The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material

Abstract

1. Introduction

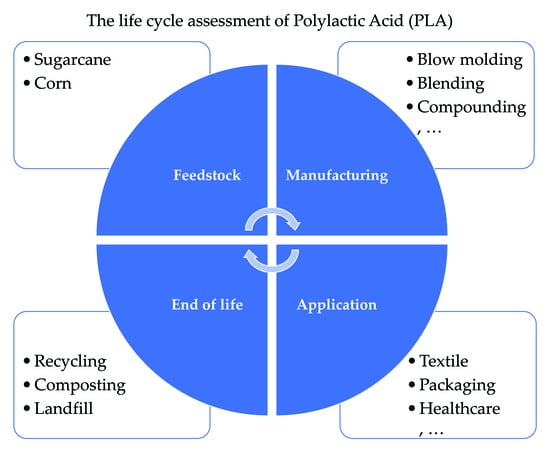

2. The Life Cycle of PLA

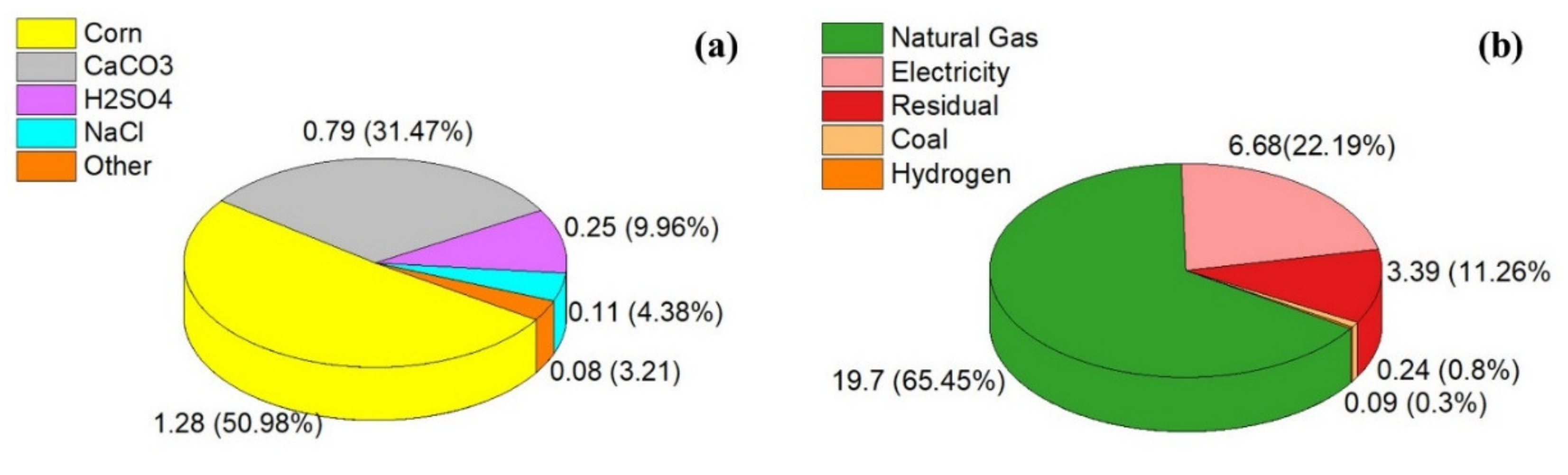

2.1. PLA Feedstock Collection and Its Conversion

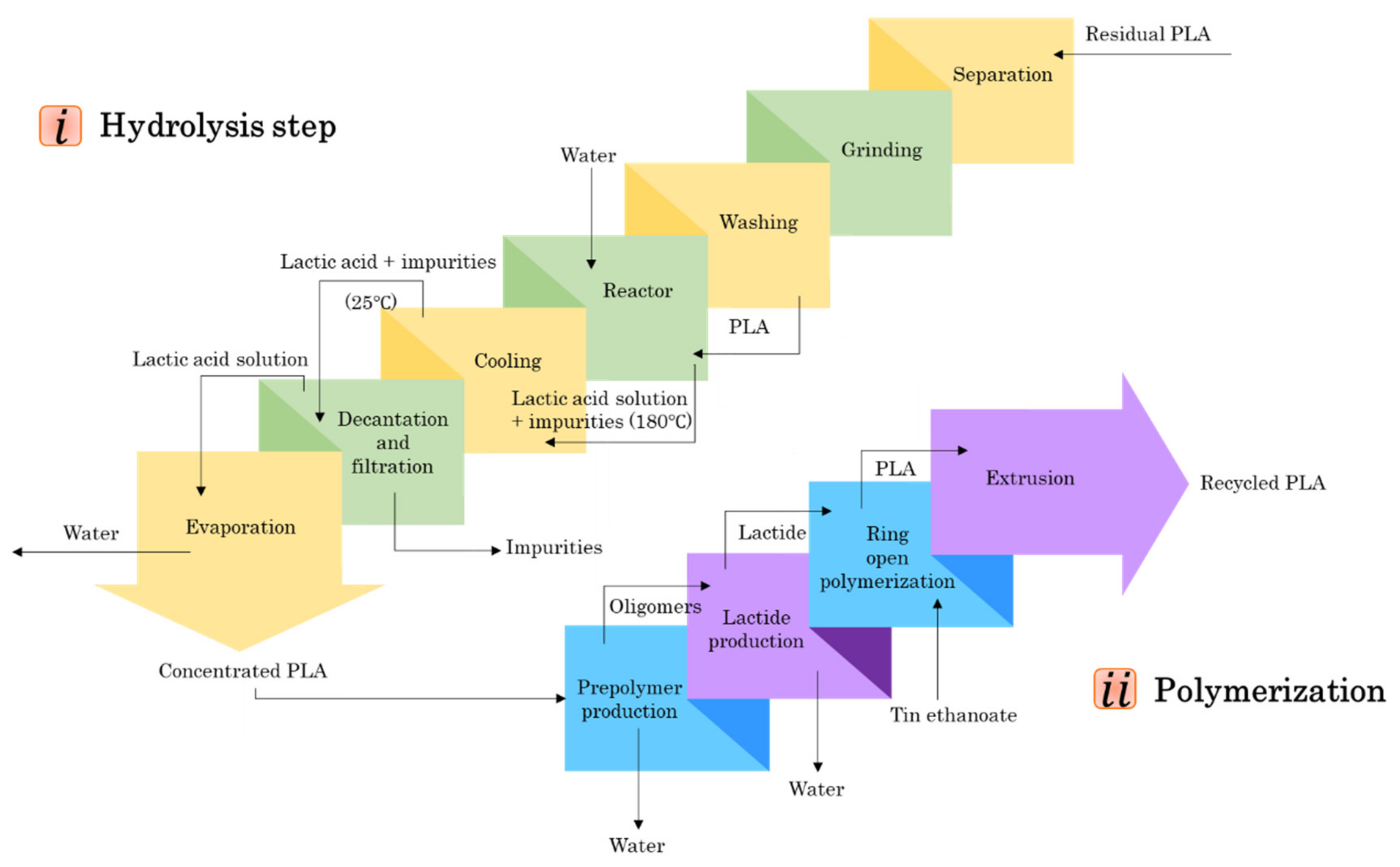

2.2. PLA Processing

2.3. Photodegradation of the Samples

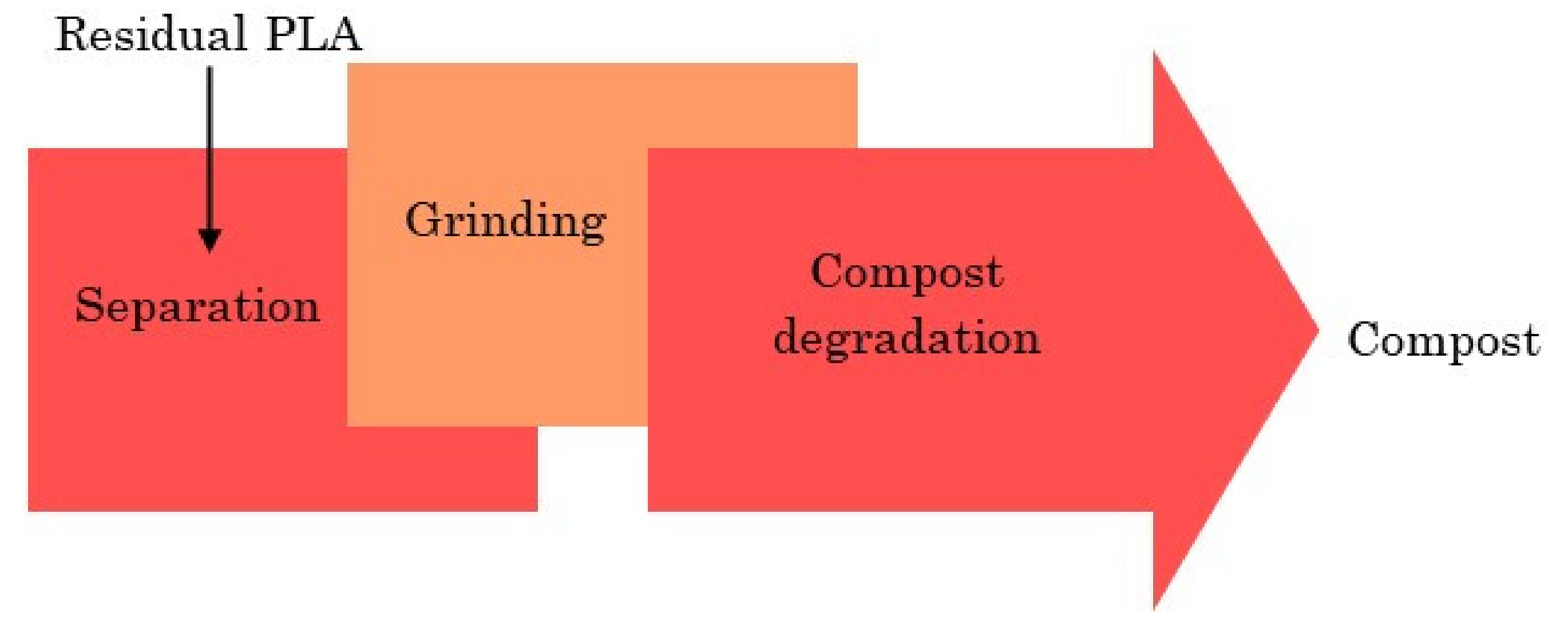

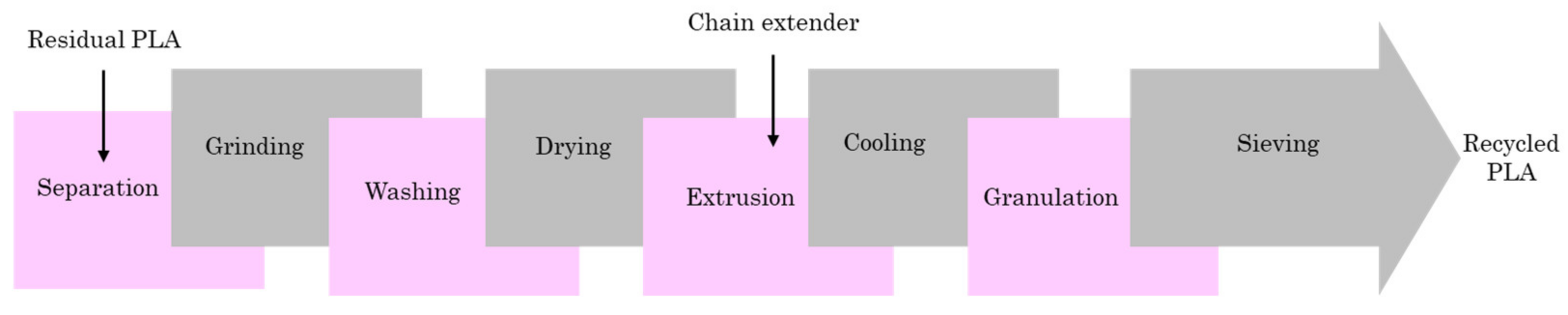

2.4. PLA EoL Options

3. Summary of the Existing LCAs of PLA

4. Summary of the Existing LCAs of PLA

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vijay Kumar, V.; Balaganesan, G.; Lee, J.K.Y.; Neisiany, R.E.; Surendran, S.; Ramakrishna, S. A Review of Recent Advances in Nanoengineered Polymer Composites. Polymers 2019, 11, 644. [Google Scholar] [CrossRef]

- Benavides, P.T.; Lee, U.; Zarè-Mehrjerdi, O. Life cycle greenhouse gas emissions and energy use of polylactic acid, bio-derived polyethylene, and fossil-derived polyethylene. J. Clean. Prod. 2020, 277, 124010. [Google Scholar] [CrossRef]

- Esameely Neisiany, R.; Enayati, M.S.; Sajkiewicz, P.; Pahlevanneshan, Z.; Ramakrishna, S. Insight into the Current Directions in Functionalized Nanocomposite Hydrogels. Front. Mater. 2020, 7, 25. [Google Scholar] [CrossRef]

- Foroughi, F.; Ghomi, E.R.; Dehaghi, F.M.; Borayek, R.; Ramakrishna, S. A Review on the Life Cycle Assessment of Cellulose: From Properties to the Potential of Making It a Low Carbon Material. Materials 2021, 14, 714. [Google Scholar] [CrossRef]

- Ryan, P.G. A Brief History of Marine Litter Research. In Marine Anthropogenic Litter; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2015; pp. 1–25. [Google Scholar]

- Ramesh, P.; Vinodh, S. State of art review on Life Cycle Assessment of polymers. Int. J. Sustain. Eng. 2020, 13, 411–422. [Google Scholar] [CrossRef]

- Feghali, E.; Tauk, L.; Ortiz, P.; Vanbroekhoven, K.; Eevers, W. Catalytic chemical recycling of biodegradable polyesters. Polym. Degrad. Stab. 2020, 179, 109241. [Google Scholar] [CrossRef]

- Suwanmanee, U.; Varabuntoonvit, V.; Chaiwutthinan, P.; Tajan, M.; Mungcharoen, T.; Leejarkpai, T. Life cycle assessment of single use thermoform boxes made from polystyrene (PS), polylactic acid, (PLA), and PLA/starch: Cradle to consumer gate. Int. J. Life Cycle Assess. 2012, 18, 401–417. [Google Scholar] [CrossRef]

- Rodríguez, L.J.; Fabbri, S.; Orrego, C.E.; Owsianiak, M. Comparative life cycle assessment of coffee jar lids made from biocomposites containing poly (lactic acid) and banana fiber. J. Environ. Manag. 2020, 266, 110493. [Google Scholar] [CrossRef]

- Ghomi, E.R.; Khosravi, F.; Tahavori, M.A.; Ramakrishna, S. Circular Economy: A Comparison Between the Case of Singapore and France. Mater. Circ. Econ. 2021, 3, 1–12. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Enayati, M.S.; Kazemi-Beydokhti, A.; Das, O.; Ramakrishna, S. Multilayered Bio-Based Electrospun Membranes: A Potential Porous Media for Filtration Applications. Front. Mater. 2020, 7, 67. [Google Scholar] [CrossRef]

- Benavides, P.T.; Dunn, J.B.; Han, J.; Biddy, M.; Markham, J. Exploring Comparative Energy and Environmental Benefits of Virgin, Recycled, and Bio-Derived PET Bottles. ACS Sustain. Chem. Eng. 2018, 6, 9725–9733. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Biopolymer production and end of life comparisons using life cycle assessment. Resour. Conserv. Recycl. 2017, 122, 295–306. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N. Environmental performance comparison of bioplastics and petrochemical plastics: A review of life cycle assessment (LCA) methodological decisions. Resour. Conserv. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Morão, A.; De Bie, F. Life Cycle Impact Assessment of Polylactic Acid (PLA) Produced from Sugarcane in Thailand. J. Polym. Environ. 2019, 27, 2523–2539. [Google Scholar] [CrossRef]

- Nitkiewicz, T.; Wojnarowska, M.; Sołtysik, M.; Kaczmarski, A.; Witko, T.; Ingrao, C.; Guzik, M. How sustainable are biopolymers? Findings from a life cycle assessment of polyhydroxyalkanoate production from rapeseed-oil derivatives. Sci. Total. Environ. 2020, 749, 141279. [Google Scholar] [CrossRef]

- Choi, B.; Yoo, S.; Park, S.-I. Carbon Footprint of Packaging Films Made from LDPE, PLA, and PLA/PBAT Blends in South Korea. Sustainability 2018, 10, 2369. [Google Scholar] [CrossRef]

- Rojas-Bringas, P.M.; De-La-Torre, G.E.; Torres, F.G. Influence of the source of starch and plasticizers on the environmental burden of starch-Brazil nut fiber biocomposite production: A life cycle assessment approach. Sci. Total. Environ. 2021, 769, 144869. [Google Scholar] [CrossRef]

- Haylock, R.; Rosentrater, K.A. Cradle-to-Grave Life Cycle Assessment and Techno-Economic Analysis of Polylactic Acid Composites with Traditional and Bio-Based Fillers. J. Polym. Environ. 2017, 26, 1484–1503. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; Martí, J.V.; García-Segura, T.; Yepes, V. Life-Cycle Assessment: A Comparison between Two Optimal Post-Tensioned Concrete Box-Girder Road Bridges. Sustainability 2017, 9, 1864. [Google Scholar] [CrossRef]

- Walker, S.; Rothman, R. Life cycle assessment of bio-based and fossil-based plastic: A review. J. Clean. Prod. 2020, 261, 121158. [Google Scholar] [CrossRef]

- Lorite, G.; Rocha, J.M.; Miilumäki, N.; Saavalainen, P.; Selkälä, T.; Morales-Cid, G.; Gonçalves, M.; Pongrácz, E.; Rocha, C.M.; Toth, G. Evaluation of physicochemical/microbial properties and life cycle assessment (LCA) of PLA-based nanocomposite active packaging. LWT 2017, 75, 305–315. [Google Scholar] [CrossRef]

- Maga, D.; Hiebel, M.; Aryan, V. A Comparative Life Cycle Assessment of Meat Trays Made of Various Packaging Materials. Sustainability 2019, 11, 5324. [Google Scholar] [CrossRef]

- Chitaka, T.Y.; Russo, V.; Von Blottnitz, H. In pursuit of environmentally friendly straws: A comparative life cycle assessment of five straw material options in South Africa. Int. J. Life Cycle Assess. 2020, 25, 1818–1832. [Google Scholar] [CrossRef]

- Gregoriadis, G. Drug Carriers in Biology and Medicine; Academic Press: Cambridge, MA, USA, 1979. [Google Scholar]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef]

- Momeni, S.; Ghomi, E.R.; Shakiba, M.; Shafiei-Navid, S.; Abdouss, M.; Bigham, A.; Khosravi, F.; Ahmadi, Z.; Faraji, M.; Abdouss, H.; et al. The Effect of Poly (Ethylene glycol) Emulation on the Degradation of PLA/Starch Composites. Polymers 2021, 13, 1019. [Google Scholar] [CrossRef]

- Blanco, I.; Ingrao, C.; Siracusa, V. Life-Cycle Assessment in the Polymeric Sector: A Comprehensive Review of Application Experiences on the Italian Scale. Polymers 2020, 12, 1212. [Google Scholar] [CrossRef]

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef] [PubMed]

- Correa-Pacheco, Z.N.; Black-Solís, J.D.; Ortega-Gudiño, P.; Sabino-Gutiérrez, M.A.; Benítez-Jiménez, J.J.; Barajas-Cervantes, A.; Bautista-Baños, S.; Hurtado-Colmenares, L.B. Preparation and Characterization of Bio-Based PLA/PBAT and Cinnamon Essential Oil Polymer Fibers and Life-Cycle Assessment from Hydrolytic Degradation. Polymers 2019, 12, 38. [Google Scholar] [CrossRef]

- Aldas, M.; Pavon, C.; De La Rosa-Ramírez, H.; Ferri, J.M.; Bertomeu, D.; Samper, M.D.; López-Martínez, J. The Impact of Biodegradable Plastics in the Properties of Recycled Polyethylene Terephthalate. J. Polym. Environ. 2021, 1–15. [Google Scholar] [CrossRef]

- Cakir, S.; Aycicek, M.; Akinci, A. Investigation of the mechanical and physical properties of PLA produced by injection molding for matrix material of polymer composites. Mater. Sci. Adv. Compos. Mater. 2018, 2, 1–7. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Luedtke, J.; Gaugler, M.; Grigsby, W.J.; Krause, A. Understanding the development of interfacial bonding within PLA/wood-based thermoplastic sandwich composites. Ind. Crop. Prod. 2019, 127, 129–134. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Alkan, U. Influence of time and room temperature on mechanical and thermal degradation of poly(lactic) acid. Therm. Sci. 2019, 23, 383–390. [Google Scholar] [CrossRef]

- Mazidi, M.M.; Edalat, A.; Berahman, R.; Hosseini, F.S. Highly-Toughened Polylactide- (PLA-) Based Ternary Blends with Significantly Enhanced Glass Transition and Melt Strength: Tailoring the Interfacial Interactions, Phase Morphology, and Performance. Macromolecules 2018, 51, 4298–4314. [Google Scholar] [CrossRef]

- Wang, X.; Pan, Y.; Yuan, H.; Su, M.; Shao, C.; Liu, C.; Guo, Z.; Shen, C.; Liu, X. Simple fabrication of superhydrophobic PLA with honeycomb-like structures for high-efficiency oil-water separation. Chin. Chem. Lett. 2020, 31, 365–368. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhang, X.; Yao, Q.; Zhang, Y.; Fu, Y. Production of acetonitrile via catalytic fast pyrolysis of biomass derived polylactic acid under ammonia atmosphere. J. Anal. Appl. Pyrolysis 2019, 140, 376–384. [Google Scholar] [CrossRef]

- Pavezi, K.J.; Rocha, A.; Bonafé, E.G.; Martins, A.F. Electrospinning-electrospraying of poly(acid lactic) solutions in binary chloroform/formic acid and chloroform/acetic acid mixtures. J. Mol. Liq. 2020, 320, 114448. [Google Scholar] [CrossRef]

- Södergård, A.; Stolt, M. Properties of lactic acid based polymers and their correlation with composition. Prog. Polym. Sci. 2002, 27, 1123–1163. [Google Scholar] [CrossRef]

- Jin, F.-L.; Hu, R.-R.; Park, S.-J. Improvement of thermal behaviors of biodegradable poly(lactic acid) polymer: A review. Compos. Part B Eng. 2019, 164, 287–296. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Li, Y.-D.; Zeng, J.-B. Progress in Toughening Poly(Lactic Acid) with Renewable Polymers. Polym. Rev. 2017, 57, 557–593. [Google Scholar] [CrossRef]

- Tsuji, H.; Kondoh, F. Synthesis of meso-lactide by thermal configurational inversion and depolymerization of poly(l-lactide) and thermal configurational inversion of lactides. Polym. Degrad. Stab. 2017, 141, 77–83. [Google Scholar] [CrossRef]

- Scaffaro, R.; Botta, L.; Maio, A.; Gallo, G. PLA graphene nanoplatelets nanocomposites: Physical properties and release kinetics of an antimicrobial agent. Compos. Part B Eng. 2017, 109, 138–146. [Google Scholar] [CrossRef]

- Chen, C.-C.; Chueh, J.-Y.; Tseng, H.; Huang, H.-M.; Lee, S.-Y. Preparation and characterization of biodegradable PLA polymeric blends. Biomaterials 2003, 24, 1167–1173. [Google Scholar] [CrossRef]

- Lim, J.S.; Park, K.-I.; Chung, G.S.; Kim, J.H. Effect of composition ratio on the thermal and physical properties of semicrystalline PLA/PHB-HHx composites. Mater. Sci. Eng. C 2013, 33, 2131–2137. [Google Scholar] [CrossRef] [PubMed]

- Sedničková, M.; Pekařová, S.; Kucharczyk, P.; Bočkaj, J.; Janigová, I.; Kleinová, A.; Jochec-Mošková, D.; Omaníková, L.; Perďochová, D.; Koutný, M.; et al. Changes of physical properties of PLA-based blends during early stage of biodegradation in compost. Int. J. Biol. Macromol. 2018, 113, 434–442. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Mathew, A.P.; Oksman, K.; Sain, M. Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J. Appl. Polym. Sci. 2005, 97, 2014–2025. [Google Scholar] [CrossRef]

- Yang, S.-L.; Wu, Z.-H.; Yang, W.; Yang, M.-B. Thermal and mechanical properties of chemical crosslinked polylactide (PLA). Polym. Test. 2008, 27, 957–963. [Google Scholar] [CrossRef]

- Suryanegara, L.; Nakagaito, A.N.; Yano, H. The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA composites. Compos. Sci. Technol. 2009, 69, 1187–1192. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Keoleian, G.; Miller, S.; Kleine, R.; Fang, A.; Mosley, J. Life Cycle Material Data Update for GREET Model; Report, No. CSS12-12 2012; University of Michigan: Ann Arbor, MI, USA, 2012. [Google Scholar]

- Vink, E.T.; Davies, S. Life Cycle Inventory and Impact Assessment Data for 2014 Ingeo™ Polylactide Production. Ind. Biotechnol. 2015, 11, 167–180. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Muller, J.; González-Martínez, C.; Chiralt, A. Combination of Poly(lactic) Acid and Starch for Biodegradable Food Packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Preparation of bioactive functional poly(lactic acid)/curcumin composite film for food packaging application. Int. J. Biol. Macromol. 2020, 162, 1780–1789. [Google Scholar] [CrossRef] [PubMed]

- Bałdowska-Witos, P.; Piotrowska, K.; Kruszelnicka, W.; Błaszczak, M.; Tomporowski, A.; Opielak, M.; Kasner, R.; Flizikowski, J. Managing the Uncertainty and Accuracy of Life Cycle Assessment Results for the Process of Beverage Bottle Moulding. Polymers 2020, 12, 1320. [Google Scholar] [CrossRef]

- Khosravi, A.; Fereidoon, A.; Khorasani, M.M.; Naderi, G.; Ganjali, M.R.; Zarrintaj, P.; Saeb, M.R.; Gutiérrez, T.J. Soft and hard sections from cellulose-reinforced poly(lactic acid)-based food packaging films: A critical review. Food Packag. Shelf Life 2020, 23, 100429. [Google Scholar] [CrossRef]

- Gan, I.; Chow, W. Antimicrobial poly(lactic acid)/cellulose bionanocomposite for food packaging application: A review. Food Packag. Shelf Life 2018, 17, 150–161. [Google Scholar] [CrossRef]

- Lasprilla, A.J.; Martinez, G.A.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly-lactic acid synthesis for application in biomedical devices—A review. Biotechnol. Adv. 2012, 30, 321–328. [Google Scholar] [CrossRef]

- Pawar, R.P.; U Tekale, S.; U Shisodia, S.; T Totre, J.; Domb, A.J. Biomedical applications of poly (lactic acid). Recent Pat. Regen. Med. 2014, 4, 40–51. [Google Scholar] [CrossRef]

- Rezvani Ghomi, E.; Khosravi, F.; Neisiany, R.E.; Singh, S.; Ramakrishna, S. Future of additive manufacturing in healthcare. Curr. Opin. Biomed. Eng. 2021, 17, 100255. [Google Scholar] [CrossRef]

- Eshkalak, S.K.; Ghomi, E.R.; Dai, Y.; Choudhury, D.; Ramakrishna, S. The role of three-dimensional printing in healthcare and medicine. Mater. Des. 2020, 194, 108940. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-looped recycling of polylactic acid used in 3D printing: An experimental investigation and life cycle assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Rossi, V.; Cleeve-Edwards, N.; Lundquist, L.; Schenker, U.; Dubois, C.; Humbert, S.; Jolliet, O. Life cycle assessment of end-of-life options for two biodegradable packaging materials: Sound application of the European waste hierarchy. J. Clean. Prod. 2015, 86, 132–145. [Google Scholar] [CrossRef]

- Wan, L.; Zhang, Y. Jointly modified mechanical properties and accelerated hydrolytic degradation of PLA by interface reinforcement of PLA-WF. J. Mech. Behav. Biomed. Mater. 2018, 88, 223–230. [Google Scholar] [CrossRef] [PubMed]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- De Andrade, M.F.C.; Souza, P.M.S.; Cavalett, O.; Morales, A.R. Life Cycle Assessment of Poly(Lactic Acid) (PLA): Comparison Between Chemical Recycling, Mechanical Recycling and Composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Maga, D.; Hiebel, M.; Thonemann, N. Life cycle assessment of recycling options for polylactic acid. Resour. Conserv. Recycl. 2019, 149, 86–96. [Google Scholar] [CrossRef]

- Mallet, B.; Lamnawar, K.; Maazouz, A. Improvement of blown film extrusion of poly(Lactic Acid): Structure-Processing-Properties relationships. Polym. Eng. Sci. 2013, 54, 840–857. [Google Scholar] [CrossRef]

- Jaszkiewicz, A.; Bledzki, A.K.; Van Der Meer, R.; Franciszczak, P.; Meljon, A. How does a chain-extended polylactide behave?: A comprehensive analysis of the material, structural and mechanical properties. Polym. Bull. 2014, 71, 1675–1690. [Google Scholar] [CrossRef]

- Meng, Q.-K.; Heuzey, M.-C.; Carreau, P.J. Effects of a Multifunctional Polymeric Chain Extender on the Properties of Polylactide and Polylactide/Clay Nanocomposites. Int. Polym. Process. 2012, 27, 505–516. [Google Scholar] [CrossRef]

- Lyu, S.; Schley, J.; Loy, B.; Lind, D.; Hobot, C.; Sparer, R.; Untereker, D. Kinetics and Time−Temperature Equivalence of Polymer Degradation. Biomacromolecules 2007, 8, 2301–2310. [Google Scholar] [CrossRef] [PubMed]

- Vink, E.T.; Rábago, K.R.; Glassner, D.A.; Gruber, P.R. Applications of life cycle assessment to NatureWorks™ polylactide (PLA) production. Polym. Degrad. Stab. 2003, 80, 403–419. [Google Scholar] [CrossRef]

- Madival, S.; Auras, R.; Singh, S.P.; Narayan, R. Assessment of the environmental profile of PLA, PET and PS clamshell containers using LCA methodology. J. Clean. Prod. 2009, 17, 1183–1194. [Google Scholar] [CrossRef]

- Piemonte, V. Bioplastic Wastes: The Best Final Disposition for Energy Saving. J. Polym. Environ. 2011, 19, 988–994. [Google Scholar] [CrossRef]

- Papong, S.; Malakul, P.; Trungkavashirakun, R.; Wenunun, P.; Chom-In, T.; Nithitanakul, M.; Sarobol, E. Comparative assessment of the environmental profile of PLA and PET drinking water bottles from a life cycle perspective. J. Clean. Prod. 2014, 65, 539–550. [Google Scholar] [CrossRef]

- Horowitz, N.; Frago, J.; Mu, D. Life cycle assessment of bottled water: A case study of Green2O products. Waste Manag. 2018, 76, 734–743. [Google Scholar] [CrossRef]

- Mahalle, L.; Alemdar, A.; Mihai, M.; Legros, N. A cradle-to-gate life cycle assessment of wood fibre-reinforced polylactic acid (PLA) and polylactic acid/thermoplastic starch (PLA/TPS) biocomposites. Int. J. Life Cycle Assess. 2014, 19, 1305–1315. [Google Scholar] [CrossRef]

- Benetto, E.; Jury, C.; Igos, E.; Carton, J.; Hild, P.; Vergne, C.; Di Martino, J. Using atmospheric plasma to design multilayer film from polylactic acid and thermoplastic starch: A screening Life Cycle Assessment. J. Clean. Prod. 2015, 87, 953–960. [Google Scholar] [CrossRef]

- Bałdowska-Witos, P.; Kruszelnicka, W.; Kasner, R.; Tomporowski, A.; Flizikowski, J.; Kłos, Z.; Piotrowska, K.; Markowska, K. Application of LCA Method for Assessment of Environmental Impacts of a Polylactide (PLA) Bottle Shaping. Polymers 2020, 12, 388. [Google Scholar] [CrossRef] [PubMed]

- Molins, G.; Álvarez, M.D.; Garrido, N.; Macanás, J.; Carrillo, F. Environmental Impact Assessment of Polylactide(PLA)/Chicken Feathers Biocomposite Materials. J. Polym. Environ. 2018, 26, 873–884. [Google Scholar] [CrossRef]

- Carus, M. Biobased Economy and Climate Change—Important Links, Pitfalls, and Opportunities. Ind. Biotechnol. 2017, 13, 41–51. [Google Scholar] [CrossRef]

| Properties | PLA |

|---|---|

| Polymer density (g/cm3) | 1.21–1.30 |

| Tensile strength (MPa) | 15.5–150 |

| Tensile modulus (GPa) | 2.7–16 |

| Ultimate strain (%) | 2–10 |

| Specific tensile strength (Nm/g) | 16.8–66.8 |

| Specific tensile modulus (kNm/g) | 0.28–3.85 |

| Glass transition temperature (°C) | 60–65 |

| Melting temperature (°C) | 130–180 |

| Subject | Goal and Scope | LCA Software/LCIA Methodology | Key Assumptions | Data Sources | Major Findings | Ref. |

|---|---|---|---|---|---|---|

| PLA manufacturing/Raw materials | Cradle-to-grave LCA of PLA production | Based on Association of Plastics Manufacturers of Europe (APME) analysis | - | Based on APME, LCI databases |

| [75] |

| PLA manufacturing/Raw materials/EoL | Cradle-to-cradle LCA of PLA compared to PET and PS thermoformed clamshell containers and consideration of their environmental impacts based on different LOI scenarios | SimaProTM/Eco-Indicator |

| Ecoinvent databases available with SimaProTM, Commercial LCI databases |

| [76] |

| Recycling and manufacturing of PLA, LOI | Investigating the LCA of PLA for three different recycling technologies for post-consumer and post-industrial waste to identify their environmental impacts compared to thermal treatment | GaBi software/Institute for Energy and Environmental Research, Heidelberg GmbH ifeu |

| Lab and pilot plant data, Commercial LCI databases |

| [70] |

| PLA manufacturing/Raw materials | Cradle-to-gate LCA of PLA production from sugarcane in Thailand considering its environmental impacts | SimaPro 8.4./Cumulative Energy Demand (CED) |

| Commercial LCI databases |

| [15] |

| PLA manufacturing/PLA products | Cradle-to-grave LCA of PLA bottle shaping and its environmental impacts identification | SimaPro 8.4./eco-indicator-99 (Damage Level) |

| - |

| [82] |

| PLA manufacturing/PLA products | Cradle-to-gate and cradle-to-grave LCA of PLA and Mater-Bi | SimaPro7.2/Cumulative Energy Demand (CED), EI-99 |

| Ecoinvent v.2.2 database |

| [77] |

| PLA manufacturing/Raw materials/EoL | Cradle-to-gate LCA of PLA drinking water bottles compared to PET bottles | SimaPro/CML 2 baseline 2000 |

| Literature, calculations, Ecoinvent database, IPCC method, Commercial LCI databases |

| [78] |

| PLA/TPS manufacturing/Raw materials | Cradle-to-gate LCA of wood fiber-reinforced PLA and PLA/TPS bio-composites in comparison with PP | None/Cumulative Energy Demand (CED)/TRACI |

| US LCI database, US-EI database |

| [80] |

| PLA manufacturing/Raw materials/EOL | Cradle-to-grave LCA of PLA and TPS multilayer film | SimaPro 7.3.3/Impact 2002+(I2002), ReCiPe |

| Ecoinvent 2.1 database, Lab and pilot plant data |

| [81] |

| Bio-based polymers and traditional plastics/manufacturing/EoL | Cradle-to-grave LCA of bio-based polymers and traditional plastics followed by EoL investigation | None/TRACI |

| Literature sources |

| [13] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezvani Ghomi, E.; Khosravi, F.; Saedi Ardahaei, A.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers 2021, 13, 1854. https://doi.org/10.3390/polym13111854

Rezvani Ghomi E, Khosravi F, Saedi Ardahaei A, Dai Y, Neisiany RE, Foroughi F, Wu M, Das O, Ramakrishna S. The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers. 2021; 13(11):1854. https://doi.org/10.3390/polym13111854

Chicago/Turabian StyleRezvani Ghomi, Erfan, Fatemeh Khosravi, Ali Saedi Ardahaei, Yunqian Dai, Rasoul Esmaeely Neisiany, Firoozeh Foroughi, Min Wu, Oisik Das, and Seeram Ramakrishna. 2021. "The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material" Polymers 13, no. 11: 1854. https://doi.org/10.3390/polym13111854

APA StyleRezvani Ghomi, E., Khosravi, F., Saedi Ardahaei, A., Dai, Y., Neisiany, R. E., Foroughi, F., Wu, M., Das, O., & Ramakrishna, S. (2021). The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers, 13(11), 1854. https://doi.org/10.3390/polym13111854