Influence of Hybridization on Tensile Behaviors of Non-Absorbable Braided Polymeric Sutures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Tensile Properties of Yarns

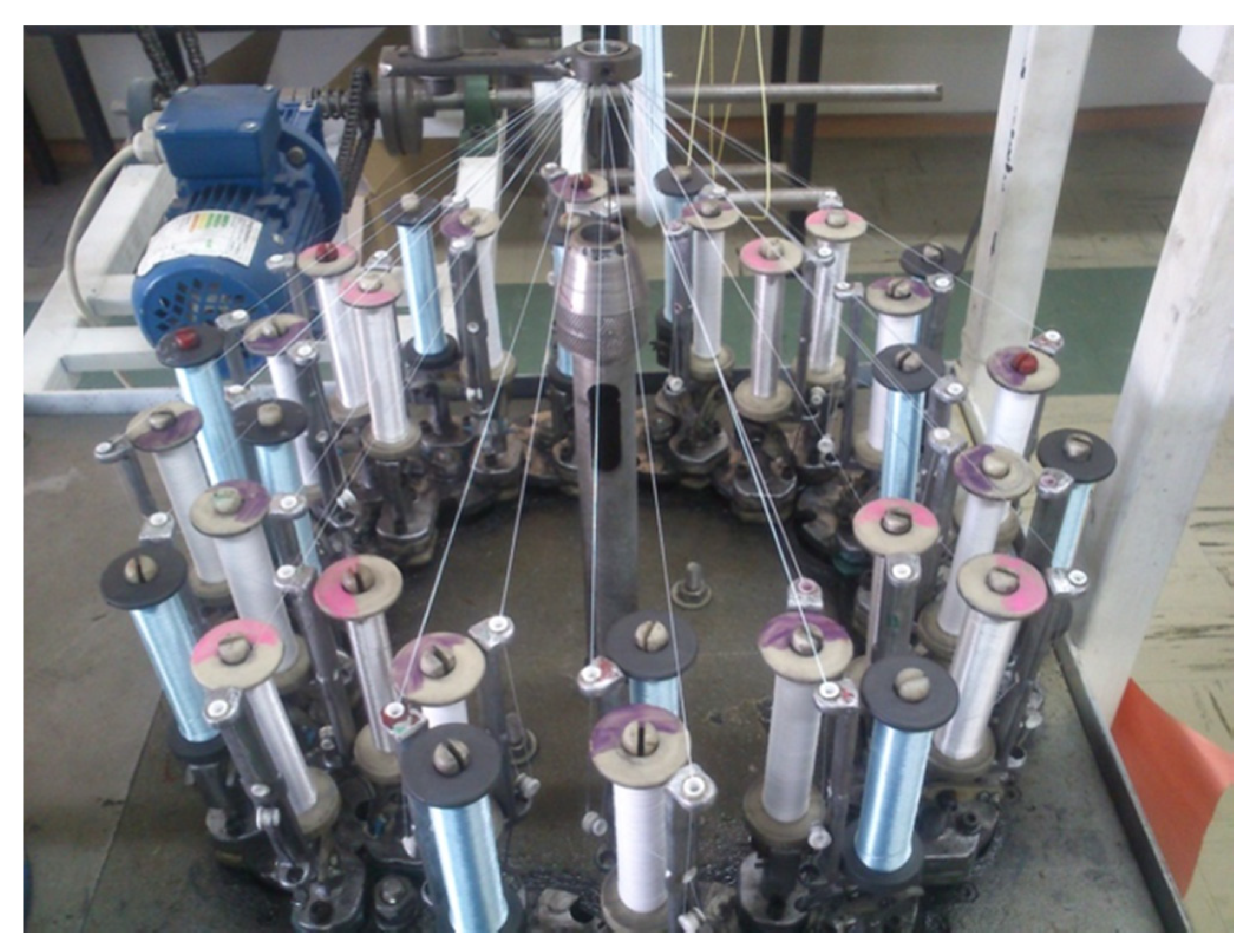

2.3. Suture Fabrication

2.4. Tensile Characteristics of Sutures

2.5. Statistical Analysis

3. Results and Discussion

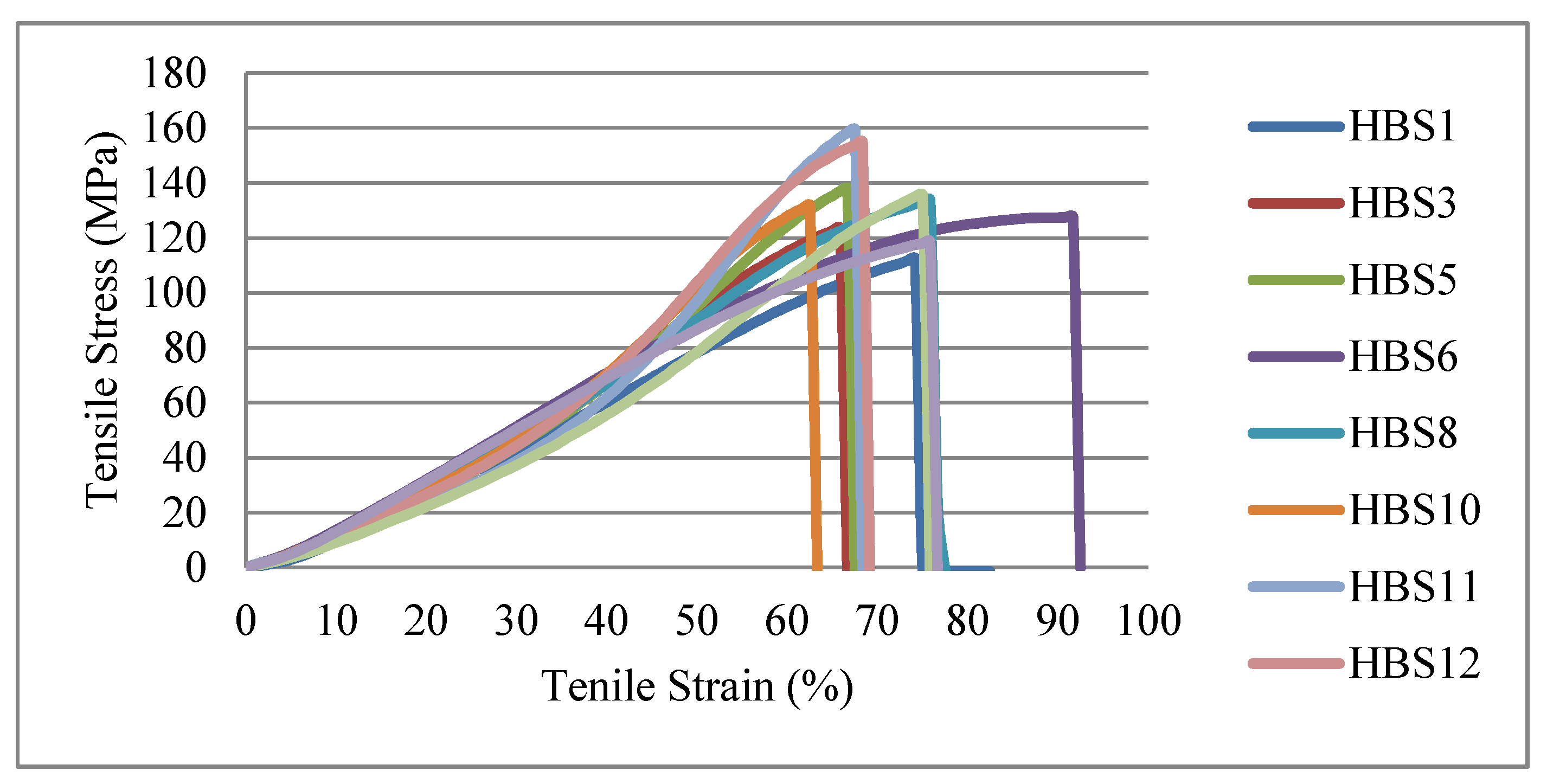

3.1. Maximum Strain

3.2. Ultimate Tensile Strength

3.3. Elastic Modulus

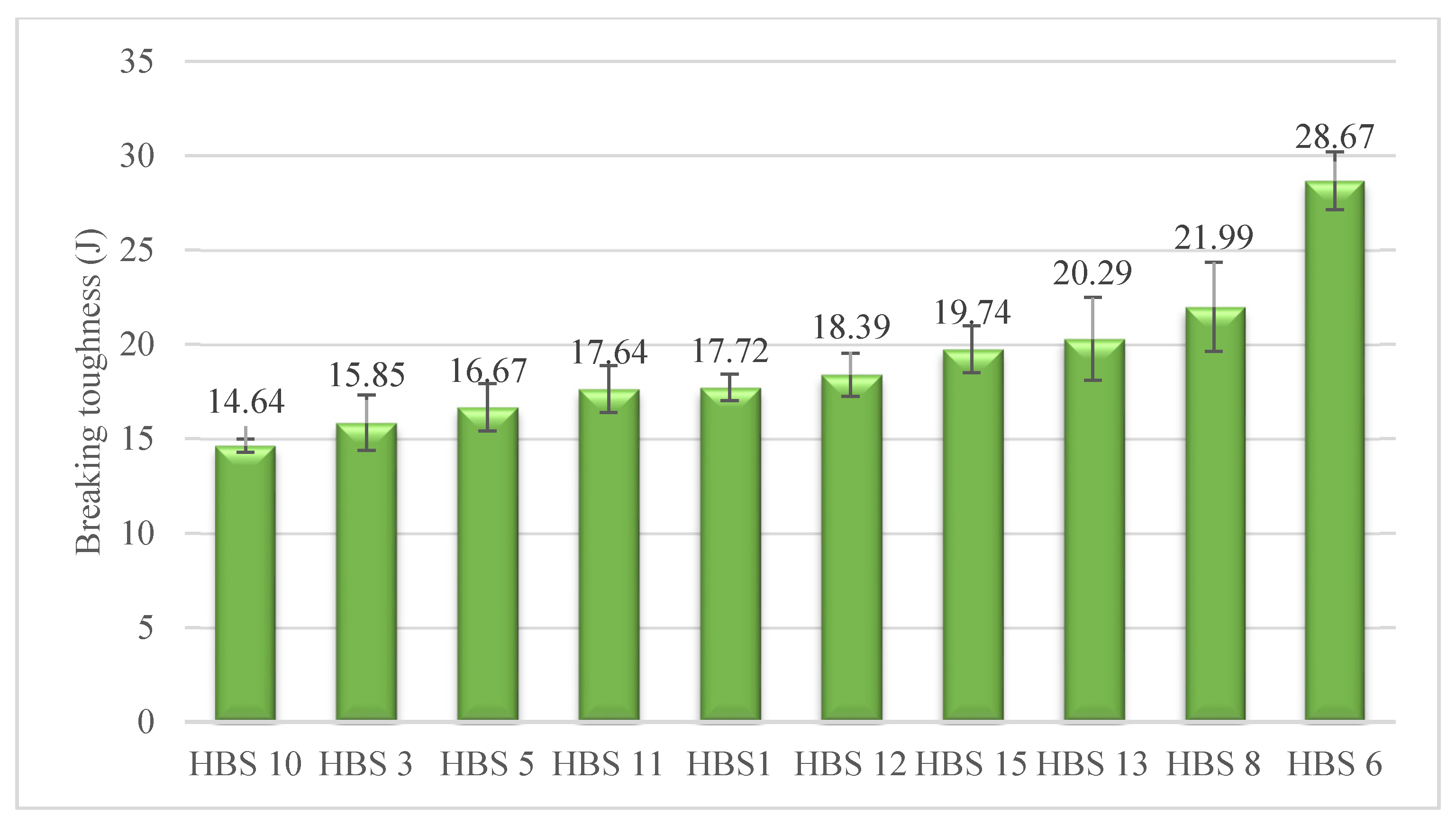

3.4. Breaking Toughness

3.5. Ranking HBSs as Regards Their Tensile Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Joseph, B.; George, A.; Gopi, S.; Kalarikkal, N.; Thomas, S. Polymer Sutures for Simultaneous Wound Healing and Drug Delivery—A Review. Int. J. Pharm. 2017, 524, 454–466. [Google Scholar] [CrossRef] [PubMed]

- Pillai, C.K.S.; Sharma, C.P. Review paper: Absorbable polymeric surgical sutures: Chemistry, production, properties, biodegradability, and performance. J. Biomater. Appl. 2010, 25, 291–366. [Google Scholar] [CrossRef] [PubMed]

- Visco, A.; Scolaro, C.; Giamporcaro, A.; De Caro, S.; Tranquillo, E.; Catauro, M. Threads made with blended biopolymers: Mechanical, physical and biological features. Polymers 2019, 11, 901. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, S.; Anand, S.C. Developments in medical textiles. Text. Prog. 2002, 32, 1–42. [Google Scholar] [CrossRef]

- Gokarneshan, N.; Velumani, K. Recent Innovations in Textile Sutures—An Approach towards Improved Surgical Procedures. Sci. J. Biomed. Eng. Biomed. Sci. 2018, 2, 1–7. [Google Scholar]

- Chellamani, K.P.; Veerasubramanian, D.; Balaji, R.S.V. Surgical Sutures: An overview. J. Acad. Indus. Res. 2013, 1, 778–782. [Google Scholar]

- Greenberg, J.A.; Clark, R.M. Advances in Suture Material for Obstetric and Gynecologic Surgery. Rev. Obstet. Gynecol. 2009, 2, 146. [Google Scholar]

- Traoré, A.S.; Guidoin, M.F.; Marois, Y.; Zhang, Z.; Douville, Y.; Guidoin, R.; King, M.W.; Legrand, A.P. Newly developed hybrid suture without lubricant: Noninvasive in vivo assessment of biocompatibility with multiparametric MR imaging. J. Investig. Surg. 2007, 20, 121–133. [Google Scholar] [CrossRef]

- Karaca, E.; Hockenberger, A.S. Analysis of the fracture morphology of polyamide, polyester, polypropylene, and silk sutures before and after implantation in vivo. J. Biomed. Mater. Res. Part B Appl. Biomater. 2008, 87, 580–589. [Google Scholar] [CrossRef]

- Debbabi, F.; Gargoubi, S.; Hadj Ayed, M.A.; Abdessalem, S.B. Development and characterization of antibacterial braided polyamide suture coated with chitosan-citric acid biopolymer. J. Biomater. Appl. 2017, 32, 384–398. [Google Scholar] [CrossRef]

- Zhong, W. Applications of Braided Structures in Medical Fields. In Braided Structures and Composites: Production, Properties, Mechanics, and Technical Applications; CRC Press: Boca Raton, FL, USA, 2008; pp. 173–195. [Google Scholar]

- Aibibu, D.; Hild, M.; Cherif, C. An overview of braiding structure in medical textile: Fiber-based implants and tissue engineering. In Advances in Braiding Technology, 1st ed.; Woodhead Publishing Series in Textiles: Cambridge, UK, 2016; pp. 171–190. [Google Scholar]

- Rawal, A.; Sibal, A.; Saraswat, H.; Kumar, V. Geometrically controlled tensile response of braided sutures. Mater. Sci. Eng. C 2015, 48, 453–456. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, Y.; Tanaka, Y.; Ohtani, A.; Nakai, A.; Hamada, H. Mechanical properties and fracture behavior of hybrid braided composite tube. In Proceedings of the ICCM International Conferences on Composite Materials, Edinburgh, Scotland, 27–31 July 2009. [Google Scholar]

- Rawal, A.; Saraswat, H.; Sibal, A. Tensile response of braided structures: A review. Text. Res. J. 2015, 85, 2083–2096. [Google Scholar] [CrossRef]

- Omeroglu, S. The effect of braiding parameters on the mechanical properties of braided ropes. Fibres. Text. East. Eur. 2006, 14, 53–57. [Google Scholar]

- Kyosev, Y. Braiding Technology for Textiles; Woodhead Publishing Series in Textiles: Cambridge, UK, 2015. [Google Scholar]

- Del Rosso, S.; Iannucci, L.; Curtis, P.T. Experimental investigation of the mechanical properties of dry microbraids and microbraid reinforced polymer composites. Compos. Struct. 2015, 125, 509–519. [Google Scholar] [CrossRef]

- Basu, A.; Chatterjee, S. A comparative study on primary wound closure by subcuticular suture using different suture materials with emphasis on complications, cosmesis and cost-effectiveness. Hell. J. Surg. 2013, 85, 374–379. [Google Scholar] [CrossRef]

- Viju, S.; Thilagavathi, G. Fabrication and characterization of silk braided sutures. Fibers Polym. 2012, 13, 782–789. [Google Scholar] [CrossRef]

- Abellán, D.; Nart, J.; Pascual, A.; Cohen, R.E.; Sanz-Moliner, J.D. Physical and mechanical evaluation of five suture materials on three knot configurations: An in vitro study. Polymers 2016, 8, 147. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Bruzzaniti, P.; Scalici, T.; Valenza, A. Pinned Hybrid Glass-Flax Composite Laminates Aged in Salt-Fog Environment: Mechanical Durability. Polymers 2020, 12, 40. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Scalici, T.; Valenza, A. Experimental assessment of the improved properties during aging of flax/glass hybrid composite laminates for marine applications. J. Appl. Polym. Sci. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridization in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Sergi, C.; Tirillò, J.; Seghini, M.C.; Sarasini, F.; Fiore, V.; Scalici, T. Durability of basalt/hemp hybrid thermoplastic composites. Polymers 2019, 11, 603. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Wang, W.; Jiang, Q.; Xiang, C.; Lou, C.W. Mechanical characterization and impact damage assessment of hybrid three-dimensional five-directional composites. Polymers 2019, 11, 1395. [Google Scholar] [CrossRef] [PubMed]

- Rawal, A.; Kumar, R.; Saraswat, H. Tensile mechanics of braided sutures. Text. Res. J. 2012, 82, 1703–1710. [Google Scholar] [CrossRef]

- Heward, A.G.; Laing, R.M.; Carr, D.J.; Niven, B.E. Tensile Performance of Nonsterile Suture Monofilaments Affected by Test Conditions. Text. Res. J. 2004, 74, 83–90. [Google Scholar] [CrossRef]

- Abdessalem, S.B.; Debbabi, F.; Jedda, H.; Elmarzougui, S.; Mokhtar, S. Tensile and Knot Performance of Polyester Braided Sutures. Text. Res. J. 2009, 79, 247–252. [Google Scholar] [CrossRef]

- Abdessalem, S.B.; Jedda, H.; Skhiri, S.; Dahmen, J.; Boughamoura, H. Improvement of mechanical performances of braided polyester sutures. Autex. Res. J. 2006, 6, 169–174. [Google Scholar]

- Debbabi, F.; Abdessalem, S.B. Modelling and experimental investigation of mechanical performances of braided polyamide sutures. Indian J. Fibre Text. Res. 2018, 43, 186–193. [Google Scholar]

- Debbabi, F.; Abdessalem, S.B. Simultaneous optimization of mechanical properties of braided polyethylene terephthalate suture subjected to hot-stretching treatment. J. Ind. Text. 2014, 45, 1417–1439. [Google Scholar] [CrossRef]

- Debbabi, F.; Abdessalem, S.B. Effect of manufacturing conditions on structural and handling properties of braided polyamide suture. J. Eng. Fiber. Fabr. 2015, 10, 121–128. [Google Scholar] [CrossRef]

- Debbabi, F.; Abdessalem, S.B. Impact of hot-stretching treatment on physical and mechanical properties of braided polyamide suture. Text. Res. J. 2016, 86, 696–709. [Google Scholar] [CrossRef]

- Kalebek, N.A.; Konur, E.E.; Ozdinc, O. Tensile and knot performance of polyester, silk, polypropylene and polydioxanone sutures. Tekst ve Muhendis 2016, 23, 172–181. [Google Scholar] [CrossRef]

- Sular, V.; Bulut, Y. Tensile, knot, and detaching from needle performances of atraumatic surgical sutures. Int. J. Polym. Mater. Polym. Biomater. 2014, 63, 256–261. [Google Scholar] [CrossRef]

- Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method; ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Hristov, K.; Armstrong-Carroll, E.; Dunn, M.; Pastore, C.; Gowayed, Y. Mechanical Behavior of Circular Hybrid Braids under Tensile Loads. Text. Res. J. 2004, 74, 20–26. [Google Scholar] [CrossRef]

- Nonabsorbable Surgical Suture. United States Pharmacopeia and National Formulary (USP 29-NF 24); National Publishing: Philadelphia, PA, USA, 2006.

- Naleway, S.E.; Lear, W.; Kruzic, J.J.; Maughan, C.B. Mechanical properties of suture materials in general and cutaneous surgery. J. Biomed. Mater. Res. Part B Appl. Biomater. 2015, 103, 735–742. [Google Scholar] [CrossRef] [PubMed]

- Standard Test Method for Breaking Strength and Elongation of Textile Webbing, Tape and Braided Material; ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- Dabiryan, H.; Johari, M.S.; Bakhtiyari, S.; Eskandari, E. Analysis of the tensile behavior of tubular braids using energy method, Part II: Experimental study. J. Text. Inst. 2017, 108, 1899–1904. [Google Scholar] [CrossRef]

- Standard Practice for Conditioning and Testing Textiles; ASTM International: West Conshohocken, PA, USA, 2008.

- Fujita, T. Choosing a better technique for midline abdominal closure. J. Am. Coll. Surg. 2014, 218, 150–152. [Google Scholar] [CrossRef]

- Marom, G.; Fischer, S.; Tuler, F.R.; Wagner, H.D. Hybrid effects in composites: Conditions for positive or negative effects versus rule-of-mixtures behaviour. J. Mater. Sci. 1978, 13, 1419–1426. [Google Scholar] [CrossRef]

- Pan, N.; Chen, K.; Monego, C.J.; Backer, S. The hybrid effects in hybrid fibre composites: Experimental study using twisted fibrous structures. Proc. R. Soc. Lond. A 1998, 454, 1109–1127. [Google Scholar] [CrossRef]

- Nanni, F.; Ruscito, G.; Forte, G.; Gusmano, G. Design, manufacture and testing of self-sensing carbon fibre-glass fibre reinforced polymer rods. Smart Mater. Struct. 2007, 16, 2368–2374. [Google Scholar] [CrossRef]

- Rajpurohit, A.; Joannès, S.; Singery, V.; Sanial, P. Hybrid Effect in In-Plane Loading of Carbon/Glass Fibre Based Inter- and Intraply Hybrid Composites. J. Compos. Sci. 2020, 4, 6. [Google Scholar] [CrossRef]

- Rana, S.; Zdraveva, E.; Pereira, C.; Fangueiro, R.; Correia, A.G. Development of hybrid braided composite rods for reinforcement and health monitoring of structures. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef] [PubMed]

- Afzali Naniz, M.; Safar Johari, M. An experimental study of the fiber hybridization effect on the mechanical performance of the 2D braided tubular composites. Mater. Res. Express 2019, 6. [Google Scholar] [CrossRef]

- Jones, K.D.; DiBenedetto, A.T. Fiber fracture in hybrid composite systems. Compos. Sci. Technol. 1994, 51, 53–62. [Google Scholar] [CrossRef]

- Manders, P.W.; Bader, M.G. The strength of hybrid glass/carbon fibre composites. J. Mater. Sci. 1981, 16, 2233–2245. [Google Scholar] [CrossRef]

- Morton, W.E.; Hearle, J.W.S. Physical Properties of Textile Fibres, 4th ed.; Woodhead Publishing Series in Textiles: Cambridge, UK, 2008. [Google Scholar]

- Pytel, A.; Kiusalaas, J. Mechanics of Materials, 2nd ed.; Cengage Learning, Inc.: Stamford, CT, USA, 2012. [Google Scholar]

- Chu, C.-C.; von Fraunhofer, J.A.; Greisler, H.P. Wound Closure Biomaterials and Devices; CRC Press: New York, NY, USA, 1997. [Google Scholar]

- Greenwald, D.; Shumway, S.; Albear, P.; Gottlieb, L. Mechanical Comparison of 10 Suture Materials before and After in Vivo Incubation. J. Surg. Res. 1994, 56, 372–377. [Google Scholar] [CrossRef] [PubMed]

- Karaca, E.; Hockenberger, A.S.; Yildiz, H. Investigating Changes in Mechanical Properties and Tissue Reaction of Silk, Polyester, Polyamide, and Polypropylene Sutures in Vivo. Text. Res. J. 2005, 75, 297–303. [Google Scholar] [CrossRef]

| Fiber Type | Number of Filament Per Yarn | Tensile Strength (MPa) | Strain at Break (%) | Elastic Modulus (MPa) | Breaking Toughness (MPa) |

|---|---|---|---|---|---|

| Polypropylene | 72 | 420.75 ± 8.45 | 21.36 ± 0.86 | 4145.34 ± 121.97 | 53.65 ± 3.81 |

| Polyamide 6 | 34 | 692.68 ± 21.51 | 18.82 ± 0.99 | 5740.74 ± 143.37 | 55.12 ± 9.53 |

| Polyester | 72 | 483.51 ± 24.63 | 20.25 ± 0.53 | 5890.81 ± 229.86 | 59.54 ± 8.45 |

| Braid ID | Fiber (%) | ||

|---|---|---|---|

| Polyamide 6 | Polypropylene | Polyester | |

| HBS.1 | 0 | 0 | 100 |

| HBS.2 | 12.5 | 12.5 | 75 |

| HBS.3 | 25 | 25 | 50 |

| HBS.4 | 37.5 | 37.5 | 25 |

| HBS.5 | 50 | 50 | 0 |

| HBS.6 | 0 | 100 | 0 |

| HBS.7 | 12.5 | 75 | 12.5 |

| HBS.8 | 25 | 50 | 25 |

| HBS.9 | 37.5 | 25 | 37.5 |

| HBS.10 | 50 | 0 | 50 |

| HBS.11 | 100 | 0 | 0 |

| HBS.12 | 75 | 12.5 | 12.5 |

| HBS.13 | 50 | 25 | 25 |

| HBS.14 | 25 | 37.5 | 37.5 |

| HBS.15 | 0 | 50 | 50 |

| Tensile Parameter | Hierarchy of HBSs |

|---|---|

| Maximum strain | (HBS10, HBS3, HBS5, HBS11, HBS12) < (HBS1, HBS15, HBS8, HBS13) < HBS6 |

| Ultimate tensile strength | HBS1 < HBS15 < HBS3 < (HBS6, HBS10) < HBS8 < (HBS5, HBS13) < HBS12 < HBS11 |

| Elastic modulus | HBS6 < (HBS1, HBS15) < (HBS8, HBS13) < HBS3 < (HBS10, HBS5) < HBS11 < HBS12 |

| Breaking Toughness | HBS10 < (HBS3, HBS5) < (HBS11, HBS1) < HBS12 < (HBS15, HBS13, HBS8) < HBS6 |

| Braid ID | Maximum Strain (%) | Ultimate Tensile Strength (MPa) | Elastic Modulus (MPa) | Total Score |

|---|---|---|---|---|

| HBS.1 | 2 | 1 | 2 | 5 |

| HBS.3 | 1 | 3 | 4 | 8 |

| HBS.5 | 1 | 6 | 5 | 12 |

| HBS.6 | 3 | 4 | 1 | 8 |

| HBS.8 | 2 | 5 | 3 | 10 |

| HBS.10 | 1 | 4 | 5 | 10 |

| HBS.11 | 1 | 8 | 6 | 15 |

| HBS.12 | 1 | 7 | 7 | 15 |

| HBS.13 | 2 | 6 | 3 | 11 |

| HBS.15 | 2 | 2 | 2 | 6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afzali Naniz, M.; Bodaghi, M.; Safar Johari, M.; Zolfagharian, A. Influence of Hybridization on Tensile Behaviors of Non-Absorbable Braided Polymeric Sutures. Polymers 2020, 12, 682. https://doi.org/10.3390/polym12030682

Afzali Naniz M, Bodaghi M, Safar Johari M, Zolfagharian A. Influence of Hybridization on Tensile Behaviors of Non-Absorbable Braided Polymeric Sutures. Polymers. 2020; 12(3):682. https://doi.org/10.3390/polym12030682

Chicago/Turabian StyleAfzali Naniz, Moqaddaseh, Mahdi Bodaghi, Majid Safar Johari, and Ali Zolfagharian. 2020. "Influence of Hybridization on Tensile Behaviors of Non-Absorbable Braided Polymeric Sutures" Polymers 12, no. 3: 682. https://doi.org/10.3390/polym12030682

APA StyleAfzali Naniz, M., Bodaghi, M., Safar Johari, M., & Zolfagharian, A. (2020). Influence of Hybridization on Tensile Behaviors of Non-Absorbable Braided Polymeric Sutures. Polymers, 12(3), 682. https://doi.org/10.3390/polym12030682