Upper Limb Design of an Anthropometric Crash Test Dummy for Low Impact Rates

Abstract

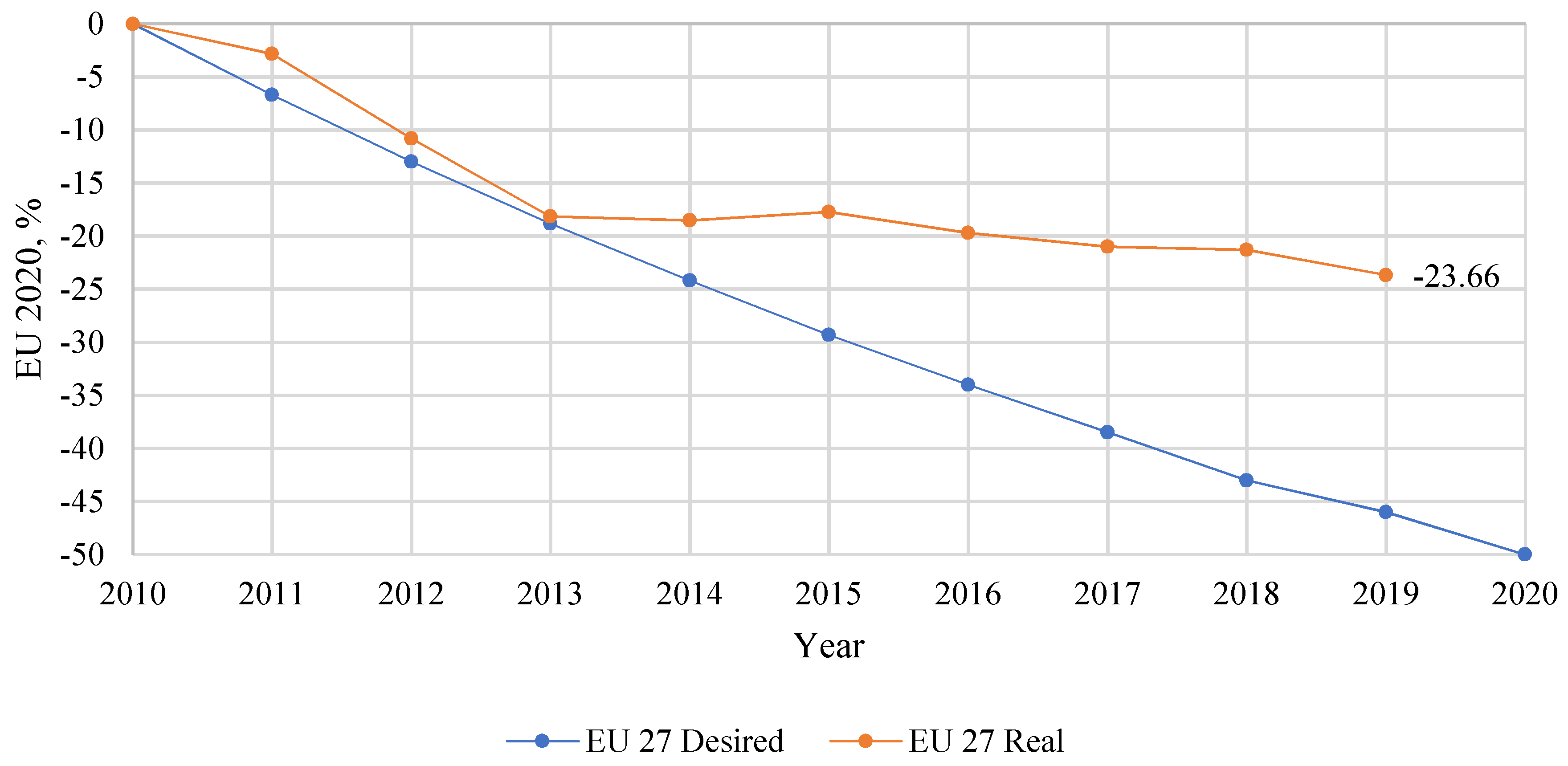

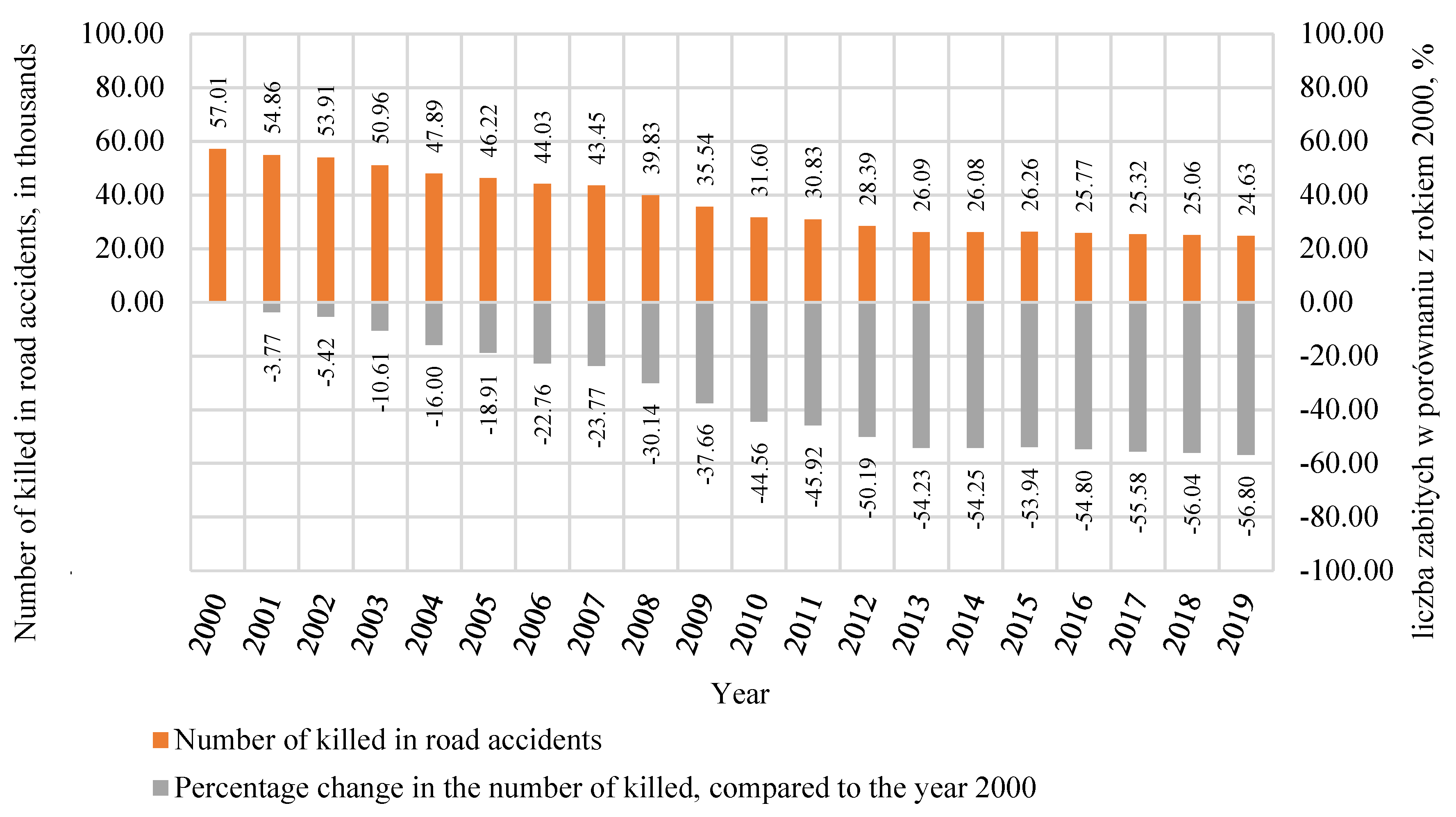

1. Introduction

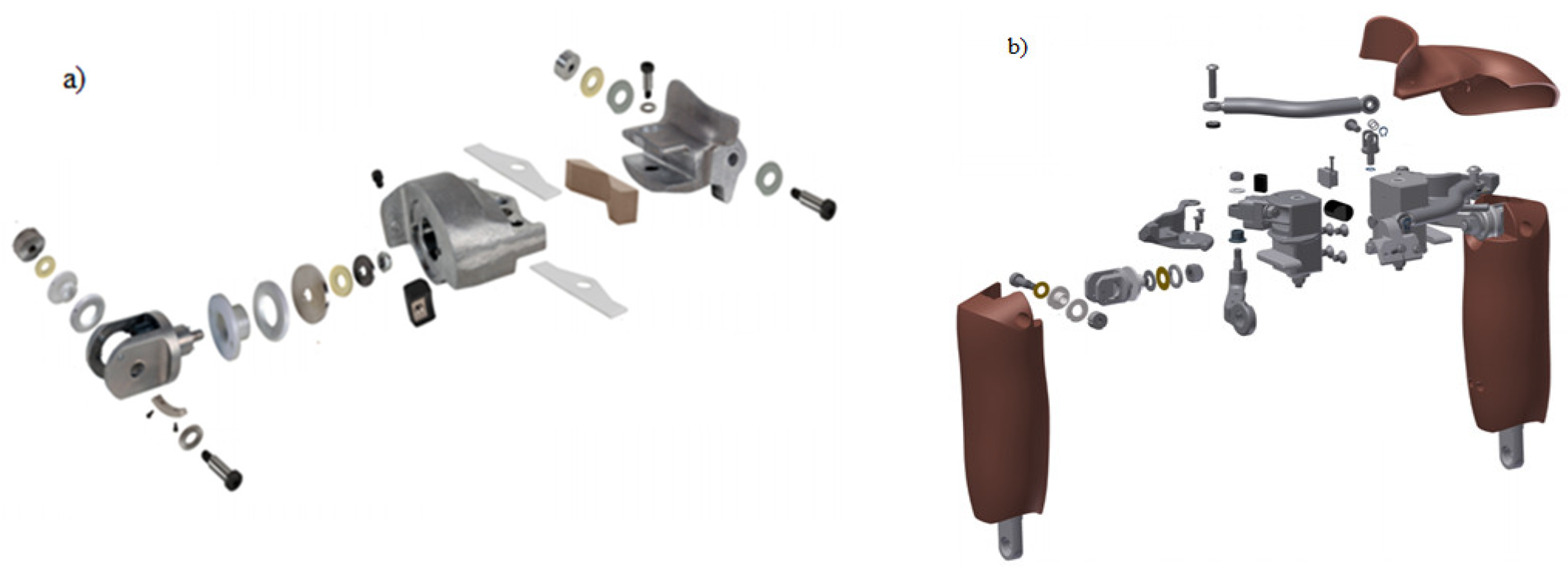

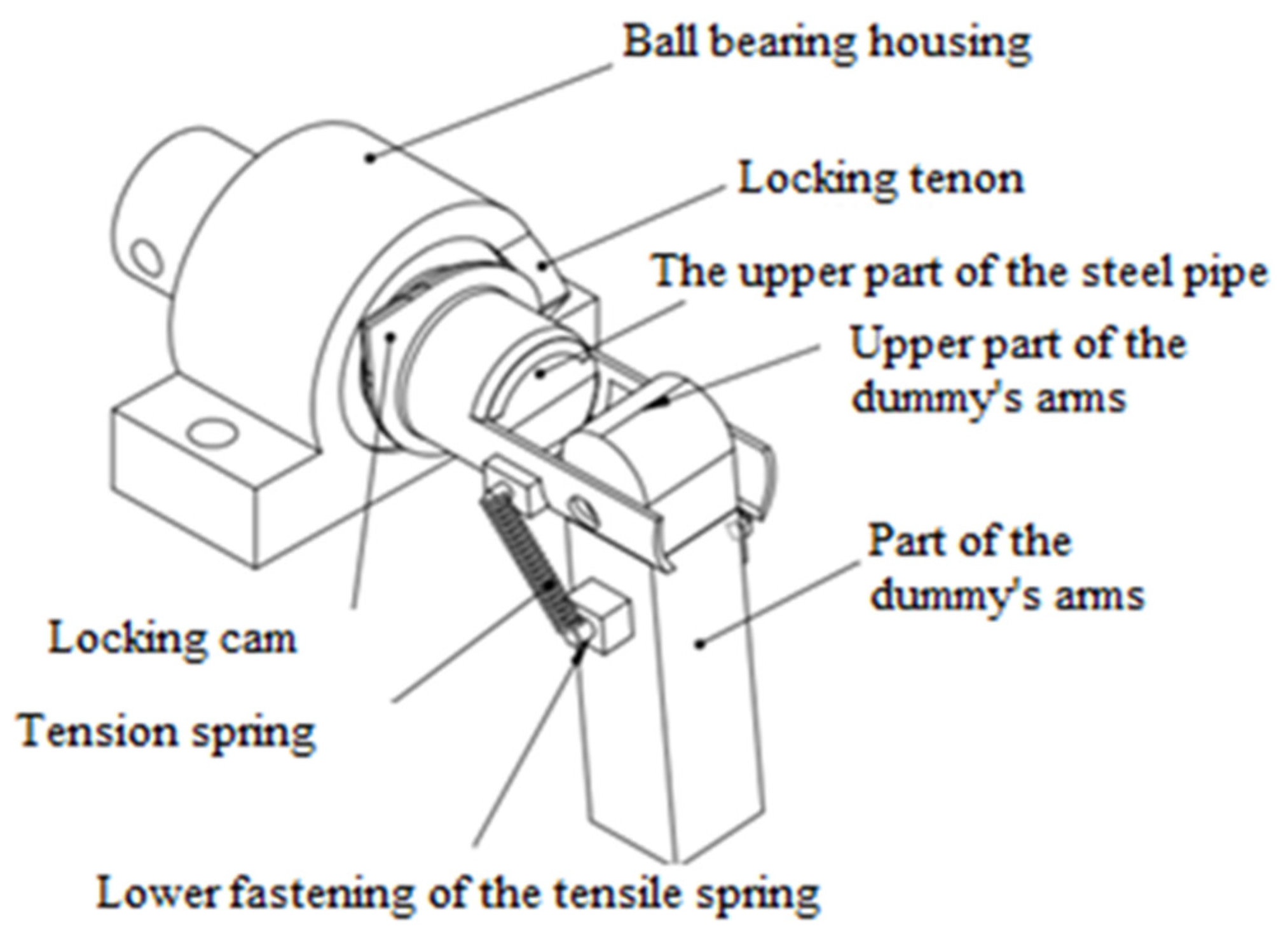

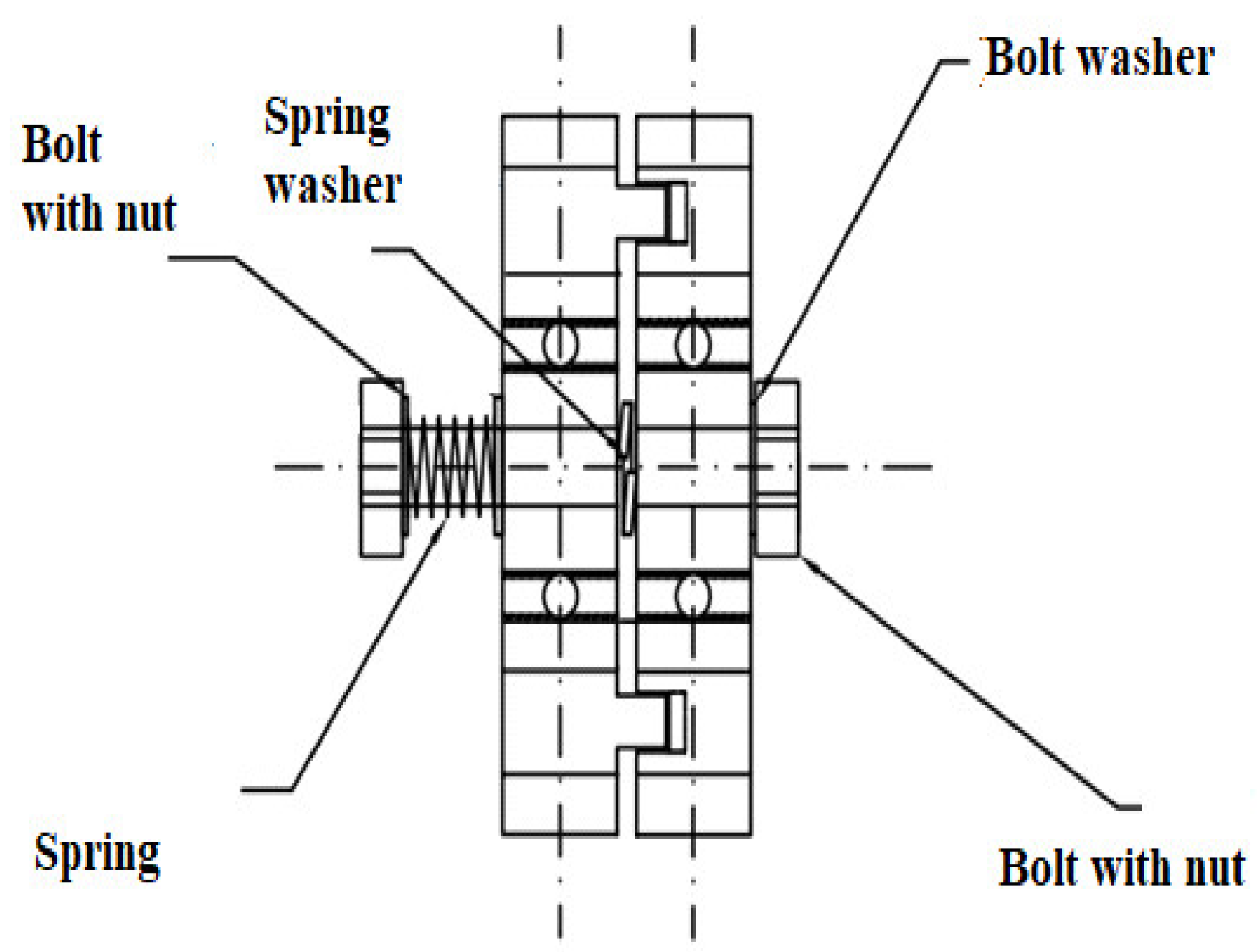

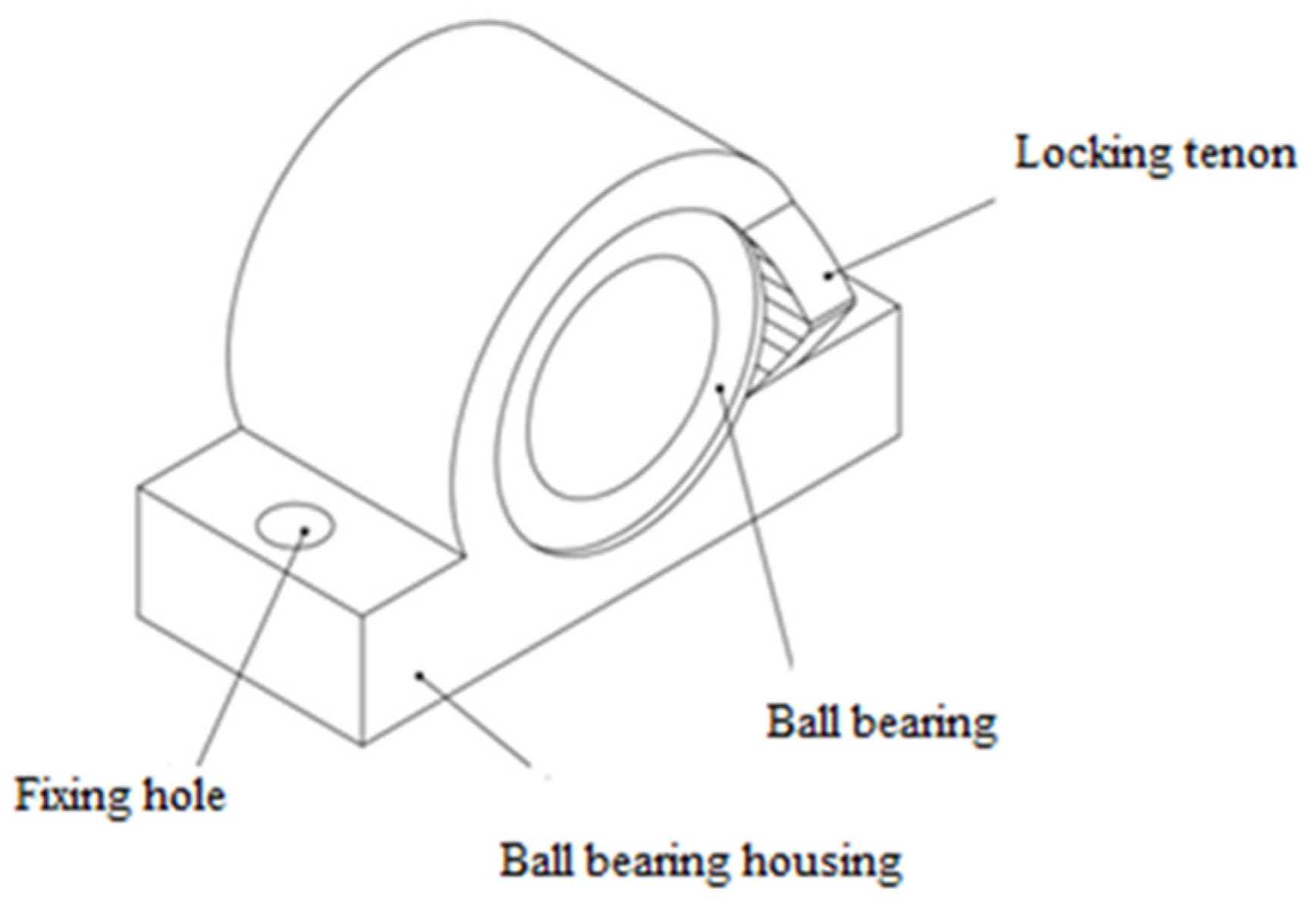

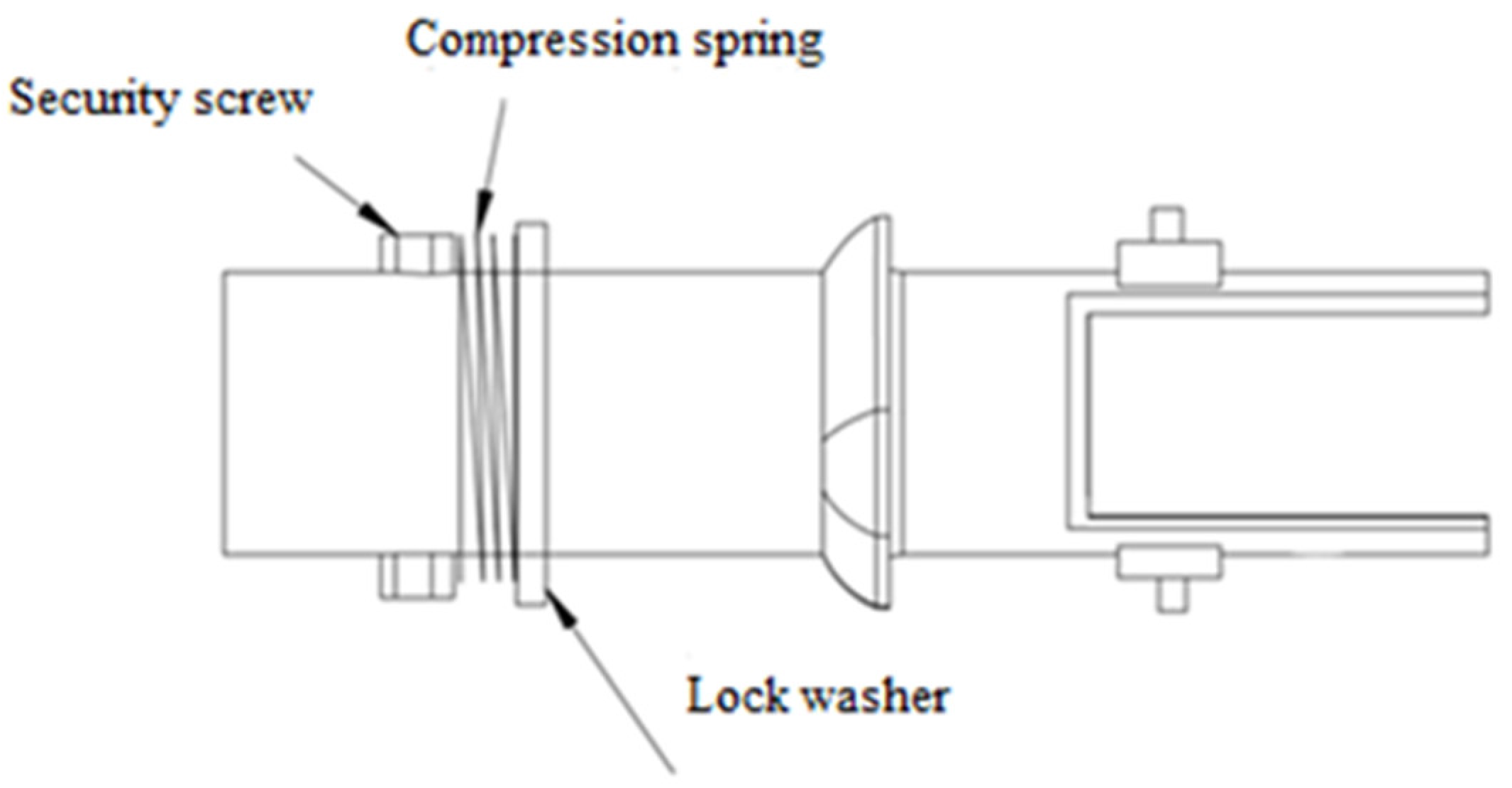

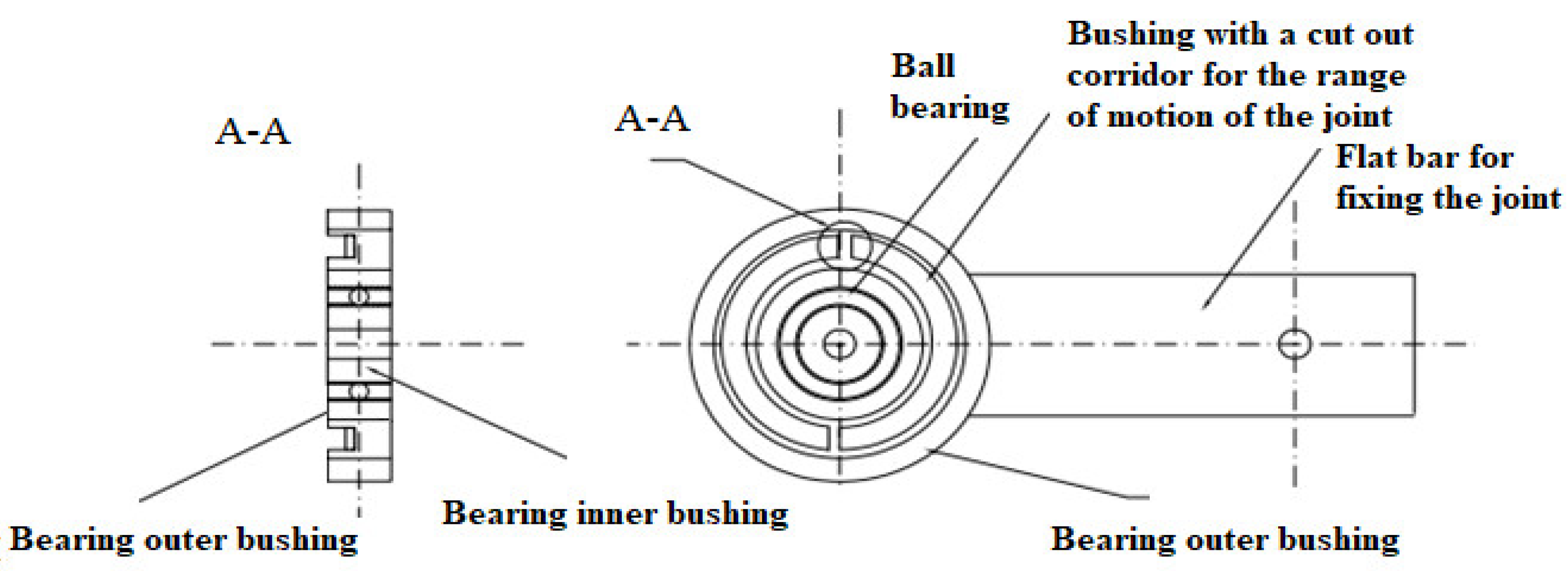

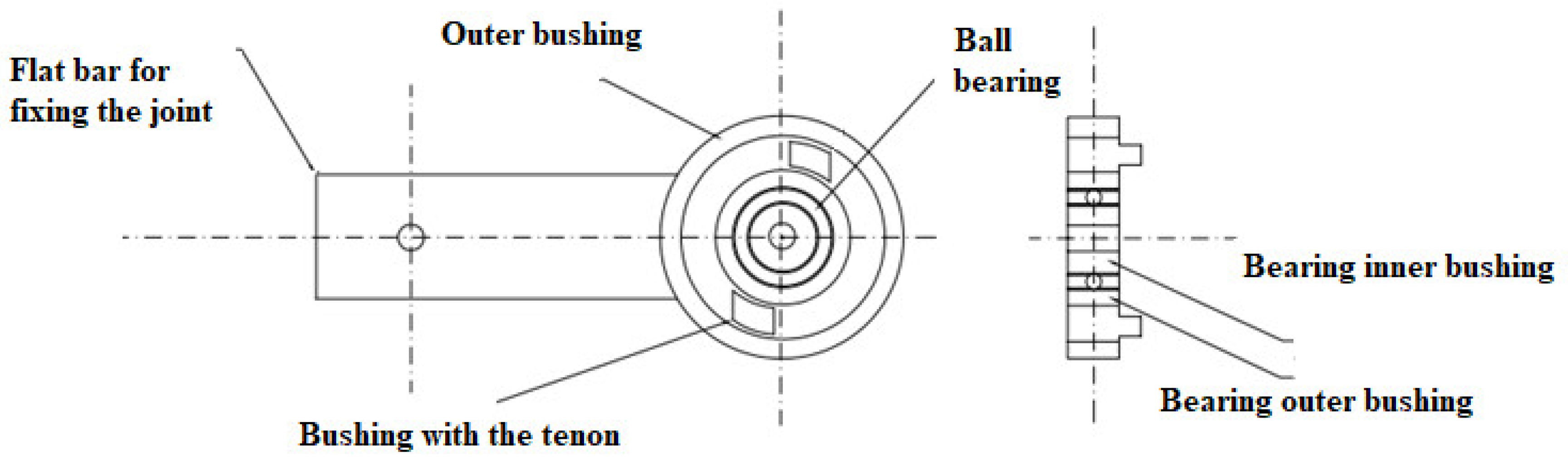

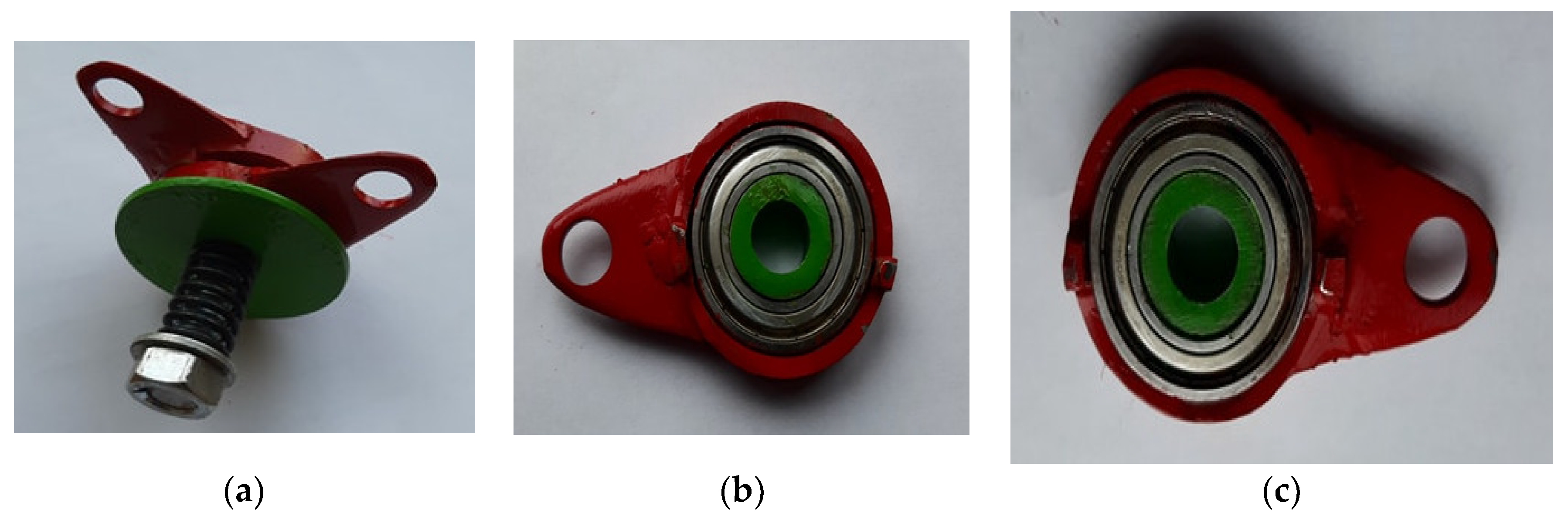

2. Construction

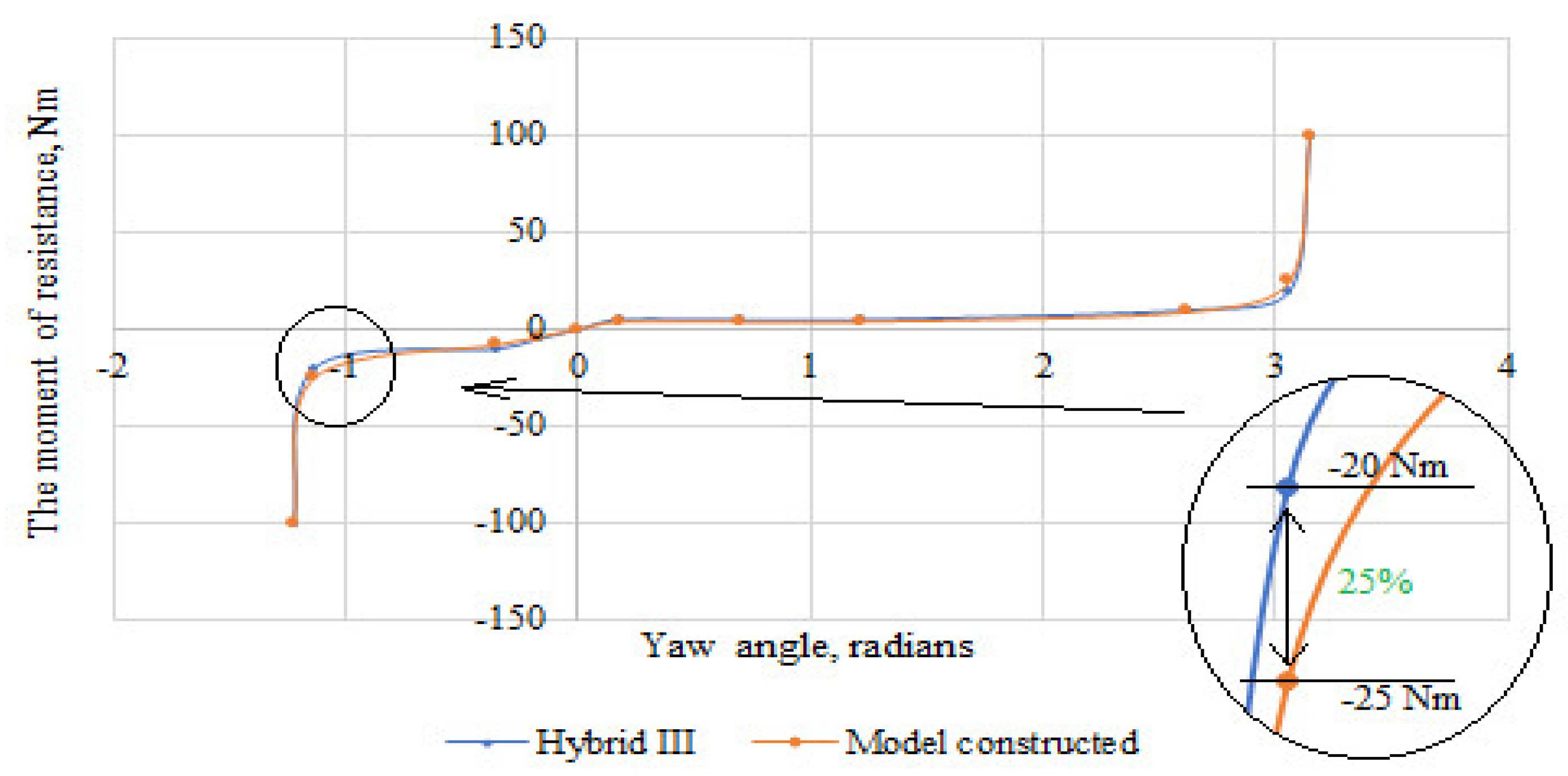

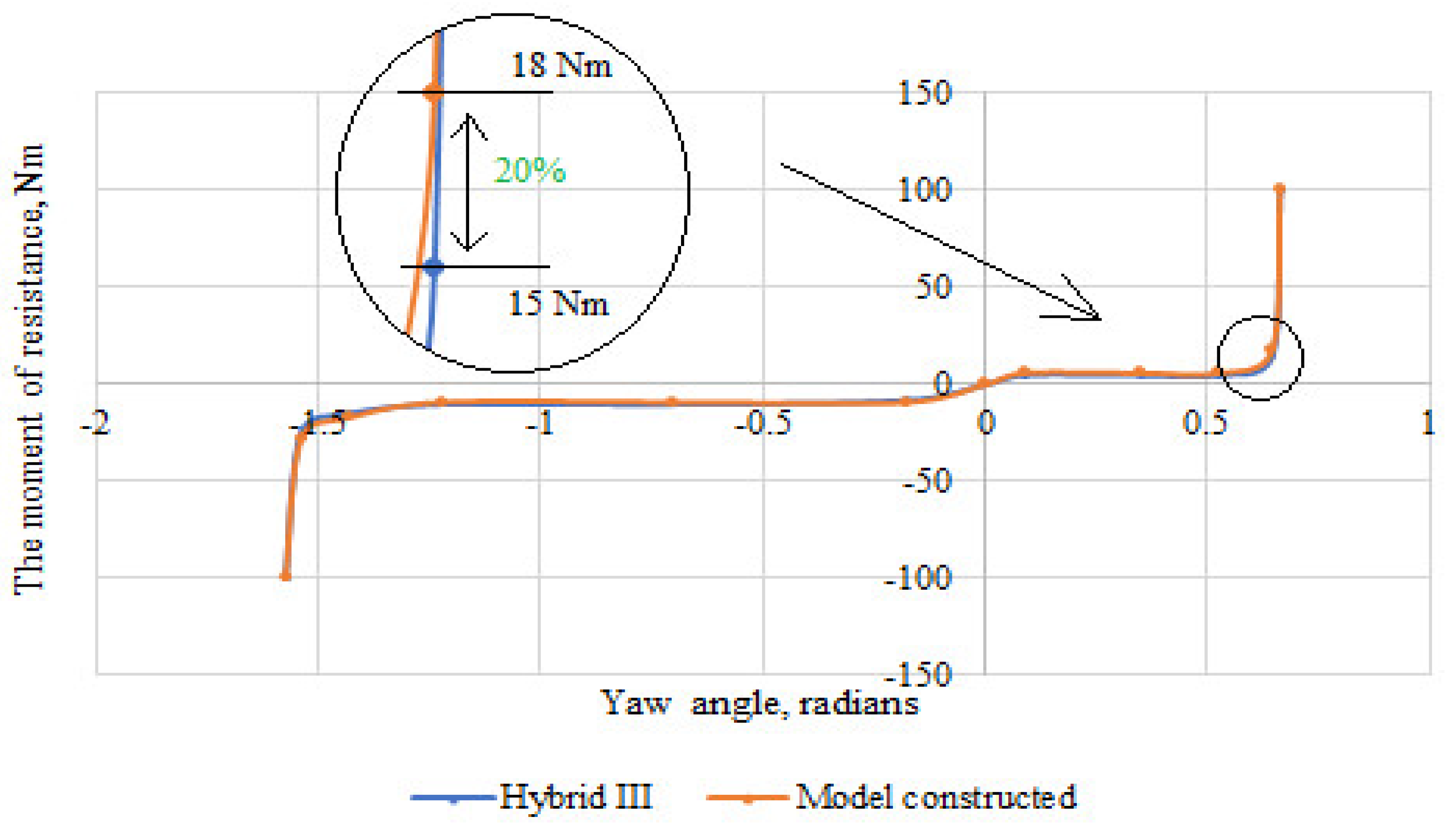

3. Results

- —component being a function of the joint articular,

- —component being a function of angular velocity in the joint,

- —fixed value selected on the basis of initial conditions,

- —moments and initial joint angles determined on the basis of geometry and equilibrium conditions of the dummy.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Road Safety Statistics 2018: What is Behind the Figures? Available online: https://ec.europa.eu/commission/presscorner/detail/en/MEMO_19_1990 (accessed on 19 July 2020).

- Szada-Borzyszkowski, W.; Szada-Borzyszkowska, M. Wpływ Prędkości Pojazdów Na Wielkość Uszkodzeń Podczas Zderzenia. Autobusy Tech. Eksploat. Syst. Transp. 2015, 16, 224–227. [Google Scholar]

- There Are More Rearward Collisions than Frontal Collisions! How to Prevent such Dangerous Events? Available online: https://www.se.pl/auto/porady/uderzen-w-tyl-jest-wiecej-niz-zderzen-czolowych-jak-zapobiegac-takim-niebezpiecznym-zdarzeniom-aa-TrHV-HuDF-Vnnt.html (accessed on 19 July 2020).

- Road Traffic Injuries and Deaths—A Global Problem. Available online: https://www.cdc.gov/injury/features/global-road-safety/index.html (accessed on 19 July 2020).

- Road Accidents. Available online: https://www.policja.pl/pol/form/1,dok.html (accessed on 19 July 2020).

- Jaśkiewicz, M.; Jaskólski, J. Wypadkowe Dane Statystyczne Na Polskich Drogach W Latach 2001–2016. Autobusy Technika Eksploatacja Systemy Transportowe 2017, 18, 20–23. [Google Scholar] [CrossRef]

- Żuchowski, A. Analysis of the influence of the car impact velocity on the loads of the dummies in the front and rear seats. Archives Automot. Eng.—Archiwum Motoryzacji 2018, 81, 159–176. [Google Scholar] [CrossRef]

- Global Status Report on Road Safety 2018; World Health Organization: Geneva, Switzerland, 2018; ISBN 978-92-4-156568-4.

- Road Accidents Are the Leading Cause of Death for Young People. WHO Is Sounding the Alarm in the Latest Report. Available online: https://moto.pl (accessed on 19 July 2020).

- Road Mortality Statistics in the, EU. Available online: https://www.europarl.europa.eu/news/pl/headlines/society/20190410STO36615/statystyki-smiertelnosci-na-drogach-w-ue-infografika (accessed on 19 July 2020).

- Europe has Broken Another Record. It Is about the Number of Fatalities in Accidents. Available online: https://www.wyborkierowcow.pl (accessed on 19 July 2020).

- Kohút, P.; Macurová, Ľ.; Rédl, M.; Ballay, M. Application of Rectification Method for Processing of Documentation from the Place of Road Accident. Archives Automot. Eng.—Archiwum Motoryzacji 2020, 88, 37–46. [Google Scholar] [CrossRef]

- Nycz, D. Influence of selected design parameters of the composite-foam cover rail on the course of the TB11 crash test of a road safety barrier forming a horizontal concave arc. Archives Automot. Eng.—Archiwum Motoryzacji 2017, 76, 107–122. [Google Scholar] [CrossRef]

- Communication from the Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of the Regions Europe on the Move Sustainable Mobility for Europe: Safe, Connected and Clean. Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/?uri=COM:2018:293:FIN (accessed on 19 July 2020).

- Health Risks When Travelling. Available online: https://www.who.int/news-room/q-a-detail/health- risks -when-traveling (accessed on 19 July 2020).

- Stockholm Declaration Third Global Ministerial Conference on Road Safety: Achieving Global Goals 2030 Stockholm. 19–20 February 2020. Available online: https://www.roadsafetysweden.com/about-the-conference/stockholm-declaration/ (accessed on 19 July 2020).

- Safe Roads in Europe. Available online: https://ec.europa.eu/poland/news/200612_roads_pl (accessed on 19 July 2020).

- Stańczyk, T.L.; Hyb, L. Technological and organisational challenges for e-mobility. Archives Automot. Eng.—Archiwum Motoryzacji 2019, 84, 57–70. [Google Scholar] [CrossRef]

- Mohan, P.; Marzougui, D.; Kan, C. Development and Validation of Hybrid III Crash Test Dummy; SAE Technical Paper 2009-01-0473; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Douglas, C.; Fildes, B.; Gibson, T. Modeling Occupants in Far-Side Impacts. Traffic Inj. Prev. 2011, 12, 508–517. [Google Scholar] [CrossRef]

- Törnvall, F.V.; Holmqvist, K.; Davidsson, J.; Svensson, M.Y.; HÅland, Y.; Öhrn, H. A New THOR Shoulder Design, A Comparison with Volunteers, the Hybrid III, and THOR NT. Traffic Inj. Prev. 2008, 8, 205–215. [Google Scholar] [CrossRef]

- Haslegrave, C.M. Dummies for crash testing motor cars. Appl. Ergon. 1974, 5, 153–160. [Google Scholar] [CrossRef]

- Kluszczyk, K.; Łukasik, R.; Czech, P.; Figlus, T.; Turoń, K. Analiza statystyk dotyczących wypadków drogowych w Polsce w latach 2005–2015. Autobusy: Technika, Eksploatacja, Systemy Transportowe 2017, 18, 247–256. [Google Scholar]

- Gibbs, J.; Wang, Z.J. Adjustable Friction Joint Assembly for Crash Test Dummy. U.S. Patent No 9754514B2, 5 September 2017. [Google Scholar]

- User Manuals. Available online: https://humanetics.humaneticsgroup.com (accessed on 19 July 2020).

- Frej, D.; Zuska, A.; Cadge, K. Analysis of vertical vibrations affecting a child transported in a child seat during a car passing over the release speed bump. Archives Automot. Eng.—Archiwum Motoryzacji 2019, 86, 111–125. [Google Scholar] [CrossRef]

- Viano, D.C. Parenteau Ch. S, Burnett R., Prasad P., Occupant responses in conventional and ABTS seats in high-speed rear sled tests. Traffic Inj. Prev. 2018, 19, 54–59. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.J. Omnidirectional Neck Assembly for Crash Test Dummy. U.S. Patent No. 9972220B2, 15 May 2018. [Google Scholar]

- Kent, R.; Shaw, G.; Lessley, D.; Crandall, J.; Kallieris, D.; Svensson, M. Comparison of Belted Hybrid III, THOR, and Cadaver Thoracic Responses in Oblique Frontal and Full Frontal Sled Tests; SAE Transactions; JSTOR: New York, NY, USA, 2003; Volume 112, pp. 71–84. Available online: www.jstor.org/stable/44745377 (accessed on 19 July 2020).

- Parent, D.; Craig, M.; Moorhouse, K. Biofidelity Evaluation of the THOR and Hybrid III 50th Percentile Male Frontal Impact Anthropomorphic Test Devices; SAE Technical Paper 2017-22-0009; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- McInnis, J.P.; Wang, Z.J.; Kloppenborg, N.M.; Gibbs, J.Q.; Benfant, L.M.; Lane, S. Joint assembly for crash test dummy. U.S. Patent 20140294485A1, 2 October 2014. [Google Scholar]

- Woley, P.F.; Wolanin, M.J. Knee joint for anthropomorphic dummy. U.S. Patent 4276032A, 30 June 1981. [Google Scholar]

- Ranking EU Progresson Road Safety 14th, Road Safety Performance Index Repor. June 2020. Available online: https://etsc.eu/13th-annual-road-safety-performance-index-pin-report/ (accessed on 19 July 2020).

- Road Safety Training. Available online: https://www.krbrd.gov.pl/tag/wypadki-w-polsce/ (accessed on 19 July 2020).

- Borovinsek, M.; Vesenjak, M.; Ulbin, M.; Ren, Z. Simulation of crash test for high containment levels of road safety barriers. Eng. Fail. Anal. 2007, 14, 1711–1718. [Google Scholar] [CrossRef]

- López-Valdés, F.J.; Juste-Lorente, O.; Maza-Frechin, M.; Pipkorn, B.; Sunnevang, C.; Lorente, A.; Aso-Vizan, A.; Davidsson, J. Analysis of occupant kinematics and dynamics in nearside oblique impacts. Traffic Inj. Prev. 2016, 17, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Żuchowski, A. Seatbelt impact on a child during a frontal collision. Archives Automot. Eng.—Archiwum Motoryzacji 2017, 75. [Google Scholar] [CrossRef]

- Amiri, S.; Naserkhaki, S.; Parnianpour, M. Modeling and validation of a detailed FE viscoelastic lumbar spine model for vehicle occupant dummies. Comput. Biol. Med. 2018, 99, 191–200. [Google Scholar] [CrossRef]

- Keon, T. Alternative Approaches to Occupant Response Evaluation in Frontal Impact, Crash Testing. SAE Int. J. Transp. Saf. 2016, 4, 202–217. [Google Scholar] [CrossRef]

- Mohyla, P.; Hajnys, J.; Sternadelová, K.; Krejčí, L.; Pagáč, M.; Konečná, K.; Krpec, P. Analysis of Welded Joint Properties on an AISI316L Stainless Steel Tube Manufactured by SLM Technology. Materials 2020, 13, 4362. [Google Scholar] [CrossRef]

- Choi, S.-W.; Kim, Y.-S.; Yum, Y.-J.; Yang, S.-Y. A Study on Strengthening Mechanical Properties of a Punch Mold for Cutting by Using an HWS Powder Material and a DED Semi-AM Method of Metal 3D Printing. J. Manuf. Mater. Process. 2020, 4, 98. [Google Scholar] [CrossRef]

- Affatato, S.; Valigi, M.C.; Logozzo, S. Knee Wear Assessment: 3D Scanners Used as a Consolidated Procedure. Materials 2020, 13, 2349. [Google Scholar] [CrossRef]

- Pellizzari, M.; Jam, A.; Tschon, M.; Fini, M.; Lora, C.; Benedetti, M. A 3D-Printed Ultra-Low Young’s Modulus β-Ti Alloy for Biomedical Applications. Materials 2020, 13, 2792. [Google Scholar] [CrossRef] [PubMed]

- Sittiwanchai, T.; Nakayama, I.; Inoue, S.; Kobayashi, J. Transhumeral prosthesis prototype with 3D printing and sEMG-based elbow joint control method. In Proceedings of the 2014 International Conference on Advanced Mechatronic Systems, Kumamoto, Japan, 10–12 August 2014; pp. 227–231. [Google Scholar] [CrossRef]

- Silveira Romero, R.C.; Machado, A.A.; Costa, K.A.; Reis, P.H.R.G.; Paiva Brito, P.; Santos Vimieiro, C.B. Development of a Passive Prosthetic Hand That Restores Finger Movements Made by Additive Manufacturing. Appl. Sci. 2020, 10, 4148. [Google Scholar] [CrossRef]

- Abdul Wahit, M.A.; Ahmad, S.A.; Marhaban, M.H.; Wada, C.; Izhar, L.I. 3D Printed Robot Hand Structure Using Four-Bar Linkage Mechanism for Prosthetic Application. Sensors 2020, 20, 4174. [Google Scholar] [CrossRef]

- Alkhatib, F.; Mahdi, E.; Cabibihan, J. Design and Analysis of Flexible Joints for a Robust 3D Printed Prosthetic Hand. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 784–789. [Google Scholar] [CrossRef]

- Desai, J.P.; Sheng, J.; Cheng, S.S.; Wang, X.; Deaton, N.J.; Rahman, N. Toward Patient-Specific 3D-Printed Robotic Systems for Surgical Interventions. IEEE Trans. Med. Robot. Bionics 2019, 1, 77–87. [Google Scholar] [CrossRef]

- Chinthavali, M. 3D printing technology for automotive applications. In Proceedings of the 2016 International Symposium on 3D Power Electronics Integration and Manufacturing (3D-PEIM), Raleigh, NC, USA, 13–15 June 2016; pp. 1–13. [Google Scholar] [CrossRef]

- Qi, Z.; Chen, Y. Investigation of Ergonomics in Photocuring 3D Printing Post-Processing Using Jack. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–18 April 2020; pp. 326–329. [Google Scholar] [CrossRef]

- Bassoli, E.; Gatto, A.; Iuliano, L.; Grazia Violante, M. 3D printing technique applied to rapid casting. Rapid Prototyp. J. 2007, 13, 148–155. [Google Scholar] [CrossRef]

- Pyo HJeong, J.W.; Yu JLee, S.G.; Kim, W. Design of 3D-Printed Hybrid Axial-Flux Motor Using 3D-Printed SMC Core. IEEE Trans. Appl. Supercond. 2020, 30, 1–4. [Google Scholar] [CrossRef]

- Frej, D.; Jaśkiewicz, M. Przegub Kolanowy Manekina Antropometrycznego do Testów Zderzeniowych, (Knee-Joint of the Anthropometric Crash Test Dummy). PL. Patent P.431522, 21 October 2019. [Google Scholar]

- Frej, D.; Jaśkiewicz, M. Przegub Barkowy Manekina Antropometrycznego do Testów Zderzeniowych, (Shoulder Joint of the Anthropometric Crash Test Dummy Application). PL. Patent P.433041, 27 February 2020. [Google Scholar]

- Hylla, P.; Domin, J. Impact of additive manufacturing temperature on strength of 3D printouts made of PLA and ABS. Min. Mach. 2020, 3, 43–52. [Google Scholar] [CrossRef]

| Body Parts | World SID 50th | BioSID | EuroSID-2 | EuroSID-1 |

|---|---|---|---|---|

| Head | 10.0 | 6.7 | 5.0 | 5.0 |

| Neck | 5.2 | 6.7 | 4.4 | 7.8 |

| Shoulder | 7.0 | 7.3 | 5.3 | 7.3 |

| Thorax | 7.9 | 6.3 | 5.2 | 5.4 |

| Abdomen | 6.4 | 3.8 | 2.6 | 0.9 |

| Pelvis | 7.8 | 4.0 | 5.3 | 1.5 |

| Overall | 7.3 | 5.7 | 4.6 | 4.4 |

| Section | Construction of a Dummy | Hybrid III | ||

|---|---|---|---|---|

| ∆φmin [deg] | ∆φmax [deg] | ∆φmin [deg] | ∆φmax [deg] | |

| Shoulder joint | 70 | 180 | 70 | 180 |

| Elbow joint | 0 | 150 | 0 | 150 |

| Wrist joint | 90 | 85 | 90 | 85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaśkiewicz, M.; Frej, D.; Tarnapowicz, D.; Poliak, M. Upper Limb Design of an Anthropometric Crash Test Dummy for Low Impact Rates. Polymers 2020, 12, 2641. https://doi.org/10.3390/polym12112641

Jaśkiewicz M, Frej D, Tarnapowicz D, Poliak M. Upper Limb Design of an Anthropometric Crash Test Dummy for Low Impact Rates. Polymers. 2020; 12(11):2641. https://doi.org/10.3390/polym12112641

Chicago/Turabian StyleJaśkiewicz, Marek, Damian Frej, Dariusz Tarnapowicz, and Milos Poliak. 2020. "Upper Limb Design of an Anthropometric Crash Test Dummy for Low Impact Rates" Polymers 12, no. 11: 2641. https://doi.org/10.3390/polym12112641

APA StyleJaśkiewicz, M., Frej, D., Tarnapowicz, D., & Poliak, M. (2020). Upper Limb Design of an Anthropometric Crash Test Dummy for Low Impact Rates. Polymers, 12(11), 2641. https://doi.org/10.3390/polym12112641