Fire Suppression and Thermal Behavior of Biobased Rigid Polyurethane Foam Filled with Biomass Incineration Waste Ash

Abstract

1. Introduction

2. Materials and Methods

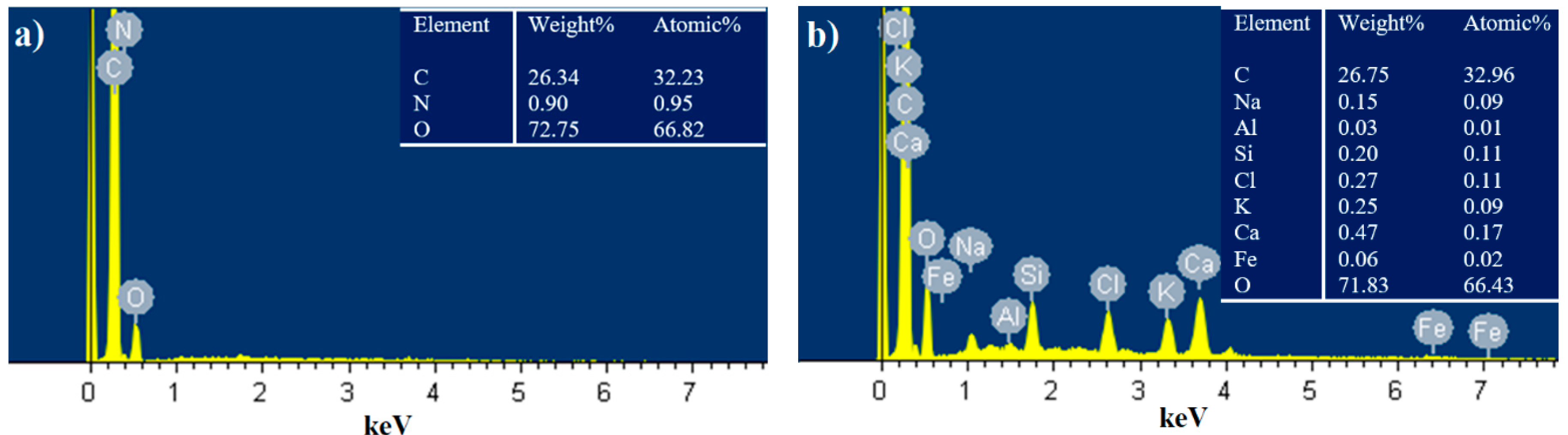

2.1. Materials

2.2. Preparation of PU and WAPU Foams

2.3. Test Methods

3. Results and Discussion

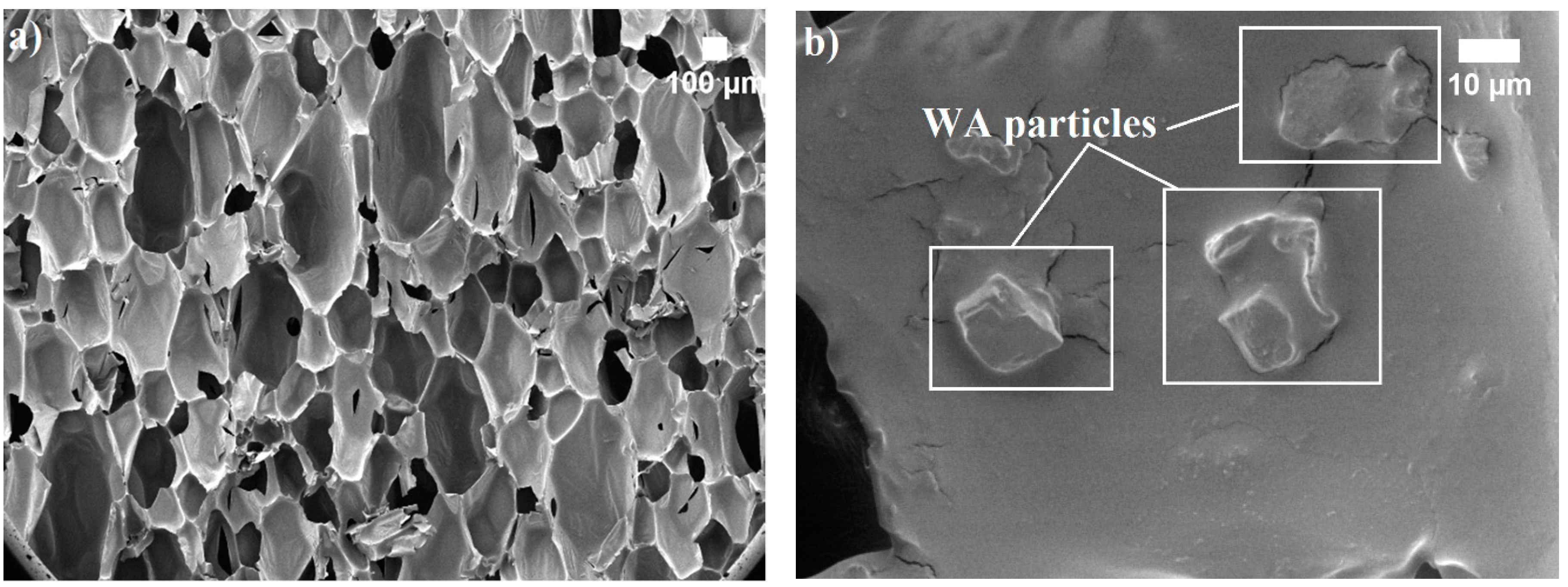

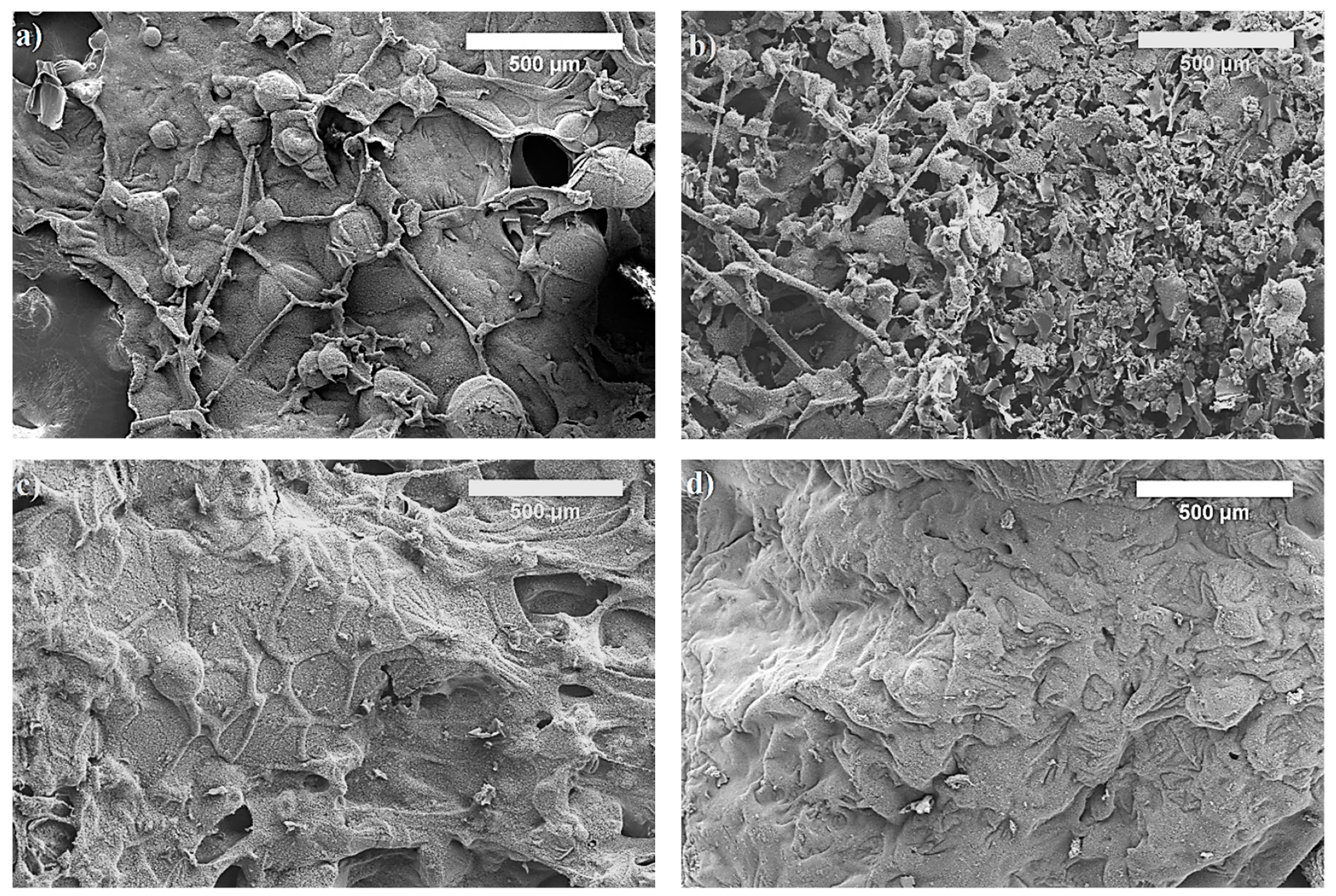

3.1. The Main Physical and Mechanical Properties of PU and WAPU Foams

3.2. Thermal Stability of PU and WAPU Foams

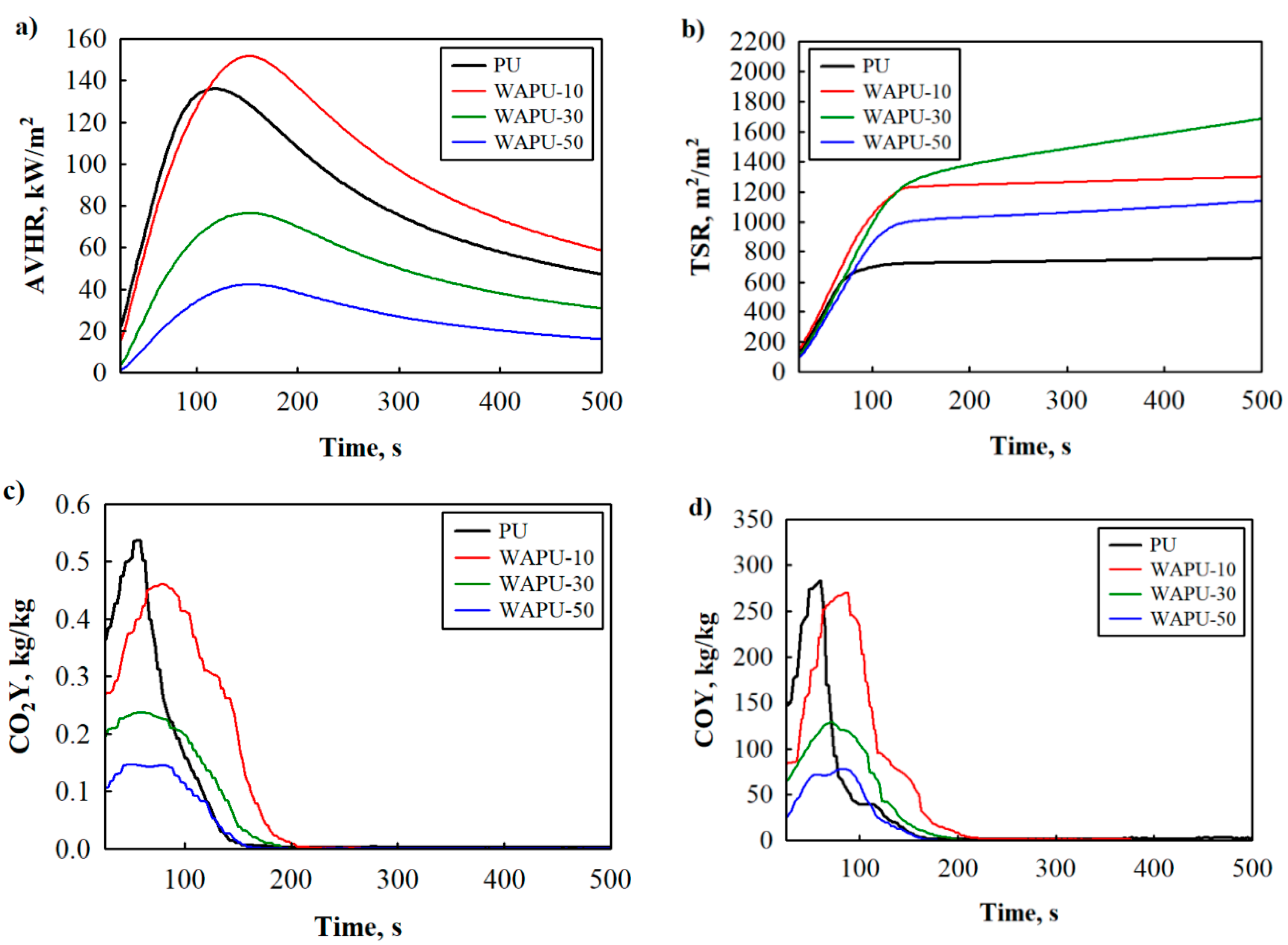

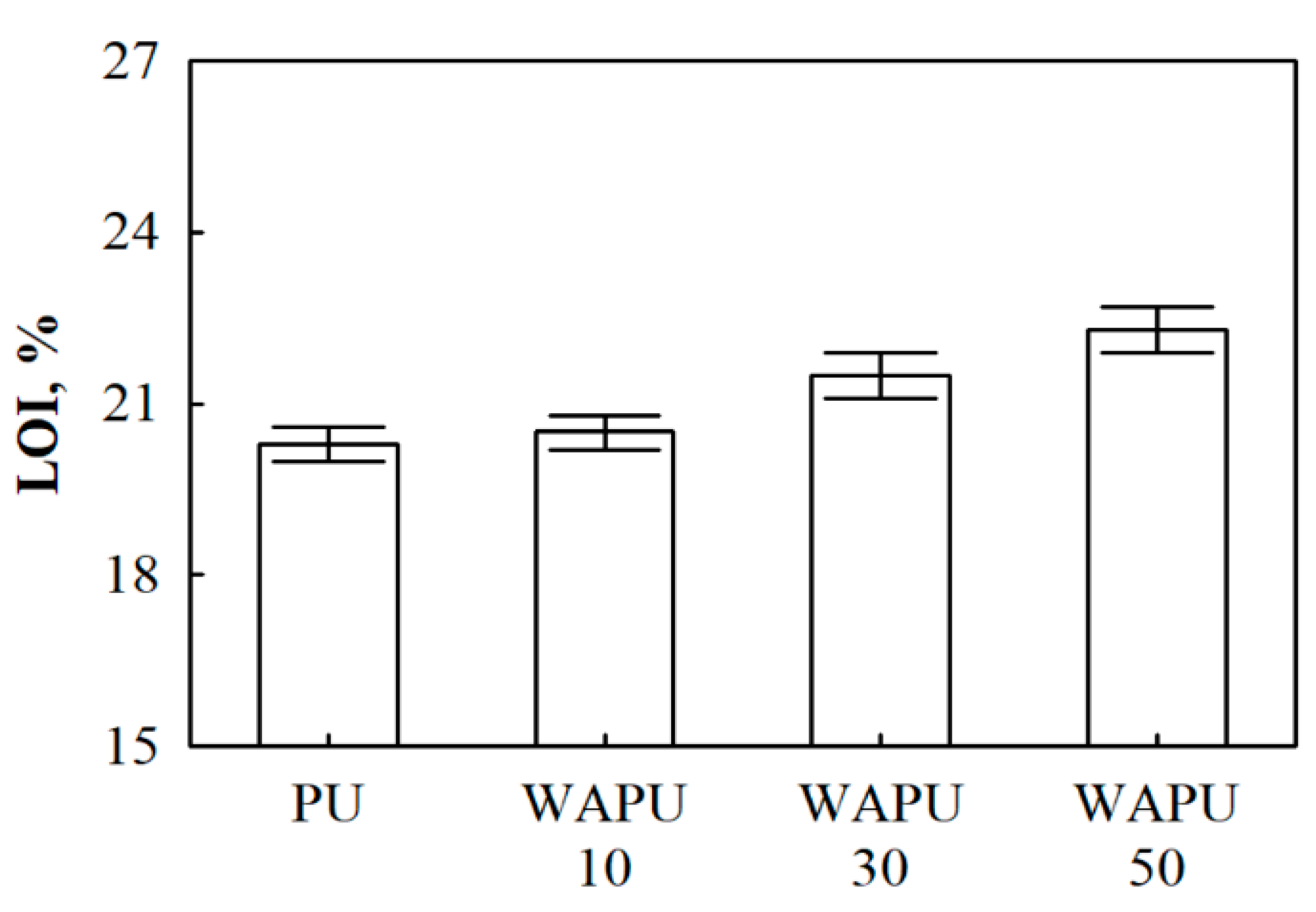

3.3. Flame Retardancy of PU and WAPU Foams

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ruiz, B.; Girón, R.P.; Suárez-Ruiz, I.; Fuente, E. From fly ash of forest biomass combustion (FBC) to micro-mesoporous silica adsorbent materials. Process Sav. Environ. 2017, 105, 164–174. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.-C.; Li, W.-Y.; Feng, J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Tamanna, K.; Raman, S.N.; Jamil, M.; Hamid, R. Utilization of wood waste ash in construction technology: A review. Constr. Build. Mater. 2020, 237, 1–11. [Google Scholar] [CrossRef]

- Foong, K.Y.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Enhancement of the mechanical properties of lightweight oil palm shell concrete using rice husk ash and manufactures sand. J. Zhejiang Univ. Sci. A 2015, 16, 59–69. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Chua, C.P.; Alengaram, U.J.; Jumaat, M.Z. Utilization of palm oil fuel ash as binder in lightweight oil palm shell geopolymer concrete. Adv. Mater. Sci. Eng. 2014, 2014, 1–6. [Google Scholar] [CrossRef]

- Yang, Z.; Huddleston, J.; Brown, H. Effects of wood ash on properties of concrete and flowable fill. J. Chem. Eng. Mater. Sci. 2016, 4, 101–114. [Google Scholar] [CrossRef]

- Adamu, M.; Tifase, A.S.; Uche, O.A.U. Engineering properties of industrial wood waste ash-concrete. Int. J. Adv. Constr. Eng. 2017, 1, 1–11. [Google Scholar]

- Ghorpade, V.G. Effect of wood waste ash on the strength characteristics of concrete. Nat. Environ. Pollut. Technol. 2012, 11, 121–124. [Google Scholar]

- Djamaluddin, A.R.; Caronge, M.A.; Tjaronge, M.W.; Lando, A.T.; Irmawaty, R. Evaluation of sustainable concrete paving blocks incorporating processed waste tea ash. Case Stud. Constr. Mater. 2020, 12, 1–12. [Google Scholar] [CrossRef]

- Kairytė, A.; Kizinievič, O.; Kizinievič, V.; Kremensas, A. Synthesis of biomass-derived bottom waste ash based rigid biopolyurethane composite foams: Rheological behaviour, structure and performance characteristics. Compos. Part A-Appl. Sci. Manuf. 2019, 117, 193–201. [Google Scholar]

- Rao, W.-H.; Xu, H.-X.; Xu, Y.-J.; Qi, M.; Liao, W.; Xu, S.; Wang, Y.-Z. Persistently flame-retardant flexible polyurethane foams by a novel phosphorus-containing polyol. Chem. Eng. J. 2018, 343, 198–206. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, T.; Zou, B.; Hu, W.; Wang, B.; Zhan, J.; Ma, C.; Hu, Y. Synthesis of a novel liquid phosphorus-containing flame retardant for flexible polyurethane foam: Combustion behaviors and thermal properties. Polym. Degrad. Stab. 2020, 171, 1–10. [Google Scholar] [CrossRef]

- Zhang, T.; Tao, Y.; Zhou, F.; Sheng, H.; Qiu, S.; Ma, C.; Hu, Y. Synthesis of hyperbranched phosphorus-containing polyurethane as char forming agent combined with ammonium polyphosphate for reducing fire hazard of polypropylene. Polym. Degrad. Stab. 2019, 165, 207–219. [Google Scholar] [CrossRef]

- Huang, G.; Gao, J.; Li, Y.; Han, L.; Wang, X. Functionalizing nano-montmorillonites by modified with intumescent flame retardant: Preparation and application in polyurethane. Polym. Degrad. Stab. 2010, 95, 245–253. [Google Scholar] [CrossRef]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-based polyurethane-polyisocyanurate composites with an intumescent flame retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- Li, Y.-C.; Yang, Y.-H.; Shields, J.R.; Davis, R.D. Layered double hydroxide-based fire resistant coatings for flexible polyurethane foam. Polymer 2015, 56, 284–292. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G.; Xie, Y. Synergistic effect of expandable graphite, melamine polyphosphate and layered double hydroxide on improving the fire behaviour of rosin-based rigid polyurethane foam. Ind. Crop. Prod. 2013, 50, 638–647. [Google Scholar] [CrossRef]

- Kairytė, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vaitkus, S.; Pundienė, I. Cleaner production of polyurethane foam: Replacement of conventional raw materials, assessment of fire resistance and environmental impact. J. Clean. Prod. 2018, 183, 760–771. [Google Scholar] [CrossRef]

- Cao, Z.-J.; Liao, W.; Wang, S.-X.; Zhao, H.-B.; Wang, Y.-Z. Polyurethane foams with functionalized graphene towards high fire-resistance, low smoke release, superior thermal insulation. Chem. Eng. J. 2019, 361, 1245–1254. [Google Scholar] [CrossRef]

- Rao, T.N.; Hussain, I.; Koo, B.H. Ehanced thermal properties of silica nanoparticles and chitosan bio-based intumescent flame retardant polyurethane coatings. Mater. Today Proc. 2019. [Google Scholar] [CrossRef]

- Członka, S.; Sienkiewicz, N.; Strąkowska, A.; Strzelec, K. Keratin feathers as a filler for rigid polyurethane foams on the basis of soybean oil polyol. Polym. Test. 2018, 72, 32–45. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R.S. Investigation on flammability of rigid polyurethane foam-mineral fillers composite. Fire Mater. 2019, 43, 917–927. [Google Scholar] [CrossRef]

- EN 12085. Thermal Insulating Products for Building Applications—Determination of Linear Dimensions of Test Specimens; European Standardization Committee: Brussels, Belgium, 2013. [Google Scholar]

- EN 1602. Thermal Insulating Products for Building Applications—Determination of the Apparent Density; European Standardization Committee: Brussels, Belgium, 2013. [Google Scholar]

- EN 12667. Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance; European Standardization Committee: Brussels, Belgium, 2001. [Google Scholar]

- EN ISO 4590. Rigid Cellular Plastics—Determination of the Volume Percentage of Open Cells and of Closed Cells; International Standardization Committee: Geneva, Switzerland, 2016. [Google Scholar]

- EN 12087. Thermal Insulating Products for Building Applications—Determination of Long Term Water Absorption by Immersion; European Standardization Committee: Brussels, Belgium, 2013. [Google Scholar]

- EN 826. Thermal Insulating Products for Building Applications—Determination of Compression Behaviour; European Standardization Committee: Brussels, Belgium, 2013. [Google Scholar]

- ISO 5660-1. Reaction-to-Fire Tests-Heat Release, Smoke Production and Mass Loss Rate Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement); International Standardization Committee: Geneva, Switzerland, 2015. [Google Scholar]

- EN 13165. Thermal Insulation Products for Buildings—Factory Made Rigid Polyurethane Foam (PU) Products – Specification; European Standardization Committee: Brussels, Belgium, 2016. [Google Scholar]

- EN 14315-1. Thermal Insulating products for Buildings—In-Situ formed Sprayed Rigid Polyurethane (PUR) and Polyisocyanurate (PIR) Foam Products - Part 1: Specification for The Rigid Foam Spray System Before Installation; European Standardization Committee: Brussels, Belgium, 2013. [Google Scholar]

- Hebda, E.; Bukowczan, A.; Michałowski, S.; Wroński, S.; Urbaniak, P.; Kaczmarek, M.; Hutnik, E.; Romaniuk, A.; Wolun-Cholewa, M.; Pielichowski, K. Examining the influence of functionalized POSS on the structure and bioactivity of flexible polyurethane foams. Mat. Sci. Eng. C Mater. 2020, 108, 1–12. [Google Scholar] [CrossRef]

- Stanzione, M.; Oliviero, M.; Cocca, M.; Errico, M.E.; Gentile, G.; Avella, M.; Lavorgna, M.; Buonocore, G.G.; Verdolotti, L. Tuning of polyurethane foam mechanical and thermal properties using ball-milled cellulose. Carbohydr. Polym. 2020, 231, 1–10. [Google Scholar] [CrossRef]

- Członka, S.; Sienkiewicz, N.; Kairytė, A.; Vaitkus, S. Colored polyurethane foams with enhanced mechanical and thermal properties. Polym. Test. 2019, 78, 1–11. [Google Scholar] [CrossRef]

- Choe, H.; Choi, Y.; Kim, J.H. Threshold cell diameter for high thermal insulation of water-blown rigid polyurethane foams. J. Ind. Eng. Chem. 2019, 73, 344–350. [Google Scholar] [CrossRef]

- Li, B.; Zhou, M.; Huo, W.; Cai, D.; Qin, P.; Cao, H.; Tan, T. Fractionation and oxypropylation of corn-stover lignin for the production of biobased rigid polyurethane foam. Ind. Crop. Prod. 2020, 143, 1–10. [Google Scholar] [CrossRef]

- Tang, G.; Liu, X.; Zhou, L.; Zhang, P.; Deng, D.; Jiang, H. Steel slag waste combined with melamine pyrophosphate as a flame retardant for rigid polyurethane foams. Adv. Powder Technol. 2020. [Google Scholar] [CrossRef]

- Zhai, Y.; Yu, Y.; Zhou, K.; Yun, Z.; Huang, W.; Liu, H.; Xia, Q.; Dai, K.; Zheng, G.; Liu, C.; et al. Flexible and wearable carbon black/thermoplastic polyurethane foam with pinnate-veined aligned porous structure for multifunctional piezoresistive sensors. Chem. Eng. J. 2020, 382, 1–12. [Google Scholar] [CrossRef]

- Gürsoy, T.; Alma, M.H. Water absorption and biodegradation properties of potato waste-based polyurethane foams. Middle East J. Sci. Res. 2017, 3, 107–114. [Google Scholar] [CrossRef][Green Version]

- Hejna, A.; Formela, K.; Saeb, M.R. Processing, mechanical and thermal assessments of polycaprolactone/agricultural wastes biocomposites. Ind. Crop. Prod. 2015, 76, 725–733. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Yang, R.; Wang, B.; Li, M.; Zhang, X.; Li, J. Preparation, characterization and thermal degradation behaviour of rigid polyurethane foam using a mic acid based polyols. Ind. Crop. Prod. 2019, 136, 121–128. [Google Scholar] [CrossRef]

- Hejna, A.; Kopczyńska, M.; Kozłowska, U.; Klein, M.; Kosmela, P.; Piszczyk, Ł. Foamed polyurethane composites with different types of ash — Morphological, mechanical and thermal behaviour assessments. Cell. Polym. 2016, 36, 287–308. [Google Scholar] [CrossRef]

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Kowalski, M.; Krauze, S.; Lewandowska, M. The influence of carbon fillers on the thermal properties of polyurethane foam. J. Therm. Anal. Calorim. 2016, 123, 283–291. [Google Scholar] [CrossRef]

- Gama, N.V.; Silva, R.; Mohseni, F.; Davarpanah, A.; Amaral, V.S.; Ferreira, A.; Barros-Timmons, A. Enhancement of physical and reaction to fire properties of crude glycerol polyurethane foams filled with expanded graphite. Polym. Test. 2018, 69, 199–207. [Google Scholar] [CrossRef]

- Kuźnia, M.; Magiera, A.; Pielichowska, K.; Ziąbka, M.; Benko, A.; Szatkowski, P.; Jerzak, W. Fluidized bed combustion fly ash as filler in composite polyurethane materials. Waste Manag. 2019, 92, 115–123. [Google Scholar] [CrossRef]

- Barczewski, M.; Kurańska, M.; Sałasińska, K.; Michałowski, S.; Prociak, A.; Uram, K.; Lewandowski, K. Rigid polyurethane foams modified with thermoset polyester-glass fiber composite waste. Polym. Test. 2020. [Google Scholar] [CrossRef]

- Yang, H.; Liu, H.; Jiang, Y.; Chen, M.; Wan, C. Density effect on flame retardancy, thermal degradation, and combustibility of rigid polyurethane foam modified by expandable graphite or ammonium polyphosphate. Polymers 2019, 11, 668. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Xu, Y.; He, Y.; Xu, M.; Shi, Z.; Hu, H.; Yang, Z.; Li, B. An effective mono-component intumescent flame retardant for the enhancement of water resistance and fire safety of thermoplastic polyurethane composites. Polym. Degrad. Stab. 2019, 167, 146–156. [Google Scholar] [CrossRef]

- Sun, R.; Åhlen, M.; Tai, C.-W.; Bajnóczi, E.G.; Klejne, F.; Ferraz, N.; Persson, I.; Strømme, M.; Cheung, O. Highly porous amorphous calcium phosphate for drug delivery and bio-medical application. Nanomaterials (Basel) 2020, 10, 20. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Li, P.; Cai, L.; Shi, S.Q. Flammability and mechanical properties of composites fabricated with CaCO3-filled pine flakes and phenol formaldehyde resin. Compos. Part B Eng. 2019, 167, 1–6. [Google Scholar] [CrossRef]

- Wang, C.; Cai, L.; Shi, S.Q.; Wang, G.; Cheng, H.; Zhang, S. Thermal and flammable properties of bamboo pulp fiber/high-density polyethylene composites: Influence of preparation technology, nano calcium carbonate and fiber content. Renew. Energy 2019, 134, 436–445. [Google Scholar] [CrossRef]

- Cai, W.; Cai, T.; He, L.; Chu, F.; Mu, X.; Han, L.; Hu, Y.; Wang, B.; Hu, W. Natural antioxidant functionalization for fabricating ambient-stable black phosphorus nanosheets toward enhancing flame retardancy and toxic gases suppression of polyurethane. J. Hazard. Mater. 2020, 387, 1–14. [Google Scholar] [CrossRef]

- Borowicz, M.; Paciorek-Sadowska, J.; Lubczak, J.; Czupryński, B. Biodegradable, flame-retardant, and bio-based rigid polyurethane/polyisocyanurate foams for thermal insulation application. Polymers 2019, 11, 1816. [Google Scholar] [CrossRef]

- Li, M.-E.; Wang, S.-X.; Han, L.-X.; Yuan, W.-J.; Cheng, J.-B.; Zhang, A.-N.; Zhao, H.-B.; Wang, Y.-Z. Hierarchically porous SiO2/polyurethane foam composites towards excellent thermal insulating, flame-retardant and smoke-suppressant performances. J. Hazard. Mater. 2020, 375, 61–69. [Google Scholar] [CrossRef]

- Xu, D.; Yu, K.; Kun, Q. Effect of tris(1-chloro-2-propyl)phosphate and modified aramid fiber on cellular structure, thermal stability and flammability of rigid polyurethane foams. Polym. Degrad. Stab. 2017, 144, 207–220. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, B.; Han, J. Flame retardancy and smoke suppression properties of flexible polyurethane foams containing an aluminium phosphate microcapsule. RSC Adv. 2017, 7, 1–10. [Google Scholar]

- Liu, H.; Zhang, B.; Han, J. Improving flame retardancy and smoke suppression properties of polyurethane foams with SiO2 microcapsule and its flame-retardant mechanism. Polym. Plast. Technol. 2018, 57, 1139–1149. [Google Scholar] [CrossRef]

| ComponentComponent | Total Amount, pbw * | |

|---|---|---|

| PU | WAPUU | |

| BioPolyol RDBioPolyol RD | 60 | 60 |

| Petol PZ 400-4G | 40 | 40 |

| Blowing agent | 2.7 | 2.7 |

| Blowing and gelling catalyst | 1.0 | 1.0 |

| Silicone surfactant | 2.5 | 2.5 |

| WA amount, wt.% | 0 | 10 or 30 or 50 |

| Isocyanate index | 125 | |

| Foam Title | Characteristics | ||||

|---|---|---|---|---|---|

| Apparent Density, kg/m3 | Cell Diameter, µm | Thermal Conductivity after 28 days, W/(mK) | Compressive Strength, kPa | Water Absorption, vol.% | |

| PU | 38.2 ± 0.4 | 475 ± 13 | 0.0336 ± 0.002 | 240 ± 17 | 5.2 ± 0.14 |

| WAPU-10 | 46.5 ± 1.2 | 218 ± 25 | 0.0349 ± 0.003 | 260 ± 29 | 5.5 ± 0.25 |

| WAPU-30 | 51.0 ± 0.5 | 200 ± 30 | 0.0357 ± 0.002 | 250 ± 11 | 5.8 ± 0.55 |

| WAPU-50 | 56.8 ± 0.6 | 201 ± 28 | 0.0361 ± 0.002 | 233 ± 14 | 6.5 ± 0.24 |

| Foam Title | T5 wt.%, °C | T50 wt.%, °C | Tmax, °C | Char Yield at 600 °C, wt.% | |||

|---|---|---|---|---|---|---|---|

| 1st Stage | 2nd Stage | 3rd Stage | 4th Stage | ||||

| PU | 213 | 470 | 211 | 309 | 462 | - | 28.2 |

| WAPU-10 | 245 | 547 | 217 | 309 | - | 590 | 33.9 |

| WAPU-30 | 236 | 562 | 222 | 308 | - | 584 | 37.8 |

| WAPU-50 | 230 | 570 | 217 | 301 | - | 580 | 40.4 |

| Foam Title | Parameter | |||

|---|---|---|---|---|

| AVHR, kW/m2 | TSR, m2/m2 | CO2Y, kg/kg | COY, kg/kg | |

| PU | 136 | 761 | 3.92 | 0.11 |

| WAPU-10 | 152 | 1307 | 4.22 | 0.14 |

| WAPU-30 | 76.6 | 1758 | 1.69 | 0.049 |

| WAPU-50 | 42.5 | 1154 | 0.926 | 0.025 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kairytė, A.; Kremensas, A.; Vaitkus, S.; Członka, S.; Strąkowska, A. Fire Suppression and Thermal Behavior of Biobased Rigid Polyurethane Foam Filled with Biomass Incineration Waste Ash. Polymers 2020, 12, 683. https://doi.org/10.3390/polym12030683

Kairytė A, Kremensas A, Vaitkus S, Członka S, Strąkowska A. Fire Suppression and Thermal Behavior of Biobased Rigid Polyurethane Foam Filled with Biomass Incineration Waste Ash. Polymers. 2020; 12(3):683. https://doi.org/10.3390/polym12030683

Chicago/Turabian StyleKairytė, Agnė, Arūnas Kremensas, Saulius Vaitkus, Sylwia Członka, and Anna Strąkowska. 2020. "Fire Suppression and Thermal Behavior of Biobased Rigid Polyurethane Foam Filled with Biomass Incineration Waste Ash" Polymers 12, no. 3: 683. https://doi.org/10.3390/polym12030683

APA StyleKairytė, A., Kremensas, A., Vaitkus, S., Członka, S., & Strąkowska, A. (2020). Fire Suppression and Thermal Behavior of Biobased Rigid Polyurethane Foam Filled with Biomass Incineration Waste Ash. Polymers, 12(3), 683. https://doi.org/10.3390/polym12030683