

- Faizal, M.A.; Beng, Y.K.; Dalimin, M.N. Tensile property of hand lay-up plain-weave woven e-glass/polyester composite: Curing pressure and Ply arrangement effect. Borneo Sci. 2006, 19, 27–34. [Google Scholar]

- Kushwaha, P.K.; Kumar, R. The studies on performance of epoxy and polyester-based composites reinforced with bamboo and glass fibers. J. Reinforc. Plast. Compos. 2010, 29, 1952–1962. [Google Scholar] [CrossRef]

- Devendra, K.; Rangaswamy, T. Strength Characterization of E-glass Fiber Reinforced Epoxy Composites with Filler Materials. J. Miner. Mater. Charact. Eng. 2013, 01, 353–357. [Google Scholar] [CrossRef] [Green Version]

- Etcheverry, M.; Barbosa, S.E. Glass fiber reinforced polypropylene mechanical properties enhancement by adhesion improvement. Materials 2012, 5, 1084–1113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tungjitpornkull, S.; Chaochanchaikul, K.; Sombatsompop, N.; Tungjitpornkull, S.; Chaochanchaikul, K.; Sombatsompop, N. Mechanical Characterization of E-Chopped Strand Glass Fiber Reinforced Wood/PVC Composites. J. Thermoplast. Compos. Mater. 2007, 20, 535–550. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Lü, R.; Li, T. Mechanical and tribological properties of PA66/PPS blend. III. Reinforced with GF. J. Appl. Polym. Sci. 2006, 102, 523–529. [Google Scholar] [CrossRef]

- Cheng, C.; He, J.; Zhang, J.; Yang, Y. Study on the time-dependent mechanical properties of glass fiber reinforced cement (GRC) with fly ash or slag. Constr. Build. Mater. 2019, 217, 128–136. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, B.; Oderji, S.Y. Experimental research on magnesium phosphate cement mortar reinforced by glass fiber. Constr. Build. Mater. 2018, 188, 729–736. [Google Scholar] [CrossRef]

- Giese, A.C.H.; Giese, D.N.; Dutra, V.F.P.; Da Silva Filho, L.C.P. Flexural behavior of reinforced concrete beams strengthened with textile reinforced mortar. J. Build. Eng. 2021, 33, 101873. [Google Scholar] [CrossRef]

| Constituents | Composition | Temperature [°C] | Time [Days] | Chemicals | Compressive Strength [MPa] | References |

|---|---|---|---|---|---|---|

| Coal fly ash & metakaolin | - | 250 | 3 | NaOH | - | [34] |

| Fly ash, GGBFS & zeolite | Al/Si | 32 | 1 | NaOH | 100 | [35] |

| Coal fly ash | Al/Si | 80 | 1 | NaOH | 18 | [36] |

| Fly ash | SiO2/Al2O3 | 85 | 3 | KOH | 19 | [37] |

| Fly Ash | Coal Type | Chemical Composition (wt.%) | Physical Properties | Ref. | ||||||||||

| SiO2 | CaO | Al2O3 | MgO | SO3 | Fe2O3 | K2O | Na2O | TiO2 | Specific Surface Area (m2/kg) | Specific Gravity | Bulk Density (kg/m3) | |||

| Sub-bituminous | 40–60 | 5–30 | 20–30 | 1–6 | 0–2 | 4–10 | 0–4 | 0–2 | - | 170–1000 | 2.1–3.0 | 540–860 | [61,62] | |

| Lignite | 15–45 | 15–40 | 10–25 | 3–10 | 0–10 | 4–15 | 0–4 | 0–6 | - | |||||

| Bituminous | 20–60 | 1–12 | 5–35 | 0–5 | 0–4 | 10–40 | 0–3 | 0–4 | - | |||||

| Anthracite | 28–57 | 1–27 | 18–36 | 1–4 | 0–9 | 3–16 | 0–4 | 0–1 | - | |||||

| GGBFS | 28–40 | 30–50 | 8–24 | 1–18 | 0.23–1.3 | - | - | - | - | 300–500 | 2.4–3.0 | 1200 | [73,75] | |

| Metakaolin | 51.9 | 0.11 | 45.39 | - | - | 0.92 | 0.45 | - | 0.76 | 10,000–29,000 | 2.2–2.6 | 300–400 | [82,85,86] | |

| Fiber Name | Chemical Composition (wt.%) | Physico-Mechanical Properties | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | Equilibrium Moisture Content (%) | ||

| Sisal | 67–78 | 10–14.2 | 8–11 | 1.03–1.45 | 347–700 | 15.4–18.79 | 2–2.5 | 12 | [119,122,123] |

| Jute | 60 | 22 | 12 | 1.3 | 393–773 | 26.5 | 1.5–1.8 | 12 | [145,146] |

| Fiber Name | Chemical Composition (wt.%) | Physico-Mechanical Properties | Ref. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | Na2O | B2O3 | Others | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | ||

| Basalt | 52.8 | 17.5 | 8.59 | 4.63 | 10.3 | 3.34 | - | ~3.34 | 2.65–2.83 | 3000–4840 | 89–110 | 3–3.15 | [99,158] |

| E-glass | 52–56 | 12–16 | 16–25 | 0–5 | - | - | 5–10 | - | 2.58 | 1.7–3.5 | 69–72 | 4.8 | [177] |

| S-glass | 65 | 25 | - | 10 | - | - | - | - | 2.48 | 2–4.5 | 85 | 5.7 | |

| AR-glass | 55–75 | 0–5 | 1–10 | - | - | - | 0–8 | - | 2.7 | 3.24 | 73.1 | 4.4 | |

| C-glass | 65 | 4 | 14 | 3 | - | - | 5.5 | - | 2.52 | 1.7–2.8 | 68.9 | 4.8 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. https://doi.org/10.3390/polym13132099

Mahmood A, Noman MT, Pechočiaková M, Amor N, Petrů M, Abdelkader M, Militký J, Sozcu S, Hassan SZU. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers. 2021; 13(13):2099. https://doi.org/10.3390/polym13132099

Chicago/Turabian StyleMahmood, Aamir, Muhammad Tayyab Noman, Miroslava Pechočiaková, Nesrine Amor, Michal Petrů, Mohamed Abdelkader, Jiří Militký, Sebnem Sozcu, and Syed Zameer Ul Hassan. 2021. "Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering" Polymers 13, no. 13: 2099. https://doi.org/10.3390/polym13132099

APA StyleMahmood, A., Noman, M. T., Pechočiaková, M., Amor, N., Petrů, M., Abdelkader, M., Militký, J., Sozcu, S., & Hassan, S. Z. U. (2021). Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers, 13(13), 2099. https://doi.org/10.3390/polym13132099