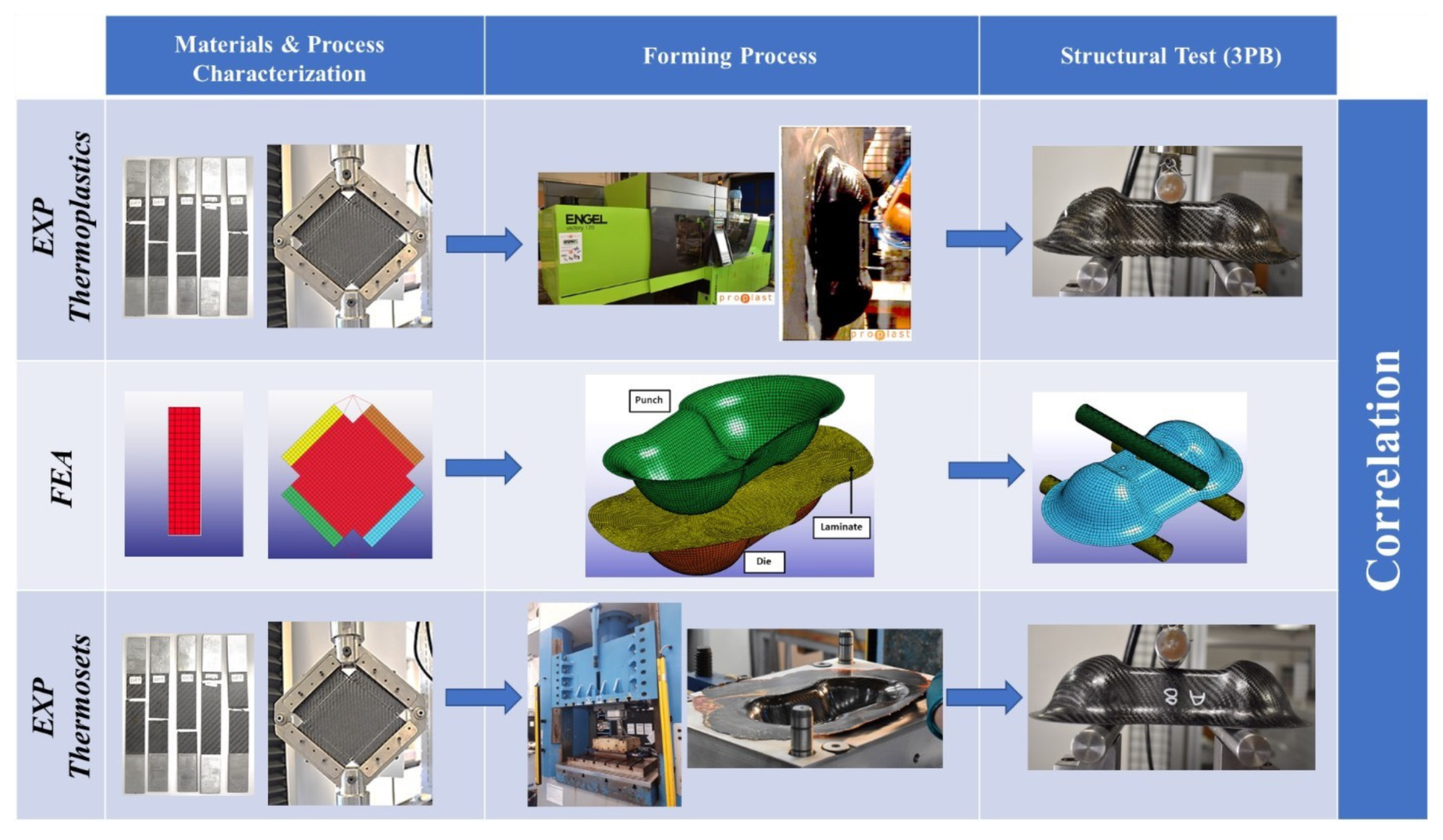

Validation of a Simulation Methodology for Thermoplastic and Thermosetting Composite Materials Considering the Effect of Forming Process on the Structural Performance

Abstract

1. Introduction

- the laminates are cut in a 2D shape, which normally is the result of a trial and error procedure,

- preform is then heated generally by an infrared oven until proper temperature to ensure the formability of the polymer matrix,

- a robotic arm moves the hot laminate into the press mold,

- the mold closes and a pressure is applied to consolidate the composite part while the laminate temperature decreases, and

- finally, the part is demolded and kept to stability in air, and then it is analyzed with non-destructive techniques for quality control check.

- the thermosetting resin has to be chemically designed for press molding, with a fast curing phase of some minutes, instead of some hours as it happens for the traditional autoclave process,

- the prepreg has to be stored at −20 °C and heated in the mold to facilitate the handling and avoid the degradation,

- the low viscosity of the thermosetting resin at the forming temperature leads to the use of vertical press machines with lower load capacity, instead of the horizontal press machines used for the thermoplastic manufacturing, and

- the mold has not to be cooled down within the process cycles because of the thermosetting composite consolidation inside the mold after the correct curing time.

2. Materials and Methods

2.1. Materials Specifications

- TEPEX® Dynalite 104-RG600(x)/47% by Bond-Laminates (Brilon, Germany), a Polypropylene organosheet reinforced with E-Glass 600 g/m2 Twill 2/2 balanced woven, here called “GF/PP”;

- TEPEX® Dynalite 201-C200(x)/45% by Bond-Laminates (Brilon, Germany), a Polyamide 66 organosheet reinforced with Carbon 200 g/m2 Twill 2/2 balanced woven, here called “CF/PA66”;

- GG240T-FF-IMP509 by Angeloni, (Venice, Italy) an Epoxy prepreg with Carbon 240 g/m2 Twill 2/2 balanced woven, here called “CF/EP—Angeloni”;

- LTM26 by Solvay (Bruxelles, Belgium), an Epoxy prepreg with Carbon 285 g/m2 Twill 2/2 balanced woven, here called “CF/EP—Solvay”.

2.2. Static Tests Characterization

2.3. Process Tests Characterization

2.3.1. Intra-Ply Evaluation (Tensile and Shear Tests)

2.3.2. Tool-Ply Evaluation (Friction Test)

2.4. Thermoforming of Double Dome

2.4.1. Horizontal Press

2.4.2. Vertical Press

2.5. Bending Test on Double Dome

2.6. Quality Check on Double Dome

3. Virtual Simulation on LS-DYNA

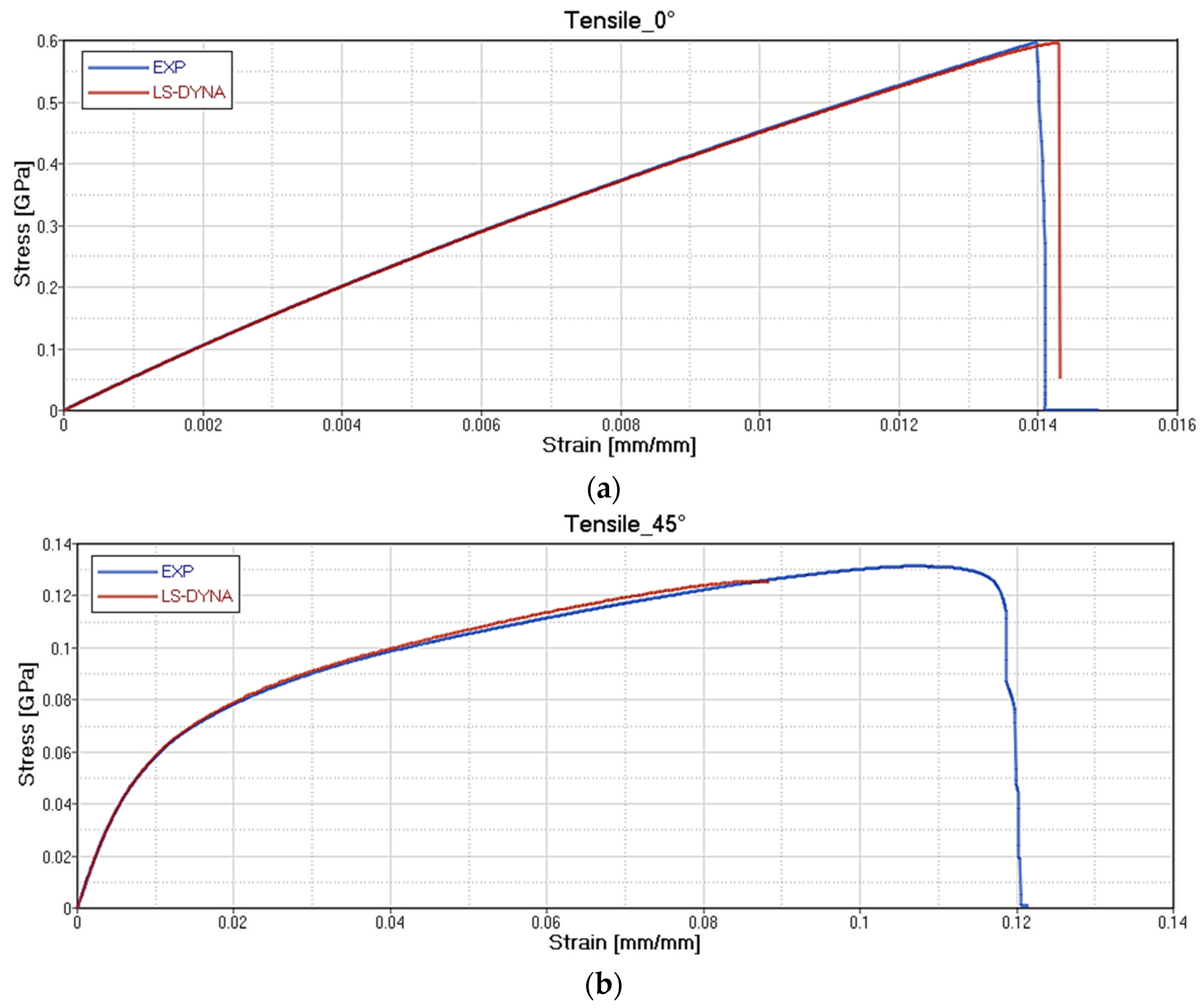

3.1. Static Tests Simulation

3.2. Process Tests Simulation

3.3. Thermoforming Simulation

3.4. Double Dome Bending Test Simulation

3.5. Mapping Procedure

4. Results and Discussion

4.1. Static Tests

4.2. Process Tests

4.3. Thermoforming Process

4.4. Structural Bending Test

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sinha, M.; Tyagi, R.K. Vehicular Light Weighting by Finite Element Simulation of E Glass—Based Composite Automotive Seat. Mater. Perform. Charact. 2019, 8, 459–478. [Google Scholar] [CrossRef]

- Mayyas, A.; Qattawi, A.; Omar, M.A.; Shan, D. Design for sustainability in automotive industry: A comprehensive review. Renew. Sustain. Energy Rev. 2012, 16, 1845–1862. [Google Scholar] [CrossRef]

- Brooks, R.; Shanmuga-Ramanan, S.M.; Arun, S. Composites in Automotive Applications: Design. Compreh. Compos. Mater. 2000, 6, 341–363. [Google Scholar]

- Al-Qureshi, H. Automobile leaf springs from composite materials. J. Mater. Process. Technol. 2001, 118, 58–61. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part. B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Messana, A.; Airale, A.G.; Ferraris, A.; Sisca, L.; Carello, M. Correlation between thermo-mechanical properties and chemical composition of aged thermoplastic and thermosetting fiber reinforced plastic materials. Mater. Werkst. 2017, 48, 447–455. [Google Scholar] [CrossRef]

- Friedrich, K.; Almajid, A.A. Manufacturing Aspects of Advanced Polymer Composites for Automotive Applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Virgillito, E.; Airale, A.G.; Ferraris, A.; Sisca, L.; Carello, M. Specific Energy Absorption Evaluation on GFRP Laminate Plate by Optical, Thermographic and Tomographic Analysis. Exp. Tech. 2018, 43, 15–24. [Google Scholar] [CrossRef]

- Henning, F.; Kärger, L.; Dörr, D.; Schirmaier, F.J.; Seuffert, J.; Bernath, A. Fast processing and continuous simulation of automotive structural composite components. Compos. Sci. Technol. 2019, 171, 261–279. [Google Scholar] [CrossRef]

- Aranberri, I.; Landa, M.; Elorza, E.; Salaberria, A.M.; Rekondo, A. Thermoformable and recyclable CFRP pultruded profile manufactured from an epoxy vitrimer. Polym. Test. 2020. [Google Scholar] [CrossRef]

- Wang, P.; Hamila, N.; Boisse, P. Thermoforming simulation of multilayer composites with continuous fibres and thermoplastic matrix. Compos. Part. B Eng. 2013, 52, 127–136. [Google Scholar] [CrossRef]

- Guzman-Maldonado, E.; Hamila, N.; Naouar, N.; Moulin, G.; Boisse, P. Simulation of thermoplastic prepreg thermoforming based on a visco-hyperelastic model and a thermal homogenization. Mater. Des. 2016, 93, 431–442. [Google Scholar] [CrossRef]

- Dörr, D.; Joppich, T.; Kugele, D.; Henning, F.; Kärger, L. A coupled thermomechanical approach for finite element forming simulation of continuously fiber-reinforced semi-crystalline thermoplastics. Compos. Part A Appl. Sci. Manuf. 2019, 125. [Google Scholar] [CrossRef]

- Kuhtz, M.; Maron, B.; Hornig, A.; Müller, M.; Langkamp, A.; Gude, M. Characterising the thermoforming behaviour of glass fibre textile reinforced thermoplastic composite materials. AIP Conf. Proc. 2018, 1960, 020014. [Google Scholar]

- Gong, Y.; Song, Z.; Ning, H.; Hu, N.; Peng, X.; Wu, X.; Zou, R.; Liu, F.; Weng, S.; Liu, Q. A comprehensive review of characterization and simulation methods for thermo-stamping of 2D woven fabric reinforced thermoplastics. Compos. Part B Eng. 2020, 203. [Google Scholar] [CrossRef]

- Lee, W.; Padvoiskis, J.; Cao, J.; de Luycker, E.; Boisse, P.; Morestin, F.; Chen, J.; Sherwood, J. Bias-extension of woven composite fabrics. Int. J. Mater. Form. 2008, 203. [Google Scholar] [CrossRef]

- Fetfatsidis, K.A.; Jauffrès, D.; Sherwood, J.A.; Chen, J. Characterization of the tool/fabric and fabric/fabric friction for woven-fabric composites during the thermostamping process. Int. J. Mater. Form. 2011, 6, 209–221. [Google Scholar] [CrossRef]

- Carello, M.; Amirth, N.; Airale, A.G.; Monti, M.; Romeo, A. Building Block Approach’ for Structural Analysis of Thermoplastic Composite Components for Automotive Applications. Appl. Compos. Mater. 2017, 24, 1309–1320. [Google Scholar] [CrossRef]

- Jayasree, N.A.; Airale, A.G.; Ferraris, A.; Messana, A.; Sisca, L.; Carello, M. Process analysis for structural optimisation of thermoplastic composite component using the building block approach. Compos. Part B Eng. 2017, 126, 119–132. [Google Scholar] [CrossRef]

- Sargent, J.; Chen, J.; Sherwood, J.A.; Cao, J.; Boisse, P.; Willem, A.; Vanclooster, K.; Lomov, S.V.; Khan, M.; Mabrouki, T.; et al. Benchmark Study of Finite Element Models for Simulating the Thermostamping of Woven-Fabric Reinforced Composites. Int. J. Mater. Form. 2010, 3, 683–686. [Google Scholar] [CrossRef]

- Lee, W.; Um, M.K.; Byun, J.H.; Boisse, P.; Cao, J. Numerical study on thermo-stamping of woven fabric composites based on double-dome stratch forming. Int. J. Mater. Form. 2010, 3, 1217–1227. [Google Scholar] [CrossRef]

- Khan, M.; Mabrouki, T.; Vidal-Salle, E.; Boisse, P. Numerical and experimental analyses of woven composite reinforcement forming using a hypoelastic behaviour. Application to the double dome benchmark. J. Mater. Process. Technol. 2010, 210, 378–388. [Google Scholar] [CrossRef]

- Xiong, H.; Hamila, N.; Boisse, P. Consolidation Modeling during Thermoforming of Thermoplastic Composite Prepregs. Materials 2019, 12, 2853. [Google Scholar] [CrossRef] [PubMed]

- Komeili, M.; Milani, A. On effect of shear-tension coupling in forming simulation of woven fabric reinforcements. Compos. Part B Eng. 2016, 99, 17–29. [Google Scholar] [CrossRef]

| Material | Molding Process | Temperature (°C) | Pressure (bar) | Cycle Time (s) |

|---|---|---|---|---|

| GF/PP | Horizontal Press | 180 | 1213 | 52 |

| CF/PA66 | Horizontal Press | 290 | 1503 | 50 |

| CF/EP—Angeloni | Vertical Press | 140 | 90 | 480 |

| CF/EP—Solvay | Vertical Press | 140 | 70 | 300 |

| Type of Test | Layers Orientation | Number of Specimens | Test Speed (mm/min) | Specimen Dimensions (mm) | Standard Reference |

|---|---|---|---|---|---|

| Tension | [0] 8 | 5 | 2 | 200 × 25 × 2 | ASTM D3039 |

| Tension | [45] 8 | 5 | 2 | 200 × 25 × 2 | ASTM D3518 |

| Four-point Bending | [0] 8 | 5 | 2 | 100 × 15 × 2 | ASTM D7264 |

| Material | Temperature (°C) | Static Frictional Coefficient μs (/) | Dynamic Frictional Coefficient μd (/) |

|---|---|---|---|

| GF/PP | 180 | 0.35 | 0.30 |

| CF/PA66 | 290 | 0.42 | 0.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sisca, L.; Locatelli Quacchia, P.T.; Messana, A.; Airale, A.G.; Ferraris, A.; Carello, M.; Monti, M.; Palenzona, M.; Romeo, A.; Liebold, C.; et al. Validation of a Simulation Methodology for Thermoplastic and Thermosetting Composite Materials Considering the Effect of Forming Process on the Structural Performance. Polymers 2020, 12, 2801. https://doi.org/10.3390/polym12122801

Sisca L, Locatelli Quacchia PT, Messana A, Airale AG, Ferraris A, Carello M, Monti M, Palenzona M, Romeo A, Liebold C, et al. Validation of a Simulation Methodology for Thermoplastic and Thermosetting Composite Materials Considering the Effect of Forming Process on the Structural Performance. Polymers. 2020; 12(12):2801. https://doi.org/10.3390/polym12122801

Chicago/Turabian StyleSisca, Lorenzo, Patrizio Tiziano Locatelli Quacchia, Alessandro Messana, Andrea Giancarlo Airale, Alessandro Ferraris, Massimiliana Carello, Marco Monti, Marta Palenzona, Andrea Romeo, Christian Liebold, and et al. 2020. "Validation of a Simulation Methodology for Thermoplastic and Thermosetting Composite Materials Considering the Effect of Forming Process on the Structural Performance" Polymers 12, no. 12: 2801. https://doi.org/10.3390/polym12122801

APA StyleSisca, L., Locatelli Quacchia, P. T., Messana, A., Airale, A. G., Ferraris, A., Carello, M., Monti, M., Palenzona, M., Romeo, A., Liebold, C., Scalera, S., Festa, A., & Codrino, P. (2020). Validation of a Simulation Methodology for Thermoplastic and Thermosetting Composite Materials Considering the Effect of Forming Process on the Structural Performance. Polymers, 12(12), 2801. https://doi.org/10.3390/polym12122801