Tensile Mechanical Behaviour of Multi-Polymer Sandwich Structures via Fused Deposition Modelling

Abstract

1. Introduction

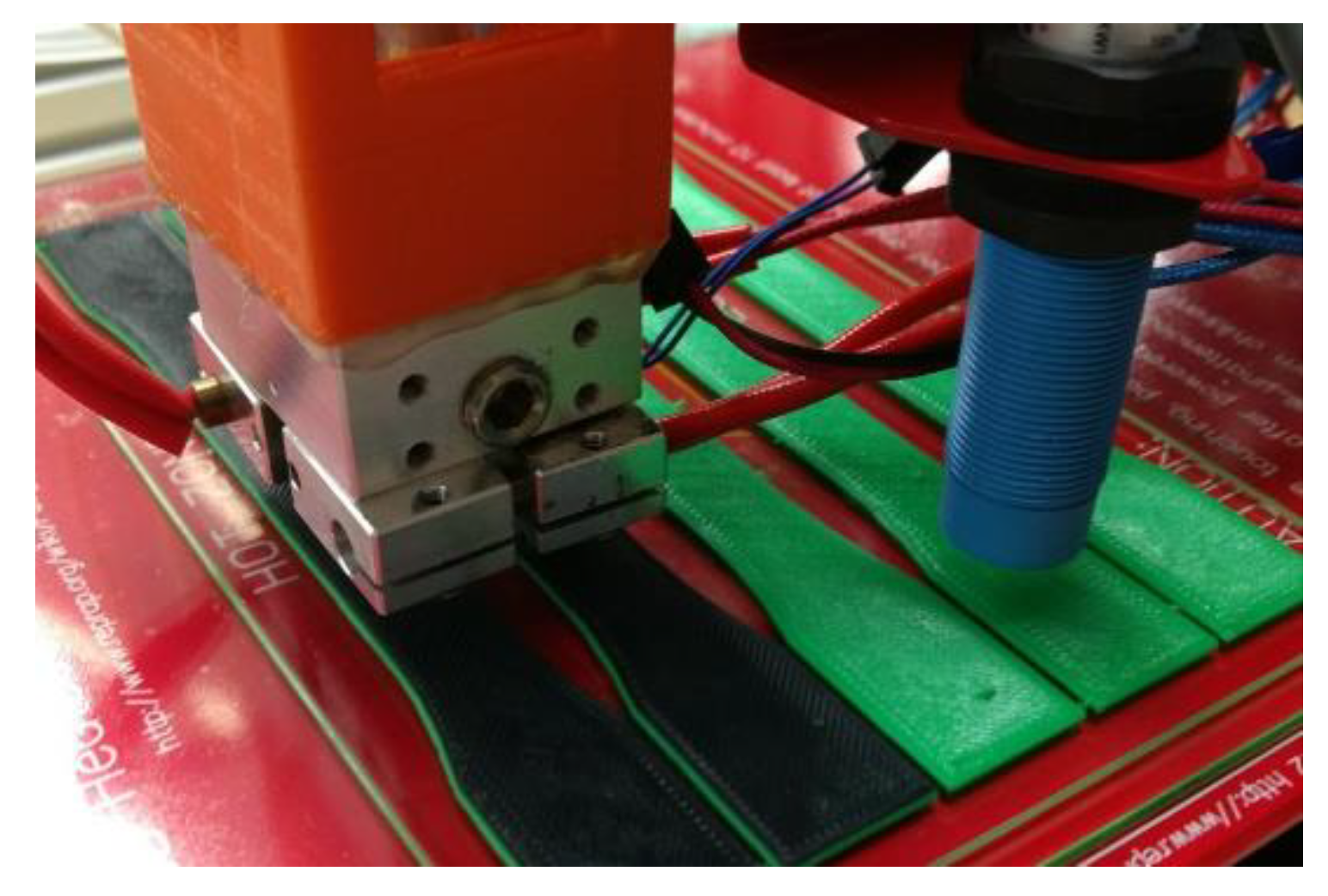

2. Materials and Methods

- PLA-ABS-PLA and PLA-HIPS-PLA

- ABS-PLA-ABS and ABS-HIPS-ABS

- HIPS-PLA-HIPS and HIPS-ABS-HIPS

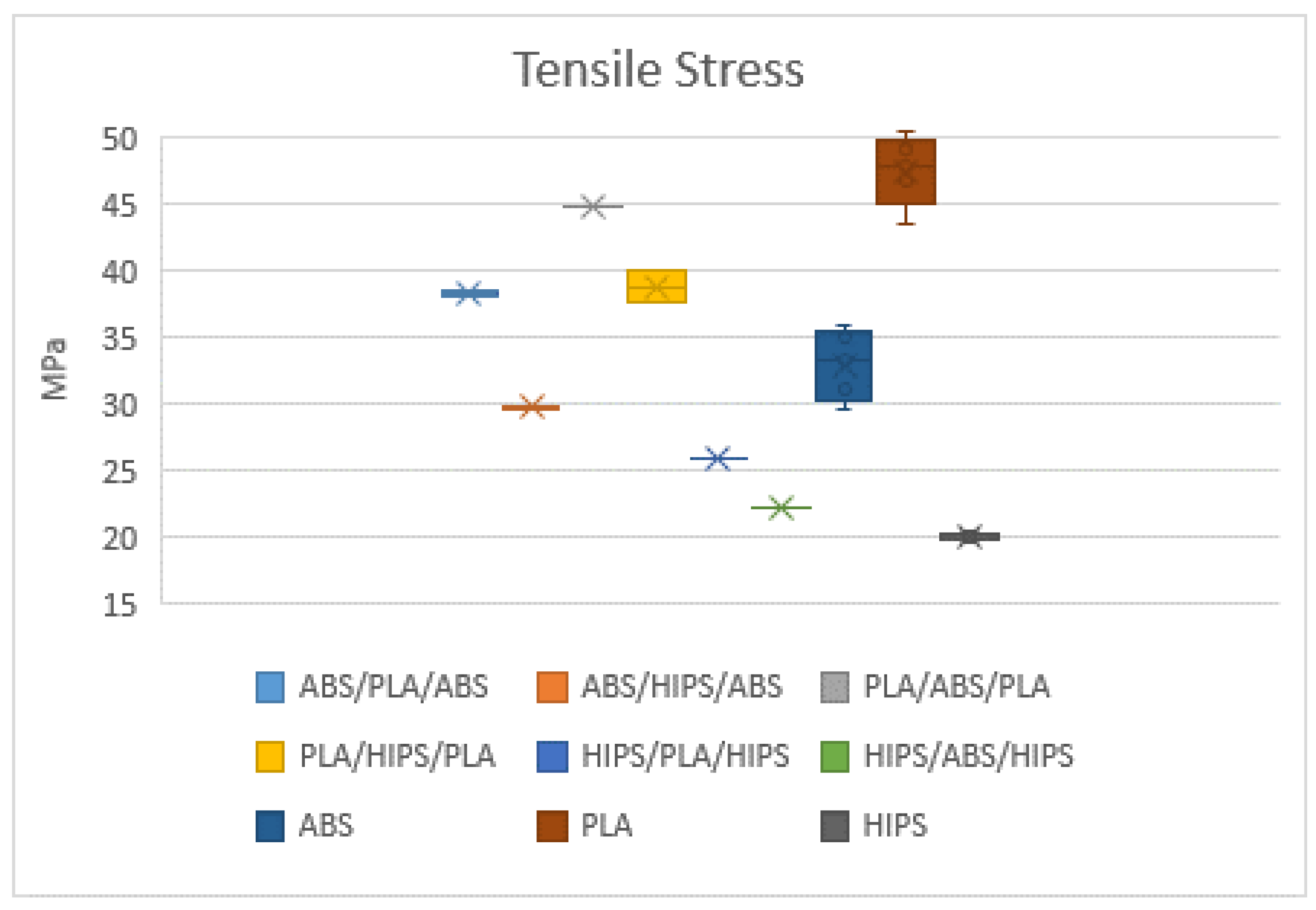

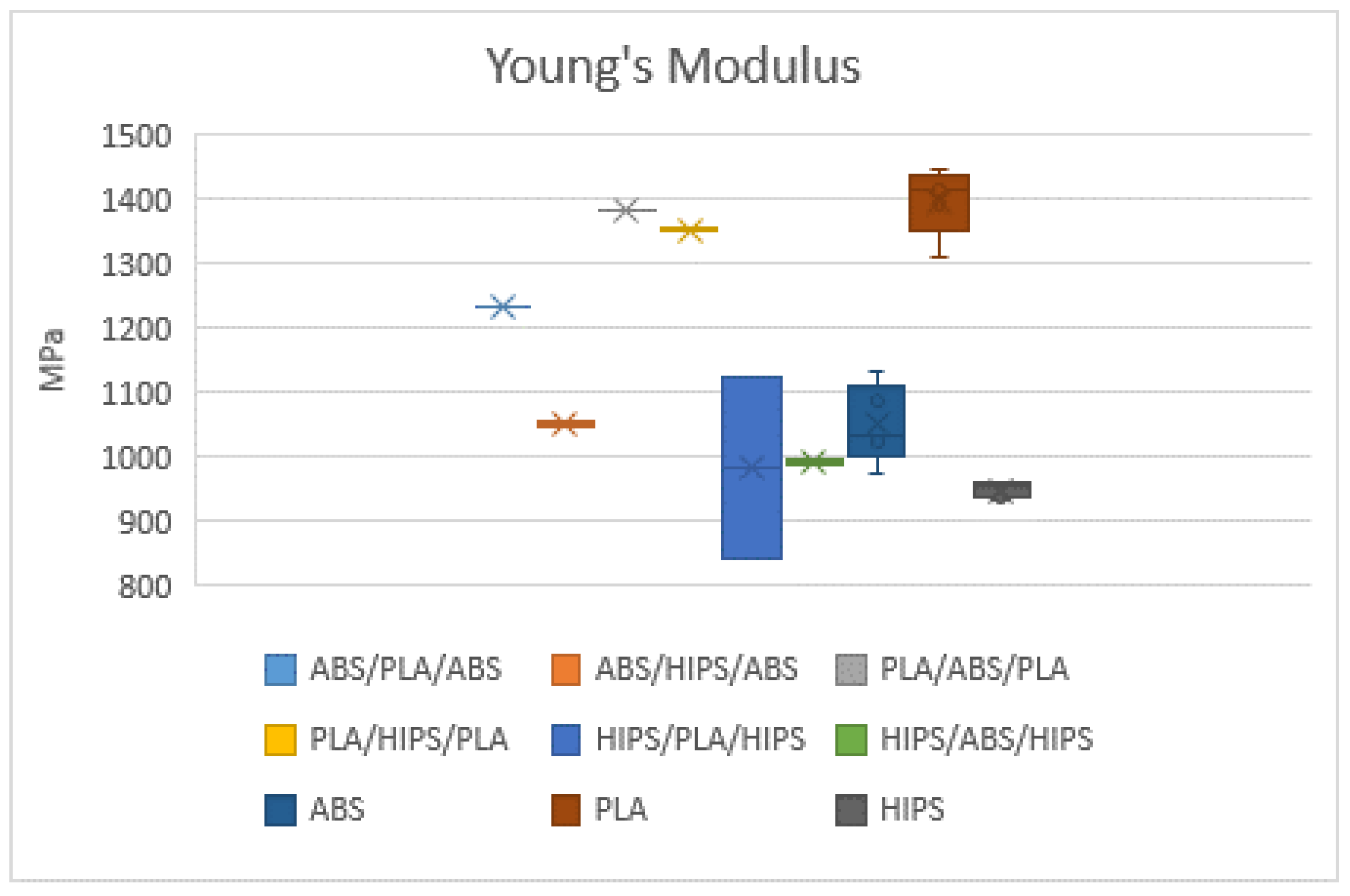

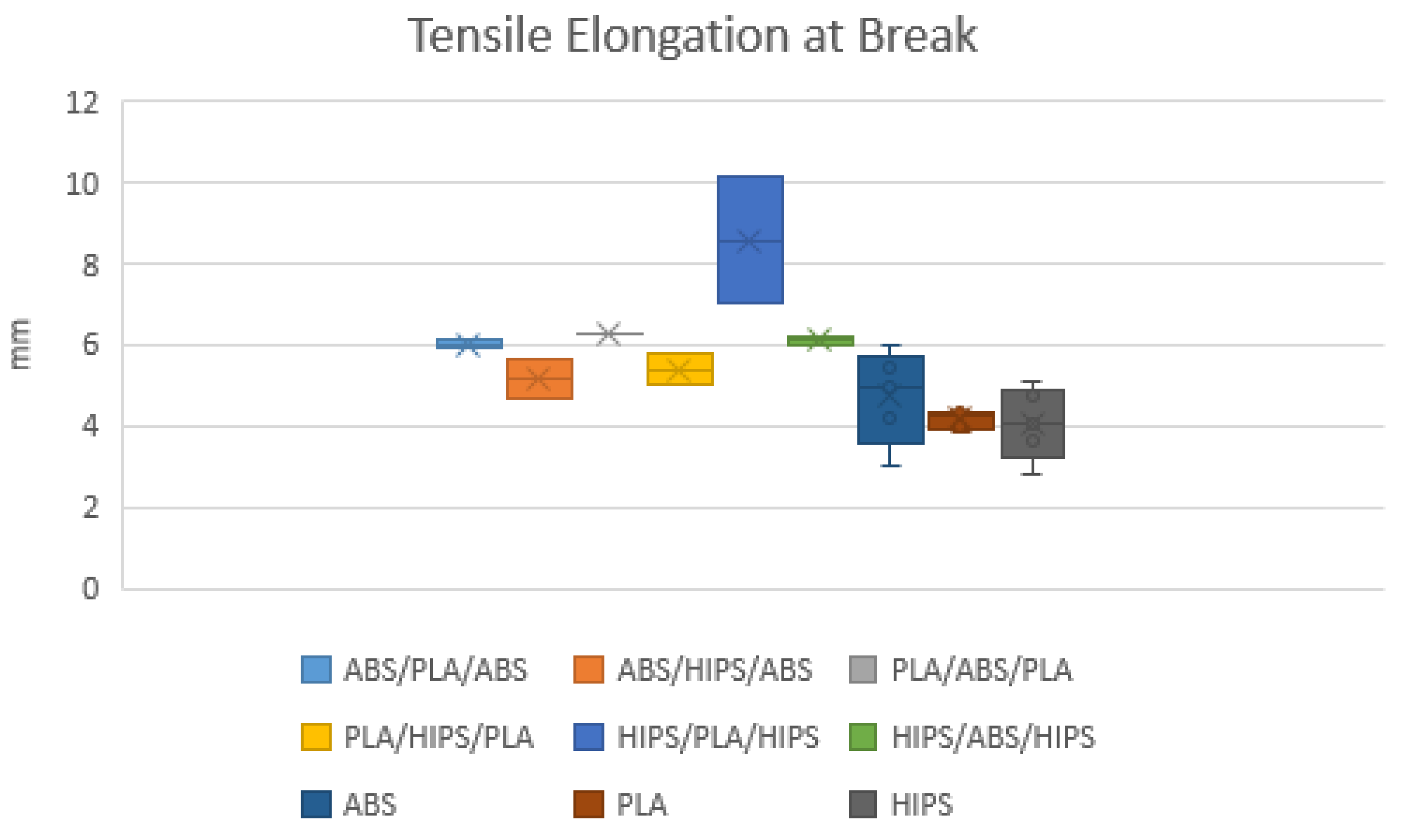

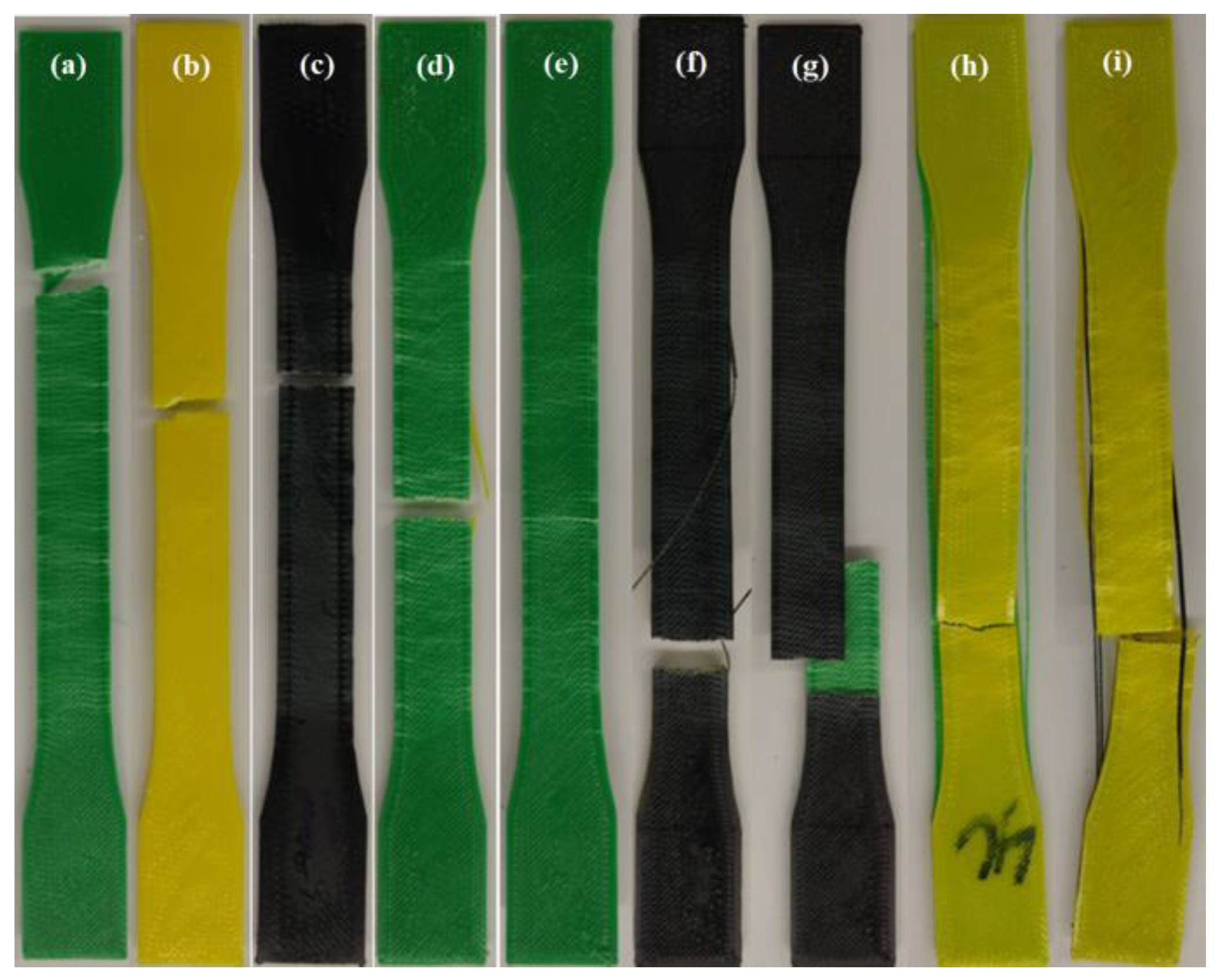

3. Results

Experimental

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gebhardt, A.; Kessler, J.; Thurn, L. Basics of 3D printing technology. In 3D Printing Understanding Additive Manufacturing, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2019; pp. 1–32. [Google Scholar]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Ng, W.L.; Chua, C.K.; Shen, Y.F. Print me an organ! Why we are not there yet. Prog. Polym. Sci. 2019, 97, 101145. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B. Design for additive manufacturing: Trends, opportunities, considerations, and constraints. Cirp Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Strong, D.; Kay, M.; Conner, B.; Wakefield, T.; Manogharan, G. Hybrid manufacturing—Integrating traditional manufacturers with additive manufacturing (AM) supply chain. Addit. Manuf. 2018, 21, 159–173. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, Y.; Ma, Y.; Qureshi, A.; Ahmad, R. A topology optimization method for hybrid subtractive–additive remanufacturing. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 2019. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Singh, R.; Singh, J.; Singh, S. Investigation for dimensional accuracy of AMC prepared by FDM assisted investment casting using nylon-6 waste based reinforced filament. Meas. J. Int. Meas. Confed. 2016, 78, 253–259. [Google Scholar] [CrossRef]

- Alghamdy, M.; Ahmad, R.; Alsayyed, B. Material selection methodology for additive manufacturing applications. Procedia CIRP 2019, 84, 486–490. [Google Scholar] [CrossRef]

- Peron, M.; Torgersen, J.; Berto, F. Assessment of tensile and fatigue behavior of PEEK specimens in a physiologically relevant environment. Frat. Integrita Strutt. 2019, 13, 425–436. [Google Scholar] [CrossRef]

- Stoia, D.I.; Linul, E.; Marsavina, L. Influence of manufacturing parameters on mechanical properties of porous materials by selective laser sintering. Materials 2019, 12, 817. [Google Scholar] [CrossRef] [PubMed]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Wei, Y.; Li, Y. 3D printing of shape memory polymer for functional part fabrication. Int. J. Adv. Manuf. Technol. 2016, 84, 2079–2095. [Google Scholar] [CrossRef]

- Liu, J.; Ma, Y.; Qureshi, A.J.; Ahmad, R. Light-weight shape and topology optimization with hybrid deposition path planning for FDM parts. Int. J. Adv. Manuf. Technol. 2018, 97, 1123–1135. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. The use of multiple materials in additive manufacturing. In Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing; Springer: Berlin, Germany, 2010; pp. 423–436. [Google Scholar]

- Biron, M. Plastics solutions for practical problems. In Thermoplastics and Thermoplastic Composites, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 883–1038. [Google Scholar]

- Kaw, A.K.; Group, F. Failure, analysis, and design of laminates. In Mechanics of Composite Materials, 2nd ed.; CRC/Taylor & Francis: Boca Raton, FL, USA, 2006; pp. 419–425. [Google Scholar]

- Ashby, M. Sandwich structures. In Metal Foams: A Design Guide; Butterworth-Heinemann: Boston, UK, 2000; pp. 113–149. [Google Scholar]

- Daniel, I.M.; Abot, J.L. Fabrication, testing and analysis of composite sandwich beams. Compos. Sci. Technol. 2000, 60, 2455–2463. [Google Scholar] [CrossRef]

- Herranen, H.; Pabut, O.; Eerme, M.; Majak, J.; Pohlak, M.; Saarna, M.; Allikas, G.; Aruniit, A. Design and testing of sandwich structures with different core materials. Medziagotyra 2012, 18, 45–50. [Google Scholar] [CrossRef][Green Version]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Tavitov, A.G.; Urzhumtsev, O.D.; Mikhalin, M.V.; Solonin, A.N. Design and fabrication of strong parts from poly (lactic acid) with a desktop 3D printer: A case with interrupted shell. Polymers 2019, 11, 760. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, L.; Fuh, J.Y.H.; Lee, H.P. Effect of porosity on mechanical properties of 3D printed polymers: Experiments and micromechanical modeling based on X-ray computed tomography analysis. Polymers 2019, 11, 1154. [Google Scholar] [CrossRef]

- Fernandez-Vicente, M.; Calle, W.; Ferrandiz, S.; Conejero, A. Effect of infill parameters on tensile mechanical behavior in desktop 3d printing. 3D Print. Addit. Manuf. 2016, 3, 183–192. [Google Scholar] [CrossRef]

- Kim, H.; Park, E.; Kim, S.; Park, B.; Kim, N.; Lee, S. Experimental study on mechanical properties of single- and dual-material 3d printed products. Procedia Manuf. 2017, 10, 887–897. [Google Scholar] [CrossRef]

- Lopes, L.R.; Silva, A.F.; Carneiro, O.S. Multi-material 3D printing: The relevance of materials affinity on the boundary interface performance. Addit. Manuf. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-material additive manufacturing of sustainable innovative materials and structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R. On the 3D printing of recycled ABS, PLA and HIPS thermoplastics for structural applications. PSU Res. Rev. 2018, 2, 115–137. [Google Scholar] [CrossRef]

- Saad, N.A.; Sabah, A. An investigation of new design of light weight structure of (ABS/PLA) by using of three dimensions printing. In Proceedings of the 13th International Conference “Standardization, Prototypes and Quality: A Means of Balkan Countries’ Collaboration”, Brasov, Romania, 3–4 November 2016; pp. 482–487. [Google Scholar]

- Brischetto, S.; Ferro, C.G.; Torre, R.; Maggiore, P. 3D FDM production and mechanical behavior of polymeric sandwich specimens embedding classical and honeycomb cores. Curved Layer. Struct. 2018, 5, 80–94. [Google Scholar] [CrossRef]

- Santosh, R.V.N.; Sarojini, J.; Vikram, K.A.; Lakshmi, V.V.K. Evaluating the mechanical properties of commonly used 3D printed ABS and PLA polymers with multi layered polymers. Int. J. Eng. Adv. Technol. 2019, 8, 2351–2356. [Google Scholar] [CrossRef]

- De Souza, A.M.C.; Cucchiara, M.G.; Ereio, A.V. ABS/HIPS blends obtained from WEEE: Influence of processing conditions and composition. J. Appl. Polym. Sci. 2016, 133, 1–7. [Google Scholar] [CrossRef]

- Dinesh, S.; Rajasekaran, T.; Dhanasekaran, M.; Vigneshwaran, K. Experimental testing on mechanical properties of sandwich structured carbon fibers reinforced composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 12180. [Google Scholar] [CrossRef]

- Galatas, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Additive manufactured sandwich composite/ABS parts for unmanned aerial vehicle applications. Polymers 2018, 10, 1262. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive manufacturing of PLA-based composites using fused filament fabrication: Effect of graphene nanoplatelet reinforcement on mechanical properties, dimensional accuracy and texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [PubMed]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Srivastava, V.K. A reviev on advances in rapid prototype 3D printing of multi-functional applications. Sci. Technol. 2017, 7, 4–24. [Google Scholar] [CrossRef]

- Generic Families of Plastic | UL Prospector. Available online: https://plastics.ulprospector.com/generics (accessed on 13 September 2018).

- Gebhardt, A.; Kessler, J.; Thurn, L. Materials. In 3D Printing Understanding Additive Manufacturing, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2019. [Google Scholar]

- ASTM international standard test method for tensile properties of plastics. ASTM Int. 2003, 8, 46–58. [CrossRef]

- Qureshi, A.J.; Mahmood, S.; Wong, W.L.E.; Talamona, D. Design for scalability and strength optimisation for components created through fdm process. In Proceedings of the 20th International Conference on Engineering Design (ICED 15), Milan, Italy, 27–30 July 2015; pp. 255–266. [Google Scholar]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Sapkota, J.; Schuschnigg, S.; Holzer, C. Effect of the printing bed temperature on the adhesion of parts produced by fused filament fabrication. Plast. Rubber Compos. 2018, 47, 17–24. [Google Scholar] [CrossRef]

- Kuo, C. Minimizing warpage of ABS prototypes built with low-cost fused deposition modeling machine using developed closed-chamber and optimal process parameters. Int. J. Adv. Manuf. Technol. 2019, 101, 593–602. [Google Scholar] [CrossRef]

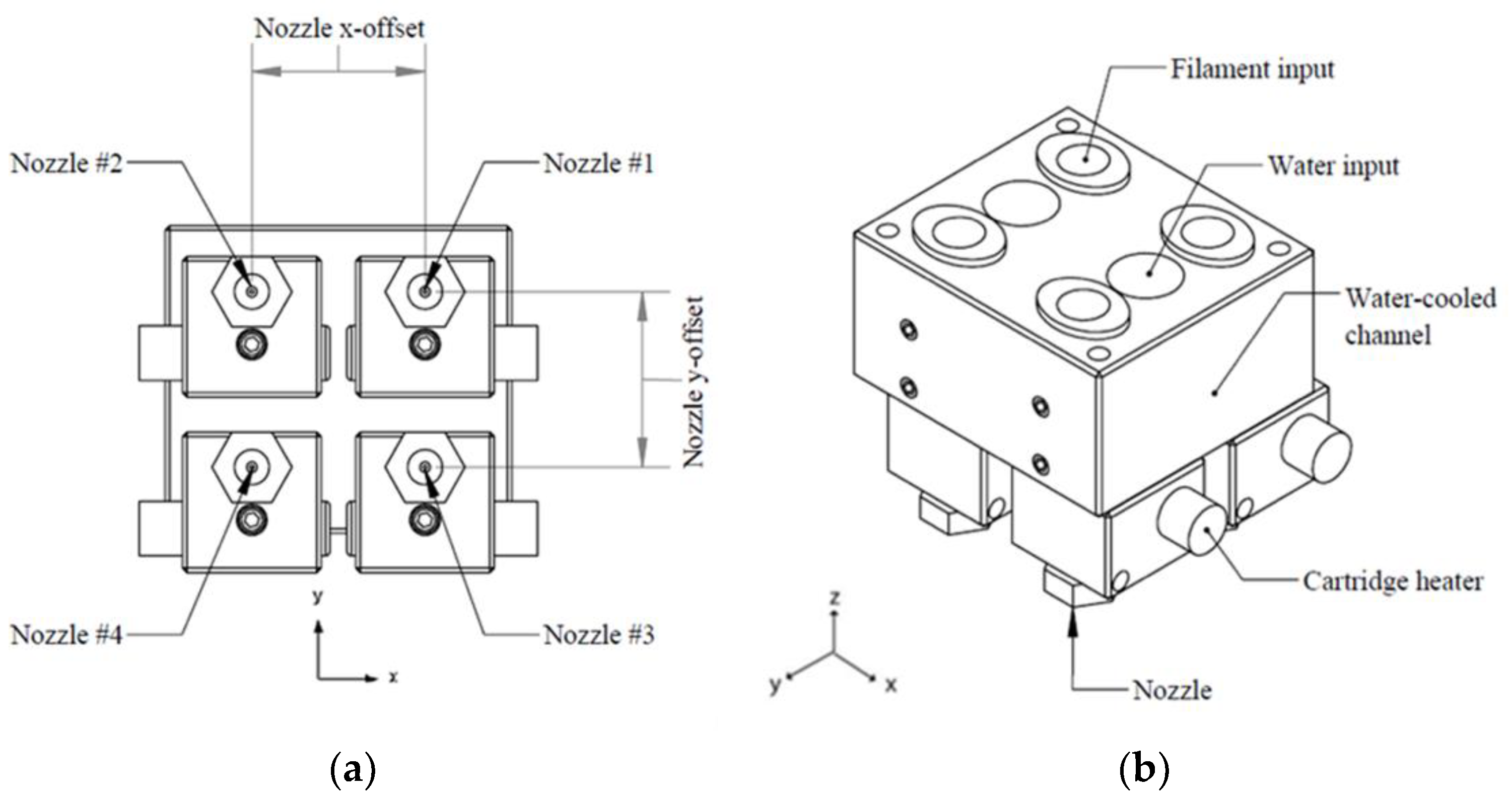

- Ali, M.H.; Mir-Nasiri, N.; Ko, W.L. Multi-nozzle extrusion system for 3D printer and its control mechanism. Int. J. Adv. Manuf. Technol. 2016, 86, 999–1010. [Google Scholar] [CrossRef]

- Casavola, C.; Cazzato, A.; Moramarco, V.; Pappalettere, C. Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater. Des. 2016, 90, 453–458. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef] [PubMed]

| Material | PLA | ABS | HIPS |

|---|---|---|---|

| Composition | Polylactic acid | Acrylonitrile butadiene styrene | High-impact polystyrene |

| Physical properties | Nominal Value | ||

| Density/Specific Gravity (23 °C) | 1.24 to 1.26 g/cm3 | 1.03 to 1.08 g/cm3 | 1.04 to 1.06 g/cm3 |

| Melt Mass-Flow Rate: | |||

| 190 °C/2.16 Kg | 2.8 to 23 g/10 min | – | – |

| 200 °C/5 Kg | – | – | 2.2 to 10 g/10 min |

| 220 °C/10.0 Kg | – | 1.0 to 36 g/10 min | – |

| Molding Shrinkage: | |||

| Flow: 23 °C·(mm/mm) | 3.7 × 10−3 to 4.1 × 10−3 | 3.9 × 10−3 to 6.5 × 10−3 | 4.5 × 10−3 to 6.1 × 10−3 |

| 23 °C | 0.30 to 1.1% | 0.40 to 0.70% | 0.50 to 0.55% |

| Mechanical Properties (23 °C) | |||

| Tensile Modulus | 890 to 3647 MPa | 1697 to 2826 MPa | 1565 to 2290 MPa |

| Tensile Strength | 17.6 to 64 MPa | 32 to 53 MPa | 20 to 31 MPa |

| Tensile Strength Yield | 15.5 to 72 MPa | 29 to 57 MPa | 16.4 to 30 MPa |

| Tensile Strength Break | 13.7 to 70 MPa | 15 to 50 MPa | 16 to 30 MPa |

| Tensile Elongation Yield | 9.8 to 10% | 2 to 21% | 4 to 61% |

| Tensile Elongation Break | 0.50 to 19% | 0.90 to 57% | 27 to 63% |

| Flexural Modulus | 2275 to 4495 MPa | 1420 to 2770 MPa | 1372 to 2454 MPa |

| Flexural Strength | 57.6 to 109 MPa | 44.6 to 89 MPa | 20.6 to 64.6 MPa |

| Thermal Properties | |||

| Glass Transition Temperature | 56.6 to 57.7 °C | 100 °C | 100 °C |

| Melting Temperature | 190 to 240 °C | 210 to 240 °C | 230 to 250 °C |

| Material Source | Hatchbox | Hatchbox | Gizmodorks |

| www.hatchbox3d.com | www.hatchbox3d.com | www.gizmodorks.com |

| Parameters, Units | Value |

|---|---|

| Infill | |

| Pattern | Rectilinear |

| Angle, ° | 45°/−45° |

| Density, % | 100 |

| Speed | |

| Travel speed, mm/s | 100 |

| Retraction speed, mm/s | 5 |

| Infill speed, mm/s | 25 |

| Quality | |

| Flow rate, % | 100 |

| Layer Thickness, mm | 0.3 |

| No. of perimeters | 3 |

| Temperature | |

| Bed, °C | 90 |

| Nozzle, °C | 240 |

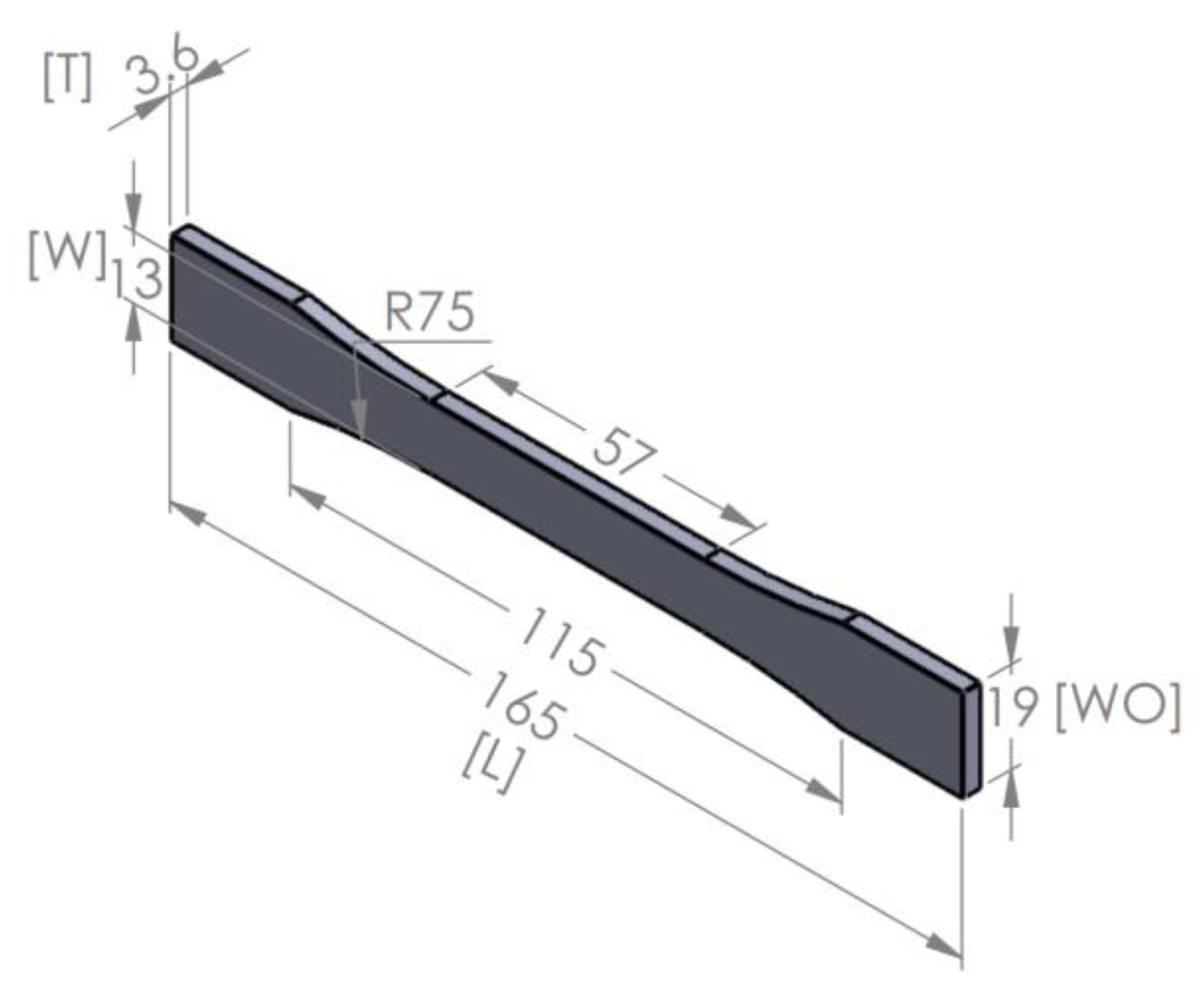

| No | Material | Length (L) | Thickness (T) | Width Overall (WO) | Width Narrow (W) |

|---|---|---|---|---|---|

| 1 | ABS | 165.12 | 3.66 | 19.10 | 13.20 |

| 2 | PLA | 165.10 | 3.60 | 19.08 | 13.15 |

| 3 | HIPS | 165.00 | 3.58 | 19.04 | 13.43 |

| 4 | ABS-PLA-ABS | 165.20 | 3.57 | 19.32 | 13.50 |

| 5 | ABS-HIPS-ABS | 165.15 | 3.62 | 19.13 | 13.25 |

| 6 | PLA-ABS-PLA | 165.00 | 3.65 | 19.30 | 13.50 |

| 7 | PLA-HIPS-PLA | 165.08 | 3.60 | 19.10 | 13.45 |

| 8 | HIPS-PLA-HIPS | 164.95 | 3.68 | 19.19 | 13.50 |

| 9 | HIPS-ABS-HIPS | 165.13 | 3.64 | 19.13 | 13.35 |

| No | Material(s) | Tensile Stress (MPa) | Tensile Elongation at Ereak (mm) | Young’s Modulus (MPa) | |||

|---|---|---|---|---|---|---|---|

| Mean | StdDev | Mean | StdDev | Mean | StdDev | ||

| 1 | ABS | 32.89 | 2.32 | 4.71 | 1.03 | 1049.78 | 54.81 |

| 2 | PLA | 47.46 | 2.37 | 4.16 | 0.20 | 1396.90 | 47.33 |

| 3 | HIPS | 20.06 | 0.26 | 6.69 | 1.92 | 933.33 | 14.69 |

| 4 | ABS-PLA-ABS | 38.28 | 0.16 | 6.02 | 0.07 | 1232.96 | 0.78 |

| 5 | ABS-HIPS-ABS | 29.67 | 0.07 | 5.16 | 0.52 | 1049.05 | 4.87 |

| 6 | PLA-ABS-PLA | 44.40 | 0.26 | 6.14 | 0.09 | 1364.27 | 16.68 |

| 7 | PLA-HIPS-PLA | 38.77 | 1.18 | 5.38 | 0.38 | 1351.27 | 2.50 |

| 8 | HIPS-PLA-HIPS | 25.87 | 0.06 | 8.57 | 1.56 | 981.45 | 141.42 |

| 9 | HIPS-ABS-HIPS | 22.21 | 0.05 | 6.10 | 0.12 | 992.02 | 3.59 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baca Lopez, D.M.; Ahmad, R. Tensile Mechanical Behaviour of Multi-Polymer Sandwich Structures via Fused Deposition Modelling. Polymers 2020, 12, 651. https://doi.org/10.3390/polym12030651

Baca Lopez DM, Ahmad R. Tensile Mechanical Behaviour of Multi-Polymer Sandwich Structures via Fused Deposition Modelling. Polymers. 2020; 12(3):651. https://doi.org/10.3390/polym12030651

Chicago/Turabian StyleBaca Lopez, David Moises, and Rafiq Ahmad. 2020. "Tensile Mechanical Behaviour of Multi-Polymer Sandwich Structures via Fused Deposition Modelling" Polymers 12, no. 3: 651. https://doi.org/10.3390/polym12030651

APA StyleBaca Lopez, D. M., & Ahmad, R. (2020). Tensile Mechanical Behaviour of Multi-Polymer Sandwich Structures via Fused Deposition Modelling. Polymers, 12(3), 651. https://doi.org/10.3390/polym12030651