Characterization and Morphology of Natural Dung Polymer for Potential Industrial Application as Bio-Based Fillers

Abstract

1. Introduction

Indian Farming, Livestock and Dung Potential

2. Material Methods

2.1. Sample Collection

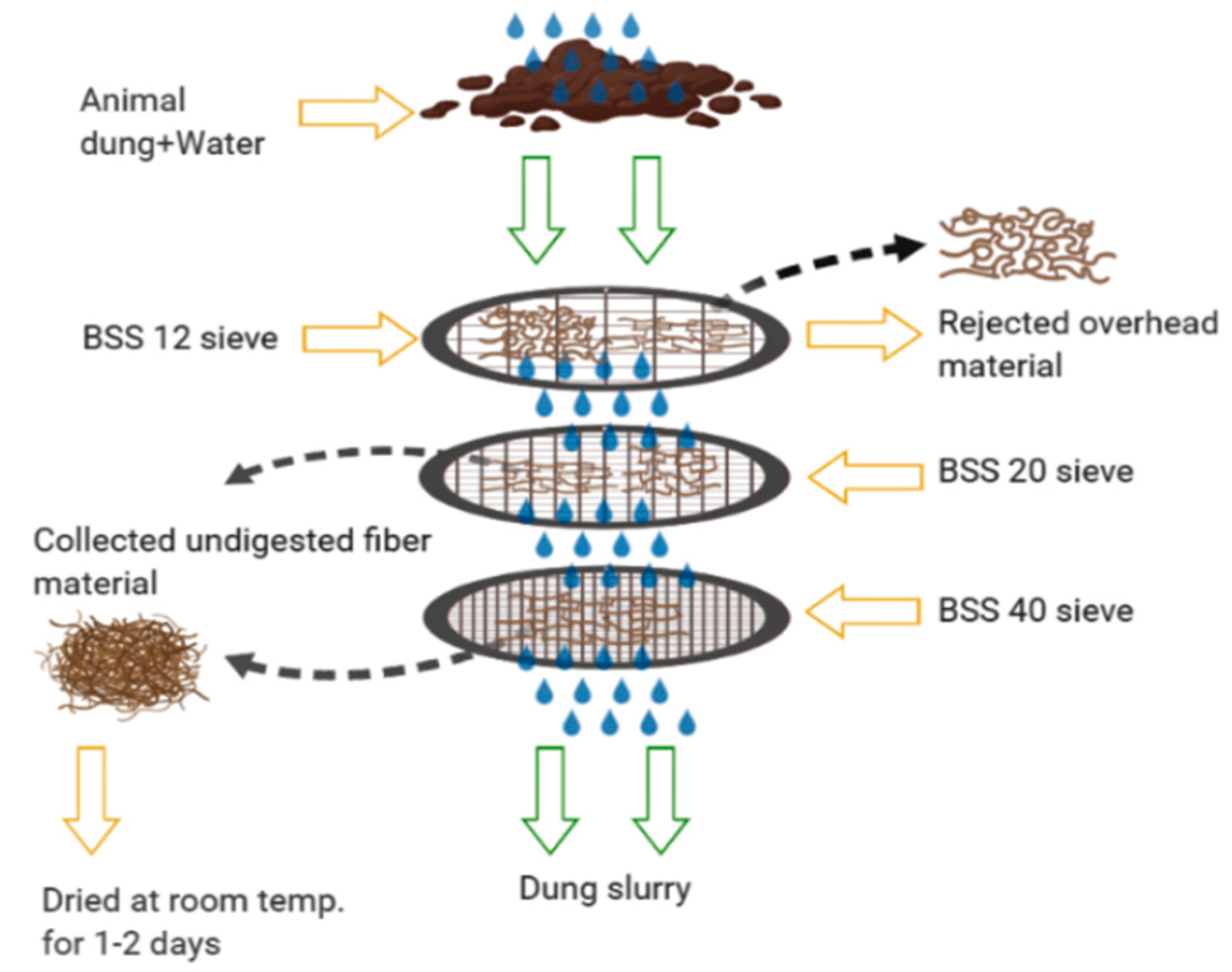

2.2. Preparation of Raw Material

2.3. Proximate and Ultimate Analysis of Raw Dung Fiber

2.4. Physical Characterization of Raw Animal Dung Fiber

2.5. Chemical Characterization

2.6. Scanning Electron Microscopy (SEM)/Energy Dispersive X-ray Spectroscopy (EDS) Imaging of Dung Fibers

2.7. Fourier Transform Infrared Spectroscopy (FTIR)

2.8. ICP-MS

2.9. Statistical Analyses

3. Results and Discussion

3.1. Initial Physical Characteristics of Ruminant Animal Waste Dung

3.1.1. Percentage Yield of Raw Material

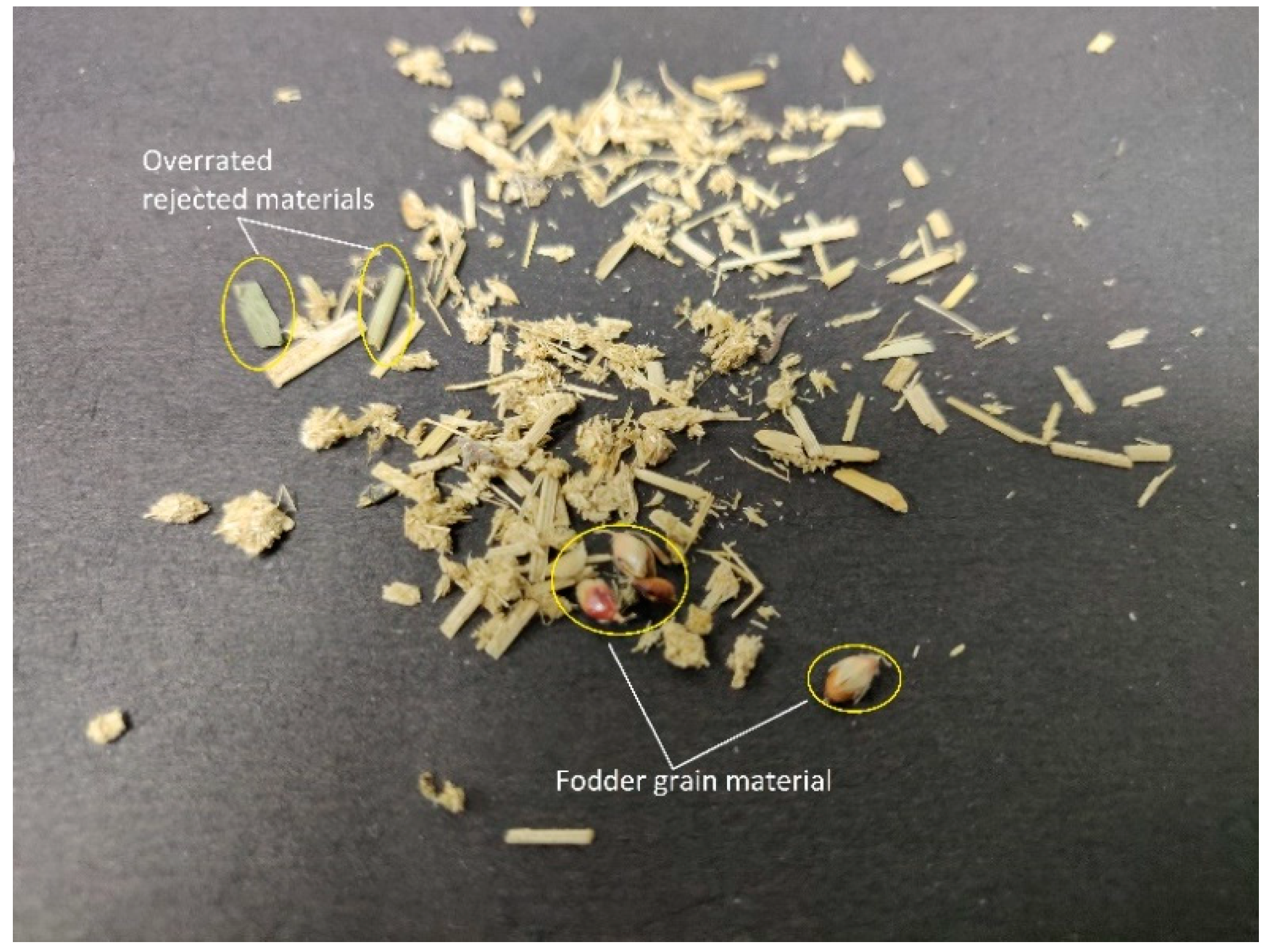

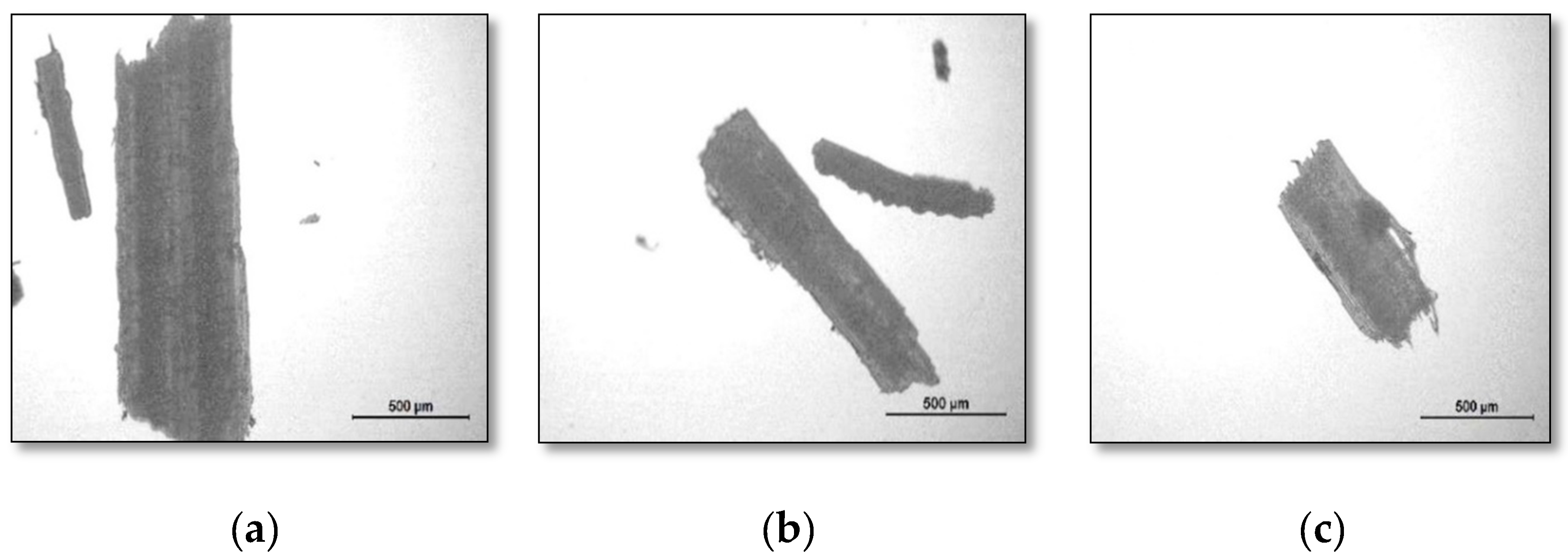

3.1.2. Morphological Analysis of All Dung Fibers

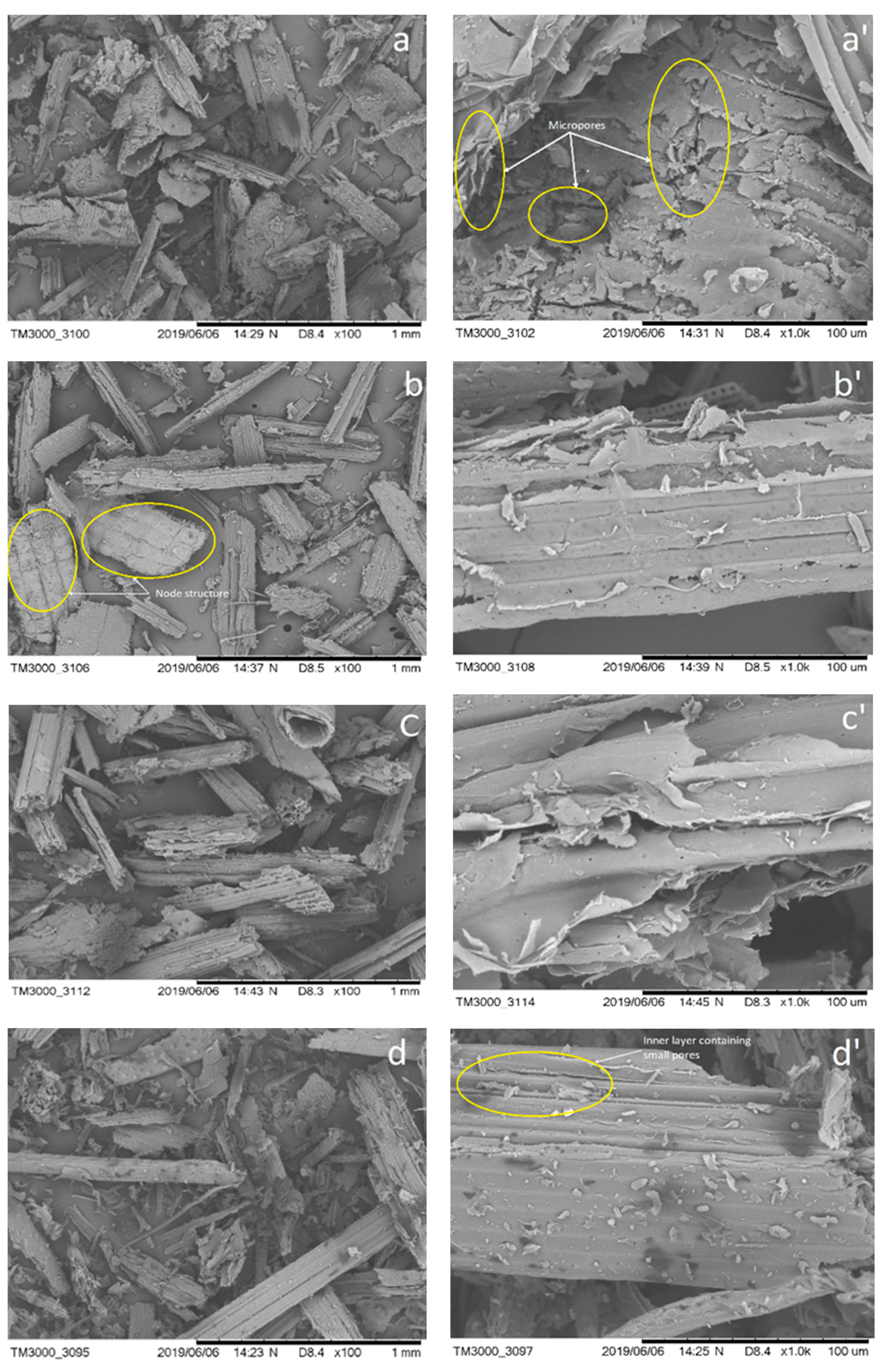

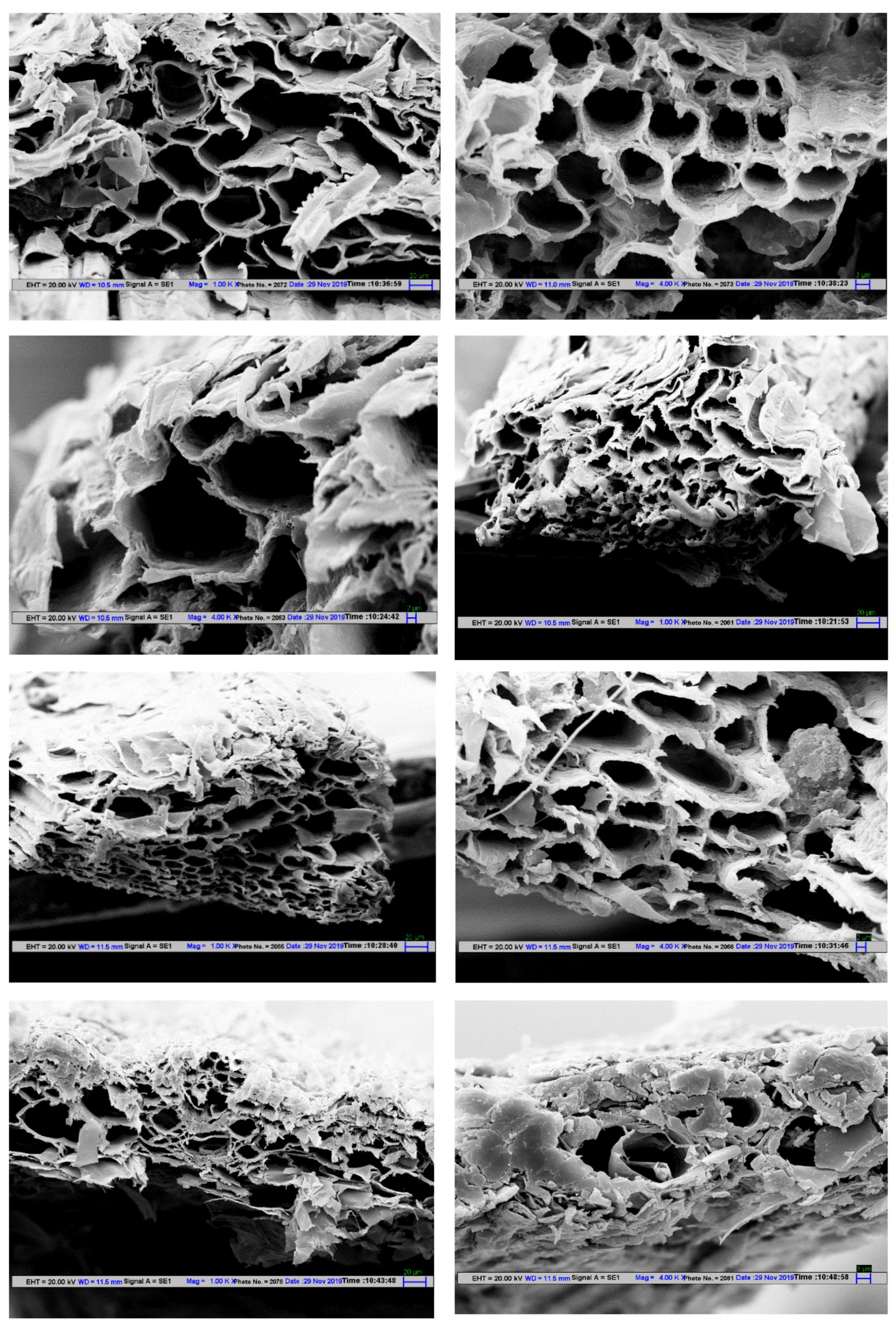

3.1.3. Scanning Electron Microscope (SEM)

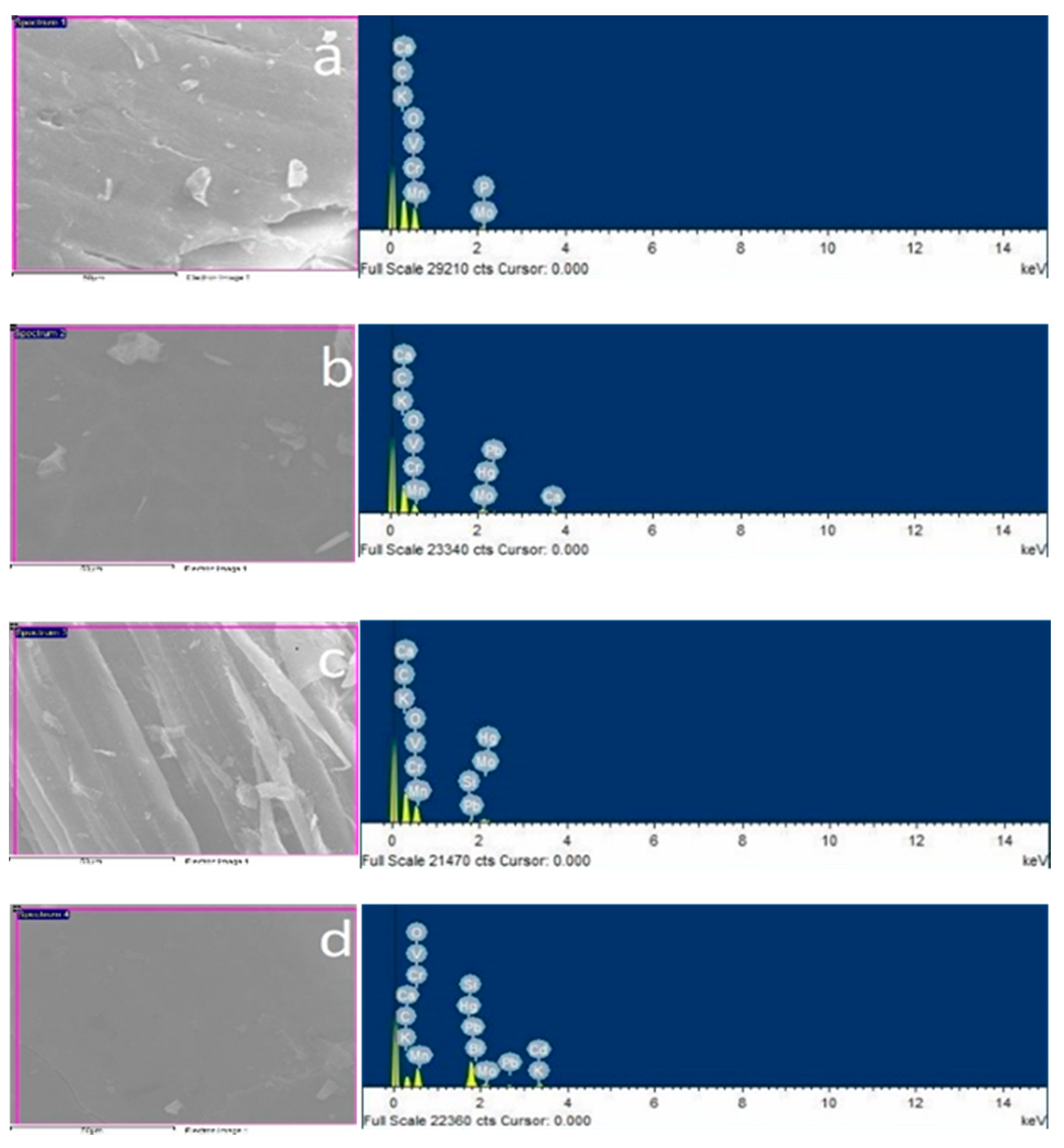

3.1.4. Energy-Dispersive Spectrometer (EDX)

3.1.5. Fourier-Transform Infrared Spectroscopy (FTIR)

3.2. Proximate and Ultimate Analysis

3.3. Chemical Characterization

3.3.1. Solubility

3.3.2. Major Chemical Composition Cellulose, Hemicellulose and Lignin Content

3.3.3. ICP-MS

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- The Global Paper Market—Current Review (2018). Available online: https://www.pgpaper.com/wp-content/uploads/2018/07/Final-The-Global-Paper-Industry-Today-2018.pdf (accessed on 1 July 2018).

- Zhuang, Z.; Ding, L.; Li, H. China’s Pulp and Paper Industry: A Review; School of Economics, Georgia Institute of Technology: Atlanta, GA, USA, 2005. [Google Scholar]

- Hujala, M.; Arminen, H.; Hill, R.C.; Puumalainen, K. Explaining the Shifts of International Trade in Pulp and Paper Industry. Science 2013, 59, 211–222. [Google Scholar] [CrossRef]

- Guo, K.; Guan, Q.; Xu, J.; Tan, W. Mechanism of Preparation of Platform Compounds from Lignocellulosic Biomass Liquefaction Catalyzed by Bronsted Acid: A Review. J. Bioresour. Bioprod. 2019, 4, 202–213. [Google Scholar]

- WRM, Belgium: Field Liberation Movement Takes Action against GE Trees, February 2017. Available online: http://wrm.org.uy/articles-from-the-wrm-bulletin/section2/belgium-field-liberation-movement-takes-action-against-ge-trees (accessed on 8 February 2017).

- Chand, R.; Prasanna, P.L.; Singh, A. Farm. Size and Productivity: Understanding the Strengths of Smallholders and Improving Their Livelihoods; Economic and Political Weekly: New Delhi, India, 2011; pp. 5–11. Available online: https://www.jstor.org/stable/23018813 (accessed on 25 June 2011).

- Grover, D.K.; Kumar, S. Economics of Production, Processing and Marketing of Fodder Crops in India; Agro-Economic Research Centre Punjab Agricultural University: Ludhiana, India, 2012. [Google Scholar] [CrossRef]

- Department of Animal Husbandry, Dairying & Fisheries, Ministry of Agriculture & Farmers’ Welfare. 20th Livestock Census-2017: Livestock Censuses; Department of Animal Husbandry, Dairying & Fisheries, Ministry of Agriculture & Farmers’ Welfare: New Delhi, India, 2017. [Google Scholar]

- Ganai, I.A. Proximate Composition Analysis and Mineral Estimation of Locally Available Wheat (Triticum aestivum L.) and Paddy (Oryza sativa L.) Straw from Jammu Region. Int. J. Pure Appl. Biosci. 2017, 5, 608–612. [Google Scholar] [CrossRef]

- Braun, U. Ultrasonographic Examination of the Reticulum, Rumen, Omasum, Abomasum, and Liver in Calves. Veter-Clin. N. Am. Food Anim. Pract. 2016, 32, 85–107. [Google Scholar] [CrossRef] [PubMed]

- Joblin, K.N.; Matsui, H.; Naylor, G.E.; Ushida, K. Degradation of Fresh Ryegrass by Methanogenic Co-Cultures of Ruminal Fungi Grown in the Presence or Absence of Fibrobacter succinogenes. Curr. Microbiol. 2002, 45, 46–53. [Google Scholar] [CrossRef] [PubMed]

- Khalid, M.; Ratnam, C.T.; Abdullah, L.C.; Walvekar, R.; Ching, Y.C.; Ketabchi, M.R. Mechanical and physical performance of cowdung-based polypropylene biocomposites. Polym. Compos. 2016, 39, 288–296. [Google Scholar] [CrossRef]

- Gupta, K.K.; Aneja, K.R.; Rana, D. Current status of cow dung as a bioresource for sustainable development. Bioresour. Bioprocess. 2016, 3, 28. [Google Scholar] [CrossRef]

- Yuan, Z.; Lin, H.; Qian, X.; Shen, J. Converting a Dilute Slurry of Hollow Tube-like Papermaking Fibers into Phase-reversible, Self-healable, and Stretchable Hydrogels. J. Bioresour. Bioprod. 2019, 4, 214–221. [Google Scholar]

- Standard Methods for the Examination of Water and Wastewater; APHA: Washington, DC, USA, 1999.

- TNAU Agritech Portal, Animal Husbandry. Available online: https://tnau.ac.in/directorate-cm/veterinary-and-animal-sciences-about-department/ (accessed on 18 February 2019).

- Ghaffar, S.H.; Fan, M.; McVicar, B. Interfacial properties with bonding and failure mechanisms of wheat straw node and internode. Compos. Part. A Appl. Sci. Manuf. 2017, 99, 102–112. [Google Scholar] [CrossRef]

- Reddy, K.O.; Maheswari, C.U.; Shukla, M.; Muzenda, E. Preparation, Chemical Composition, Characterization, and Properties of Napier Grass Paper Sheets. Sep. Sci. Technol. 2014, 49, 1527–1534. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Qi, H. Tribological and physio-mechanical characterization of cow dung fibers reinforced friction composites: An effective utilization of cow dung waste. Tribol. Int. 2019, 131, 200–211. [Google Scholar] [CrossRef]

- Luo, H.; Xiong, G.; Ma, C.; Chang, P.; Yao, F.; Zhu, Y.; Zhang, C.; Wan, Y. Mechanical and thermo-mechanical behaviors of sizing-treated corn fiber/polylactide composites. Polym. Test. 2014, 39, 45–52. [Google Scholar] [CrossRef]

- Nigam, J. Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. J. Biotechnol. 2001, 87, 17–27. [Google Scholar] [CrossRef]

- Shakhes, J.; Marandi, M.A.; Zeinaly, F.; Saraian, A.; Saghafi, T. Tobacco residuals as promising lignocellulosic materials for pulp and paper industry. BioResources 2011, 6, 4481–4493. [Google Scholar]

- Baptist, K.J. Characterisation of Ugandan selected grasses and tree leaves for pulp extraction for paper industry. Int. J. Sci. Technol. Res. 2013, 2, 146–154. [Google Scholar]

- Sridach, W. Pulping and paper properties of Palmyra palm fruit fibers. Songklanakarin J. Sci. Technol. 2010, 32, 201–205. [Google Scholar]

- Levitin, N. The extractives of Birch, Aspen, Elm and Maple: Review and discussion. Pulp Pap. Canada 1970, 71, 81–84. [Google Scholar]

- Çöpür, Y.; Tozluoglu, A. A comparison of kraft, PS, kraft-AQ and kraft-NaBH4 pulps of Brutia pine. Bioresour. Technol. 2008, 99, 909–913. [Google Scholar] [CrossRef]

- Saijonkari-Pahkala, K. Non-wood plants as raw material for pulp and paper. Agric. Food Sci. 2001, 10, 101. [Google Scholar] [CrossRef]

- Shatalov, A.; Pereira, H. Influence of stem morphology on pulp and paper properties of Arundo donax L. reed. Ind. Crop. Prod. 2002, 15, 77–83. [Google Scholar] [CrossRef]

- Schott, S. Development of Wheat Straw Paste, Obtained by the Vapor Phase Xplosion Process, for a Paper-Modeling Application of the Compressive Strength of Paper. Ph.D. Thesis, Grenoble Institute of Technology, Grenoble, France, 2000. [Google Scholar]

- Deniz, I.; Kırcı, H.; Ates, S. Optimisation of wheat straw Triticum drum kraft pulping. Ind. Crop. Prod. 2004, 19, 237–243. [Google Scholar] [CrossRef]

- Kaur, H.; Dutt, D. Anatomical, morphological and chemical characterization of lignocellulose by-products of lemon and sofia grasses obtained after recuperation of essential oils by steam distillation. Cellul. Chem. Technol. 2013, 47, 83–94. [Google Scholar]

- Jiménez, L.; Rodríguez, A.; Serrano, L.; Moral, A. Organosolv ethanolamine pulping of olive wood: Influence of the process variables on the strength properties. Biochem. Eng. J. 2008, 39, 230–235. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Chio, C.; Yang, C.; Su, E.; Jin, Y.; Cao, F.; Qin, W. Delignification overmatches hemicellulose removal for improving hydrolysis of wheat straw using the enzyme cocktail from Aspergillus niger. Bioresour. Technol. 2019, 274, 459–467. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Dutt, D.; Tyagi, C.H. Complete characterization of wheat straw (Triticum aestivum pbw-343 l. Emend. Fiori & paol.)–A renewable source of fibres for pulp and paper making. BioResources 2011, 6, 154–177. [Google Scholar]

- Prasad, S.; Singh, A.; Joshi, H. Ethanol as an alternative fuel from agricultural, industrial and urban residues. Resour. Conserv. Recycl. 2007, 50, 1–39. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, X.; Tang, X.; Xu, Y. Process for calcium xylonate production as a concrete admixture derived from in-situ fermentation of wheat straw pre-hydrolysate. Bioresour. Technol. 2018, 261, 288–293. [Google Scholar] [CrossRef]

- Kaparaju, P.L.-N.; Felby, C. Characterization of lignin during oxidative and hydrothermal pre-treatment processes of wheat straw and corn stover. Bioresour. Technol. 2010, 101, 3175–3181. [Google Scholar] [CrossRef]

- Demirbaş, A. Relationships between lignin contents and heating values of biomass. Energy Convers. Manag. 2001, 42, 183–188. [Google Scholar] [CrossRef]

- Rodríguez, A.; Serrano, L.; Moral, A.; Jiménez, L. Pulping of rice straw with high-boiling point organosolv solvents. Biochem. Eng. J. 2008, 42, 243–247. [Google Scholar] [CrossRef]

| Sample Name | % of Fiber (db) |

|---|---|

| IDF | 10.08 ± 0.06 b |

| JDF | 11 ± 0.4 a |

| BDF | 11.5 ± 0.08 a |

| Sample Name | Min. Length of Fiber (mm) | Max. Length of Fiber (mm) | Avg. Length of Fiber (mm) | Min. Diameter of Fiber (µm) | Max. Diameter of Fiber (µm) | Avg. Diameter of Fiber (µm) |

|---|---|---|---|---|---|---|

| IDF | 0.09 ± 0.03 a | 1.6 ± 0.09 b | 0.85 | 51 ± 1.71 c | 1803 ± 1.12 c | 927 |

| JDF | 0.11 ± 0.02 a | 2.1 ± 0.18 a | 1.11 | 57 ± 1.26 b | 1833 ± 1.71 b | 945 |

| BDF | 0.12 ± 0.04 a | 2.26 ± 0.06 a | 1.20 | 68 ± 1.61 a | 1892 ± 1.18 a | 980 |

| Sr.N | Parameters (on Dry Weight Basis of Samples) | IDF | JDF | BDF | WS |

|---|---|---|---|---|---|

| Proximate properties | |||||

| 1. | Moisture (%) | 5.40 ± 1.22 b | 6.14 ± 0.76 ab | 6.35 ± 0.49 a | 6.47 ± 1.33 a |

| 2. | Total solids (TS) (%) | 94.60 ± 1 a | 93.86 ± 0.62 ab | 93.65 ± 0.40 b | 93.53 ± 1.09 b |

| 3. | * Volatile solids (VS) (%) | 92.85 ± 0.7 c | 94.51 ± 0.08 b | 95.91 ± 0.57 a | 92.94 ± 0.77 c |

| Ultimate properties | |||||

| 4. | ** C (%) | 44.54 ± 0.90 a | 45 ± 0.75 a | 45.02 ± 0.70 a | 45.82 ± 0.71 a |

| 5. | ** H (%) | 5.82 ± 0.65 a | 5.92 ± 0.79 a | 5.89 ± 0.50 a | 6.69 ± 0.40 a |

| 6. | ** N (%) | 0.48 ± 0.09 a | 0.46 ± 0.10 a | 0.50 ± 0.08 a | 0.51 ± 0.07 a |

| Sample Name (Percentage Based on Bone Dry Weight) | Ethanol-Benzene Solubility, % (1:1 v/v) | 1% NaOH Solubility, % | Hot Water Solubility, % | Cold Water Solubility, % |

|---|---|---|---|---|

| IDF | 1.64 ± 0.08 c | 42.20 ± 0.93 a | 13.5 ± 0.15 c | 6 ± 0.08 c |

| JDF | 1.35 ± 0.07 c | 41.56 ± 0.74 ab | 13 ± 0.16 d | 7 ± 0.15 b |

| BDF | 2 ± 0.12 b | 40.02 ± 0.33 b | 14 ± 0.12 b | 8 ± 0.12 a |

| WS | 3.07 ± 0.24 a | 40.10 ± 0.28 b | 20 ± 0.37 a | 7 ± 0.16 b |

| Sample | Cellulose (%) | Hemicellulose (%) | Lignin (%) * | Ash (%) |

|---|---|---|---|---|

| IDF | 31.34 ± 0.91 b | 23.46 ± 0.97 a | 12.96 ± 0.69 ab | 7.06 ± 0.7 a |

| JDF | 29.94 ± 1.65 b | 22.07 ± 0.56 ab | 12.06 ± 0.74 b | 5.49 ± 0.08 b |

| BDF | 31.19 ± 0.82 b | 21.03 ± 0.34 b | 11.97 ± 0.71 b | 4.09 ± 0.57 c |

| WS | 39.36 ± 0.64 a | 23.65 ± 1.02 a | 13.91 ± 0.52 a | 7.15 ± 0.77 a |

| Element | IDF | JDF | BDF | WS |

|---|---|---|---|---|

| µg/gm | ||||

| Macronutrient | ||||

| Mg | 1694.9 | 2358.3 | 1786.4 | 2423.7 |

| K | 27.4 | 29.7 | 35.2 | 2189.3 |

| Ca | 64.4 | 65.1 | 71.2 | 75.0 |

| Micronutrient | ||||

| Fe | 220.7 | 151.6 | 479.5 | 652.9 |

| Zn | 23.3 | 23.6 | 23.6 | 30.8 |

| Mn | 11.5 | 11.7 | 8.5 | 11.6 |

| B | 223.1 | 196.3 | 222.1 | 212.6 |

| Mo | 0.8 | 0.6 | 0.8 | 1.8 |

| Cu | 4.2 | 5.7 | 7.2 | 16.6 |

| Heavy metal | ||||

| Pb | 4.7 | 9.3 | 8.7 | 9.6 |

| Ni | 0.4 | 0.3 | 2.4 | 2.2 |

| Cd | 0.2 | 0.1 | 0.0 | 0.2 |

| Cr | 0.7 | 0.5 | 4.5 | 4.2 |

| Al | 38.7 | 39.1 | 56.9 | 74.2 |

| Bi | 0.0 | 0.0 | 0.0 | 0.0 |

| Co | 0.1 | 0.1 | 0.1 | 0.2 |

| Ba | 10.7 | 14.6 | 23.0 | 44.6 |

| V | 0.3 | 0.3 | 0.6 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fasake, V.; Dashora, K. Characterization and Morphology of Natural Dung Polymer for Potential Industrial Application as Bio-Based Fillers. Polymers 2020, 12, 3030. https://doi.org/10.3390/polym12123030

Fasake V, Dashora K. Characterization and Morphology of Natural Dung Polymer for Potential Industrial Application as Bio-Based Fillers. Polymers. 2020; 12(12):3030. https://doi.org/10.3390/polym12123030

Chicago/Turabian StyleFasake, Vinayak, and Kavya Dashora. 2020. "Characterization and Morphology of Natural Dung Polymer for Potential Industrial Application as Bio-Based Fillers" Polymers 12, no. 12: 3030. https://doi.org/10.3390/polym12123030

APA StyleFasake, V., & Dashora, K. (2020). Characterization and Morphology of Natural Dung Polymer for Potential Industrial Application as Bio-Based Fillers. Polymers, 12(12), 3030. https://doi.org/10.3390/polym12123030