Ultrafine PVDF Nanofibers for Filtration of Air-Borne Particulate Matters: A Comprehensive Review

Abstract

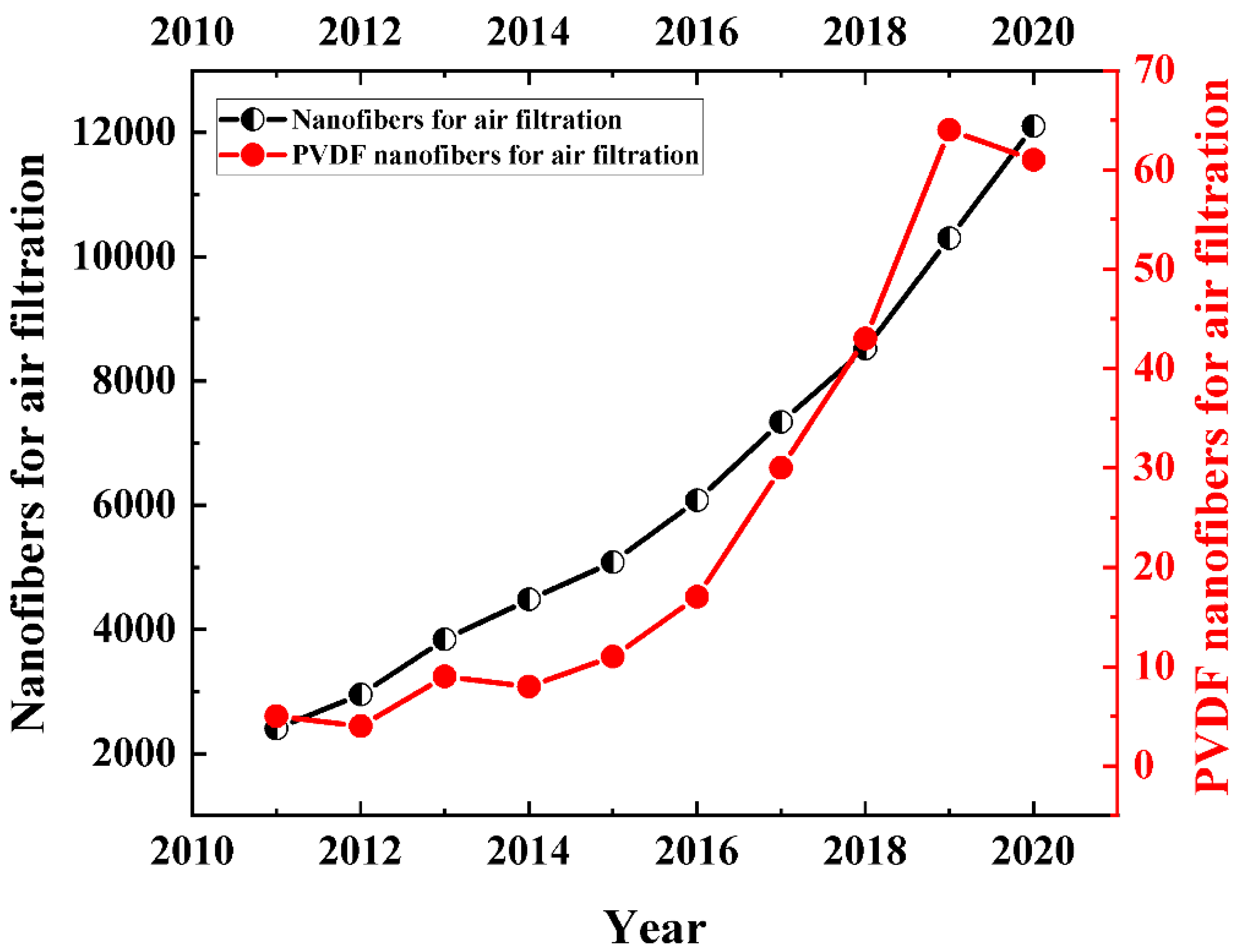

1. Introduction

2. Fabrication of Ultrafine Fibers

2.1. Electrospinning

2.2. Solution Blowing

3. Filtration of PMs Using Ultrafine Fibers

3.1. Measure of Performance of Air Filters

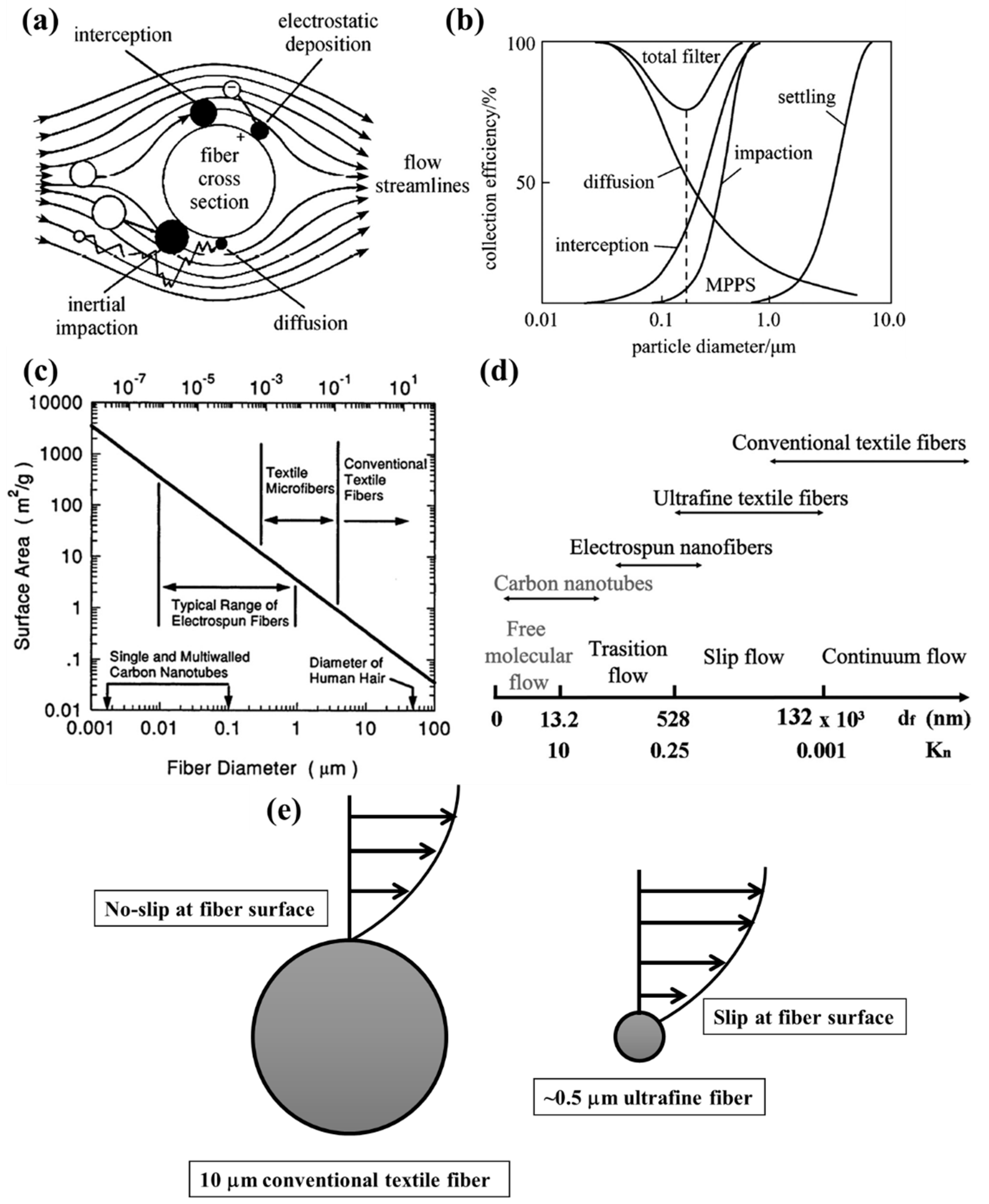

3.2. Mechanism of PM Filtration

3.3. Collection Efficiency of Fibrous Filters and Emphasis of Ultrafine Fibers

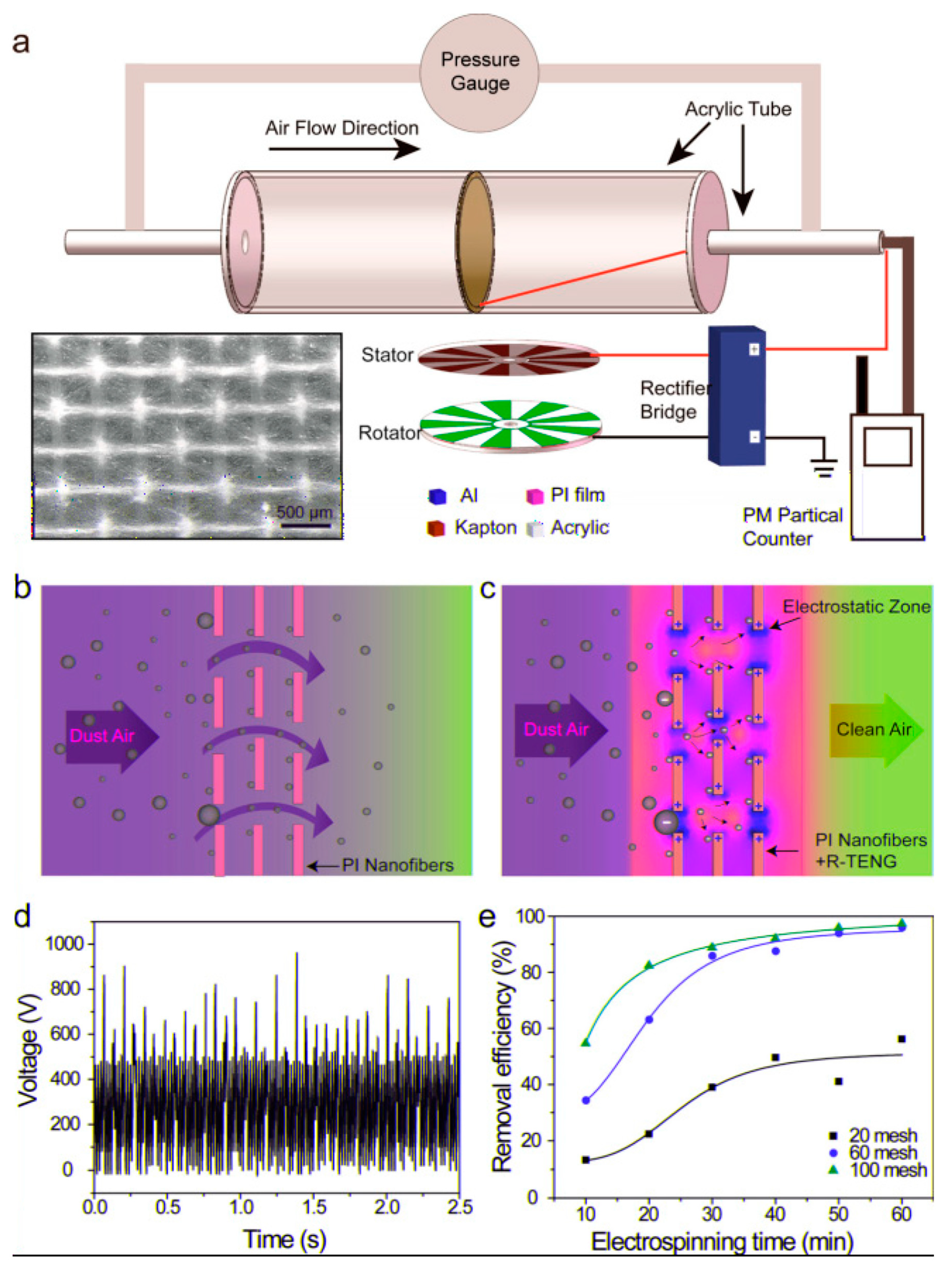

3.4. Some Examples of Ultrafine Fiber-Based Filters in Air Filtration

4. Ultrafine PVDF Nanofibers for PM Removal

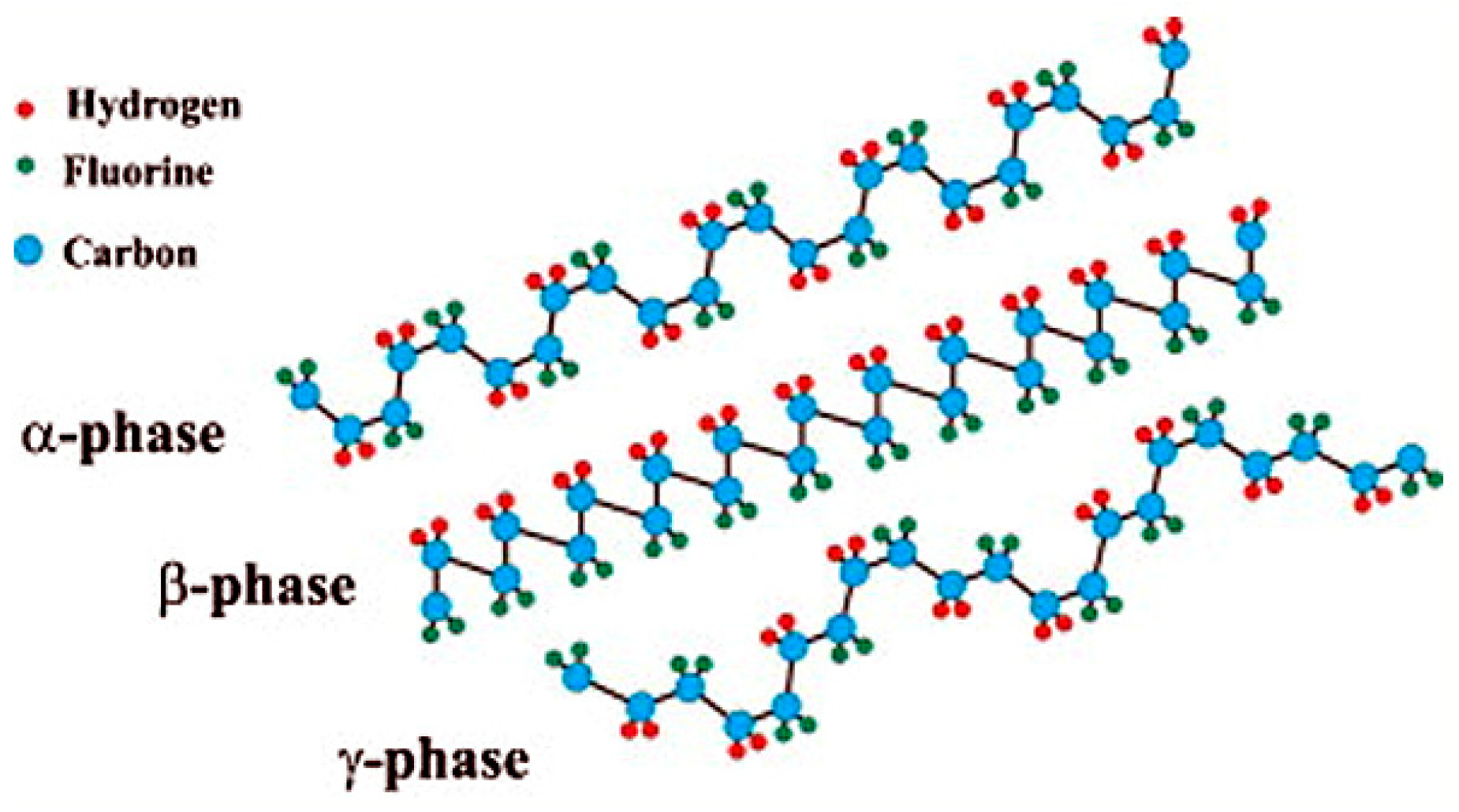

4.1. Structure and Properties of PVDF

4.2. Fabrication of Ultrafine PVDF Fibers

4.2.1. Synthesis of Ultrafine PVDF Fibers by Electrospinning

4.2.2. Synthesis of Ultrafine PVDF Fibers by Solution Blowing

4.3. Ultrafine PVDF Fibers for Filtering Air-Borne PMs

4.3.1. Mono-Layer Ultrafine Electret PVDF Nanofiber Filter

4.3.2. Multi-Layer Ultrafine Electret PVDF Nanofiber Filter

4.3.3. Multi-Component and Hybrid Ultrafine PVDF Nanofiber Filter

4.3.4. Biocompatibility of PVDF Nanofiber-Based Filter

5. Conclusions

- The charge decay and lack of washability of the electret filter membranes, which is also common for general N95 category masks that use an electret meltblown layer in the face masks.

- The charge retention capacity depend on electrical conductivity and localized trap sites. This issue is often tackled with incorporation of the second phase particle, such as SiO2, Fe2O3, etc.

- Charge decay in humid conditions, which can be tackled with superhydrophobic coatings.

- Scalability issues in development of aforementioned nanoweb/tree-like structures, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Organization. Air Pollution. Available online: https://www.who.int/health-topics/air-pollution#tab=tab_1 (accessed on 17 March 2021).

- Kyrkilis, G.; Chaloulakou, A.; Kassomenos, P.A. Development of an aggregate Air Quality Index for an urban Mediterranean agglomeration: Relation to potential health effects. Environ. Int. 2007, 33, 670–676. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.H.; Kabir, E.; Kabir, S. A review on the human health impact of airborne particulate matter. Environ. Int. 2015, 74, 136–143. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Health Effects of Particulate Matter. Policy Implications for Countries in Eastern Europe. Caucasus and Central Asia; World Health Organization Regional Office for Europe: Copenhagen, Denmark, 2013; pp. 6–7. [Google Scholar]

- Zaheer, J.; Jeon, J.; Lee, S.B.; Kim, J.S. Effect of particulate matter on human health, prevention, and imaging using PET or SPECT. Prog. Med. Phys. 2018, 29, 81–91. [Google Scholar] [CrossRef]

- Ministry of Environment, Forest and Climate Change, Central Pollution Control Board. National Air Quality Index. Available online: https://app.cpcbccr.com/AQI_India/ (accessed on 19 March 2021).

- Löndahl, J.; Pagels, J.; Swietlicki, E.; Zhou, J.; Ketzel, M.; Massling, A.; Bohgard, M. A set-up for field studies of respiratory tract deposition of fine and ultrafine particles in humans. J. Aerosol Sci. 2006, 37, 1152–1163. [Google Scholar] [CrossRef]

- Meng, X.; Zhang, Y.; Yang, K.Q.; Yang, Y.K.; Zhou, X.L. Potential harmful effects of PM2. 5 on occurrence and progression of acute coronary syndrome: Epidemiology, mechanisms, and prevention measures. Int. J. Environ. Res. Public Health 2016, 13, 748. [Google Scholar] [CrossRef]

- Hwang, S.; Roh, J.; Park, W.M. Comparison of the relative performance efficiencies of melt-blown and glass fiber filter media for managing fine particles. Aerosol Sci. Technol. 2018, 52, 451–458. [Google Scholar] [CrossRef]

- Yin, X.; Yu, J.; Ding, B. Electrospun Fibers for Filtration (ch. 07). In Handbook of Fibrous Materials; Jinlian, H., Kumar, B., Jing, L., Eds.; Wiley-VCH: Weinheim, Germany, 2020; pp. 175–206. [Google Scholar] [CrossRef]

- Thakur, R.; Das, D.; Das, A. Electret air filters. Sep. Purif. Rev. 2013, 42, 87–129. [Google Scholar] [CrossRef]

- Li, H.; Ke, Y.; Hu, Y. Polymer nanofibers prepared by template melt extrusion. J. Appl. Polym. Sci. 2006, 99, 10181023. [Google Scholar] [CrossRef]

- Kakoria, A.; Sinha-Ray, S. A review on biopolymer-based fibers via electrospinning and solution blowing and their applications. Fibers 2018, 6, 45. [Google Scholar] [CrossRef]

- Midha, V.K.; Dakuri, A. Spun bonding technology and fabric properties: A review. J. Text. Eng. Fash. Technol. 2017, 1, 1–9. [Google Scholar] [CrossRef]

- Shambaugh, R.L. A macroscopic view of the melt-blowing process for producing microfibers. Ind. Eng. Chem. Res. 1988, 27, 2363–2372. [Google Scholar] [CrossRef]

- Sinha-Ray, S.; Sinha-Ray, S.; Yarin, A.L.; Pourdeyhimi, B. Application of solution-blown 20–50 nm nanofibers in filtration of nanoparticles: The efficient van der Waals collectors. J. Membr. Sci. 2015, 485, 132–150. [Google Scholar] [CrossRef]

- Sinha-Ray, S.; Sinha-Ray, S.; Yarin, A.L.; Pourdeyhimi, B. Theoretical and experimental investigation of physical mechanisms responsible for polymer nanofiber formation in solution blowing. Polymers 2015, 56, 452–463. [Google Scholar] [CrossRef]

- Matulevicius, J.; Kliucininkas, L.; Martuzevicius, D.; Krugly, E.; Tichonovas, M.; Baltrusaitis, J. Design and characterization of electrospun polyamide nanofiber media for air filtration applications. J. Nanomater. 2014, 2014. [Google Scholar] [CrossRef]

- Souzandeh, H.; Johnson, K.S.; Wang, Y.; Bhamidipaty, K.; Zhong, W.H. Soy-protein-based nanofabrics for highly efficient and multifunctional air filtration. ACS Appl. Mater. Interfaces 2016, 8, 20023–20031. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishna, S.; Jose, R.; Archana, P.S.; Nair, A.S.; Balamurugan, R.; Venugopal, J.; Teo, W.E. Science and engineering of electrospun nanofibers for advances in clean energy, water filtration, and regenerative medicine. J. Mater. Sci. 2010, 45, 6283–6312. [Google Scholar] [CrossRef]

- Vasita, R.; Katti, D.S. Nanofibers and their applications in tissue engineering. Int. J. Nanomed. 2006, 1, 15. [Google Scholar] [CrossRef]

- Nemati, S.; Kim, S.J.; Shin, Y.M.; Shin, H. Current progress in application of polymeric nanofibers to tissue engineering. Nano Converg. 2019, 6, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Lou, K.; Qi, R.; Guo, Z.; Shin, B.; Liu, G.; Shan, F. Nature-inspired capillary-driven welding process for boosting metal-oxide nanofiber electronics. ACS Appl. Mater. Interfaces 2018, 10, 20703–20711. [Google Scholar] [CrossRef]

- Wang, L.; Haugen, N.O.; Wu, Z.; Shu, X.; Jia, Y.; Ma, J.; Yu, S.; Li, H.; Chai, Q. Ferroelectric BaTiO3@ ZnO heterostructure nanofibers with enhanced pyroelectrically-driven-catalysis. Ceram. Int. 2019, 45, 90–95. [Google Scholar] [CrossRef]

- Lu, W.; He, T.; Xu, B.; He, X.; Adidharma, H.; Radosz, M.; Gasem, K.; Fan, M. Progress in catalytic synthesis of advanced carbon nanofibers. J. Mater. Chem. A 2017, 5, 13863–13881. [Google Scholar] [CrossRef]

- Sinha-Ray, S.; Zhang, W.; Stoltz, B.; Sahu, R.P.; Sinha-Ray, S.; Yarin, A.L. Swing-like pool boiling on nano-textured surfaces for microgravity applications related to cooling of high-power microelectronics. NPJ Microgravity 2017, 3, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Yarin, A.L.; Pourdeyhimi, B.; Ramakrishna, S. Fundamentals and Applications of Micro- and Nanofibers; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar] [CrossRef]

- Theron, A.; Zussman, E.; Yarin, A.L. Electrostatic field-assisted alignment of electrospun nanofibres. Nanotechnology 2001, 12, 384. [Google Scholar] [CrossRef]

- Yarin, A.L.; Koombhongse, S.; Reneker, D.H. Bending instability in electrospinning of nanofibers. J. Appl. Phys. 2001, 89, 3018–3026. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, W.; Yang, Y.; Wang, K.; Yu, D.G. From Taylor cone to solid nanofiber in tri-axial electrospinning: Size relationships. Results Phys. 2019, 15, 102770. [Google Scholar] [CrossRef]

- Partheniadis, I.; Nikolakakis, I.; Laidmäe, I.; Heinämäki, J. A Mini-Review: Needleless Electrospinning of Nanofibers for Pharmaceutical and Biomedical Applications. Processes 2020, 8, 673. [Google Scholar] [CrossRef]

- Niu, H.; Lin, T. Fiber generators in needleless electrospinning. J. Nanomater. 2012, 2012. [Google Scholar] [CrossRef]

- Yarin, A.L.; Zussman, E. Upward needleless electrospinning of multiple nanofibers. Polymers 2004, 45, 2977–2980. [Google Scholar] [CrossRef]

- Jirsak, O.; Sanetrnik, F.; Lukas, D.; Kotek, V.; Martinova, L.; Chaloupek, J. Method of Nanofibres Production from a Polymer Solution Using Electrostatic Spinning and a Device for Carrying out the Method. U.S. Patent 7,585,437, 8 September 2009. [Google Scholar]

- Gao, Y.; Zhang, J.; Su, Y.; Wang, H.; Wang, X.X.; Huang, L.P.; Yu, M.; Ramakrishna, S.; Long, Y.Z. Recent progress and challenges in solution blow spinning. Mater. Horiz. 2020, 8, 426–447. [Google Scholar] [CrossRef]

- Daristotle, J.L.; Behrens, A.M.; Sandler, A.D.; Kofinas, P. A review of the fundamental principles and applications of solution blow spinning. ACS Appl. Mater. Interfaces 2016, 8, 34951–34963. [Google Scholar] [CrossRef]

- Wang, X.; Um, I.C.; Fang, D.; Okamoto, A.; Hsiao, B.S.; Chu, B. Formation of water-resistant hyaluronic acid nanofibers by blowing-assisted electro-spinning and non-toxic post treatments. Polymers 2005, 46, 4853–4867. [Google Scholar] [CrossRef]

- Sinha-Ray, S.; Yarin, A.L.; Pourdeyhimi, B. The production of 100/400 nm inner/outer diameter carbon tubes by solution blowing and carbonization of core–shell nanofibers. Carbon 2010, 48, 3575–3578. [Google Scholar] [CrossRef]

- Podgorski, A.; Bałazy, A.; Gradoń, L. Application of nanofibers to improve the filtration efficiency of the most penetrating aerosol particles in fibrous filters. Chem. Eng. Sci. 2006, 61, 6804–6815. [Google Scholar] [CrossRef]

- Brown, R.C. Air Filtration: An Integrated Approach to the Theory and Applications of Fibrous Filters; Elsevier: Amsterdam, The Netherlands, 1993. [Google Scholar] [CrossRef]

- Fikenzer, S.; Uhe, T.; Lavall, D.; Rudolph, U.; Falz, R.; Busse, M.; Laufs, U. Effects of surgical and FFP2/N95 face masks on cardiopulmonary exercise capacity. Clin. Res. Cardiol. 2020, 109, 1522–1530. [Google Scholar] [CrossRef] [PubMed]

- Perna, G.; Cuniberti, F.; Daccò, S.; Nobile, M.; Caldirola, D. Impact of respiratory protective devices on respiration: Implications for panic vulnerability during the COVID-19 pandemic. J. Affect. Disord. 2020, 277, 772–778. [Google Scholar] [CrossRef] [PubMed]

- Kyung, S.Y.; Kim, Y.; Hwang, H.; Park, J.W.; Jeong, S.H. Risks of N95 face mask use in subjects with COPD. Resp. Care 2020, 65, 658–664. [Google Scholar] [CrossRef] [PubMed]

- Hopkins, S.R.; Dominelli, P.B.; Davis, C.K.; Guenette, J.A.; Luks, A.M.; Molgat-Seon, Y.; Sá, R.C.; Sheel, A.W.; Swenson, E.R.; Stickland, M.K. Face masks and the cardiorespiratory response to physical activity in health and disease. Ann. Am. Thorac. Soc. 2021, 18, 399–407. [Google Scholar] [CrossRef]

- Chuanfang, Y. Aerosol filtration application using fibrous media—An industrial perspective. Chin. J. Chem. Eng. 2012, 20, 1–9. [Google Scholar] [CrossRef]

- Li, P.; Wang, C.; Zhang, Y.; Wei, F. Air filtration in the free molecular flow regime: A review of high-efficiency particulate air filters based on carbon nanotubes. Small 2014, 10, 4543–4561. [Google Scholar] [CrossRef]

- Davies, C.N. Filtration of aerosols. J. Aerosol Sci. 1983, 14, 147–161. [Google Scholar] [CrossRef]

- Banks, D.O.; Hall, M.S.; Kurowski, G.J. Numerical determination of electrically enhanced fiber collection efficiency. J. Aerosol Sci. 1983, 14, 87–97. [Google Scholar] [CrossRef]

- Pich, J.; Emi, H.; Kanaoka, C. Coulombic deposition mechanism in electret filters. J. Aerosol Sci. 1987, 18, 29–35. [Google Scholar] [CrossRef]

- Kim, J.H.; Mulholland, G.W.; Kukuck, S.R.; Pui, D.Y. Slip correction measurements of certified PSL nanoparticles using a nanometer differential mobility analyzer (nano-DMA) for Knudsen number from 0.5 to 83. J. Res. Natl. Inst. Stand. Technol. 2005, 110, 31. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.S.; Otani, Y. Removal of nanoparticles from gas streams by fibrous filters: A review. Ind. Eng. Chem. Res. 2013, 52, 5–17. [Google Scholar] [CrossRef]

- Bai, H.; Qian, X.; Fan, J.; Shi, Y.; Duo, Y.; Guo, C.; Wang, X. Theoretical Model of Single Fiber Efficiency and the Effect of Microstructure on Fibrous Filtration Performance: A Review. Ind. Eng. Chem. Res. 2021, 60, 3–36. [Google Scholar] [CrossRef]

- Martin, S.B., Jr.; Moyer, E.S. Electrostatic respirator filter media: Filter efficiency and most penetrating particle size effects. Appl. Occup. Environ. Hyg. 2000, 15, 609–617. [Google Scholar] [CrossRef]

- Moyer, E.S.; Bergman, M.S. Electrostatic N-95 respirator filter media efficiency degradation resulting from intermittent sodium chloride aerosol exposure. Appl. Occup. Environ. Hyg. 2000, 15, 600–608. [Google Scholar] [CrossRef]

- Lee, K.W.; Liu, B.Y.H. On the minimum efficiency and the most penetrating particle size for fibrous filters. J. Air Pollut. Control. Assoc. 1980, 30, 377–381. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, S.; Yin, X.; Yu, J.; Ding, B. Slip-effect functional air filter for efficient purification of PM 2.5. Sci. Rep. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Graham, K.; Ouyang, M.; Raether, T.; Grafe, T.; McDonald, B.; Knauf, P. Polymeric nanofibers in air filtration applications. In Proceedings of the 5th Annual Technical Conference & Expo of the American Filtration & Separations Society, Galveston, TX, USA, 9–12 April 2002. [Google Scholar] [CrossRef]

- Langmuir, I. Report on Smokes and Filters. Filtration of Aerosols and the Development of Filter Materials; Office of Scientific Research and Development: Washington, DC, USA, 1942. [CrossRef]

- Torgeson, W.L. The Theoretical Collection Efficiency of Fibrous Filters Due to the Combined Effects of Inertia, Diffusion and Interception; Litton Systems, Inc., Applied Science Division: St. Paul, MN, USA, 1964. [Google Scholar]

- Liu, B.Y.; Rubow, K.L. Efficiency, pressure drop and figure of merit of high efficiency fibrous and membrane filter media. In Proceedings of the 5th World Filtration Congress, Nice, France, 5–8 June 1990; p. 112. [Google Scholar] [CrossRef]

- Lee, K.W.; Liu, B.Y.H. Theoretical study of aerosol filtration by fibrous filters. Aerosol Sci. Technol. 1982, 1, 147–161. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Tafreshi, H.V. On the importance of fibers’ cross-sectional shape for air filters operating in the slip flow regime. Powder Technol. 2011, 212, 425–431. [Google Scholar] [CrossRef]

- Israel, R.; Rosner, D.E. Use of a generalized Stokes number to determine the aerodynamic capture efficiency of non-Stokesian particles from a compressible gas flow. Aerosol Sci. Technol. 1982, 2, 45–51. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, C.; Hsu, P.C.; Zhang, C.; Liu, N.; Zhang, J.; Lee, H.R.; Lu, Y.; Qiu, Y.; Chu, S.; et al. Nanofiber air filters with high-temperature stability for efficient PM2.5 removal from the pollution sources. Nano Lett. 2016, 16, 3642–3649. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Song, J.; Long, Y.; Jia, C.; Liu, Z.; Li, L.; Yang, C.; Liu, J.; Lin, S.; Wang, H.; et al. Large-scale blow spinning of heat-resistant nanofibrous air filters. Nano Res. 2020, 13, 861–867. [Google Scholar] [CrossRef]

- Huang, J.J.; Tian, Y.; Wang, R.; Tian, M.; Liao, Y. Fabrication of bead-on-string polyacrylonitrile nanofibrous air filters with superior filtration efficiency and ultralow pressure drop. Sep. Purif. Technol. 2020, 237, 116377. [Google Scholar] [CrossRef]

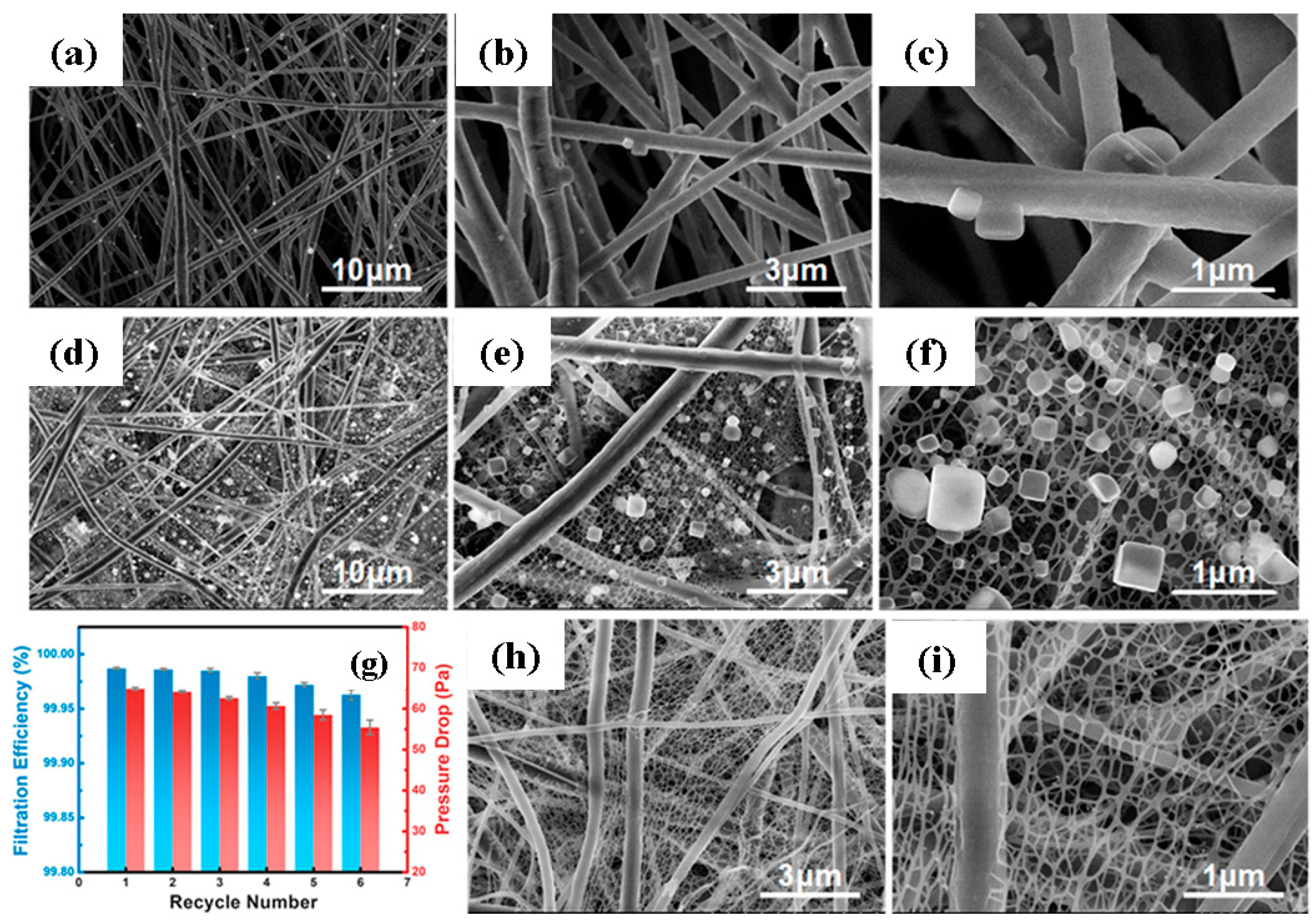

- Polat, Y.; Calisir, M.; Gungor, M.; Sagirli, M.N.; Atakan, R.; Akgul, Y.; Kilic, A. Solution blown nanofibrous air filters modified with glass microparticles. J. Ind. Text. 2019. [Google Scholar] [CrossRef]

- Li, Y.; Cao, L.; Yin, X.; Si, Y.; Yu, J.; Ding, B. Semi-Interpenetrating polymer network biomimetic structure enables superelastic and thermostable nanofibrous aerogels for cascade filtration of PM2.5. Adv. Funct. Mater. 2020, 30, 1910426. [Google Scholar] [CrossRef]

- Zhang, S.; Tanioka, A.; Okamoto, M.; Haraoka, Y.; Hayashi, N.; Matsumoto, H. High-quality nanofibrous nonwoven air filters: Additive effect of water-jet nanofibrillated celluloses on their performance. ACS Appl. Polym. Mater. 2020, 2, 2830–2838. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Q.; Zhang, L.; Wang, S.; Harper, D.P.; Wu, Q.; Young, T.M. Preparation of electrospun nanofibrous poly (vinyl alcohol)/cellulose nanocrystals air filter for efficient particulate matter removal with repetitive usage capability via facile heat treatment. Chem. Eng. J. 2020, 399, 125768. [Google Scholar] [CrossRef]

- Zhang, C.; Yao, L.; Yang, Z.; Kong, E.S.W.; Zhu, X.; Zhang, Y. Graphene oxide-modified polyacrylonitrile nanofibrous membranes for efficient air filtration. ACS Appl. Nano Mater. 2019, 2, 3916–3924. [Google Scholar] [CrossRef]

- Deneff, J.I.; Walton, K.S. Production of metal-organic framework-bearing polystyrene fibers by solution blow spinning. Chem. Eng. Sci. 2019, 203, 220–227. [Google Scholar] [CrossRef]

- Gu, G.Q.; Han, C.B.; Lu, C.X.; He, C.; Jiang, T.; Gao, Z.L.; Li, C.J.; Wang, Z.L. Triboelectric nanogenerator enhanced nanofiber air filters for efficient particulate matter removal. ACS Nano 2017, 11, 6211–6217. [Google Scholar] [CrossRef]

- Shen, B.; Zhang, D.; Wei, Y.; Zhao, Z.; Ma, X.; Zhao, X.; Wang, S.; Yang, W. Preparation of Ag doped keratin/PA6 nanofiber membrane with enhanced air filtration and antimicrobial properties. Polymers 2019, 11, 1511. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Fu, X.; Zheng, M.; Wang, Y.; Li, Y.; Xiang, A.; Zhong, W.H. Natural polypeptides treat pollution complex: Moisture-resistant multi-functional protein nanofabrics for sustainable air filtration. Nano Res. 2018, 11, 4265–4277. [Google Scholar] [CrossRef]

- Karagozlu, M.Z.; Karadeniz, F.; Kim, S.K. Anti-HIV activities of novel synthetic peptide conjugated chitosan oligomers. Int. J. Biol. Macromol. 2014, 66, 260–266. [Google Scholar] [CrossRef]

- Gough, C.R.; Callaway, K.; Spencer, E.; Leisy, K.; Jiang, G.; Yang, S.; Hu, X. Biopolymer-Based Filtration Materials. ACS Omega 2021, 6, 11804–11812. [Google Scholar] [CrossRef]

- Min, K.; Kim, S.; Kim, S. Silk protein nanofibers for highly efficient, eco-friendly, optically translucent, and multifunctional air filters. Sci. Rep. 2018, 8, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, S.; Liu, L.; Yu, J.; Ding, B. A Fluffy Dual-Network Structured Nanofiber/Net Filter Enables High-Efficiency Air Filtration. Adv. Funct. Mater. 2019, 29, 1904108. [Google Scholar] [CrossRef]

- Nalwa, H.S. Recent developments in ferroelectric polymers. J. Macromol. Sci. Part C Polym. Rev. 1991, 31, 341–432. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly (vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Kochervinskii, V.V. The structure and properties of block poly (vinylidene fluoride) and systems based on it. Russ. Chem. Rev. 1996, 65, 865. [Google Scholar] [CrossRef]

- Martins, P.; Caparros, C.; Gonçalves, R.; Martins, P.M.; Benelmekki, M.; Botelho, G.; Lanceros-Mendez, S. Role of nanoparticle surface charge on the nucleation of the electroactive β-poly (vinylidene fluoride) nanocomposites for sensor and actuator applications. J. Phys. Chem. C 2012, 116, 15790–15794. [Google Scholar] [CrossRef]

- Sencadas, V.; Gregorio, R., Jr.; Lanceros-Méndez, S. α to β phase transformation and microestructural changes of PVDF films induced by uniaxial stretch. J. Macromol. Sci. 2009, 48, 514–525. [Google Scholar] [CrossRef]

- Eberle, G.; Schmidt, H.; Eisenmenger, W. Piezoelectric polymer electrets. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 624–646. [Google Scholar] [CrossRef]

- Motamedi, A.S.; Mirzadeh, H.; Hajiesmaeilbaigi, F.; Bagheri-Khoulenjani, S.; Shokrgozar, M. Effect of electrospinning parameters on morphological properties of PVDF nanofibrous scaffolds. Prog. Biomater. 2017, 6, 113–123. [Google Scholar] [CrossRef]

- Gee, S.; Johnson, B.; Smith, A.L. Optimizing electrospinning parameters for piezoelectric PVDF nanofiber membranes. J. Membr. Sci. 2018, 563, 804–812. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Q.; Lin, K.; Zhou, L.; Ni, Z. Piezoelectric and optoelectronic properties of electrospinning hybrid PVDF and ZnO nanofibers. Mater. Res. Express 2018, 5, 035057. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Y.; Fan, L.; Kang, W.; Cheng, B. Fabrication of polyvinylidene fluoride tree-like nanofiber via one-step electrospinning. Mater. Des. 2016, 92, 95–101. [Google Scholar] [CrossRef]

- Cozza, E.S.; Monticelli, O.; Marsano, E.; Cebe, P. On the electrospinning of PVDF: Influence of the experimental conditions on the nanofiber properties. Polym. Int. 2013, 62, 41–48. [Google Scholar] [CrossRef]

- Jiyong, H.; Yinda, Z.; Hele, Z.; Yuanyuan, G.; Xudong, Y. Mixed effect of main electrospinning parameters on the β-phase crystallinity of electrospun PVDF nanofibers. Smart Mater. Struct. 2017, 26, 085019. [Google Scholar] [CrossRef]

- Andrew, J.S.; Clarke, D.R. Effect of electrospinning on the ferroelectric phase content of polyvinylidene difluoride fibers. Langmuir 2008, 24, 670–672. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.H.; Kang, H.W. Advanced electrospinning using circle electrodes for freestanding PVDF nanofiber film fabrication. Appl. Surf. Sci. 2018, 455, 251–257. [Google Scholar] [CrossRef]

- Medeiros, E.S.; Glenn, G.M.; Klamczynski, A.P.; Orts, W.J.; Mattoso, L.H. Solution blow spinning: A new method to produce micro-and nanofibers from polymer solutions. J. Appl. Polym. Sci. 2009, 113, 2322–2330. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Li, N.; Wang, X.; Shi, L.; Wu, E.; Zhuang, X. UV-crosslinked Solution Blown PVDF Nanofiber Mats for Protective Applications. Fibers Polym. 2020, 21, 489–497. [Google Scholar] [CrossRef]

- Dias, G.C.; Cellet, T.S.; Santos, M.C.; Sanches, A.O.; Malmonge, L.F. PVDF nanofibers obtained by solution blow spinning with use of a commercial airbrush. J. Polym. Res. 2019, 26, 87. [Google Scholar] [CrossRef]

- Liu, R.Q.; Wang, X.X.; Fu, J.; Zhang, Q.Q.; Song, W.Z.; Xu, Y.; Chen, Y.Q.; Ramakrishna, S.; Long, Y.Z. Preparation of nanofibrous PVDF membrane by solution blow spinning for mechanical energy harvesting. Nanomaterials 2019, 9, 1090. [Google Scholar] [CrossRef]

- Su, Q.; Jiang, Z.; Li, B. A mixed solvent approach to make poly (vinylidene fluoride) nanofibers with high β-phase using solution blow spinning. High. Perform. Polym. 2020, 32, 1160–1168. [Google Scholar] [CrossRef]

- Choi, S.; Lee, H.M.; Kim, H.S. High performance and moisture stable humidity sensors based on polyvinylidene fluoride nanofibers by improving electric conductivity. Polym. Eng. Sci. 2019, 59, 304–310. [Google Scholar] [CrossRef]

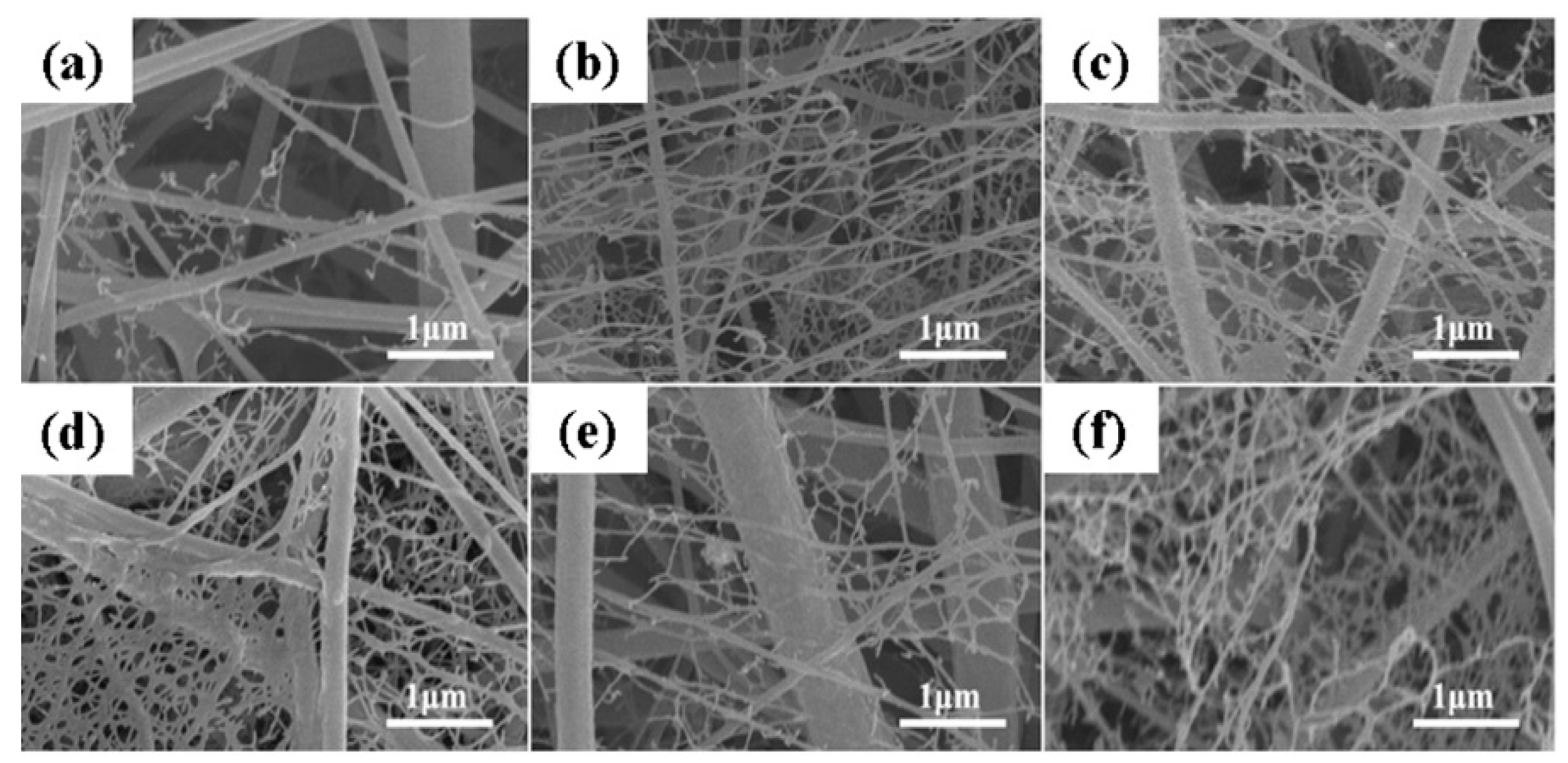

- Zaarour, B.; Tina, H.; Zhu, L.; Jin, X. Branched nanofibers with tiny diameters for air filtration via one-step electrospinning. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Tan, N.P.B.; Paclijan, S.S.; Ali, H.N.M.; Hallazgo, C.M.J.S.; Lopez, C.J.F.; Ebora, Y.C. Solution blow spinning (SBS) nanofibers for composite air filter masks. ACS Appl. Nano Mater. 2019, 2, 2475–2483. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Zhu, Z.; Chen, R.; Chen, X.; Zeng, J.; Xu, G.; Wei, C.; Zhang, Q.; Bai, J.; et al. Fabrication of nanofiber filters for electret air conditioning filter via a multi-needle electrospinning. AIP Adv. 2020, 10, 105217. [Google Scholar] [CrossRef]

- Leung, W.W.F.; Sun, Q. Electrostatic charged nanofiber filter for filtering airborne novel coronavirus (COVID-19) and nano-aerosols. Sep. Purif. Technol. 2020, 250, 116886. [Google Scholar] [CrossRef]

- Al Rai, A.; Stojanovska, E.; Fidan, G.; Yetgin, E.; Polat, Y.; Kilic, A.; Demir, A.; Yilmaz, S. Structure and performance of electroblown PVDF-based nanofibrous electret filters. Polym. Eng. Sci. 2020, 60, 1186–1193. [Google Scholar] [CrossRef]

- Lolla, D.; Lolla, M.; Abutaleb, A.; Shin, H.U.; Reneker, D.H.; Chase, G.G. Fabrication, polarization of electrospun polyvinylidene fluoride electret fibers and effect on capturing nanoscale solid aerosols. Materials 2016, 9, 671. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Electret polyvinylidene fluoride nanofibers hybridized by polytetrafluoroethylene nanoparticles for high-efficiency air filtration. ACS Appl. Mater. Interfaces 2016, 8, 23985–23994. [Google Scholar] [CrossRef]

- Kim, J.; Jasper, W.; Hinestroza, J. Direct probing of solvent-induced charge degradation in polypropylene electret fibres via electrostatic force microscopy. J. Microsc. 2007, 225, 72–79. [Google Scholar] [CrossRef] [PubMed]

- Cantaloube, B.; Dreyfus, G.; Lewiner, J. Vapor-induced depolarization currents in electrets. J. Polym. Sci. Polym. Phys. Ed. 1979, 17, 95–101. [Google Scholar] [CrossRef]

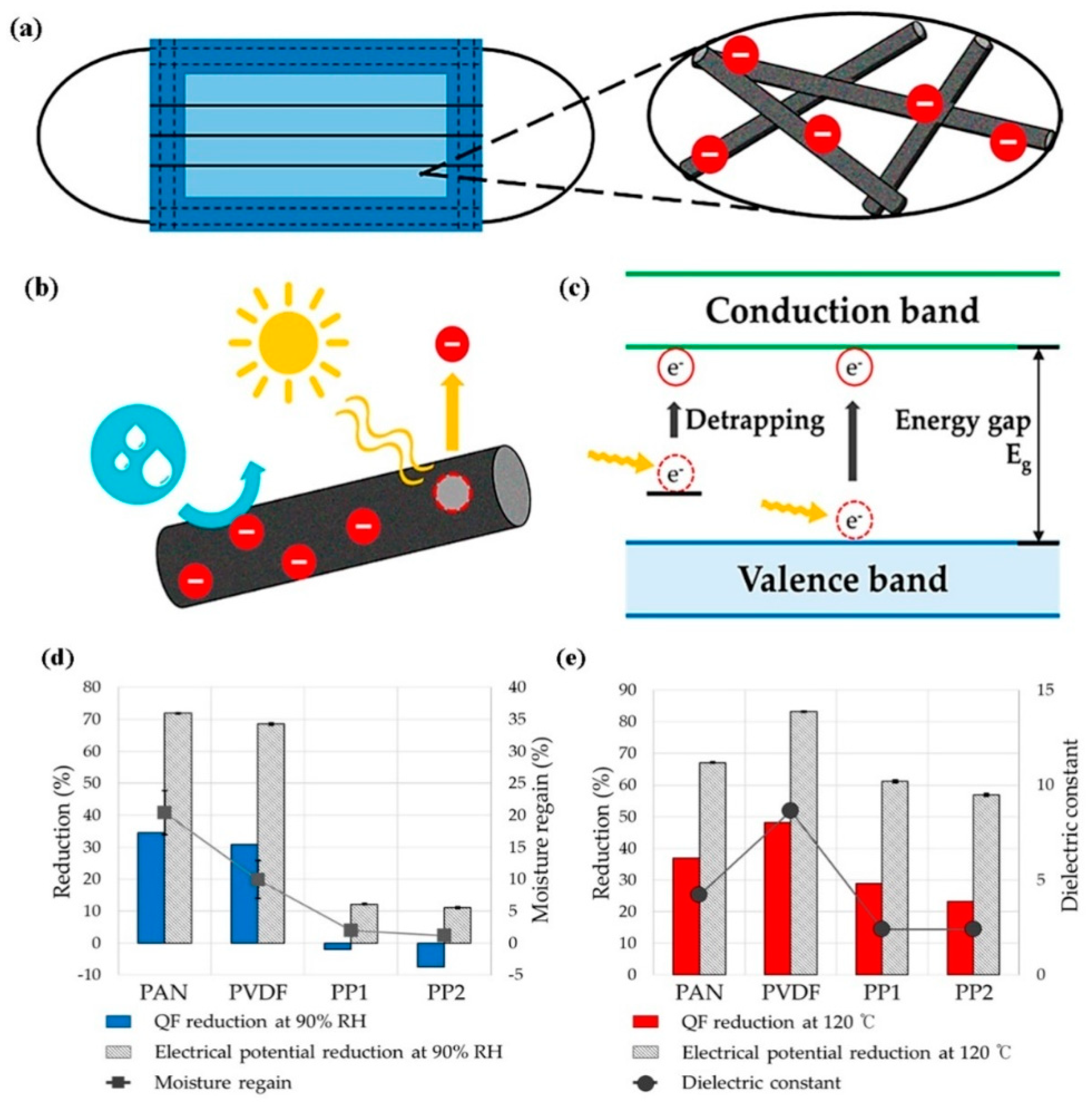

- Lee, J.; Kim, J. Material properties influencing the charge decay of electret filters and their impact on filtration performance. Polymers 2020, 12, 721. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, S.; Liu, L.; Yu, J.; Ding, B. High-performance PM0.3 air filters using self-polarized electret nanofiber/nets. Adv. Funct. Mater. 2020, 30, 1909554. [Google Scholar] [CrossRef]

- Sun, Q.; Leung, W.W.F. Enhanced nano-aerosol loading performance of multilayer PVDF nanofiber electret filters. Sep. Purif. Technol. 2020, 240, 116606. [Google Scholar] [CrossRef]

- Sun, Q.; Leung, W.W.F. Charged PVDF multi-layer filters with enhanced filtration performance for filtering nano-aerosols. Sep. Purif. Technol. 2019, 212, 854–876. [Google Scholar] [CrossRef]

- Leung, W.W.F.; Sun, Q. , Charged PVDF multilayer nanofiber filter in filtering simulated airborne novel coronavirus (COVID-19) using ambient nano-aerosols. Sep. Purif. Technol. 2020, 245, 116887. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, C.; Huang, X.; Zhang, T.; Wang, X.; Min, M.; Wang, L.; Huang, H.; Hsiao, B.S. Anionic surfactant-triggered steiner geometrical poly (vinylidene fluoride) nanofiber/nanonet air filter for efficient particulate matter removal. ACS Appl. Mater. Interfaces 2018, 10, 42891–42904. [Google Scholar] [CrossRef]

- Cai, M.; He, H.; Zhang, X.; Yan, X.; Li, J.; Chen, F.; Yuan, D.; Ning, X. Efficient synthesis of PVDF/PI side-by-side bicomponent nanofiber membrane with enhanced mechanical strength and good thermal stability. Nanomaterials 2019, 9, 39. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Cao, L.; Yin, X.; Si, Y.; Yu, J.; Ding, B. Ultrafine, self-crimp, and electret nano-wool for low-resistance and high-efficiency protective filter media against PM0.3. J. Colloid Interface Sci. 2020, 578, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Li, Y.; Si, Y.; Yin, X.; Yu, J.; Ding, B. Electrospun polyvinylidene fluoride/SiO2 nanofibrous membranes with enhanced electret property for efficient air filtration. Compos. Commun. 2019, 13, 57–62. [Google Scholar] [CrossRef]

- Han, K.S.; Lee, S.; Kim, M.; Park, P.; Lee, M.H.; Nah, J. Electrically activated ultrathin PVDF-TrFE air filter for high-efficiency PM1.0 filtration. Adv. Funct. Mater. 2019, 29, 1903633. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, J.; Dong, C.; Shao, Y.; Liu, Y.; Li, J.; Zhong, C.; Ye, L.; Song, R.; Zhang, H.; et al. Improved Electret Properties of Poly (Vinylidene Fluoride)/Lithium Niobate Nanocomposites for Applications in Air Filters. Macromol. Mater. Eng. 2019, 304, 1900003. [Google Scholar] [CrossRef]

- Liu, F.; Li, M.; Li, F.; Weng, K.; Qi, K.; Liu, C.; Ni, Q.; Tao, X.; Zhang, J.; Shao, W.; et al. Preparation and properties of PVDF/Fe3O4 nanofibers with magnetic and electret effects and their application in air filtration. Macromol. Mater. Eng. 2020, 305, 1900856. [Google Scholar] [CrossRef]

- Palmieri, V.; De Maio, F.; De Spirito, M.; Papi, M. Face masks and nanotechnology: Keep the blue side up. Nano Today 2021, 37, 101077. [Google Scholar] [CrossRef]

- Han, J.; He, S. Need for assessing the inhalation of micro (nano) plastic debris shed from masks, respirators, and home-made face coverings during the COVID-19 pandemic. Environ. Pollut. 2021, 268, 115728. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Xu, Y.; Qian, Y.; Chen, X.; Ouyang, Y.; Yuan, W.E. 3D structured self-powered PVDF/PCL scaffolds for peripheral nerve regeneration. Nano Energy 2020, 69, 104411. [Google Scholar] [CrossRef]

- Yu, Y.; Sun, H.; Orbay, H.; Chen, F.; England, C.G.; Cai, W.; Wang, X. Biocompatibility and in vivo operation of implantable mesoporous PVDF-based nanogenerators. Nano Energy 2016, 27, 275–281. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanyal, A.; Sinha-Ray, S. Ultrafine PVDF Nanofibers for Filtration of Air-Borne Particulate Matters: A Comprehensive Review. Polymers 2021, 13, 1864. https://doi.org/10.3390/polym13111864

Sanyal A, Sinha-Ray S. Ultrafine PVDF Nanofibers for Filtration of Air-Borne Particulate Matters: A Comprehensive Review. Polymers. 2021; 13(11):1864. https://doi.org/10.3390/polym13111864

Chicago/Turabian StyleSanyal, Ayishe, and Sumit Sinha-Ray. 2021. "Ultrafine PVDF Nanofibers for Filtration of Air-Borne Particulate Matters: A Comprehensive Review" Polymers 13, no. 11: 1864. https://doi.org/10.3390/polym13111864

APA StyleSanyal, A., & Sinha-Ray, S. (2021). Ultrafine PVDF Nanofibers for Filtration of Air-Borne Particulate Matters: A Comprehensive Review. Polymers, 13(11), 1864. https://doi.org/10.3390/polym13111864