Enhanced Catalytic Dye Decolorization by Microencapsulation of Laccase from P. Sanguineus CS43 in Natural and Synthetic Polymers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Laccase Purification

2.3. Enzyme Characterization

2.4. Enzymatic Activity Assay for Laccase

2.5. Microcapsules Formation

2.6. Microcapsules Characterization and Activity Measurements

2.7. pH and Thermal Stability Measurements

2.8. Decolorization Measurements

3. Results

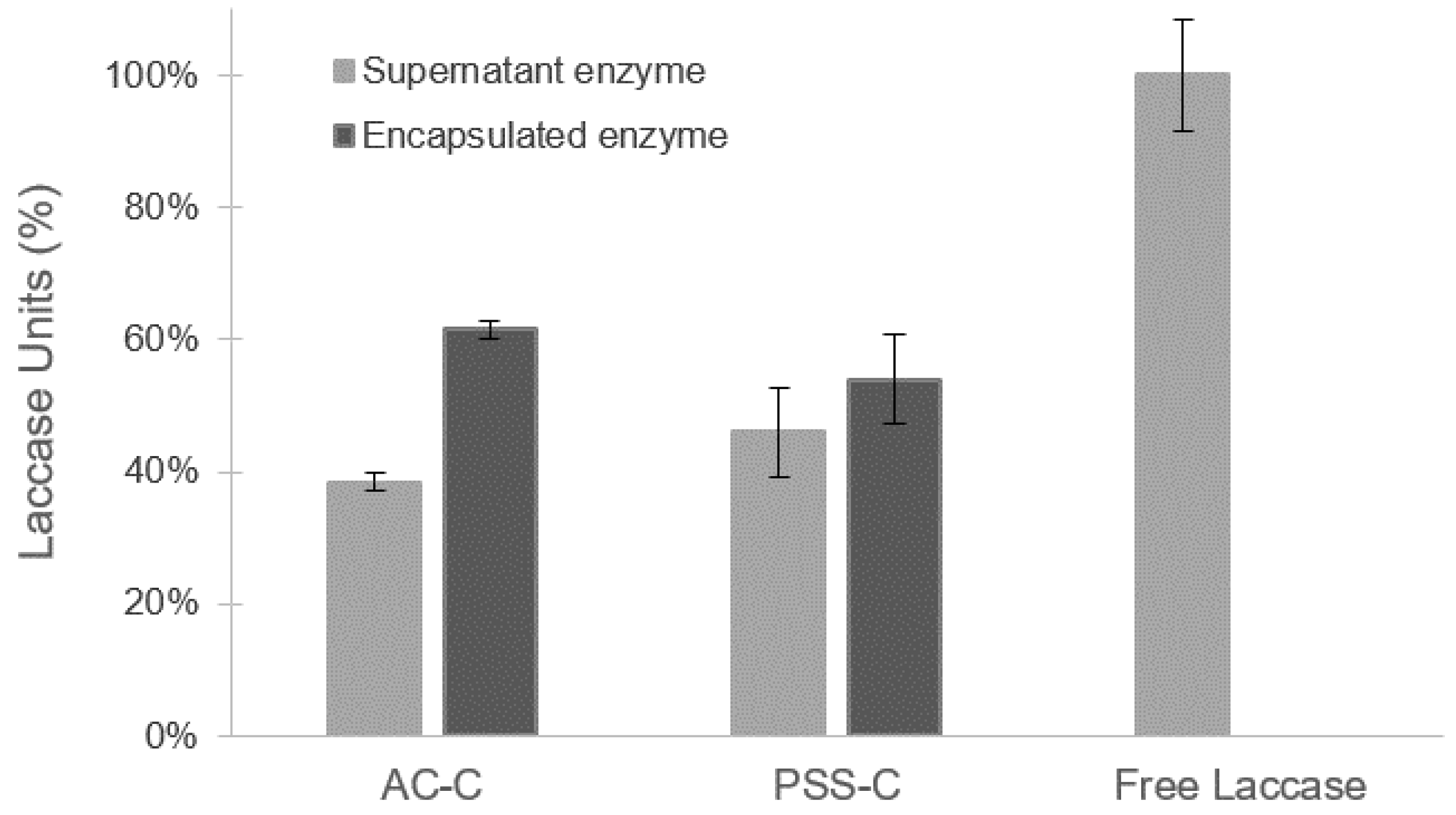

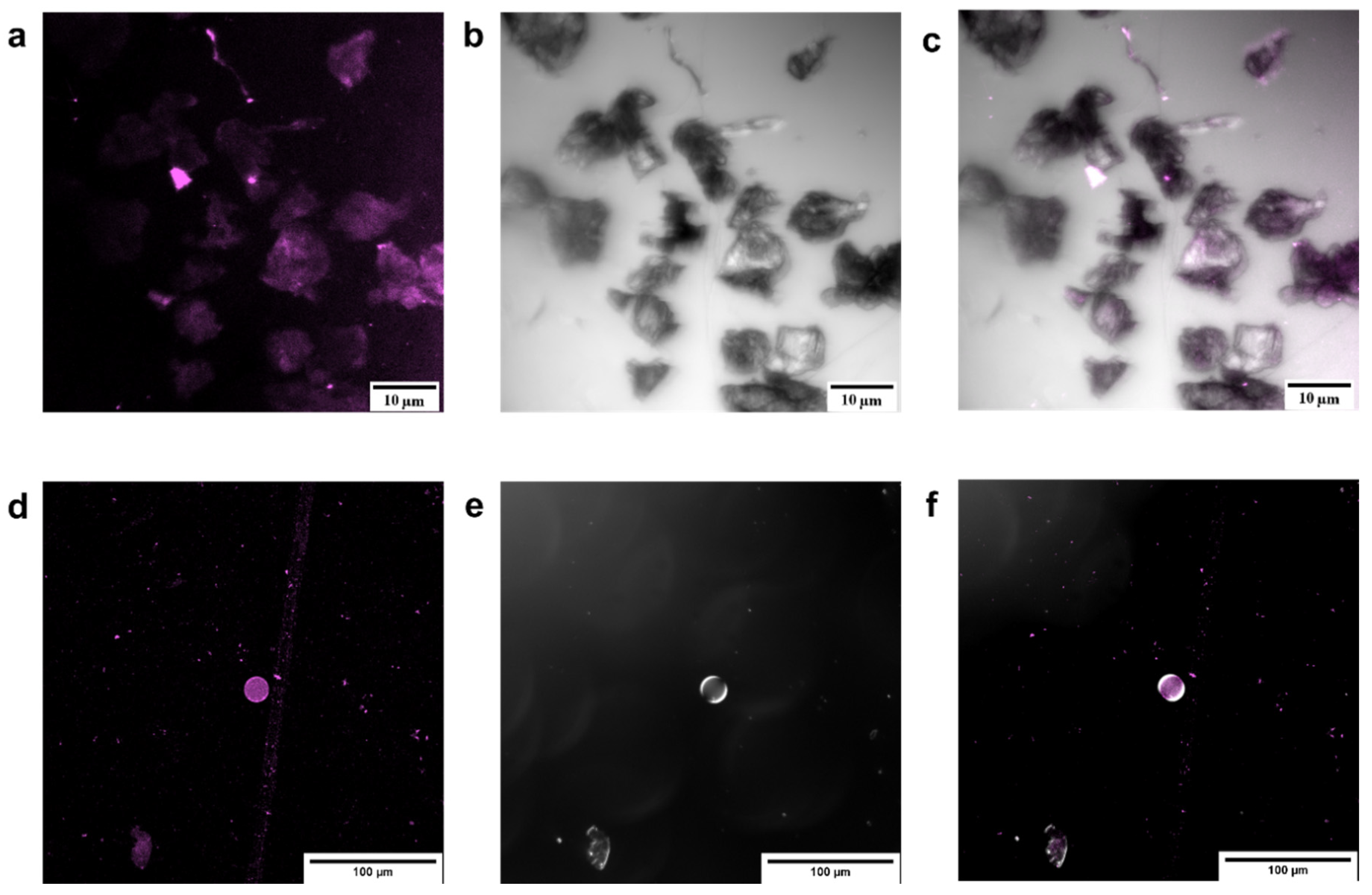

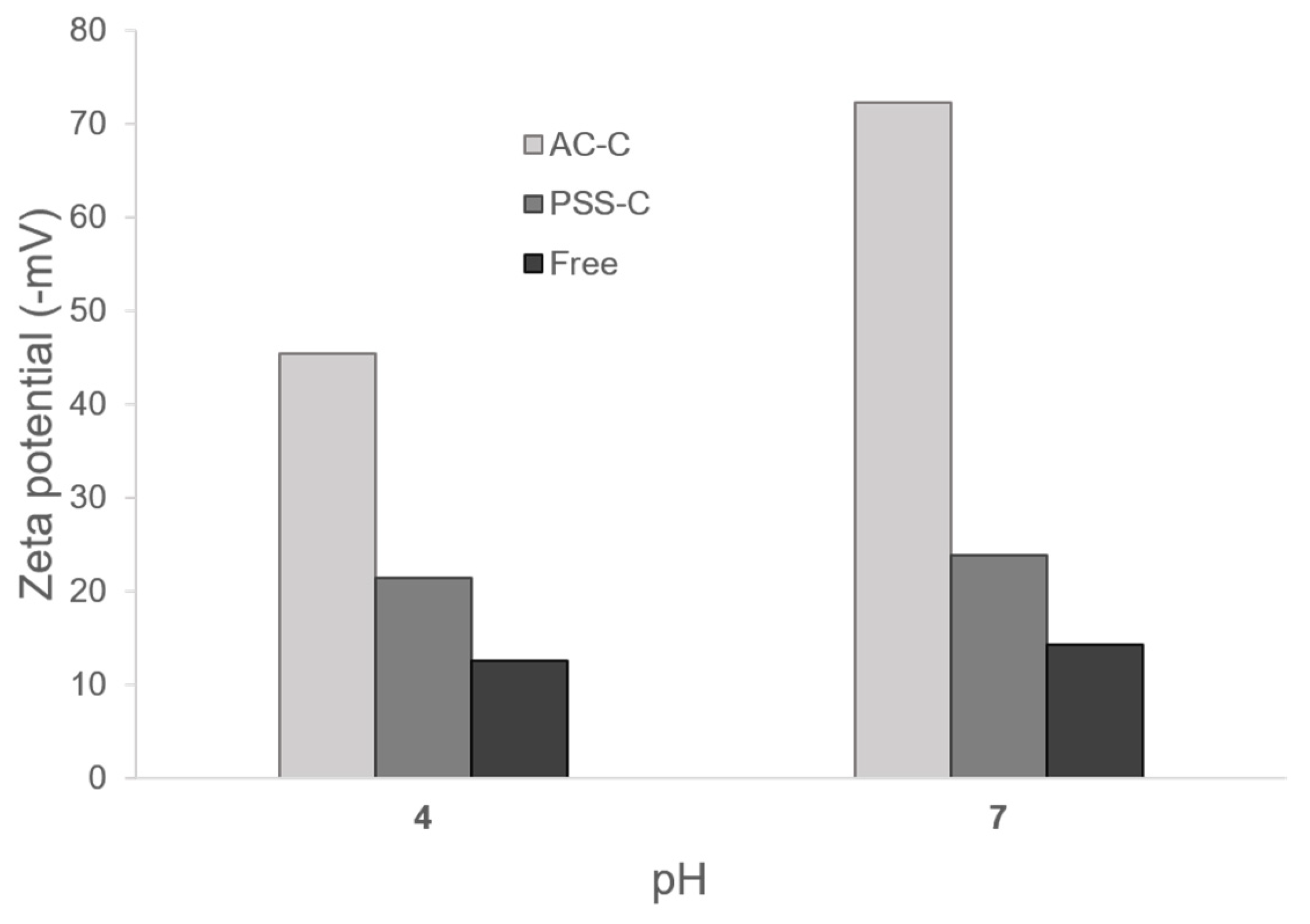

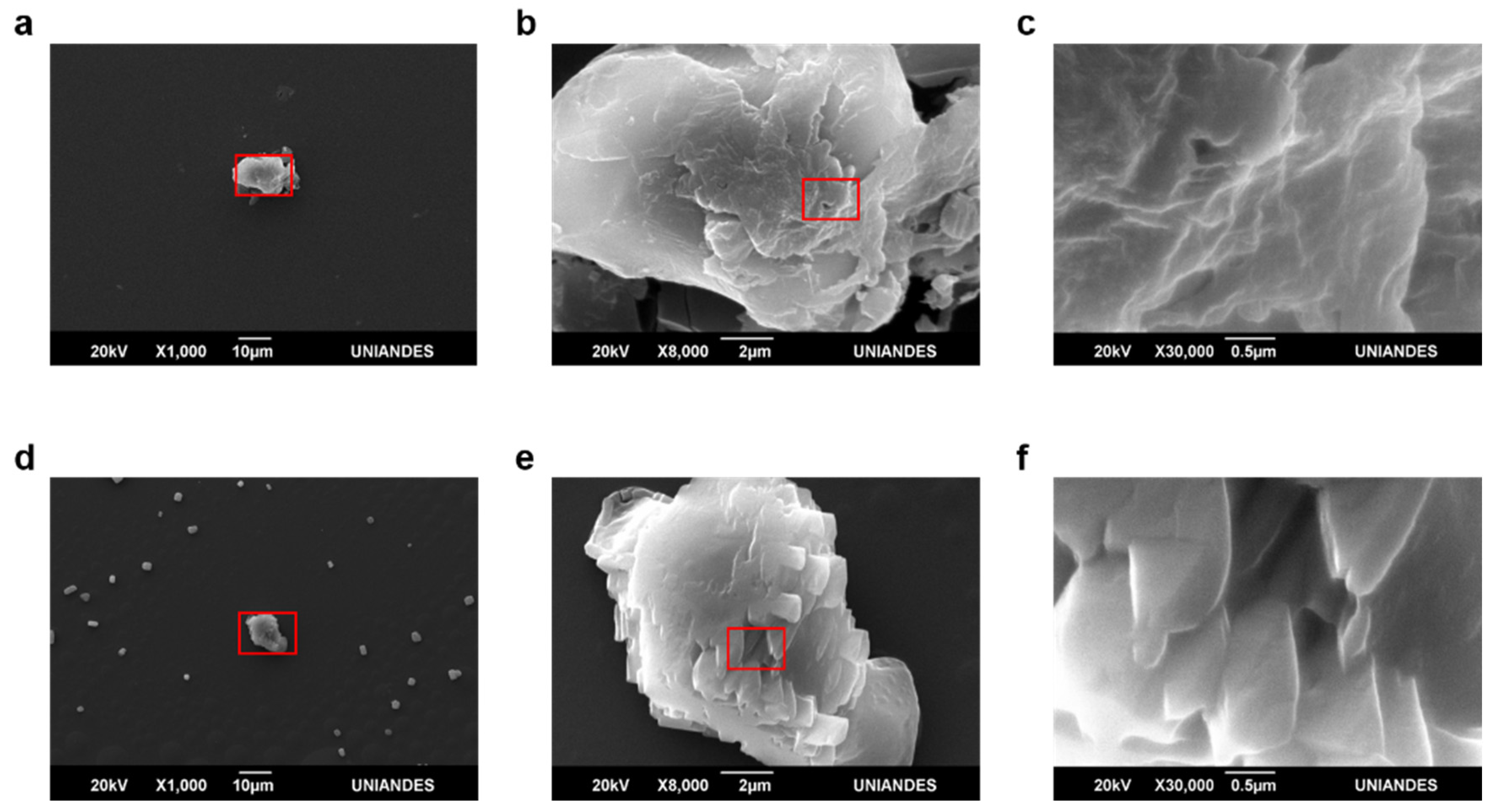

3.1. Microcapsules Characterization

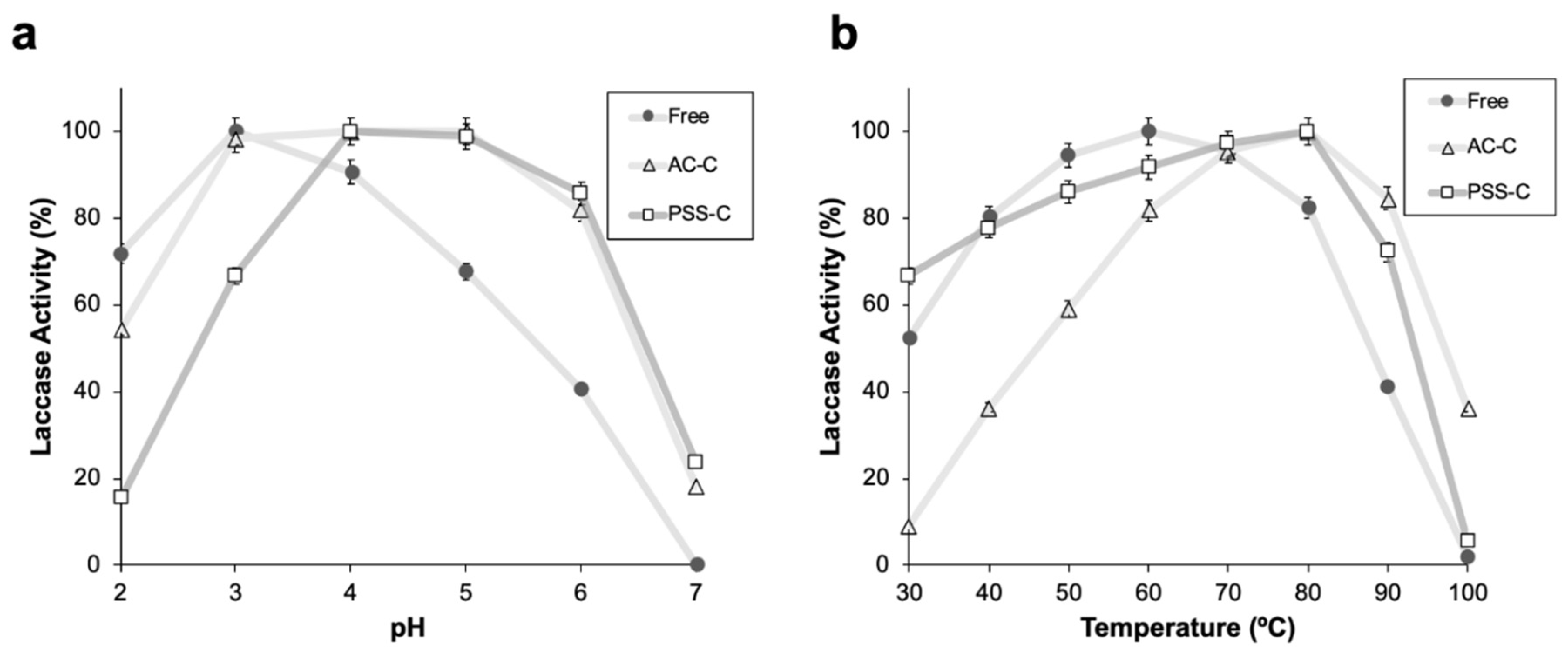

3.2. pH and Thermal Stability

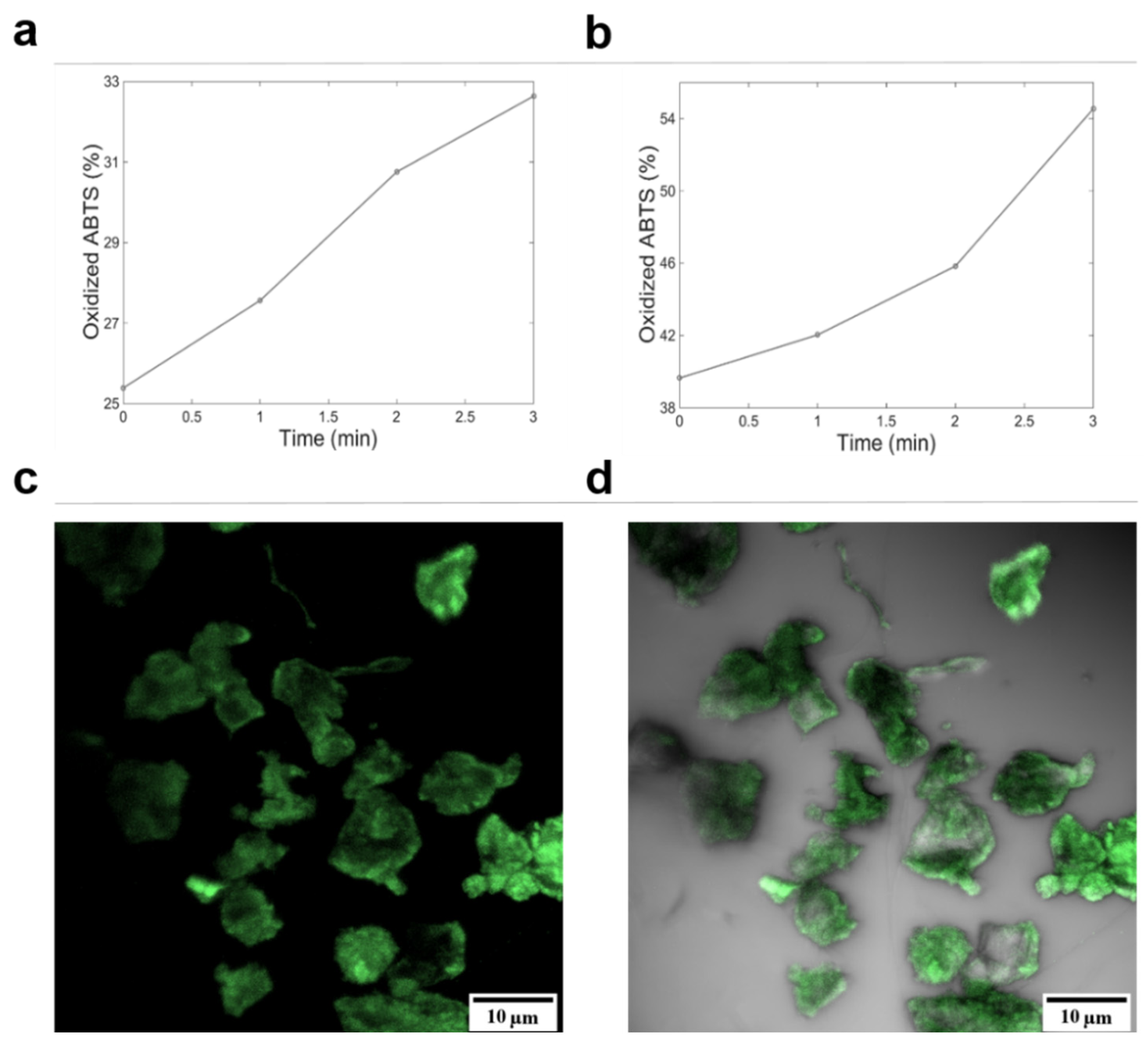

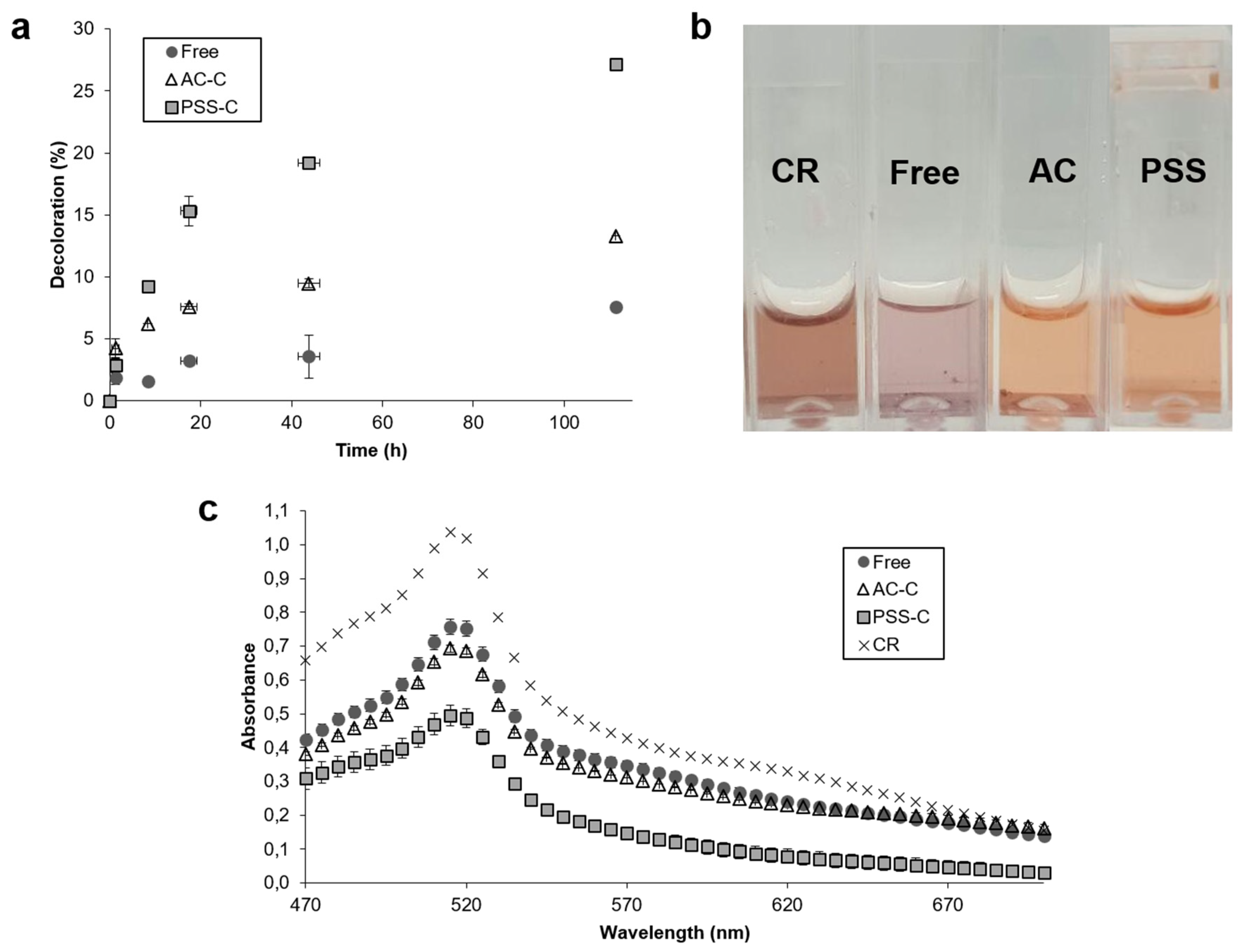

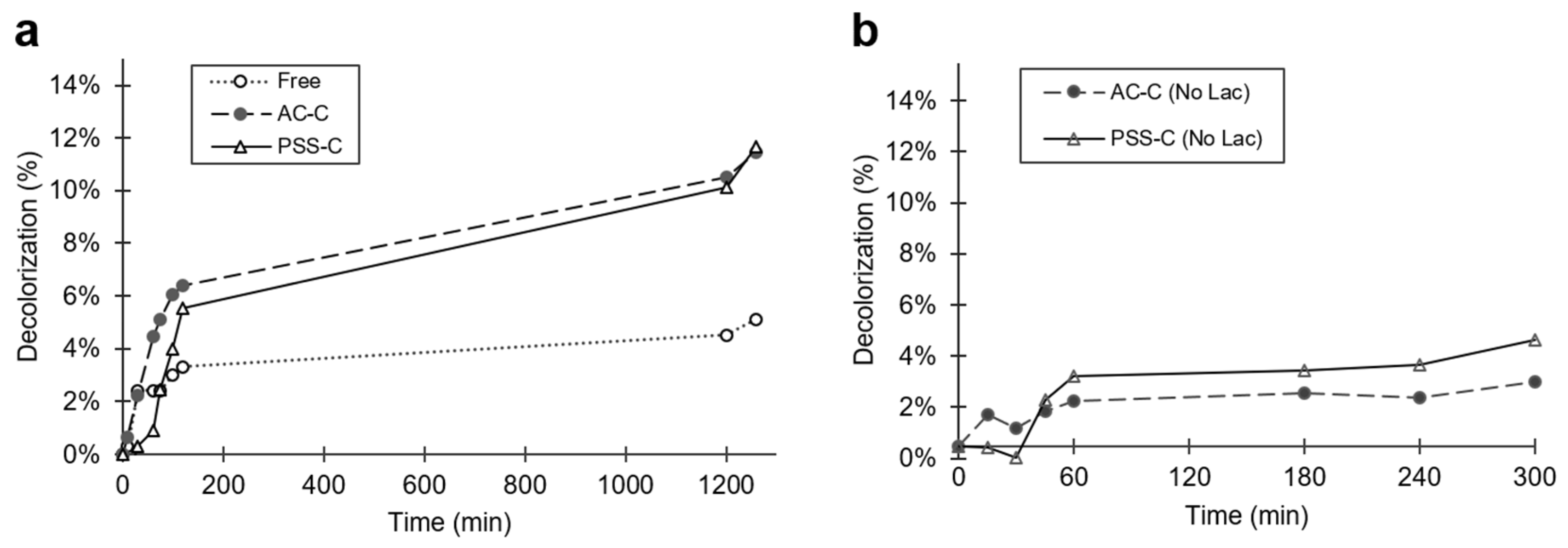

3.3. Decolorization Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sen, S.K.; Raut, S.; Bandyopadhyay, P.; Raut, S. Fungal decolouration and degradation of azo dyes: A review. Fungal Biol. Rev. 2016, 30, 112–133. [Google Scholar] [CrossRef]

- Anku, W.W.; Mamo, M.A.; Govender, P.P. Phenolic Compounds in Water: Sources, Reactivity, Toxicity and Treatment Methods. In Phenolic Compounds—Natural Sources, Importance and Applications; InTech: London, UK, 2017. [Google Scholar]

- Pirkarami, A.; Olya, M.E. Removal of dye from industrial wastewater with an emphasis on improving economic efficiency and degradation mechanism. J. Saudi Chem. Soc. 2017, 21, S179–S186. [Google Scholar] [CrossRef]

- Pandey, A.; Singh, P.; Iyengar, L. Bacterial decolorization and degradation of azo dyes. Int. Biodeterior. Biodegrad. 2007, 59, 73–84. [Google Scholar] [CrossRef]

- Ozdemir, S.; Cirik, K.; Akman, D.; Sahinkaya, E.; Cinar, O. Treatment of azo dye-containing synthetic textile dye effluent using sulfidogenic anaerobic baffled reactor. Bioresour. Technol. 2013, 146, 135–143. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, A.B.; Cervantes, F.J.; van Lier, J.B. Review paper on current technologies for decolourisation of textile wastewaters: Perspectives for anaerobic biotechnology. Bioresour. Technol. 2007, 98, 2369–2385. [Google Scholar] [CrossRef] [PubMed]

- Christie, R. Colour Chemistry; RSC Paperbacks; Royal Society of Chemistry: Cambridge, UK, 2007; ISBN 978-0-85404-573-0. [Google Scholar]

- Martins, L.O.; Soares, C.M.; Pereira, M.M.; Teixeira, M.; Costa, T.; Jones, G.H.; Henriques, A.O. Molecular and biochemical characterization of a highly stable bacterial laccase that occurs as a structural component of the Bacillus subtilis endospore coat. J. Biol. Chem. 2002, 277, 18849–18859. [Google Scholar] [CrossRef]

- Jadhav, A.J.; Srivastava, V.C. Adsorbed solution theory based modeling of binary adsorption of nitrobenzene, aniline and phenol onto granulated activated carbon. Chem. Eng. J. 2013, 229, 450–459. [Google Scholar] [CrossRef]

- Gupta, N.; Kushwaha, A.K.; Chattopadhyaya, M.C. Application of potato (Solanum tuberosum) plant wastes for the removal of methylene blue and malachite green dye from aqueous solution. Arab. J. Chem. 2016, 9, S707–S716. [Google Scholar] [CrossRef]

- Babuponnusami, A.; Muthukumar, K. A review on Fenton and improvements to the Fenton process for wastewater treatment. J. Environ. Chem. Eng. 2014, 2, 557–572. [Google Scholar] [CrossRef]

- Lopez-Barbosa, N.; Ornelas, N.; Osma, J.F. Uses of laccase in the monitoring and treatment of water and food. Laccase Appl. Investig. Insights 2017, 207–230. [Google Scholar]

- Osma, J.F.; Toca-Herrera, J.L.; Rodríguez-Couto, S. Biodegradation of a simulated textile effluent by immobilised-coated laccase in laboratory-scale reactors. Appl. Catal. A Gen. 2010, 373, 147–153. [Google Scholar] [CrossRef]

- Van Der Zee, F.P.; Villaverde, S. Combined anaerobic-aerobic treatment of azo dyes - A short review of bioreactor studies. Water Res. 2005, 39, 1425–1440. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.T.; Cerniglia, C.E. Mutagenicity of azo dyes: Structure-activity relationships. Mutat. Res. Genet. Toxicol. 1992, 277, 201–220. [Google Scholar] [CrossRef]

- Couto, S.R. Decolouration of industrial azo dyes by crude laccase from Trametes hirsuta. J. Hazard. Mater. 2007, 148, 768–770. [Google Scholar] [CrossRef]

- Rodríguez-Delgado, M.; Orona-Navar, C.; García-Morales, R.; Hernandez-Luna, C.; Parra, R.; Mahlknecht, J.; Ornelas-Soto, N. Biotransformation kinetics of pharmaceutical and industrial micropollutants in groundwaters by a laccase cocktail from Pycnoporus sanguineus CS43 fungi. Int. Biodeterior. Biodegrad. 2016, 108, 34–41. [Google Scholar] [CrossRef]

- Garcia-Morales, R.; Rodríguez-Delgado, M.; Gomez-Mariscal, K.; Orona-Navar, C.; Hernandez-Luna, C.; Torres, E.; Parra, R.; Cárdenas-Chávez, D.; Mahlknecht, J.; Ornelas-Soto, N. Biotransformation of Endocrine-Disrupting Compounds in Groundwater: Bisphenol A, Nonylphenol, Ethynylestradiol and Triclosan by a Laccase Cocktail from Pycnoporus sanguineus CS43. Water. Air. Soil Pollut. 2015, 226. [Google Scholar] [CrossRef]

- Pezzella, C.; Giacobbe, S.; Giacobelli, V.G.; Guarino, L.; Kylic, S.; Sener, M.; Sannia, G.; Piscitelli, A. Green routes towards industrial textile dyeing: A laccase based approach. J. Mol. Catal. B Enzym. 2016, 134, 274–279. [Google Scholar] [CrossRef]

- Wang, S.; Chen, W.; He, S.; Zhao, Q.; Li, X.; Sun, J.; Jiang, X. Mesosilica-coated ultrafine fibers for highly efficient laccase encapsulation. Nanoscale 2014, 6, 6468–6472. [Google Scholar] [CrossRef]

- Jun, L.Y.; Yon, L.S.; Mubarak, N.M.; Bing, C.H.; Pan, S.; Danquah, M.K.; Abdullah, E.C.; Khalid, M. An overview of immobilized enzyme technologies for dye and phenolic removal from wastewater. J. Environ. Chem. Eng. 2019, 7, 102961. [Google Scholar] [CrossRef]

- Singh, J.; Roychoudhury, A.; Srivastava, M.; Solanki, P.R.; Lee, D.W.; Lee, S.H.; Malhotra, B.D. A dual enzyme functionalized nanostructured thulium oxide based interface for biomedical application. Nanoscale 2014, 6, 1195–1208. [Google Scholar] [CrossRef]

- Fathi, Z.; Doustkhah, E.; Rostamnia, S.; Darvishi, F.; Ghodsi, A.; Ide, Y. Interaction of Yarrowia lipolytica lipase with dithiocarbamate modified magnetic carbon Fe3O4@C-NHCS2H core-shell nanoparticles. Int. J. Biol. Macromol. 2018, 117, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Allam, N.G.; Ismail, G.A.; El-Gemizy, W.M.; Salem, M.A. Biosynthesis of silver nanoparticles by cell-free extracts from some bacteria species for dye removal from wastewater. Biotechnol. Lett. 2019, 41, 379–389. [Google Scholar] [CrossRef]

- Fan, J.; Yu, C.; Gao, F.; Lei, J.; Tian, B.; Wang, L.; Luo, Q.; Tu, B.; Zhou, W.; Zhao, D. Cubic Mesoporous Silica with Large Controllable Entrance Sizes and Advanced Adsorption Properties. Angew. Chemie 2003, 115, 3254–3258. [Google Scholar] [CrossRef]

- Ratautas, D.; Marcinkevičiene, L.; Meškys, R.; Kulys, J. Mediatorless electron transfer in glucose dehydrogenase/laccase system adsorbed on carbon nanotubes. Electrochim. Acta 2015, 174, 940–944. [Google Scholar] [CrossRef]

- Campaña, A.L.; Sotelo, D.C.; Oliva, H.A.; Aranguren, A.; Ornelas-Soto, N.; Cruz, J.C.; Osma, J.F. Fabrication and Characterization of a Low-Cost Microfluidic System for the Manufacture of Alginate–Lacasse Microcapsules. Polymers (Basel) 2020, 12, 1158. [Google Scholar] [CrossRef] [PubMed]

- Niku-Paavola, M.L.; Raaska, L.; Itävaara, M. Detection of white-rot fungi by a non-toxic stain. Mycol. Res. 1990, 94, 27–31. [Google Scholar] [CrossRef]

- Ramírez-Cavazos, L.; Junghanns, C.; Ornelas-Soto, N.; Cárdenas-Chávez, D.; Hernández-Luna, C.; Demarche, P.; Enaud, E.; García-Morales, R.; Agathos, S.N.; Parra, R. Purification and characterization of two thermostable laccases from Pycnoporus sanguineus and potential role in degradation of endocrine disrupting chemicals. J. Mol. Catal. B Enzym. 2014, 108, 32–42. [Google Scholar] [CrossRef]

- Dai, Y.; Niu, J.; Liu, J.; Yin, L.; Xu, J. In situ encapsulation of laccase in microfibers by emulsion electrospinning: Preparation, characterization, and application. Bioresour. Technol. 2010, 101, 8942–8947. [Google Scholar] [CrossRef]

- Carneiro-da-Cunha, M.G.; Cerqueira, M.A.; Souza, B.W.S.; Carvalho, S.; Quintas, M.A.C.; Teixeira, J.A.; Vicente, A.A. Physical and thermal properties of a chitosan/alginate nanolayered PET film. Carbohydr. Polym. 2010, 82, 153–159. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Li, D.; Coates, N.E.; Segalman, R.A.; Cahill, D.G. Thermal conductivity and elastic constants of PEDOT:PSS with high electrical conductivity. Macromolecules 2015, 48, 585–591. [Google Scholar] [CrossRef]

- Kulig, D.; Zimoch-Korzycka, A.; Jarmoluk, A.; Marycz, K. Study on alginate-chitosan complex formed with different polymers ratio. Polymers (Basel) 2016, 8, 167. [Google Scholar] [CrossRef] [PubMed]

- Singare, P.U.; Lokhande, R.S.; Madyal, R.S. Thermal degradation studies of polystyrene sulfonic and polyacrylic carboxylic cationites. Russ. J. Gen. Chem. 2010, 80, 527–532. [Google Scholar] [CrossRef]

- Arica, M.Y.; Bayramoǧlu, G.; Biçak, N. Characterisation of tyrosinase immobilised onto spacer-arm attached glycidyl methacrylate-based reactive microbeads. Process Biochem. 2004, 39, 2007–2017. [Google Scholar] [CrossRef]

- Flory, P.J. Principles of Polymer Chemistry; Baker lectures 1948; Cornell University Press: Ithaca, NY, USA, 1953; ISBN 9780801401343. [Google Scholar]

- Nie, J.; Wang, Z.; Hu, Q. Difference between Chitosan Hydrogels via Alkaline and Acidic Solvent Systems. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef] [PubMed]

- Palmieri, G.; Giardina, P.; Sannia, G. Laccase-mediated Remazol Brilliant Blue R decolorization in a fixed-bed bioreactor. Biotechnol. Prog. 2005, 21, 1436–1441. [Google Scholar] [CrossRef] [PubMed]

- Stloukal, R.; Watzková, J.; Gregušová, B. Dye decolorisation by laccase immobilised in lens-Shaped poly(Vinyl alcohol) hydrogel capsules. Chem. Pap. 2014, 68, 1514–1520. [Google Scholar] [CrossRef]

- Moilanen, U.; Osma, J.F.; Winquist, E.; Leisola, M.; Couto, S.R. Decolorization of simulated textile dye baths by crude laccases from Trametes hirsuta and Cerrena unicolor. Eng. Life Sci. 2010, 10, 242–247. [Google Scholar] [CrossRef]

- Lu, L.; Zhao, M.; Wang, Y. Immobilization of laccase by alginate-chitosan microcapsules and its use in dye decolorization. World J. Microbiol. Biotechnol. 2007, 23, 159–166. [Google Scholar] [CrossRef]

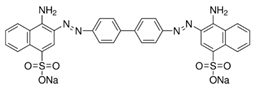

| Dye | λmax (nm) | Color Index Number | Color Index Name | Structure |

|---|---|---|---|---|

| Congo Red | 500 | 22120 | Direct Red 28 |  |

| Treatment | Advantages | Disadvantages |

|---|---|---|

| Free laccase |

|

|

| AC-C |

|

|

| PSS-C |

|

|

| Fungi | [Dye] (mg L−1) | % of Decolorization | Physical State | Enzyme Activity (U L−1) | Enzyme Activity per Dye Concentration | Ref. |

|---|---|---|---|---|---|---|

| P. Sanguineus | 70 | 27.1% | Encapsulated in PSS | 2000 | 28.6 U mg−1 | This study |

| P. Sanguineus | 70 | 13.3% | Encapsulated in alginate/chitosan | 2000 | 28.6 U mg−1 | This study |

| Trametes Versicolor | 10 | 48% | Encapsulated in poly(vinyl alcohol) | 1340 | 134 U mg−1 | [39] |

| Pleurotus ostreatus | 31 | 70% | Encapsulated in alginate/chitosan | 120,000 | 3871 U mg−1 | [38] |

| M. Thermophila | 100 | 3% | Encapsulated in alginate/chitosan | Not reported | - | [41] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopez-Barbosa, N.; Campaña, A.L.; Cruz, J.C.; Ornelas-Soto, N.; Osma, J.F. Enhanced Catalytic Dye Decolorization by Microencapsulation of Laccase from P. Sanguineus CS43 in Natural and Synthetic Polymers. Polymers 2020, 12, 1353. https://doi.org/10.3390/polym12061353

Lopez-Barbosa N, Campaña AL, Cruz JC, Ornelas-Soto N, Osma JF. Enhanced Catalytic Dye Decolorization by Microencapsulation of Laccase from P. Sanguineus CS43 in Natural and Synthetic Polymers. Polymers. 2020; 12(6):1353. https://doi.org/10.3390/polym12061353

Chicago/Turabian StyleLopez-Barbosa, Natalia, Ana Lucía Campaña, Juan C. Cruz, Nancy Ornelas-Soto, and Johann F. Osma. 2020. "Enhanced Catalytic Dye Decolorization by Microencapsulation of Laccase from P. Sanguineus CS43 in Natural and Synthetic Polymers" Polymers 12, no. 6: 1353. https://doi.org/10.3390/polym12061353

APA StyleLopez-Barbosa, N., Campaña, A. L., Cruz, J. C., Ornelas-Soto, N., & Osma, J. F. (2020). Enhanced Catalytic Dye Decolorization by Microencapsulation of Laccase from P. Sanguineus CS43 in Natural and Synthetic Polymers. Polymers, 12(6), 1353. https://doi.org/10.3390/polym12061353