Inkjet Printing of PEDOT:PSS Based Conductive Patterns for 3D Forming Applications

Abstract

1. Introduction

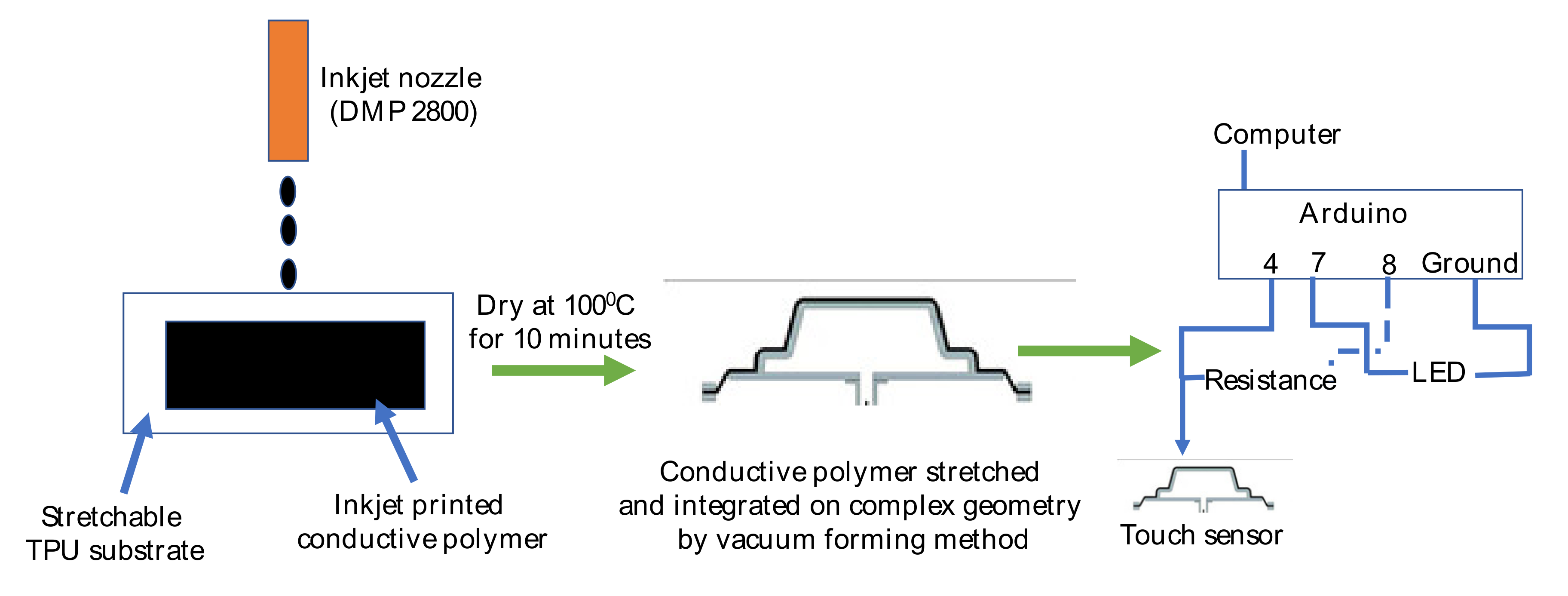

2. Experimental

2.1. Printing

2.2. Characterization

3. Results and Discussion

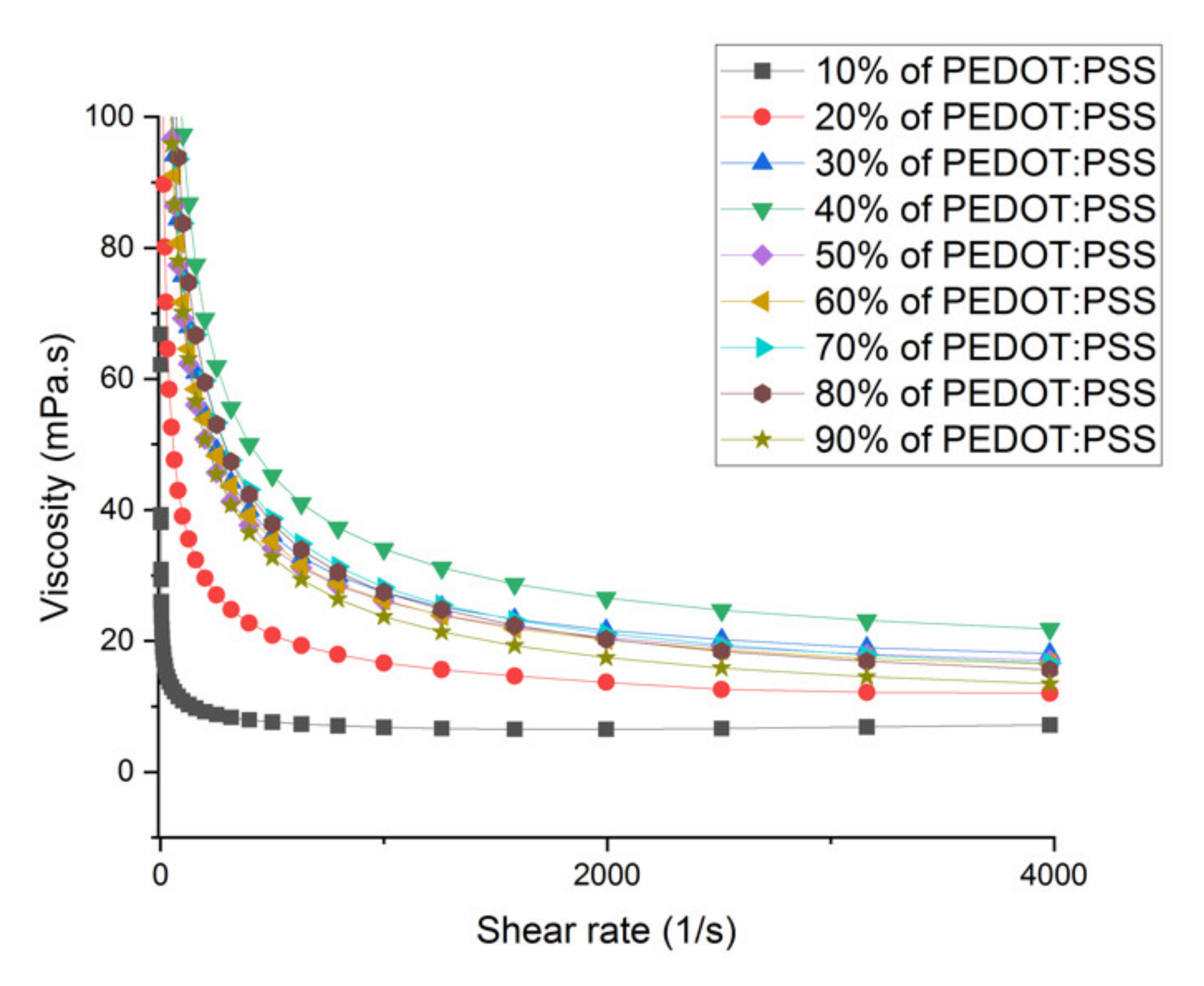

3.1. Ink Formulation

3.2. Printability

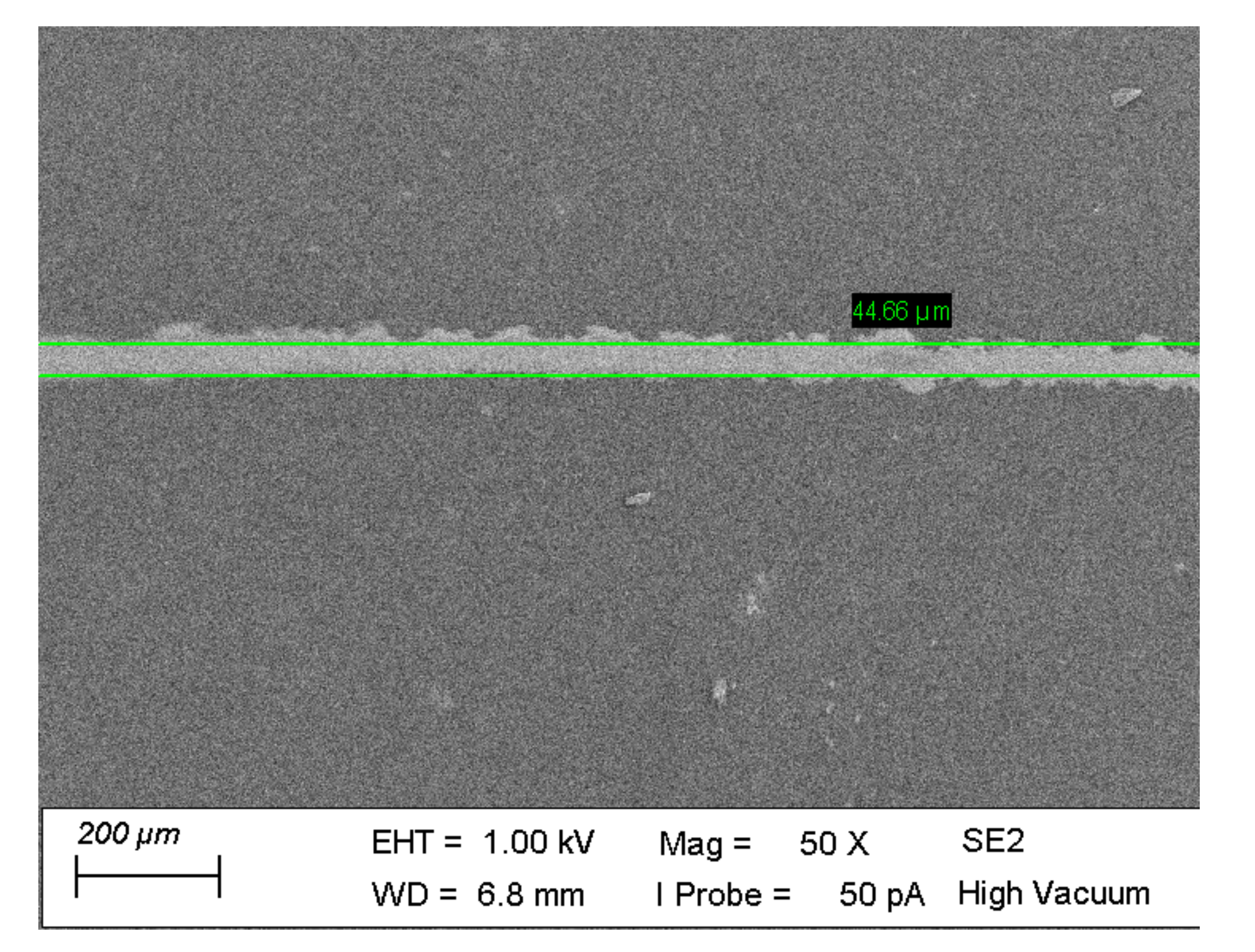

3.3. Printing Resolution

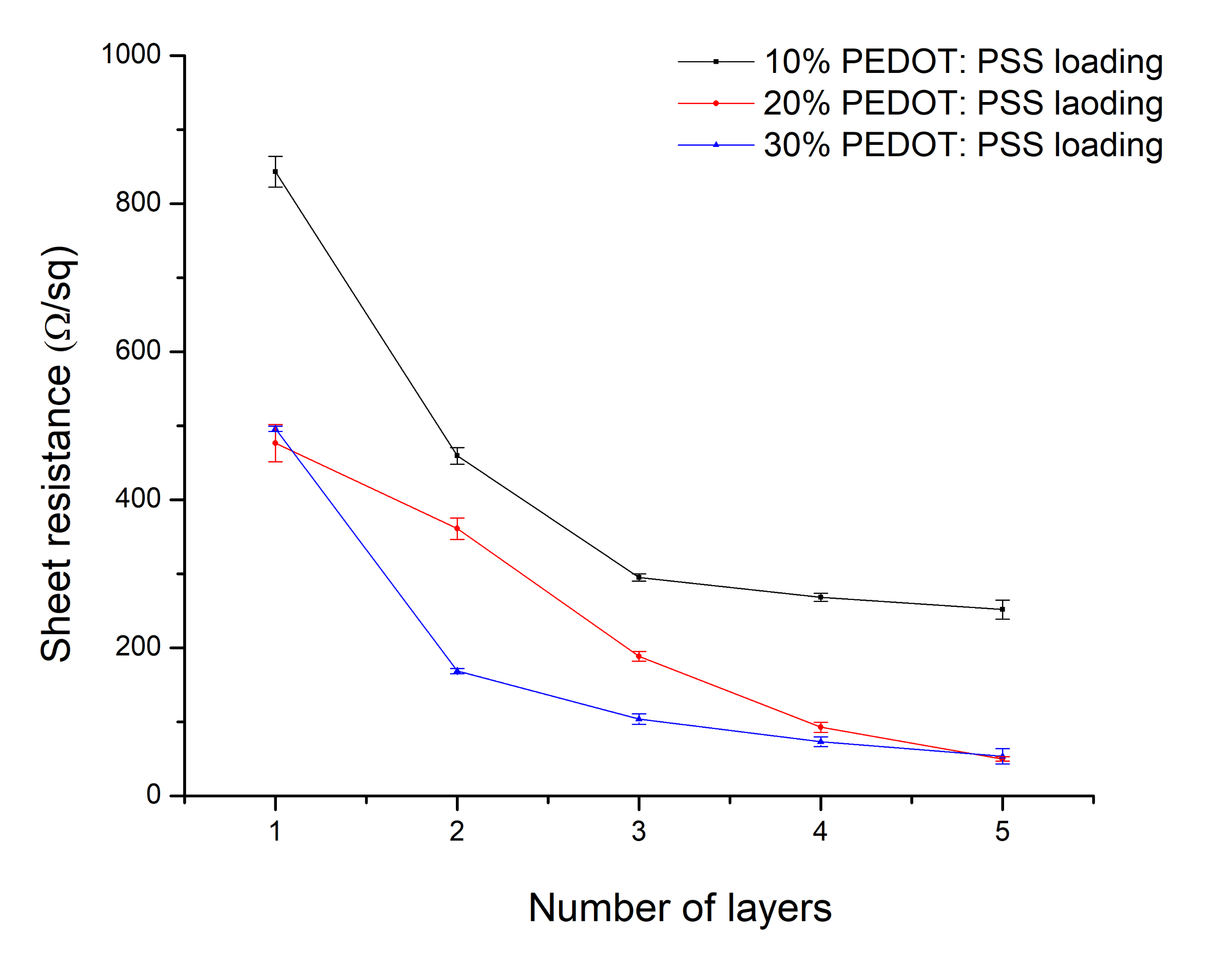

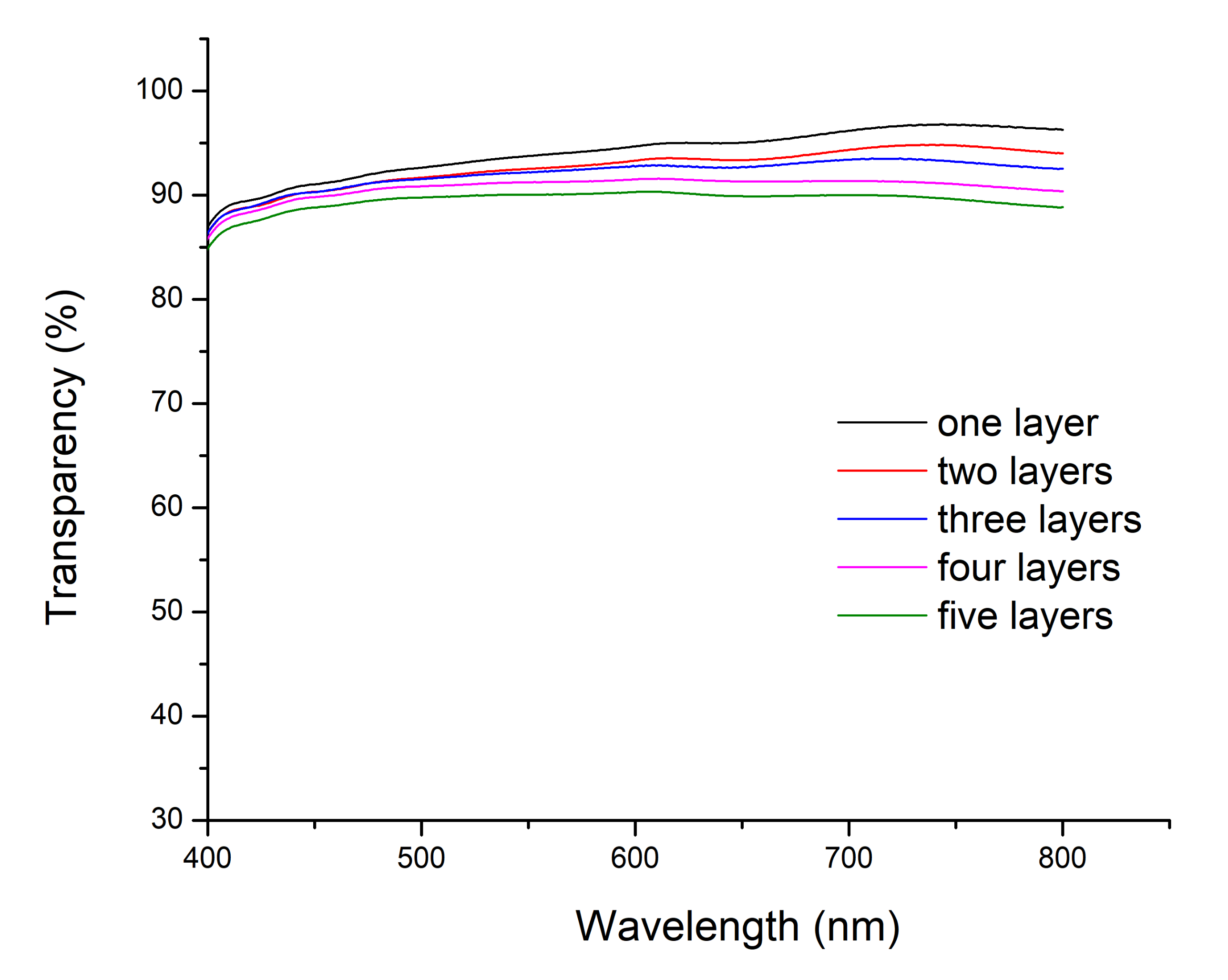

3.4. Opto-Electronic and Morphological Characterization

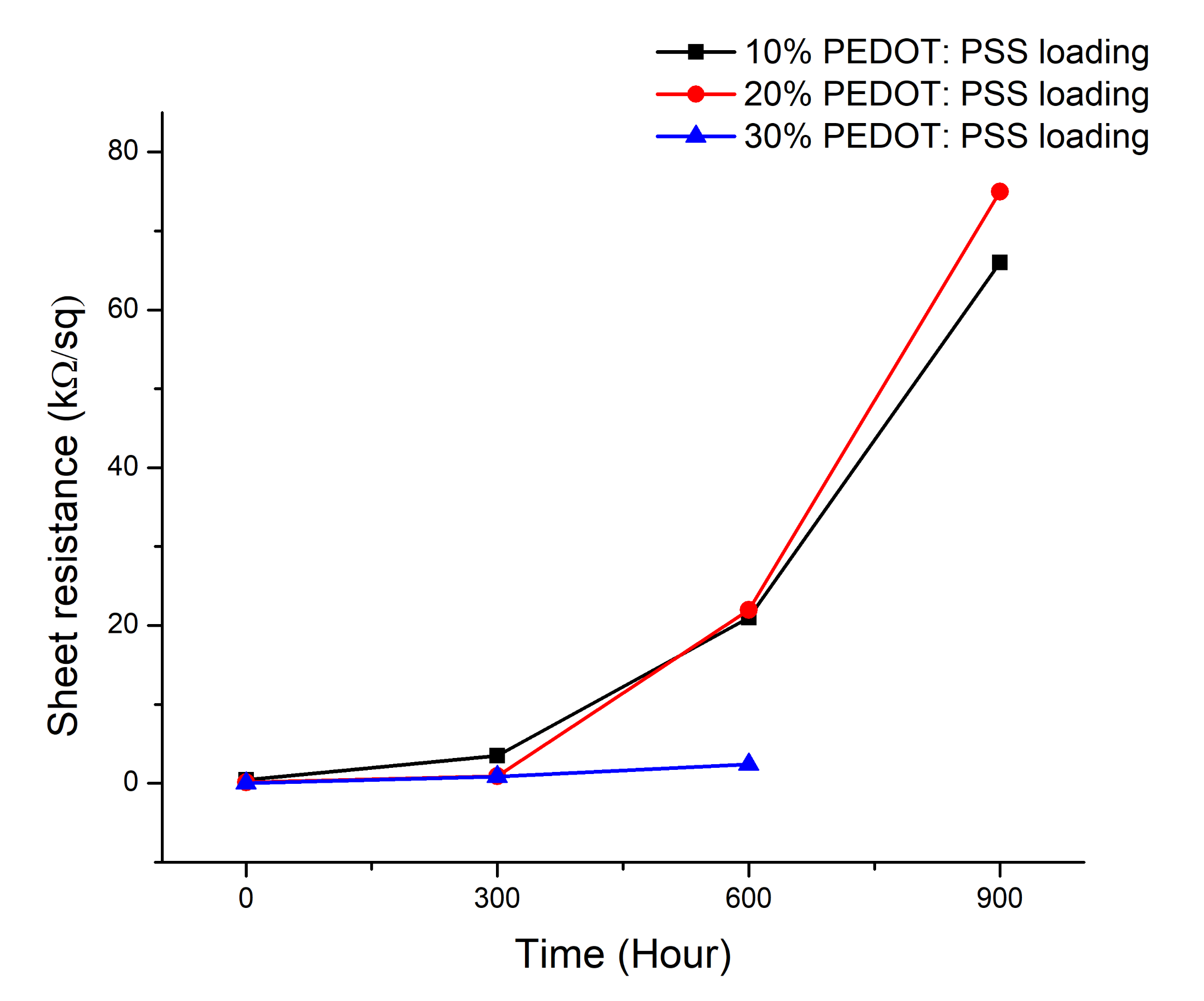

3.5. Influence of UV Exposure on the Opto-Electronic Properties

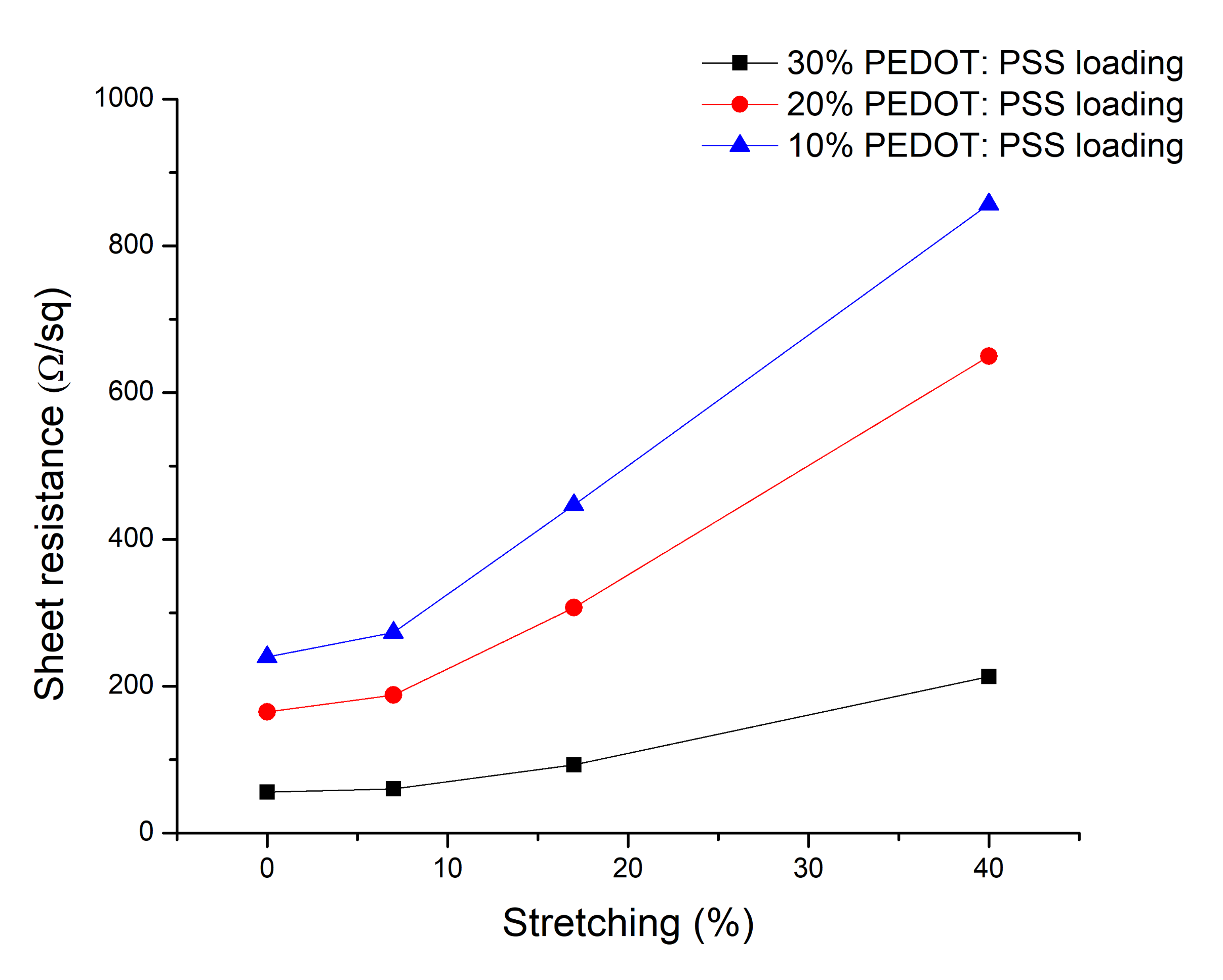

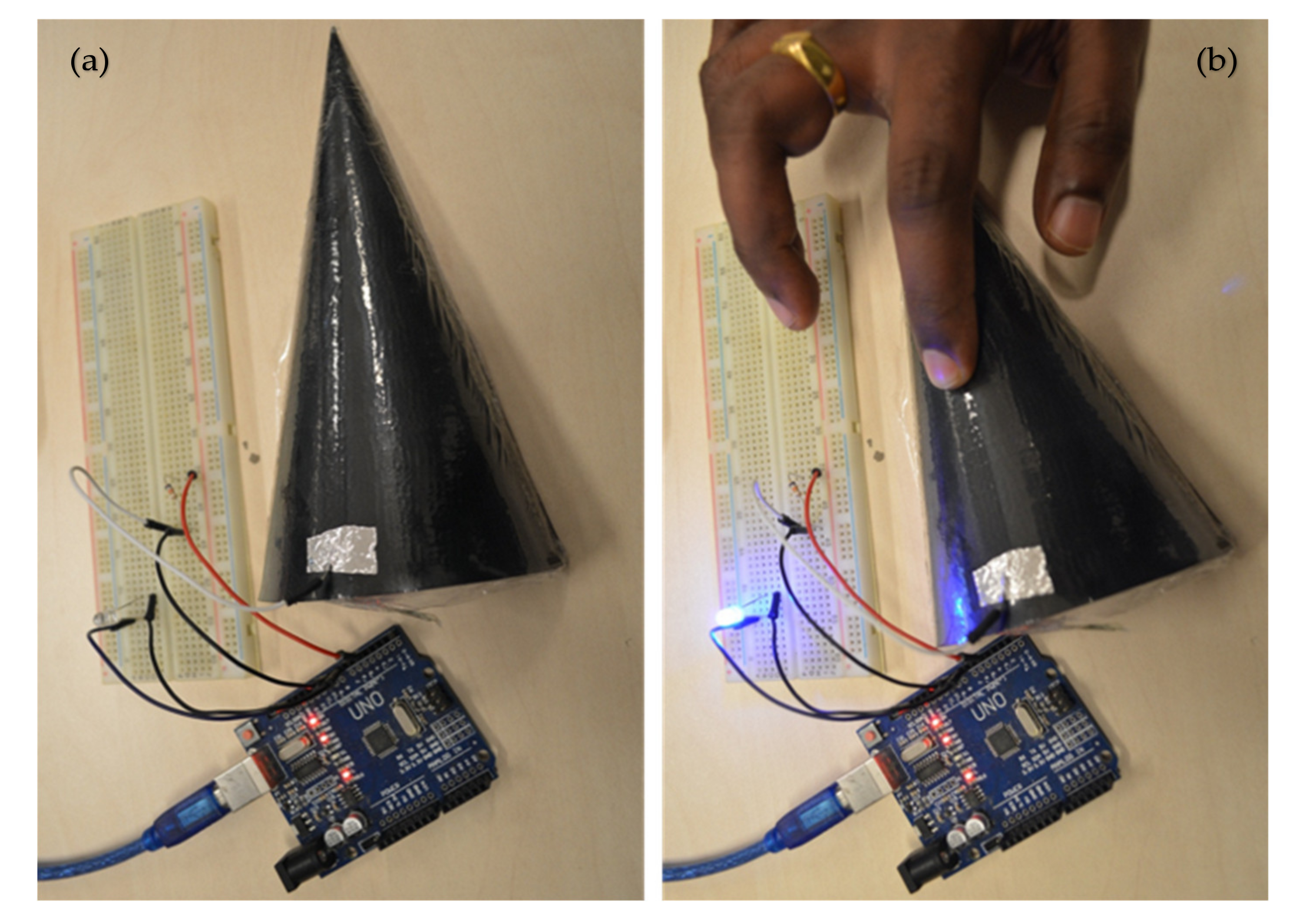

3.6. Influence of Stretching for 3D Forming Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ellmer, K. Past achievements and future challenges in the development of optically transparent electrodes. Nat. Photonics 2012, 6, 809–817. [Google Scholar] [CrossRef]

- Huang, X.; Zeng, Z.; Fan, Z.; Liu, J.; Zhang, H. Graphene-Based Electrodes. Adv. Mater. 2012, 24, 5979–6004. [Google Scholar] [CrossRef]

- Han, T.; Lee, Y.; Choi, M.; Woo, S.; Bae, S.; Hong, B.H.; Ahn, J.; Lee, T. Extremely efficient flexible organic light-emitting diodes with modified graphene anode. Nat. Photonics 2012, 6, 105–110. [Google Scholar] [CrossRef]

- Rowell, M.W.; Topinka, M.A.; Mcgehee, M.D. Organic solar cells with carbon nanotube network electrodes. Appl. Phys. Lett. 2006, 88, 23–25. [Google Scholar] [CrossRef]

- Hu, L.; Li, J.; Liu, J.; Grüner, G.; Marks, T. Flexible organic light-emitting diodes with transparent carbon nanotube electrodes: Problems and solutions. Nanotechnology 2010, 21, 155202. [Google Scholar] [CrossRef]

- Kim, Y.H.; Sachse, C.; Machala, M.L.; May, C.; Müller-meskamp, L.; Leo, K. Highly Conductive PEDOT: PSS Electrode with Optimized Solvent and Thermal Post-Treatment for ITO—Free Organic Solar Cells. Adv. Funct. Mater. 2011, 21, 1076–1081. [Google Scholar] [CrossRef]

- Kim, Y.H.; Lee, J.; Hofmann, S.; Gather, M.C.; Müller-meskamp, L.; Leo, K. Achieving High Effi ciency and Improved Stability in ITO—Free Transparent Organic Light-Emitting Diodes with Conductive Polymer Electrodes. Adv. Funct. Mater. 2013, 23, 3763–3769. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, J.; Zhang, Y.; Cui, H.; Yin, D.; Bi, Y. Improved efficiency of indium-tin-oxide-free flexible organic light-emitting devices. Org. Electron. 2014, 15, 478–483. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, J.; Zhang, Y.; Cui, H.; Yin, D.; Bi, Y.; Song, J.; Chen, Q.; Sun, H. Improved efficiency of indium-tin-oxide-free organic light-emitting devices using PEDOT: PSS/graphene oxide composite anode. Org. Electron. 2015, 26, 81–85. [Google Scholar] [CrossRef]

- Wei, B.; Pan, S.; Wang, T.; Tian, Z.; Chen, G. Solution-processed Ag-nanowire/ZnO—Nanoparticle composite transparent electrode for fl exible organic solar cells. Nanotechnology 2016, 27, 1–7. [Google Scholar] [CrossRef]

- Guo, C.F.; Chen, Y.; Tang, L.; Wang, F.; Ren, Z. Enhancing the Scratch Resistance by Introducing Chemical Bonding in Highly Stretchable and Transparent Electrodes. Nano. Lett. 2016, 16, 594–600. [Google Scholar] [CrossRef]

- Kim, D.W.; Han, J.W.; Lim, K.T.; Kim, Y.H. Highly Enhanced Light-Outcoupling E ffi ciency in ITO—Free Organic Light-Emitting Diodes Using Surface Nanostructure Embedded High–Refractive Index Polymers. ACS Appl. Mater. Interfaces 2018, 10, 985–991. [Google Scholar] [CrossRef]

- Emmott, C.J.M.; Urbina, A.; Nelson, J. Environmental and economic assessment of ITO-free electrodes for organic solar cells. Sol. Energy Mater. Sol. Cells 2012, 97, 14–21. [Google Scholar] [CrossRef]

- McCoul, D.; Hu, W.; Gao, M.; Mehta, V.; Pei, Q. Recent Advances in Stretchable and Transparent Electronic Materials. Adv. Electron. Mater. 2016, 2, 1–51. [Google Scholar] [CrossRef]

- Kim, D.H.; Rogers, J.A. Stretchable electronics: Materials strategies and devices. Adv. Mater. 2008, 20, 4887–4892. [Google Scholar] [CrossRef]

- Wagner, S.; Bauer, S. Materials for stretchable electronics. MRS Bull. 2012, 37, 207–213. [Google Scholar] [CrossRef]

- Yao, S.; Zhu, Y. Nanomaterial-enabled stretchable conductors: Strategies, materials and devices. Adv. Mater. 2015, 27, 1480–1511. [Google Scholar] [CrossRef]

- Nagels, S.; Deferme, W. Fabrication approaches to interconnect based devices for stretchable electronics: A review. Materials (Basel) 2018, 11, 375. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.K.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef]

- Yan, C.; Lee, P.S. Stretchable energy storage and conversion devices. Small 2014, 10, 3443–3460. [Google Scholar] [CrossRef]

- Gonzalez, M.; Axisa, F.; Bulcke, M.V.; Brosteaux, D.; Vandevelde, B.; Vanfleteren, J. Design of metal interconnects for stretchable electronic circuits using finite element analysis. In Proceedings of the EuroSime 2007: International Conference on Thermal Mechanical and Multi-Physics Simulation Experiments in Microelectronics Micro-Systems, London, UK, 16–18 April 2007. [Google Scholar] [CrossRef]

- Hu, W.; Niu, X.; Li, L.; Yun, S.; Yu, Z. Intrinsically stretchable transparent electrodes based on silver-nanowire-crosslinked-polyacrylate composites. Nanotechnology 2012, 23, 344002. [Google Scholar] [CrossRef]

- Liu, H.-S.; Pan, B.-C.; Liou, G.-S. Highly transparent AgNW/PDMS stretchable electrodes for elastomeric electrochromic devices. Nanoscale 2017, 9, 2633–2639. [Google Scholar] [CrossRef]

- Xu, X.; Han, G.; Yu, H.; Jin, X.; Yang, J. Resistance change of stretchable composites based on inkjet-printed silver nanowires. J. Phys. D Appl. Phys. 2020, 53, 05LT02. [Google Scholar] [CrossRef]

- Al-Milaji, K.N.; Huang, Q.; Li, Z.; Ng, T.N.; Zhao, H. Direct Embedment and Alignment of Silver Nanowires by Inkjet Printing for Stretchable Conductors. ACS Appl. Electron. Mater. 2020, 2, 3289–3298. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, Y. Gravure printing of water-based silver nanowire ink on plastic substrate for flexible electronics. Sci. Rep. 2018, 8, 1. [Google Scholar] [CrossRef]

- He, X.; He, R.; Lan, Q.; Wu, W.; Duan, F.; Xiao, J.; Zhang, M.; Zeng, Q.; Wu, J.; Liu, J. Screen-printed fabrication of PEDOT: PSS/silver nanowire composite films for transparent heaters. Materials (Basel) 2017, 10, 220. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, Y. Printing conductive nanomaterials for flexible and stretchable electronics: A review of materials, processes, and applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Fernandes, D.F.; Majidi, C.; Tavakoli, M. Digitally printed stretchable electronics: A review. J. Mater. Chem. C 2019, 7, 14035–14068. [Google Scholar] [CrossRef]

- Sannicolo, T.; Lagrange, M.; Cabos, A.; Celle, C.; Simonato, J.P.; Bellet, D. Metallic Nanowire-Based Transparent Electrodes for Next Generation Flexible Devices: A Review. Small 2016, 12, 6052–6075. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Lee, J.A.; Vosgueritchian, M.; Tee, B.C.K.; Bolander, J.A.; Bao, Z. Electronic properties of transparent conductive films of PEDOT:PSS on stretchable substrates. Chem. Mater. 2012, 24, 373–382. [Google Scholar] [CrossRef]

- Savagatrup, S.; Chan, E.; Renteria, G.S.M.; Printz, A.D.; Zaretski, A.V.; O’Connor, T.F.; Rodriquez, D.; Valle, E.; Lipomi, D.J. Plasticization of PEDOT:PSS by common additives for mechanically robust organic solar cells and wearable sensors. Adv. Funct. Mater. 2015, 25, 427–436. [Google Scholar] [CrossRef]

- Oh, J.Y.; Kim, S.; Baik, H.K.; Jeong, U. Conducting Polymer Dough for Deformable Electronics. Adv. Mater. 2016, 28, 4455–4461. [Google Scholar] [CrossRef]

- Cummins, G.; Desmulliez, M.P.Y. Inkjet printing of conductive materials: A review. Circuit World 2012, 38, 193–213. [Google Scholar] [CrossRef]

- Cao, X.; Chen, H.; Gu, X.; Liu, B.; Wang, W.; Cao, Y.; Wu, F.; Zhou, C. Screen printing as a scalable and low-cost approach for rigid and flexible thin-film transistors using separated carbon nanotubes. ACS Nano 2014, 8, 12769–12776. [Google Scholar] [CrossRef]

- Pudas, M.; Halonen, N.; Granat, P.; Vähäkangas, J. Gravure printing of conductive particulate polymer inks on flexible substrates. Prog. Org. Coat. 2005, 54, 310–316. [Google Scholar] [CrossRef]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. 2009, 93, 394–412. [Google Scholar] [CrossRef]

- López, M.A.; Sánchez, J.C.; Estrada, M. Characterization of PEDOT:PSS dilutions for inkjet printing applied to OLED fabrication. In Proceedings of the 7th International Caribbean Conference on Devices, Circuits and Systems, Cancun, Mexico, 28–30 April 2008; pp. 11–14. [Google Scholar] [CrossRef]

- Garma, L.D.; Ferrari, M.L.; Scognamiglio, P.; Greco, F.; Santoro, F. Inkjet printed PEDOT:PSS multi-electrode arrays for low-cost in vitro electrophysiology. Lab Chip 2019, 19, 3776–3786. [Google Scholar] [CrossRef]

- Bihar, E.; Corzo, D.; Hidalgo, T.C.; Rosas, -V.D.; Salama, K.N.; Inal, S.; Baran, D. Fully Inkjet-Printed, Ultrathin and Conformable Organic Photovoltaics as Power Source Based on Cross-Linked PEDOT: PSS Electrodes. Adv. Mater. Technol. 2020, 5, 2000226. [Google Scholar] [CrossRef]

- Waremra, R.S.; Betaubun, P. Analysis of Electrical Properties Using the four point Probe Method. E3S Web Conf. 2018, 73, 1–4. [Google Scholar] [CrossRef]

- Gilissen, K. Upscaling of Organic Light Emitting Devices: A Focus on Innovative Materials, Versatile Printing Techniques and State-of-the-Art Post-Treatments. Ph.D. Thesis, University of Hasselt, Hasselt, Belgium, 2016. [Google Scholar]

- Van Der Pauw, L.J. A method of measuring specific resistivity and hall effect of discs of arbitrary shape. Philips Res. Rep. 1958, 13, 1–9. [Google Scholar]

- Czichos, H.; Saito, T.; Smith, L. Electrical Properties. In Springer Handbook of Materials Measurement Methods; Smith, L., Ed.; Springer: Berlin, Germany, 2006. [Google Scholar]

- Reynolds, O. XXIX. An Experimental Investigation of the Circumstances Which Determine Whether the Motion of Water Shall Be Direct or Sinuous, and of the Law of Resistance in Parallel Channels. Philos. Trans. R. Soc. Lond. 1883, 174, 935–982. [Google Scholar]

- Bergeron, V.; Bonn, D.; Martin, J.Y.; Vovelle, L. Controlling droplet deposition with polymer additives. Nature 2000, 405, 772–775. [Google Scholar] [CrossRef]

- McKinley, G.H.; Renardy, M. Wolfgang von Ohnesorge. Phys. Fluids 2011, 23, 127101. [Google Scholar] [CrossRef]

- Fromm, J.E. Numerical Calculation of the Fluid Dynamics of Drop-on-Demand Jets. IBM J. Res. Dev. 1984, 28, 322–333. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive nanomaterials for printed electronics. Small 2014, 10, 3515–3535. [Google Scholar] [CrossRef]

- Stegen, J. Mechanics of carbon nanotube scission under sonication. J. Chem. Phys. 2014, 140, 244908. [Google Scholar] [CrossRef]

- Finn, D.J.; Lotya, M.; Coleman, J.N. Inkjet printing of silver nanowire networks. ACS Appl. Mater. Interfaces 2015, 7, 9254–9261. [Google Scholar] [CrossRef]

- Yin, Z.P.; Huang, Y.A.; Bu, N.B.; Wang, X.M.; Xiong, Y.L. Inkjet printing for flexible electronics: Materials, processes and equipments. Chin. Sci. Bull. 2010, 55, 3383–3407. [Google Scholar] [CrossRef]

- Castrejon, -P.J.R.; Baxter, W.R.; Morgan, J.; Temple, S.; Martin, G.D.; Hutchings, I.M. Future, opportunities and challenges of inkjet technologies. At. Sprays 2013, 23, 541–565. [Google Scholar] [CrossRef]

- FUJIFILM. FUJIFILM Dimatix Ink Tutorial. Available online: https://www.cnfusers.cornell.edu/sites/default/files/Equipment-Resources/Ink%20formulation%20tutorial.pdf (accessed on 3 December 2020).

- Levchik, S.V.; Weil, E.D. Thermal decomposition, combustion and fire-retardancy of polyurethanes—A review of the recent literature. Polym. Int. 2004, 53, 1585–1610. [Google Scholar] [CrossRef]

- Soltman, D.; Subramanian, V. Inkjet-printed line morphologies and temperature control of the coffee ring effect. Langmuir 2008, 24, 2224–2231. [Google Scholar] [CrossRef] [PubMed]

- CR Models for Surface Free Energy Calculation. Available online: https://www.kruss-scientific.com/fileadmin/user_upload/website/literature/kruss-tn306-en.pdf (accessed on 3 December 2020).

- Van Osch, T.H.J.; Perelaer, J.; De Laat, A.W.M.; Schubert, U.S. Inkjet printing of narrow conductive tracks on untreated polymeric substrates. Adv. Mater. 2008, 20, 343–345. [Google Scholar] [CrossRef]

- Elschner, A. Solar Energy Materials & Solar Cells The spectral sensitivity of PEDOT: PSS films. Sol. Energy Mater. Sol. Cells 2011, 95, 1333–1338. [Google Scholar] [CrossRef]

| Sample Number | PEDOT:PSS (vol.%) | DMSO (Vol.%) | Viscosity @22 °C in mPa.s (η) | Surface Tension @ 22 °C in mN/m (γ) | Density in mg/cm3 (ρ) | Ohnesorge Number (Oh) | Z Number |

|---|---|---|---|---|---|---|---|

| 1 | 90 | 10 | 15.48 | 62 | 1.03 | 0.42 | 2.38 |

| 2 | 80 | 20 | 15.61 | 60 | 1.04 | 0.43 | 2.33 |

| 3 | 70 | 30 | 16.60 | 57 | 1.05 | 0.47 | 2.13 |

| 4 | 60 | 40 | 16.54 | 56 | 1.08 | 0.46 | 2.18 |

| 5 | 50 | 50 | 17.06 | 53 | 1.09 | 0.48 | 2.08 |

| 6 | 40 | 60 | 21.48 | 46.5 | 1.11 | 0.65 | 1.54 |

| 7 | 30 | 70 | 14.04 | 49 | 1.11 | 0.41 | 2.44 |

| 8 | 20 | 80 | 12.13 | 46 | 1.12 | 0.37 | 2.70 |

| 9 | 10 | 90 | 7.12 | 44 | 1.14 | 0.22 | 4.55 |

| Surface Treatment | Contact Angle of Water on TPU | Contact Angle of Diiodomethane on TPU | |||

|---|---|---|---|---|---|

| No treatment | 67.5 | 42.4 | 38.3 | 7.3 | 45.7 |

| Corona treatment | 52.1 | 32.2 | 43.2 | 13.4 | 56.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basak, I.; Nowicki, G.; Ruttens, B.; Desta, D.; Prooth, J.; Jose, M.; Nagels, S.; Boyen, H.-G.; D’Haen, J.; Buntinx, M.; et al. Inkjet Printing of PEDOT:PSS Based Conductive Patterns for 3D Forming Applications. Polymers 2020, 12, 2915. https://doi.org/10.3390/polym12122915

Basak I, Nowicki G, Ruttens B, Desta D, Prooth J, Jose M, Nagels S, Boyen H-G, D’Haen J, Buntinx M, et al. Inkjet Printing of PEDOT:PSS Based Conductive Patterns for 3D Forming Applications. Polymers. 2020; 12(12):2915. https://doi.org/10.3390/polym12122915

Chicago/Turabian StyleBasak, Indranil, Gudrun Nowicki, Bart Ruttens, Derese Desta, Jeroen Prooth, Manoj Jose, Steven Nagels, Hans-Gerd Boyen, Jan D’Haen, Mieke Buntinx, and et al. 2020. "Inkjet Printing of PEDOT:PSS Based Conductive Patterns for 3D Forming Applications" Polymers 12, no. 12: 2915. https://doi.org/10.3390/polym12122915

APA StyleBasak, I., Nowicki, G., Ruttens, B., Desta, D., Prooth, J., Jose, M., Nagels, S., Boyen, H.-G., D’Haen, J., Buntinx, M., & Deferme, W. (2020). Inkjet Printing of PEDOT:PSS Based Conductive Patterns for 3D Forming Applications. Polymers, 12(12), 2915. https://doi.org/10.3390/polym12122915