Synergistic Effects of Hybrid Carbonaceous Fillers of Carbon Fibers and Reduced Graphene Oxides on Enhanced Heat-Dissipation Capability of Polymer Composites

Abstract

1. Introduction

2. Materials and Methods

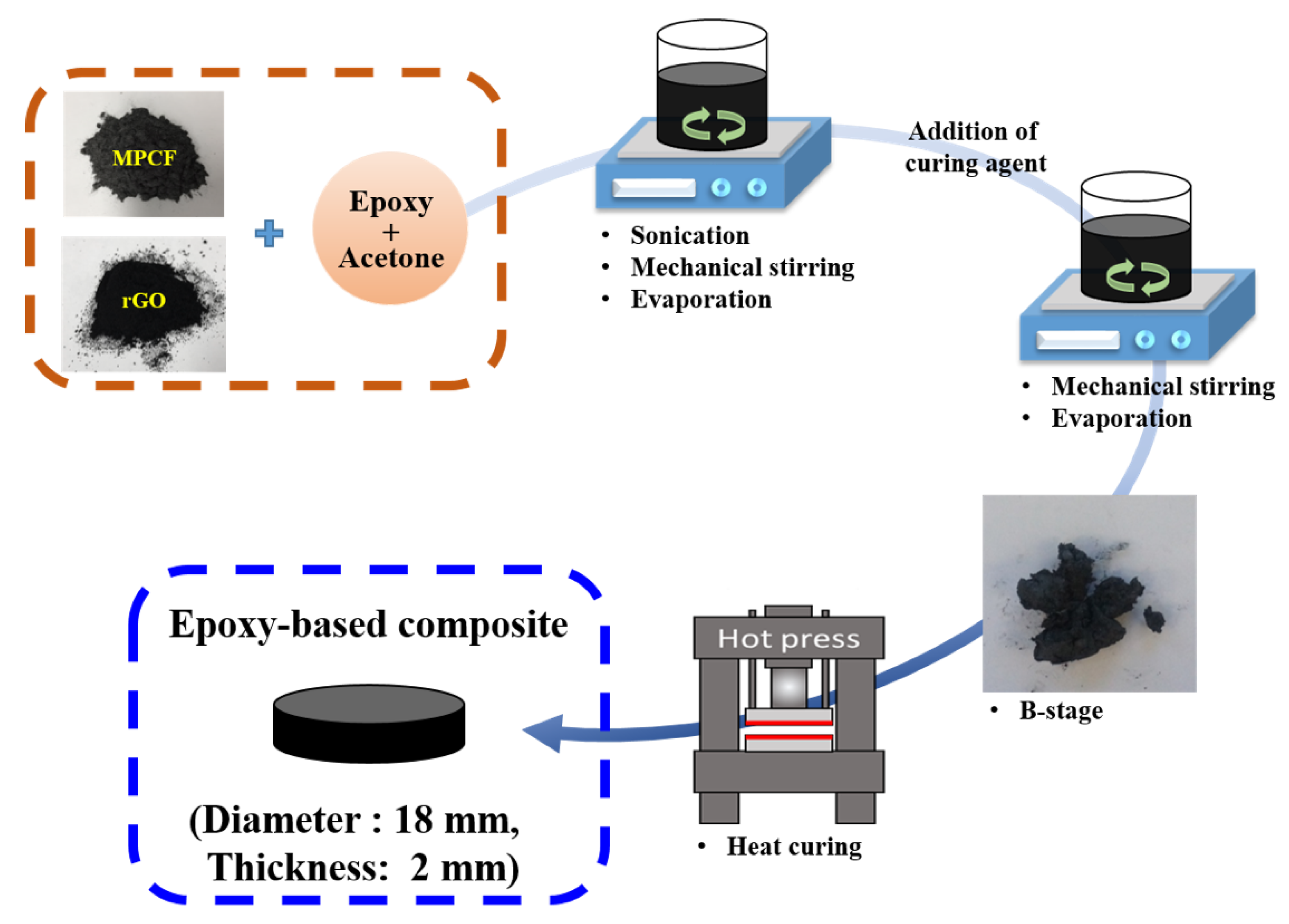

2.1. Preparation of Thermally Conductive Epoxy-Based Composites

2.2. Characterization of Thermally Conductive Carbonaceous Fillers and Epoxy-Based Composites

3. Results and Discussion

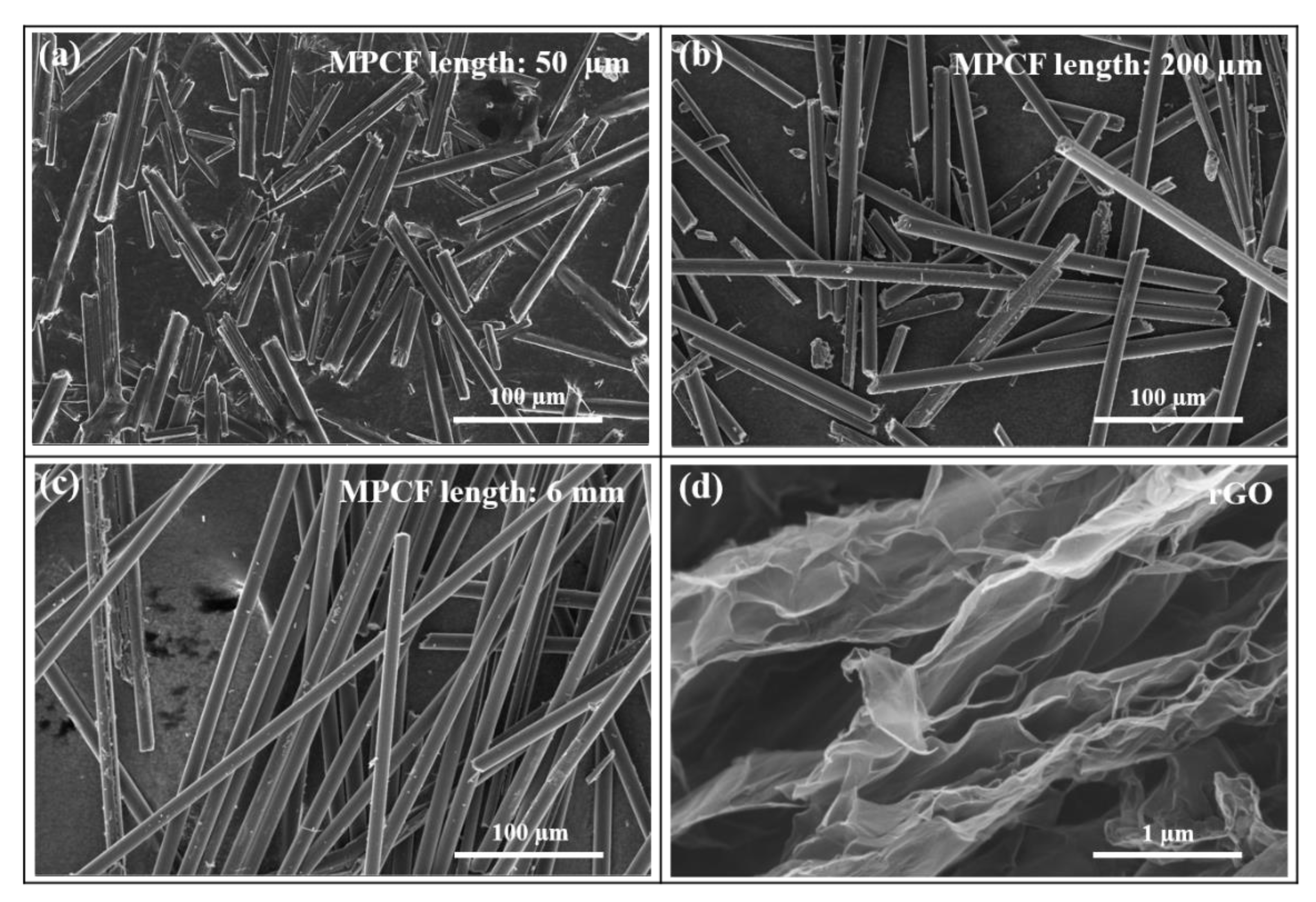

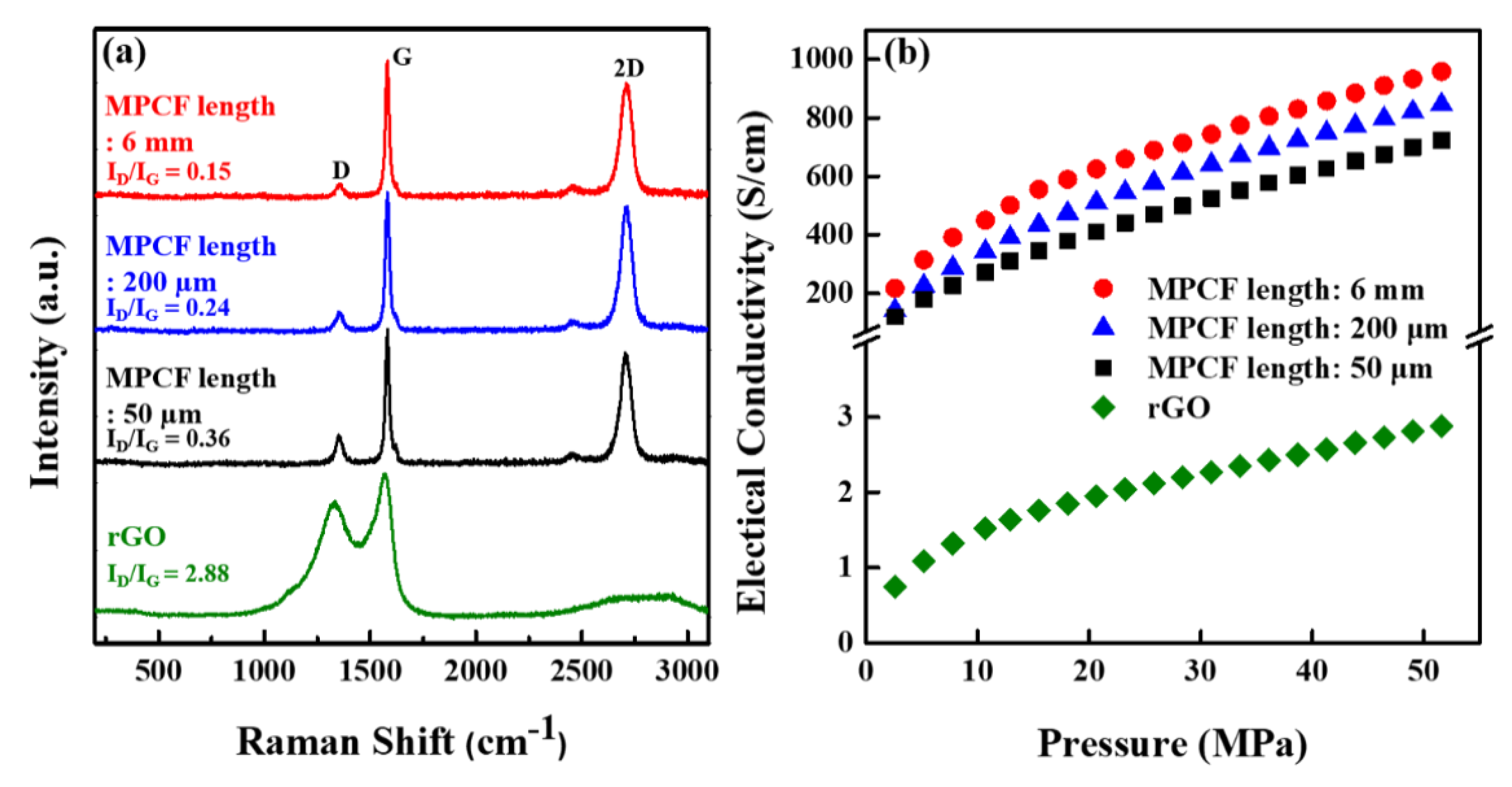

3.1. Characterization of Thermally Conductive Carbonaceous Fillers

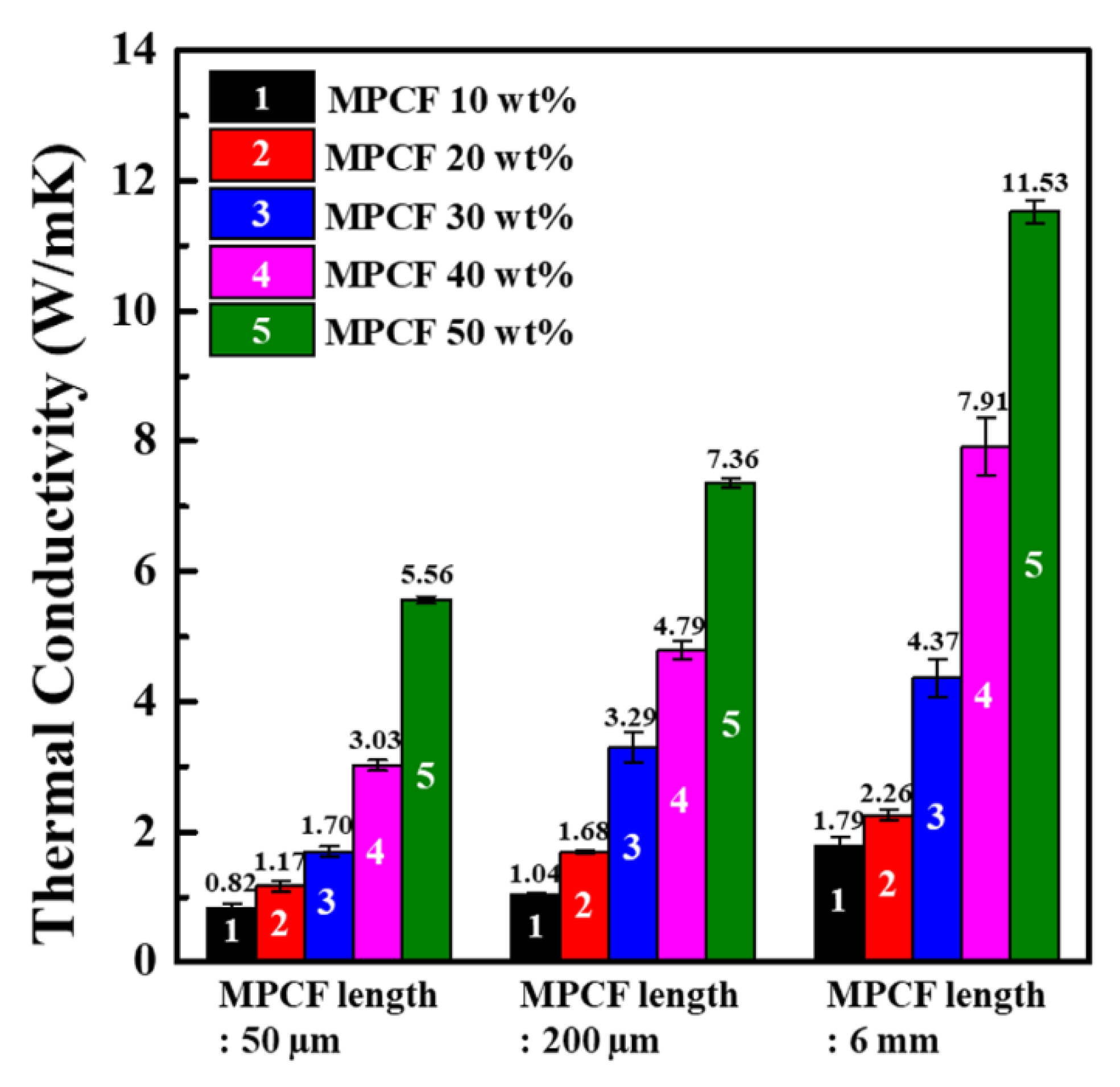

3.2. Effect of Mesophase Pitch-Based Carbon Fiber (MPCF) Length on Thermal Conductivity of Epoxy-Based Composites

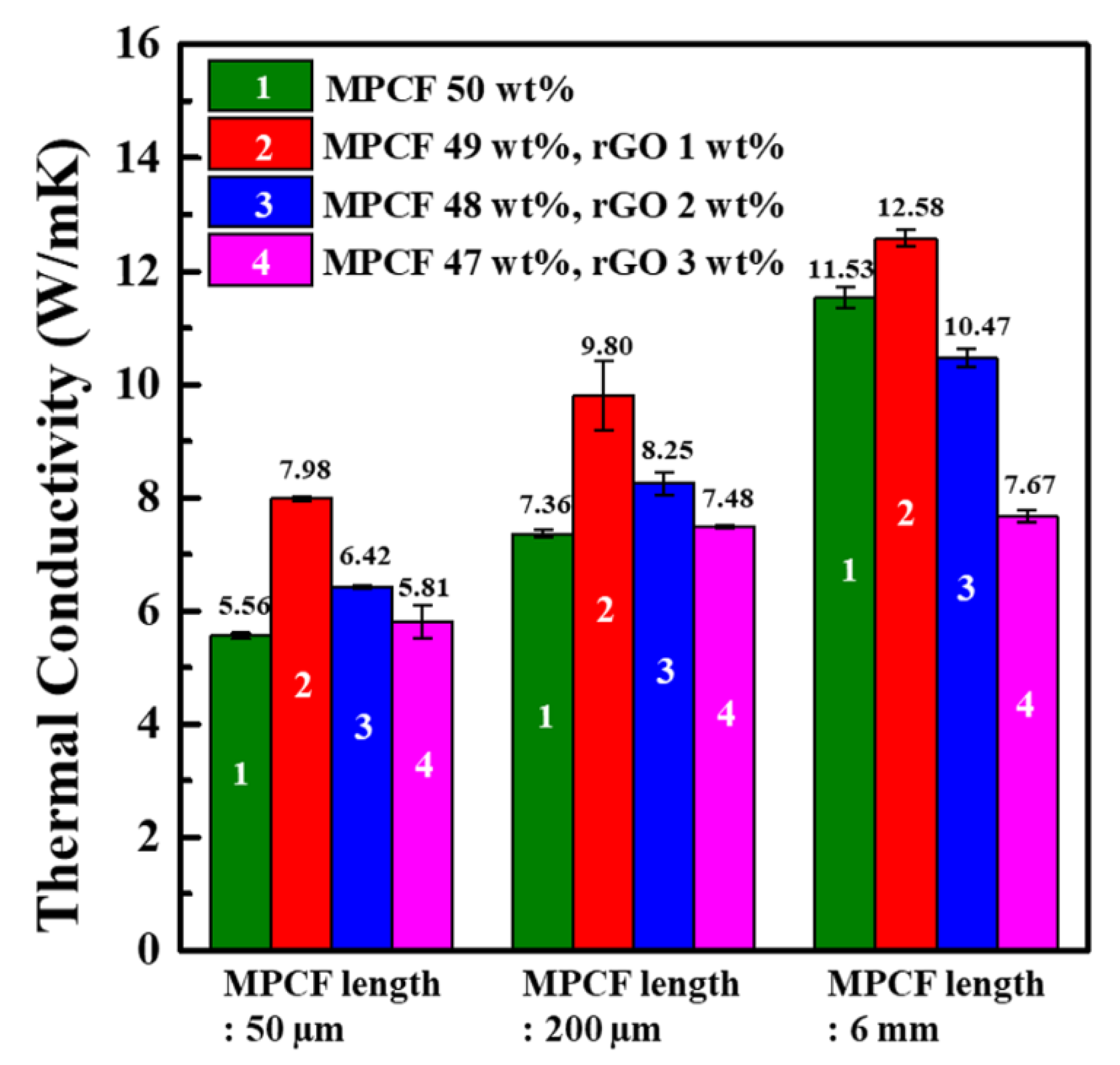

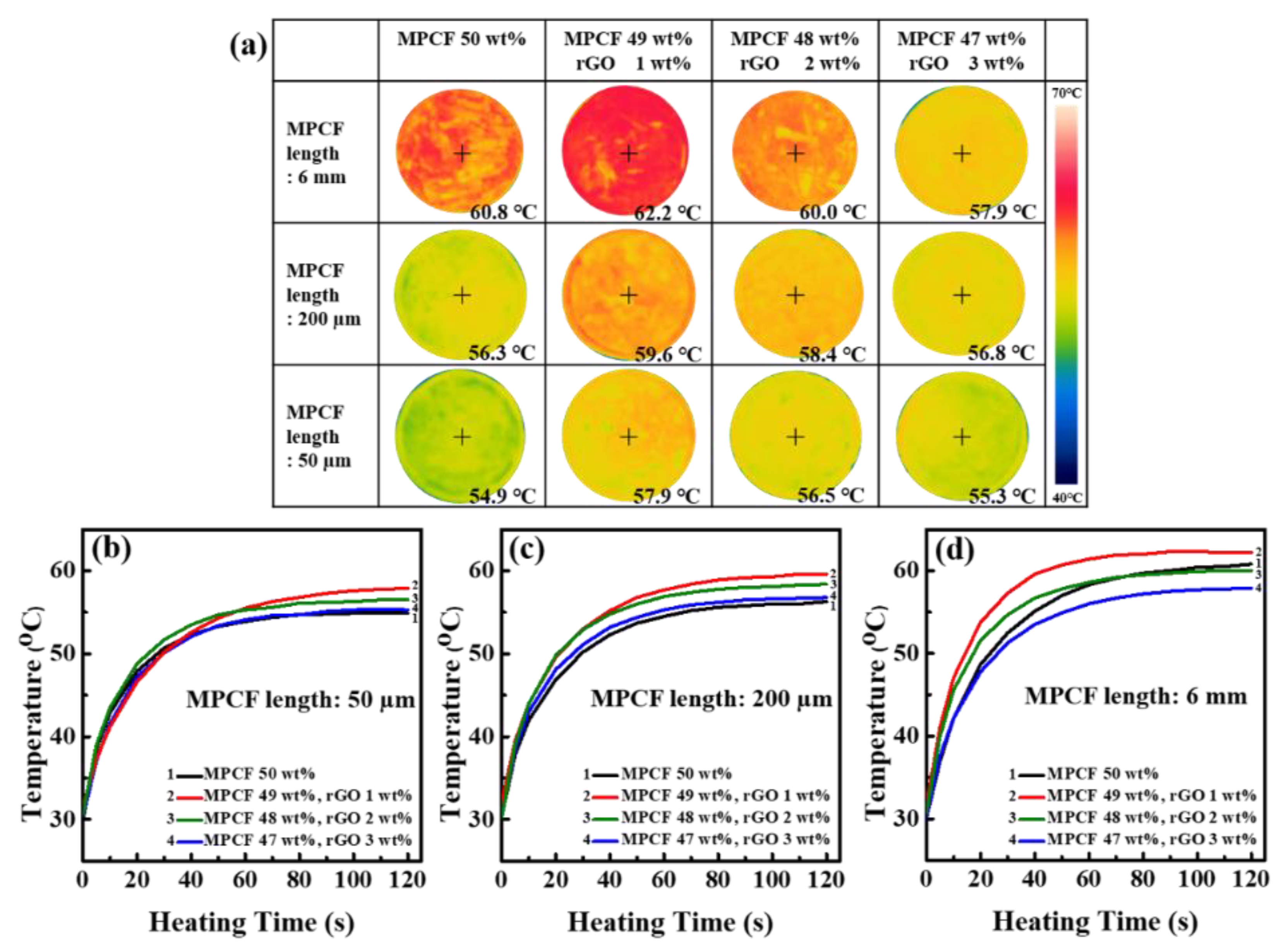

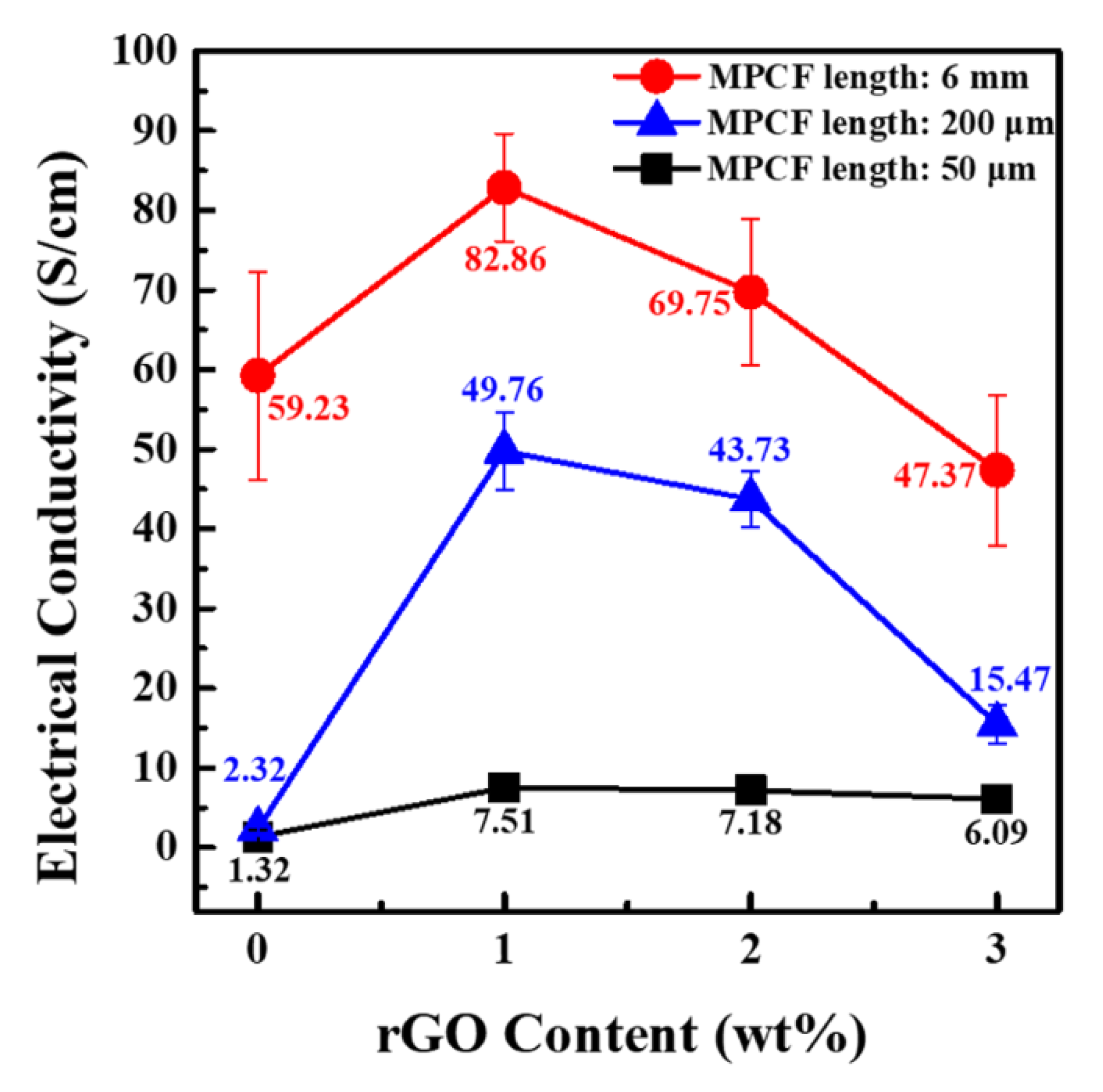

3.3. Synergistic Effects of Hybrid Fillers of MPCF and Reduced Graphene Oxide (rGO) on Thermal Conductivity of Epoxy-Based Composites

3.4. Theoretical Approach of Thermal Conductivity in the MPCF-rGO/Epoxy Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef]

- Gong, F.; Li, H.; Wang, W.; Xia, D.; Liu, Q.; Papavassiliou, D.; Xu, Z. Recent advances in graphene-based free-standing films for thermal management: synthesis, properties, and applications. Coatings 2018, 8, 63. [Google Scholar] [CrossRef]

- Zeng, J.; Fu, R.; Shen, Y.; He, H.; Song, X. High thermal conductive epoxy molding compound with thermal conductive pathway. J. Appl. Polym. 2009, 113, 2117–2125. [Google Scholar] [CrossRef]

- Yu, L.; Park, J.S.; Lim, Y.S.; Lee, C.S.; Shin, K.; Moon, H.J.; Yang, C.-M.; Lee, Y.S.; Han, H. Carbon hybrid fillers composed of carbon nanotubes directly grown on graphene nanoplatelets for effective thermal conductivity in epoxy composites. Nanotechnology 2013, 24, 155604. [Google Scholar] [CrossRef]

- Liu, Z.; Tu, R.; Liao, Q.; Hu, H.; Yang, J.; He, Y.; Bian, H.; Ma, L.; Liu, W. High thermal conductivity of flake graphite reinforced polyethylene composites fabricated by the powder mixing method and the melt-extruding process. Polymers 2018, 10, 693. [Google Scholar] [CrossRef]

- Krause, B.; Rzeczkowski, P.; Potschke, P. Thermal conductivity and electrical resistivity of melt-mixed polypropylene composites containing mixtures of carbon-based fillers. Polymers 2019, 11, 1073. [Google Scholar] [CrossRef]

- Gu, J.; Liang, C.; Zhao, X.; Gan, B.; Qiu, H.; Guo, Y.; Yang, X.; Zhang, Q.; Wang, D. Highly thermally conductive flame-retardant epoxy nanocomposites with reduced ignitability and excellent electrical conductivities. Compos. Sci. Technol. 2017, 139, 83–89. [Google Scholar] [CrossRef]

- Dai, W.; Yu, J.; Wang, Y.; Song, Y.; Alam, F.E.; Nishimura, K.; Lin, C.; Jiang, N. Enhanced thermal conductivity for polyimide composites with a three-dimensional silicon carbide nanowire@graphene sheets filler. J. Mater. Chem. A 2015, 3, 4884–4891. [Google Scholar] [CrossRef]

- Lee, Y.S.; Lee, S.-Y.; Kim, K.S.; Noda, S.; Shim, S.E.; Yang, C.-M. Effective heat transfer pathways of thermally conductive networks formed by one-dimensional carbon materials with different sizes. Polymers 2019, 11, 1661. [Google Scholar] [CrossRef]

- Zeng, C.; Lu, S.; Song, L.; Xiao, X.; Gao, J.; Pan, L.; He, Z.; Yu, J. Enhanced thermal properties in a hybrid graphene-alumina filler for epoxy composites. RSC Adv. 2015, 5, 35773–35782. [Google Scholar] [CrossRef]

- Yu, A.; Ramesh, P.; Sun, X.; Bekyarova, E.; Itkis, M.E.; Haddon, R.C. Enhanced thermal conductivity in a hybrid graphite nanoplatelet – carbon nanotube filler for epoxy composites. Adv. Mater. 2018, 20, 4740–4744. [Google Scholar] [CrossRef]

- Emmerich, F.G. Young’s modulus, thermal conductivity, electrical resistivity and coefficient of thermal expansion of mesophase pitch-based carbon fibers. Carbon 2014, 79, 274–293. [Google Scholar] [CrossRef]

- Khan, M.O.; Leung, S.N.; Chan, E.; Naguib, H.E.; Dawson, F.; Adinkrah, V. Effects of microsized and nanosized carbon fillers on the thermal and electrical properties of polyphenylene sulfide based composites. Polym. Eng. Sci. 2013, 53, 2398–2406. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Kim, P.; Shi, L.; Majumdar, A.; McEuen, P. Thermal transport measurements of individual multiwalled nanotubes. Phys. Rev. Lett. 2001, 87, 215502. [Google Scholar] [CrossRef]

- Pop, E.; Mann, D.; Wang, Q.; Goodson, K.; Dai, H. Thermal conductance of an individual single-wall carbon nanotube above room temperature. Nano Lett. 2006, 6, 96–100. [Google Scholar] [CrossRef]

- Zhang, G. Thermal Transports in Carbon-Based Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 120–124. [Google Scholar]

- Mohan, V.B.; Lau, K.; Hui, D.; Bhattacharyya, D. Graphene-based materials and their composites: A review on production, applications and product limitations. Compos. Part B Eng. 2018, 142, 200–220. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, L.; Lin, J.; Cui, P.; Li, M.; Du, X. Thermal conductivity of epoxy composites filled by thermally reduced graphite oxide with different reduction degree. J. Compos. Mater. 2017, 51, 1743–1752. [Google Scholar] [CrossRef]

- Hwang, H.; Kim, C.H.; Wee, J.-H.; Han, J.H.; Yang, C.-M. High-density graphene/single-walled carbon nanohorn composite supercapacitor electrode with high volumetric capacitance. Appl. Surf. Sci. 2019, 489, 708–716. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/polymer nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, J.S.; Lee, K.Y.; Park, K.H.; Bae, J.-S.; Mubarak, M.; Lee, H. Elucidation of an intrinsic parameter for evaluating the electrical quality of graphene flakes. Sci. Rep. 2019, 9, 557. [Google Scholar] [CrossRef]

- Düppenbecker, P.M.J. Development of A High-Resolution, MRI-Compatible PET Detector Using Digital Silicon Photomultipliers. Doctoral Thesis, King’s College London, London, UK, 2016. [Google Scholar]

- Kim, S.Y.; Jang, H.G.; Yang, C.-M.; Yang, B.J. Multiscale prediction of thermal conductivity for nanocomposites containing crumpled carbon nanofillers with interfacial characteristics. Compos. Sci. Technol. 2018, 155, 169–176. [Google Scholar] [CrossRef]

- Jung, H.J.; Kim, Y.-J.; Lee, D.H.; Han, J.H.; Yang, K.S.; Yang, C.-M. Pore structure characterization of poly (vinylidene chloride)-derived nanoporous carbons. Carbon Lett. 2012, 13, 236–242. [Google Scholar] [CrossRef]

- Cho, J.; Lee, H.; Nan, K.-H.; Yeo, H.; Yang, C.-M.; Seong, D.G.; Lee, D.; Kim, S.Y. Enhanced electrical conductivity of polymer nanocomposite based on edge-selectively functionalized graphene nanoplatelets. Compos. Sci. Technol. 2020, 189, 108001. [Google Scholar] [CrossRef]

- Yu, J.; Choi, H.; Kim, H.; Kim, S. Synergistic effect of hybrid graphene nanoplatelet and multi-walled carbon nanotube fillers on the thermal conductivity of polymer composites and theoretical modeling of the synergistic effect. Compos. Part A 2016, 88, 79–85. [Google Scholar] [CrossRef]

- Kim, S.; Noh, Y.; Yu, J. Improved thermal conductivity of polymeric composites fabricated by solvent-free processing for the enhanced dispersion of nanofillers and a theoretical approach for composites containing multiple heterogeneities and geometrized nanofillers. Compos. Sci. Technol. 2014, 101, 79–85. [Google Scholar] [CrossRef]

- Ata, S.; Subramaniam, C.; Nishizawa, A.; Yamada, T.; Hata, K. Highly thermally conductive yet flexible composite of carbon fiber, carbon nanotube, and rubber obtained by decreasing the thermal resistivity at the interface between carbon fiber and carbon nanotube. Adv. Eng. Mater. 2017, 19, 1600596. [Google Scholar] [CrossRef]

- Mahanta, N.K.; Abramson, A.R. Thermal conductivity of graphene and graphene oxide nanoplatelets. In Proceedings of the 13th Inter Society Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 30 May–1 June 2012; pp. 1–6. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.S.; Yu, J.; Shim, S.E.; Yang, C.-M. Synergistic Effects of Hybrid Carbonaceous Fillers of Carbon Fibers and Reduced Graphene Oxides on Enhanced Heat-Dissipation Capability of Polymer Composites. Polymers 2020, 12, 909. https://doi.org/10.3390/polym12040909

Lee YS, Yu J, Shim SE, Yang C-M. Synergistic Effects of Hybrid Carbonaceous Fillers of Carbon Fibers and Reduced Graphene Oxides on Enhanced Heat-Dissipation Capability of Polymer Composites. Polymers. 2020; 12(4):909. https://doi.org/10.3390/polym12040909

Chicago/Turabian StyleLee, Yun Seon, Jaesang Yu, Sang Eun Shim, and Cheol-Min Yang. 2020. "Synergistic Effects of Hybrid Carbonaceous Fillers of Carbon Fibers and Reduced Graphene Oxides on Enhanced Heat-Dissipation Capability of Polymer Composites" Polymers 12, no. 4: 909. https://doi.org/10.3390/polym12040909

APA StyleLee, Y. S., Yu, J., Shim, S. E., & Yang, C.-M. (2020). Synergistic Effects of Hybrid Carbonaceous Fillers of Carbon Fibers and Reduced Graphene Oxides on Enhanced Heat-Dissipation Capability of Polymer Composites. Polymers, 12(4), 909. https://doi.org/10.3390/polym12040909