Effect of Cellulose and Cellulose Nanocrystal Contents on the Biodegradation, under Composting Conditions, of Hierarchical PLA Biocomposites

Abstract

1. Introduction

2. Materials

3. Experimental Procedure

3.1. Statistical Experimental Design

3.2. Composite Preparation

3.3. Biodegradation—Composting Setup

3.4. Analytical Characterization

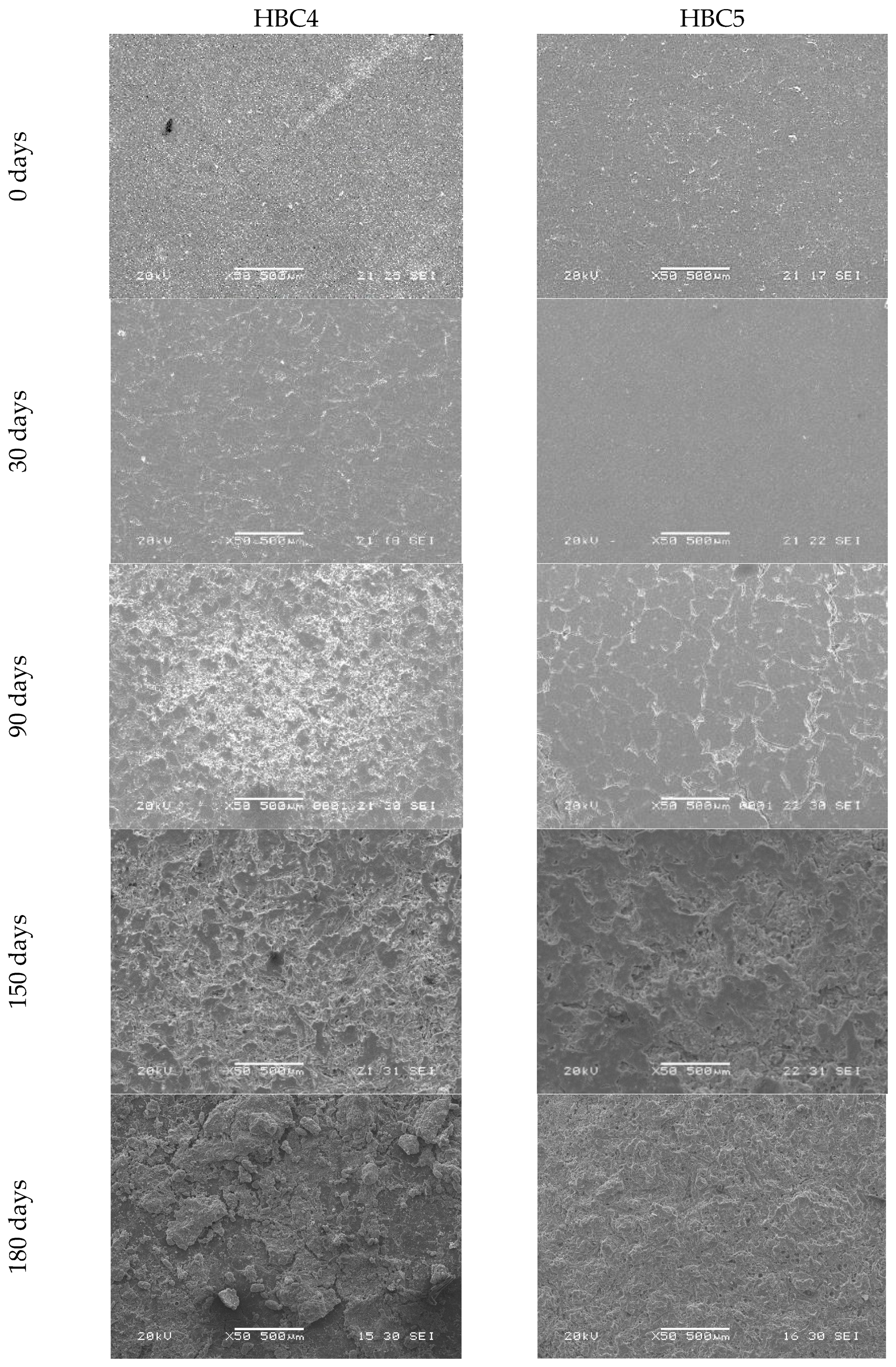

3.4.1. Scanning Electronic Microscopy (SEM)

3.4.2. Weight Loss Monitoring

3.4.3. Gel Permeation Chromatography (GPC)

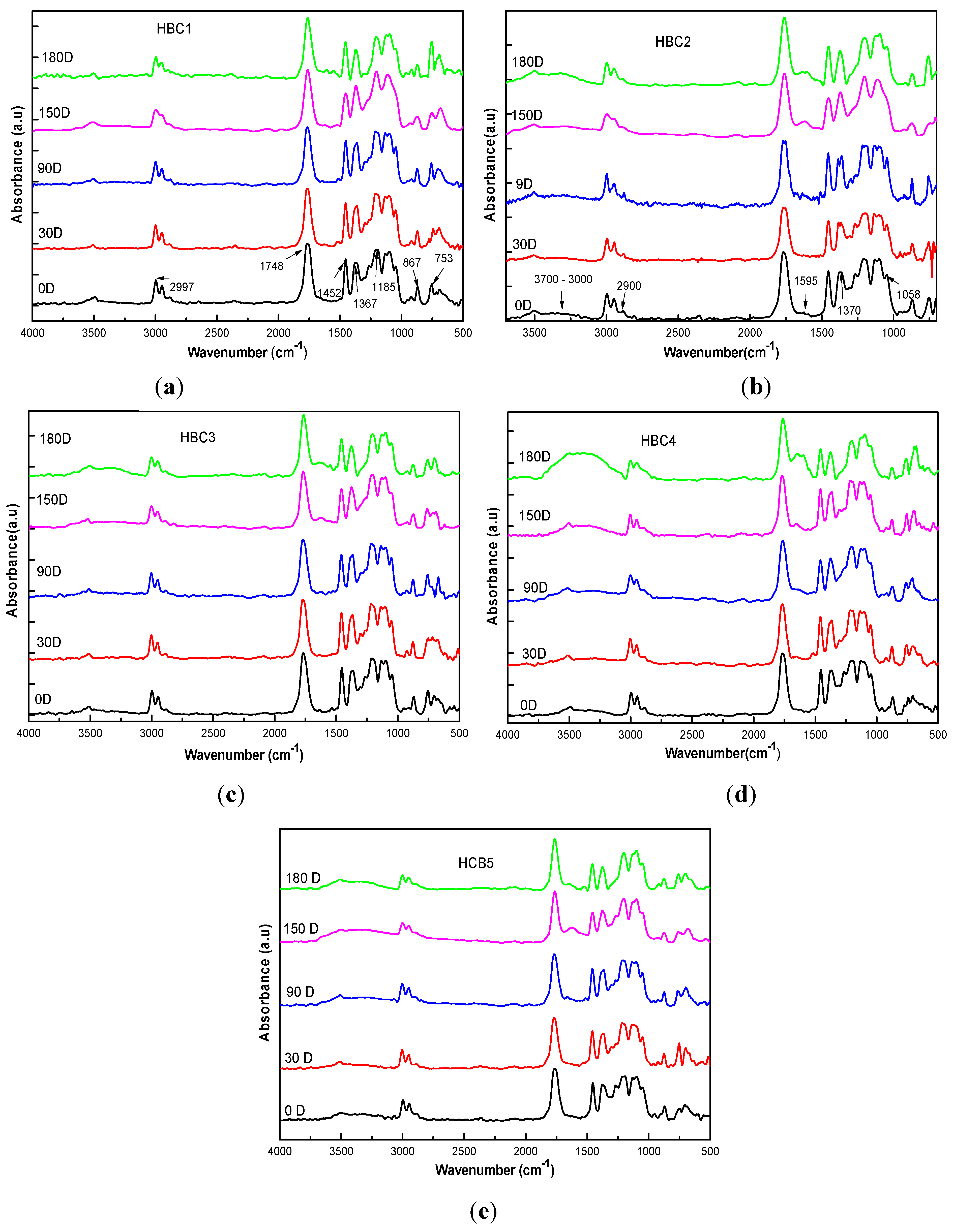

3.4.4. Infrared Fourier Transformed Spectroscopy (FTIR)

3.4.5. Differential Scanning Calorimetry (DSC)

4. Results

4.1. Morphological Analysis

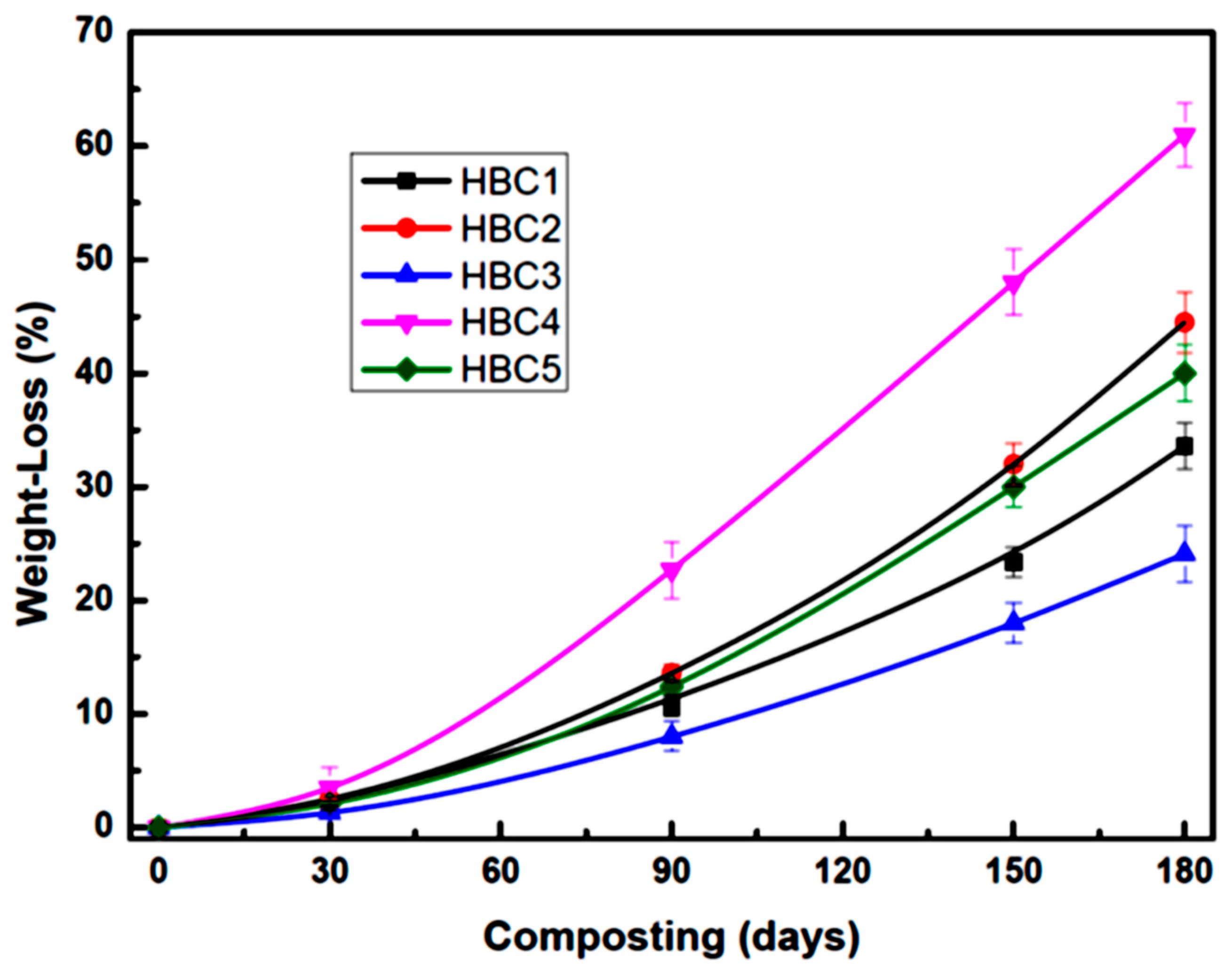

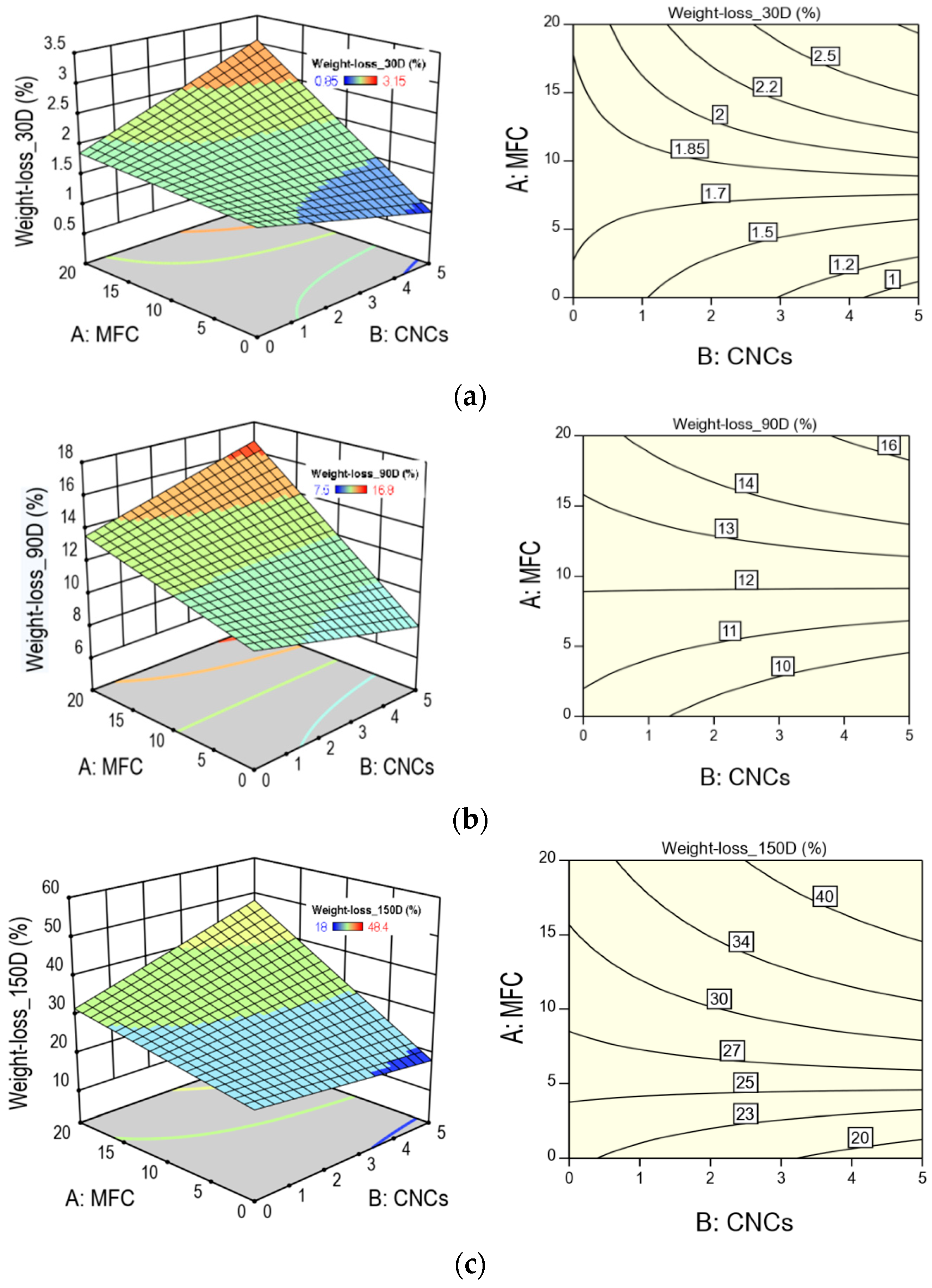

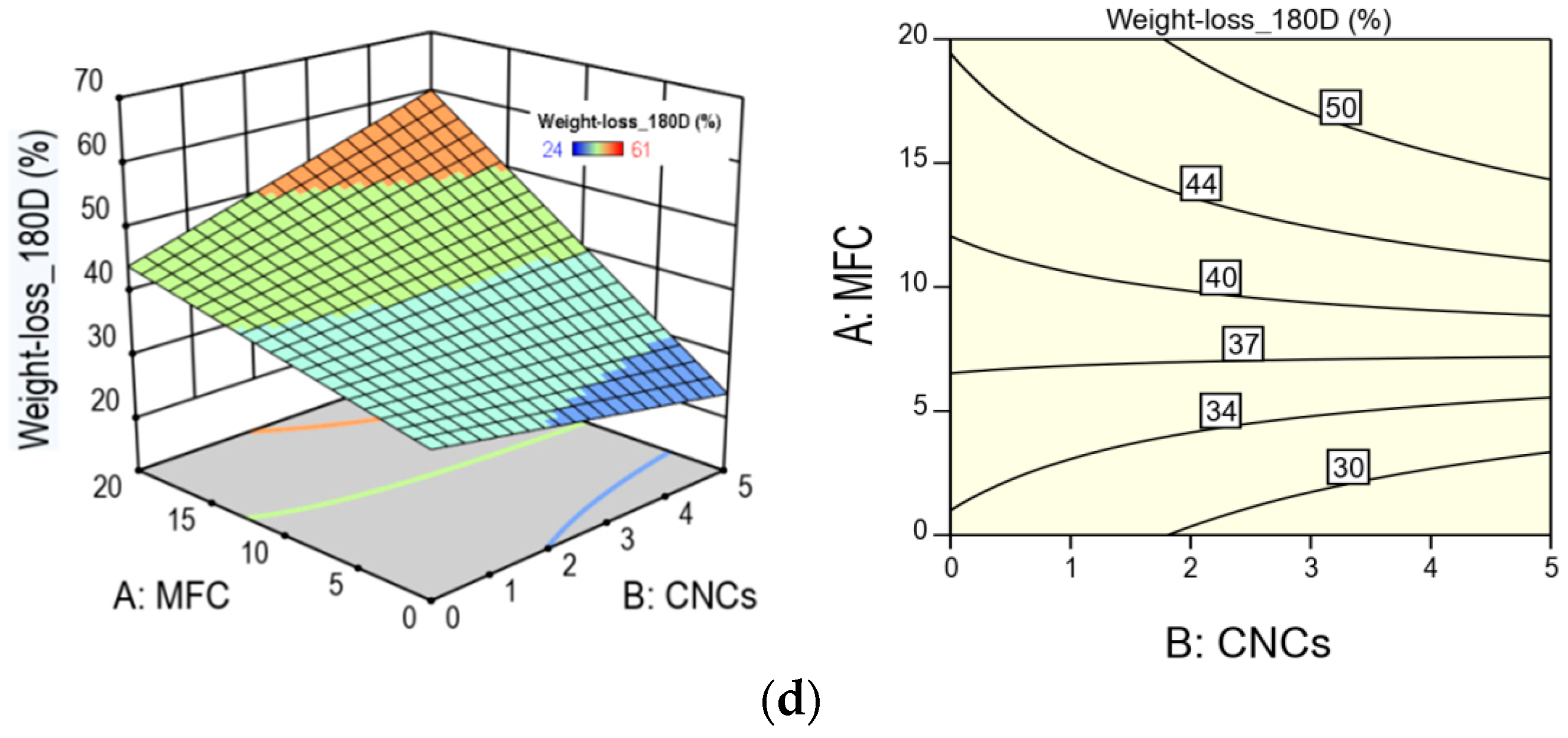

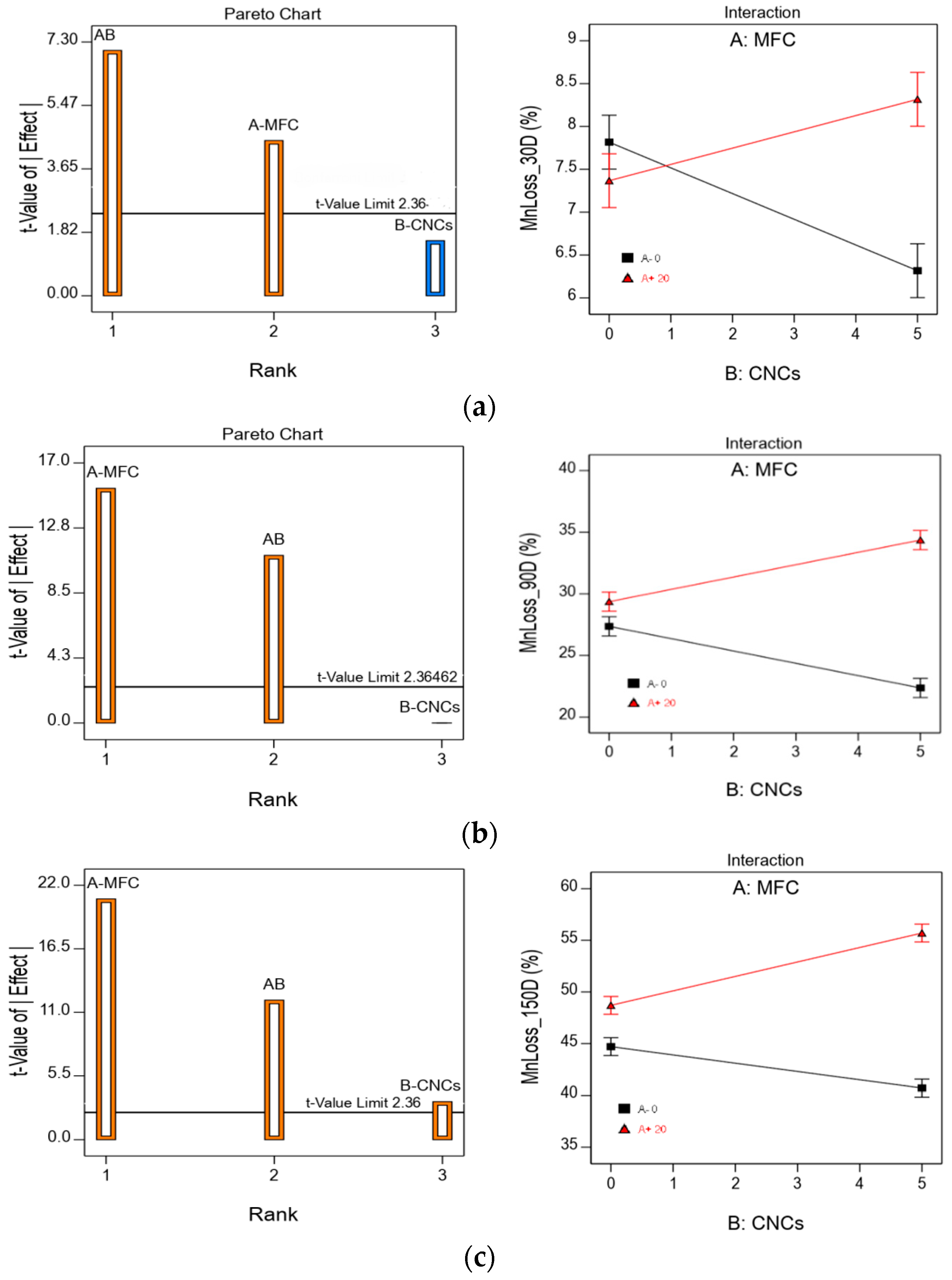

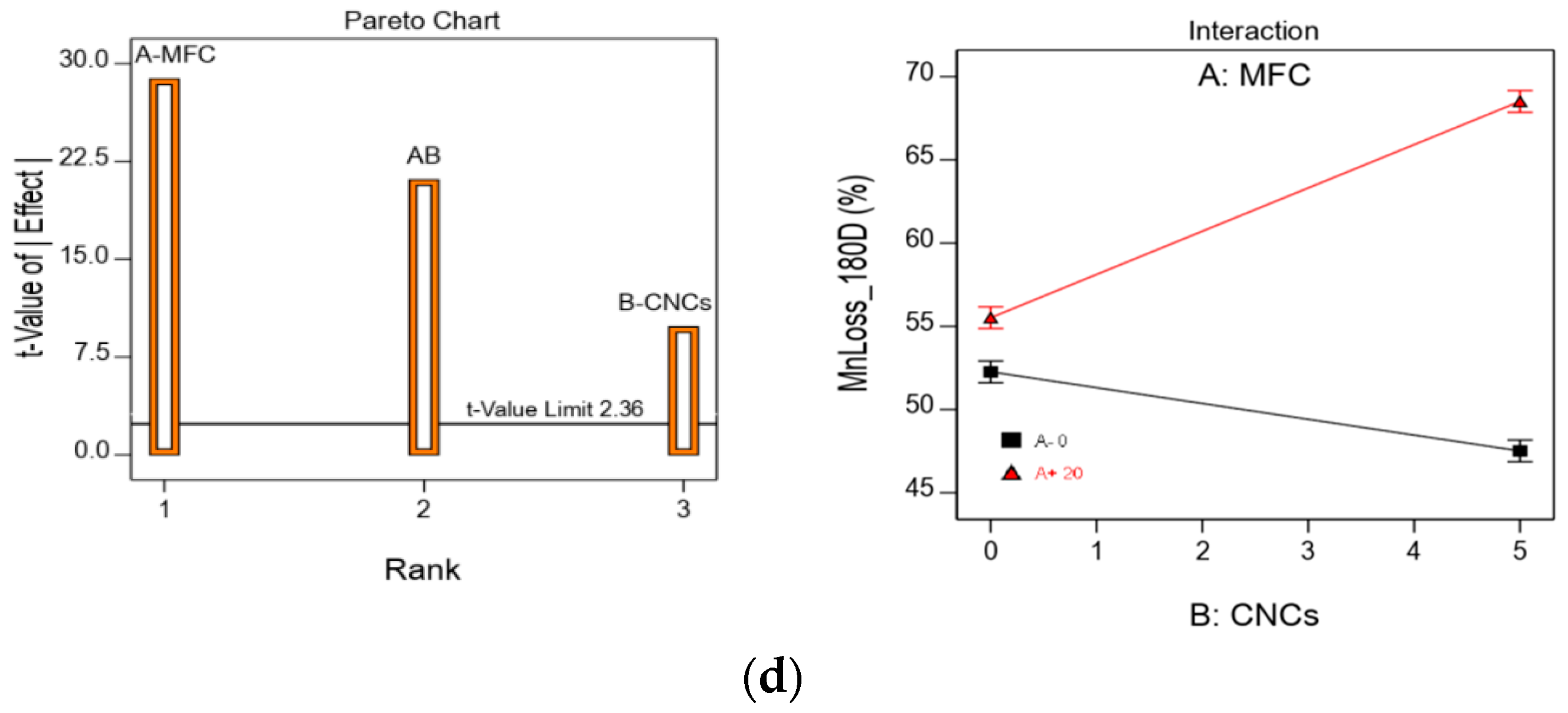

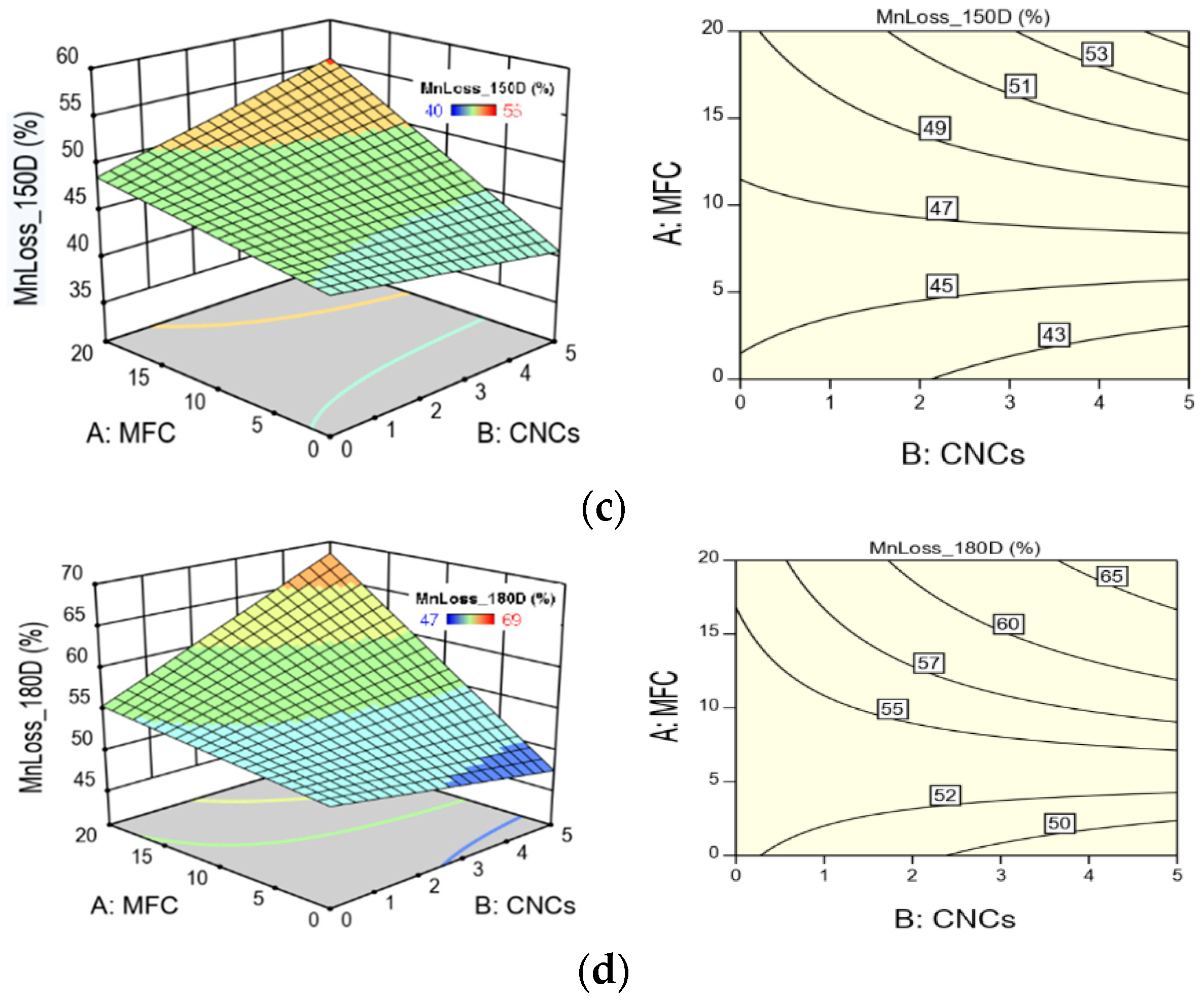

4.2. Weight Loss

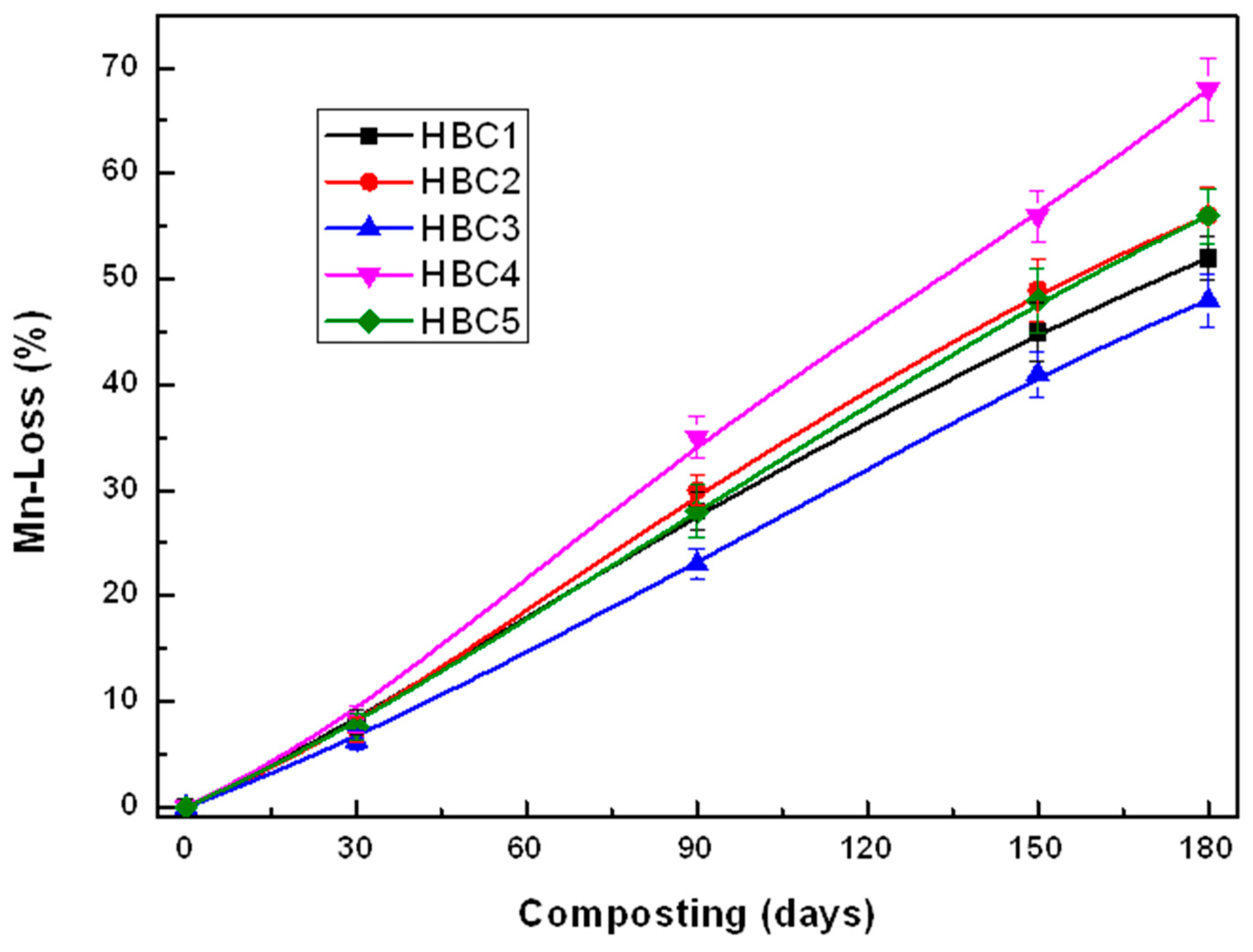

4.3. Molecular Weight Analysis

4.4. Infrared Spectroscopy (FTIR) Analysis

4.5. Differential Scanning Calorimetry (DSC) Analysis

4.6. Statistical Experimental Design

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geyer, R.; Jambeck, J.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Hassan, S.; Haq, I.U. Pervasive Pollution Problems Caused by Plastics and its Degradation. Int. J. Online Biomed. Eng. (iJOE) 2019, 15, 29–39. [Google Scholar] [CrossRef]

- Gorrasi, G.; Pantani, R. Effect of PLA grades and morphologies on hydrolytic degradation at composting temperature: Assessment of structural modification and kinetic parameters. Polym. Degrad. Stab. 2013, 98, 1006–1014. [Google Scholar] [CrossRef]

- Saadi, Z.; Rasmont, A.; Cesar, G.; Bewa, H.; Benguigui, L. Fungal Degradation of Poly(l-lactide) in Soil and in Compost. J. Polym. Environ. 2011, 20, 273–282. [Google Scholar] [CrossRef]

- Musioł, M.; Sikorska, W.; Adamus, G.; Janeczek, H.; Richert, J.; Malinowski, R.; Jiang, G.; Kowalczuk, M. Forensic engineering of advanced polymeric materials. Part III—Biodegradation of thermoformed rigid PLA packaging under industrial composting conditions. Waste Manag. 2016, 52, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Qi, X.; Ren, Y.; Wang, X. New advances in the biodegradation of Poly(lactic) acid. Int. Biodeterior. Biodegrad. 2017, 117, 215–223. [Google Scholar] [CrossRef]

- Frone, A.; Berlioz, S.; Chailan, J.-F.; Panaitescu, D.; Donescu, D. Cellulose fiber-reinforced polylactic acid. Polym. Compos. 2011, 32, 976–985. [Google Scholar] [CrossRef]

- Huda, M.S.; Mohanty, A.K.; Drzal, L.T.; Schut, E.; Misra, M. “Green” composites from recycled cellulose and poly(lactic acid): Physico-mechanical and morphological properties evaluation. J. Mater. Sci. 2005, 40, 4221–4229. [Google Scholar] [CrossRef]

- Dzul-Cervantes, M.; Herrera-Franco, P.; Tábi, T.; Valadez-Gonzalez, A. Using Factorial Design Methodology to Assess PLA-g-Ma and Henequen Microfibrillated Cellulose Content on the Mechanical Properties of Poly(lactic acid) Composites. Int. J. Polym. Sci. 2017, 2017, 1–14. [Google Scholar] [CrossRef]

- Graupner, N.; Müssig, J. Cellulose Fiber-Reinforced PLA versus PP. Int. J. Polym. Sci. 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Khosravia, A.; Fereidoona, A.; Mehdi, M.; Naderi, G.; Reza-Ganjali, M.; Zarrintaj, P.; Reza-Saeb, M.; Gutiérrez, T. Soft and hard sections from cellulose-reinforced poly(lactic acid)-based food packaging films: A critical review. Food Packag. Shelf Life 2020, 23, 100429. [Google Scholar] [CrossRef]

- Pei, A.; Zhou, Q.; Berglund, L.A. Functionalized cellulose nanocrystals as biobased nucleation agents in poly(l-lactide) (PLLA)—Crystallization and mechanical property effects. Compos. Sci. Technol. 2010, 70, 815–821. [Google Scholar] [CrossRef]

- Bitinis, N.; Fortunati, E.; Verdejo, R.; Bras, J.; Kenny, J.; Torre, L.; López-Manchado, M. Poly(lactic ac-id)/natural rubber/cellulose nanocrystal bionanocomposites. Part II: Properties evaluation. Carbohydr. Polym. 2013, 96, 621–627. [Google Scholar] [CrossRef]

- Fortunati, E.; Luzi, F.; Puglia, D.; Petrucci, R.; Kenny, J.M.; Torre, L. Processing of PLA nanocomposites with cellulose nanocrystals extracted from Posidonia oceanica waste: Innovative reuse of coastal plant. Ind. Crop. Prod. 2015, 67, 439–447. [Google Scholar] [CrossRef]

- Rosli, N.; Ahmad, I. Application of cellulose nanocrystals (CNC) as reinforcing materials in bio-nanocomposites. J. Polym. Sci. Technol. 2019, 4, 22–32. [Google Scholar]

- Kumar, R.; Kumari, S.; Rai, B.; Das, R.; Kumar, G. Effect of nano-cellulosic fiber on mechanical and barrier properties of polylactic acid (PLA) green nanocomposite film. Mater. Res. Express 2019, 6, 125108. [Google Scholar] [CrossRef]

- Clarkson, C.M.; Azrak, S.M.E.A.; Schueneman, G.T.; Snyder, J.F.; Youngblood, J.P. Crystallization kinetics and morphology of small concentrations of cellulose nanofibrils (CNFs) and cellulose nanocrystals (CNCs) melt-compounded into poly(lactic acid) (PLA) with plasticizer. Polymer 2020, 187, 122101. [Google Scholar] [CrossRef]

- Le Phuong, H.; Izzati Ayob, N.; Blanford, C.; Nurul, F.; Mohammad, R.N.; Szekely, G. Nonwoven Membrane Supports from Renewable Resources: Bamboo Fiber Reinforced Poly(Lactic Acid) Composites. ACS Sustain. Chem. Eng. 2019, 7, 11885–11893. [Google Scholar] [CrossRef]

- Shuai, C.; Zan, J.; Deng, F.; Yang, Y.; Peng, S.; Zhao, Z. Core–shell-Structured ZIF-8@PDA-HA with Con-trollable Zinc Ion Release and Superior Bioactivity for Improving a Poly-l-lactic Acid Scaffold. ACS Sustain. Chem. Eng. 2021, 9, 1814–1825. [Google Scholar] [CrossRef]

- Feng, J.; Xu, X.; Xu, Z.; Xie, H.; Song, P.; Li, L.; Huang, G.; Wang, H. One-Pot, Solvent- and Catalyst-Free Synthesis of Polyphosphoramide as an Eco-Benign and Effective Flame Retardant for Poly(lactic acid). ACS Sustain. Chem. Eng. 2020, 8, 16612–16623. [Google Scholar] [CrossRef]

- Blaker, J.J.; Lee, K.-Y.; Bismarck, A. Hierarchical Composites Made Entirely from Renewable Resources. J. Biobased Mater. Bioenergy 2011, 5, 1–16. [Google Scholar] [CrossRef]

- Lee, K.-Y.; Ho, K.K.; Schlufter, K.; Bismarck, A. Hierarchical composites reinforced with robust short sisal fibre preforms utilising bacterial cellulose as binder. Compos. Sci. Technol. 2012, 72, 1479–1486. [Google Scholar] [CrossRef]

- Lee, K.; Bharadia, P.; Jonny JBlaker, J.; Bismarck, A. Short sisal fibre reinforced bacterial cellulose polylac-tide nanocomposites using hairy sisal fibres as reinforcement. Compos. Part A 2012, 43, 2065–2074. [Google Scholar] [CrossRef]

- Halász, K.; Csóka, L. Plasticized Biodegradable Poly(lactic acid) Based Composites Containing Cellulose in Micro- and Nanosize. J. Eng. 2012, 2013, 1–9. [Google Scholar] [CrossRef]

- Hajlane, A.; Kaddami, H.; Joffe, R. Chemical modification of regenerated cellulose fibres by cellulose nano-crystals: Towards hierarchical structure for structural composites reinforcement. Ind. Crop. Prod. 2017, 100, 41–50. [Google Scholar] [CrossRef]

- Pichandi, S.; Rana, S.; Parveen, S.; Fangueiro, R. A green approach of improving interface and performance of plant fibre composites using microcrystalline cellulose. Carbohydr. Polym. 2018, 197, 137–146. [Google Scholar] [CrossRef]

- Doineau, E.; Cathala, B.; Benezet, J.-C.; Bras, J.; Le Moigne, N. Development of Bio- Inspired Hierarchical Fi-bres to Tailor the Fibre/Matrix Interphase in (Bio)composites. Polymers 2021, 13, 804. [Google Scholar] [CrossRef] [PubMed]

- Itävaara, M.; Karjomaa, S.; Selin, J.-F. Biodegradation of polylactide in aerobic and anaerobic thermophilic conditions. Chemosphere 2002, 46, 879–885. [Google Scholar] [CrossRef]

- Kale, G.; Auras, R.; Singh, S.P. Comparison of the degradability of poly(lactide) packages in composting and ambient exposure conditions. Packag. Technol. Sci. 2007, 20, 49–70. [Google Scholar] [CrossRef]

- Pantani, R.; Sorrentino, A. Influence of crystallinity on the biodegradation rate of injection-moulded poly(lactic acid) samples in controlled composting conditions. Polym. Degrad. Stab. 2013, 98, 1089–1096. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef]

- Gorrasi, G.; Pantani, R. Hydrolysis and Biodegradation of Poly(lactic acid). Adv. Polym. Sci. 2017, 279, 119–151. [Google Scholar] [CrossRef]

- Fortunati, E.; Puglia, D.; Monti, M.; Santulli, C.; Maniruzzaman, M.; Foresti, M.L.; Vazquez, A.; Kenny, J.M. Okra (Abelmoschus esculentus) Fibre Based PLA Composites: Mechanical Behaviour and Biodegradation. J. Polym. Environ. 2013, 21, 726–737. [Google Scholar] [CrossRef]

- Kale, R.D.; Gorade, V.G.; Madye, N.; Chaudhary, B.; Bangde, P.S.; Dandekar, P.P. Preparation and characterization of biocomposite packaging film from poly(lactic acid) and acylated microcrystalline cellulose using rice bran oil. Int. J. Biol. Macromol. 2018, 118, 1090–1102. [Google Scholar] [CrossRef] [PubMed]

- Xu, A.; Wang, Y.; Gao, J.; Wang, J. Facile fabrication of a homogeneous cellulose/polylactic acid composite film with improved biocompatibility, biodegradability and mechanical properties. Green Chem. 2019, 21, 4449–4456. [Google Scholar] [CrossRef]

- Putri, D.N.; Perdani, M.S.; Arbiantia, R.; Suryanegarab, L.; Hermansyaha, H. Effect of cellulose fiber from sorghum bagasse on the mechanical properties and biodegradability of polylactic acid. Energy Rep. 2020, 6, 221–226. [Google Scholar]

- Oluwabunmi, K.; D’Souza, N.A.; Zhao, W.; Choi, T.-Y.; Theyson, T. Compostable, fully biobased foams using PLA and micro cellulose for zero energy buildings. Sci. Rep. 2020, 10, 1–20. [Google Scholar] [CrossRef]

- Bolio-López, G.; Veleva, L.; Valadez-González, A.; Quintana-Owen, P. Weathering and biodegradation of polylactic acid composite reinforced with cellulose whiskers. Rev. Mex. Ing. Química 2013, 12, 143–153. [Google Scholar]

- Luzi, F.; Fortunati, E.; Puglia, D.; Petrucci, R.; Kenny, J.; Torre, L. Study of disintegrability in compost and enzymatic degradation of PLA and PLA nanocomposites reinforced with cellulose nanocrystals extracted from Po-sidonia Oceanica. Polym. Degrad. Stab. 2015, 121, 105–115. [Google Scholar] [CrossRef]

- Pandey, J.K.; Sunyong-Lee, S.; Sung-Hoon, A. Preparation and Properties of Bio-Nanoreinforced Composites from Biodegradable Polymer Matrix and cellulose Whiskers. J. Appl. Polym. Sci. 2010, 115, 2493–2501. [Google Scholar] [CrossRef]

- Hegyesi, N.; Zhang, Y.; Kohári, A.; Polyák, P.; Sui, X.; Pukánszky, B. Enzymatic degradation of PLA/cellulose nanocrystal composites. Ind. Crop. Prod. 2019, 141, 111799. [Google Scholar] [CrossRef]

- Kalita, N.; Nagarb, M.; Mudenura, C.; Kalamdhadc, A.; Katiyara, V. Biodegradation of modified Poly(lactic acid) based biocomposite films under thermophilic composting conditions. Polym. Test. 2019, 76, 522–536. [Google Scholar] [CrossRef]

- Dai, L.; Li, D.; He, J. Degradation of graft polymer and blend based on cellulose and poly(L-lactide). J. Appl. Polym. Sci. 2013, 130, 2257–2264. [Google Scholar] [CrossRef]

- Rogovina, S.Z. Biodegradable polymer composites based on synthetic and natural polymers of various classes. Polym. Sci. Ser. C 2016, 58, 62–73. [Google Scholar] [CrossRef]

- Arrieta, M.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J. PLA-PHB/cellulose based films: Me-chanical, barrier and disintegration properties. Polym. Degrad. Stab. 2014, 107, 139–149. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 5th ed.; John Wiley & Sons: Hoboken, NJ, USA, 1978. [Google Scholar]

- Moo-Tun, N.; Iñiguez-Covarrubias, G.; Valadez-Gonzalez, A. Assessing the effect of PLA, cellulose microfi-bers and CaCO3 on the properties of starch-based foams using a factorial design. Polym. Test. 2020, 86, 106482. [Google Scholar] [CrossRef]

- Cojocaru, C.; Clima, L. Polymer assisted ultrafiltration of AO7 anionic dye from aqueous solutions: Experi-mental design, multivariate optimization, and molecular docking insights. J. Membr. Sci. 2020, 604, 118054. [Google Scholar] [CrossRef]

- Li, Z.; Rabnawaz, M.; Khan, B. Response Surface Methodology Design for Biobased and Sustainable Coat-ings for Water- and Oil-Resistant Paper. ACS Appl. Polym. Mater. 2020, 2, 1378–1387. [Google Scholar] [CrossRef]

- Hardian, R.; Liang, Z.; Zhang, X.; Szekely, G. Artificial intelligence: The silver bullet for sustainable materi-als development. Green Chem. 2020, 22, 7521–7528. [Google Scholar] [CrossRef]

- Greene, J. Biodegradation of Compostable Plastics in Green Yard-Waste Compost Environment. J. Polym. Environ. 2007, 15, 269–273. [Google Scholar] [CrossRef]

- Masmoudi, F.; Bessadok, A.; Dammak, M.; Jaziri, M.; Ammar, E. Biodegradable packaging materials concep-tion based on starch and polylactic acid (PLA) reinforced with cellulose. Environ. Sci. Pollut. Res. 2016, 23, 20904–20914. [Google Scholar] [CrossRef] [PubMed]

- Badia, J.; Strömberg, E.; Kittikorn, T.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Relevant factors for the eco-design of polylactide/sisal biocomposites to control biodegradation in soil in an end-of-life scenario. Polym. Degrad. Stab. 2017, 143, 9–19. [Google Scholar] [CrossRef]

- Lv, S.; Zhang, Y.; Gu, J.; Tan, H. Biodegradation behavior and modelling of soil burial effect on degradation rate of PLA blended with starch and wood flour. Colloids Surf. B Biointerfaces 2017, 159, 800–808. [Google Scholar] [CrossRef]

- Agarwal, M.; Koelling, K.W.; Chalmers, J.J. Characterization of the Degradation of Polylactic Acid Polymer in a Solid Substrate Environment. Biotechnol. Prog. 1998, 14, 517–526. [Google Scholar] [CrossRef]

- Hassan, M.M.; Le Guen, M.J.; Tucker, N.; Parker, K. Thermo-mechanical, morphological and water absorption properties of thermoplastic starch/cellulose composite foams reinforced with PLA. Cellulose 2019, 26, 4463–4478. [Google Scholar] [CrossRef]

- Smidt, E.; Eckhardt Ku Lechner, P.; Schulten, H.R.; Leinweber, P. Characterization of different decompost-ing stages of biowaste using FT-IR spectroscopy and pyrolysis-field ionization mass spectrometry. Biodegradation 2005, 16, 67–79. [Google Scholar] [CrossRef]

- Smidt, E.; Meissl, K. The applicability of Fourier transform infrared (FT-IR) spectroscopy in waste management. Waste Manag. 2007, 27, 268–276. [Google Scholar] [CrossRef]

- Bouapao, L.; Tsuji, H.; Tashiro, K.; Zhang, J.; Hanesaka, M. Crystallization, spherulite growth, and structure of blends of crystalline and amorphous poly(lactide)s. Polymer 2009, 50, 4007–4017. [Google Scholar] [CrossRef]

- Sambha’a, E.; Lallam, A.; Jada, A. Effect of Hydrothermal Polylactic Acid Degradation on Polymer Molecu-lar Weight and Surface Properties. J. Polym. Environ. 2010, 18, 532–538. [Google Scholar] [CrossRef]

| Levels | Factors | ||

|---|---|---|---|

| MFC (wt.%) | CNC (wt.%) | ||

| −1 (lower) | 0 | 0 | |

| 1 (higher) | 20 | 5 | |

| Experimental matrix design | |||

| PLA (wt.%) | MFC (wt.%) | CNC (wt.%) | |

| HBC1 | 100 | 0 | 0 |

| HBC2 | 80 | 20 | 0 |

| HBC3 | 95 | 0 | 5 |

| HBC4 | 75 | 20 | 5 |

| HBC5 (central point) | 87.5 | 10 | 2.5 |

| HBC1 | 0 Days | 30 Days | 90 Days | 150 Days | 180 Days |

|---|---|---|---|---|---|

| Tg (°C) | 60 | 60 | 60 | 59 | 58 |

| Tcc (°C) | 97 | 97 | 95 | 94 | 93 |

| Tm1 (°C) | 151 | 150 | 150 | 149 | 149 |

| Tm2 (°C) | 166 | 163 | 162 | 160 | 159 |

| Xc (%) | 4 | 38 | 41 | 35 | 32 |

| HBC2 | 0 days | 30 days | 90 days | 150 days | 180 days |

| Tg (°C) | 59 | 59 | 59 | 58 | 58 |

| Tcc (°C) | 97 | 96 | 95 | 110 | 99 |

| Tm1 (°C) | 151 | 151 | 151 | 147 | 140 |

| Tm2 (°C) | 165 | 163 | 161 | 156 | 151 |

| Xc (%) | 9 | 43 | 32 | 27 | 21 |

| HBC3 | 0 days | 30 days | 90 days | 150 days | 180 days |

| Tg (°C) | 58 | 59 | 57 | 58 | 57 |

| Tcc (°C) | 102 | 104 | 104 | 101 | 100 |

| Tm1 (°C) | 154 | 154 | 153 | 151 | 140 |

| Tm2 (°C) | 162 | 161 | 160 | 158 | 151 |

| Xc (%) | 7 | 42 | 37 | 23 | 24 |

| HBC4 | 0 days | 30 days | 90 days | 150 days | 180 days |

| Tg (°C) | 59 | 58 | 57 | 56 | 55 |

| Tcc (°C) | 97 | 96 | 95 | 96 | 95 |

| Tm1 (°C) | 151 | 150 | 150 | 150 | 145 |

| Tm2 (°C) | 162 | 162 | 161 | 160 | 155 |

| Xc (%) | 12 | 45 | 31 | 22 | 11 |

| HBC5 | 0 days | 30 days | 90 days | 150 days | 180 days |

| Tg (°C) | 58 | 58 | 57 | 56 | 55 |

| Tcc (°C) | 98 | 96 | 95 | 96 | 96 |

| Tm1 (°C) | 152 | 151 | 151 | 151 | 141 |

| Tm2 (°C) | 161 | 161 | 160 | 159 | 152 |

| Xc (%) | 8 | 40 | 32 | 25 | 16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galera Manzano, L.M.; Ruz Cruz, M.Á.; Moo Tun, N.M.; Valadez González, A.; Mina Hernandez, J.H. Effect of Cellulose and Cellulose Nanocrystal Contents on the Biodegradation, under Composting Conditions, of Hierarchical PLA Biocomposites. Polymers 2021, 13, 1855. https://doi.org/10.3390/polym13111855

Galera Manzano LM, Ruz Cruz MÁ, Moo Tun NM, Valadez González A, Mina Hernandez JH. Effect of Cellulose and Cellulose Nanocrystal Contents on the Biodegradation, under Composting Conditions, of Hierarchical PLA Biocomposites. Polymers. 2021; 13(11):1855. https://doi.org/10.3390/polym13111855

Chicago/Turabian StyleGalera Manzano, Luciano Miguel, Miguel Ángel Ruz Cruz, Nora Magally Moo Tun, Alex Valadez González, and José Herminsul Mina Hernandez. 2021. "Effect of Cellulose and Cellulose Nanocrystal Contents on the Biodegradation, under Composting Conditions, of Hierarchical PLA Biocomposites" Polymers 13, no. 11: 1855. https://doi.org/10.3390/polym13111855

APA StyleGalera Manzano, L. M., Ruz Cruz, M. Á., Moo Tun, N. M., Valadez González, A., & Mina Hernandez, J. H. (2021). Effect of Cellulose and Cellulose Nanocrystal Contents on the Biodegradation, under Composting Conditions, of Hierarchical PLA Biocomposites. Polymers, 13(11), 1855. https://doi.org/10.3390/polym13111855