Foams with Enhanced Ductility and Impact Behavior Based on Polypropylene Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PP Composites

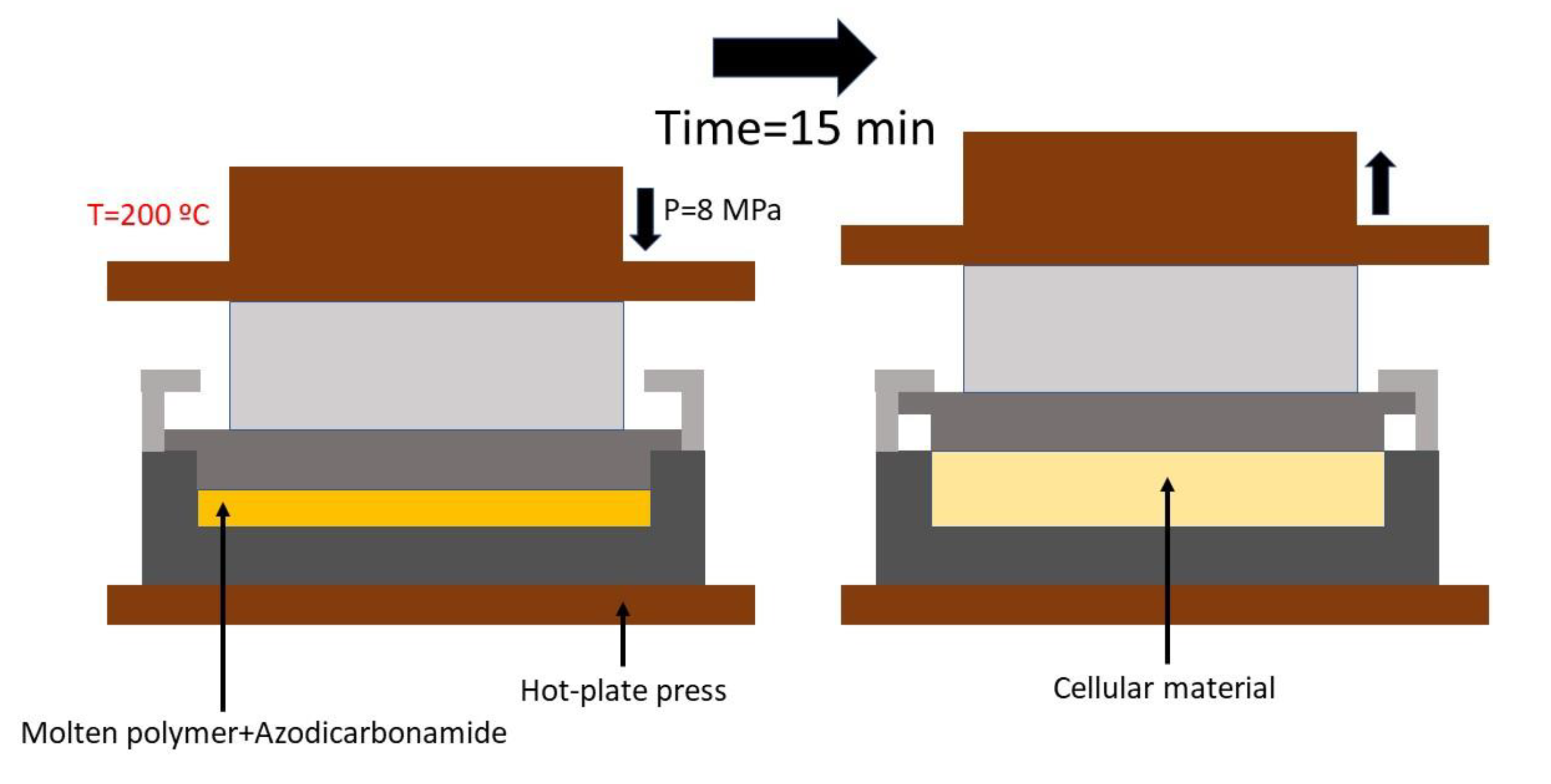

2.3. Foaming Process

2.4. Characterization

3. Results and Discussion

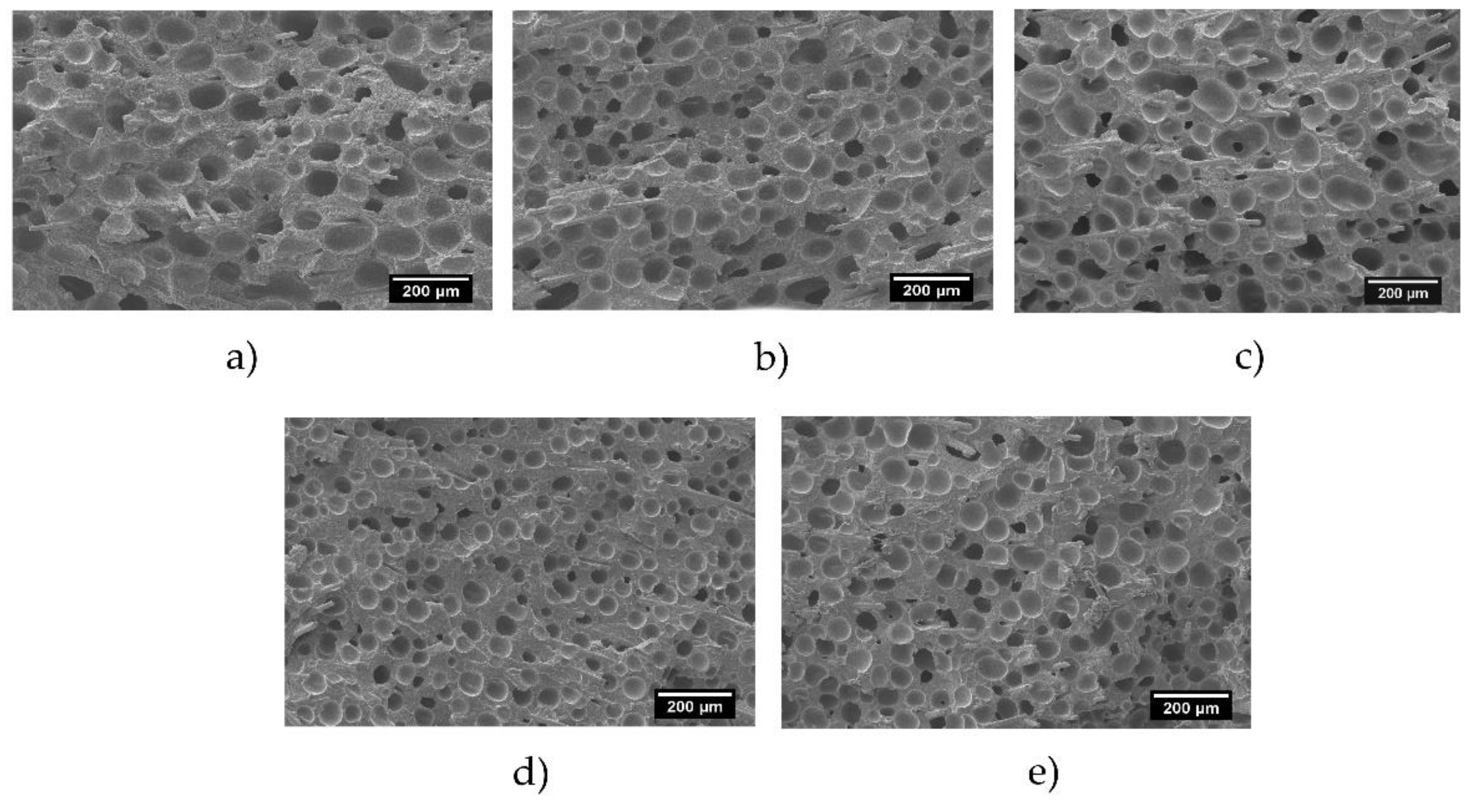

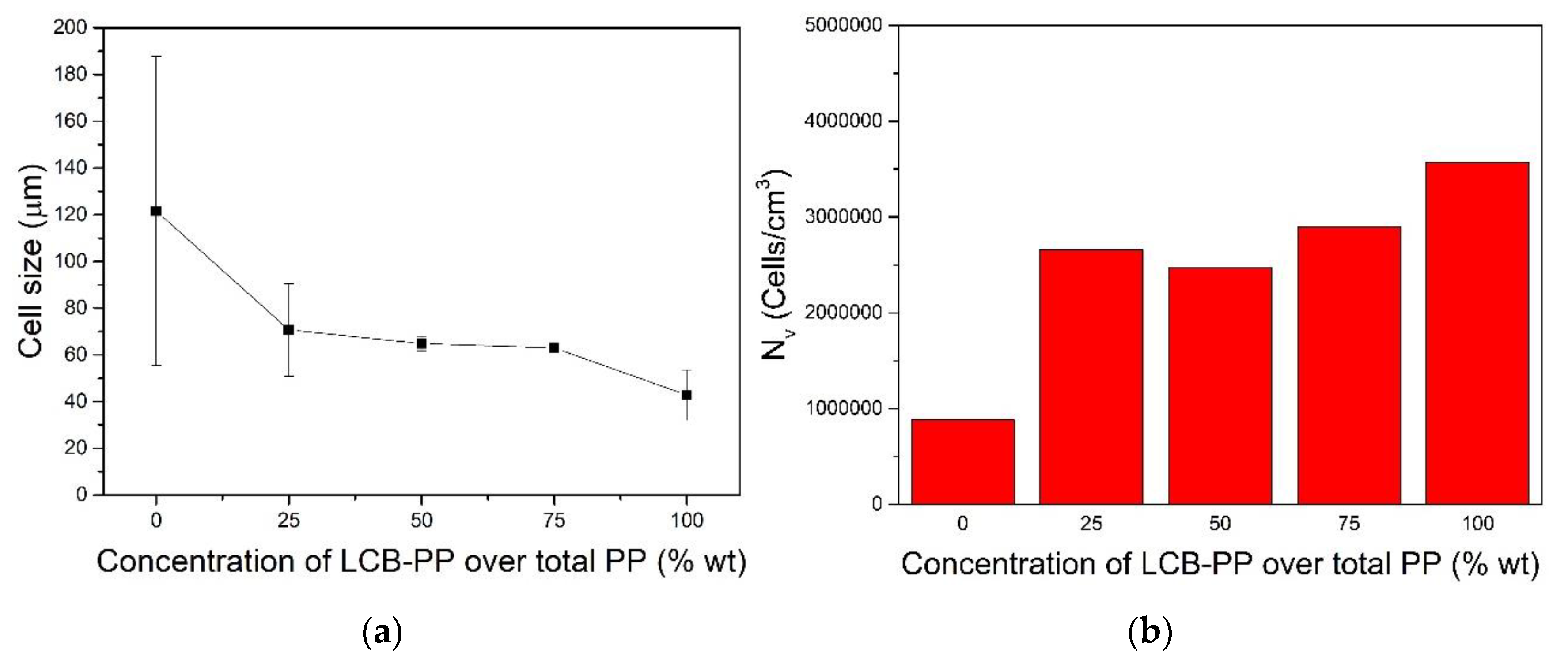

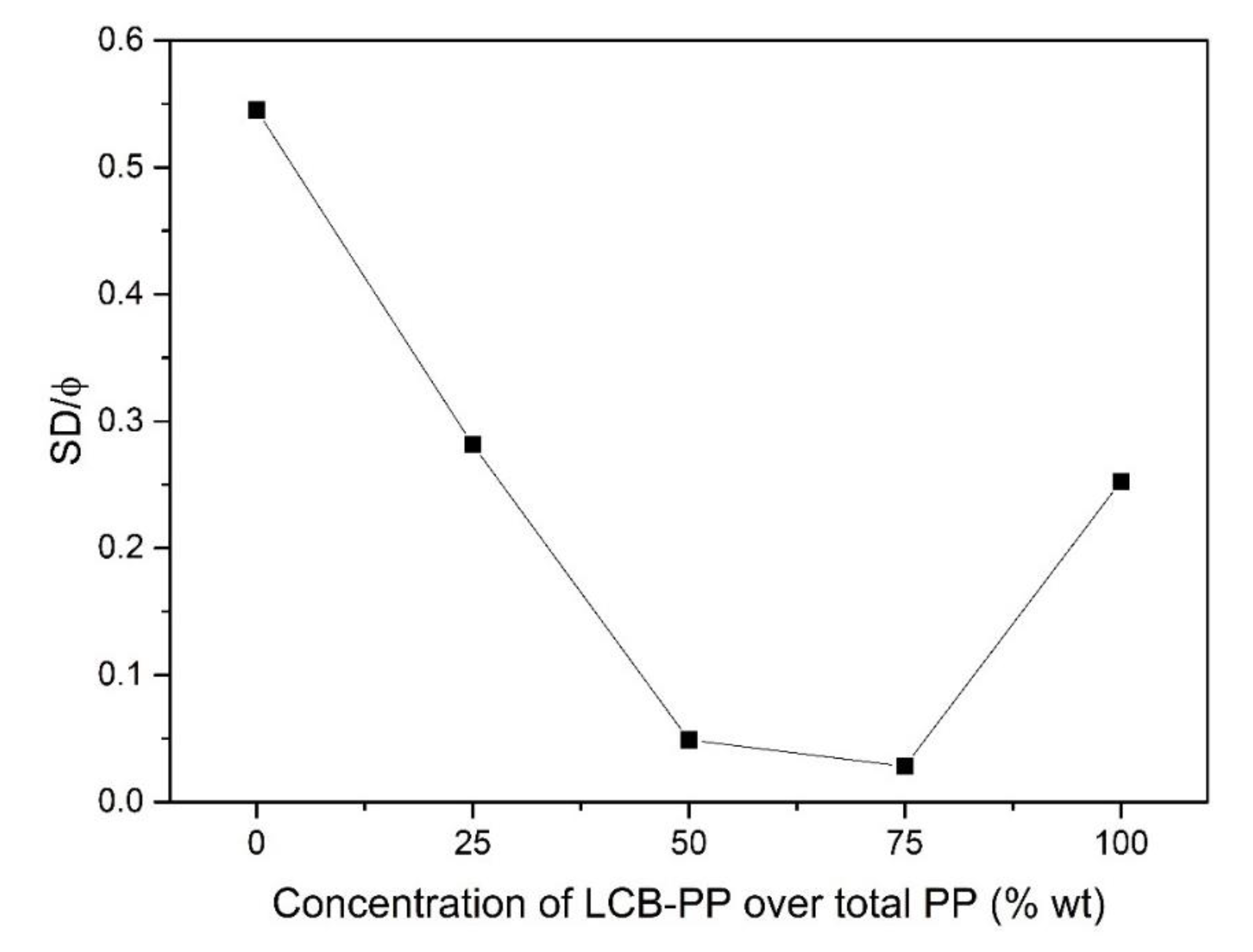

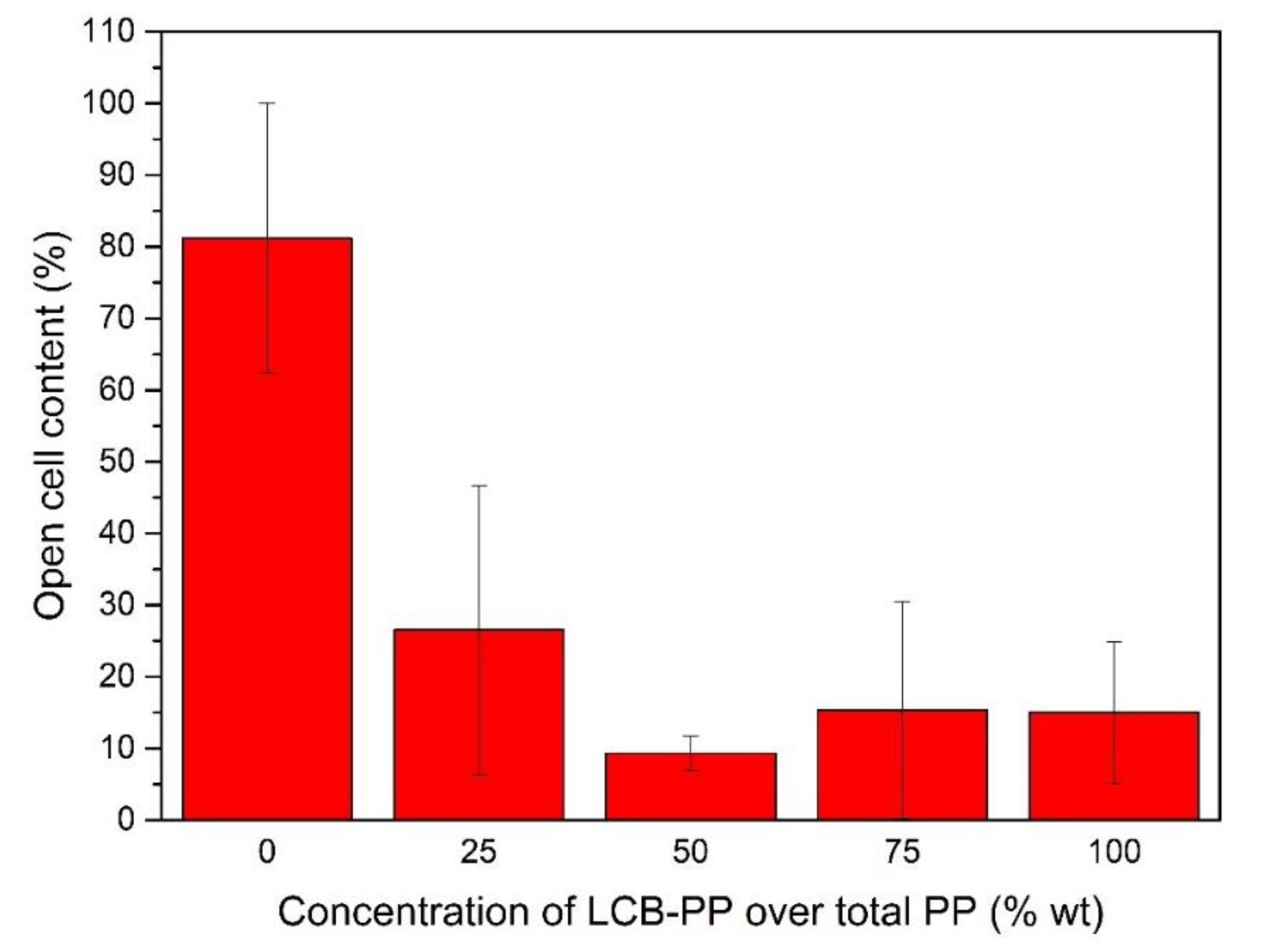

3.1. Cellular Structure

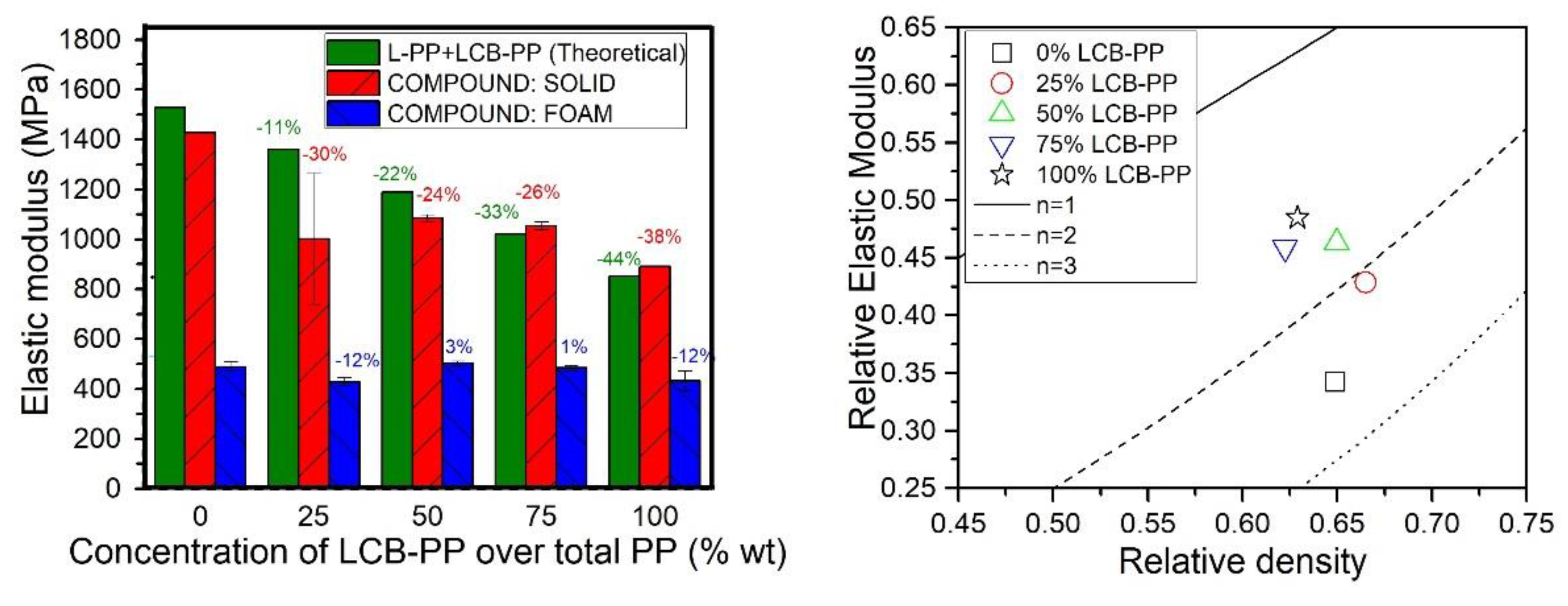

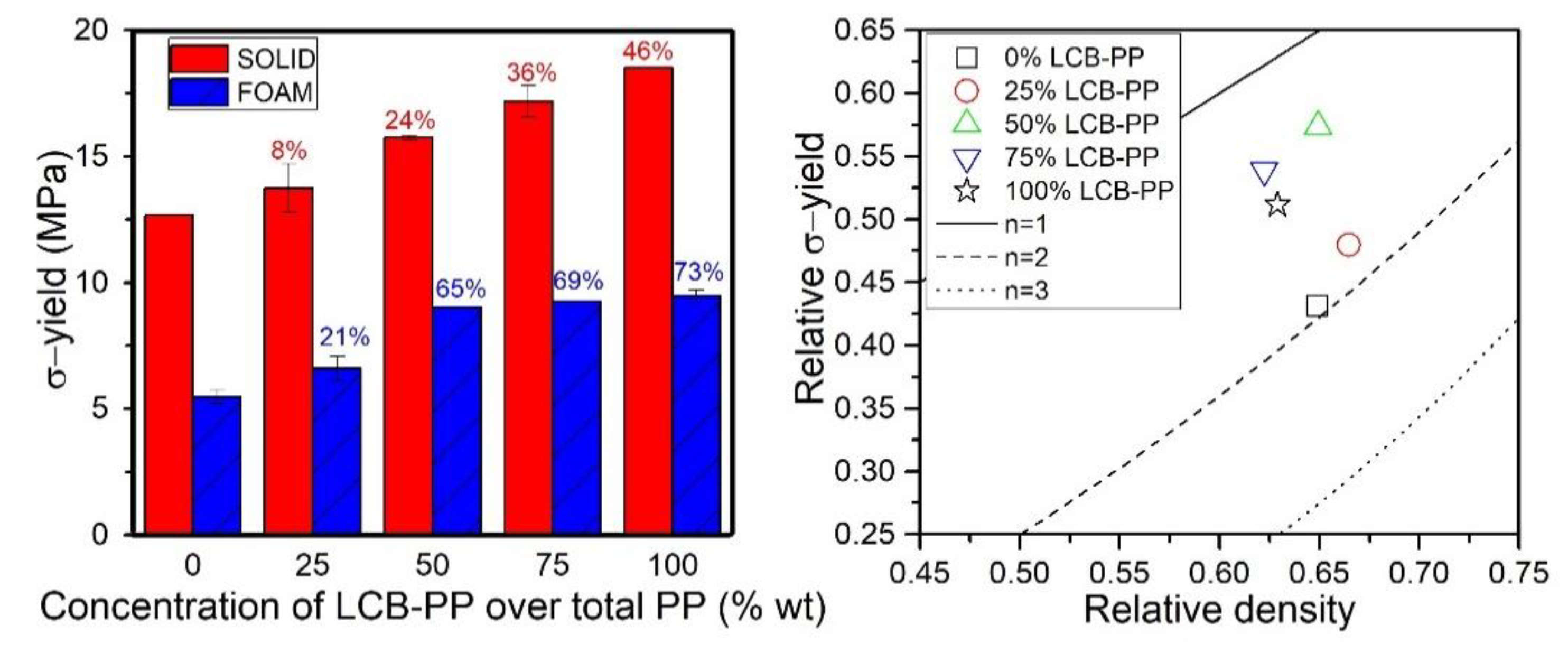

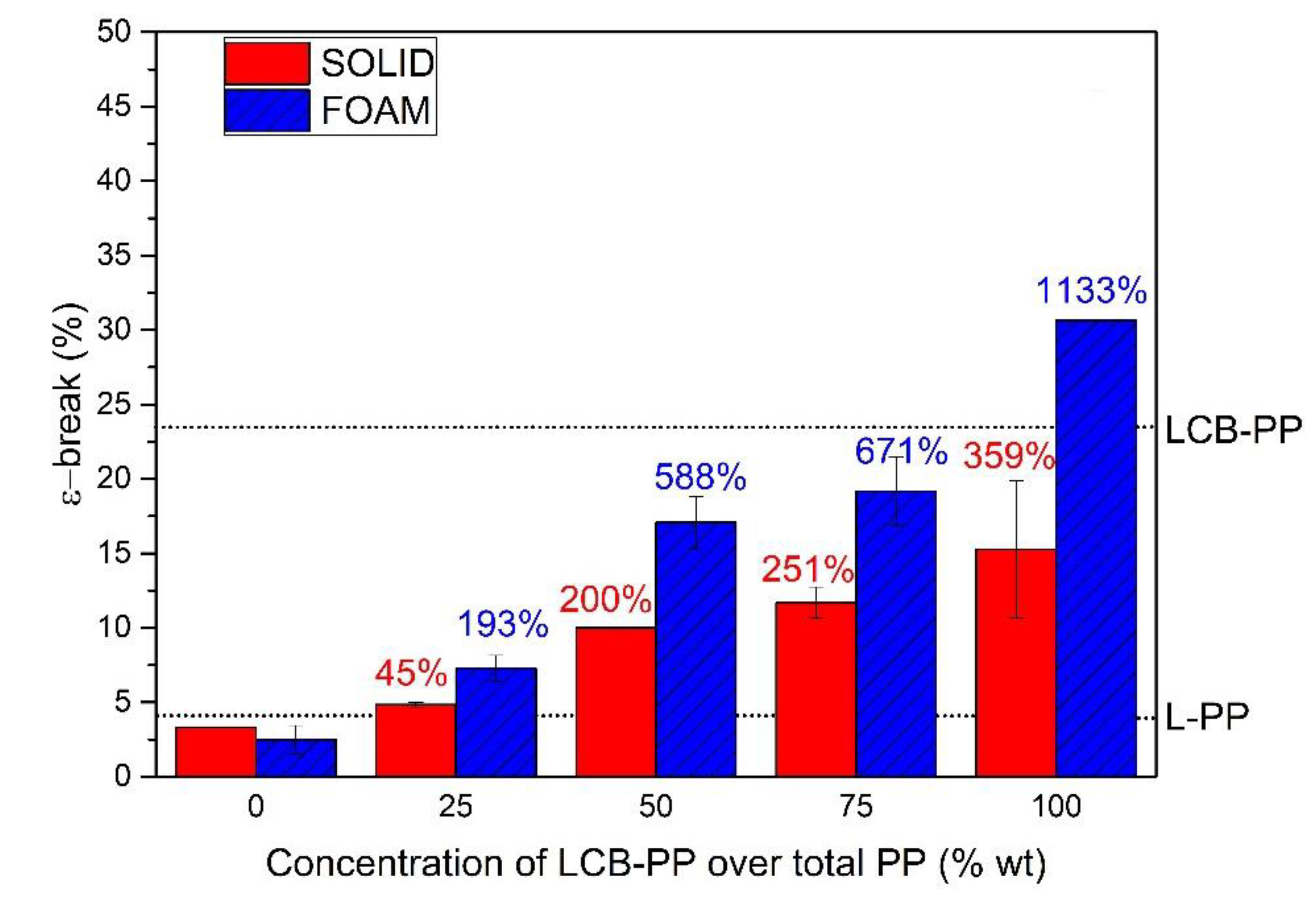

3.2. Mechanical Properties: Tensile Tests

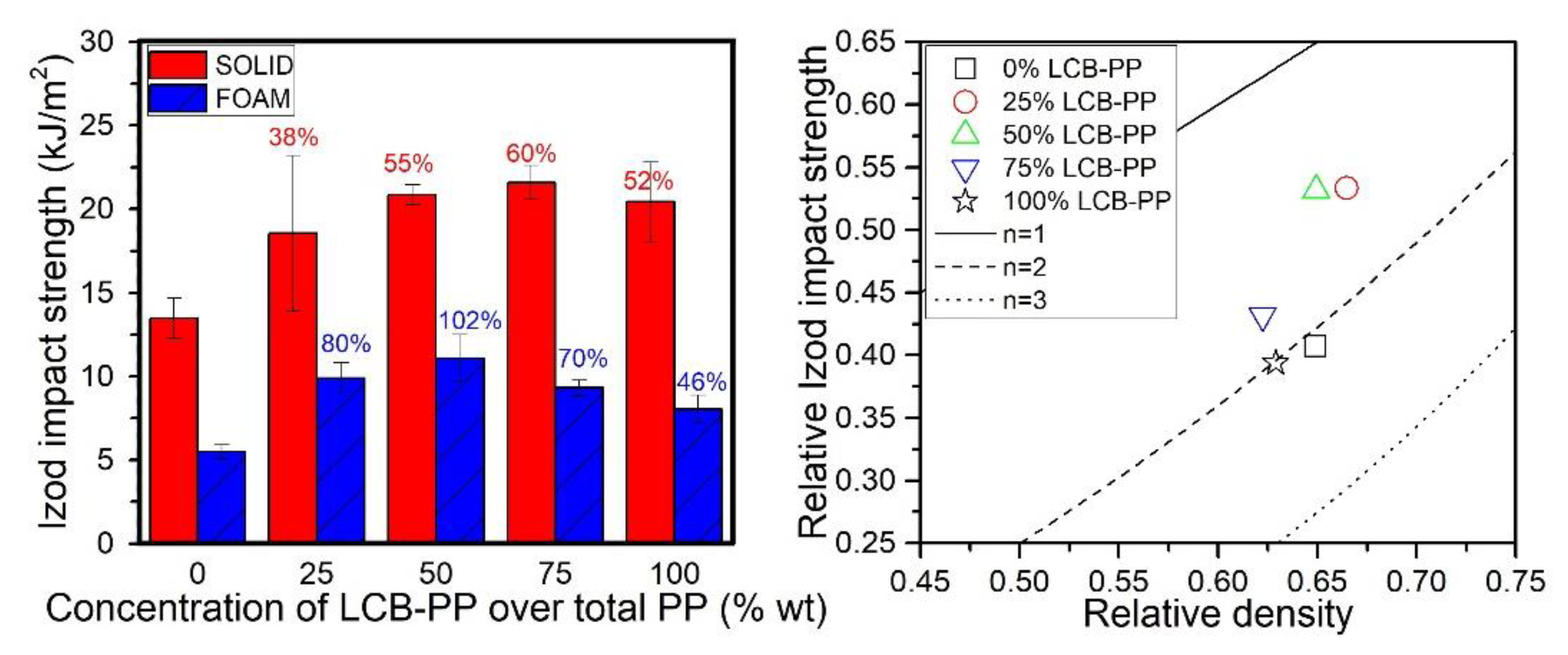

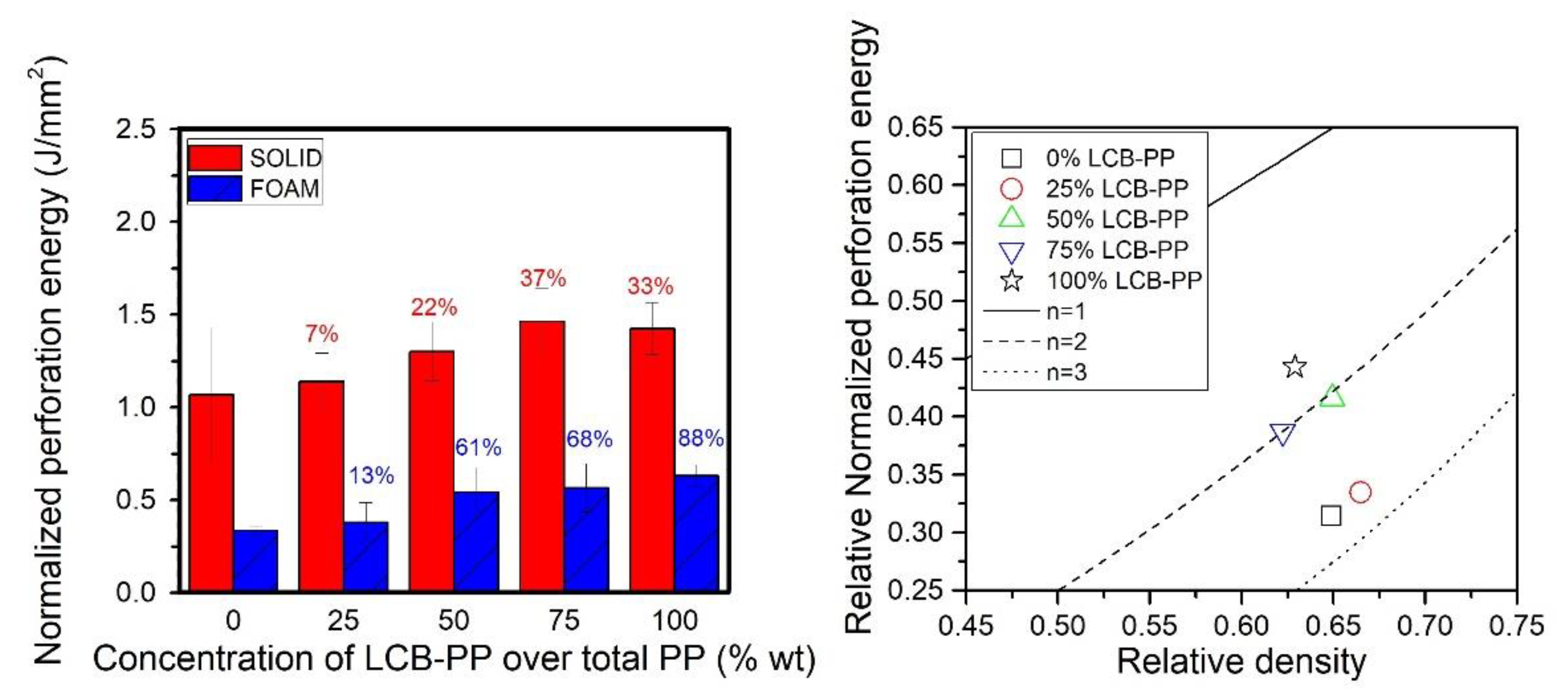

3.3. Mechanical Properties: Impact Tests

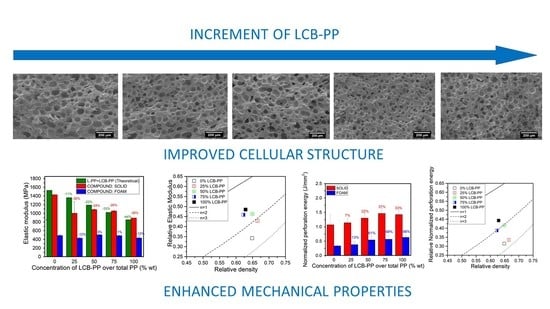

3.4. Overall View

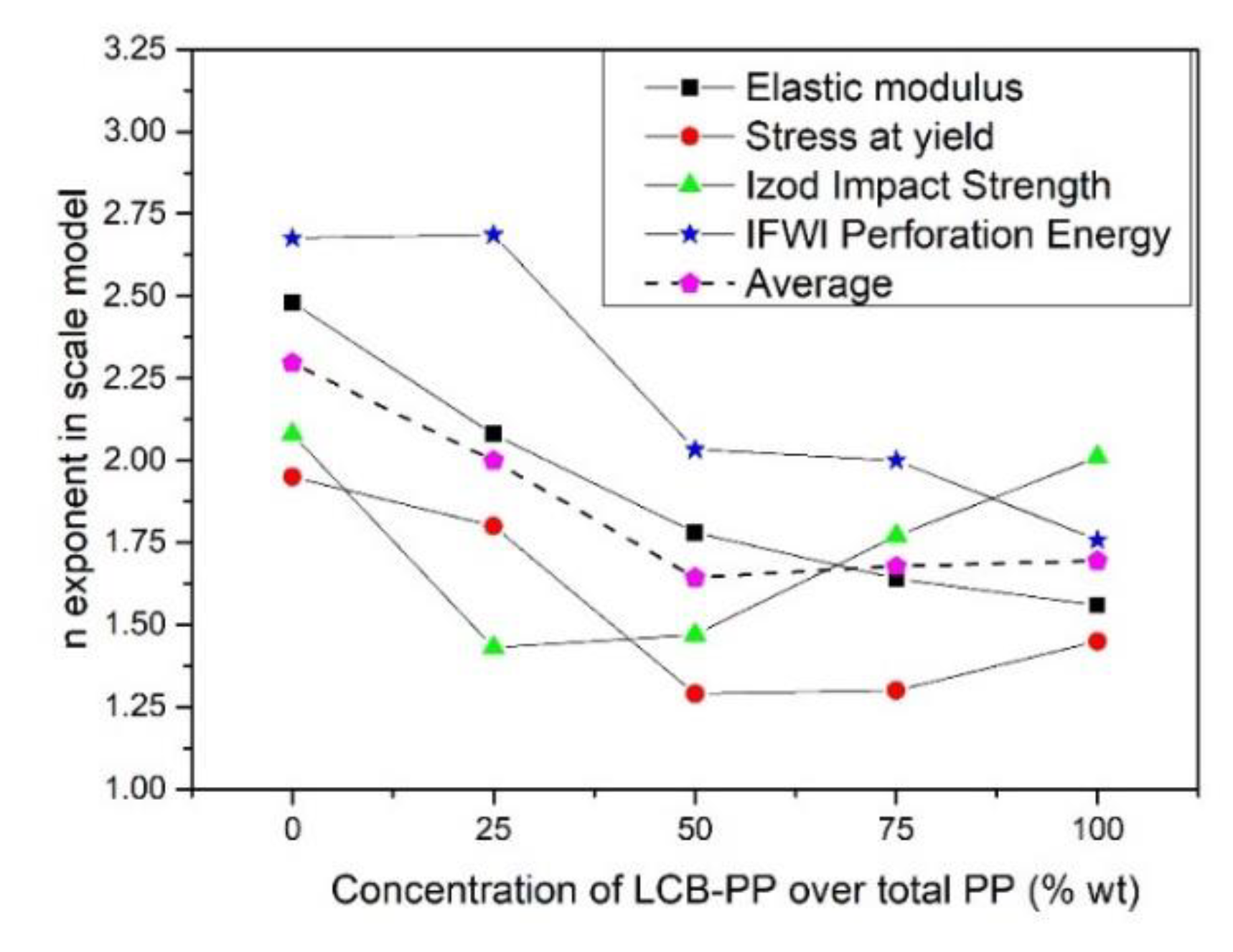

- An overall reduction of the values of exponent n when the LCB-PP content present in the samples was increased. Achieving a better behavior in the foams than in the solids when the material comprising the cell walls is the same as in the solid samples can only be explained taking into account the changes achieved with regard to the morphology of the cellular structure. Moreover, in Figure 3, Figure 4, and Figure 5, it could be observed that the cell size was reduced, the homogeneity of cellular structure was improved, and the open cell content was reduced until 50% LCB-PP compound, and then, the trend smoothed. This trend seems to be correlated with the plateau (or slightly worsening) that is reached for some magnitudes for LCB-PP contents higher than 50%, as can be seen in the average of the n exponents. Moreover, the 50% LCB-PP compound was characterized by its low open cell content, that following the literature [49] could be the reason for its good properties. This implies that there is a determinate percentage for which an increment of LCB-PP does not improve the cellular structure (and then, the mechanical properties). This have been seen previously by Laguna-Gutierrez, in pure blends of L-PP and LCB-PP, obtained also by improved compression molding [43].

- The low values of n obtained for impact properties, especially for IFWI, being the expected values near to 4. A good explanation for the outstanding values of impact absorbed energy could be based on the outstanding values of elongation at break. Some studies have shown that a poor behavior at falling weight impact tests was due to the reduction in elongation at break [54]. In our case, the elongation was not reduced when foaming, in fact, it was increased and this increment in ductility could lead to an increment in the toughness of the foams. This increment of elongation at break in foams when the LCB-PP content was raised to values above to those achieved for the solids with the same composition can be also explained by an optimized quality of the cellular structure [51,52,53].

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ma, L.F.; Wang, W.K.; Bao, R.Y.; Yang, W.; Xie, B.H.; Yang, M.B. Toughening of polypropylene with beta-nucleated thermoplastic vulcanizates based on polypropylene/ethylene-propylene-diene rubber blends. Mater. Des. 2013, 51, 536–543. [Google Scholar] [CrossRef]

- Sharma, R.; Maiti, S.N. Effects of crystallinity of PP and flexibility of SEBS-g-MA copolymer on the mechanical properties of PP/SEBS-g-MA blends. Polym. Plast. Technol. Eng. 2014, 53, 229–238. [Google Scholar] [CrossRef]

- Fanegas, N.; Gómez, M.A.; Jiménez, I.; Marco, C.; Garcia-Martínez, J.M.; Ellis, G. Optimizing the balance between impact strength and stiffness in polypropylene/elastomer blends by incorporation of a nucleating agent. Polym. Eng. Sci. 2008, 48, 80–87. [Google Scholar] [CrossRef]

- Karger-Kocsis, J. Polypropylene: Structure, Blends and Composites; Chapman & Hall: London, UK, 1995; Volume 3. [Google Scholar]

- Karger-Kocsis, J. Polypropylene: Structure, Blends and Composites; Chapman & Hall: London, UK, 1994; Volume 1. [Google Scholar]

- Li, C.; Yang, S.; Wang, J.; Guo, J.; Wu, H.; Guo, S. Unique impact behavior and toughening mechanism of the polypropylene and poly (ethylene-co-octene) alternating multilayered blends with superior toughness. RSC Adv. 2014, 4, 55119–55132. [Google Scholar] [CrossRef]

- Mae, H.; Omiya, M.; Kishimoto, K. Tensile behavior of polypropylene blended with bimodal distribution of styrene-ethylene-butadiene-styrene particle size. J. Appl. Polym. Sci. 2008, 107, 3520–3528. [Google Scholar] [CrossRef]

- Zebarjad, S.M.; Bagheri, R.; Reihani, S.M.; Lazzeri, A. Deformation, yield and fracture of elastomer-modified polypropylene. J. Appl. Polym. Sci. 2003, 90, 3767–3779. [Google Scholar] [CrossRef]

- Doshev, P.; Lach, R.; Lohse, G.; Heuvelsland, A.; Grellmann, W.; Radusch, H.J. Fracture characteristics and deformation behavior of heterophasic ethylene–propylene copolymers as a function of the dispersed phase composition. Polymer 2005, 46, 9411–9422. [Google Scholar] [CrossRef]

- Keskin, R.; Adanur, S. Improving toughness of polypropylene with thermoplastic elastomers in injection molding. Polym. Plast. Technol. Eng. 2011, 50, 20–28. [Google Scholar] [CrossRef]

- Du, H.; Zhang, Y.; Liu, H.; Liu, K.; Jin, M.; Li, X.; Zhang, J. Influence of phase morphology and crystalline structure on the toughness of rubber-toughened isotatic polypropylene blends. Polymer 2014, 55, 5001–5012. [Google Scholar] [CrossRef]

- Fasce, L.A.; Pettarin, V.; Marano, C.; Rink, M.; Frontini, P.M. Biaxial yielding of polypropylene/elastomeric polyolefin blends: Effect of elastomer content and thermal annealing. Polym. Eng. Sci. 2009, 48, 1414–1423. [Google Scholar] [CrossRef]

- Tang, W.; Tang, J.; Yuan, H.; Jin, R. Crystallization behavior and mechanical properties of polypropylene random copolymer/poly (ethylene-octene) blends. J. Appl. Polym. 2011, 122, 461–468. [Google Scholar] [CrossRef]

- Uotila, R.; Hippi, U.; Paavola, S.; Seppälä, J. Compatibilization of PP/elastomer/microsilica composites with functionalized polyolefins: Effect on microstructure and mechanical properties. Polymer 2005, 46, 7923–7930. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Vuluga, Z.; Radovici, C.; Nicolae, C. Morphological investigation of PP/nanosilica composites containing SEBS. Polym. Test. 2012, 31, 355–365. [Google Scholar] [CrossRef]

- Lim, J.W.; Hassan, A.; Rahmat, A.R.; Wahit, M.U. Rubber-toughened polypropylene nanocomposite: Effect of polyethylene octene copolymer on mechanical properties and phase morphology. J. Appl. Polym. Sci. 2006, 99, 3441–3450. [Google Scholar] [CrossRef]

- Lim, J.W.; Hassan, A.; Rahmat, A.R.; Wahit, M.U. Morphology, thermal and mechanical behavior of polypropylene nanocomposites toughened with poly (ethylene-co-octene). Polym. Int. 2006, 55, 204–215. [Google Scholar] [CrossRef]

- Lim, J.W.; Hassan, A.; Rahmat, A.R.; Wahit, M.U. Mechanical behaviour and fracture toughness evaluation of rubber toughened polypropylene nanocomposites. Plast. Rubber Compos. 2006, 35, 37–46. [Google Scholar] [CrossRef]

- Kim, D.H.; Fasulo, P.D.; Rodgers, W.R.; Paul, D.R. Effect of the ratio of maleated polypropylene to organoclay on the structure and properties of TPO-based nanocomposites. Part I: Morphology and mechanical properties. Polymer 2007, 48, 5960–5978. [Google Scholar] [CrossRef]

- Lim, J.W.; Hassan, A.; Rahmat, A.R.; Wahit, M.U. Phase morphology and mechanical properties of rubber-toughened polypropylene nanocomposites: Effect of elastomer polarity. Polym. Plast. Technol. Eng. 2008, 47, 411–419. [Google Scholar] [CrossRef]

- Martín, Z.; Jiménez, I.; Gómez-Fatou, M.A.; West, M.; Hitchcock, A.P. Interfacial interactions in polypropylene- organoclay- elastomer nanocomposites: Influence of polar modifications on the location of the clay. Macromolecules 2011, 44, 2179–2189. [Google Scholar] [CrossRef]

- Zhou, Y.; Rangari, V.; Mahfuz, H.; Jeelani, S.; Mallick, P.K. Experimental study on thermal and mechanical behavior of polypropylene, talc/polypropylene and polypropylene/clay nanocomposites. Mater. Sci. Eng. A 2005, 402, 109–117. [Google Scholar] [CrossRef]

- Wu, J.H.; Chen, C.W.; Wu, Y.T.; Wu, G.T.; Kuo, M.C.; Tsai, Y. Mechanical properties, morphology, and crystallization behavior of polypropylene/elastomer/talc composites. Polym. Compos. 2015, 36, 69–77. [Google Scholar] [CrossRef]

- Denac, M.; Musil, V.; Šmit, I. Polypropylene/talc/SEBS (SEBS-g-MA) composites. Part 2. Mechanical properties. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1282–1290. [Google Scholar] [CrossRef]

- Throne, J.L.; Progelhof, R.C.; Kumar, S. Closed-Cell Foam Behavior under Dynamic Loading-III. Impact Loading of High. Density Foams. J. Cell. Plast. 1985, 21, 123–140. [Google Scholar] [CrossRef]

- Klempner, D.; Frisch, K.C. Handbook of Polymeric Foams and Foam Technology; Hanser: Munich, Germany, 1991. [Google Scholar]

- Tejeda, E.H.; Sahagún, C.Z.; González-Núñez, R.; Rodrigue, D. Morphology and mechanical properties of foamed polyethylene-polypropylene blends. J. Cell. Plast. 2005, 41, 417–435. [Google Scholar] [CrossRef]

- Bureau, M.N.; Kumar, V. Fracture toughness of high density polycarbonate microcellular foams. J Cell. Plast. 2006, 42, 229–240. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Selke, S.E.; Matuana, L.M. Relationship between cell morphology and impact strength of microcellular foamed high-density polyethylene/polypropylene blends. Polym. Eng. Sci. 2004, 44, 1551–1560. [Google Scholar] [CrossRef]

- Bao, J.B.; Weng, G.S.; Zhao, L.; Liu, Z.F.; Chen, Z.R. Tensile and impact behavior of polystyrene microcellular foams with bi-modal cell morphology. J Cell. Plast. 2014, 50, 381–393. [Google Scholar] [CrossRef]

- Bao, J.B.; Junior, A.N.; Weng, G.S.; Wang, J.; Fang, Y.W.; Hu, G.H. Tensile and impact properties of microcellular isotactic polypropylene (PP) foams obtained by supercritical carbon dioxide. J Supercrit. Fluid 2016, 111, 63–73. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Rohleder, M.; Kirschling, H.; Chate, A. Correlation between morphology and notched impact strength of microcellular foamed polycarbonate. J Cell. Plast. 2010, 46, 415–440. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Rohleder, M.; Kirschling, H.; Chate, A. Microcellular polycarbonate with improved notched impact strength produced by injection moulding with physical blowing agent. Cell. Polym. 2008, 27, 327. [Google Scholar] [CrossRef]

- Stumpf, M.; Spörrer, A.; Schmidt, H.W.; Altstädt, V. Influence of supramolecular additives on foam morphology of injection-molded i-PP. J. Cell. Plast. 2011, 47, 519–534. [Google Scholar] [CrossRef]

- Michaeli, W.; Flórez, L.; Obeloer, D.; Brinkmann, M. Improving the impact behaviour of structural foams. Cell. Polym. 2009, 28, 269–287. [Google Scholar] [CrossRef]

- Michaeli, W.; Florez, L.; Obeloer, D.; Brinkmann, M. Analysis of the impact properties of structural foams. J. Cell. Plast. 2009, 45, 321–351. [Google Scholar] [CrossRef]

- Zhou, Y.; Gong, W.; He, L. Application of a novel organic nucleating agent: Cucurbit [6] uril to improve polypropylene injection foaming behavior and their physical properties. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Spoerrer, A.N.; Bangarusampath, D.S.; Altstaedt, V. The Challenge of Foam Injection-Moulding-Possibilities to Improve Surface Appearance, Foam Morphology and Mechanical Properties. Cell. Polym. 2008, 27, 101. [Google Scholar] [CrossRef]

- Estrada-Nunez, S.A.; Gonzalez-Nunez, R.; Rodrigue, D. The effect of composition on impact properties of foamed HDPE/PP blends. Cell. Polym. 2006, 25, 277. [Google Scholar] [CrossRef]

- Gong, W.; Fu, H.; Zhang, C.; Ban, D.; Yin, X.; He, Y.; Pei, X. Study on Foaming Quality and Impact Property of Foamed Polypropylene Composites. Polymers 2018, 10, 1375. [Google Scholar] [CrossRef]

- Muñoz-Pascual, S.; Lopez-Gonzalez, E.; Saiz-Arroyo, C.; Rodriguez-Perez, M.A. Effect of Mold Temperature on the Impact Behavior and Morphology of Injection Molded Foams Based on Polypropylene Polyethylene–Octene Copolymer Blends. Polymers 2019, 11, 894. [Google Scholar] [CrossRef]

- Li, S.; Xiao, M.; Guan, Y.; Wei, D.; Xiao, H.; Zheng, A. A novel strategy for the preparation of long chain branching polypropylene and the investigation on foamability and rheology. Eur. Polym. J. 2012, 48, 362–371. [Google Scholar] [CrossRef]

- Laguna-Gutierrez, E.; Van Hooghten, R.; Moldenaers, P.; Rodriguez-Perez, M.A. Understanding the foamability and mechanical properties of foamed polypropylene blends by using extensional rheology. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Wang, L.; Hikima, Y.; Ishihara, S.; Ohshima, M. Fabrication of lightweight microcellular foams in injection-molded polypropylene using the synergy of long-chain branches and crystal nucleating agents. Polymer 2017, 128, 119–127. [Google Scholar] [CrossRef]

- Lopez-Gil, A.; Saiz-Arroyo, C.; Tirado, J.; Rodriguez-Perez, M.A. Production of non-crosslinked thermoplastic foams with a controlled density and a wide range of cellular structures. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- ASTM D6226-10, Standard Test Method for Open Cell Content of Rigid Cellular Plastics; ASTM International: West Conshohocken, PA, USA, 2010.

- Pinto, J.; Solórzano, E.; Rodriguez-Perez, M.A.; de Saja, J.A. Characterization of the cellular structure based on user-interactive image analysis procedures. J. Cell. Plast. 2013, 49, 555–575. [Google Scholar] [CrossRef]

- Kumar, V. Process Synthesis for Manufacturing Microcellular Thermoplastic Parts; Massachusetts Institute of Technology: Cambridge, MA, USA, 1988. [Google Scholar]

- Laguna-Gutierrez, E.; Lopez-Gil, A.; Saiz-Arroyo, C.; Van Hooghten, R.; Moldenaers, P.; Rodriguez-Perez, M.A. Extensional rheology, cellular structure, mechanical behavior relationships in HMS PP/montmorillonite foams with similar densities. J. Polym. Res. 2016, 23, 251. [Google Scholar] [CrossRef]

- Sun, X.; Kharbas, H.; Peng, J.; Turng, L.S. A novel method of producing lightweight microcellular injection molded parts with improved ductility and toughness. Polymer 2015, 56, 102–110. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Su, B.; Turng, L.S. Fabrication of super-ductile PP/LDPE blended parts with a chemical blowing agent. J. Appl. Polym. Sci. 2017, 133. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Cao, G.H.; Cheng, Y.F. Effect of cellular uniformity on the necking propagation of foam injection Molded PP/HDPE blend parts. J. Appl. Polym. Sci. 2020, 49124. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Su, B.; Turng, L.S. Influence of Processing Conditions on the Morphological Structure and Ductility of Water-Foamed Injection Molded PP/LDPE Blended Parts. Cell. Polym. 2017, 36, 51–74. [Google Scholar] [CrossRef]

- Avalle, M.; Scattina, A. Mechanical properties and impact behavior of a microcellular structural foam. Lat. Am. J. Solids Struct. 2013, 11, 200–222. [Google Scholar] [CrossRef]

| Sample | L-PP (% wt) | LCB-PP (% wt) | MAPP (% wt) | SEBS (% wt) | HNT-QM (% wt) | GF (% wt) |

|---|---|---|---|---|---|---|

| 0% LCB-PP | 56.50 | 0.00 | 2.5 | 20 | 1 | 20 |

| 25% LCB-PP | 43.37 | 14.13 | 2.5 | 20 | 1 | 20 |

| 50% LCB-PP | 28.25 | 28.25 | 2.5 | 20 | 1 | 20 |

| 75% LCB-PP | 14.13 | 43.37 | 2.5 | 20 | 1 | 20 |

| 100% LCB-PP | 0.00 | 56.50 | 2.5 | 20 | 1 | 20 |

| Sample | Elastic Modulus (MPa) | Stress at Yield (MPa) | Strain at Break (%) |

|---|---|---|---|

| L-PP | 1528 ± 42 | 23.87 ± 0.26 | 4.29 ± 0.25 |

| LCB-PP | 852 ± 21 | 25.06 ± 0.35 | 22.87 ± 14.41 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muñoz-Pascual, S.; Saiz-Arroyo, C.; Vuluga, Z.; Corobea, M.C.; Rodriguez-Perez, M.A. Foams with Enhanced Ductility and Impact Behavior Based on Polypropylene Composites. Polymers 2020, 12, 943. https://doi.org/10.3390/polym12040943

Muñoz-Pascual S, Saiz-Arroyo C, Vuluga Z, Corobea MC, Rodriguez-Perez MA. Foams with Enhanced Ductility and Impact Behavior Based on Polypropylene Composites. Polymers. 2020; 12(4):943. https://doi.org/10.3390/polym12040943

Chicago/Turabian StyleMuñoz-Pascual, Santiago, Cristina Saiz-Arroyo, Zina Vuluga, Mihai Cosmin Corobea, and Miguel Angel Rodriguez-Perez. 2020. "Foams with Enhanced Ductility and Impact Behavior Based on Polypropylene Composites" Polymers 12, no. 4: 943. https://doi.org/10.3390/polym12040943

APA StyleMuñoz-Pascual, S., Saiz-Arroyo, C., Vuluga, Z., Corobea, M. C., & Rodriguez-Perez, M. A. (2020). Foams with Enhanced Ductility and Impact Behavior Based on Polypropylene Composites. Polymers, 12(4), 943. https://doi.org/10.3390/polym12040943