Study on the Properties of Transparent Bamboo Prepared by Epoxy Resin Impregnation

Abstract

1. Introduction

2. Experimental Part

2.1. Materials

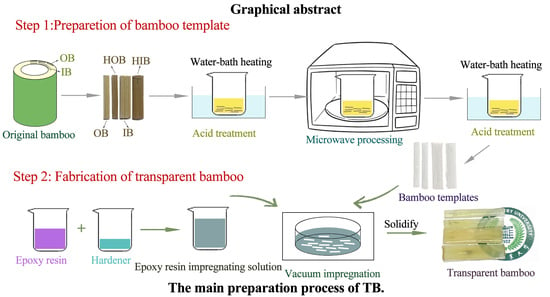

2.2. Experimental Method

2.2.1. Pre-Processing

2.2.2. Preparation of Bamboo Templates

2.2.3. Fabrication of Transparent Bamboo

2.3. Characterization

2.3.1. Fourier Transform Infrared Spectrum (FTIR) Analysis

2.3.2. Scanning Electron Microscope (SEM) Testing

2.3.3. Lignin Content Testing

2.3.4. Light Transmittance Testing

2.3.5. Mechanical Strength Testing

3. Results and Discussion

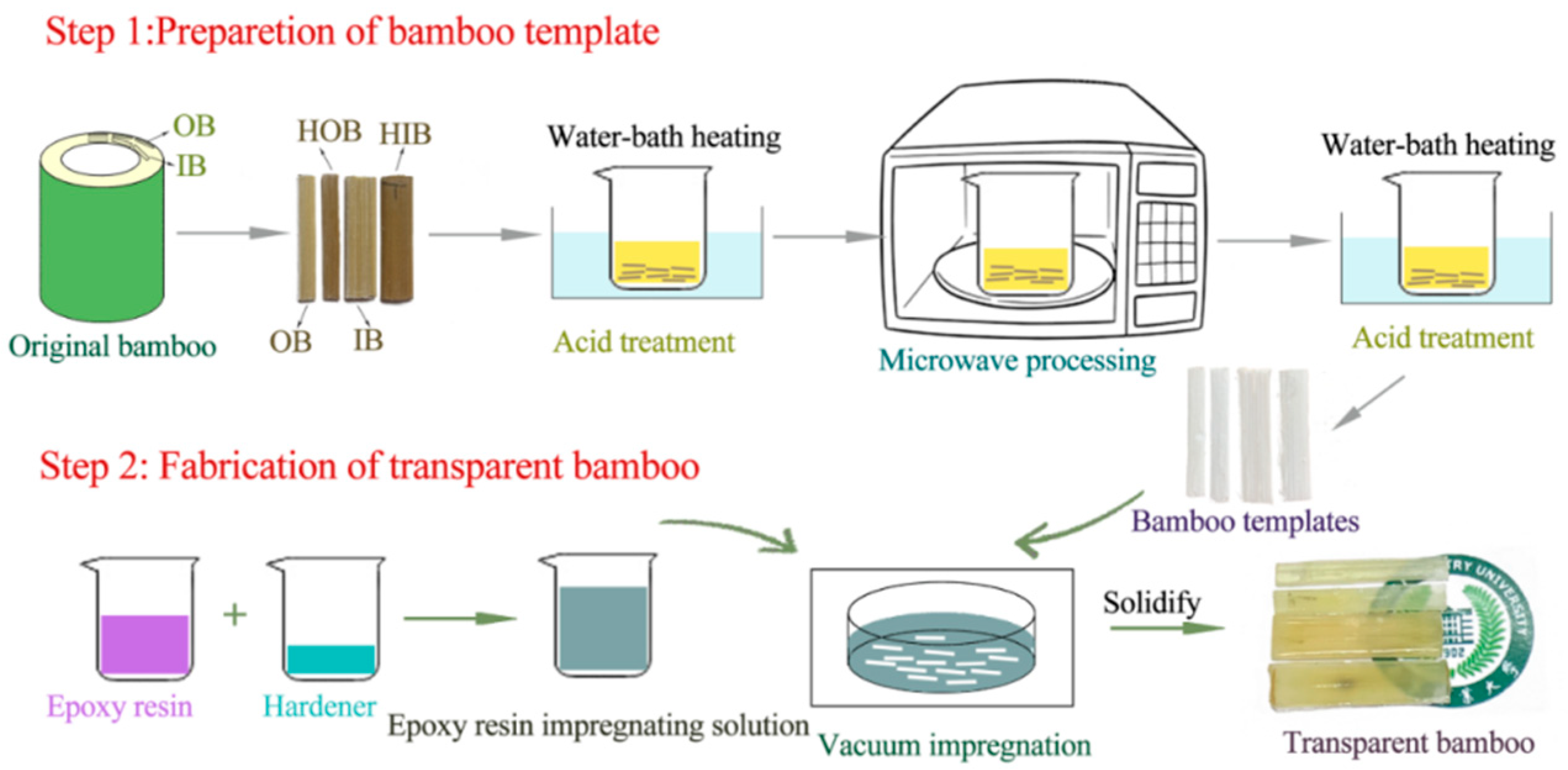

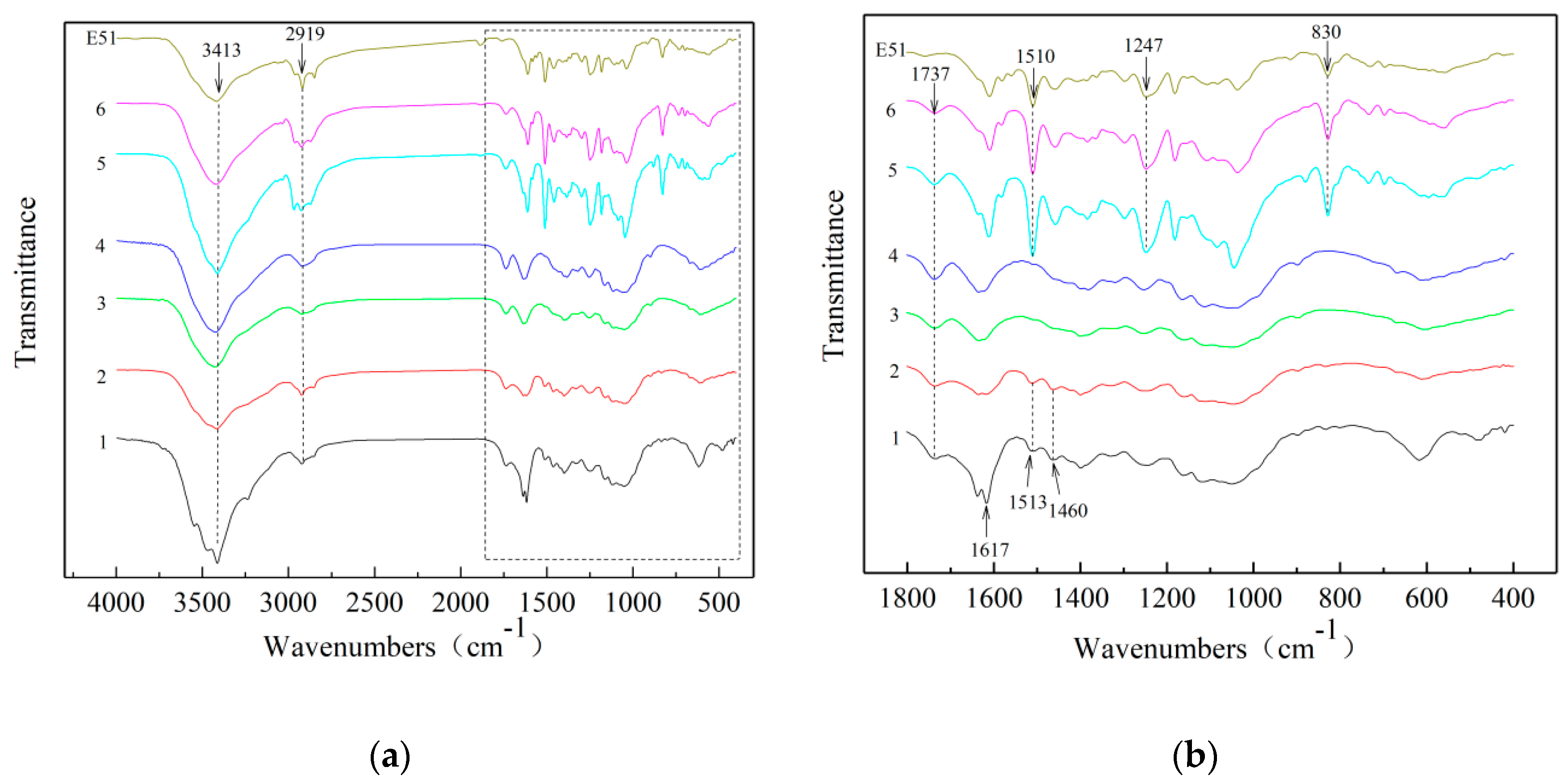

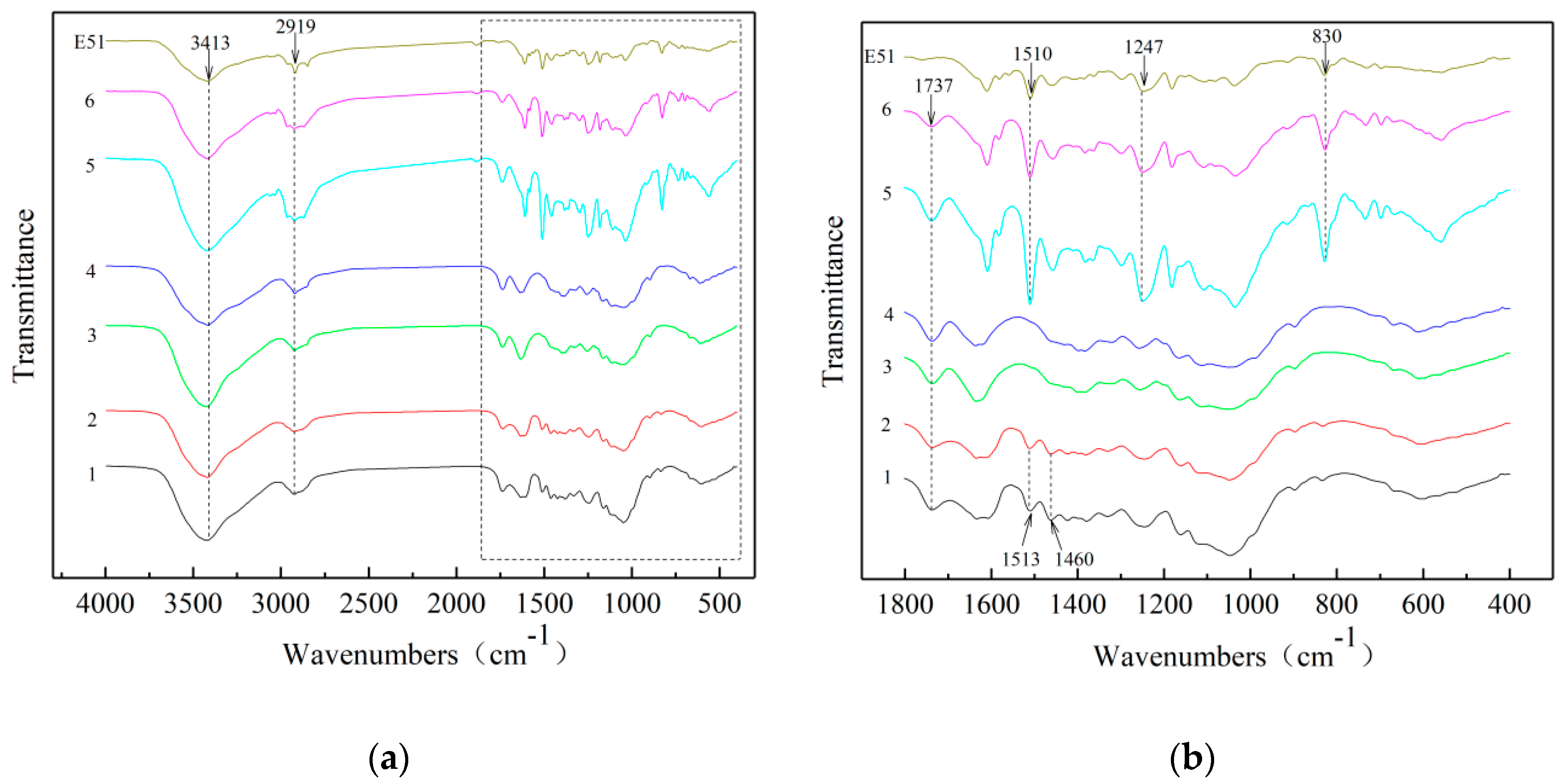

3.1. FTIR Analysis

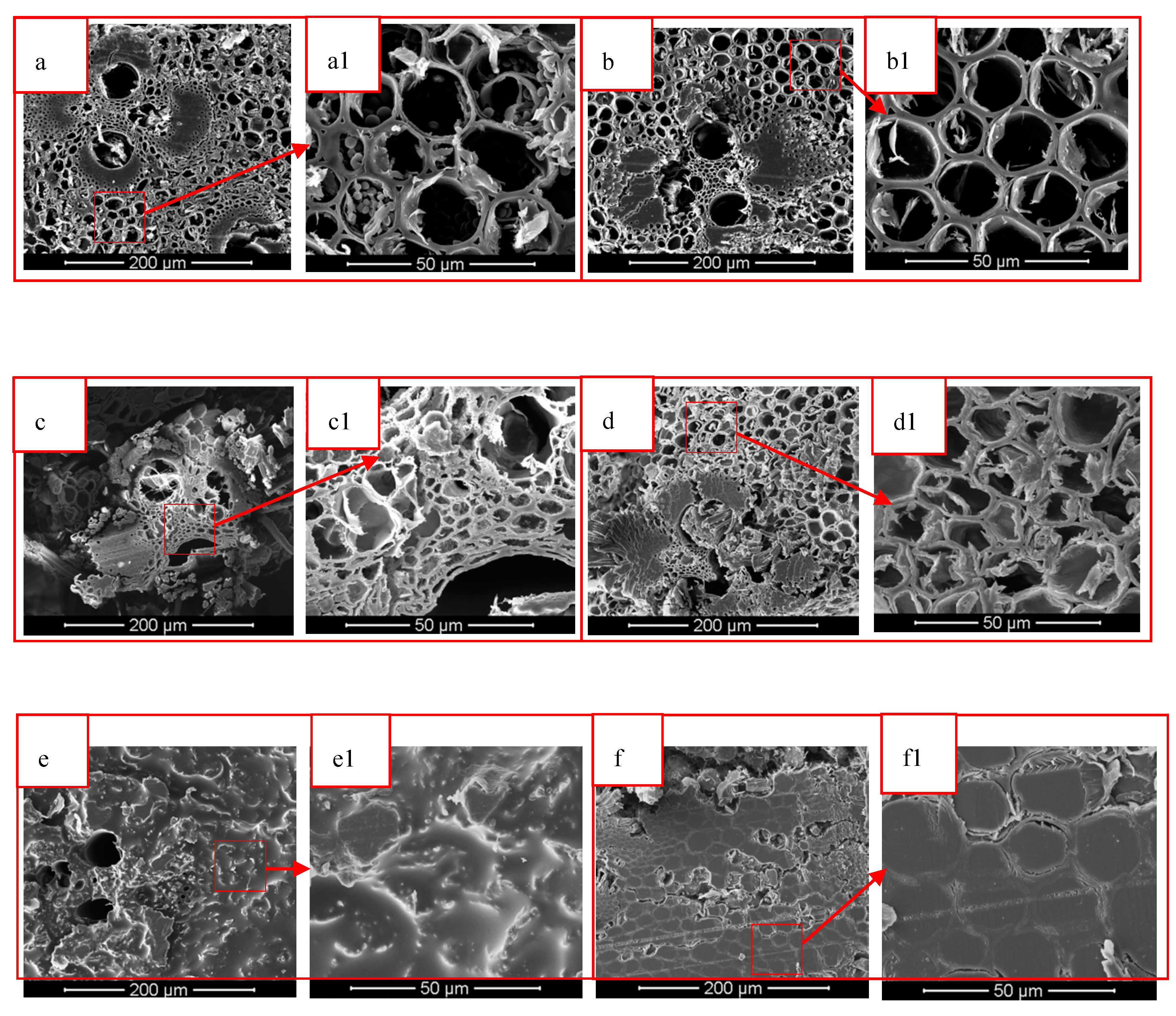

3.2. SEM Testing

3.3. Lignin Content Testing

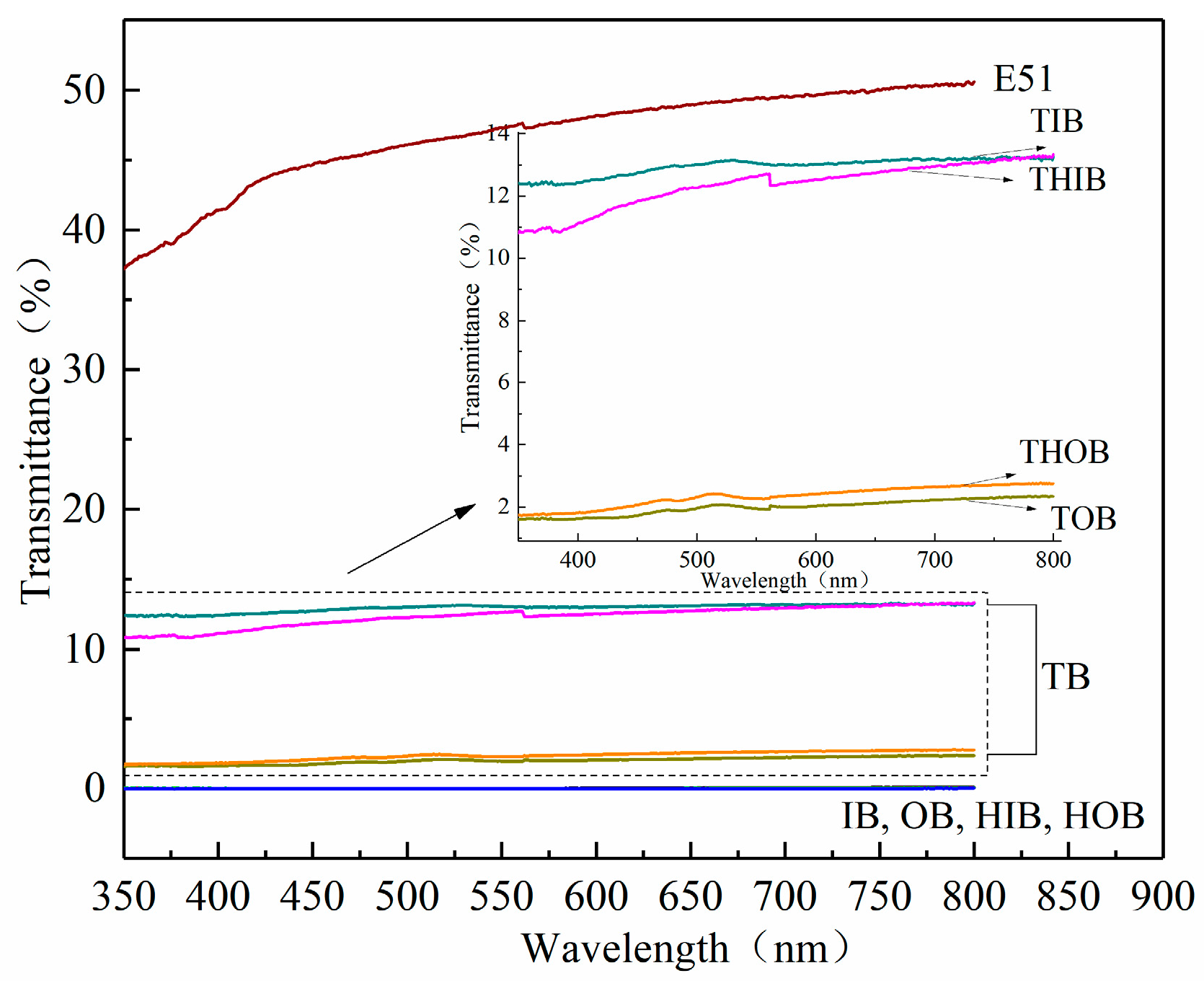

3.4. Light Transmittance Testing

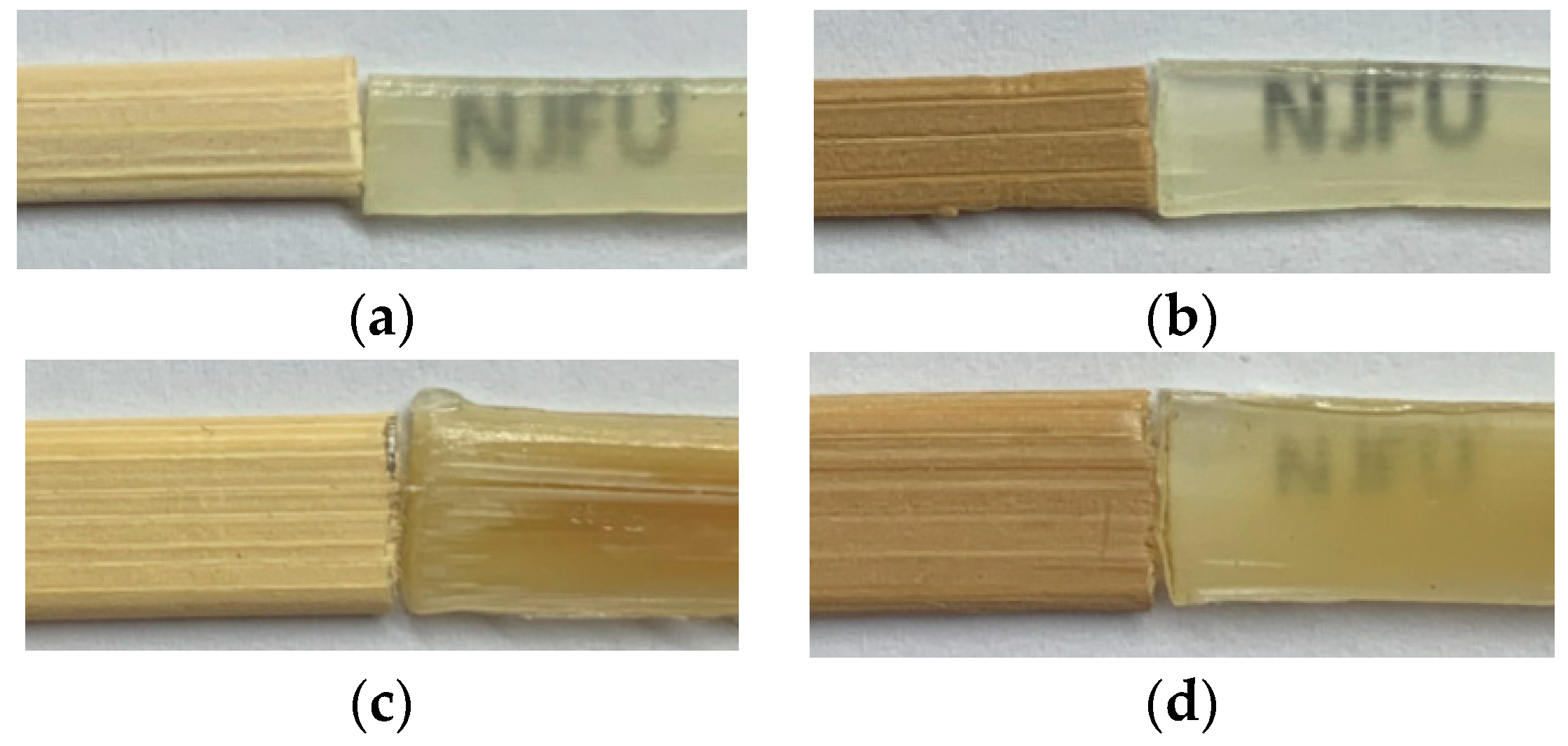

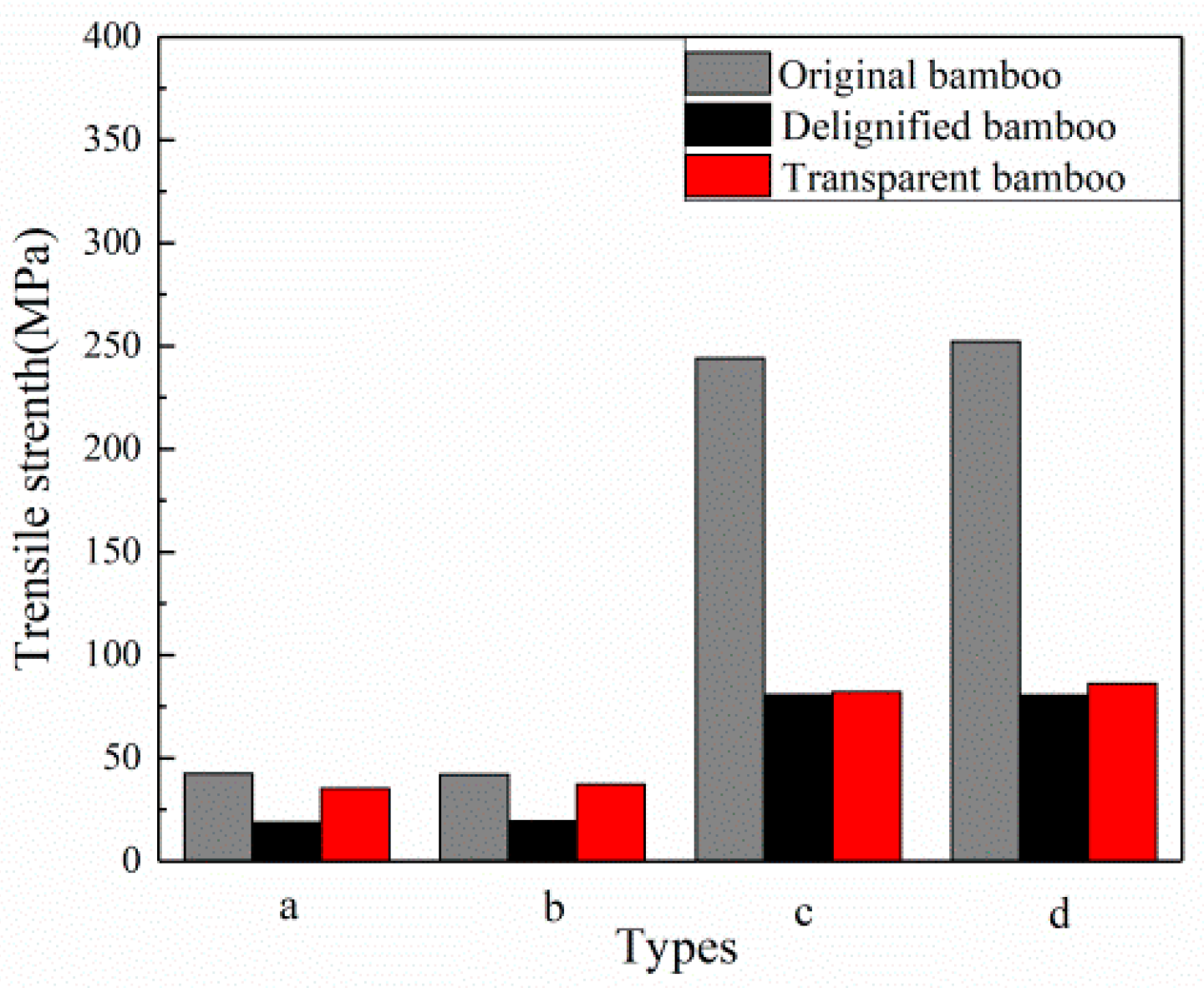

3.5. Mechanical Strength Testing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, W.; Chen, D.; Yong, Q.; Huang, C.; Huang, S. Improving enzymatic hydrolysis of acid-pretreated bamboo residues using amphiphilic surfactant derived from dehydroabietic acid. Bioresour. Technol. 2019, 293, 122055. [Google Scholar] [CrossRef] [PubMed]

- Scirlock, J.M.O.; Dayton, D.C.; Hames, B. Bamboo: An overlooked biomass resource? Biomass Bioenerg. 2000, 19, 229–244. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.Y.; Han, J.T.; Wu, Z.H.; Zhang, J.L. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef]

- Jiang, Z.H. Bamboo and rattan in the world. Shenyang Liaoning Sci. Technol. Press 2002, 2, 4–5. [Google Scholar]

- Song, S.S.; Fei, B.H.; Liu, X.Z. Bamboo furniture processing technology and its future development. Timber Process. Mach. 2012, 29, 43–48. [Google Scholar]

- Wang, G.; Jiang, Z.H.; Liu, X.M.; Fei, B.H.; Zhang, Y.; Qiu, Y.X. Status and development of bamboo standards at home and abroad. Timber Ind. 2012, 26, 43–45. [Google Scholar]

- Li, Z.; Chen, C.; Mi, R.; Gan, W.; Dai, J.; Jiao, M.; Xie, H.; Yao, Y.; Xiao, S.; Hu, L. A Strong, tough, and scalable structural material from fast-growing bamboo. Adv. Mater. 2020, 32, 1906308. [Google Scholar] [CrossRef]

- Sun, S.; Zhao, Z. Influence of acid on the curing process of tannin-sucrose adhesives. Bioresources 2018, 13, 7683–7697. [Google Scholar] [CrossRef]

- Huang, S.; Jiang, Q.; Yu, B.; Nie, Y.; Ma, Z.; Ma, L. Combined chemical modification of bamboo material prepared using vinyl acetate and methyl methacrylate: Dimensional stability, chemical structure, and dynamic mechanical properties. Polymers 2019, 11, 1651. [Google Scholar] [CrossRef]

- Kim, H.; Okubo, K.; Fujii, T.; Takemura, K. Influence of fiber extraction and surface modification on mechanical properties of green composites with bamboo fiber. J. Adhes. Sci. Technol. 2013, 27, 1348–1358. [Google Scholar] [CrossRef]

- Xu, Y.Q.; Chen, H.; Yang, F. Effect of low-temperature plasma treatment on surface properties of bamboo silk decorative materials. Furniture 2019, 40, 21–27. [Google Scholar]

- Vanholme, R.; Morreel, K.; Ralph, J.; Boerjan, W. Lignin engineering. Curr. Opin. Plant Biol. 2008, 11, 278. [Google Scholar] [CrossRef] [PubMed]

- Fink, S. Transparent wood—A new approach in the functional study of wood structure. Holzforschung 1992, 46, 403–408. [Google Scholar] [CrossRef]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly anisotropic, highly transparent wood composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically transparent wood from a nanoporous cellulosic template: Combining functional and structural performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef] [PubMed]

- Yaddanapudi, H.S.; Hickerson, N.; Saini, S.; Tiwari, A. Fabrication and characterization of transparent wood for next generation smart building applications. Vacuum 2017, 146, 649–654. [Google Scholar] [CrossRef]

- Jia, C.; Chen, C.; Mi, R.; Li, T.; Dai, J.; Yang, Z.; Pei, Y.; He, S.; Bian, H.; Jang, S.; et al. Clear wood toward high-performance building materials. ASC Nano 2019, 13, 9993–10001. [Google Scholar] [CrossRef]

- Huang, C.; Wang, X.; Liang, C.; Jiang, X.; Yang, G.; Xu, J.; Yong, Q. A sustainable process for procuring biologically active fractions of high-purity xylooligosaccharides and water-soluble lignin from moso bamboo prehydrolyzate. Biotechnol. Biofuels 2019, 12, 189. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Yang, X.; Ji, H.; Zhong, T.; Wang, G. A comparative study of the microstructure and water permeability between flattened bamboo and bamboo culm. J. Wood Sci. 2019, 65, 64. [Google Scholar] [CrossRef]

- Huang, C.; Lin, W.; Lai, C.; Li, X.; Jin, Y.; Yong, Q. Coupling the post-extraction process to remove residual lignin and alter the recalcitrant structures for improving the enzymatic digestibility of acid-pretreated bamboo residues. Bioresour. Technol. 2019, 285, 121355. [Google Scholar] [CrossRef]

- Lin, W.; Xing, S.; Jin, Y.; Lu, X.; Huang, C.; Yong, Q. Insight into understanding the performance of deep eutectic solvent pretreatment on improving enzymatic digestibility of bamboo residues. Bioresour. Technol. 2020, 306, 123163. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of structural carbohydrates and lignin in biomass. Lab. Anal. Proced. 2008, 1617, 1–16. [Google Scholar]

- Wang, Y.; Fu, S.Y. Research progress in transparent wood. China Pulp Pap. 2018, 37, 68–72. [Google Scholar]

- Wu, Y.; Wu, J.M.; Wang, S.Q.; Feng, X.H.; Chen, H.; Tang, Q.W.; Zhang, H.Q. Measurement of mechanical properties of multilayer waterborne coatings on wood by nanoindentation. Holzforschung 2019, 73, 1–7. [Google Scholar] [CrossRef]

- Li, Y.F.; Liu, Y.X.; Wang, X.M.; Wu, Q.L.; Yu, H.P.; Li, J. Wood-polymer composites prepared by the in situ polymerization of monomers within wood. Appl. Polym. Sci. 2010, 119, 3207–3216. [Google Scholar] [CrossRef]

- Ding, W.D.; Koubaa, A.; Chaala, A. Dimensional stability of methyl methacrylate hardened hybrid poplar wood. Bioresources 2011, 7, 504–520. [Google Scholar]

- Wu, J.M.; Wu, Y.; Yang, F.; Tang, C.Y.; Huang, Q.T.; Zhang, J.L. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part A Appl. Sci. Manuf. 2019, 117, 324–331. [Google Scholar] [CrossRef]

- Dong, H.; Zheng, L.; Yu, P.; Jiang, Q.; Wu, Y.; Huang, C.; Yin, B. Characterization and application of lignin-carbohydrate complexes from lignocellulosic materials as antioxidants for scavenging in vitro and in vivo reactive oxygen species. ACS Sustain. Chem. Eng. 2020, 8, 256–266. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, J.; Huang, Q.; Yang, F.; Wang, Y.; Liang, X.; Li, J. Study on the colorimetry properties of transparent wood prepared from six wood species. ACS Omega 2020, 5, 1782–1788. [Google Scholar] [CrossRef]

- Xian, X.; Xian, D. Microstructure of bamboo and its relationship with mechanical properties. J. Bamboo Res. 1990, 9, 10–23. [Google Scholar]

| Types | L (mm) | b (mm) | h (mm) | M1 (g) | M2 (g) | Absolute Dry Density (g·cm−3) |

|---|---|---|---|---|---|---|

| IB | 3 | 4.40 | 1.1 ± 0.05 | 0.068 (0.001) | 0.062 (0.002) | 0.44 |

| OB | 3 | 7.80 | 1.8 ± 0.05 | 0.280 (0.018) | 0.253 (0.014) | 0.62 |

| HIB | 3 | 4.40 | 1.1 ± 0.05 | 0.065 (0.004) | 0.062 (0.006) | 0.40 |

| HOB | 3 | 7.80 | 1.8 ± 0.05 | 0.260 (0.013) | 0.250 (0.010) | 0.55 |

| Type | Maximum Tensile Strength (MPa) | Tensile Strength in Literature [30] (MPa) | |

|---|---|---|---|

| a | IB | 42.39 (3.95) | 52.40 |

| DIB | 18.71 (4.01) | -- | |

| TIB | 35.31 (3.78) | -- | |

| b | HIB | 42.13 (1.29) | -- |

| DHIB | 19.32 (5.13) | -- | |

| THIB | 37.28 (5.41) | -- | |

| c | OB | 244.16 (6.94) | 293.00 |

| DOB | 80.70 (8.92) | -- | |

| TOB | 82.18 (3.81) | -- | |

| d | HOB | 252.30 (16.29) | -- |

| DHOB | 80.59 (12.46) | -- | |

| THOB | 86.17 (3.29) | -- | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Wang, Y.; Yang, F.; Wang, J.; Wang, X. Study on the Properties of Transparent Bamboo Prepared by Epoxy Resin Impregnation. Polymers 2020, 12, 863. https://doi.org/10.3390/polym12040863

Wu Y, Wang Y, Yang F, Wang J, Wang X. Study on the Properties of Transparent Bamboo Prepared by Epoxy Resin Impregnation. Polymers. 2020; 12(4):863. https://doi.org/10.3390/polym12040863

Chicago/Turabian StyleWu, Yan, Yajing Wang, Feng Yang, Jing Wang, and Xuehua Wang. 2020. "Study on the Properties of Transparent Bamboo Prepared by Epoxy Resin Impregnation" Polymers 12, no. 4: 863. https://doi.org/10.3390/polym12040863

APA StyleWu, Y., Wang, Y., Yang, F., Wang, J., & Wang, X. (2020). Study on the Properties of Transparent Bamboo Prepared by Epoxy Resin Impregnation. Polymers, 12(4), 863. https://doi.org/10.3390/polym12040863