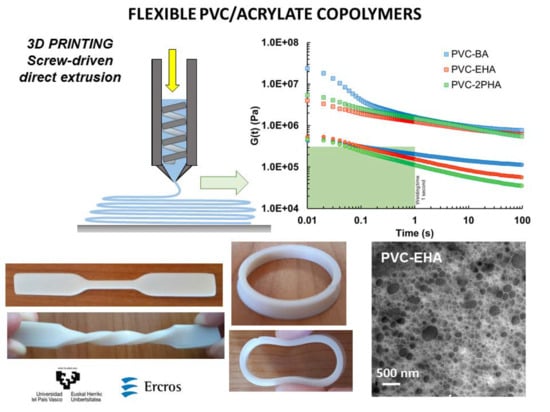

How Is Rheology Involved in 3D Printing of Phase-Separated PVC-Acrylate Copolymers Obtained by Free Radical Polymerization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Polymerization Procedure

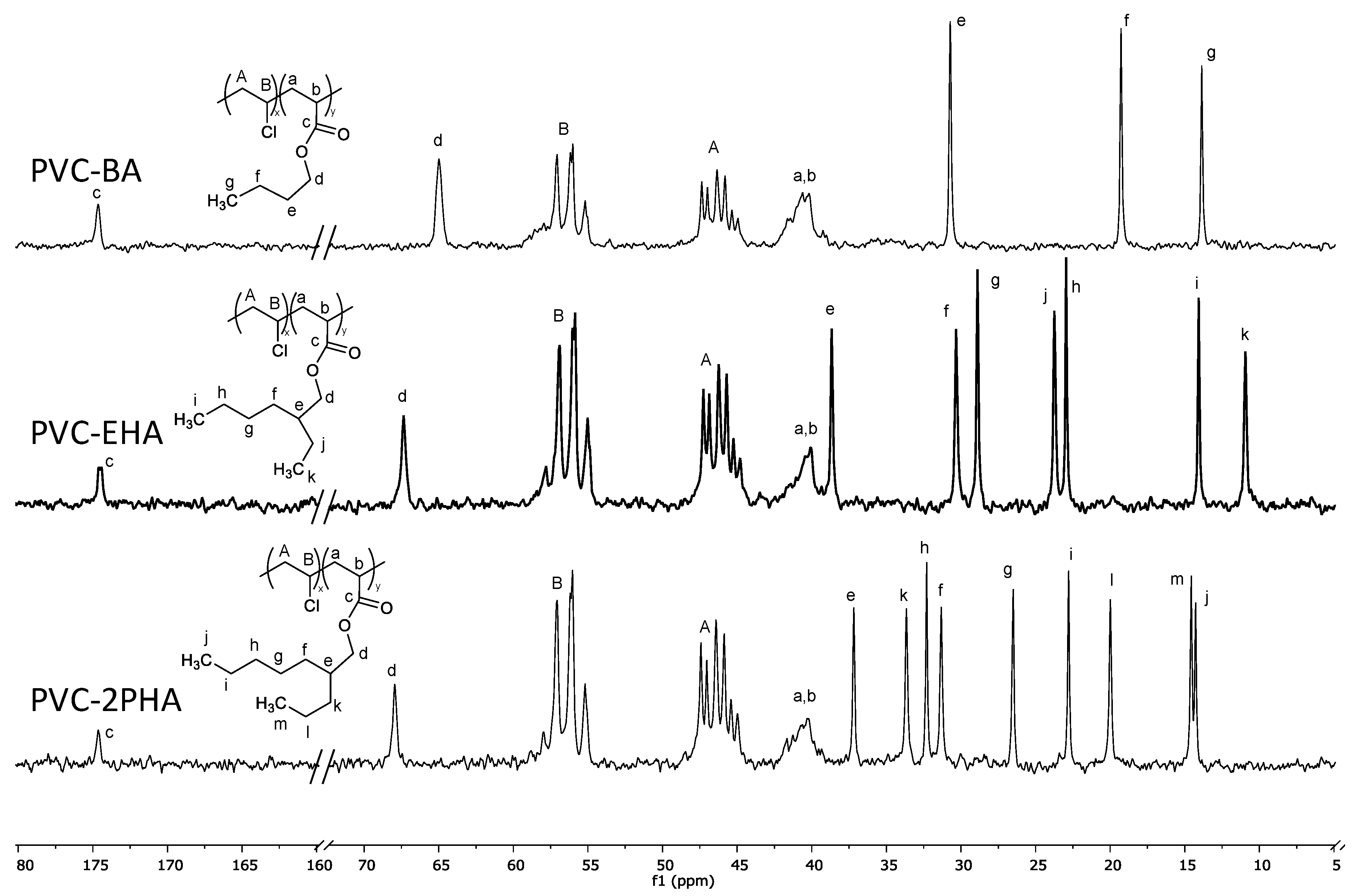

2.3. Nuclear Magnetic Resonance (NMR)

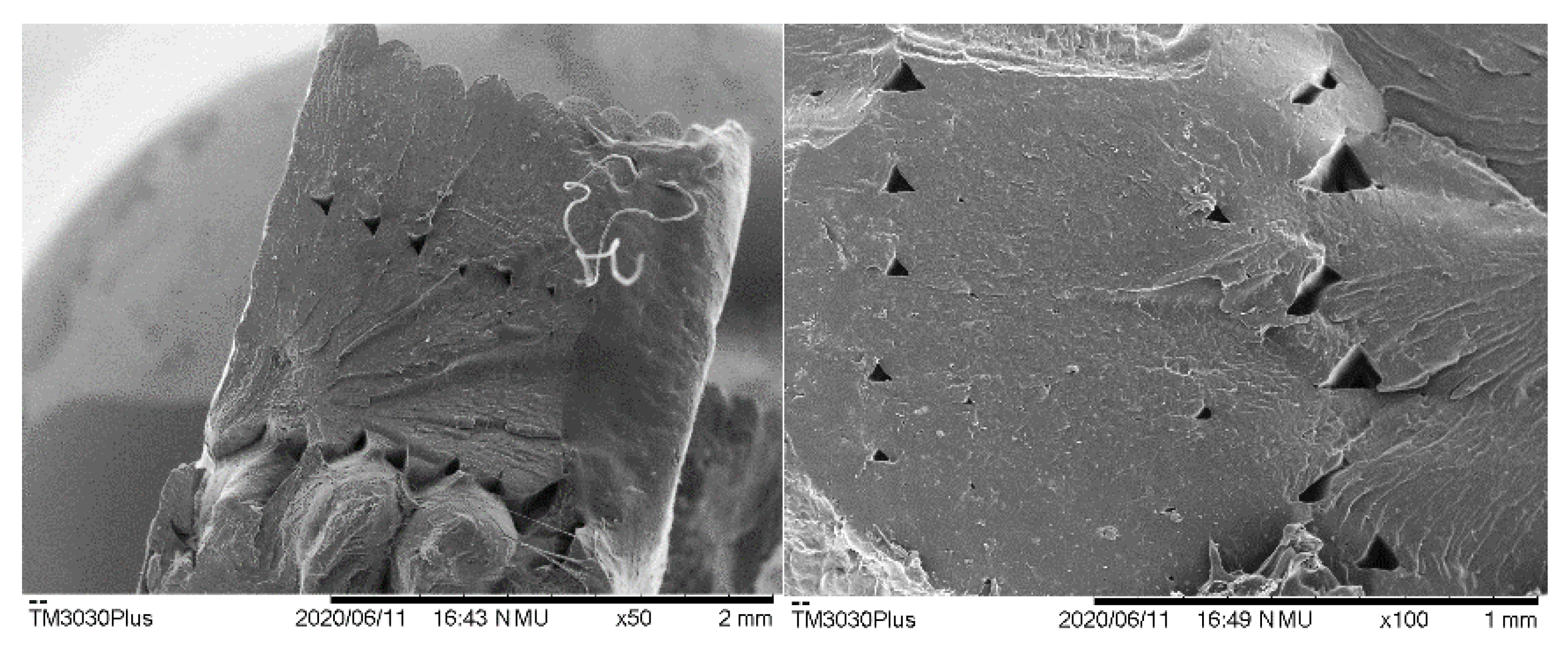

2.4. Microscopy

2.5. Size Exclusion Chromatography (SEC)

2.6. Mechanical-Thermal Analysis

2.7. Rheological Measurements

2.8. Printing Conditions

2.9. Mechanical Properties of Printed Specimens

3. Results and Discussion

3.1. Characterization

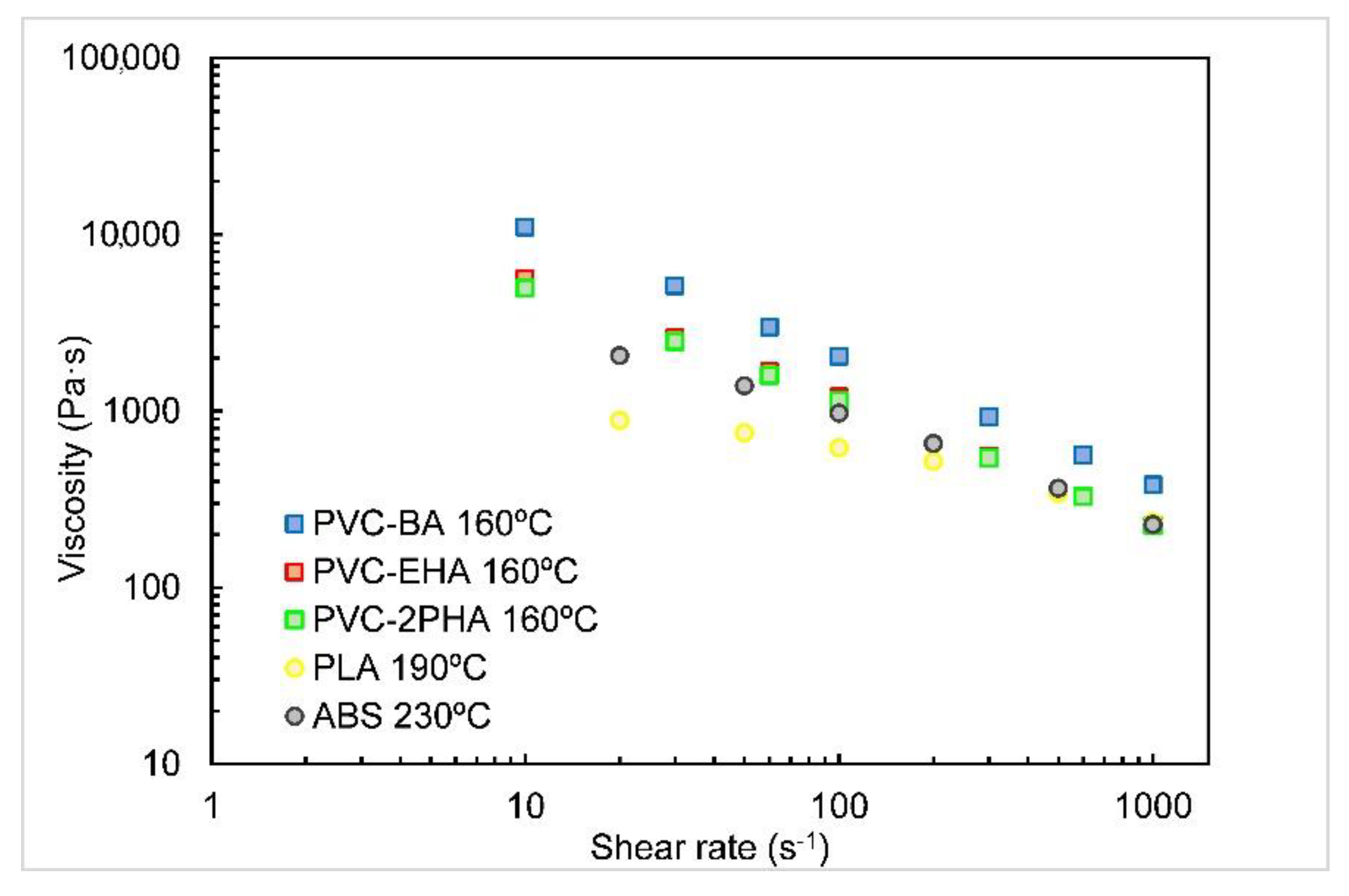

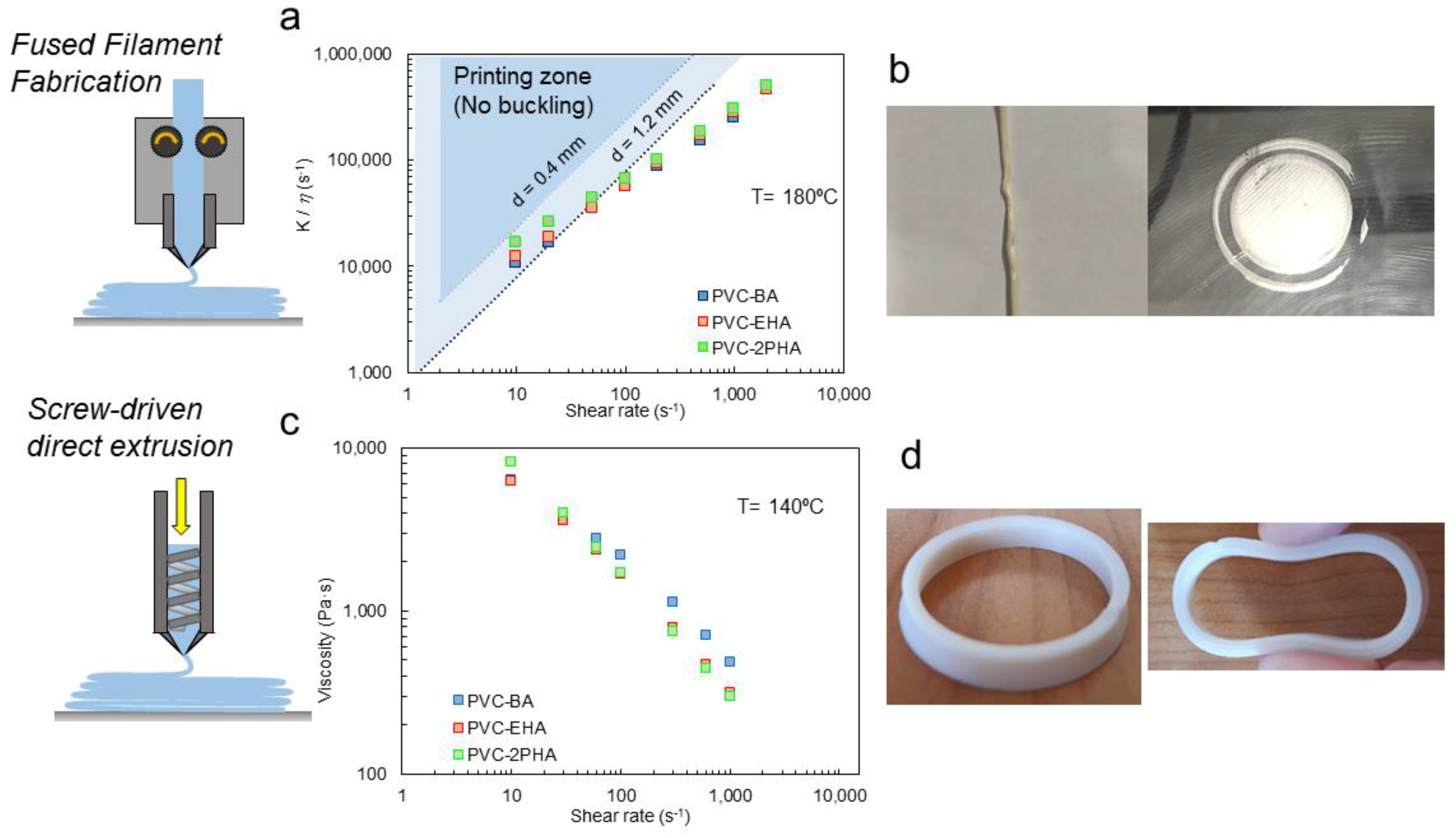

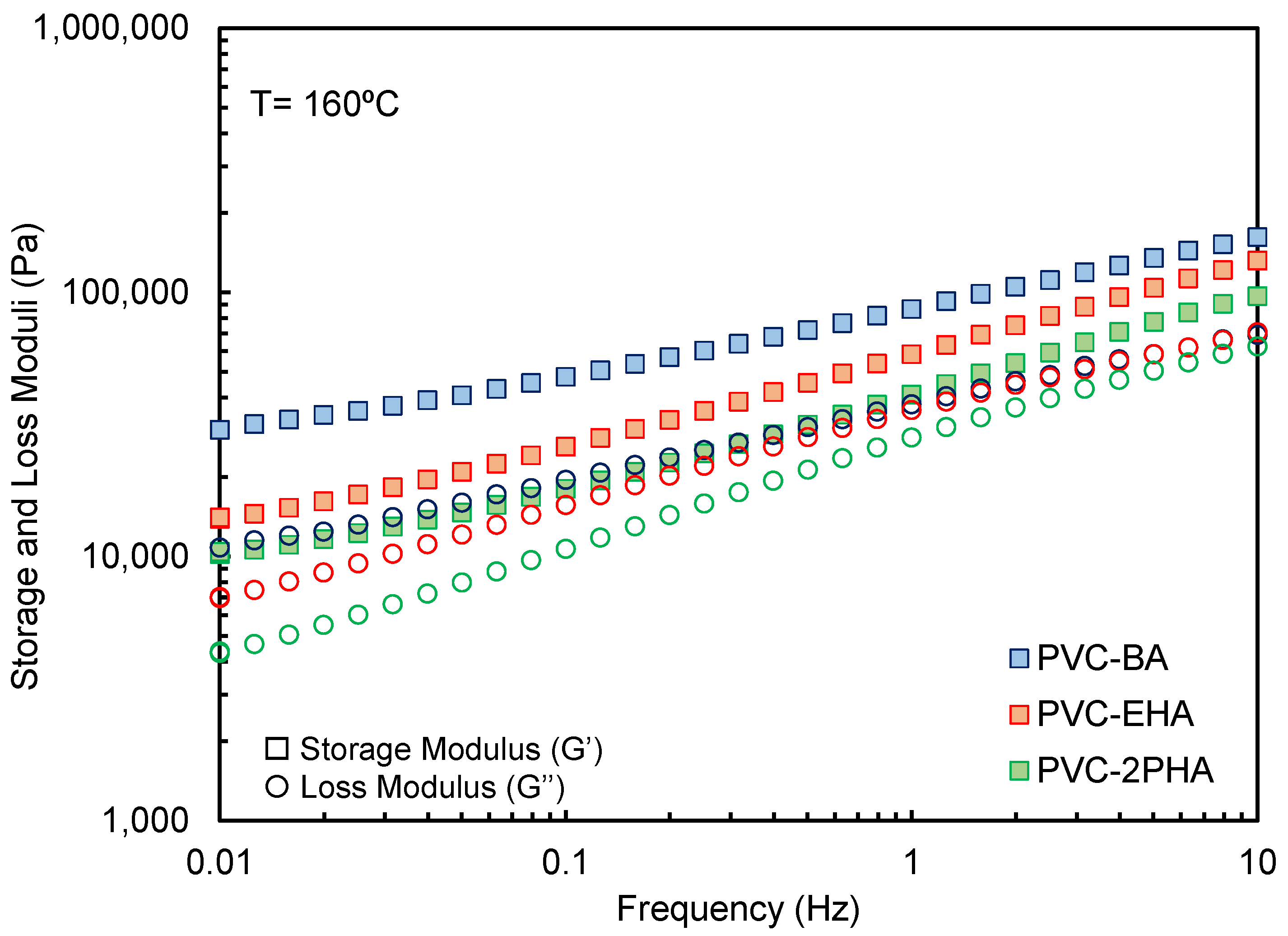

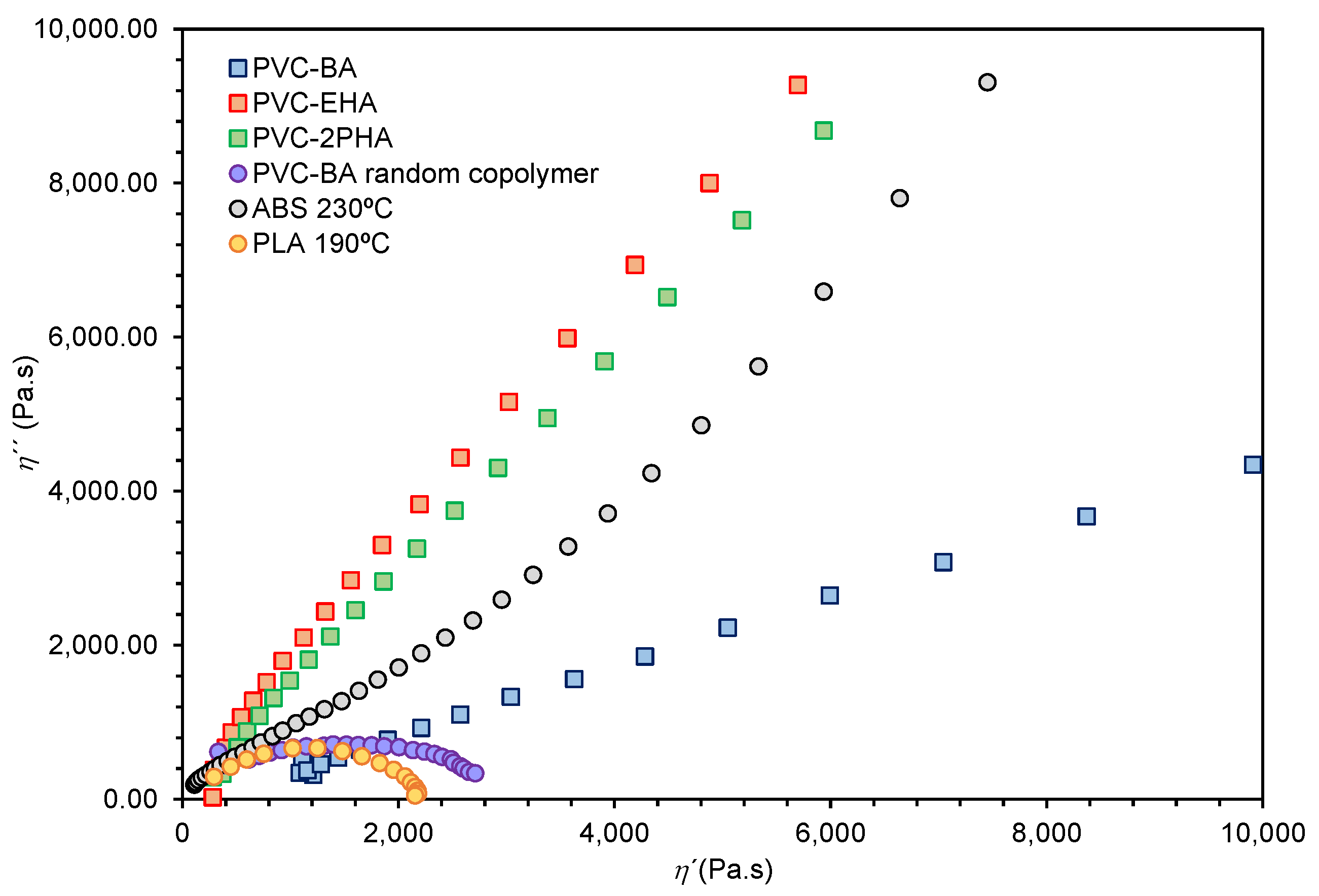

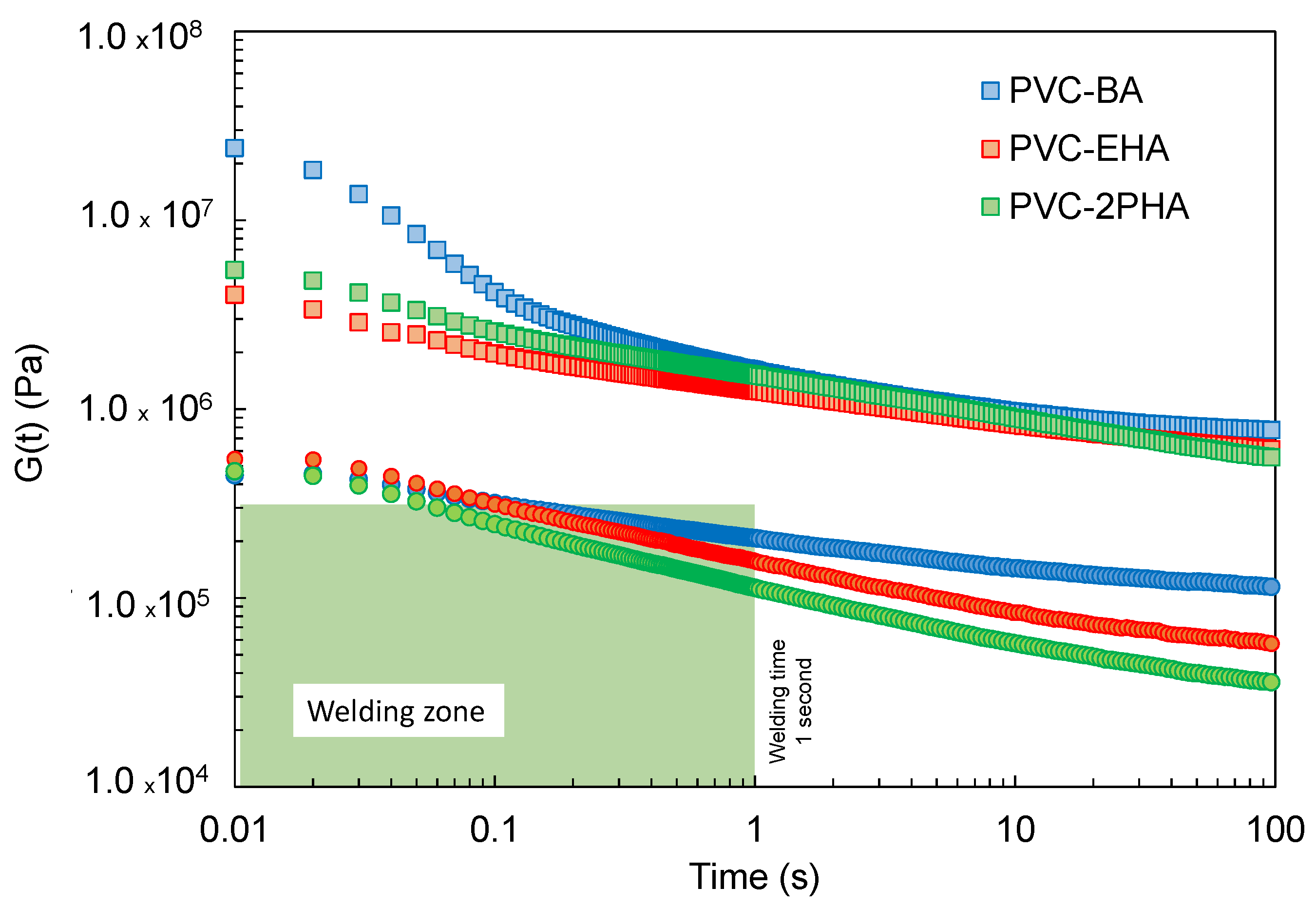

3.2. Rheological Study under 3D-Printing Conditions

3.3. Influence of Viscoelastic Characteristics on 3D-Printing Performance

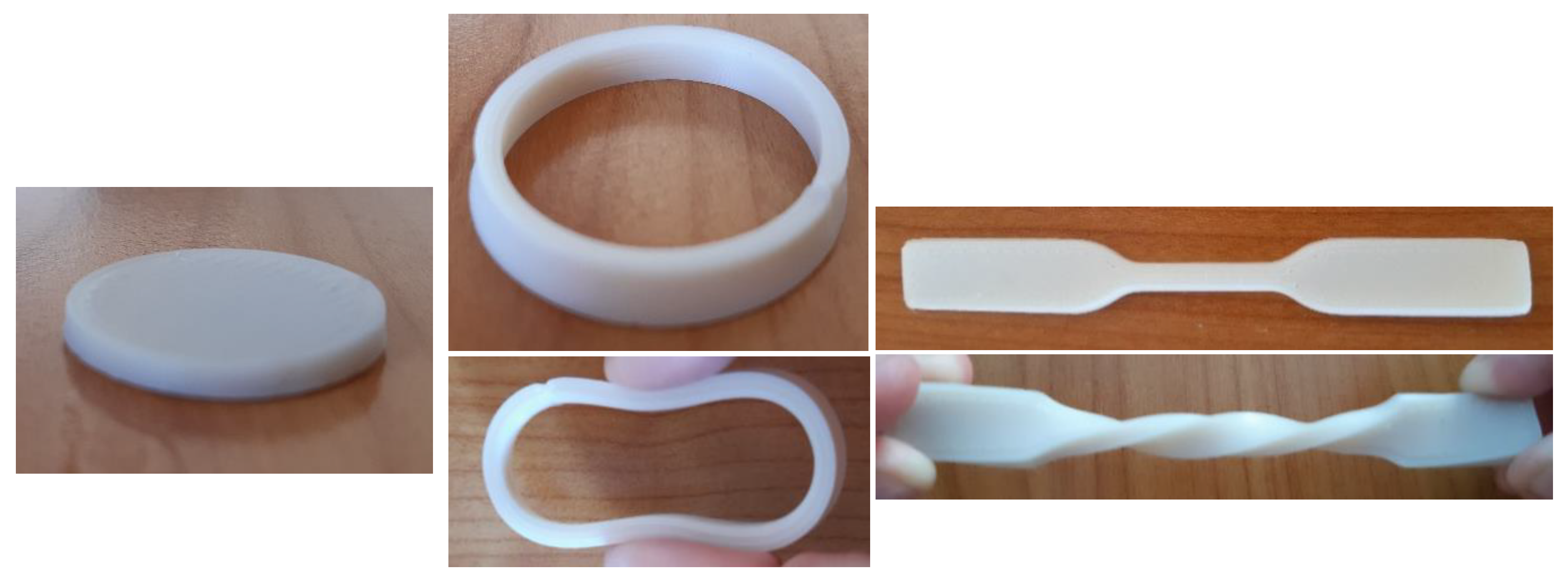

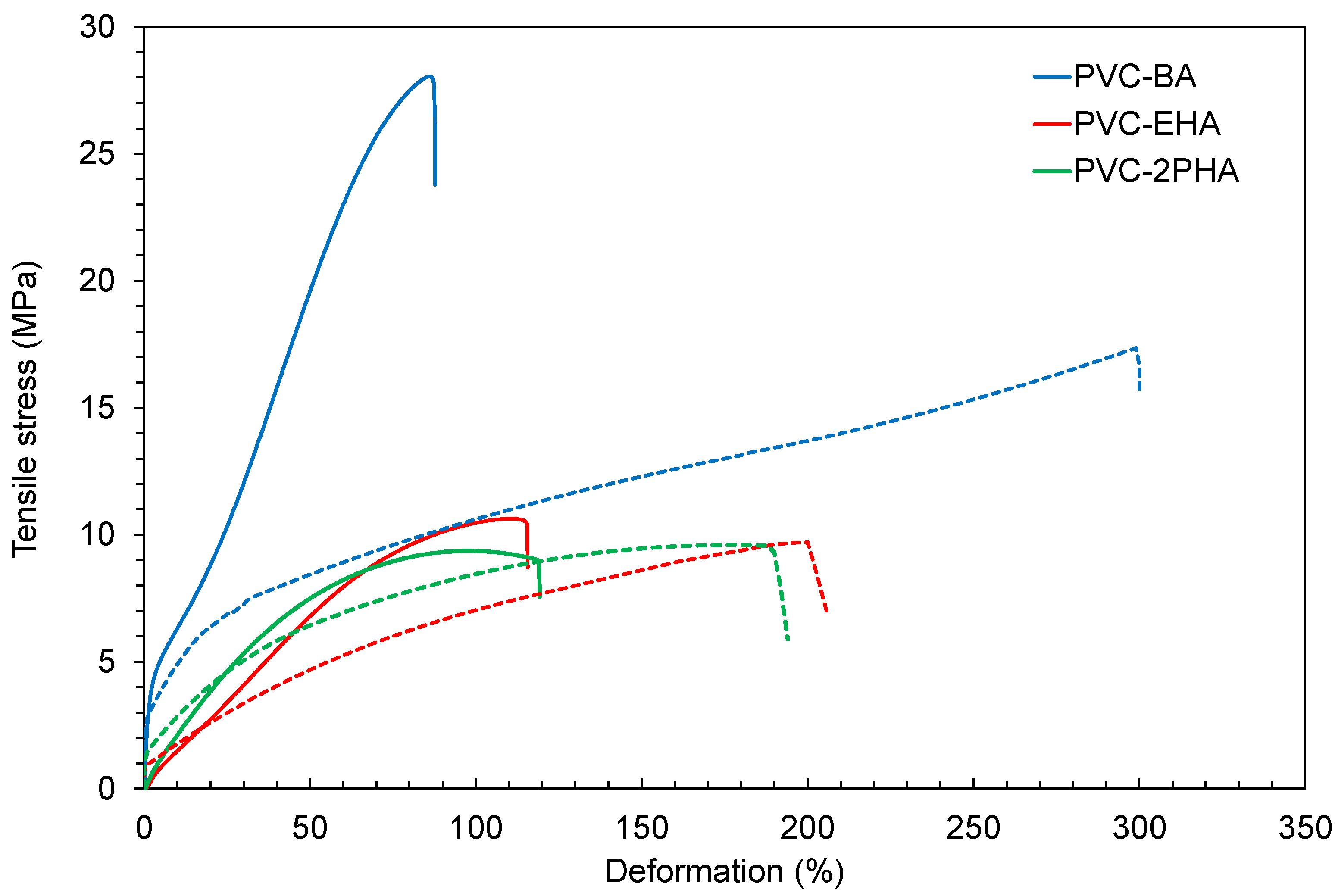

3.4. Printing Study and Mechanical Properties of Tensile Test Specimens

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modeling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Bhandari, B. A comparative study between syringe-based and screw-based 3D food printers by computational simulation. Comput. Electron. Agric. 2019, 162, 397–404. [Google Scholar] [CrossRef]

- Duty, C.; Ajinjeru, C.; Kishore, V.; Compton, B.; Hmeidat, N.; Chen, X.; Liu, P.; Hassen, A.A.; Lindahl, J.; Kunc, V. What makes a material printable? A viscoelastic model for extrusion-based 3D printing of polymers. J. Manuf. Process. 2018, 35, 526–537. [Google Scholar] [CrossRef]

- Gilmer, E.L.; Miller, D.; Chatham, C.A.; Zawaski, C.; Fallon, J.J.; Pekkanen, A.; Long, T.E.; Williams, C.B.; Bortner, M.J. Model analysis of feedstock behavior in fused filament fabrication: Enabling rapid materials screening. Polymer 2017, 152, 51–61. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P.D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef]

- Seppala, J.E.; Hoon Han, S.; Hillgartner, K.E.; Davis, C.S.; Migler, K.B. Weld formation during material extrusion additive manufacturing. Soft Matter 2017, 13, 6761–6769. [Google Scholar] [CrossRef]

- Costanzo, A.; Spotorno, R.; Candal, M.V.; Fernández, M.M.; Müller, A.J.; Graham, R.S.; Cavallo, D.; McIlroy, C. Residual alignment and its effect on weld strength in material-extrusion 3D-printing of polylactic acid. Addit. Manuf. 2020, 36, 101415. [Google Scholar]

- Coogan, T.J.; Kazmer, D.O. Prediction of interlayer strength in material extrusion additive manufacturing. Addit. Manuf. 2020, 35, 101368. [Google Scholar] [CrossRef]

- BATES, F.S. Polymer-Polymer Phase Behavior. Science 1991, 251, 898–905. [Google Scholar] [CrossRef] [PubMed]

- Bates, F.S. Block copolymers near the microphase separation transition. 2. Linear dynamic mechanical properties. Macromolecules 1984, 17, 2607–2613. [Google Scholar] [CrossRef]

- Lyngaae-Jørgensen, J. Melt Flow Properties of Block Copolymers. In Processing, Structure and Properties of Block Copolymers; Folkes, M.J., Ed.; Elsevier Applied Science Publishers: London, UK; New York, NY, USA, 1985; pp. 75–123. ISBN 978-94-009-4936-2. [Google Scholar]

- Majesté, J.-C.; Santamaria, A. Rheology and Viscoelasticity of Multiphase Polymer Systems: Blends and Block Copolymers. In Handbook of Multiphase Polymer Systems; Boudenne, A., Ibos, L., Candau, Y., Thomas, S., Eds.; Wiley: Hoboken, NJ, USA, 2011; Volume I, pp. 311–354. [Google Scholar]

- Gopi, S.; Kontopoulou, M. Investigation of thermoplastic melt flow and dimensionless groups in 3D bioplotting. Rheol. Acta 2020, 59, 83–93. [Google Scholar] [CrossRef]

- Mendes, R.; Fanzio, P.; Campo-Deaño, L.; Galindo-Rosales, F.J. Microfluidics as a platform for the analysis of 3D printing problems. Materials 2019, 12, 2839. [Google Scholar] [CrossRef] [PubMed]

- Ciacci, L.; Passarini, F.; Vassura, I. The European PVC cycle: In-use stock and flows. Resour. Conserv. Recycl. 2017, 123, 108–116. [Google Scholar] [CrossRef]

- Boix, M.; Pascual, B.; Conde, J.I.; Badillo, G.; Hogt, A.H.; Vanduffel, K.; Calafel, M.I.; Santamaría, A. Better color and thermal stability of suspension PVC produced on industrial scale by continuous initiator dosing technology. J. Appl. Polym. Sci. 2020, in press. [Google Scholar]

- Ahmad, N.M.; Heatley, F.; Lovell, P.A. Chain Transfer to Polymer in Free-Radical Solution Polymerization of n -Butyl Acrylate Studied by NMR Spectroscopy. Macromolecules 1998, 31, 2822–2827. [Google Scholar] [CrossRef]

- Plessis, C.; Arzamendi, G.; Leiza, J.R.; Schoonbrood, H.A.S.; Charmot, D.; Asua, J.M. Seeded Semibatch Emulsion Polymerization of n -Butyl Acrylate. Kinetics and Structural Properties. Macromolecules 2000, 33, 5041–5047. [Google Scholar] [CrossRef]

- Calafel, I.; Muñoz, M.E.; Santamaría, A.; Boix, M.; Conde, J.I.; Pascual, B. PVC/PBA random copolymers prepared by Living Radical Polymerization (SET–DTLRP): Entanglements and chain dimensions. Eur. Polym. J. 2015, 73, 202–211. [Google Scholar] [CrossRef]

- Mijangos, C.; Lopez, D. Compositional Assignments for Chemically Modified PVC by Two-Dimensional NMR Spectroscopy. Macromolecules 1995, 28, 1364–1369. [Google Scholar] [CrossRef]

- López, D.; Mijangos, C.; Muñoz, M.E.; Santamaría, A. Viscoelastic Properties of Thermoreversible Gels from Chemically Modified PVCs †. Macromolecules 1996, 29, 7108–7115. [Google Scholar] [CrossRef]

- Shach-Caplan, M.; Narkis, M.; Silverstein, M.S. Modification of porous suspension-PVC particles by stabilizer-free aqueous dispersion polymerization of absorbed monomers. Polym. Eng. Sci. 2002, 42, 911–924. [Google Scholar] [CrossRef]

- Walsh, D.J.; McKeown, J.G. Compatibility of polyacrylates and polymethacrylates with poly(vinyl chloride): 1. Compatibility and temperature variation. Polymer 1980, 21, 1330–1334. [Google Scholar] [CrossRef]

- Venkataraman, N.; Rangarajan, S.; Matthewson, M.J.; Harper, B.; Safari, A.; Danforth, S.C.; Wu, G.; Langrana, N.; Guceri, S.; Yardimci, A. Feedstock material property—Process relationships in fused deposition of ceramics (FDC). Rapid Prototyp. J. 2000, 6, 244–253. [Google Scholar] [CrossRef]

- Calafel, I.; Aguirresarobe, R.H.; Peñas, M.I.; Santamaria, A.; Tierno, M.; Conde, J.I.; Pascual, B. Searching for Rheological Conditions for FFF 3D Printing with PVC Based Flexible Compounds. Materials 2020, 13, 178. [Google Scholar] [CrossRef]

- Münstedt, H. Elastic Behavior of Polymer Melts. Rheology and Processing; Hanser Publishers: Munich, Germany, 2019; ISBN 978-1-56990-754-2. [Google Scholar]

- Calafel, M.I.; Aguirresarobe, R.H.; Sadaba, N.; Boix, M.; Conde, J.I.; Pascual, B.; Santamaria, A. Tuning the viscoelastic features required for 3D printing of PVC-acrylate copolymers obtained by single electron transfer-degenerative chain transfer living radical polymerization (SET-DTLRP). Express Polym. Lett. 2018, 12, 824–835. [Google Scholar] [CrossRef]

- Vermant, J.; Cioccolo, G.; Golapan Nair, K.; Moldenaers, P. Coalescence suppression in model immiscible polymer blends by nano-sized colloidal particles. Rheol. Acta 2004, 43, 529–538. [Google Scholar] [CrossRef]

- Elias, L.; Fenouillot, F.; Majeste, J.C.; Cassagnau, P. Morphology and rheology of immiscible polymer blends filled with silica nanoparticles. Polymer 2007, 48, 6029–6040. [Google Scholar] [CrossRef]

- Palierne, J.F. Linear rheology of viscoelastic emulsions with interfacial tension. Rheol. Acta 1990, 29, 204–214. [Google Scholar] [CrossRef]

- Calafel, I.; Fernández, M.; Santamaría, A.; Boix, M.; Conde, J.I.; Pascual, B. PVC/PBA random copolymers obtained by SET–DTLRP: Pressure effect on glass transition, rheology, and processing. J. Vinyl Addit. Technol. 2019, 25, 76–84. [Google Scholar] [CrossRef]

- Solorio-Rodríguez, L.E.; Vega-Rios, A. Filament Extrusion and Its 3D Printing of Poly(Lactic Acid)/Poly(Styrene-co-Methyl Methacrylate) Blends. Appl. Sci. 2019, 9, 5153. [Google Scholar] [CrossRef]

- Byron, B.R.; Robert, C.; Armstrong, O.H. Dynamics of Polymeric Liquids, Volume 1: Fluid Mechanics, 2nd ed.; John Wiley and Sons Inc.: New York, NY, USA, 1987; ISBN 978-0-471-80245-7. [Google Scholar]

- Peña, J.J.; Guzmán, G.M.; Santamaria, A. Determination of capillary entrance pressure losses and first normal stress difference in polystyrene and high impact polystyrene melts. Polym. Eng. Sci. 1981, 21, 307–311. [Google Scholar] [CrossRef]

- Ho, K.Y.; Dodou, K. Rheological studies on pressure-sensitive silicone adhesives and drug-in-adhesive layers as a means to characterise adhesive performance. Int. J. Pharm. 2007, 333, 24–33. [Google Scholar] [CrossRef] [PubMed]

- Seppala, J.E.; Migler, K.D. Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2016, 12, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D printing of high density polyethylene by fused filament fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- Rasselet, D.; Caro-Bretelle, A.S.; Taguet, A.; Lopez-Cuesta, J.M. Reactive compatibilization of PLA/PA11 blends and their application in additive manufacturing. Materials 2019, 12, 485. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Dawood, M.; El-Tahan, M.W.; Zheng, B. Bond behavior of superelastic shape memory alloys to carbon fiber reinforced polymer composites. Compos. Part B Eng. 2015, 77, 238–247. [Google Scholar] [CrossRef]

| Parameter | Units | BA | EHA | 2PHA |

|---|---|---|---|---|

| Amount of acrylate | kg | 22.7 | 23.1 | 22.0 |

| Amount of VCM | kg | 55.0 | 59.5 | 61.0 |

| Amount of initiator | kg | 0.680 | 0.714 | 0.722 |

| Reaction time | min | 243 | 148 | 300 |

| VCM conversion | % | 79 | 83 | 84 |

| Sample | Acrylate Composition in the Reaction Mixture (%) | Acrylate Composition in the Copolymer (%) * | Mw ** (g mol−1) | Mn ** (g mol−1) | IP |

|---|---|---|---|---|---|

| PVC-BA | 30 | 33 | 296,250 | 65,400 | 4.5 |

| PVC-EHA | 30 | 30 | 208,200 | 61,100 | 3.4 |

| PVC-2PHA | 30 | 34 | 188,800 | 56,550 | 3.3 |

| Sample | Printing Temperature (°C) | Maximum Speed (mm/s) | Bed Temperature (°C) |

|---|---|---|---|

| PVC-BA | 120–160 | 8 | 30–60 |

| PVC-EHA | 120–160 | 8 | 30–80 |

| PVC-2PHA | 120–160 | 8 | 30–60 |

| Properties | PVC-BA | PVC-EHA | PVC-2PHA | |||

|---|---|---|---|---|---|---|

| Compression Moulding | 3D | Compression Moulding | 3D | Compression Moulding | 3D | |

| Tensile stress (MPa) | 17.3 ± 2.2 | 27.9 ± 0.3 | 9.7 ± 0.3 | 10.5 ± 0.1 | 9.6 ± 1.8 | 8.9 ± 0.7 |

| Deformation at break (%) | 292 ± 4 | 91 ± 3 | 204 ± 9 | 116 ± 6 | 188 ± 3 | 122 ± 6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peñas, M.I.; Calafel, M.I.; Aguirresarobe, R.H.; Tierno, M.; Conde, J.I.; Pascual, B.; Santamaría, A. How Is Rheology Involved in 3D Printing of Phase-Separated PVC-Acrylate Copolymers Obtained by Free Radical Polymerization. Polymers 2020, 12, 2070. https://doi.org/10.3390/polym12092070

Peñas MI, Calafel MI, Aguirresarobe RH, Tierno M, Conde JI, Pascual B, Santamaría A. How Is Rheology Involved in 3D Printing of Phase-Separated PVC-Acrylate Copolymers Obtained by Free Radical Polymerization. Polymers. 2020; 12(9):2070. https://doi.org/10.3390/polym12092070

Chicago/Turabian StylePeñas, Mario Iván, Miren Itxaso Calafel, Roberto Hernández Aguirresarobe, Manuel Tierno, José Ignacio Conde, Belén Pascual, and Antxon Santamaría. 2020. "How Is Rheology Involved in 3D Printing of Phase-Separated PVC-Acrylate Copolymers Obtained by Free Radical Polymerization" Polymers 12, no. 9: 2070. https://doi.org/10.3390/polym12092070

APA StylePeñas, M. I., Calafel, M. I., Aguirresarobe, R. H., Tierno, M., Conde, J. I., Pascual, B., & Santamaría, A. (2020). How Is Rheology Involved in 3D Printing of Phase-Separated PVC-Acrylate Copolymers Obtained by Free Radical Polymerization. Polymers, 12(9), 2070. https://doi.org/10.3390/polym12092070