Chitosan/Montmorillonite Coatings for the Fabrication of Food-Safe Greaseproof Paper

Abstract

1. Introduction

2. Methods

2.1. Materials

2.2. Preparation of Chitosan Solution and MMT/Chitosan Solution

2.2.1. Chitosan Solution

2.2.2. MMT/Chitosan Mixture

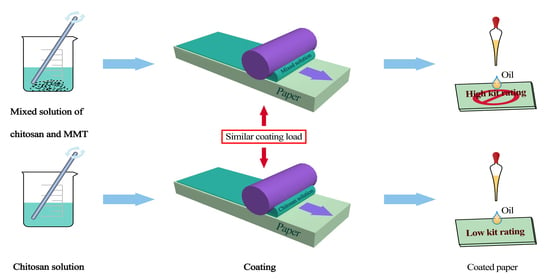

2.2.3. Coating Preparation

2.3. Coating Load, Thickness

2.4. Grease Resistance

2.5. Experimental Design and Statistical Study

2.6. Grease Permeability (GP)

2.7. Air Permeability Analysis

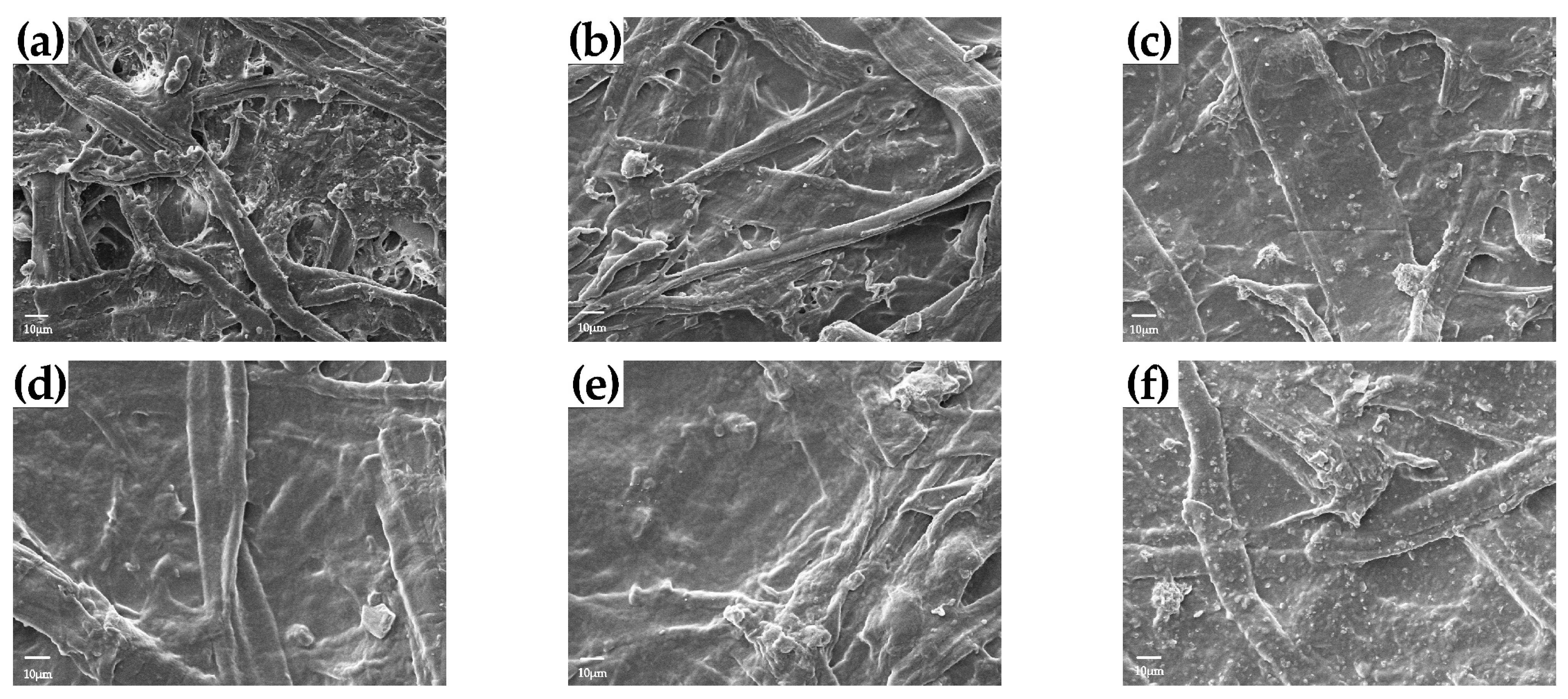

2.8. Scanning Electron Microscopy (SEM)

2.9. Contact Angles (CAs)

2.10. Surface Roughness

2.11. Thermogravimetric Analysis (TGA)

2.12. Mechanical Properties

3. Results and Discussion

3.1. RSM Results

3.2. Coating Load, and Thickness of the Paper

3.3. The Oil Resistance and Grease Permeability of Paper

3.4. The Air Permeability of Paper

3.5. The Oil Contact Angles (OCAs) and Water Contact Angles (WCAs) of Paper

3.6. TGA and DGA of Paper and Coating

3.7. The TS and ITR of Paper

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deshwal, G.K.; Panjagari, N.R.; Alam, T. An overview of paper and paper based food packaging materials: Health safety and environmental concerns. J. Food Sci. Technol. Mysore 2019, 56, 4391–4403. [Google Scholar] [CrossRef]

- Raheem, D. Application of plastics and paper as food packaging materials—An overview. Emir. J. Food Agric. 2013, 25, 177–188. [Google Scholar] [CrossRef]

- Kansal, D.; Hamdani, S.S.; Ping, R.; Sirinakbumrung, N.; Rabnawaz, M. Food-Safe Chitosan-Zein Dual-Layer Coating for Water- and Oil-Repellant Paper Substrates. ACS Sustain. Chem. Eng. 2020, 8, 6887–6897. [Google Scholar] [CrossRef]

- Zhang, W.; Xiao, H.; Qian, L. Enhanced water vapour barrier and grease resistance of paper bilayer-coated with chitosan and beeswax. Carbohyd. Polym. 2014, 101, 401–406. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Zang, Y.H.; Du, J. Effects of Starch on Latex Migration and on Paper Coating Properties. Ind. Eng. Chem. Res. 2011, 50, 9781–9786. [Google Scholar] [CrossRef]

- Rabnawaz, M.; Wyman, I.; Auras, R.; Cheng, S. A roadmap towards green packaging: The current status and future outlook for polyesters in the packaging industry. Green Chem. 2017, 19, 4737–4753. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Schaider, L.A.; Balan, S.A.; Blum, A.; Andrews, D.Q.; Strynar, M.J.; Dickinson, M.E.; Lunderberg, D.M.; Lang, J.R.; Peaslee, G.F. Fluorinated Compounds in U.S. Fast Food Packaging. Environ. Sci. Tech. Let. 2017, 4, 105–111. [Google Scholar] [CrossRef]

- Kansal, D.; Hamdani, S.S.; Ping, R.; Rabnawaz, M. Starch and Zein Biopolymers as a Sustainable Replacement for PFAS, Silicone Oil, and Plastic-Coated Paper. Ind. Eng. Chem. Res. 2020, 26, 12075–12084. [Google Scholar] [CrossRef]

- Hamdani, S.S.; Li, Z.; Rabnawaz, M.; Kamdem, D.P.; Khan, B.A. Chitosan–Graft–Poly (dimethylsiloxane)/Zein Coatings for the Fabrication of Environmentally Friendly Oil-and Water-Resistant Paper. ACS Sustain. Chem. Eng. 2020, 8, 5147–5155. [Google Scholar] [CrossRef]

- Vaswani, S.; Koskinen, J.; Hess, D.W. Surface modification of paper and cellulose by plasma-assisted deposition of fluorocarbon films. Surf. Coat. Technol. 2005, 195, 121–129. [Google Scholar] [CrossRef]

- Dassuncao, C.; Hu, X.C.; Nielsen, F.; Weihe, P.; Grandjean, P.; Sunderland, E.M. Shifting global exposures to poly-and perfluoroalkyl substances (PFASs) evident in longitudinal birth cohorts from a seafood-consuming population. Environ. Sci. Technol. 2018, 52, 3738–3747. [Google Scholar] [CrossRef]

- Rosenmai, A.K.; Taxvig, C.; Svingen, T.; Trier, X.; van Vugt Lussenburg, B.M.A.; Pedersen, M.; Lesné, L.; Jégou, B.; Vinggaard, A.M. Fluorinated alkyl substances and technical mixtures used in food paper-packaging exhibit endocrine-related activity in vitro. Androl. US 2016, 4, 662–672. [Google Scholar] [CrossRef] [PubMed]

- Khwaldia, K. Water vapor barrier and mechanical properties of paper-sodium caseinate and paper-sodium caseinate-paraffin wax films. J. Food Biochem. 2010, 34, 998–1013. [Google Scholar] [CrossRef]

- Khwaldia, K.; Arab Tehrany, E.; Desobry, S. Biopolymer coatings on paper packaging materials. Compr. Rev. Food. Sci. F 2010, 9, 82–91. [Google Scholar] [CrossRef]

- Nechita, P. Review on polysaccharides used in coatings for food packaging papers. Coatings 2020, 10, 566. [Google Scholar] [CrossRef]

- Kansal, D.; Rabnawaz, M. Fabrication of oil- and water-resistant paper without creating microplastics on disposal. J. Appl. Polym. Sci. 2021, 138, 49692. [Google Scholar] [CrossRef]

- Li, Z.; Rabnawaz, M. Oil-and water-resistant coatings for porous cellulosic substrates. ACS Appl. Polym. Mater. 2018, 1, 103–111. [Google Scholar] [CrossRef]

- Li, Z.; Rabnawaz, M.; Khan, B. Response Surface Methodology Design for Biobased and Sustainable Coatings for Water-and Oil-Resistant Paper. ACS Appl. Polym. Mater. 2020, 2, 1378–1387. [Google Scholar] [CrossRef]

- Kopacic, S.; Walzl, A.; Zankel, A.; Leitner, E.; Bauer, W. Alginate and chitosan as a functional barrier for paper-based packaging materials. Coatings 2018, 8, 235. [Google Scholar] [CrossRef]

- Li, Z.; Rabnawaz, M.; Sarwar, M.G.; Khan, B.; Nair, A.K.; Sirinakbumrung, N.; Kamdem, D.P. A closed-loop and sustainable approach for the fabrication of plastic-free oil-and water-resistant paper products. Green Chem. 2019, 21, 5691–5700. [Google Scholar] [CrossRef]

- Wang, S.; Jing, Y. Effects of formation and penetration properties of biodegradable montmorillonite/chitosan nanocomposite film on the barrier of package paper. Appl. Clay Sci. 2017, 138, 74–80. [Google Scholar] [CrossRef]

- Aldana, D.S.; Villa, E.D.; De, M.; Hernández, D.; Casarrubias, L.B. Barrier Properties of Polylactic Acid in Cellulose Based Packages Using Montmorillonite as Filler. Polymers 2014, 6, 2386–2403. [Google Scholar] [CrossRef]

- Reis, A.B.; Yoshida, C.M.; Reis, A.P.C.; Franco, T.T. Application of chitosan emulsion as a coating on Kraft paper. Polym. Int. 2011, 60, 963–969. [Google Scholar] [CrossRef]

- Yong, J.; Chen, F.; Yang, Q.; Huo, J.; Hou, X. Superoleophobic surfaces. Chem. Soc. Rev. 2017, 46, 4168–4217. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Rabnawaz, M. Fabrication of food-safe water-resistant paper coatings using a melamine primer and polysiloxane outer layer. ACS Omega 2018, 3, 11909–11916. [Google Scholar] [CrossRef] [PubMed]

- Cardenas, G.; Miranda, S.P. FTIR and TGA studies of chitosan composite films. J. Chil. Chem. Soc. 2004, 49, 291–295. [Google Scholar] [CrossRef]

- Wang, S.F.; Shen, L.; Tong, Y.J.; Chen, L.; Phang, I.Y.; Lim, P.Q.; Liu, T.X. Biopolymer chitosan/montmorillonite nanocomposites: Preparation and characterization. Polym. Degrad. Stabil. 2005, 90, 123–131. [Google Scholar] [CrossRef]

- Metasari, A. Effects of Chitosan/Montmorillonite Nanocomposites Films on the Growth of Bacteria in Laboratory Media. Biosci. Biotechnol. ICBB 2011, 1, 261–269. [Google Scholar]

| Variables | Responses | |||

|---|---|---|---|---|

| Sample No. | X1 a (%) | X2 b (%) | Y1 (Coating Load) (g/m2) | Y2 (Kit Rating) |

| 1 | 2 | 0.15 | 3.81 | 8 |

| 2 | 1 | 0.15 | 3.11 | 5 |

| 3 | 2 | 0.15 | 3.65 | 8 |

| 4 | 1 | 0.3 | 3.50 | 4 |

| 5 | 3 | 0 | 3.99 | 8 |

| 6 | 1 | 0 | 3.17 | 4 |

| 7 | 3 | 0.3 | 4.42 | 7 |

| 8 | 3 | 0.15 | 4.21 | 8 |

| 9 | 2 | 0.3 | 4.18 | 6 |

| 10 | 2 | 0 | 3.45 | 6 |

| 11 | 2 | 0.15 | 3.93 | 7 |

| 12 | 2 | 0.15 | 3.78 | 8 |

| Term | Estimate | Std. Error | p-Value |

|---|---|---|---|

| Coating Load | |||

| b0 | 3.78 | 0.06 | <0.0001 * |

| b1 | 0.47 | 0.05 | <0.0001 * |

| b2 | 0.25 | 0.05 | 0.0017 * |

| b11 | −0.09 | 0.08 | 0.2769 |

| b22 | 0.07 | 0.08 | 0.4079 |

| Kit Rating | |||

| b0 | 7.58 | 0.23 | <0.0001 * |

| b1 | 1.67 | 0.21 | <0.0001 * |

| b2 | −0.17 | 0.21 | 0.4512 |

| b11 | −0.75 | 0.31 | 0.0479 * |

| b22 | −1.25 | 0.31 | 0.0053 * |

| Sample Name | Coating Load (g/m2) | Material Thickness (μm) |

|---|---|---|

| Un | / | 102.1 ± 2.4 |

| C2 | 3.45 ± 0.03 | 106.0 ± 2.4 |

| C2M0.1 | 3.65 ± 0.2 | 106.6 ± 1.9 |

| C2M0.3 | 4.18 ± 0.22 | 108.1 ± 2.3 |

| C2.5 | 3.76 ± 0.11 | 107.1 ± 2.5 |

| C2.5M0.1 | 3.94 ± 0.09 | 108.2 ± 1.7 |

| C2.5M0.3 | 4.49 ± 0.17 | 107.1 ± 1.9 |

| C3 | 3.99 ± 0.19 | 109.1 ± 3.1 |

| C3M0.1 | 4.26 ± 0.15 | 110.0 ± 2.8 |

| C3M0.3 | 4.42 ± 0.17 | 109.6 ± 1.6 |

| Different. Papers | Un | C2 | C2M0.1 | C2M0.3 | C2.5 | C2.5M0.1 | C2.5M0.3 | C3 | C3M0.1 | C3M0.3 |

|---|---|---|---|---|---|---|---|---|---|---|

| Ra (μm) | 7.06 | 5.49 | 5.57 | 5.85 | 5.26 | 5.42 | 5.74 | 5.09 | 5.38 | 5.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Zhao, L.; He, B. Chitosan/Montmorillonite Coatings for the Fabrication of Food-Safe Greaseproof Paper. Polymers 2021, 13, 1607. https://doi.org/10.3390/polym13101607

Wang K, Zhao L, He B. Chitosan/Montmorillonite Coatings for the Fabrication of Food-Safe Greaseproof Paper. Polymers. 2021; 13(10):1607. https://doi.org/10.3390/polym13101607

Chicago/Turabian StyleWang, Kaipeng, Lihong Zhao, and Beihai He. 2021. "Chitosan/Montmorillonite Coatings for the Fabrication of Food-Safe Greaseproof Paper" Polymers 13, no. 10: 1607. https://doi.org/10.3390/polym13101607

APA StyleWang, K., Zhao, L., & He, B. (2021). Chitosan/Montmorillonite Coatings for the Fabrication of Food-Safe Greaseproof Paper. Polymers, 13(10), 1607. https://doi.org/10.3390/polym13101607