Cellulose Pulp- and Castor Oil-Based Polyurethanes for Lubricating Applications: Influence of Streptomyces Action on Barley and Wheat Straws

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Solid-State Fermentation

2.3. Soda Pulping

2.4. Oleogel Processing

2.5. Characterization Techniques

3. Results

3.1. Cellulose Pulp Composition

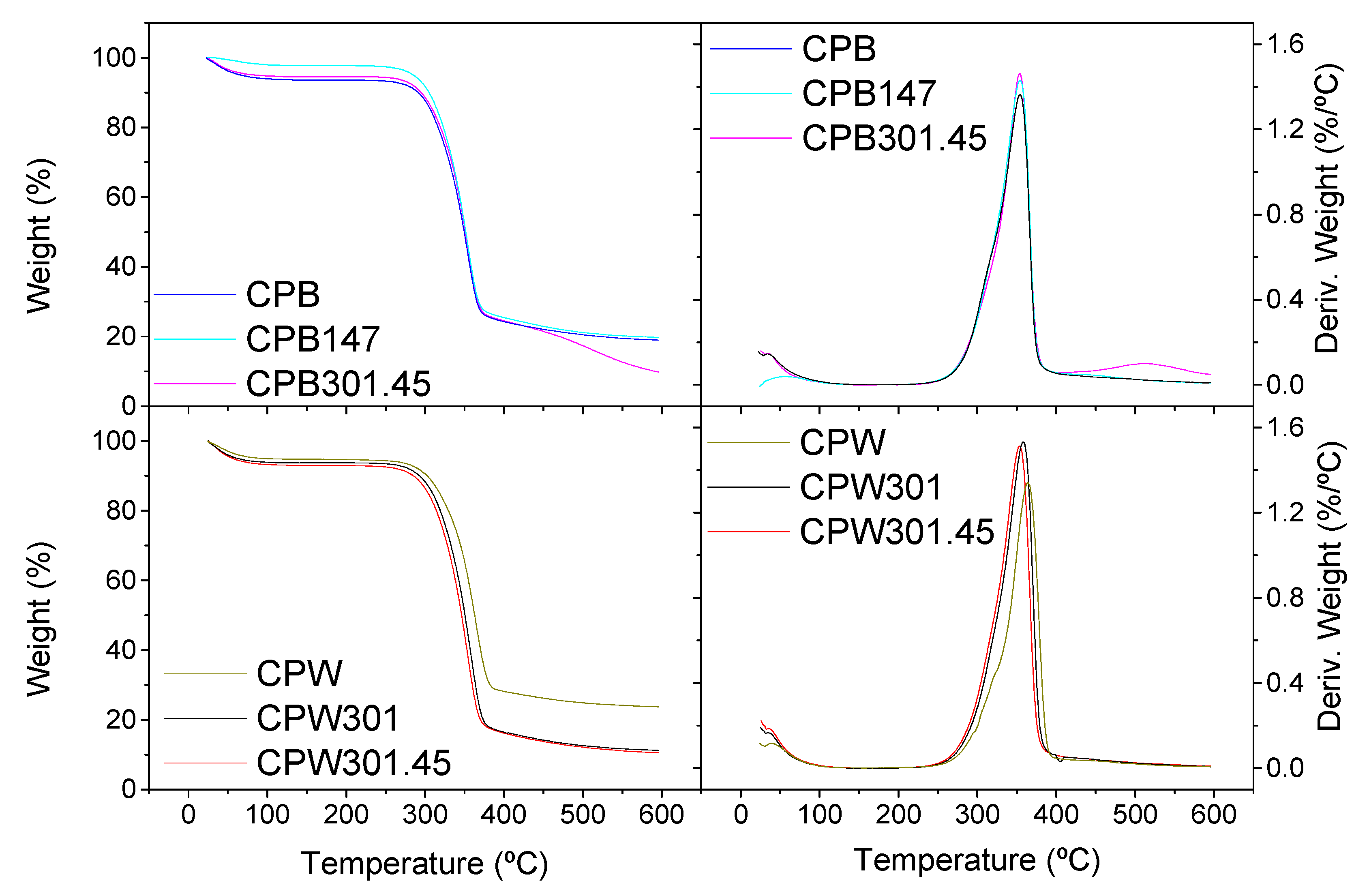

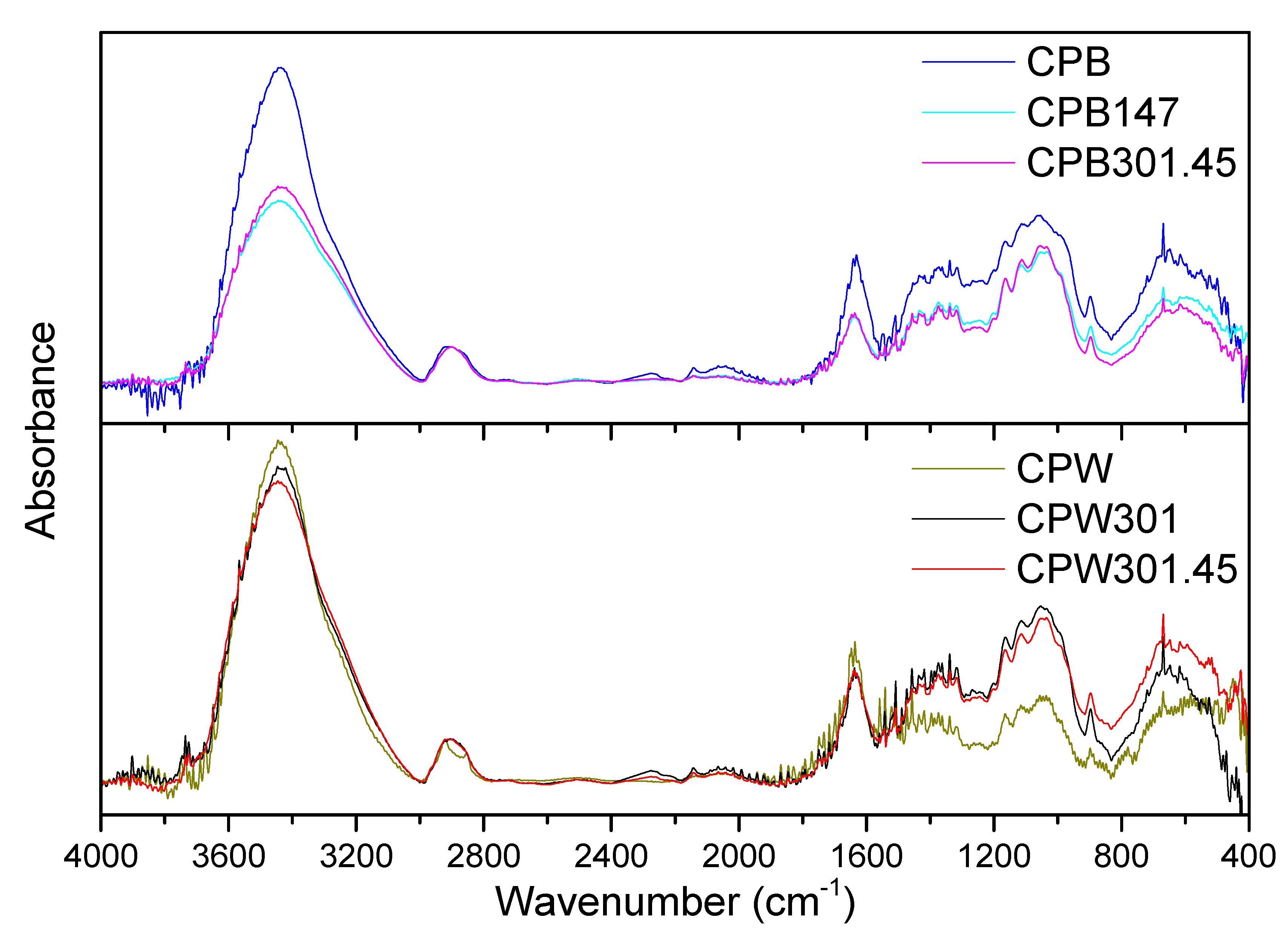

3.2. TGA and FTIR Spectroscopy of Cellulose Pulps

3.3. Polymerization Degree of Cellulose Pulps

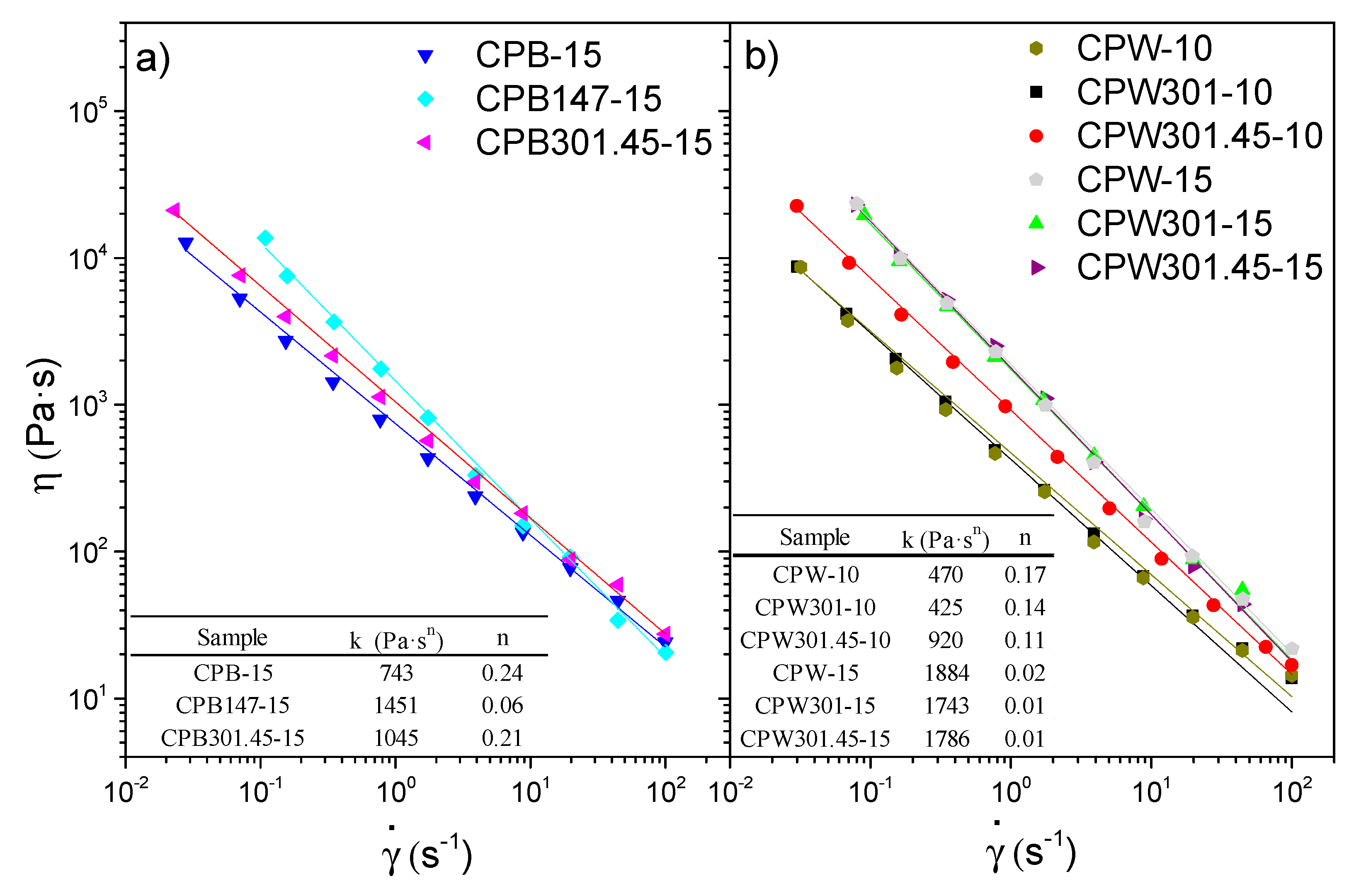

3.4. Rheology of Cellulose-Pulp-Based Oleogels

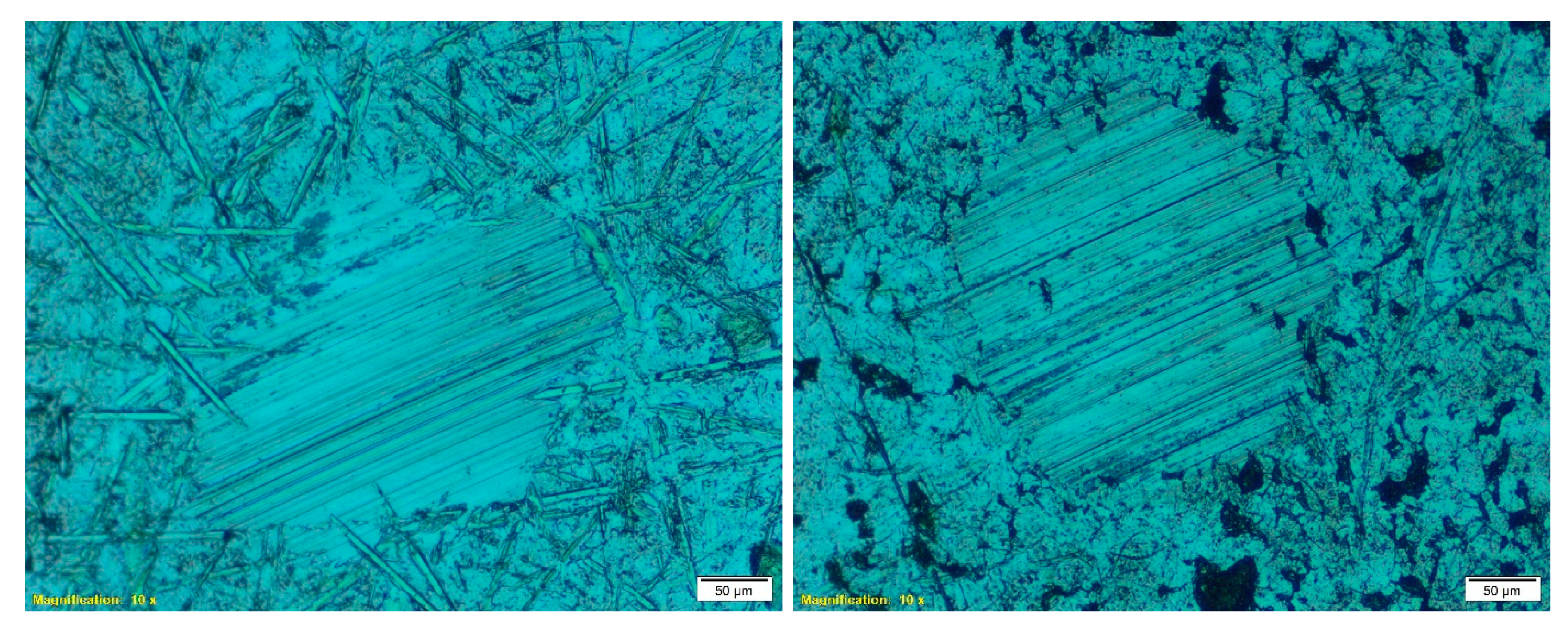

3.5. Tribological Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cao, Z.; Fan, Z.; Chen, Y.; Li, M.; Shen, T.; Zhu, C.; Ying, H. Efficient preparation of 5-hydroxymethylfurfural from cellulose in a biphasic system over hafnyl phosphates. Appl. Catal. B Environ. 2019, 244, 170–177. [Google Scholar] [CrossRef]

- Choi, H.Y.; Jeong, Y.G. Microstructures and piezoelectric performance of eco-friendly composite films based on nanocellulose and barium titanate nanoparticle. Compos. Part B Eng. 2019, 168, 58–65. [Google Scholar] [CrossRef]

- Younesi, M.; Akkus, A.; Akkus, O. Microbially-derived nanofibrous cellulose polymer for connective tissue regeneration. Mater. Sci. Eng. C 2019, 99, 96–102. [Google Scholar] [CrossRef] [PubMed]

- Amarasekara, A.S.; Gutierrez Reyes, C.D. Brønsted acidic ionic liquid catalyzed one-pot conversion of cellulose to furanic biocrude and identification of the products using LC-MS. Renew. Energy 2019, 136, 352–357. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, G.; Gao, M.; Cao, S.; Li, L.; Liu, S.; Xie, C.; Huang, L.; Yu, S.; Ragauskas, A.J. Clean production of 5-hydroxymethylfurfural from cellulose using a hydrothermal/biomass-based carbon catalyst. J. Clean. Prod. 2019, 213, 1096–1102. [Google Scholar] [CrossRef]

- Manan, F.A.A.; Hong, W.W.; Abdullah, J.; Yusof, N.A.; Ahmad, I. Nanocrystalline cellulose decorated quantum dots based tyrosinase biosensor for phenol determination. Mater. Sci. Eng. C 2019, 99, 37–46. [Google Scholar] [CrossRef]

- Konuklu, Y.; Erzin, F.; Akar, H.B.; Turan, A.M. Cellulose-based myristic acid composites for thermal energy storage applications. Sol. Energy Mater. Sol. Cells 2019, 193, 85–91. [Google Scholar] [CrossRef]

- Vasiljevic, L.; Pavlović, S. Biodegradable polymers based on proteins and carbohydrates. In Advances in Applications of Industrial Biomaterials; Pellicer, E., Nikolic, D., Sort, J., Baró, M.D., Zivic, F., Grujovic, N., Grujic, R., Pelemis, S., Eds.; Springer: New York, NY, USA, 2017; pp. 87–101. [Google Scholar] [CrossRef]

- Tripathi, A.; Parsons, G.N.; Khan, S.A.; Rojas, O.J. Synthesis of organic aerogels with tailorable morphology and strength by controlled solvent swelling following Hansen solubility. Sci. Rep. 2018, 8, 2106. [Google Scholar] [CrossRef]

- Tripathi, A.; Parsons, G.N.; Rojas, O.J.; Khan, S.A. Featherlight, mechanically robust cellulose ester aerogels for environmental remediation. ACS Omega 2017, 2, 4297–4305. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Chen, L. A green composite hydrogel based on cellulose and clay as efficient absorbent of colored organic effluent. Carbohydr. Polym. 2019, 210, 314–321. [Google Scholar] [CrossRef]

- Singh, A.; Sarkar, D.J.; Mittal, S.; Dhaka, R.; Maiti, P.; Singh, A.; Raghav, T.; Solanki, D.; Ahmed, N.; Singh, S.B. Zeolite reinforced carboxymethyl cellulose-Na+-g-cl-poly(AAm) hydrogel composites with pH responsive phosphate release behavior. J. Appl. Polym. Sci. 2019, 136, 47332. [Google Scholar] [CrossRef]

- Gallego, R.; Arteaga, J.F.; Valencia, C.; Franco, J.M. Chemical modification of methyl cellulose with HMDI to modulate the thickening properties in castor oil. Cellulose 2013, 20, 495–507. [Google Scholar] [CrossRef]

- Gallego, R.; Arteaga, J.F.; Valencia, C.; Franco, J.M. Thickening properties of several NCO-functionalized cellulose derivatives in castor oil. Chem. Eng. Sci. 2015, 134, 260–268. [Google Scholar] [CrossRef]

- Gallego, R.; Arteaga, J.F.; Valencia, C.; Franco, J.M. Rheology and thermal degradation of isocyanate-functionalized methyl cellulose-based oleogels. Carbohydr. Polym. 2013, 98, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Borrero-López, A.M.; Blánquez, A.; Valencia, C.; Hernández, M.; Arias, M.E.; Eugenio, M.E.; Fillat, Ú.; Franco, J.M. Valorization of soda lignin from wheat straw solid-state fermentation: Production of oleogels. ACS Sustain. Chem. Eng. 2018, 6, 5198–5205. [Google Scholar] [CrossRef]

- Gallego, R.; Arteaga, J.F.; Valencia, C.; Díaz, M.J.; Franco, J.M. Gel-like dispersions of HMDI-cross-linked lignocellulosic materials in castor oil: Toward completely renewable lubricating grease formulations. ACS Sustain. Chem. Eng. 2015, 3, 2130–2141. [Google Scholar] [CrossRef]

- Delgado, M.; Secouard, S.; Valencia, C.; Franco, J. On the Steady-State Flow and Yielding Behaviour of Lubricating Greases. Fluids 2019, 4, 6. [Google Scholar] [CrossRef] [Green Version]

- Sánchez, R.; Valencia, C.; Franco, J.M. Rheological and Tribological Characterization of a New Acylated Chitosan-Based Biodegradable Lubricating Grease: A Comparative Study with Traditional Lithium and Calcium Greases. Tribol. Trans. 2014, 57, 445–454. [Google Scholar] [CrossRef]

- Sánchez, R.; Stringari, G.B.; Franco, J.M.; Valencia, C.; Gallegos, C. Use of chitin, chitosan and acylated derivatives as thickener agents of vegetable oils for bio-lubricant applications. Carbohydr. Polym. 2011, 85, 705–714. [Google Scholar] [CrossRef]

- Borrero-López, A.M.; Martín-Sampedro, R.; Ibarra, D.; Valencia, C.; Eugenio, M.E.; Franco, J.M. Evaluation of lignin-enriched side-streams from different biomass conversion processes as thickeners in bio-lubricant formulations. Int. J. Biol. Macromol. 2020, 162, 1398–1413. [Google Scholar] [CrossRef]

- Borrero-López, A.M.; Valencia, C.; Franco, J.M. Rheology of lignin-based chemical oleogels prepared using diisocyanate crosslinkers: Effect of the diisocyanate and curing kinetics. Eur. Polym. J. 2017, 89, 311–323. [Google Scholar] [CrossRef]

- Cortés-Triviño, E.; Valencia, C.; Franco, J.M. Influence of epoxidation conditions on the rheological properties of gel-like dispersions of epoxidized kraft lignin in castor oil. Holzforschung 2017, 71, 777–784. [Google Scholar] [CrossRef]

- Cortés-Triviño, E.; Valencia, C.; Delgado, M.A.; Franco, J.M. Rheology of epoxidized cellulose pulp gel-like dispersions in castor oil: Influence of epoxidation degree and the epoxide chemical structure. Carbohydr. Polym. 2018, 199, 563–571. [Google Scholar] [CrossRef]

- Núñez, N.; Martín-Alfonso, J.E.; Eugenio, M.E.; Valencia, C.; Díaz, M.J.; Franco, J.M. Preparation and characterization of gel-like dispersions based on cellulosic pulps and castor oil for lubricant applications. Ind. Eng. Chem. Res. 2011, 50, 5618–5627. [Google Scholar] [CrossRef]

- Núñez, N.; Martín-Alfonso, J.E.; Valencia, C.; Sánchez, M.C.; Franco, J.M. Rheology of new green lubricating grease formulations containing cellulose pulp and its methylated derivative as thickener agents. Ind. Crops Prod. 2012, 37, 500–507. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Yañez, R.; Valencia, C.; Franco, J.M.; Díaz, M.J. Optimization of the methylation conditions of kraft cellulose pulp for its use as a thickener agent in biodegradable lubricating greases. Ind. Eng. Chem. Res. 2009, 48, 6765–6771. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Núñez, N.; Valencia, C.; Franco, J.M.; Díaz, M.J. Formulation of new biodegradable lubricating greases using ethylated cellulose pulp as thickener agent. J. Ind. Eng. Chem. 2011, 17, 818–823. [Google Scholar] [CrossRef]

- Borrero-López, A.M.; Valencia, C.; Franco, J.M. Green and facile procedure for the preparation of liquid and gel-like polyurethanes based on castor oil and lignin: Effect of processing conditions on the rheological properties. J. Clean. Prod. 2020, 277, 123367. [Google Scholar] [CrossRef]

- Thomas, V.; Jayabalan, M. Studies on the effect of virtual crosslinking on the hydrolytic stability of novel aliphatic polyurethane ureas for blood contact applications. J. Biomed. Mater. Res. 2001, 56, 144–157. [Google Scholar] [CrossRef]

- Panda, S.S.; Panda, B.P.; Mohanty, S.; Nayak, S.K. The castor oil based water borne polyurethane dispersion; effect of -NCO/OH content: Synthesis, characterization and properties. Green Process. Synth. 2016, 6, 341–351. [Google Scholar] [CrossRef]

- Labafzadeh, S.R. Cellulose-Based Materials. Ph.D. Thesis, University of Helsinki, Helsinki, Finland, 2015. [Google Scholar]

- Huang, L.; Sun, N.; Ban, L.; Wang, Y.; Yang, H. Ability of different edible fungi to degrade crop straw. AMB Express 2019, 9, 4. [Google Scholar] [CrossRef] [PubMed]

- Becarelli, S.; Chicca, I.; Siracusa, G.; La China, S.; Gentini, A.; Lorenzi, R.; Munz, G.; Petroni, G.; Levin, D.B.; Di Gregorio, S. Hydrocarbonoclastic Ascomycetes to enhance co-composting of total petroleum hydrocarbon (TPH) contaminated dredged sediments and lignocellulosic matrices. New Biotechnol. 2019, 50, 27–36. [Google Scholar] [CrossRef] [PubMed]

- Vila-Costa, M.; Sebastián, M.; Pizarro, M.; Cerro-Gálvez, E.; Lundin, D.; Gasol, J.M.; Dachs, J. Microbial consumption of organophosphate esters in seawater under phosphorus limited conditions. Sci. Rep. 2019, 9, 233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saarela, M.H. Safety aspects of next generation probiotics. Curr. Opin. Food Sci. 2019, 30, 8–13. [Google Scholar] [CrossRef]

- Kasli, I.M.; Thomas, O.R.T.; Overton, T.W. Use of a design of experiments approach to optimise production of a recombinant antibody fragment in the periplasm of Escherichia coli: Selection of signal peptide and optimal growth conditions. AMB Express 2019, 9, 5. [Google Scholar] [CrossRef] [PubMed]

- Arias, M.E.; Blánquez, A.; Hernández, M.; Rodríguez, J.; Ball, A.S.; Jiménez-Morillo, N.T.; González-Vila, F.J.; González-Pérez, J.A. Role of a thermostable laccase produced by Streptomyces ipomoeae in the degradation of wheat straw lignin in solid state fermentation. J. Anal. Appl. Pyrolysis 2016, 122, 202–208. [Google Scholar] [CrossRef]

- Borrero-López, A.M.; Blánquez, A.; Valencia, C.; Hernández, M.; Arias, M.E.; Franco, J.M. Influence of solid-state fermentation with Streptomyces on the ability of wheat and barley straws to thicken castor oil for lubricating purposes. Ind. Crops Prod. 2019, 140, 111625. [Google Scholar] [CrossRef]

- Kiiskinen, L.L.; Palonen, H.; Linder, M.; Viikari, L.; Kruus, K. Laccase from Melanocarpus albomyces binds effectively to cellulose. FEBS Lett. 2004, 576, 251–255. [Google Scholar] [CrossRef] [Green Version]

- Saarinen, T.; Orelma, H.; Grönqvist, S.; Andberg, M.; Holappa, S.; Laine, J. Adsorption of different laccases on cellulose and lignin surfaces. Bioresources 2009, 4, 94–110. [Google Scholar]

- De Souza, W.R. Microbial degradation of lignocellulosic biomass. In Sustainable Degradation of Lignocellulosic Biomass—Techniques, Applications and Commercialization; Chandel, A., Ed.; IntechOpen: London, UK, 2013; pp. 207–248. [Google Scholar] [CrossRef] [Green Version]

- Quintana, E. Enzymatic and Chemical Treatments to Obtain Pulps with High-Cellulose Content. Ph.D. Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2016. [Google Scholar]

- Liu, C.; Wang, H.; Karim, A.M.; Sun, J.; Wang, Y. Catalytic fast pyrolysis of lignocellulosic biomass. Chem. Soc. Rev. 2014, 43, 7594–7623. [Google Scholar] [CrossRef] [PubMed]

- Ciolacu, D.; Ciolacu, F.; Popa, V.I. Amorphous cellulose—Structure and characterization. Cell. Chem. Technol. 2011, 45, 13–21. [Google Scholar]

- Ciolacu, D.; Kovac, J.; Kokol, V. The effect of the cellulose-binding domain from Clostridium cellulovorans on the supramolecular structure of cellulose fibers. Carbohydr. Res. 2010, 345, 621–630. [Google Scholar] [CrossRef] [PubMed]

- Janzon, R.; Puls, J.; Bohn, A.; Potthast, A.; Saake, B. Upgrading of paper grade pulps to dissolving pulps by nitren extraction: Yields, molecular and supramolecular structures of nitren extracted pulps. Cellulose 2008, 15, 739. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Valencia, C.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Evaluation of different polyolefins as rheology modifier additives in lubricating grease formulations. Mater. Chem. Phys. 2011, 128, 530–538. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Valencia, C.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Rheological modification of lubricating greases with recycled polymers from different plastics waste. Ind. Eng. Chem. Res. 2009, 48, 4136–4144. [Google Scholar] [CrossRef]

- Heyer, P.; Läuger, J. Correlation between friction and flow of lubricating greases in a new tribometer device. Lubr. Sci. 2009, 21, 253–268. [Google Scholar] [CrossRef]

- Delgado, M.A.; Cortés-Triviño, E.; Valencia, C.; Franco, J.M. Tribological study of epoxide-functionalized alkali lignin-based gel-like biogreases. Tribol. Int. 2020, 146, 106231. [Google Scholar] [CrossRef]

- Gallego, R.; Cidade, T.; Sánchez, R.; Valencia, C.; Franco, J.M. Tribological behaviour of novel chemically modified biopolymer-thickened lubricating greases investigated in a steel–steel rotating ball-on-three plates tribology cell. Tribol. Int. 2016, 94, 652–660. [Google Scholar] [CrossRef] [Green Version]

| Sample | Klason Lignin (%) | Soluble Lignin (%) | Glucose (%) | Xylose (%) | Arabinose (%) | Extracts (%) | Ashes (%) |

|---|---|---|---|---|---|---|---|

| CPB | 2.2 ± 0.2 | 0.3 ± 0.1 | 62.2 ± 0.5 | 30.3 ± 0.5 | 3.2 ± 0.2 | 0.66 | 1.2 ± 0.2 |

| CPB147 | 2.1 ± 0.3 | 0.3 ± 0.0 | 65.3 ± 0.8 | 28.1 ± 2.1 | 3.0 ± 0.2 | 0.44 | 1.3 ± 0.2 |

| CPB301.45 | 3.5 ± 0.3 | 0.4 ± 0.0 | 64.2 ± 1.3 | 27.6 ± 0.7 | 3.1 ± 0.0 | 0.41 | 1.2 ± 0.0 |

| CPW | 6.3 ± 0.3 | 1.1 ± 0.1 | 55.5 ± 2.6 | 21.6 ± 1.8 | 1.1 ± 0.3 | 5.08 | 1.2 ± 0.2 |

| CPW301 | 6.3 ± 0.6 | 0.3 ± 0.2 | 62.0 ± 2.2 | 29.7 ± 0.7 | 2.5 ± 0.0 | 1.14 | 0.6 ± 0.4 |

| CPW301.45 | 4.0 ± 1.4 | 0.4 ± 0.0 | 61.2 ± 3.5 | 31.1 ± 3.7 | 4.3 ± 2.5 | 0.27 | 1.3 ± 0.3 |

| Sample | Tonset (°C) | Tmax (°C) | Tfinal (°C) | ΔW (%) | Residue (%) |

|---|---|---|---|---|---|

| CPB | 290 | 355 | 368 | 75 | 19 |

| CPB147 | 288 | 354 | 368 | 78 | 20 |

| CPB301.45 | 288/473 | 355/515 | 368/553 | 72/13 | 10 |

| CPW | 293 | 364 | 380 | 71 | 24 |

| CPW301 | 291 | 358 | 373 | 82 | 11 |

| CPW301.45 | 286 | 354 | 370 | 82 | 11 |

| Relative Crystallinity Index | EH (kJ) | Intrinsic Viscosity (cm3/g) | Polymerization Degree | |

|---|---|---|---|---|

| CPB | 1.24 | 11.31 | 494 | 1185 |

| CPB147 | 1.29 | 11.18 | 492 | 1178 |

| CPB301.45 | 1.51 | 11.31 | 700 | 1875 |

| CPW | 2.03 | 11.24 | 397 | 944 |

| CPW301 | 1.45 | 11.31 | 544 | 1344 |

| CPW301.45 | 1.10 | 10.78 | 608 | 1556 |

| Oleogels | Friction Coefficient | Wear Scar Surface (µm2) | Wear Scar Diameter (µm) |

|---|---|---|---|

| CPB-15 | 0.081 ± 0.003 | 55,640 ± 2803 | 315 ± 32 |

| CPB147-15 | 0.082 ± 0.003 | 41,024 ± 14,467 | 263 ± 69 |

| CPB301.45-15 | 0.089 ± 0.006 | 28,551 ± 5918 | 190 ± 28 |

| CPW-10 | 0.077 ± 0.003 | 35,669 ± 5704 | 217 ± 24 |

| CPW301-10 | 0.077 ± 0.006 | 105,796 ± 7362 | 366 ± 2 |

| CPW301.45-10 | 0.085 ± 0.006 | 63,314 ± 13,295 | 286 ± 23 |

| CPW-15 | 0.099 ± 0.010 | 35,148 ± 504 | 215 ± 23 |

| CPW301-15 | 0.088 ± 0.010 | 22,306 ± 11,749 | 161 ± 23 |

| CPW301.45-15 | 0.108 ± 0.013 | 25,205 ± 3769 | 193 ± 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borrero-López, A.M.; Valencia, C.; Blánquez, A.; Hernández, M.; Eugenio, M.E.; Franco, J.M. Cellulose Pulp- and Castor Oil-Based Polyurethanes for Lubricating Applications: Influence of Streptomyces Action on Barley and Wheat Straws. Polymers 2020, 12, 2822. https://doi.org/10.3390/polym12122822

Borrero-López AM, Valencia C, Blánquez A, Hernández M, Eugenio ME, Franco JM. Cellulose Pulp- and Castor Oil-Based Polyurethanes for Lubricating Applications: Influence of Streptomyces Action on Barley and Wheat Straws. Polymers. 2020; 12(12):2822. https://doi.org/10.3390/polym12122822

Chicago/Turabian StyleBorrero-López, Antonio M., Concepción Valencia, Alba Blánquez, Manuel Hernández, María E. Eugenio, and José M. Franco. 2020. "Cellulose Pulp- and Castor Oil-Based Polyurethanes for Lubricating Applications: Influence of Streptomyces Action on Barley and Wheat Straws" Polymers 12, no. 12: 2822. https://doi.org/10.3390/polym12122822

APA StyleBorrero-López, A. M., Valencia, C., Blánquez, A., Hernández, M., Eugenio, M. E., & Franco, J. M. (2020). Cellulose Pulp- and Castor Oil-Based Polyurethanes for Lubricating Applications: Influence of Streptomyces Action on Barley and Wheat Straws. Polymers, 12(12), 2822. https://doi.org/10.3390/polym12122822