Conversion of Starchy Waste Streams into Polyhydroxyalkanoates Using Cupriavidus necator DSM 545

Abstract

1. Introduction

2. Materials and Methods

2.1. Bacterial Strain and Starchy Substrates

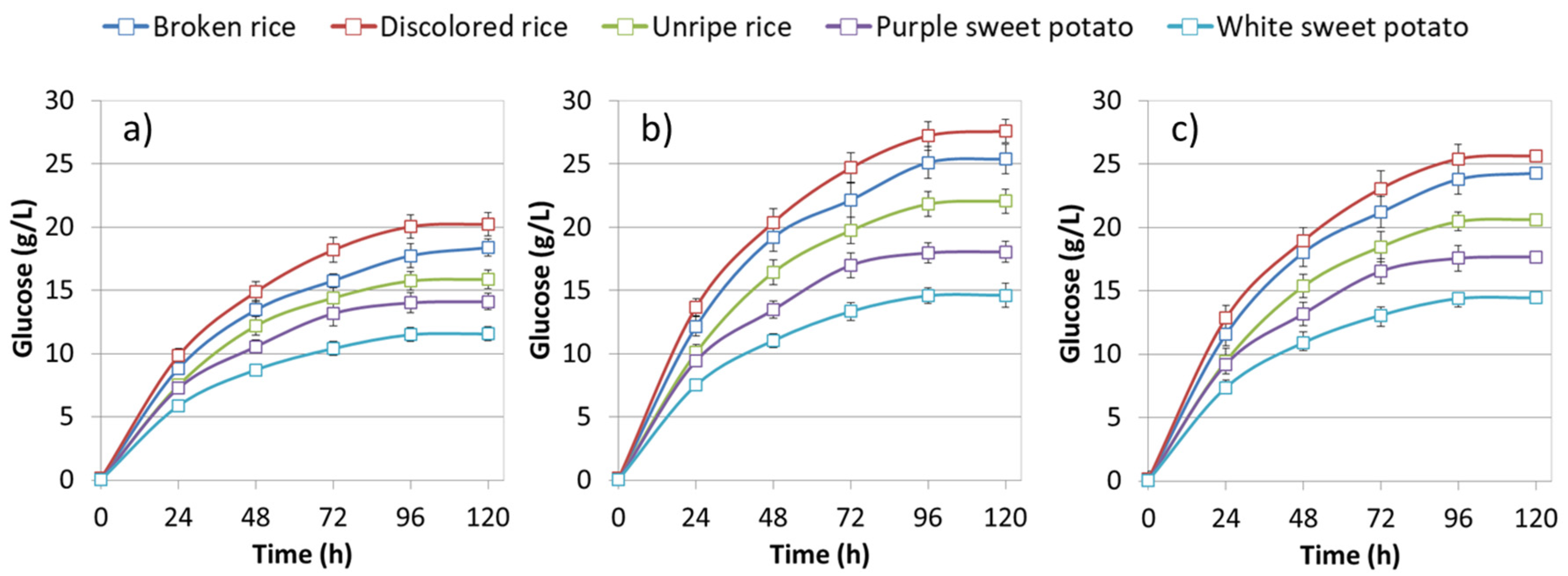

2.2. Enzymatic Loading Optimization

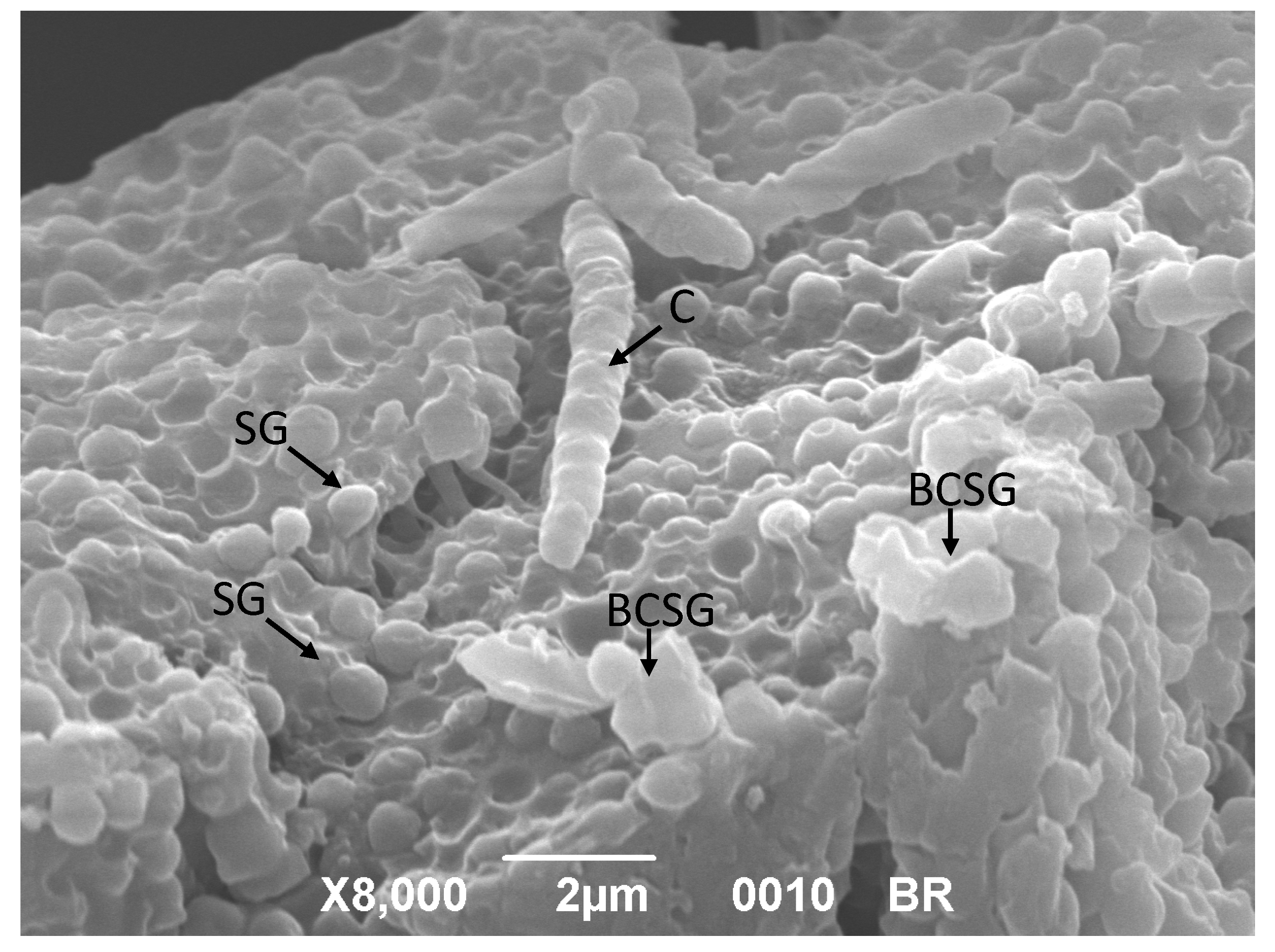

2.3. Scanning Electron Microscopy (SEM) Analysis

2.4. Culture Media and Production of PHAs from Simultaneous Saccharification and Fermentation (SSF)

2.5. PHAs Analysis

3. Results and Discussion

3.1. Starchy Waste Composition

3.2. Optimization of Enzymatic Saccharification of Starchy Substrates

3.3. PHA Production by C. necator DSM 545 on Starch-Rich Waste

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- PlasticsEurope. Plastics—The Facts 2018. In Proceedings of the Plastic Shape the Future: The Special Show of K 2019, Dusseldorf, Germany, 16–23 October 2019. [Google Scholar]

- Ryan, P.G.; Moore, C.J.; Van Franeker, J.A.; Moloney, C.L. Monitoring the abundance of plastic debris in the marine environment. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1999–2012. [Google Scholar] [CrossRef]

- Reddy, C.S.K.; Ghai, R.R.; Kalia, V.C. Polyhydroxyalkanoates: An overview. Bioresour. Technol. 2003, 87, 137–146. [Google Scholar] [CrossRef]

- Romanelli, M.G.; Povolo, S.; Favaro, L.; Fontana, F.; Basaglia, M.; Casella, S. Engineering Delftia acidovorans DSM39 to produce polyhydroxyalkanoates from slaughterhouse waste. Int. J. Biol. Macromol. 2014, 71, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Khanna, S.; Srivastava, A.K. Recent advances in microbial polyhydroxyalkanoates. Process Biochem. 2005, 40, 607–619. [Google Scholar] [CrossRef]

- Titz, M.; Kettl, K.H.; Shahzad, K.; Koller, M.; Schnitzer, H.; Narodoslawsky, M. Process optimization for efficient biomediated PHA production from animal-Based waste streams. Clean Technol. Environ. Policy 2012, 14, 495–503. [Google Scholar] [CrossRef]

- Sudesh, K.; Abe, H.; Doi, Y. Synthesis, structure and properties of polyhydroxyalkanoates: Biological polyesters. Prog. Polym. Sci. 2000, 25, 1503–1555. [Google Scholar] [CrossRef]

- Barham, P.J.; Keller, A.; Otun, E.L.; Holmes, P.A. Crystallization and morphology of a bacterial thermoplastic: Poly-3-Hydroxybutyrate. J. Mater. Sci. 1984, 19, 2781–2794. [Google Scholar] [CrossRef]

- Rai, R.; Keshavarz, T.; Roether, J.A.; Boccaccini, A.R.; Roy, I. Medium chain length polyhydroxyalkanoates, promising new biomedical materials for the future. Mater. Sci. Eng. R Rep. 2011, 72, 29–47. [Google Scholar] [CrossRef]

- Bucci, D.Z.; Tavares, L.B.B.; Sell, I. PHB packaging for the storage of food products. Polym. Test. 2005, 24, 564–571. [Google Scholar] [CrossRef]

- Siracusa, V.; Karpova, S.; Olkhov, A.; Zhulkina, A.; Kosenko, R.; Iordanskii, A. Gas Transport Phenomena and Polymer Dynamics in PHB/PLA Blend Films as Potential Packaging Materials. Polymers 2020, 12, 647. [Google Scholar] [CrossRef] [PubMed]

- Philip, S.; Keshavarz, T.; Akiyama, I.R. Polyhydroxyalkanoates: Biodegradable polymers with a range of applications. J. Chem. Technol. Biotechnol. 2007, 82, 233–247. [Google Scholar] [CrossRef]

- Penczek, S. Models of Biopolymers by Ring-Opening Polymerization; CRC Press: Boca Raton, FL, USA, 2018; p. 394. [Google Scholar]

- Mozejko-Ciesielska, J.; Marciniak, P.; Szacherska, K. Polyhydroxyalkanoates synthesized by Aeromonas species: Trends and challenges. Polymers 2019, 11, 1328. [Google Scholar] [CrossRef] [PubMed]

- Tan, G.Y.A.; Chen, C.L.; Li, L.; Ge, L.; Wang, L.; Razaad, I.M.N.; Li, Y.; Zhao, L.; Mo, Y.; Wang, J.Y. Start a research on biopolymer polyhydroxyalkanoate (PHA): A review. Polymers 2014, 6, 706–754. [Google Scholar] [CrossRef]

- Obruca, S.; Sedlacek, P.; Koller, M.; Kucera, D.; Pernicova, I. Involvement of polyhydroxyalkanoates in stress resistance of microbial cells: Biotechnological consequences and applications. Biotechnol. Adv. 2018, 36, 856–870. [Google Scholar] [CrossRef] [PubMed]

- Crutchik, D.; Franchi, O.; Caminos, L.; Jeison, D.; Belmonte, M.; Pedrouso, A.; Val del Rio, A.; Mosquera-Corral, A.; Campos, J.L. Polyhydroxyalkanoates (PHAs) Production: A Feasible Economic Option for the Treatment of Sewage Sludge in Municipal Wastewater Treatment Plants? Water 2020, 12, 1118. [Google Scholar] [CrossRef]

- Akiyama, M.; Tsuge, T.; Doi, Y. Environmental life cycle comparison of polyhydroxyalkanoates produced from renewable carbon resources by bacterial fermentation. Polym. Degrad. Stab. 2003, 80, 183–194. [Google Scholar] [CrossRef]

- Favaro, L.; Basaglia, M.; Casella, S. Improving polyhydroxyalkanoate production from inexpensive carbon sources by genetic approaches: A review. Biofuels Bioprod. BioRefin. 2019, 13, 208–227. [Google Scholar] [CrossRef]

- Blunt, W.; Levin, D.B.; Cicek, N. Bioreactor operating strategies for improved polyhydroxyalkanoate (PHA) productivity. Polymers 2018, 10, 1197. [Google Scholar] [CrossRef]

- Verlinden, R.A.J.; Hill, D.J.; Kenard, M.A.; Williams, C.D.; Radecka, I. Bacterial synthesis of biodegradable polyhydroxyalkanoates. J. Appl. Microbiol. 2007, 102, 1437–1449. [Google Scholar] [CrossRef]

- Golden, M.S.; Morrison, B.; Golden, J.S. Bioeconomy numbers. BioResources 2015, 10, 4411–4440. [Google Scholar]

- Koller, M.; Maršálek, L.; de Sousa Dias, M.M.; Braunegg, G. Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. New Biotechnol. 2017, 37, 24–38. [Google Scholar] [CrossRef] [PubMed]

- Obruca, S.; Marova, I.; Snajdar, O.; Mravcova, L.; Svoboda, Z. Production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Cupriavidus necator from waste rapeseed oil using propanol as a precursor of 3-hydroxyvalerate. Biotechnol. Lett. 2010, 32, 1925–1932. [Google Scholar] [CrossRef] [PubMed]

- Alibardi, L.; Green, K.; Favaro, L.; Vale, P.; Soares, A.; Cartmell, E.; Bajón Fernández, Y. Performance and stability of sewage sludge digestion under CO2 enrichment: A pilot study. Bioresour. Technol. 2017, 245, 581–589. [Google Scholar] [CrossRef]

- Scott, E.; Peter, F.; Sanders, J. Biomass in the manufacture of industrial products-the use of proteins and amino acids. Appl. Microbiol. Biotechnol. 2007, 75, 751–762. [Google Scholar] [CrossRef]

- Shah, A.T.; Favaro, L.; Alibardi, L.; Cagnin, L.; Sandon, A.; Cossu, R.; Casella, S.; Basaglia, M. Bacillus sp. strains to produce bio-hydrogen from the organic fraction of municipal solid waste. Appl. Energy 2016, 176, 116–124. [Google Scholar] [CrossRef]

- Myburgh, M.W.; Cripwell, R.A.; Favaro, L.; van Zyl, W.H. Application of industrial amylolytic yeast strains for the production of bioethanol from broken rice. Bioresour. Technol. 2019, 294, 122222. [Google Scholar] [CrossRef]

- Favaro, L.; Jansen, T.; van Zyl, W.H. Exploring industrial and natural Saccharomyces cerevisiae strains for the bio-Based economy from biomass: The case of bioethanol. Crit. Rev. Biotechnol. 2019, 39, 800–816. [Google Scholar] [CrossRef]

- Cripwell, R.A.; Favaro, L.; Viljoen-Bloom, M.; van Zyl, W.H. Consolidated bioprocessing of raw starch to ethanol by Saccharomyces cerevisiae: Achievements and challenges. Biotechnol. Adv. 2020, in press. [Google Scholar] [CrossRef]

- Abbondanzi, F.; Biscaro, G.; Carvalho, G.; Favaro, L.; Lemos, P.; Paglione, M.; Torri, C. Fast method for the determination of short-Chain-Length polyhydroxyalkanoates (scl-PHAs) in bacterial samples by In Vial-Thermolysis (IVT). New Biotechnol. 2017, 39, 29–35. [Google Scholar] [CrossRef]

- Abbas, A.; Ansumali, S. Global Potential of Rice Husk as a Renewable Feedstock for Ethanol Biofuel Production. Bioenergy Res. 2010, 3, 328–334. [Google Scholar] [CrossRef]

- Wu, C.S. Preparation and Characterization of Polyhydroxyalkanoate Bioplastic-Based Green Renewable Composites from Rice Husk. J. Polym. Environ. 2014, 22, 384–392. [Google Scholar] [CrossRef]

- Heng, K.S.; Hatti-Kaul, R.; Adam, F.; Fukui, T.; Sudesh, K. Conversion of rice husks to polyhydroxyalkanoates (PHA) via a three-Step process: Optimized alkaline pretreatment, enzymatic hydrolysis, and biosynthesis by Burkholderia cepacia USM (JCM 15050). J. Chem. Technol. Biotechnol. 2016, 92, 100–108. [Google Scholar] [CrossRef]

- Narayanan, A.; Kumar, V.A.S.; Ramana, K.V. Production and characterization of poly (3-hydroxybutyrateco-3-hydroxyvalerate) from Bacillus mycoides DFC1 using rice husk hydrolyzate. Waste Biomass Valorization 2014, 5, 109–118. [Google Scholar] [CrossRef]

- Ahn, J.; Jho, E.H.; Kim, M.; Nam, K. Increased 3HV Concentration in the Bacterial Production of 3-Hydroxybutyrate (3HB) and 3-Hydroxyvalerate (3HV) Copolymer with Acid-Digested Rice Straw Waste. J. Polym. Environ. 2016, 24, 98–103. [Google Scholar] [CrossRef]

- Ahn, J.; Jho, E.H.; Nam, K. Effect of acid-digested rice straw waste feeding methods on the 3HV fraction of bacterial poly(3-hydroxybutyrate-co-3-hydroxyvalerate) production. Process Biochem. 2016, 51, 2119–2126. [Google Scholar] [CrossRef]

- Favaro, L.; Cagnin, L.; Basaglia, M.; Pizzocchero, V.; van Zyl, W.H.; Casella, S. Production of bioethanol from multiple waste streams of rice milling. Bioresour. Technol. 2017, 244, 151–159. [Google Scholar] [CrossRef]

- Obruca, S.; Benesova, P.; Marsalek, L.; Marova, I. Use of lignocellulosic materials for PHA production. Chem. Biochem. Eng. Q. 2015, 29, 135–144. [Google Scholar] [CrossRef]

- Ugwu, C.U.; Tokiwa, Y.; Aoyagi, H. Utilization of Broken Rice for the Production of Poly(3-hydroxybutyrate). J. Polym. Environ. 2012, 20, 254–257. [Google Scholar] [CrossRef]

- Haas, R.; Jin, B.; Zepf, F.T. Production of poly(3-hydroxybutyrate) from waste potato starch. Biosci. Biotechnol. Biochem. 2008, 72, 253–256. [Google Scholar] [CrossRef]

- Gowda, V.; Shivakumar, S. Agrowaste-Based Polyhydroxyalkanoate (PHA) production using hydrolytic potential of Bacillus thuringiensis IAM 12077. Braz. Arch. Biol. Technol. 2014, 57, 55–61. [Google Scholar] [CrossRef]

- Locatelli, G.O.; Finkler, L.; Finkler, C.L.L. Orange and passion fruit wastes characterization, substrate hydrolysis and cell growth of Cupriavidus necator, as proposal to converting of residues in high value added product. Anais da Academia Brasileira de Ciências 2019, 91, e20180058. [Google Scholar] [CrossRef] [PubMed]

- Dalsasso, R.R.; Pavan, F.A.; Bordignon, S.E.; de Aragão, G.M.F.; Poletto, P. Polyhydroxybutyrate (PHB) production by Cupriavidus necator from sugarcane vinasse and molasses as mixed substrate. Process Biochem. 2019, 85, 12–18. [Google Scholar] [CrossRef]

- Olofsson, K.; Bertilsson, M.; Lidén, G. A short review on SSF–An interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol. Biofuels 2008, 1, 7. [Google Scholar] [CrossRef] [PubMed]

- Cripwell, R.; Favaro, L.; Rose, S.H.; Basaglia, M.; Cagnin, L.; Casella, S.; van Zyl, W. Utilisation of wheat bran as a substrate for bioethanol production using recombinant cellulases and amylolytic yeast. Appl. Energy 2015, 160, 610–617. [Google Scholar] [CrossRef]

- Torri, C.; Cordiani, H.; Samorì, C.; Favaro, L.; Fabbri, D. Fast procedure for the analysis of poly (hydroxyalkanoates) in bacterial cells by off-Line pyrolysis/gas-Chromatography with flame ionization detector. J. Chromatogr. A 2014, 1359, 230–236. [Google Scholar] [CrossRef]

- Braunegg, G.; Sonnleitner, B.; Lafferty, R.M. A rapid gas chromatographic method for the determination of poly-beta-hydroxybutyric acid in microbial biomass. Appl. Microbiol. Biotechnol. 1978, 6, 29–37. [Google Scholar] [CrossRef]

- Gamero, J.E.R.; Favaro, L.; Pizzocchero, V.; Lomolino, G.; Basaglia, M.; Casella, S. Nuclease expression in efficient polyhydroxyalkanoates-Producing bacteria could yield cost reduction during downstream processing. Bioresour. Technol. 2018, 261, 176–181. [Google Scholar] [CrossRef]

- Nunes, L.V.; de Barros Correa, F.F.; de Oliva Neto, P.; Mayer, C.R.M.; Escaramboni, B.; Campioni, T.S.; de Barros, N.R.; Herculano, R.D.; Fernández Núñez, E.G. Lactic acid production from submerged fermentation of broken rice using undefined mixed culture. World J. Microbiol. Biotechnol. 2017, 33, 1–10. [Google Scholar] [CrossRef]

- Yokoi, H.; Maki, R.; Hirose, J.; Hayashi, S. Microbial production of hydrogen from starch-Manufacturing wastes. Biomass Bioenergy 2002, 22, 389–395. [Google Scholar] [CrossRef]

- Singh, J.; Dartois, A.; Kaur, L. Starch digestibility in food matrix: A review. Trends Food Sci. Technol. 2010, 21, 168–180. [Google Scholar] [CrossRef]

- Englyst, K.N.; Englyst, H.N. Carbohydrate bioavailability. Br. J. Nutr. 2005, 94, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Rusendi, D.; Sheppard, J.D. Hydrolysis of potato processing waste for the production of poly-β-hydroxybutyrate. Bioresour. Technol. 1995, 54, 191–196. [Google Scholar] [CrossRef]

- Lee, S.C.; Lee, S.Y.; Chang, H.N.; Chang, Y.K.; Woo, S.I. Poly( 3-Hydroxybutyric Acid). Biotechnol. Bioenergy 1994, 43, 892–898. [Google Scholar]

- Kasem, S.; Waters, D.L.E.; Rice, N.F.; Shapter, F.M.; Henry, R.J. The endosperm morphology of rice and its wild relatives as observed by scanning electron microscopy. Rice 2011, 4, 12–20. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Q.; Yang, H.; Gu, G. Effects of cell fermentation time and biomass drying strategies on the recovery of poly-3-hydroxyalkanoates from Alcaligenes eutrophus using a surfactant-chelate aqueous system. Process Biochem. 2001, 36, 773–779. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, R.H.; Koutinas, A.A.; Webb, C. Microbial biodegradable plastic production from a wheat-based biorefining strategy. Process Biochem. 2010, 45, 153–163. [Google Scholar] [CrossRef]

- Kedia, G.; Passanha, P.; Dinsdale, R.M.; Guwy, A.J.; Lee, M.; Esteves, S.R. Addressing the challenge of optimum polyhydroxyalkanoate harvesting: Monitoring real time process kinetics and biopolymer accumulation using dielectric spectroscopy. Bioresour. Technol. 2013, 134, 143–150. [Google Scholar] [CrossRef]

- Povolo, S.; Basaglia, M.; Fontana, F.; Morelli, A.; Casella, S. Poly(hydroxyalkanoate) production by Cupriavidus necator from fatty waste can be ebhanched by phaZ1 inactivation. Chem. Biochem. Eng. Q. 2015, 29, 67–74. [Google Scholar] [CrossRef]

| (% DM) | |||||||

|---|---|---|---|---|---|---|---|

| Substrate | % DM 1 | Starch | Protein | Ash | Cellulose | Hemicellulose | Lignin |

| Broken rice | 88.11 | 77.74 | 8.31 | 0.47 | 0.22 | 0.54 | - |

| Discolored rice | 87.87 | 84.61 | 8.02 | 0.50 | 0.11 | 0.90 | - |

| Unripe rice | 87.87 | 68.58 | 9.86 | 1.54 | 1.80 | 3.68 | - |

| Purple sweet potato | 33.88 | 55.79 | 7.70 | 4.51 | 3.22 | 1.65 | 0.79 |

| White sweet potato | 29.37 | 44.66 | 7.17 | 3.74 | 3.31 | 1.07 | 0.60 |

| Substrate | CDM 1 (g/L) | Time (h) | 3HB (% CDM 1) | 3HB (g/L) |

|---|---|---|---|---|

| Glucose | 7.08 ± 0.07 | 72 | 70.00 ± 0.77 | 4.95 ± 0.05 |

| 8.51 ± 0.08 | 96 | 77.60 ± 0.81 | 6.60 ± 0.07 | |

| Broken rice | 12.99 ± 0.06 | 72 | 39.51 ± 0.24 | 5.13 ± 0.03 |

| 13.32 ± 0.09 | 96 | 44.09 ± 0.19 | 5.18 ± 0.02 | |

| Discolored rice | 8.87 ± 2.17 | 72 | 20.10 ± 1.31 | 1.95 ± 0.13 |

| 11.33 ± 1.32 | 96 | 31.69 ± 1.23 | 3.65 ± 0.14 | |

| Unripe rice | 11.86 ± 0.24 | 72 | 19.39 ± 0.35 | 2.30 ± 0.04 |

| 11.29 ± 0.16 | 96 | 17.81 ± 0.40 | 2.02 ± 0.05 | |

| Purple sweet potato | 10.86 ± 1.75 | 72 | 31.05 ± 0.73 | 3.39 ± 0.08 |

| 10.48 ± 0.00 | 96 | 34.42 ± 0.17 | 3.61 ± 0.02 | |

| White sweet potato | 11.10 ± 0.66 | 72 | 27.67 ± 1.11 | 3.12 ± 0.13 |

| 10.51 ± 0.24 | 96 | 22.10 ± 0.87 | 2.33 ± 0.09 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brojanigo, S.; Parro, E.; Cazzorla, T.; Favaro, L.; Basaglia, M.; Casella, S. Conversion of Starchy Waste Streams into Polyhydroxyalkanoates Using Cupriavidus necator DSM 545. Polymers 2020, 12, 1496. https://doi.org/10.3390/polym12071496

Brojanigo S, Parro E, Cazzorla T, Favaro L, Basaglia M, Casella S. Conversion of Starchy Waste Streams into Polyhydroxyalkanoates Using Cupriavidus necator DSM 545. Polymers. 2020; 12(7):1496. https://doi.org/10.3390/polym12071496

Chicago/Turabian StyleBrojanigo, Silvia, Elettra Parro, Tiziano Cazzorla, Lorenzo Favaro, Marina Basaglia, and Sergio Casella. 2020. "Conversion of Starchy Waste Streams into Polyhydroxyalkanoates Using Cupriavidus necator DSM 545" Polymers 12, no. 7: 1496. https://doi.org/10.3390/polym12071496

APA StyleBrojanigo, S., Parro, E., Cazzorla, T., Favaro, L., Basaglia, M., & Casella, S. (2020). Conversion of Starchy Waste Streams into Polyhydroxyalkanoates Using Cupriavidus necator DSM 545. Polymers, 12(7), 1496. https://doi.org/10.3390/polym12071496