Nano- And Microfiber-Based Fully Fabric Triboelectric Nanogenerator For Wearable Devices

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

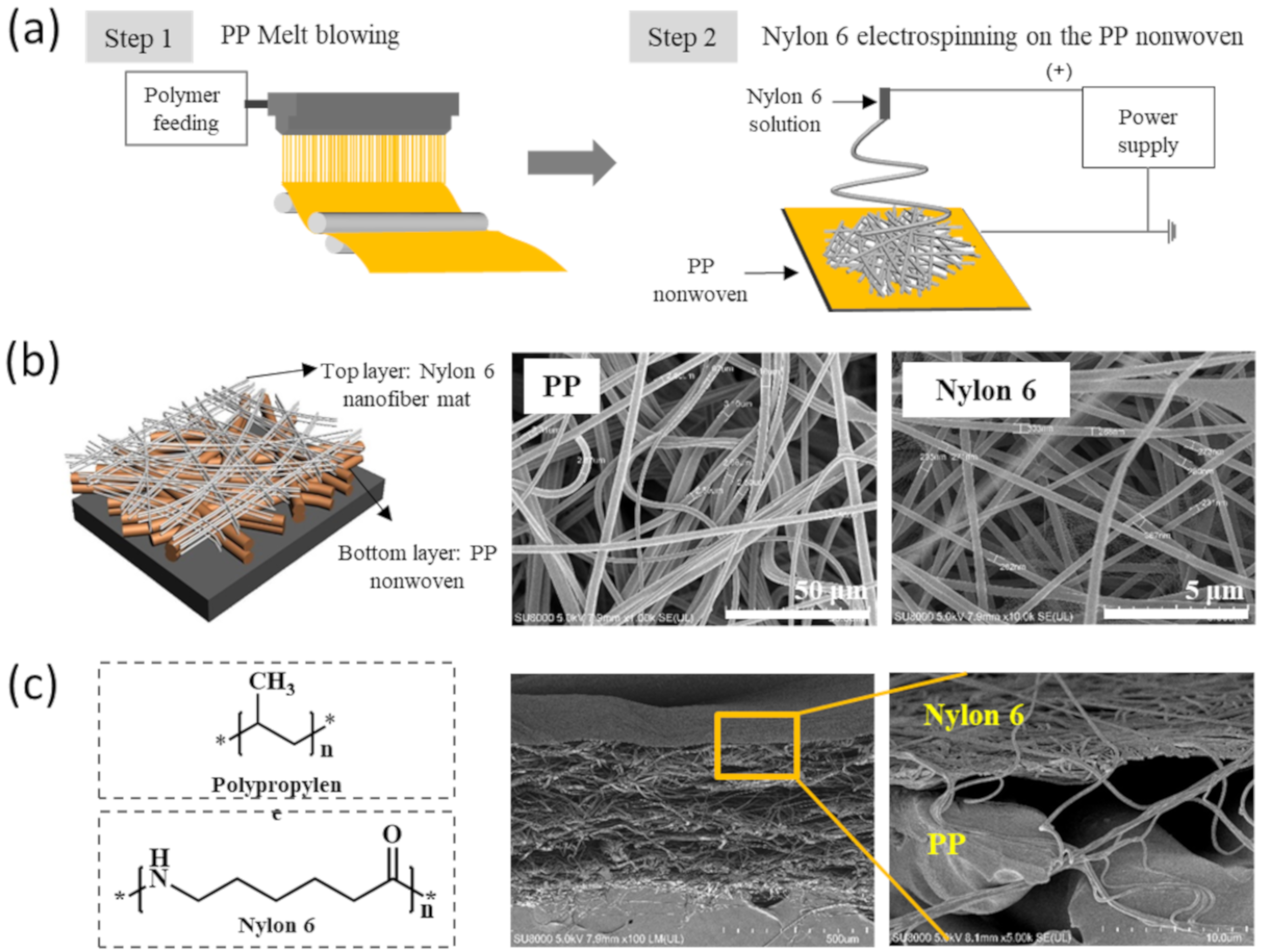

2.2. Fabrication of Nonwoven Triboelectric Layers

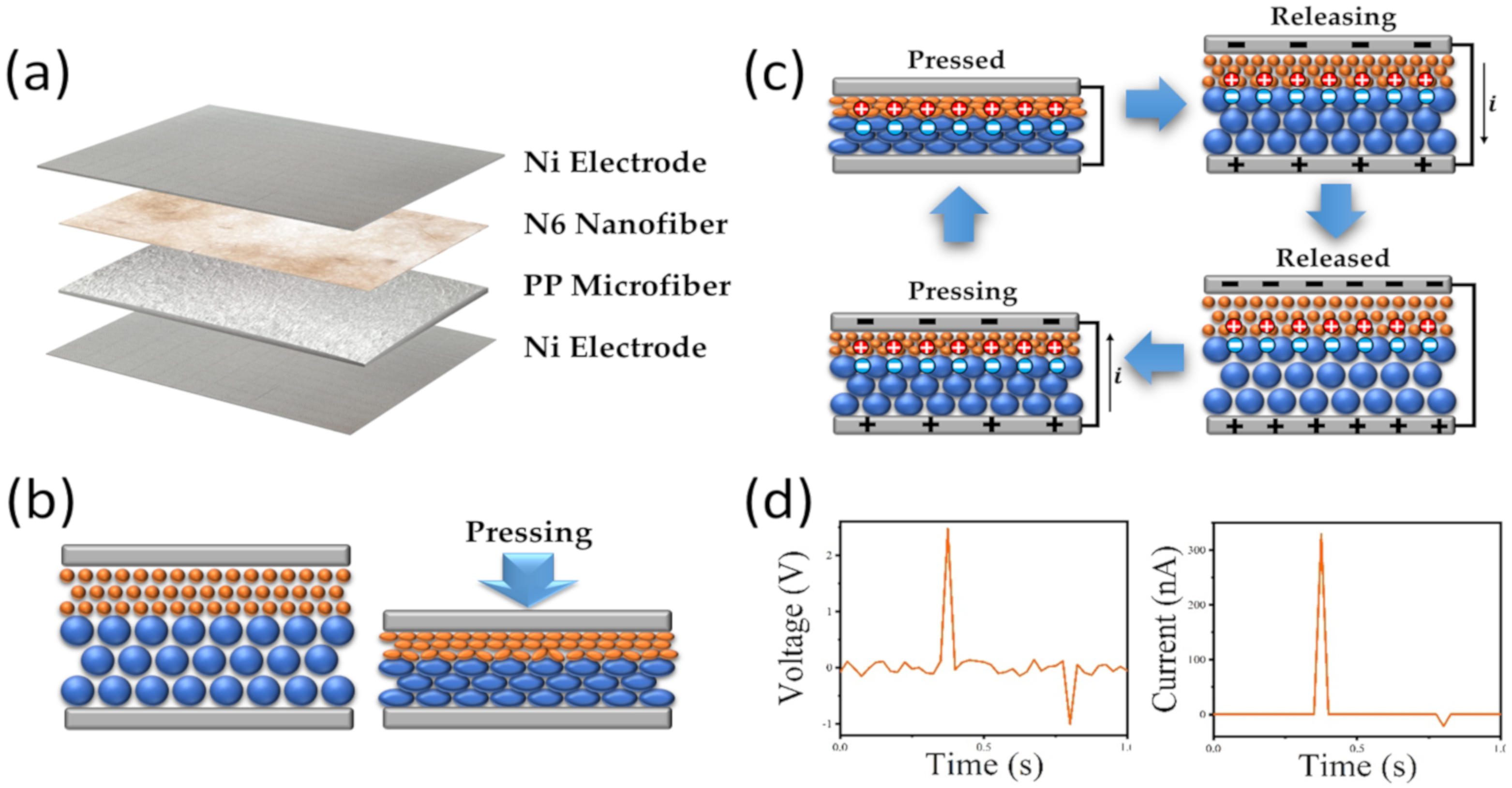

2.3. Fabrication of the NMF-TENGs

2.4. Characterization

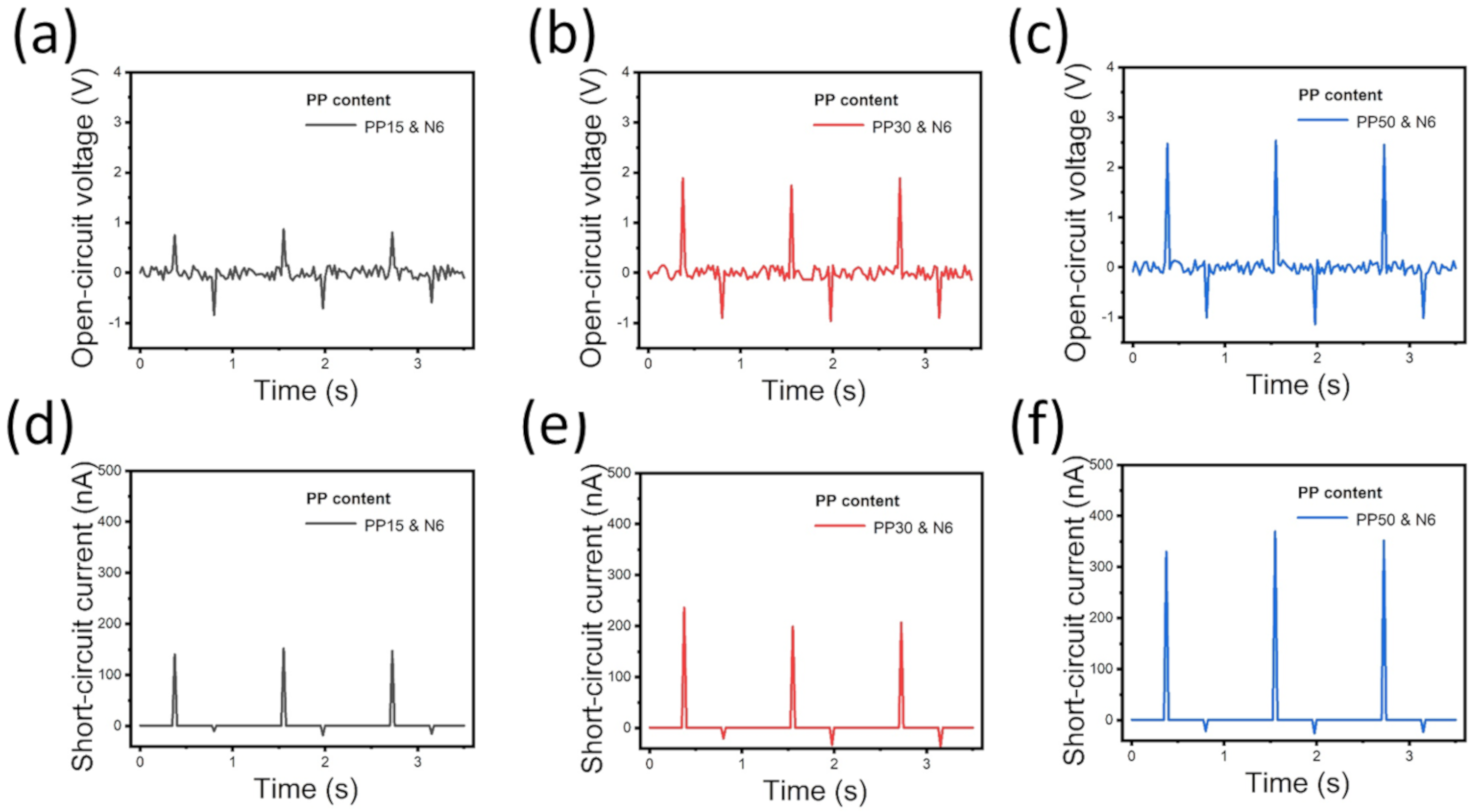

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [PubMed]

- Pang, C.; Lee, C.; Suh, K.-Y. Recent Advances in flexible sensors for wearable and implantable devices. J. Appl. Polym. Sci. 2013, 130, 1429–1441. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Najafabadi, A.I.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Ryu, S.; Lee, P.; Chou, J.B.; Xu, R.; Zhao, R.; Hart, A.J.; Kim, S.-G. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion. ACS Nano 2015, 9, 5929–5936. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Huang, X.H.; Ma, C.W.; Yang, Y.J. A flexible capacitive tactile sensing array with floating electrodes. J. Micromech. Microeng. 2009, 19, 115001. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile sensing-from humans to humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- Li, Z.; Shen, J.; Abdalla, I.; Yu, J.; Ding, B. Nanofibrous membrane constructed wearable triboelectric nanogenerator for high performance biomechanical energy harvesting. Nano Energy 2017, 36, 341–348. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Lee, T. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef]

- Wang, C.; Hu, K.; Zhao, C.; Zou, Y.; Liu, Y.; Qu, X.; Jiang, D.; Li, Z.; Zhang, M.-R.; Li, Z. Customization of conductive elastomer based on PVA/PEI for stretchable sensors. Small 2020, 16, 1904758. [Google Scholar] [CrossRef]

- Zhao, L.; Li, H.; Meng, J.; Li, Z. The recent advances in self-powered medical information sensors. InfoMat 2020, 2, 212–234. [Google Scholar] [CrossRef]

- Pu, X.; Liu, M.; Li, L.; Han, S.; Li, X.; Jiang, C.; Du, C.; Luo, J.; Hu, W.; Wang, Z.L. Wearable textile-based in-plane microsupercapacitors. Adv. Energy Mater. 2016, 6, 1601254. [Google Scholar] [CrossRef]

- Pu, X.; Li, L.; Liu, M.; Jiang, C.; Du, C.; Zhao, Z.; Hu, W.; Wang, Z.L. Wearable self-charging power textile based on flexible yarn supercapacitors and fabric nanogenerators. Adv. Mater. 2016, 28, 98–105. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Huang, Y.; Zhang, N.; Zou, N.; Liu, R.; Tao, C.; Fan, X.; Wang, Z.L. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nat. Energy 2016, 1, 16138. [Google Scholar] [CrossRef]

- Liu, L.; Yu, Y.; Yan, C.; Li, K.; Zheng, Z. Wearable energy-dense and power-dense supercapacitor yarns enabled by scalable graphene–metallic textile composite electrodes. Nat. Commun. 2015, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Wu, Y.S.; Kan, E.C.; Fan, J. Breathable and flexible piezoelectric ZnO@PVDF fibrous nanogenerator for wearable applications. Polymers 2018, 10, 745. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.; Ding, Y.; Bian, J.; Xu, Z.; Yin, Z.; Huang, Y. Ultra-stretchable piezoelectric nanogenerators via large-scale aligned fractal inspired micro/nanofibers. Polymers 2017, 9, 714. [Google Scholar] [CrossRef]

- He, J.; Qian, S.; Niu, X.; Zhang, N.; Qian, J.; Hou, X.; Mu, J.; Geng, W.; Chou, X. Piezoelectric-enhanced triboelectric nanogenerator fabric for biomechanical energy harvesting. Nano Energy 2019, 64, 103933. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, C.; Han, C.B.; Fan, F.R.; Tang, W.; Wang, Z.L. Woven structured triboelectric nanogenerator for wearable devices. ACS Appl. Mater. Inter. 2014, 6, 14695–14701. [Google Scholar] [CrossRef]

- Jeong, J.; Kwon, J.H.; Lim, K.; Biswas, S.; Tibaldi, A.; Lee, S.; Oh, H.J.; Kim, J.; Ko, J.; Lee, D.; et al. Comparative study of triboelectric nanogenerators with differently woven cotton textiles for wearable electronics. Polymers 2019, 11, 1443. [Google Scholar] [CrossRef]

- Yang, P.K.; Lin, Z.H.; Pradel, K.C.; Lin, L.; Li, X.; Wen, X.; He, J.; Wang, Z.L. Paper-based origami triboelectric nanogenerators and self-powered pressure sensors. ACS Nano 2015, 9, 901–907. [Google Scholar] [CrossRef]

- Li, C.; Cao, R.; Zhang, X. Breathable materials for triboelectric effect-based wearable electronics. Appl. Sci 2018, 8, 2485. [Google Scholar] [CrossRef]

- Zheng, Q.; Zou, Y.; Zhang, Y.; Liu, Z.; Shi, B.; Wang, X.; Jin, Y.; Quyang, H.; Li, Z.; Wang, Z.L. Biodegradable triboelectric nanogenerator as a life-time designed implantable power source. Sci. Adv. 2016, 2, e1501478. [Google Scholar] [CrossRef]

- Cho, S.; Yun, Y.; Jang, S.; Ra, Y.; Choi, J.H.; Hwang, H.J.; Choi, D.; Choi, D. Universal biomechanical energy harvesting from joint movements using a direction-switchable triboelectric nanogenerator. Nano Energy 2020, 71, 104584. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors–Principles, problems and perspectives. Faraday Discuss. 2015, 176, 447–458. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Lin, L.; Xie, Y.; Jing, Q.; Niu, S.; Wang, Z.L. Sliding-triboelectric nanogenerators based on in-plane charge-separation mechanism. Nano Lett. 2013, 13, 2226–2233. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, H.; Chen, J.; Jing, Q.; Zhou, Y.S.; Wen, X.; Wang, Z.L. Single-electrode-based sliding triboelectric nanogenerator for self-powered displacement vector sensor system. ACS Nano 2013, 7, 7342–7351. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, J.; Du, X.; Wang, J.; Cao, R.; Yin, Y.; Zhang, X.; Yuan, Z.; Xing, Y.; Pui, D.Y.H.; et al. All-nanofiber-based ultralight stretchable triboelectric nanogenerator for self-powered wearable electronics. ACS Appl. Energy Mater. 2018, 1, 2326–2332. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, Y.; Song, W.; Wang, H.; Gao, M.; Cho, M.; Park, I. Zinc oxide-enhanced piezoelectret polypropylene microfiber for mechanical energy harvesting. ACS Appl. Mater. Inter. 2018, 10, 19940–19947. [Google Scholar] [CrossRef]

- Kang, H.; Kim, H.; Kim, S.; Shin, H.J.; Cheon, S.; Huh, J.H.; Lee, D.Y.; Lee, S.; Kim, S.-W.; Cho, J.H. Mechanically robust silver nanowires network for triboelectric nanogenerators. Adv. Funct. Mater. 2016, 26, 7717–7724. [Google Scholar] [CrossRef]

- Lee, K.Y.; Chun, J.; Lee, J.H.; Kim, K.N.; Kang, N.R.; Kim, J.Y.; Kim, M.H.; Shin, K.-S.; Gupta, M.K.; Baik, J.M.; et al. Hydrophobic sponge structure-based triboelectric nanogenerator. Adv. Mater. 2014, 26, 5037–5042. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Lin, Z.H.; Jing, Q.; Bai, P.; Pan, C.; Yang, Y.; Zhou, Y.; Wang, Z.L. Toward large-scale energy harvesting by a nanoparticle-enhanced triboelectric nanogenerator. Nano Lett. 2013, 13, 847–853. [Google Scholar] [CrossRef] [PubMed]

- Chun, J.; Ye, B.U.; Lee, J.W.; Choi, D.; Kang, C.Y.; Kim, S.W.; Wang, Z.L.; Baik, J.M. Boosted output performance of triboelectric nanogenerator via electric double layer effect. Nat. Commun. 2016, 7, 12985. [Google Scholar] [CrossRef] [PubMed]

- Zhong, J.; Zhang, Y.; Zhong, Q.; Hu, Q.; Hu, B.; Wang, Z.L.; Zhou, J. Fiber-based generator for wearable electronics and mobile medication. ACS Nano 2014, 8, 6273–6280. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, M.; Qiu, Q.; Yu, J.; Ding, B. Multilayered fiber-based triboelectric nanogenerator with high performance for biomechanical energy harvesting. Nano Energy 2018, 53, 726–733. [Google Scholar] [CrossRef]

- Huang, T.; Wang, C.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. Human walking-driven wearable all-fiber triboelectric nanogenerator containing electrospun polyvinylidene fluoride piezoelectric nanofibers. Nano Energy 2015, 14, 226–235. [Google Scholar] [CrossRef]

- Ye, B.U.; Kim, B.J.; Ryu, J.; Lee, J.Y.; Baik, J.M.; Hong, K. Electrospun ion gel nanofibers for flexible triboelectric nanogenerator: Electrochemical effect on output power. Nanoscale 2015, 7, 16189–16194. [Google Scholar] [CrossRef] [PubMed]

- Quan, T.; Wang, X.; Wang, Z.L.; Yang, Y. Hybridized electromagnetic–triboelectric nanogenerator for a self-powered electronic watch. ACS Nano 2015, 9, 12301–12310. [Google Scholar] [CrossRef]

- Shen, J.; Li, Z.; Yu, J.; Ding, B. Humidity-resisting triboelectric nanogenerator for high performance biomechanical energy harvesting. Nano Energy 2017, 40, 282–288. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Z.L.; Yang, Y.A. A one-structure-based hybridized nanogenerator for scavenging mechanical and thermal energies by triboelectric–piezoelectric–pyroelectric effects. Adv. Mater. 2016, 28, 2881–2887. [Google Scholar] [CrossRef] [PubMed]

- Cheon, S.; Kang, H.; Kim, H.; Son, Y.; Lee, J.Y.; Shin, H.J.; Kim, S.; Cho, J.H. High-performance triboelectric nanogenerators based on electrospun polyvinylidene fluoride–silver nanowire composite nanofibers. Adv. Funct. Mater. 2018, 28, 1703778. [Google Scholar] [CrossRef]

- Zheng, Y.; Cheng, L.; Yuan, M.; Wang, Z.; Zhang, L.; Qin, Y.; Jing, T. An electrospun nanowire-based triboelectric nanogenerator and its application in a fully self-powered UV detector. Nanoscale 2014, 6, 7842–7846. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Qu, J.; Daoud, W.A.; Wang, L.; Qi, T. Flexible composite-nanofiber based piezo-triboelectric nanogenerators for wearable electronics. J. Mater. Chem. A 2019, 7, 13347–13355. [Google Scholar] [CrossRef]

- Yan, S.; Lu, J.; Lu, J.; Song, W.; Xiao, R. Flexible triboelectric nanogenerator based on cost-effective thermoplastic polymeric nanofiber membranes for body-motion energy harvesting with high humidity-resistance. Nano Energy 2018, 18, 248–255. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, B.; Wang, N.; Kang, W.; Zhang, W.; Xing, K.; Yang, W. Development and performance study of polypropylene/polyester bicomponent melt-blowns for filtration. J. Appl. Polym. Sci. 2012, 124, 296–301. [Google Scholar] [CrossRef]

- Moreira, A.C.F.; Dartora, P.C.; dos Santos, F.P. Polyethylenes in blown films: Effect of molecular structure on sealability and crystallization kinetics. Polym. Eng. Sci. 2017, 57, 52–59. [Google Scholar] [CrossRef]

- Feng, J. Preparation and properties of poly(lactic acid) fiber melt blown non-woven disordered mats. Mater. Lett. 2017, 189, 180–183. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Lian, M.; Zheng, G.; Dai, K.; Guo, Z.; Liu, C.; Shen, C. Continuous fabrication of polymer microfiber bundles with interconnected microchannels for oil/water separation. Appl. Mater. Today 2017, 9, 77–81. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, H.; Wang, Z.; Zheng, G.; Liu, P.; Dai, K.; Liu, C.; Shen, C. Bioinspired concentric-cylindrical multilayered scaffolds with controllable architectures: Facile preparation and biological applications. ACS Appl. Mater. Interfaces 2018, 10, 43512–43522. [Google Scholar] [CrossRef]

- Test Methods for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test; ASTM F3160–3; ASTM International: West Conshohocken, PA, USA, 2011.

- Garcia, C.; Trendafilova, I.; de Villoria, R.G.; Sanchez del Rio, J. Self-powered pressure sensor based on the triboelectric effect and its analysis using dynamic mechanical analysis. Nano Energy 2018, 50, 401–409. [Google Scholar] [CrossRef]

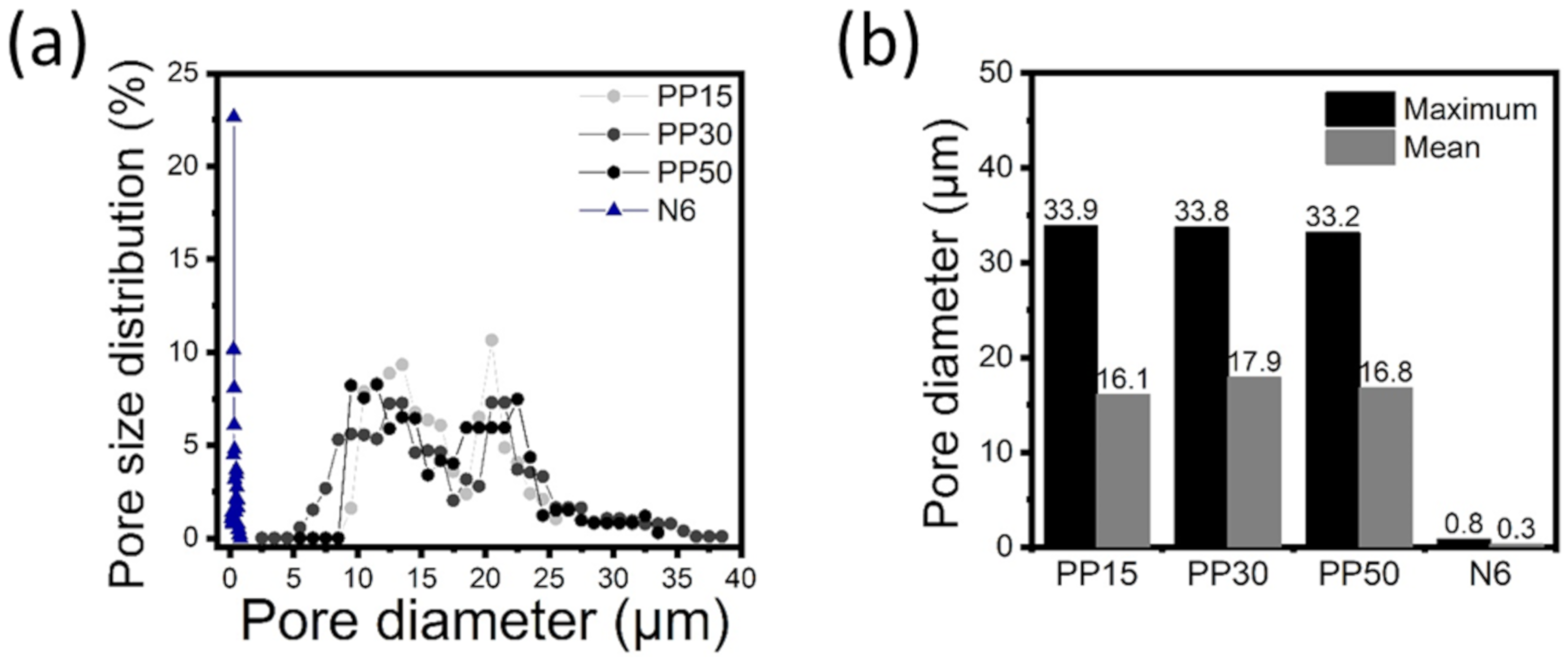

| Label | Diameter | Thickness (μm) | Air Permeability (l/m2/s) | Mean Pore Size | Maximum Pore Size | Porosity (%) |

|---|---|---|---|---|---|---|

| PP15 | 2.4 ± 0.2 μm | 180 | 766.3 ± 42.7 | 16.1 | 34.0 | 74.8 |

| PP30 | 2.7 ± 0.2 μm | 350 | 367.7 ± 17.2 | 17.9 | 33.8 | 77.3 |

| PP50 | 2.7 ± 0.5 μm | 600 | 266.0 ± 17.9 | 16.8 | 33.2 | 80.3 |

| Nylon 6 | 283.8 ± 13.6 nm | 80 | 86.6 ± 2.1 | 0.3 | 0.8 | 87.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, J.H.; Oh, H.J.; Song, J.; Kim, D.K.; Yeang, B.J.; Ko, J.H.; Kim, S.H.; Lee, W.; Lim, S.J. Nano- And Microfiber-Based Fully Fabric Triboelectric Nanogenerator For Wearable Devices. Polymers 2020, 12, 658. https://doi.org/10.3390/polym12030658

Bae JH, Oh HJ, Song J, Kim DK, Yeang BJ, Ko JH, Kim SH, Lee W, Lim SJ. Nano- And Microfiber-Based Fully Fabric Triboelectric Nanogenerator For Wearable Devices. Polymers. 2020; 12(3):658. https://doi.org/10.3390/polym12030658

Chicago/Turabian StyleBae, Jong Hyuk, Hyun Ju Oh, Jinkyu Song, Do Kun Kim, Byeong Jin Yeang, Jae Hoon Ko, Seong Hun Kim, Woosung Lee, and Seung Ju Lim. 2020. "Nano- And Microfiber-Based Fully Fabric Triboelectric Nanogenerator For Wearable Devices" Polymers 12, no. 3: 658. https://doi.org/10.3390/polym12030658

APA StyleBae, J. H., Oh, H. J., Song, J., Kim, D. K., Yeang, B. J., Ko, J. H., Kim, S. H., Lee, W., & Lim, S. J. (2020). Nano- And Microfiber-Based Fully Fabric Triboelectric Nanogenerator For Wearable Devices. Polymers, 12(3), 658. https://doi.org/10.3390/polym12030658