Tensile and Flexural Properties of Silica Nanoparticles Modified Unidirectional Kenaf and Hybrid Glass/Kenaf Epoxy Composites

Abstract

1. Introduction

2. Materials and Methods

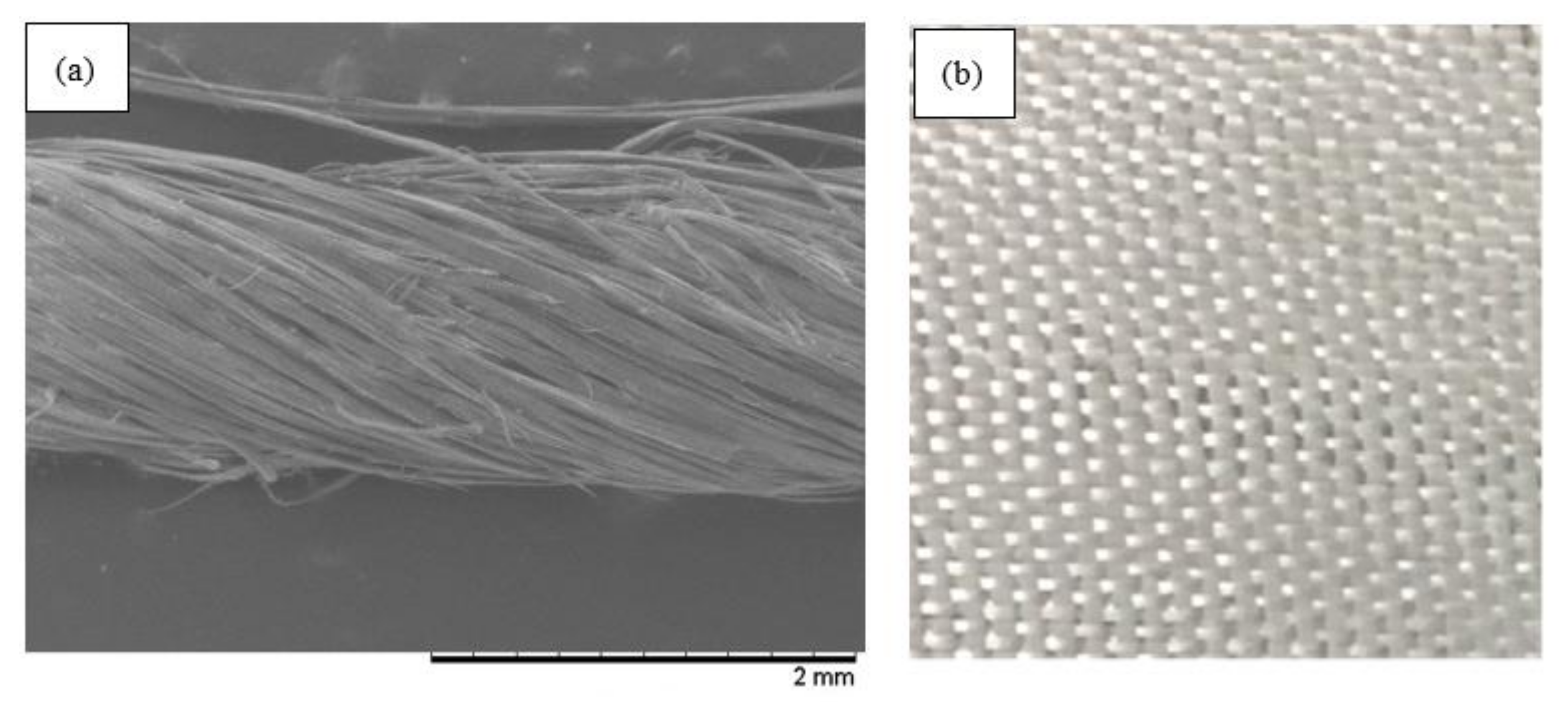

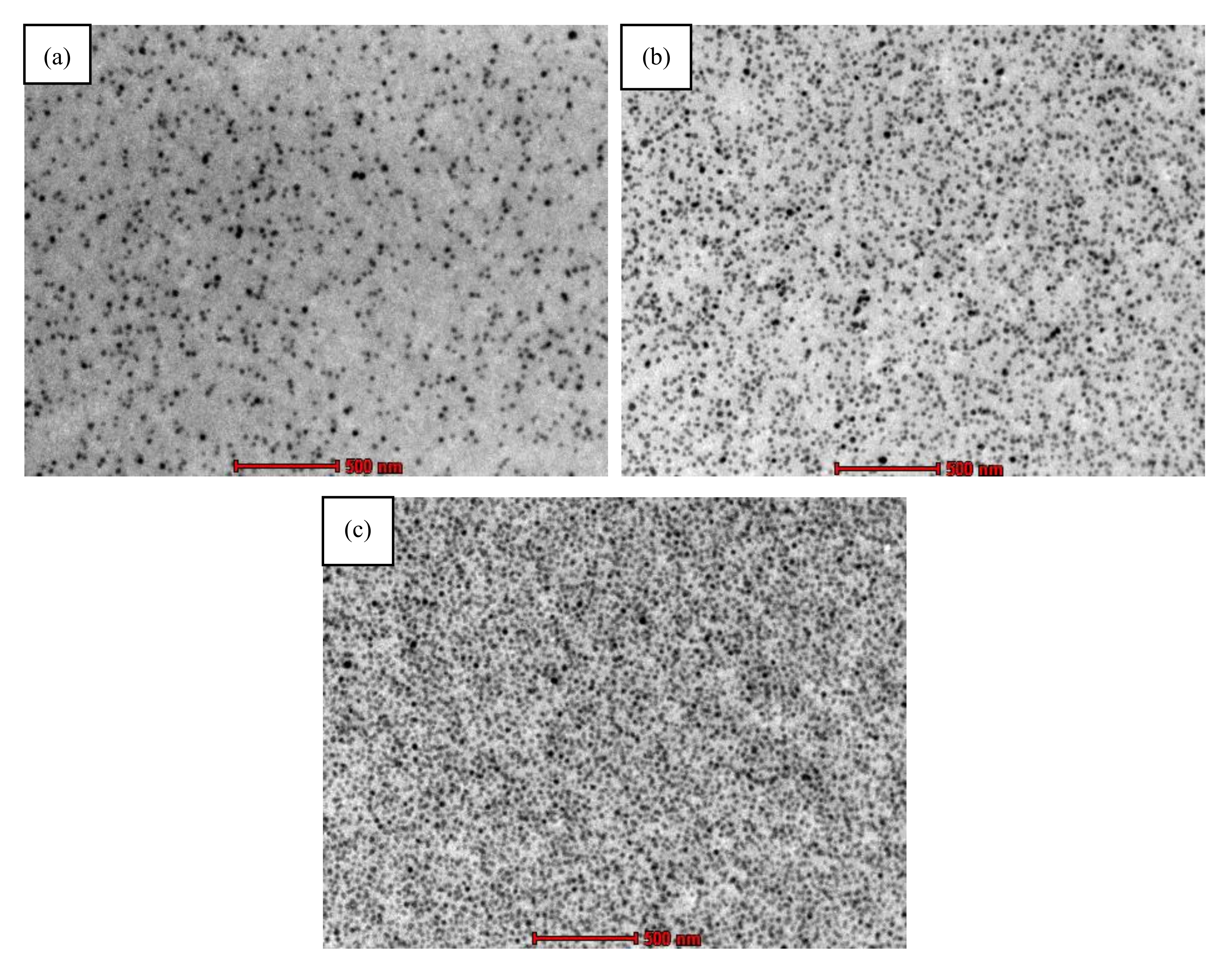

2.1. Materials

2.2. Fabrication of KFRP and Hybrid GKFRP Composites

2.3. Mechanical Testing

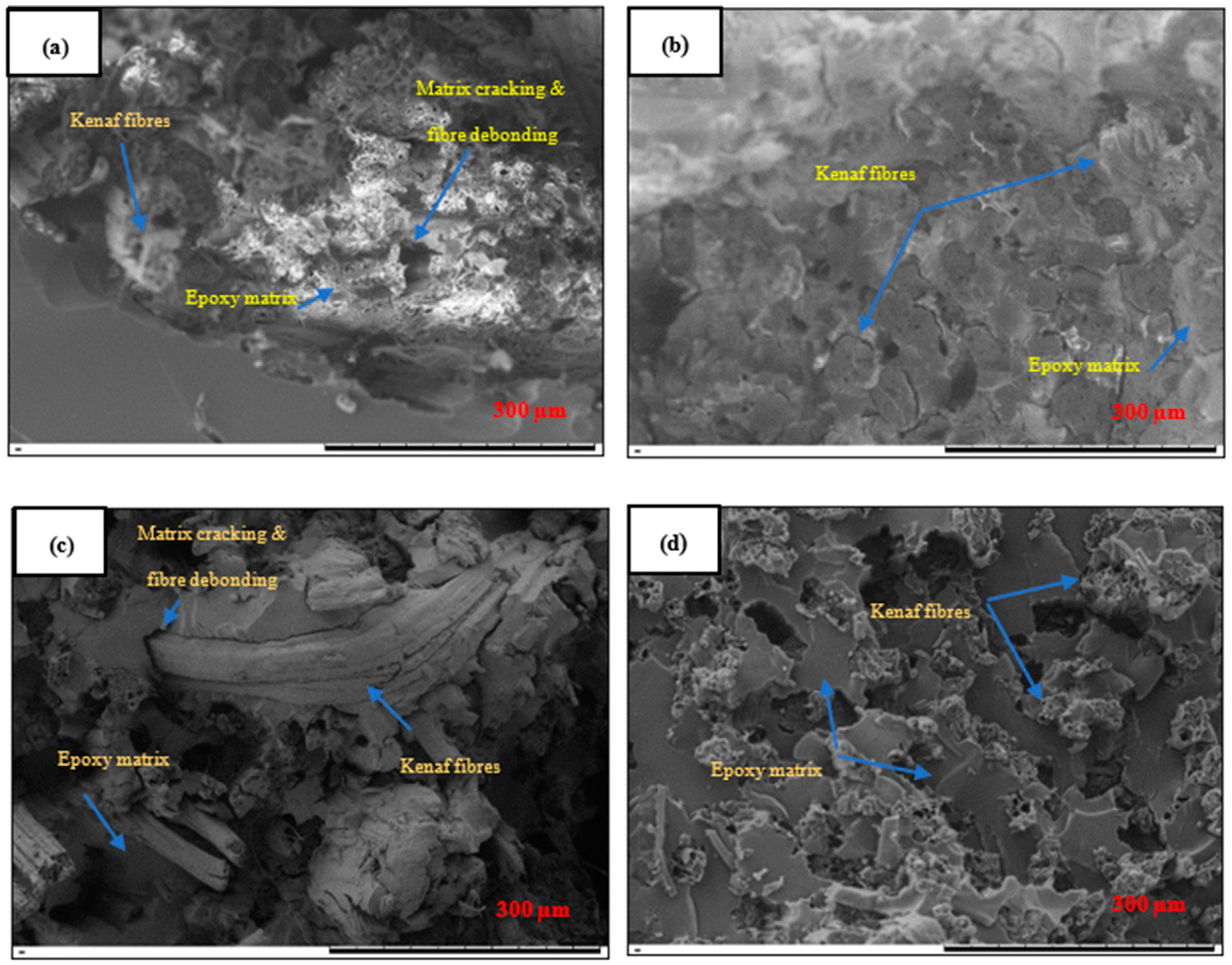

2.4. Microstructure Evaluation

3. Results and Discussion

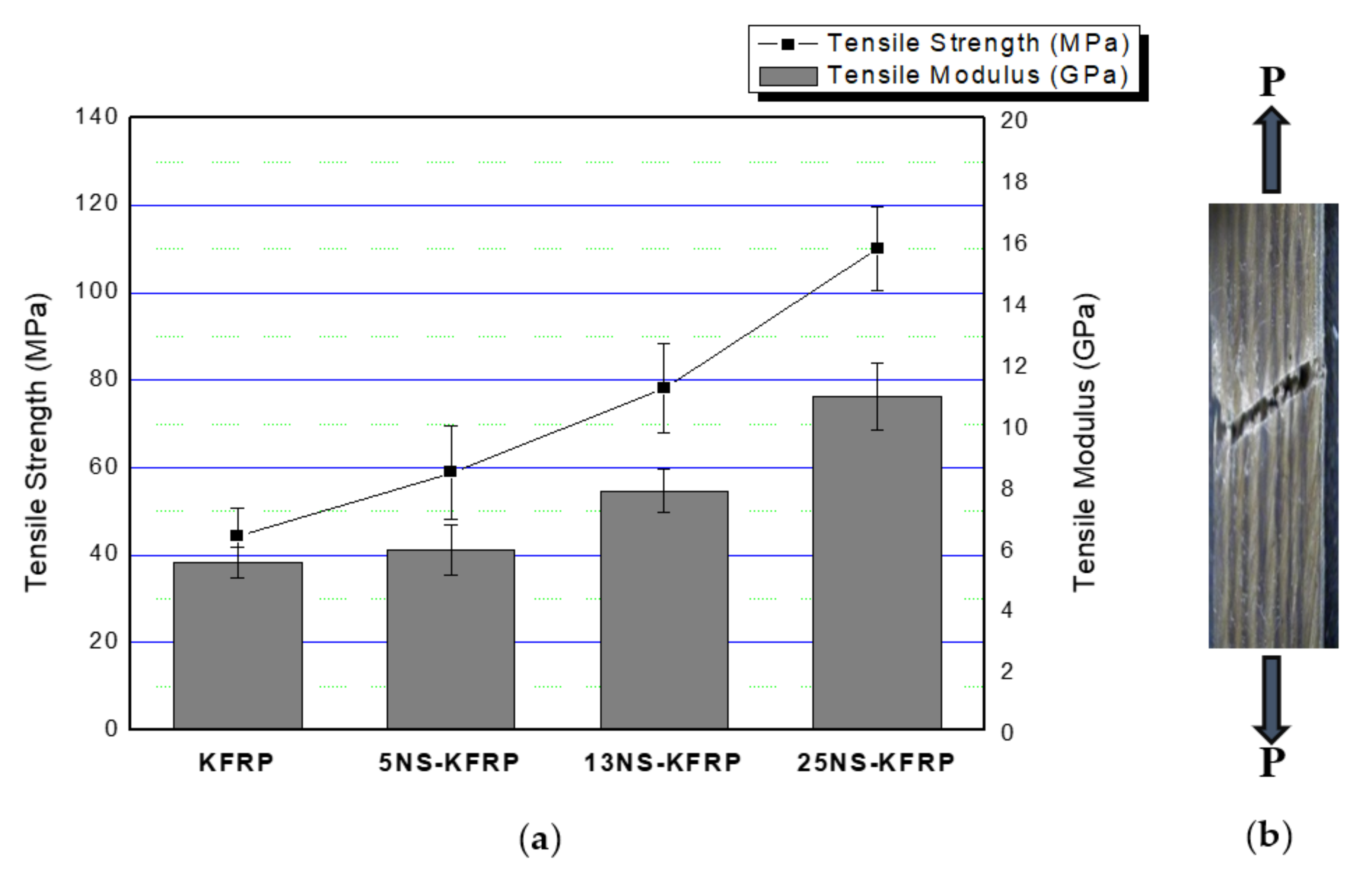

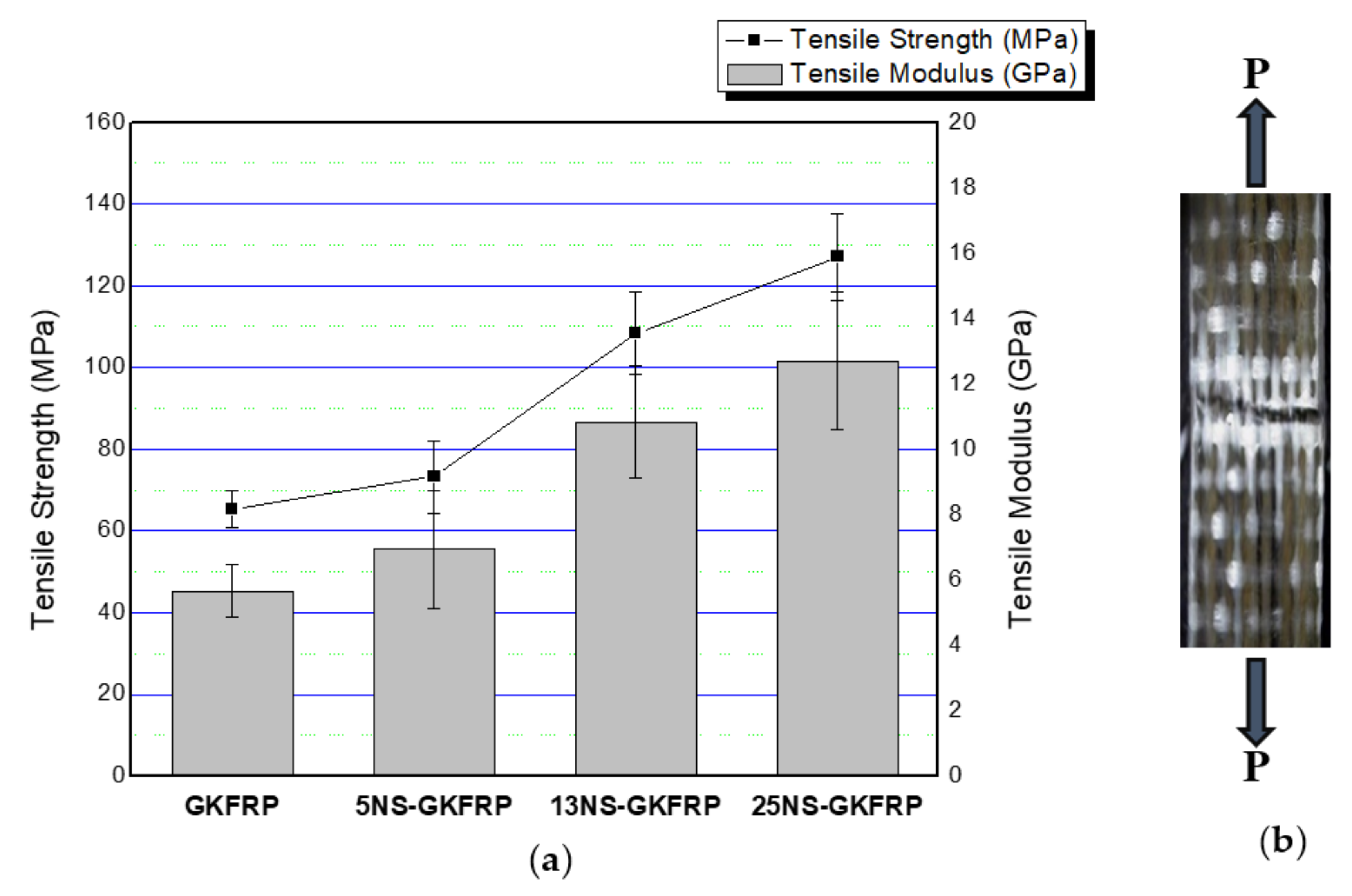

3.1. Tensile Properties

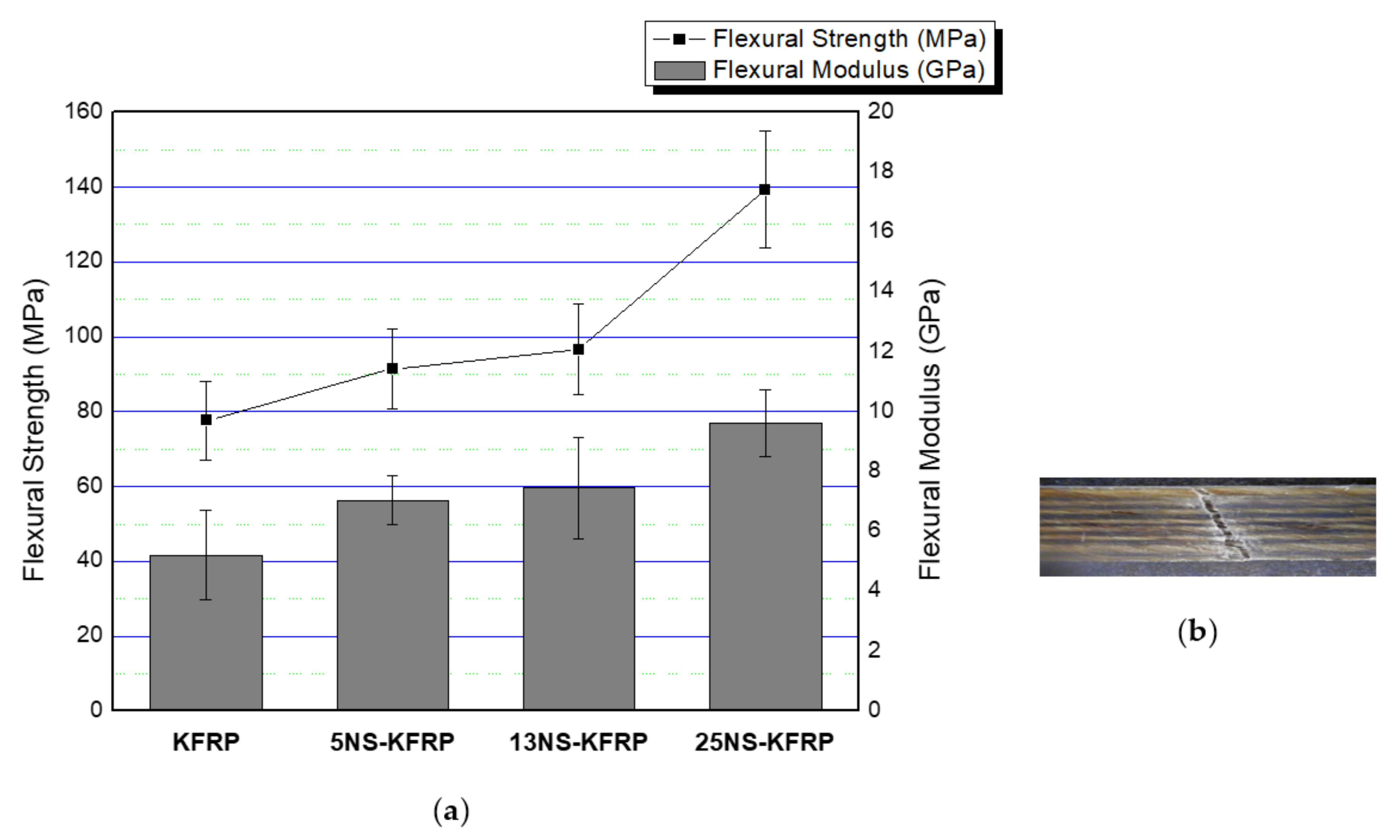

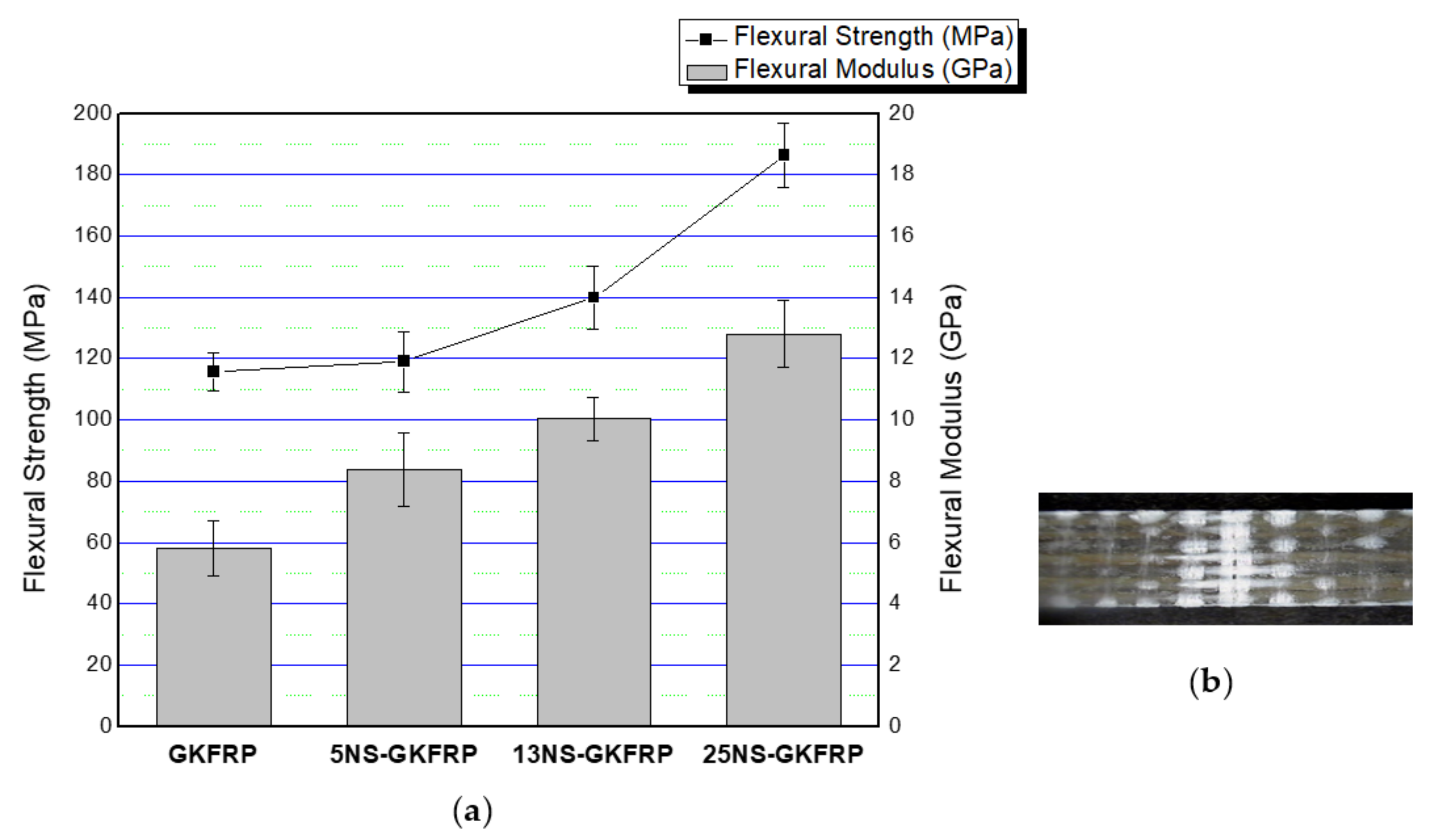

3.2. Flexural Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Wang, K.; Zhang, W.; Qi, C.; Zhang, S.; Li, J. Hybrid HNTs-kenaf fiber modified soybean meal-based adhesive with PTGE for synergistic reinforcement of wet bonding strength and toughness. Int. J. Adhes. Adhes. 2018, 87, 173–180. [Google Scholar] [CrossRef]

- Manap, N.; Jumahat, A.; Sapiai, N. Effect of nanosilica content on longitudinal and transverse tensile properties of unidirectional kenaf composite. J. Teknol. 2015, 76, 123–130. [Google Scholar] [CrossRef][Green Version]

- Saba, N.; Paridah, M.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Ramesh, M. Kenaf (Hibiscus cannabinus L.) fibre based bio-materials: A review on processing and properties. Prog. Mater. Sci. 2016, 78–79, 1–92. [Google Scholar] [CrossRef]

- Saba, N.; Alothman, O.Y.; Saba, N.; Jawaid, M. Magnesium hydroxide reinforced kenaf fibers/epoxy hybrid composites: Mechanical and thermomechanical properties. Constr. Build. Mater. 2019, 201, 138–148. [Google Scholar] [CrossRef]

- Bajuri, F.; Mazlan, N.; Ishak, M.; Imatomi, J. Flexural and Compressive Properties of Hybrid Kenaf/Silica Nanoparticles in Epoxy Composite. Procedia Chem. 2016, 19, 955–960. [Google Scholar] [CrossRef]

- Muhammad, Y.H.; Ahmad, S.; Abu Bakar, M.A.; Mamun, A.A.; Heim, H.P. Mechanical properties of hybrid glass/kenaf fibre-reinforced epoxy composite with matrix modification using liquid epoxidised natural rubber. J. Reinf. Plast. Compos. 2015, 34, 896–906. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Fereidoon, A. Preparation and characterization of short kenaf fiber-based biocomposites reinforced with multi-walled carbon nanotubes. Compos. Part B Eng. 2019, 162, 314–322. [Google Scholar] [CrossRef]

- Majeed, K.; Jawaid, M.; Hassan, A.; Abu Bakar, A.; Khalil, H.A.; Salema, A.A.; Inuwa, I.M. Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites. Mater. Des. 2013, 46, 391–410. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Mahmud, J. Flexural and tensile properties of kenaf/glass fibres hybrid composites filled with carbon nanotubes. J. Teknol. 2015, 76, 115–120. [Google Scholar] [CrossRef][Green Version]

- Nayak, B.A.; Shubham; Prusty, R.K.; Ray, B.C. Effect of nanosilica and nanoclay reinforcement on flexural and thermal properties of glass fiber/epoxy composites. Mater. Today Proc. 2020, in press. [Google Scholar] [CrossRef]

- Jena, A.; Shubham; Prusty, R.K.; Ray, B.C. Mechanical and thermal behaviour of multi-layer graphene and nanosilica reinforced glass Fiber/Epoxy composites. Mater. Today Proc. 2020, in press. [Google Scholar] [CrossRef]

- Monfared, R.M.; Ayatollahi, M.R.; Isfahani, R.B. Synergistic effects of hybrid MWCNT/nanosilica on the tensile and tribological properties of woven carbon fabric epoxy composites. Theor. Appl. Fract. Mech. 2018, 96, 272–284. [Google Scholar] [CrossRef]

- Mirzapour, A.; Asadollahi, M.H.; Baghshaei, S.; Akbari, M. Effect of nanosilica on the microstructure, thermal properties and bending strength of nanosilica modified carbon fiber/phenolic nanocomposite. Compos. Part A Appl. Sci. Manuf. 2014, 63, 159–167. [Google Scholar] [CrossRef]

- Khodadadi, A.; Liaghat, G.; Vahid, S.; Sabet, A.; Hadavinia, H. Ballistic performance of Kevlar fabric impregnated with nanosilica/PEG shear thickening fluid. Compos. Part B Eng. 2019, 162, 643–652. [Google Scholar] [CrossRef]

- Hein, M.A. Ultra-wideband radar sensors for biomedical diagnostics and imaging. In Proceedings of the 2012 IEEE International Conference on Ultra-Wideband, Syracuse, NY, USA, 17–20 September 2012. [Google Scholar]

- Jumahat, M.T.B.A.; Kasolang, S. Wear properties of nanosilica filled epoxy polymers and FRP composites. J. Tribol. 2015, 6, 24–36. [Google Scholar]

- Jumahat, A.; Soutis, C.; Jones, F.R.; Hodzic, A. Improved Compressive Properties of a Unidirectional Cfrp Laminate Using Nanosilica Particles. Adv. Compos. Lett. 2010, 19, 204–207. [Google Scholar] [CrossRef]

- Manap, N.; Jumahat, A.; Rahman, N.A.; Rahman, N.A.A. NaOH treated Kenaf/Glass hybrid composite: The effects of nanosilica on longitudinal and transverse tensile properties. J. Phys. Conf. Ser. 2020, 1432, 012046. [Google Scholar] [CrossRef]

- Hashim, U.; Jumahat, A.; Mahmud, J. Improved tensile properties of basalt fibre reinforced polymer composites using silica nanoparticles. Mater. und Werkst. 2019, 50, 1149–1155. [Google Scholar] [CrossRef]

- Pickering, K.L.; Sawpan, M.A.; Jayaraman, J.; Fernyhough, A. Influence of loading rate, alkali fibre treatment and crystallinity on fracture toughness of random short hemp fibre reinforced polylactide bio-composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1148–1156. [Google Scholar] [CrossRef]

- Asumani, O.; Reid, R.; Paskaramoorthy, R. The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

| Composition of UD Kenaf and Hybrid Kenaf/Glass Composites | Designation |

|---|---|

| Unidirectional (UD) kenaf fiber reinforced polymer composites | KFRP |

| 5 wt % nanosilica in UD kenaf fiber reinforced polymer composites | 5NS-KFRP |

| 13 wt % nanosilica in UD kenaf fiber reinforced polymer composites | 13NS-KFRP |

| 25 wt % nanosilica in UD kenaf fiber reinforced polymer composites | 25NS-KFRP |

| Hybrid woven glass/UD kenaf fiber reinforced polymer composites | GKFRP |

| 5 wt % nanosilica in hybrid woven glass/UD kenaf fiber reinforced polymer composites | 5NS-GKFRP |

| 13 wt % nanosilica in hybrid woven glass/UD kenaf fiber reinforced polymer composites | 13NS-GKFRP |

| 25 wt % nanosilica in hybrid woven glass/UD kenaf fiber reinforced polymer composites | 25NS-GKFRP |

| Composites | Tensile Properties | Flexural Properties | ||

|---|---|---|---|---|

| Tensile Strength (MPa) | Tensile Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) | |

| KFRP | 49.48 ± 6.45 | 5.45 ± 0.52 | 77.63 ± 10.45 | 5.21 ± 0.50 |

| 5NS-KFRP | 58.84 ± 10.80 | 5.88 ± 0.81 | 91.45 ± 10.83 | 7.05 ± 0.76 |

| 13NS-KFRP | 78.17 ± 10.14 | 7.81 ± 0.69 | 96.67 ± 12.12 | 7.46 ± 1.71 |

| 25NS-KFRP | 109.96 ± 9.61 | 10.9 ± 1.12 | 139.34 ± 15.58 | 9.62 ± 1.10 |

| GKFRP | 65.29 ± 9.16 | 5.61 ± 0.37 | 115.71 ± 6.27 | 5.86 ± 0.12 |

| 5NS-GKFRP | 73.29 ± 8.83 | 6.94 ± 1.81 | 119.05 ± 9.82 | 8.39 ± 1.22 |

| 13NS-GKFRP | 108.35 ± 10.11 | 10.83 ± 1.72 | 139.89 ± 10.14 | 10.03 ± 0.73 |

| 25NS-GKFRP | 127.14 ± 10.62 | 12.7 ± 2.14 | 186.33 ± 10.56 | 12.81 ± 1.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sapiai, N.; Jumahat, A.; Jawaid, M.; Midani, M.; Khan, A. Tensile and Flexural Properties of Silica Nanoparticles Modified Unidirectional Kenaf and Hybrid Glass/Kenaf Epoxy Composites. Polymers 2020, 12, 2733. https://doi.org/10.3390/polym12112733

Sapiai N, Jumahat A, Jawaid M, Midani M, Khan A. Tensile and Flexural Properties of Silica Nanoparticles Modified Unidirectional Kenaf and Hybrid Glass/Kenaf Epoxy Composites. Polymers. 2020; 12(11):2733. https://doi.org/10.3390/polym12112733

Chicago/Turabian StyleSapiai, Napisah, Aidah Jumahat, Mohammad Jawaid, Mohamad Midani, and Anish Khan. 2020. "Tensile and Flexural Properties of Silica Nanoparticles Modified Unidirectional Kenaf and Hybrid Glass/Kenaf Epoxy Composites" Polymers 12, no. 11: 2733. https://doi.org/10.3390/polym12112733

APA StyleSapiai, N., Jumahat, A., Jawaid, M., Midani, M., & Khan, A. (2020). Tensile and Flexural Properties of Silica Nanoparticles Modified Unidirectional Kenaf and Hybrid Glass/Kenaf Epoxy Composites. Polymers, 12(11), 2733. https://doi.org/10.3390/polym12112733