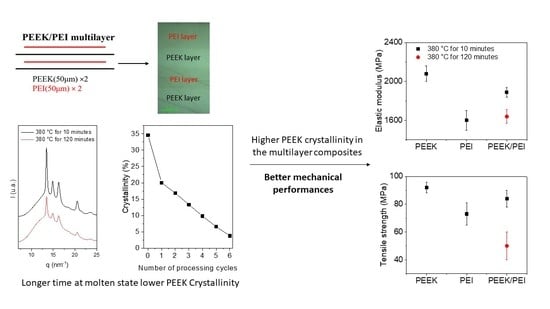

Fabrication and Characterization of PEEK/PEI Multilayer Composites

Abstract

:1. Introduction

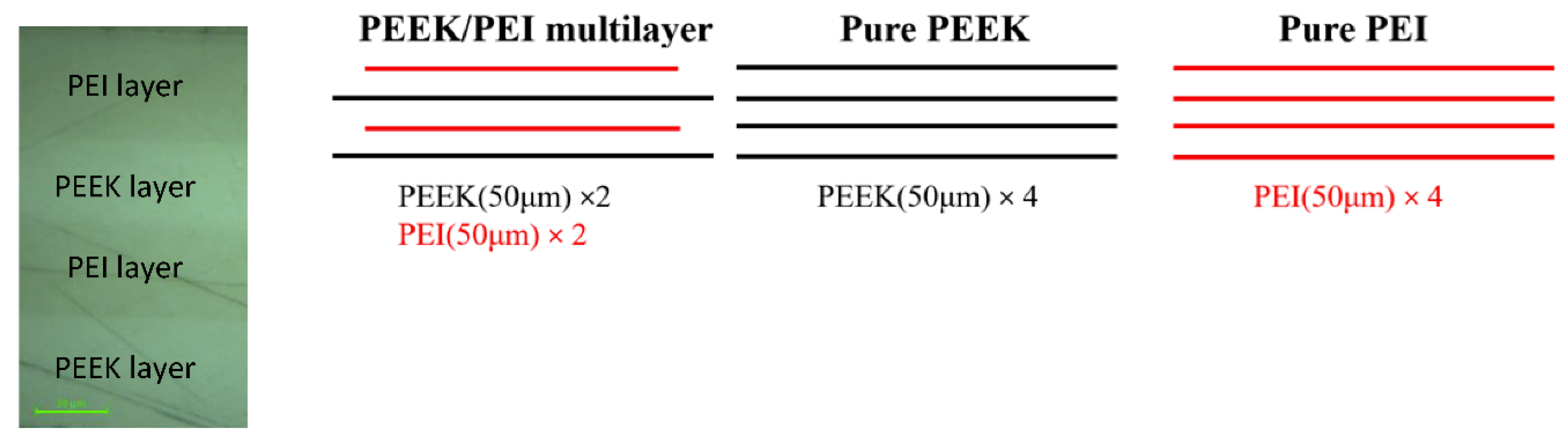

2. Materials, Processing, and Experimental Methods

2.1. Materials

2.2. Fabrication of PEEK/PEI Films

2.3. Experimental Techniques

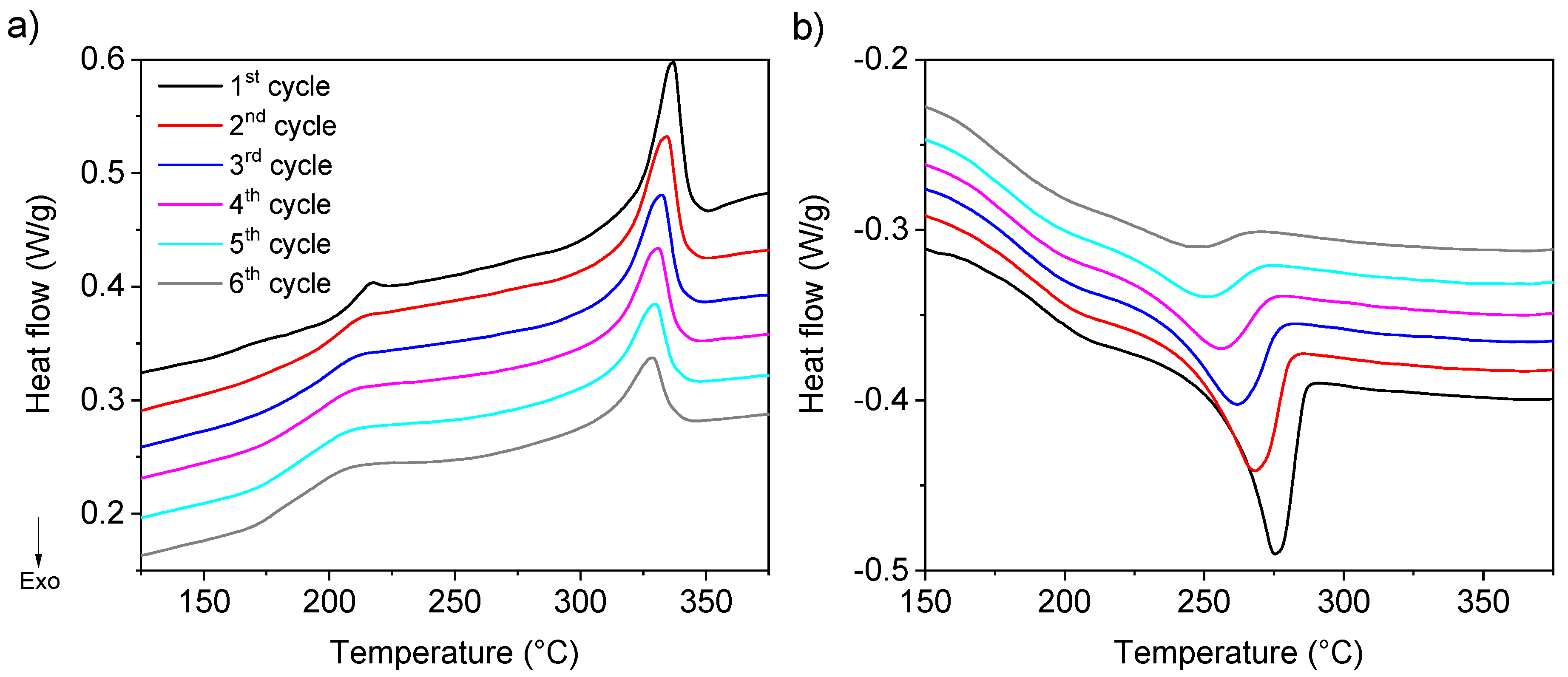

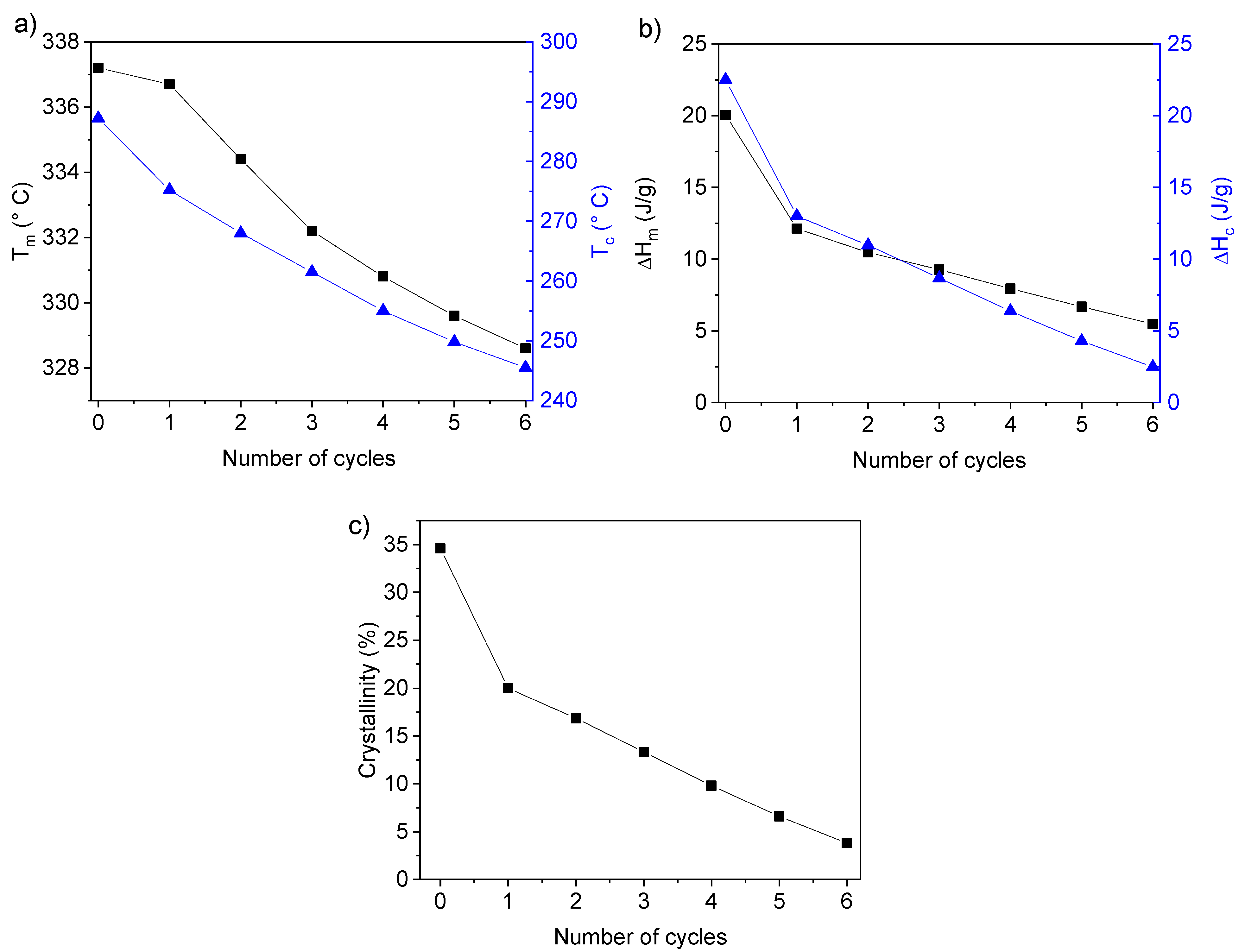

2.3.1. Differential Scanning Calorimetry

2.3.2. Synchrotron

2.3.3. Dynamic Mechanical Analysis

2.3.4. Mechanical Tests (Tensile Tests)

3. Results and Discussion

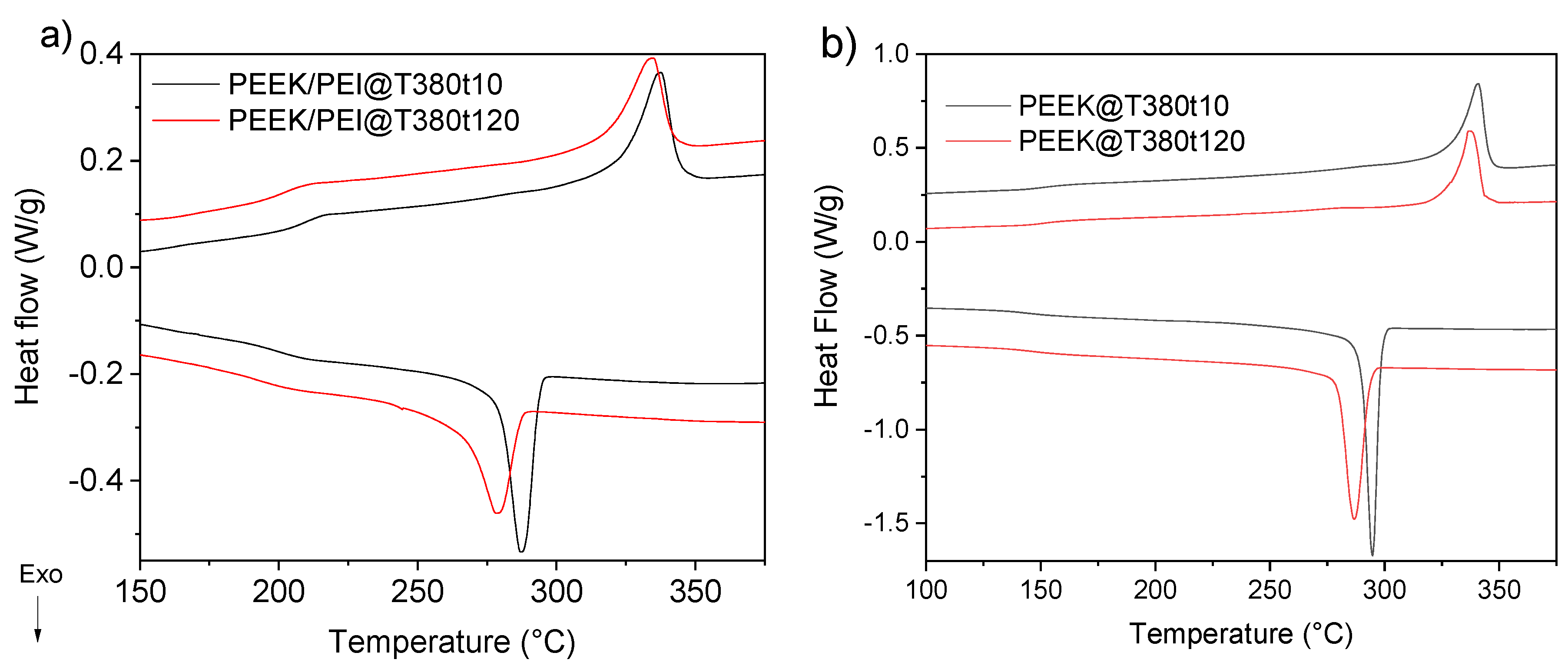

3.1. PEEK/PEI Interface Evolution with Different Processing Time at High Temperature

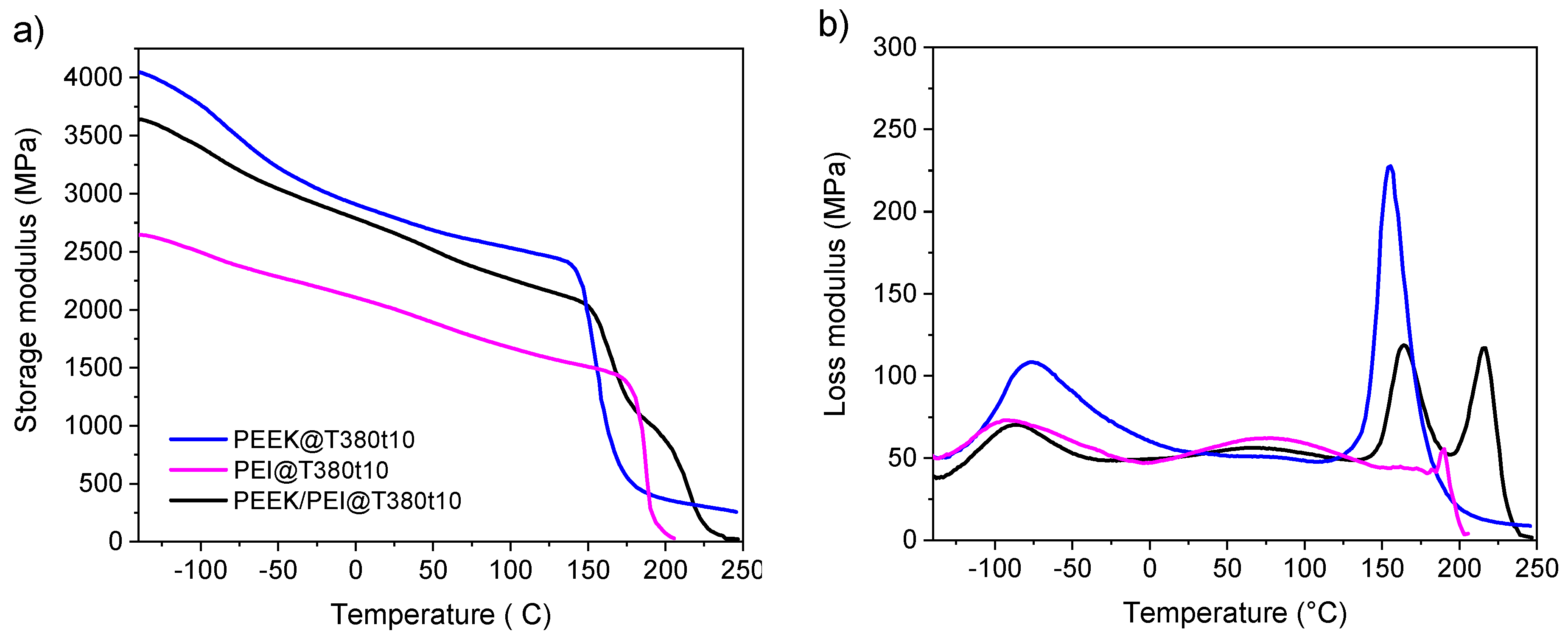

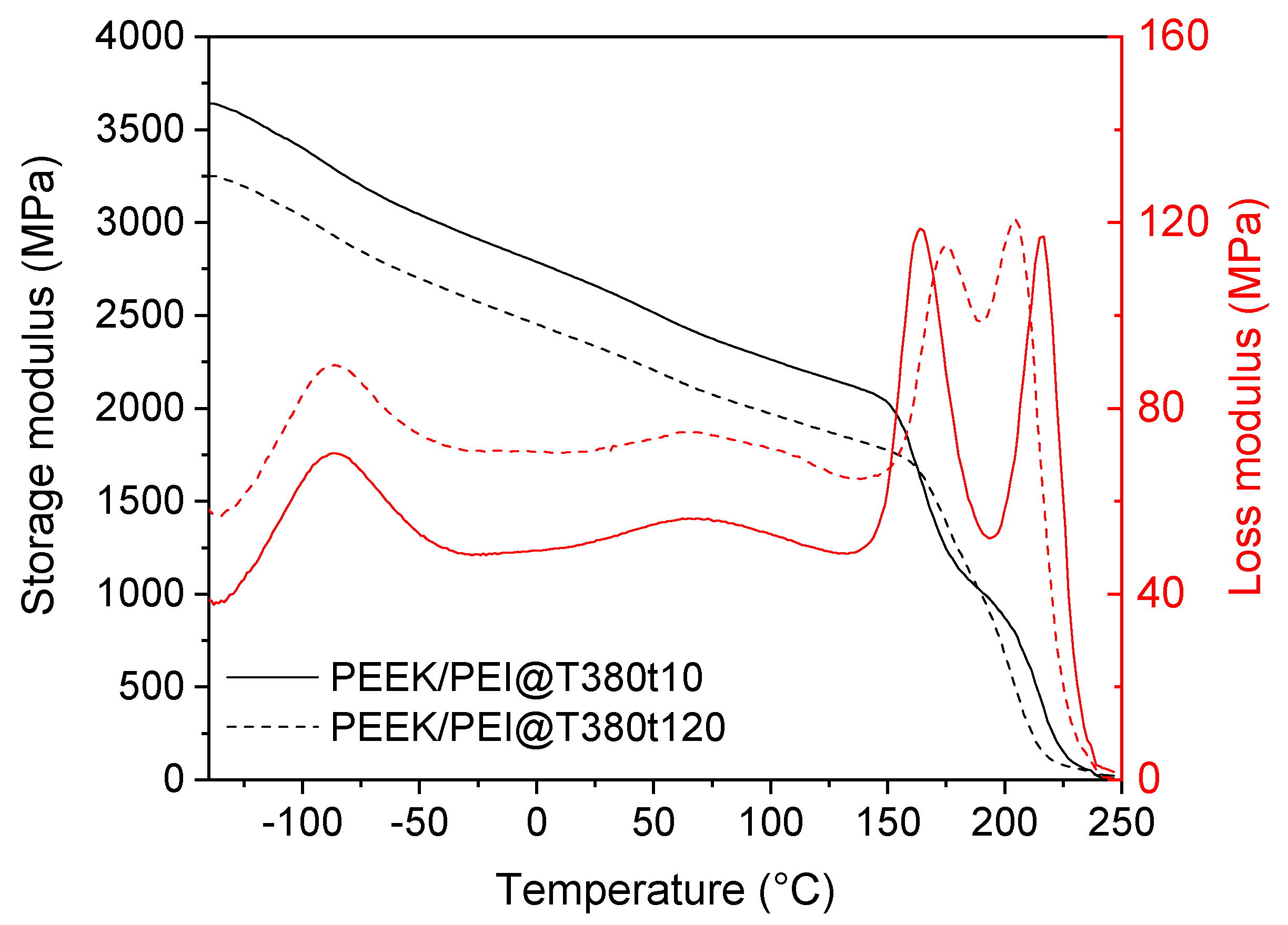

3.2. Thermo-Mechanical Properties

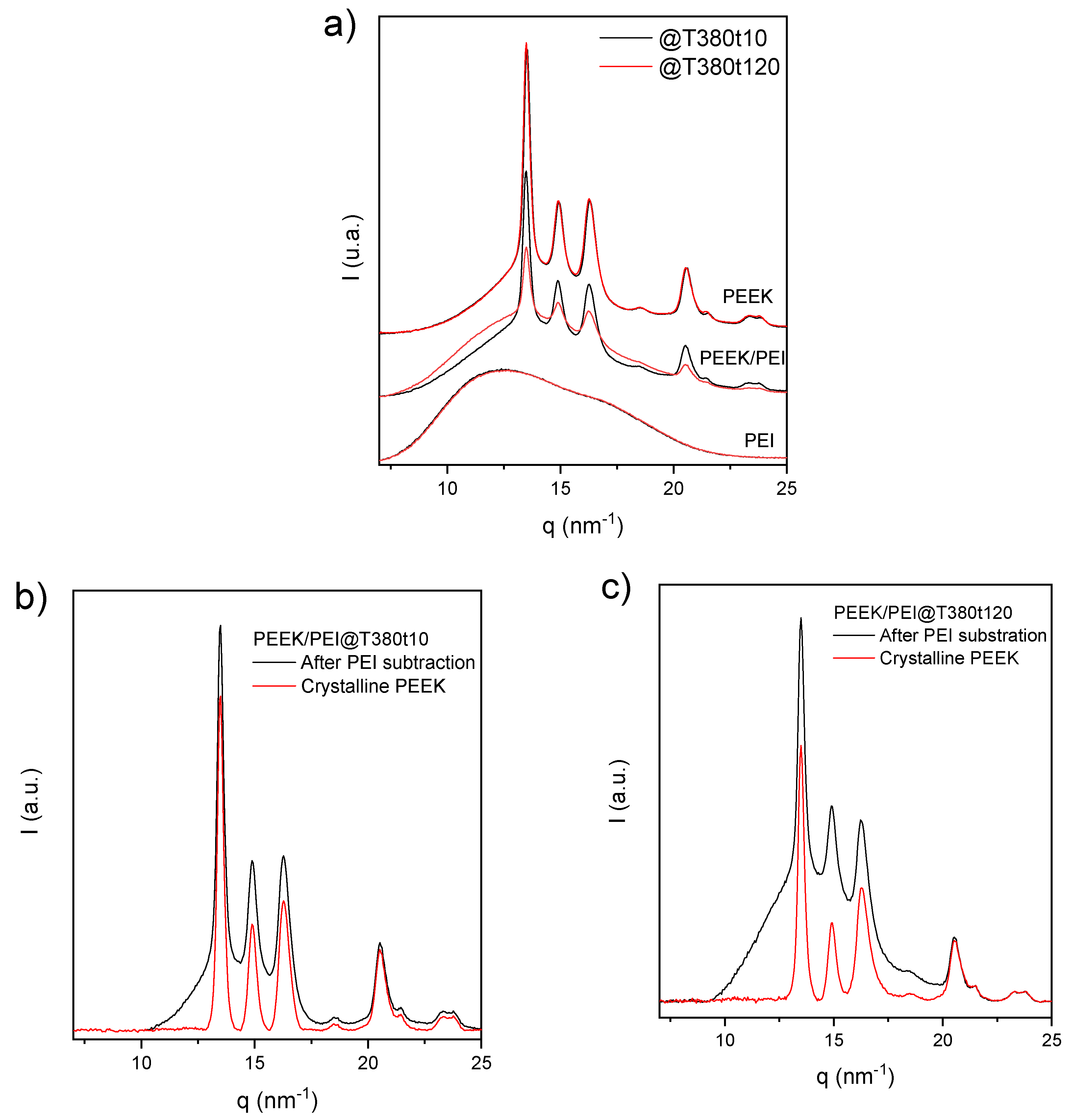

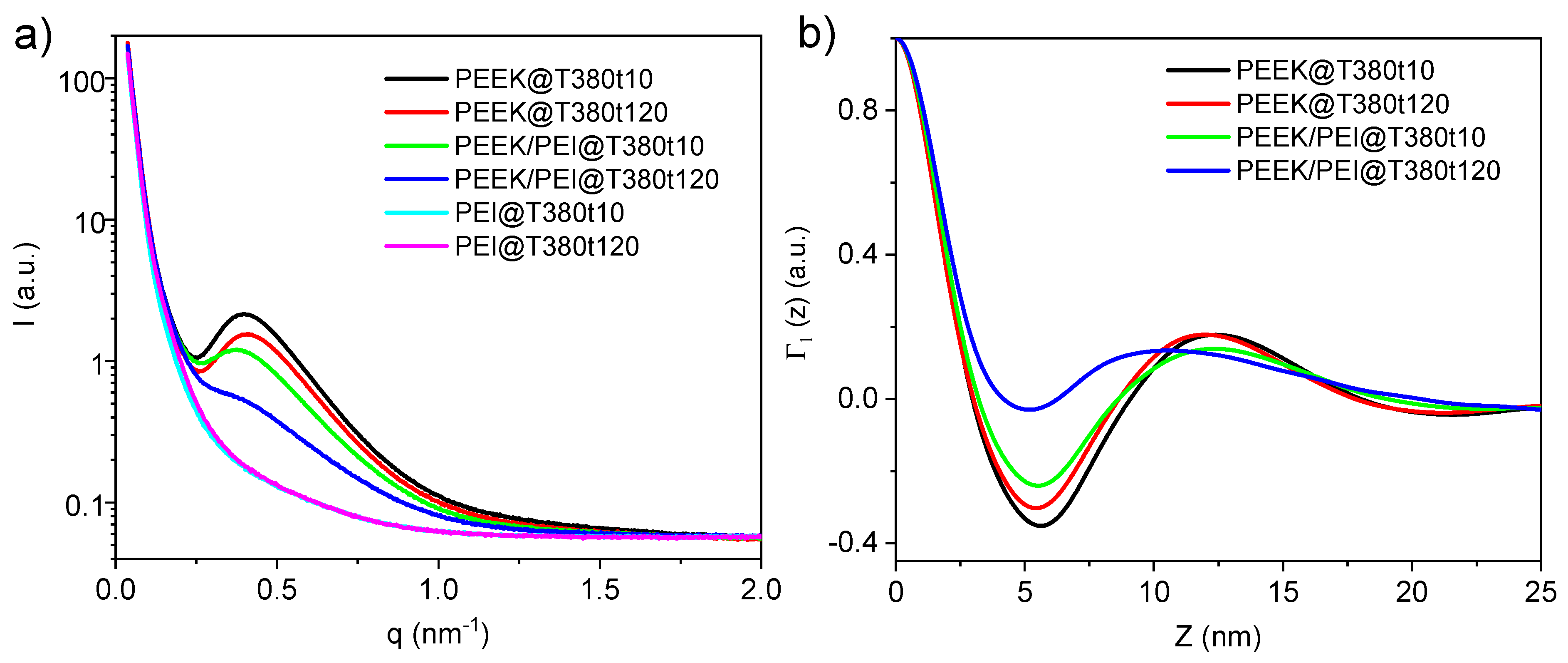

3.3. SAXS/WAXS Characterisation

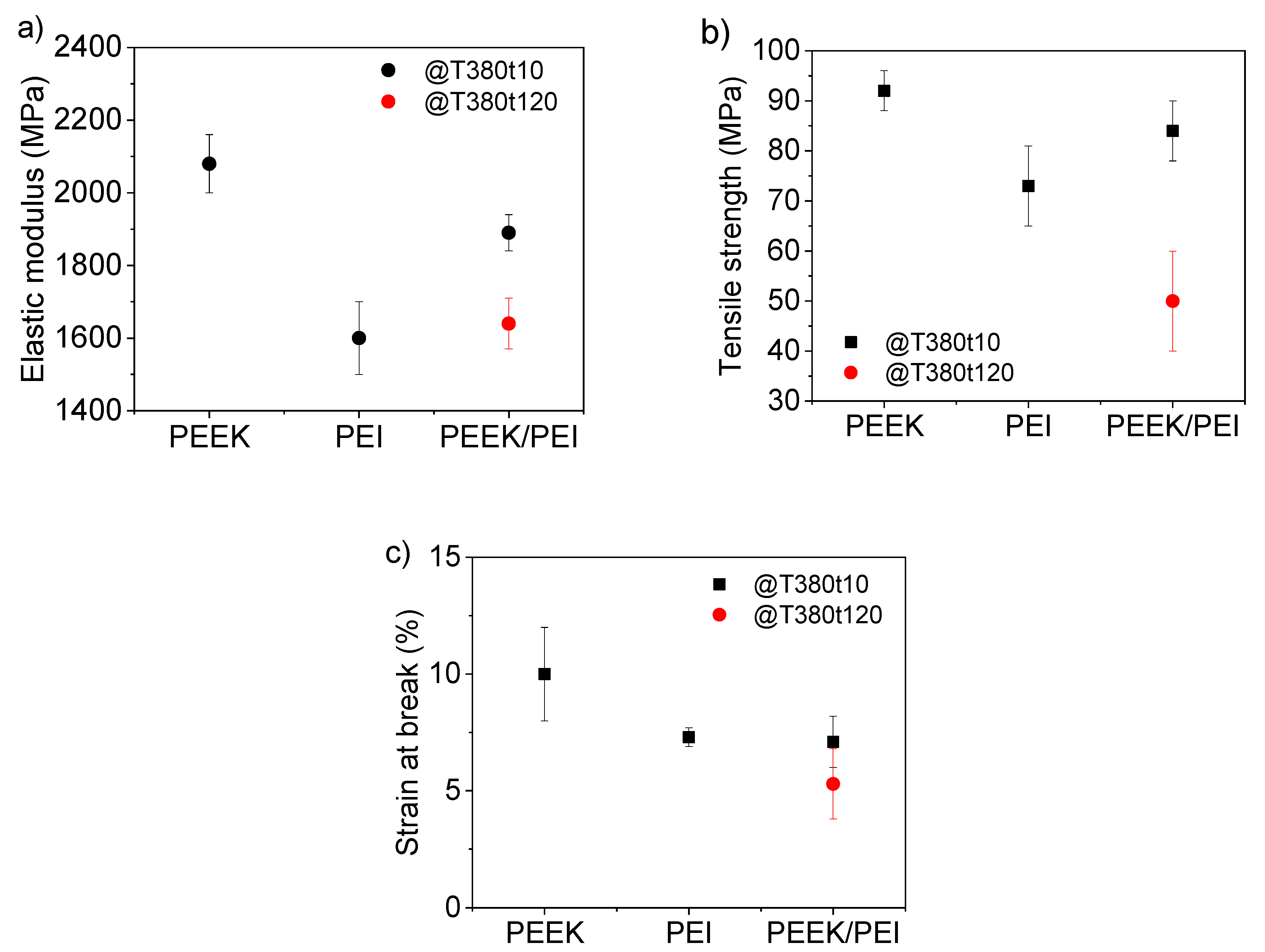

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kumar, S.; Mishra, R.K.; Nandi, T. Experimental and theoretical investigations of the high performance blends of PEEK/PEI. J. Polym. Eng. 2018, 38, 351–361. [Google Scholar] [CrossRef]

- Harris, J.E.; Robeson, L.M. Miscible blends of poly(aryl ether ketone)s and polyetherimides. J. Appl. Polym. Sci. 1988, 35, 1877–1891. [Google Scholar] [CrossRef]

- Langhe, D.; Ponting, M. Manufacturing and Novel Applications of Multilayer Polymer Films; William Andrew: Norwich, NY, USA, 2015; ISBN 978-0-323-37125-4. [Google Scholar]

- Pratte, J.; Nicolais, L. Polyetheretherketone (PEEK) Composites: An Update on Processing-Morphology-Property Relationships. In Wiley Encyclopedia of Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; ISBN 978-1-118-09729-8. [Google Scholar]

- Crevecoeur, G.; Groeninckx, G. Binary blends of poly(ether ether ketone) and poly(ether imide): Miscibility, crystallization behavior and semicrystalline morphology. Macromolecules 1991, 24, 1190–1195. [Google Scholar] [CrossRef]

- Jenkins, M.J. Crystallisation in miscible blends of PEEK and PEI. Polymer 2001, 42, 1981–1986. [Google Scholar] [CrossRef]

- Hsiao, B.S.; Verma, R.K.; Sauer, B.B. Crystallization study of poly(etheretherketone)/poly(etherimide) blends by real-time small-angle X-ray scattering. J. Macromol. Sci.-Phys. 1998, B37, 365–374. [Google Scholar] [CrossRef]

- Lee, C.H.; Okada, T.; Saito, H.; Inoue, T. Exclusion of non-crystalline polymer from the interlamellar region in polymer blends: Poly(ether ether ketone) poly(ether imide) blend by small-angle X-ray scattering. Polymer 1997, 38, 31–34. [Google Scholar] [CrossRef]

- Ramani, R.; Alam, S. Free volume study on the miscibility of PEEK/PEI blend using positron annihilation and dynamic mechanical thermal analysis. J. Phys. Conf. Ser. 2015, 618, 012035. [Google Scholar] [CrossRef] [Green Version]

- Kong, X.H.; Tang, H.; Dong, L.S.; Teng, F.G.; Feng, Z.L. Miscibility and crystallization behavior of solution-blended PEEK/PI blends. J. Polym. Sci. Part B. 1998, 36, 2267–2274. [Google Scholar] [CrossRef]

- Chen, H.-L.; Porter, R.S. Phase and crystallization behavior of solution-blended poly(ether ether ketone) and poly(ether imide). Polym. Eng. Sci. 1992, 32, 1870–1875. [Google Scholar] [CrossRef]

- Chun, Y.S.; Lee, H.S.; Jung, H.C.; Kim, W.N. Thermal properties of melt-blended poly(ether ether ketone) and poly(ether imide). J. Appl. Polym. Sci. 1999, 72, 733–739. [Google Scholar] [CrossRef]

- Jonas, A.M.; Ivanov, D.A.; Yoon, D.Y. The semicrystalline morphology of poly(ether-ether-ketone) blends with poly(ether-imide). Macromolecules 1998, 31, 5352–5362. [Google Scholar] [CrossRef]

- Brassard, D.; Dubé, M.; Tavares, J.R. Resistance welding of thermoplastic composites with a nanocomposite heating element. Compos. Part B 2019, 165, 779–784. [Google Scholar] [CrossRef]

- Chen, G.; Chen, Y.; Huang, T.; He, Z.; Xu, J.; Liu, P. Pore Structure and Properties of PEEK Hollow Fiber Membranes: Influence of the Phase Structure Evolution of PEEK/PEI Composite. Polymers 2019, 11, 1398. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grouve, W.J.B.; Akkerman, R. Multi-scale effects in the consolidation of thermoplastic laminates. Int. J. Mater. Form. 2009, 2, 157. [Google Scholar] [CrossRef]

- Ramani, R.; Alam, S. Composition optimization of PEEK/PEI blend using model-free kinetics analysis. Thermochim. Acta 2010, 511, 179–188. [Google Scholar] [CrossRef]

- Hudson, S.; Davis, D.; Lovinger, A. Semicrystalline morphology of poly(aryl ether ether ketone)/poly(ether imide) blends. Macromolecules 1992, 25, 1759–17365. [Google Scholar] [CrossRef]

- Wang, R.; Cheng, K.; Advincula, R.C.; Chen, Q. On the thermal processing and mechanical properties of 3D-printed polyether ether ketone. MRS Commun. 2019, 9, 1046–1052. [Google Scholar] [CrossRef]

- Martin, A.C.; Lakhera, N.; DiRienzo, A.L.; Safranski, D.L.; Schneider, A.S.; Yakacki, C.M.; Frick, C.P. Amorphous-to-crystalline transition of Polyetheretherketone–carbon nanotube composites via resistive heating. Compos. Sci. Technol. 2013, 89, 110–119. [Google Scholar] [CrossRef]

- Li, W.; Wang, G.; Jiang, Z.; Liu, C.; Huo, P.; Zhang, S. Preparation and Characterization of high-strength poly(ether ether ketone) films. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Regis, M.; Bellare, A.; Pascolini, T.; Bracco, P. Characterization of thermally annealed PEEK and CFR-PEEK composites: Structure-properties relationships. Polym. Degrad. Stab. 2017, 136, 121–130. [Google Scholar] [CrossRef]

- Schultz, J.; Chu, J.N. The influence of microstructure on the failure behavior of PEEK. J. Mater. Sci. 1990, 25, 3746–3752. [Google Scholar]

- Diamond Light Source B22 Beamline Description. 2019. Available online: https://www.diamond.ac.uk/Instruments/Soft-Condensed-Matter/B22.html;jsessionid=563C583D82142A16BC41D7D0565CF79D (accessed on 23 November 2020).

- Filik, J.; Ashton, A.W.; Chang, P.C.Y.; Chater, P.A.; Day, S.J.; Drakopoulos, M.; Gerring, M.W.; Hart, M.L.; Magdysyuk, O.V.; Michalik, S.; et al. Processing two-dimensional X-ray diffraction and small-angle scattering data in DAWN 2. J. Appl. Crystallogr. 2017, 50, 959–966. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- The Physics of Polymers—Concepts for Understanding Their Structures and Behavior |Gert R. Strobl|; Springer: Berlin/Heidelberg, Germany, 1997; Available online: https://www.springer.com/la/book/9783540252788 (accessed on 25 September 2018).

- Bicakci, S.; Cakmak, M. Kinetics of rapid structural changes during heat setting of preoriented PEEK/PEI blend films as followed by spectral birefringence technique. Polymer 2002, 43, 2737–2746. [Google Scholar] [CrossRef]

- Jenkins, M.J. Relaxation behaviour in blends of PEEK and PEI. Polymer 2000, 41, 6803–6812. [Google Scholar] [CrossRef]

- Jonas, A.; Legras, R. Relation between PEEK semicrystalline morphology and its subglass relaxations and glass transition. Macromolecules 1993, 26, 813–824. [Google Scholar] [CrossRef]

- Denault, J.; Dumouchel, M. Consolidation Process of PEEK/Carbon Composite for Aerospace Applications. Adv. Perform. Mater. 1998, 5, 83–96. [Google Scholar] [CrossRef]

- Deslandes, Y.; Day, M.; Sabir, N.-F.; Suprunchuk, T. Crystallization of poly(aryl-ether-ether-ketone): Effect of thermal history of the melt on crystallization kinetics. Polym. Compos. 1989, 10, 360–366. [Google Scholar] [CrossRef]

- Jonas, A.; Legras, R. Thermal stability and crystallization of poly(aryl ether ether ketone). Polymer 1991, 32, 2691–2706. [Google Scholar] [CrossRef]

- White, K.L.; Jin, L.; Ferrer, N.; Wong, M.; Bremner, T.; Sue, H.-J. Rheological and thermal behaviors of commercial poly(aryletherketone)s. Polym. Eng. Sci. 2018, 53, 651–661. [Google Scholar] [CrossRef]

- Browne, M.M.; Forsyth, M.; Goodwin, A.A. The effect of solvent uptake on the relaxation behaviour, morphology and mechanical properties of a poly(ether ether ketone) poly(etherimide) blend. Polymer 1997, 38, 1285–1290. [Google Scholar] [CrossRef]

- Gensler, R.; Béguelin, P.; Plummer, C.J.G.; Kausch, H.-H.; Münstedt, H. Tensile behaviour and fracture toughness of poly(ether ether ketone)/poly(ether imide) blends. Polym. Bull. 1996, 37, 111–118. [Google Scholar] [CrossRef]

| Material | Storage Modulus (25 °C) | Tg (Onset) | Tg (Peak) | β Peak (°C) | γ Peak (°C) |

|---|---|---|---|---|---|

| PEEK | 2797 | 149 | 155 | −76.5 | |

| PEI | 2006 | 179 | - | 77.4 | −91.2 |

| PEEK/PEI | 2657 | 154/206 | 165/216 | 69.9 | −86.7 |

| Material | Tc | Tm | ΔHm | Xc (%) |

|---|---|---|---|---|

| PEEK/PEI@T380t10 | 287.2 | 337.6 | 22.6 | 34.6 |

| PEEK/PEI@T380t120 | 278.6 | 335.4 | 19.4 | 29.8 |

| PEEK@T380t10 | 295.1 | 340.8 | 45.1 | 34.7 |

| PEEK@T380t120 | 287.1 | 337.2 | 44.9 | 34.5 |

| Sample | Processing Time at 380 °C (min) | Long Spacing (L, nm) | Lamellar Thickness (Lc, nm) | Linear Crystallinity (XCL) |

|---|---|---|---|---|

| PEEK | 10 | 12.4 | 3.64 | 29.3 |

| PEEK | 120 | 12.0 | 3.51 | 29.3 |

| PEEK/PEI | 10 | 12.4 | 3.54 | 28.7 |

| PEEK/PEI | 120 | 10.6 | 3.31 | 31.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alvaredo-Atienza, Á.; Chen, L.; San-Miguel, V.; Ridruejo, Á.; Fernández-Blázquez, J.P. Fabrication and Characterization of PEEK/PEI Multilayer Composites. Polymers 2020, 12, 2765. https://doi.org/10.3390/polym12122765

Alvaredo-Atienza Á, Chen L, San-Miguel V, Ridruejo Á, Fernández-Blázquez JP. Fabrication and Characterization of PEEK/PEI Multilayer Composites. Polymers. 2020; 12(12):2765. https://doi.org/10.3390/polym12122765

Chicago/Turabian StyleAlvaredo-Atienza, Ángel, Lu Chen, Verónica San-Miguel, Álvaro Ridruejo, and Juan P. Fernández-Blázquez. 2020. "Fabrication and Characterization of PEEK/PEI Multilayer Composites" Polymers 12, no. 12: 2765. https://doi.org/10.3390/polym12122765

APA StyleAlvaredo-Atienza, Á., Chen, L., San-Miguel, V., Ridruejo, Á., & Fernández-Blázquez, J. P. (2020). Fabrication and Characterization of PEEK/PEI Multilayer Composites. Polymers, 12(12), 2765. https://doi.org/10.3390/polym12122765