Solution Blow Spinning of High-Performance Submicron Polyvinylidene Fluoride Fibres: Computational Fluid Mechanics Modelling and Experimental Results

Abstract

1. Introduction

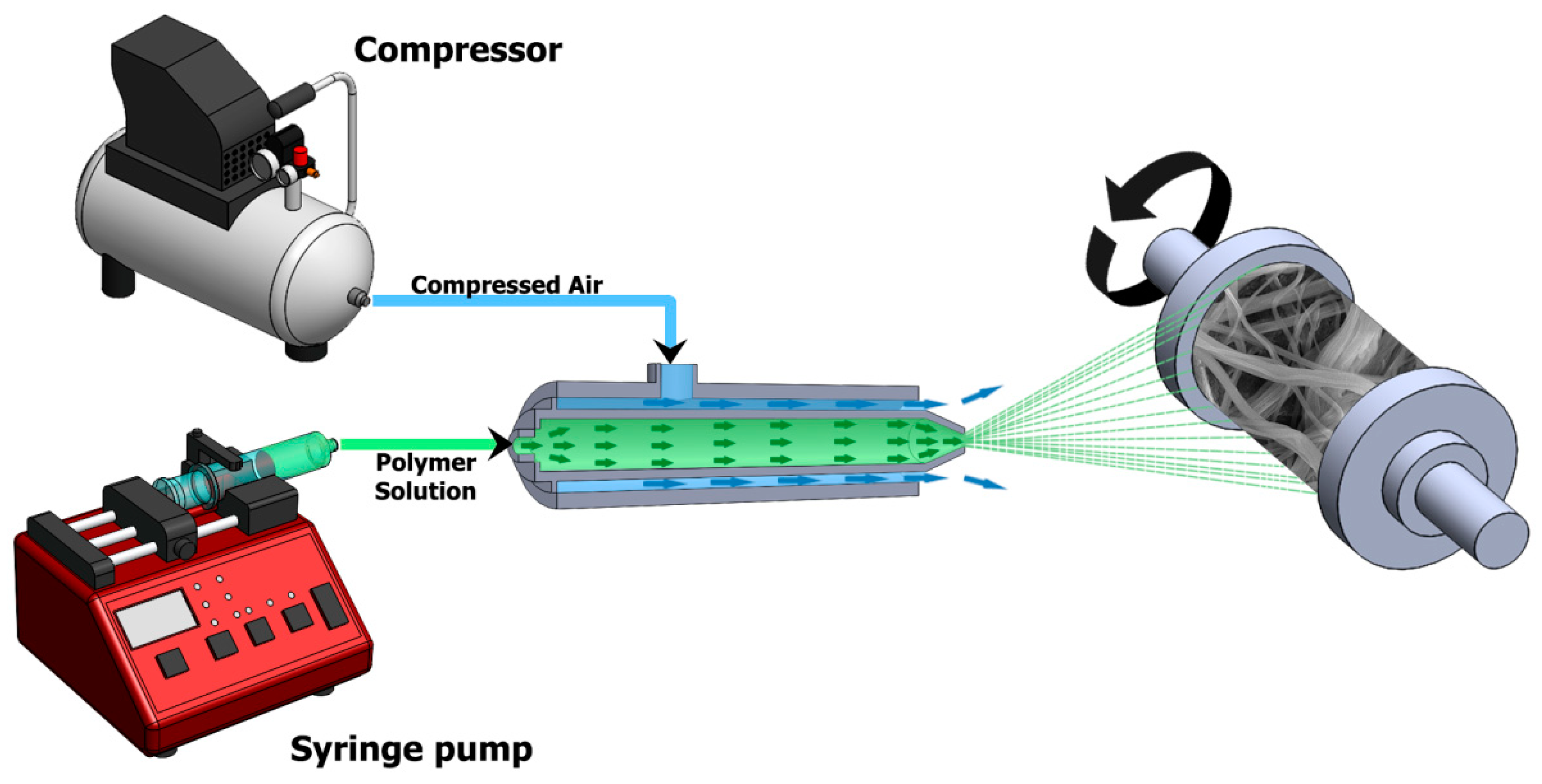

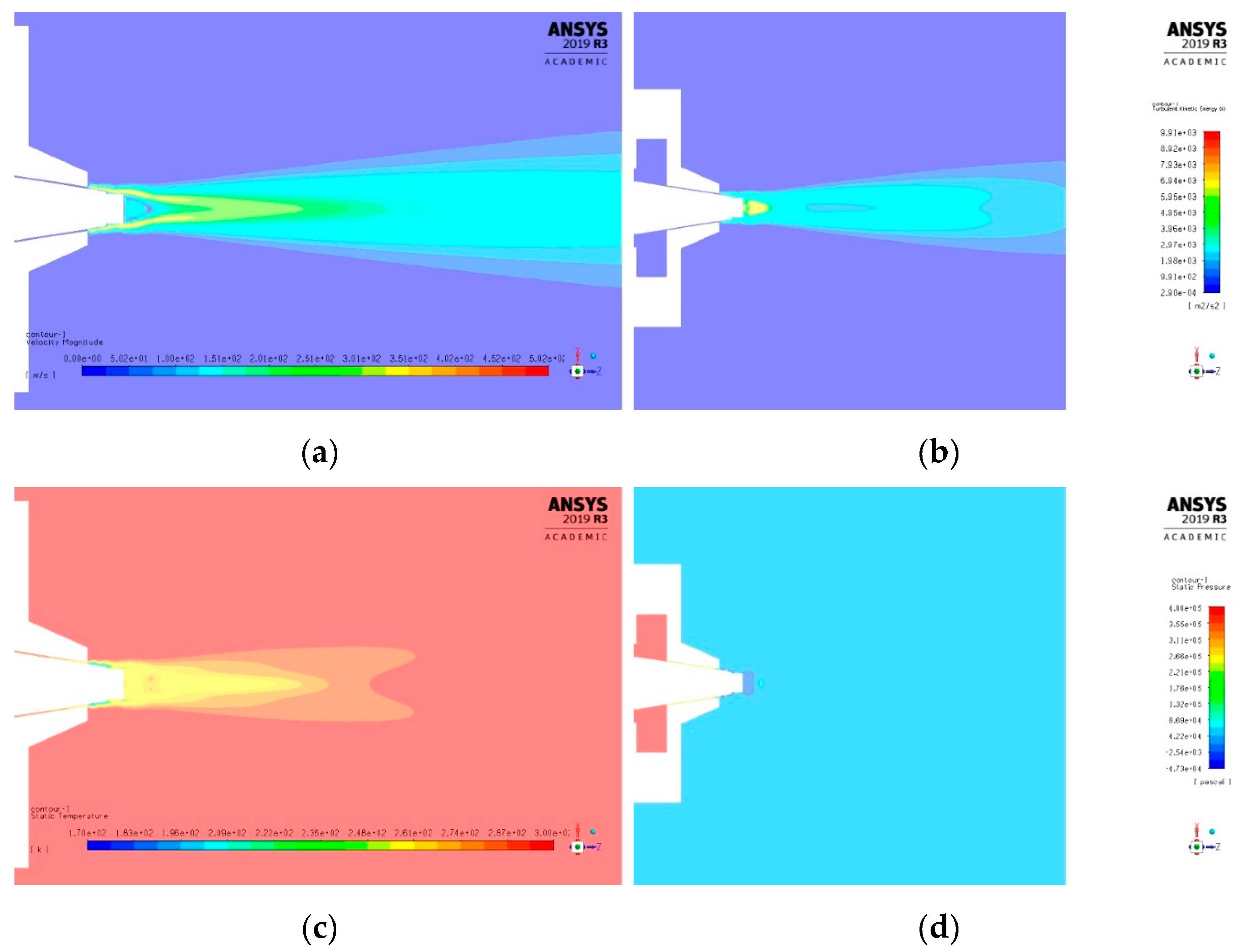

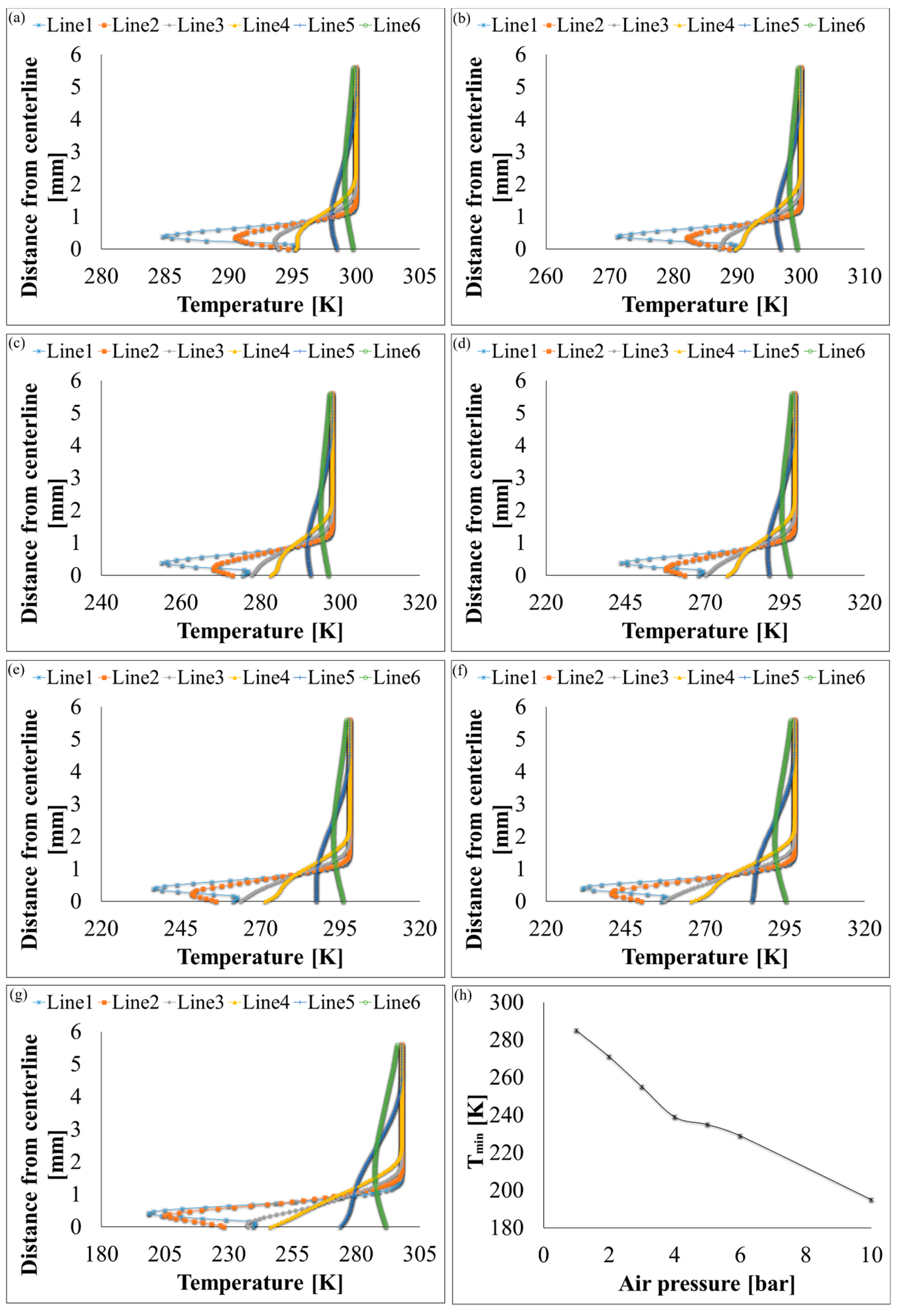

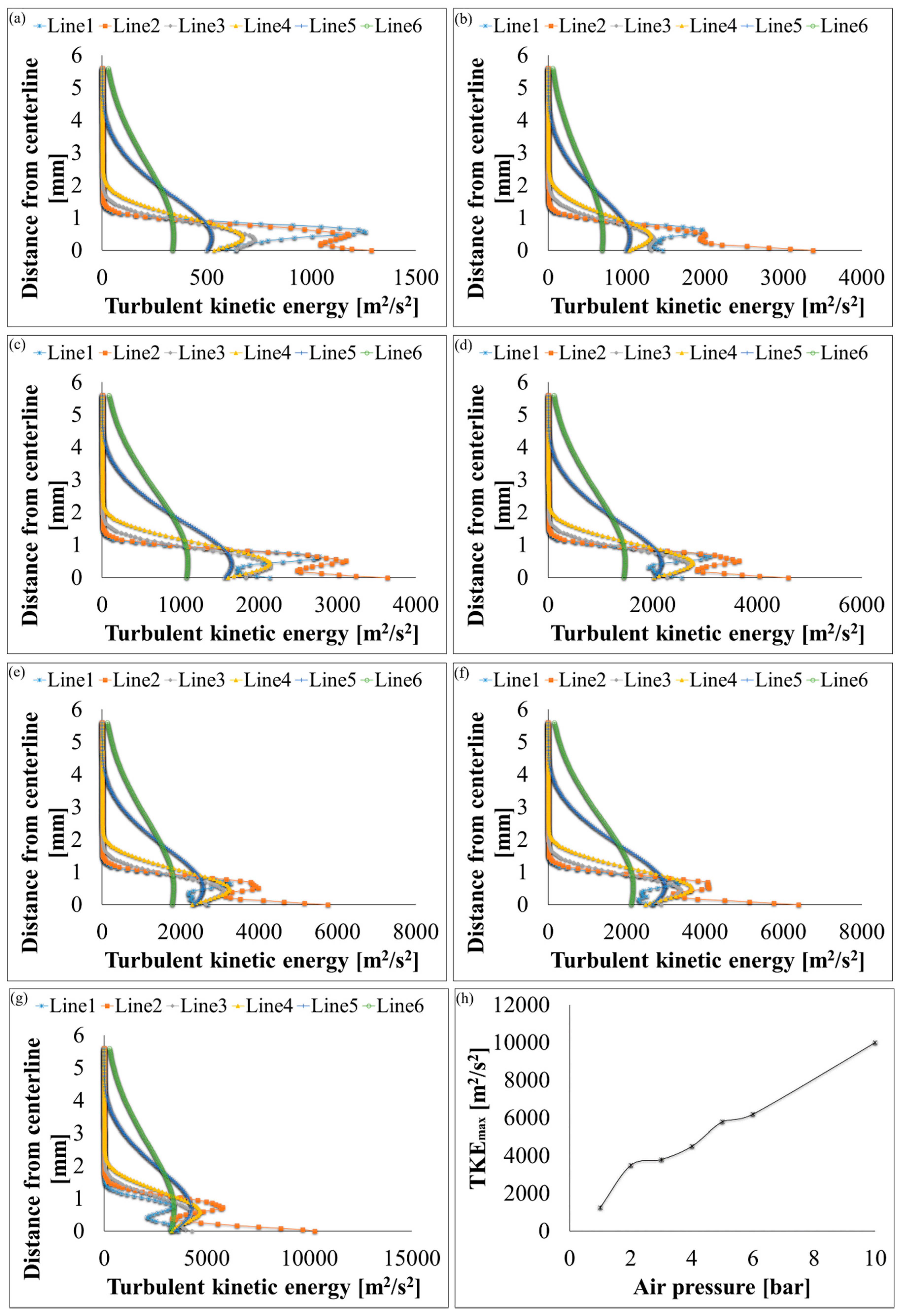

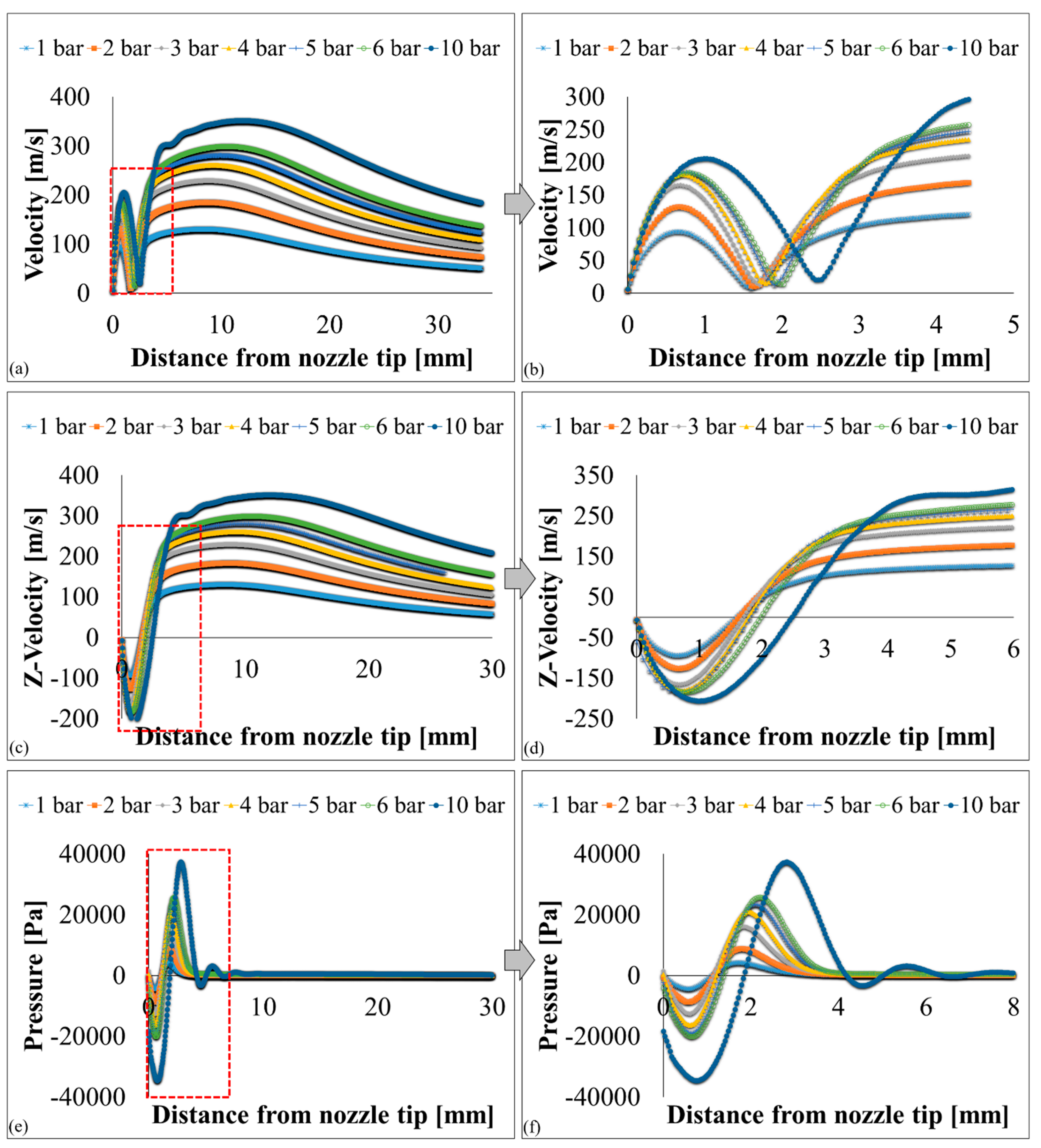

2. Experimental Work

2.1. Materials

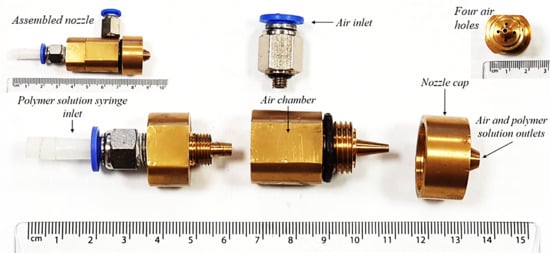

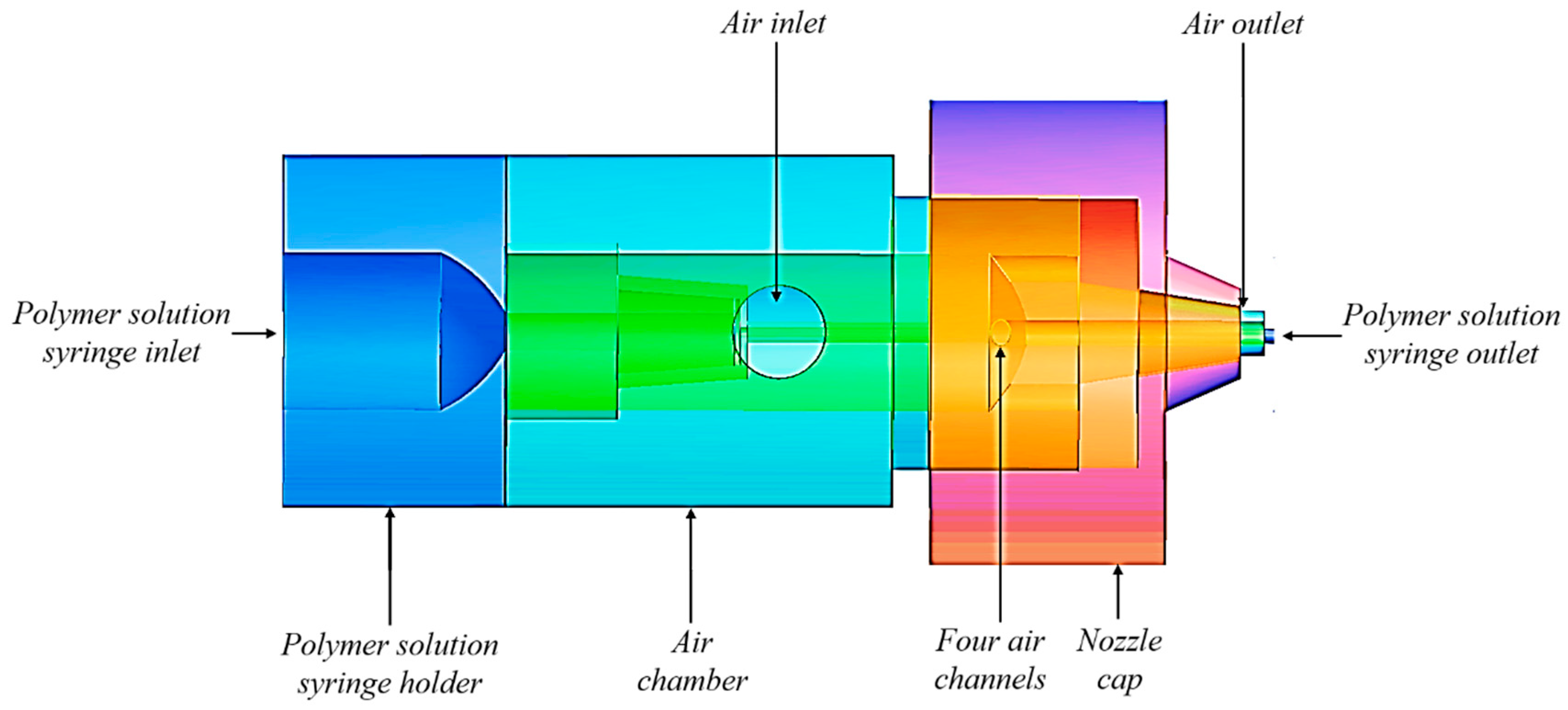

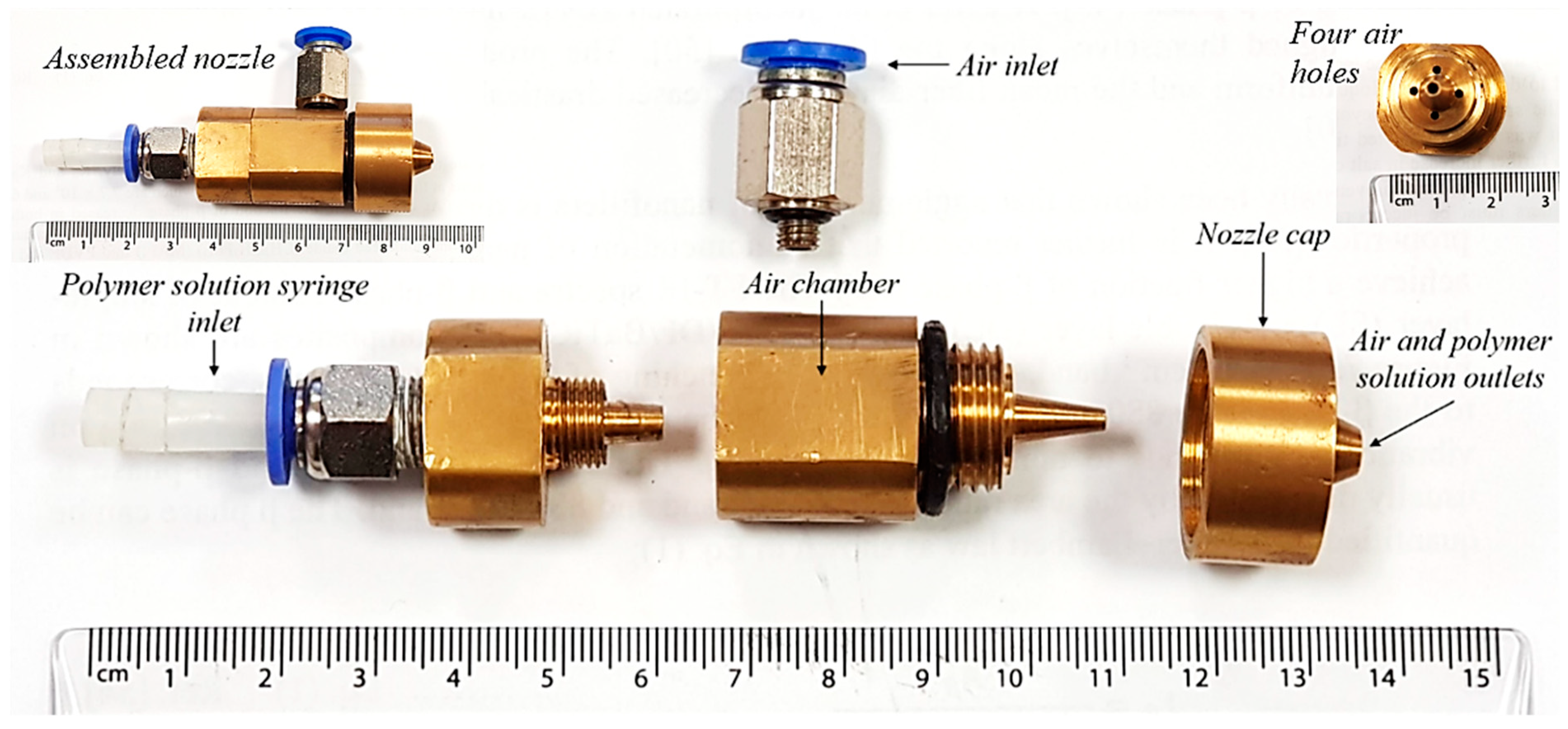

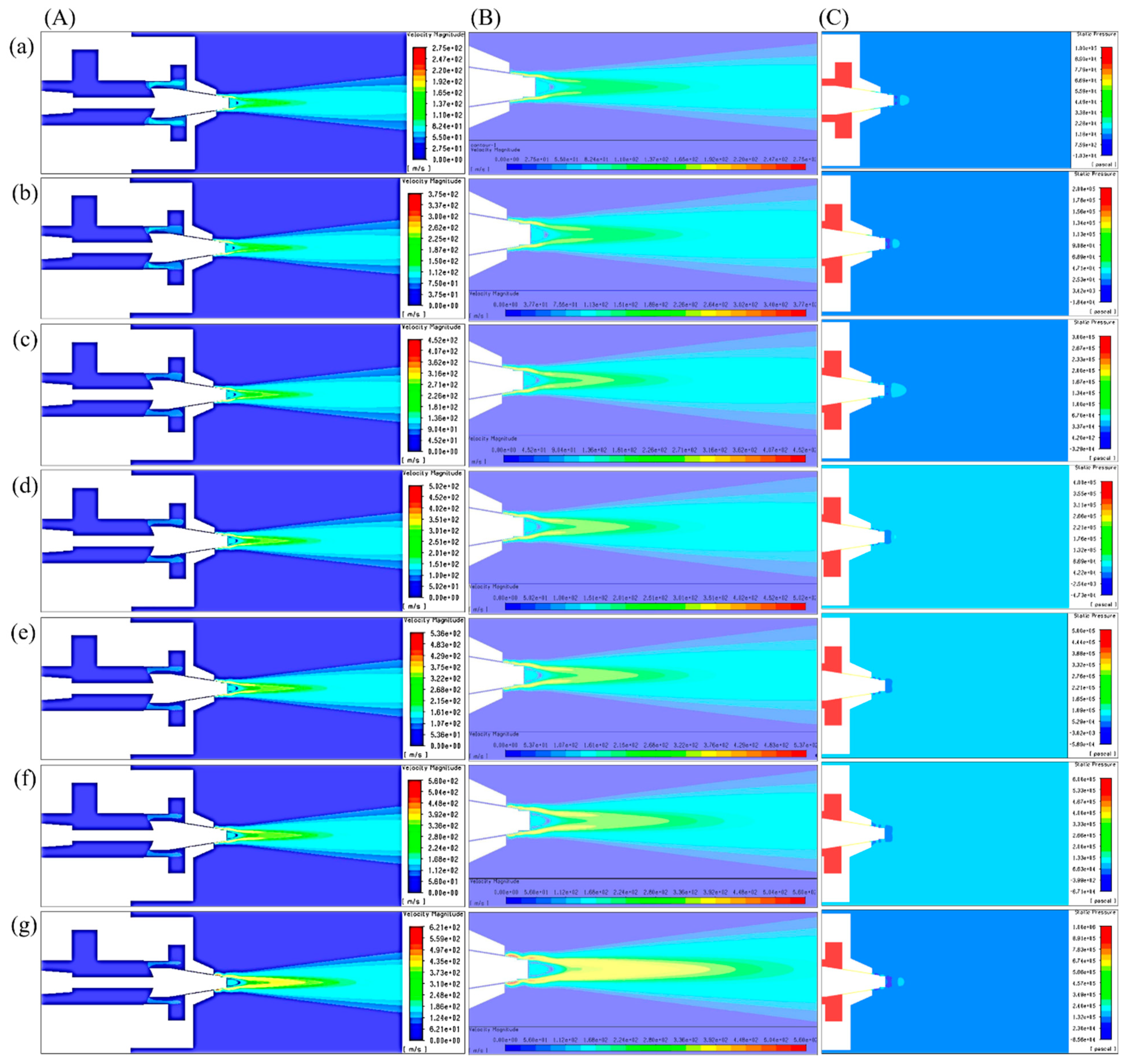

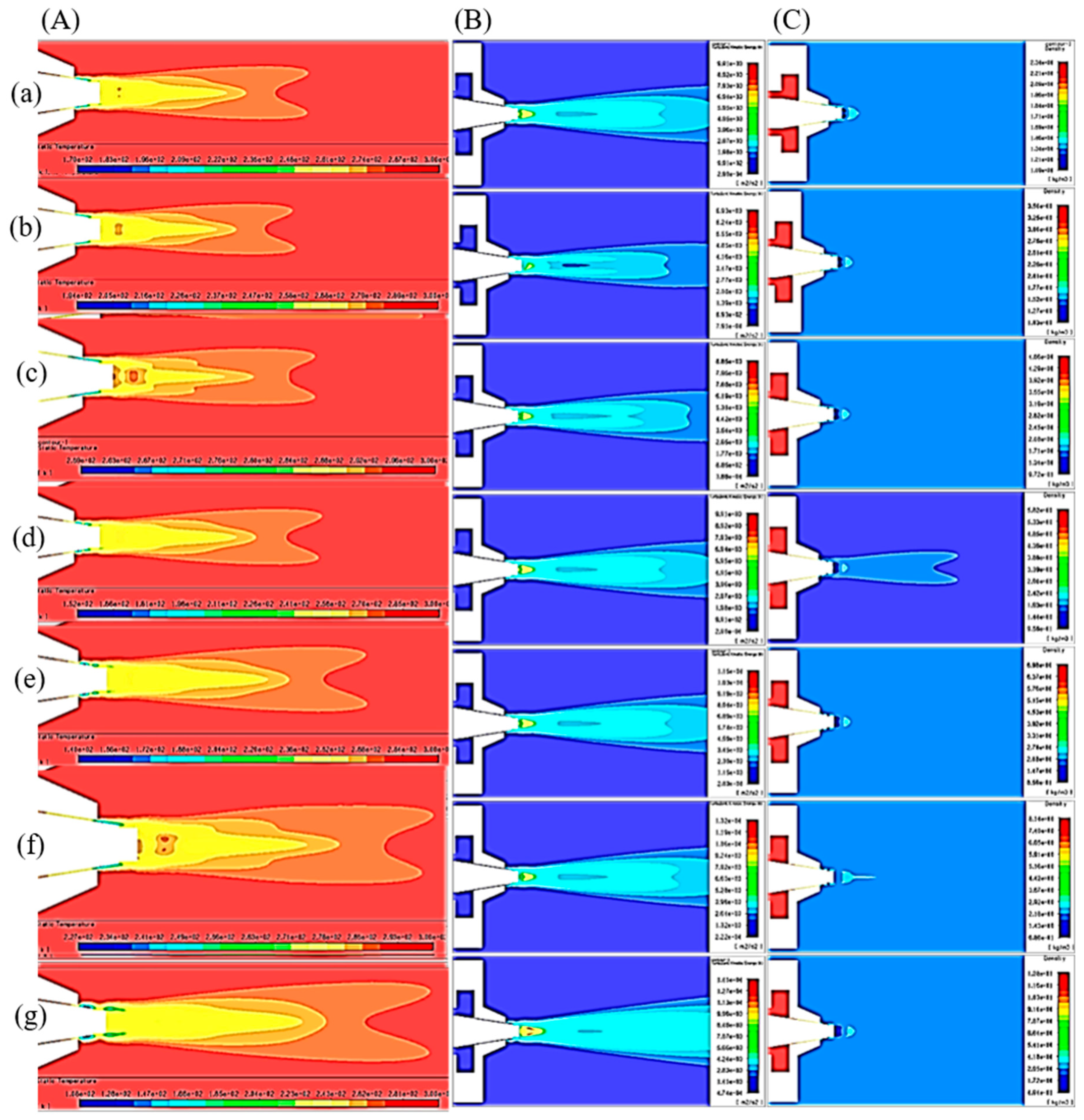

2.2. Nozzle Design

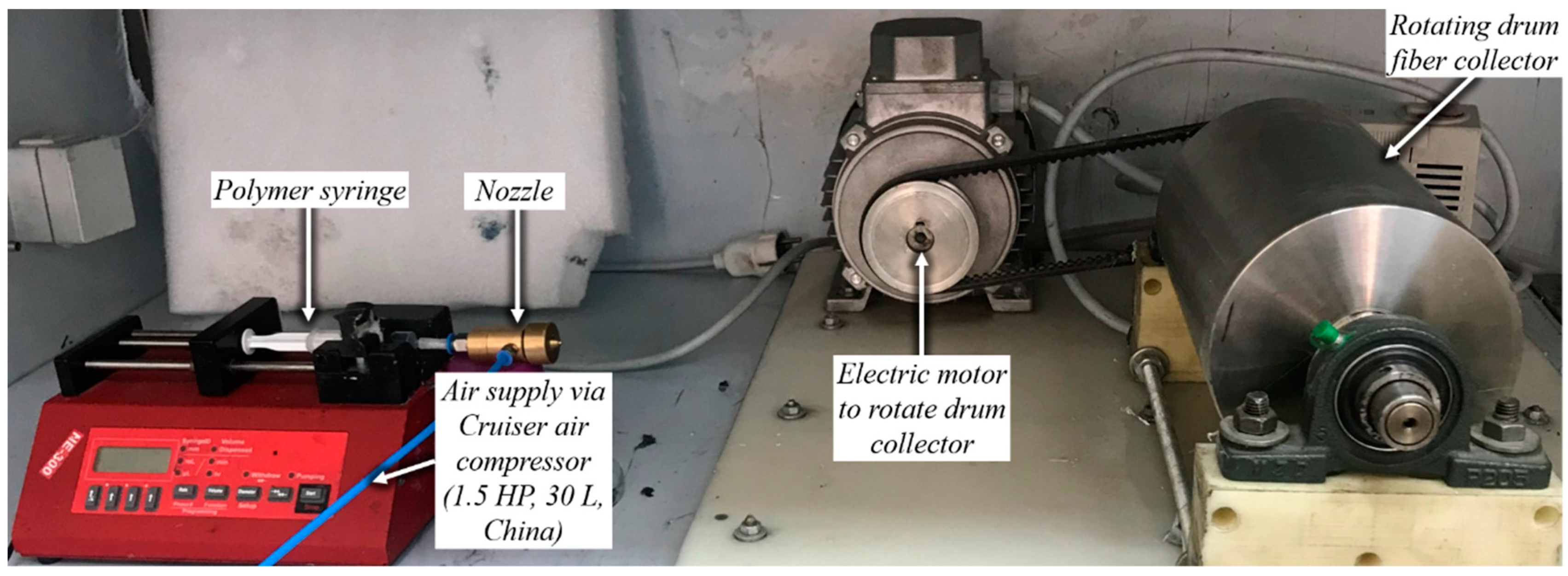

2.3. Experimental Setup

2.4. Production of Samples/Fibres

2.5. Characterization

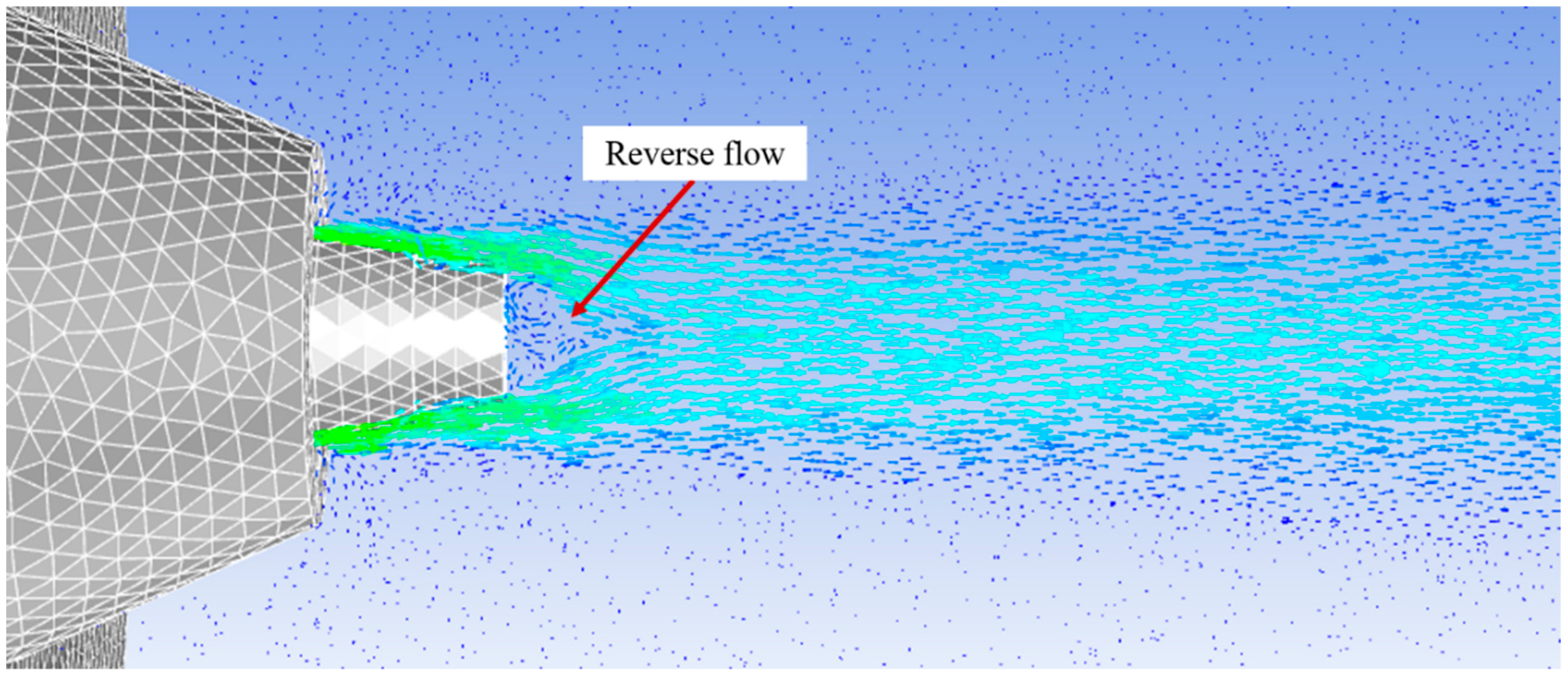

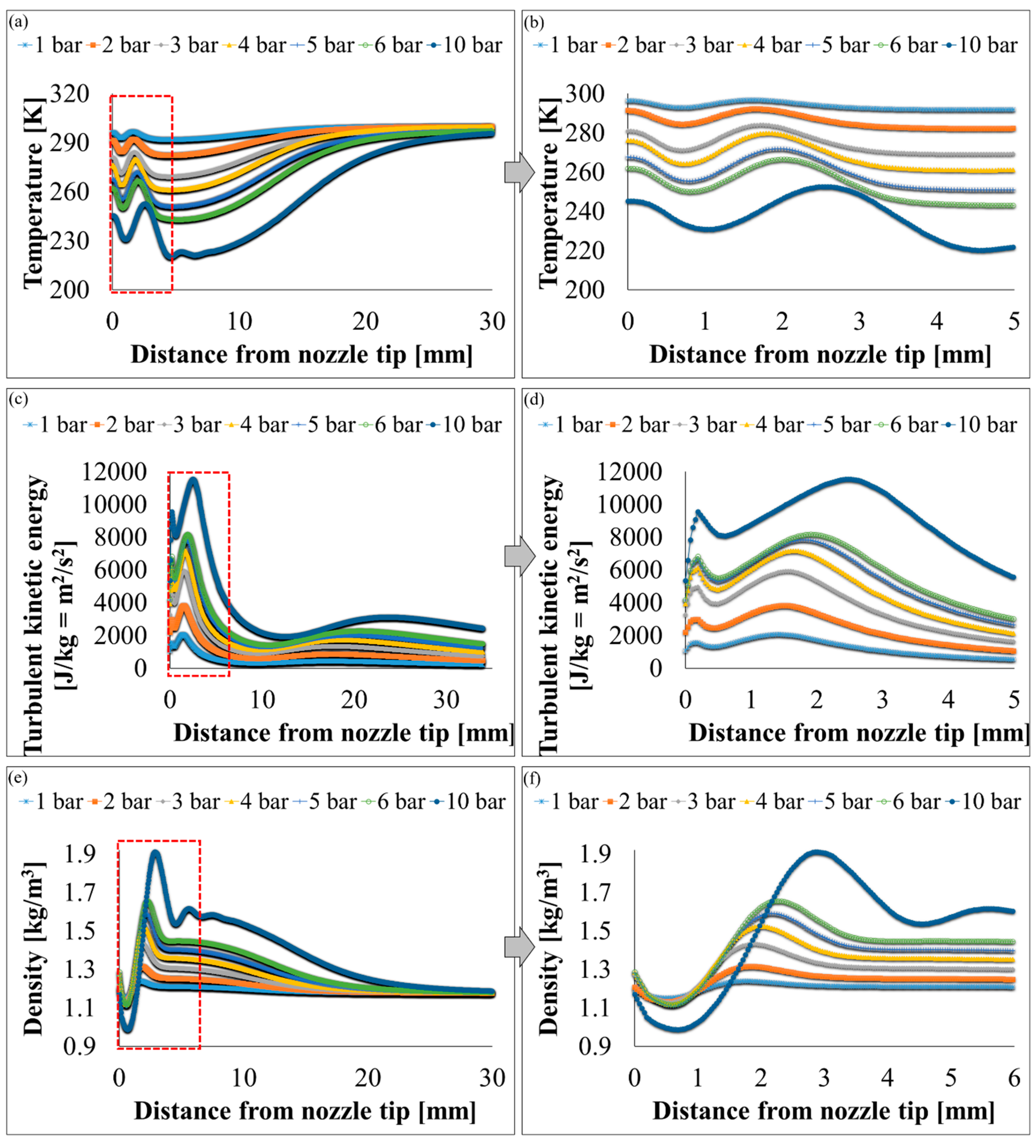

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kawai, H. The Piezoelectricity of Poly (vinylidene Fluoride). Jpn. J. Appl. Phys. 1969, 8, 975–976. [Google Scholar] [CrossRef]

- Persano, L.; Dagdeviren, C.; Su, Y.; Zhang, Y.; Girardo, S.; Pisignano, D.; Huang, Y.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 2013, 4, 1610–1633. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Tan, L.; Pan, X.; Liu, G.; He, Y.; Jin, W.; Li, M.; Hu, Y.; Gu, H. Self-Powered Viscosity and Pressure Sensing in Microfluidic Systems Based on the Piezoelectric Energy Harvesting of Flowing Droplets. ACS Appl. Mater. Interfaces 2017, 9, 28586–28595. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.S.; Chung, J.; Hwang, G.-T.; Jeong, C.K.; Jung, Y.; Kwak, J.-H.; Kang, H.; Byun, M.; Kim, W.D.; Hur, S.; et al. Flexible inorganic piezoelectric acoustic nanosensors for biomimetic artificial hair cells. Adv. Funct. Mater. 2014, 24, 6914–6921. [Google Scholar] [CrossRef]

- Seo, M.H.; Yoo, J.Y.; Choi, S.Y.; Lee, J.S.; Choi, K.; Jeong, C.K.; Lee, K.J.; Yoon, J.B. Versatile Transfer of an Ultralong and Seamless Nanowire Array Crystallized at High Temperature for Use in High-Performance Flexible Devices. ACS Nano 2017, 11, 1520–1529. [Google Scholar] [CrossRef]

- Zou, H.; Li, X.; Peng, W.; Wu, W.; Yu, R.; Wu, C.; Ding, W.; Hu, F.; Liu, R.; Zi, Y.; et al. Piezo-Phototronic Effect on Selective Electron or Hole Transport through Depletion Region of Vis–NIR Broadband Photodiode. Adv. Mater. 2017, 29, 1–10. [Google Scholar] [CrossRef]

- Guo, R.; Guo, Y.; Duan, H.; Li, H.; Liu, H. Synthesis of Orthorhombic Perovskite-Type ZnSnO3 Single-Crystal Nanoplates and Their Application in Energy Harvesting. ACS Appl. Mater. Interfaces 2017, 9, 8271–8279. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Z.M.; Xu, X.; Lim, C.T.; Ramakrishna, S. Preparation of core-shell structured PCL-r-gelatin bi-component nanofibers by coaxial electrospinning. Chem. Mater. 2004, 16, 3406–3409. [Google Scholar] [CrossRef]

- Xu, X.; Zhuang, X.; Chen, X.; Wang, X.; Yang, L.; Jing, X. Preparation of core-sheath composite nanofibers by emulsion electrospinning. Macromol. Rapid Commun. 2006, 27, 1637–1642. [Google Scholar] [CrossRef]

- Jiyong, H.; Yuanyuan, G.; Hele, Z.; Yinda, Z.; Xudong, Y. Effect of electrospinning parameters on piezoelectric properties of electrospun PVDF nanofibrous mats under cyclic compression. J. Text. Inst. 2017, 109, 843–850. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X. Investigation on a new annular melt-blowing die using numerical simulation. Ind. Eng. Chem. Res. 2013, 52, 4597–4605. [Google Scholar] [CrossRef]

- Sun, Y.F.; Liu, B.W.; Wang, X.H.; Zeng, Y.C. Air-Flow Field of the Melt-Blowing Slot Die via Numerical Simulation and Multiobjective Genetic Algorithms. J. Appl. Polym. Sci. 2011, 122, 3520–3527. [Google Scholar] [CrossRef]

- Vural, M.; Behrens, A.M.; Ayyub, O.B.; Ayoub, J.J.; Kofinas, P. Sprayable elastic conductors based on block copolymer silver nanoparticle composites. ACS Nano 2014, 9, 336–344. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Kopperstad, P.; West, M.; Hedin, N.; Fong, H. Generation of Polymer Ultrafine Fibers Through Solution (Air-) Blowing. J. Appl. Polym. Sci. 2009, 114, 3479–3486. [Google Scholar] [CrossRef]

- Tandon, B.; Kamble, P.; Olsson, R.T.; Blaker, J.J.; Cartmell, S.H. Fabrication and characterisation of stimuli responsive piezoelectric PVDF and hydroxyapatite-filled PVDF fibrous membranes. Molecules 2019, 24, 1903. [Google Scholar] [CrossRef]

- Magaz, A.; Roberts, A.D.; Faraji, S.; Nascimento, T.R.L.; Medeiros, E.S.; Zhang, W.; Greenhalgh, R.; Mautner, A.; Li, X.; Blaker, J.J. Porous, Aligned, and Biomimetic Fibers of Regenerated Silk Fibroin Produced by Solution Blow Spinning. Biomacromolecules 2018, 19, 4542–4553. [Google Scholar] [CrossRef]

- Han, W.; Xie, S.; Sun, X.; Wang, X.; Yan, Z. Optimization of airflow field via solution blowing for chitosan/PEO nanofiber formation. Fibers Polym. 2017, 18, 1554–1560. [Google Scholar] [CrossRef]

- Lou, H.; Han, W.; Wang, X. Numerical study on the solution blowing annular jet and its correlation with fiber morphology. Ind. Eng. Chem. Res. 2014, 53, 2830–2838. [Google Scholar] [CrossRef]

- Drabek, J.; Zatloukal, M. Meltblown technology for production of polymeric microfibers/nanofibers: A review. Phys. Fluids 2019, 31, 091301. [Google Scholar] [CrossRef]

- Hassan, M.A.; Anantharamaiah, N.; Khan, S.A.; Pourdeyhimi, B. Computational Fluid Dynamics Simulations and Experiments of Meltblown Fibrous Media: New Die Designs to Enhance Fiber Attenuation and Filtration Quality. Ind. Eng. Chem. Res. 2016, 55, 2049–2058. [Google Scholar] [CrossRef]

- Moore, E.M.; Shambaugh, R.; Papavassiliou, D.V. Papavassiliou, Analysis of isothermal annular jets: Comparison of computational fluid dynamics and experimental data. J. Appl. Polym. Sci. 2004, 94, 909–922. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.N.; Disimile, P.J. Effect of Turbulence Model in Numerical Simulation of Single Round Jet at Low Reynolds Number. Int. J. Comput. Eng. Res. 2017, 7, 29–44. [Google Scholar]

- Gopalakrishnan, R.N.; Disimile, P.J. CFD analysis of twin turbulent impinging round jets at different impingement angles. Fluids 2018, 3, 79. [Google Scholar] [CrossRef]

- Ray, S.S.; Sinha-Ray, S.; Yarin, A.L.; Pourdeyhimi, B. Theoretical and experimental investigation of physical mechanisms responsible for polymer nanofiber formation in solution blowing. Polymer (Guildf) 2015, 56, 452–463. [Google Scholar] [CrossRef]

- Available online: https://www.oxfordreference.com/view/10.1093/oi/authority.20110803100025554 (accessed on 25 April 2020).

- Jassim, E.; Abdi, M.A.; Muzychka, Y. Computational fluid dynamics study for flow of natural gas through high-pressure supersonic nozzles: Part 1. Real gas effects and shockwave. Pet. Sci. Technol. 2008, 26, 1757–1772. [Google Scholar] [CrossRef]

- Haddadi, S.A.; Ghaderi, S.; Amini, M.; Ramazani, S.A. ScienceDirect Mechanical and piezoelectric characterizations of electrospun PVDF-nanosilica fibrous scaffolds for biomedical applications. Mater. Today Proc. 2018, 5, 15710–15716. [Google Scholar] [CrossRef]

- Yun, J.S.; Park, C.K.; Jeong, Y.H.; Cho, J.H.; Paik, J.; Yoon, S.H.; Hwang, K. The Fabrication and Characterization of Piezoelectric PZT/PVDF Electrospun Nanofiber Composites. Nanomater. Nanotechnol. 2016, 6, 62433. [Google Scholar] [CrossRef]

- Howling, A.A.; Guittienne, P.; Furno, I. Two-fluid plasma model for radial Langmuir probes as a converging nozzle with sonic choked flow, and sonic passage to supersonic flow. Phys. Plasmas 2019, 26, 7–10. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, N.; Liao, R.; Zhao, H.; Shi, B. Study of mechanical choked Venturi nozzles used for liquid flow controlling. Flow Meas. Instrum. 2019, 65, 158–165. [Google Scholar] [CrossRef]

- Hariharan, P.; Giarra, M.; Reddy, V.; Day, S.W.; Manning, K.B.; Deutsch, S.; Stewart, S.F.C.; Myers, M.R.; Berman, M.R.; Burgreen, G.W.; et al. Multilaboratory particle image velocimetry analysis of the FDA benchmark nozzle model to support validation of computational fluid dynamics simulations. J. Biomech. Eng. 2011, 133, 1–14. [Google Scholar] [CrossRef]

- Okada, A.; Uno, Y.; Onoda, S.; Habib, S. Computational fluid dynamics analysis of working fluid flow and debris movement in wire EDMed kerf. CIRP Ann.-Manuf. Technol. 2009, 58, 209–212. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, L.; Tong, L.; Chen, Y. Choked flow characteristics of subcritical refrigerant flowing through converging-diverging nozzles. Entropy 2014, 16, 5810–5821. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atif, R.; Combrinck, M.; Khaliq, J.; Hassanin, A.H.; Shehata, N.; Elnabawy, E.; Shyha, I. Solution Blow Spinning of High-Performance Submicron Polyvinylidene Fluoride Fibres: Computational Fluid Mechanics Modelling and Experimental Results. Polymers 2020, 12, 1140. https://doi.org/10.3390/polym12051140

Atif R, Combrinck M, Khaliq J, Hassanin AH, Shehata N, Elnabawy E, Shyha I. Solution Blow Spinning of High-Performance Submicron Polyvinylidene Fluoride Fibres: Computational Fluid Mechanics Modelling and Experimental Results. Polymers. 2020; 12(5):1140. https://doi.org/10.3390/polym12051140

Chicago/Turabian StyleAtif, Rasheed, Madeleine Combrinck, Jibran Khaliq, Ahmed H. Hassanin, Nader Shehata, Eman Elnabawy, and Islam Shyha. 2020. "Solution Blow Spinning of High-Performance Submicron Polyvinylidene Fluoride Fibres: Computational Fluid Mechanics Modelling and Experimental Results" Polymers 12, no. 5: 1140. https://doi.org/10.3390/polym12051140

APA StyleAtif, R., Combrinck, M., Khaliq, J., Hassanin, A. H., Shehata, N., Elnabawy, E., & Shyha, I. (2020). Solution Blow Spinning of High-Performance Submicron Polyvinylidene Fluoride Fibres: Computational Fluid Mechanics Modelling and Experimental Results. Polymers, 12(5), 1140. https://doi.org/10.3390/polym12051140