Effect of Different Bond Parameters on the Mechanical Properties of FRP and Concrete Interface

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Properties

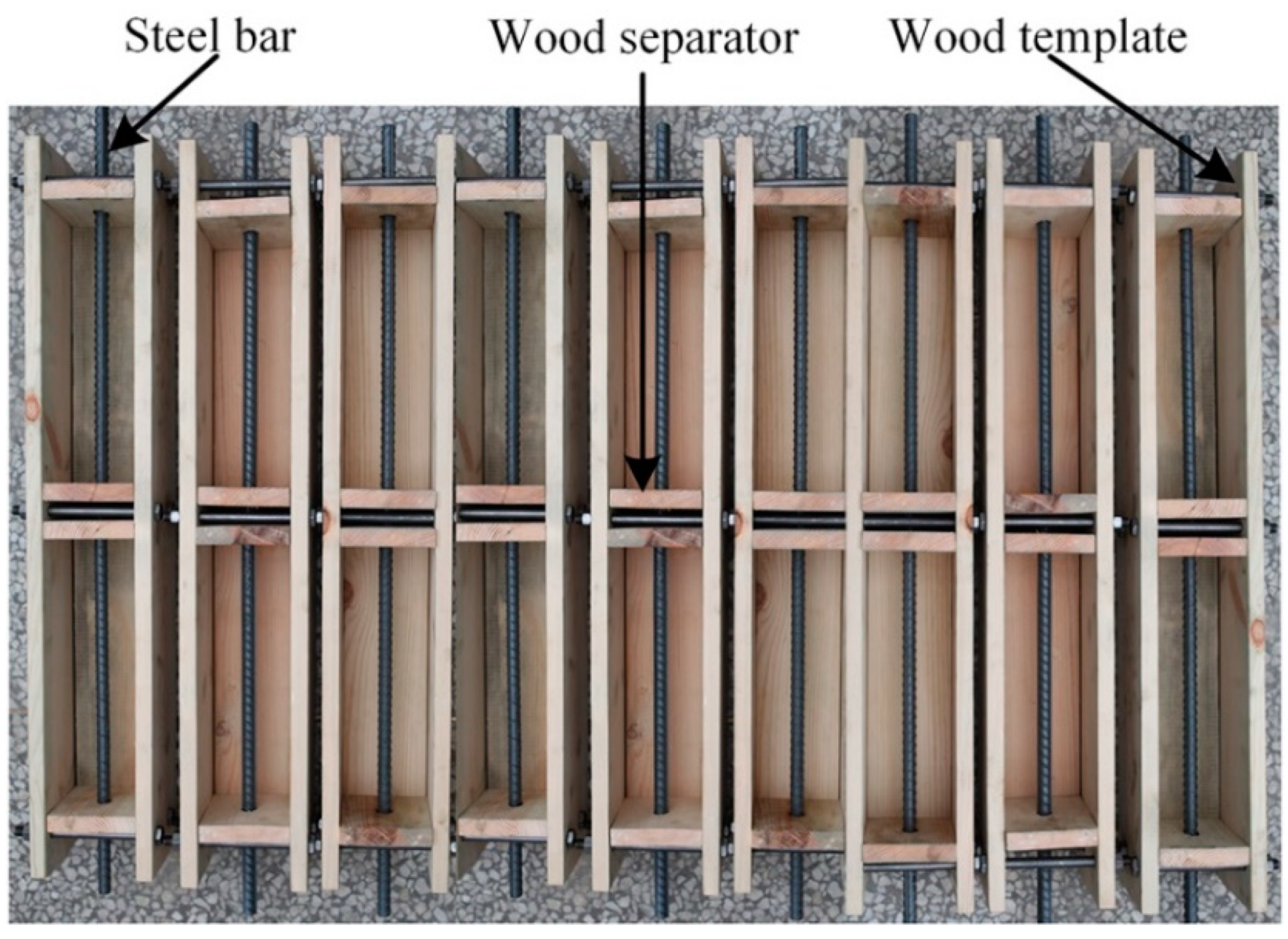

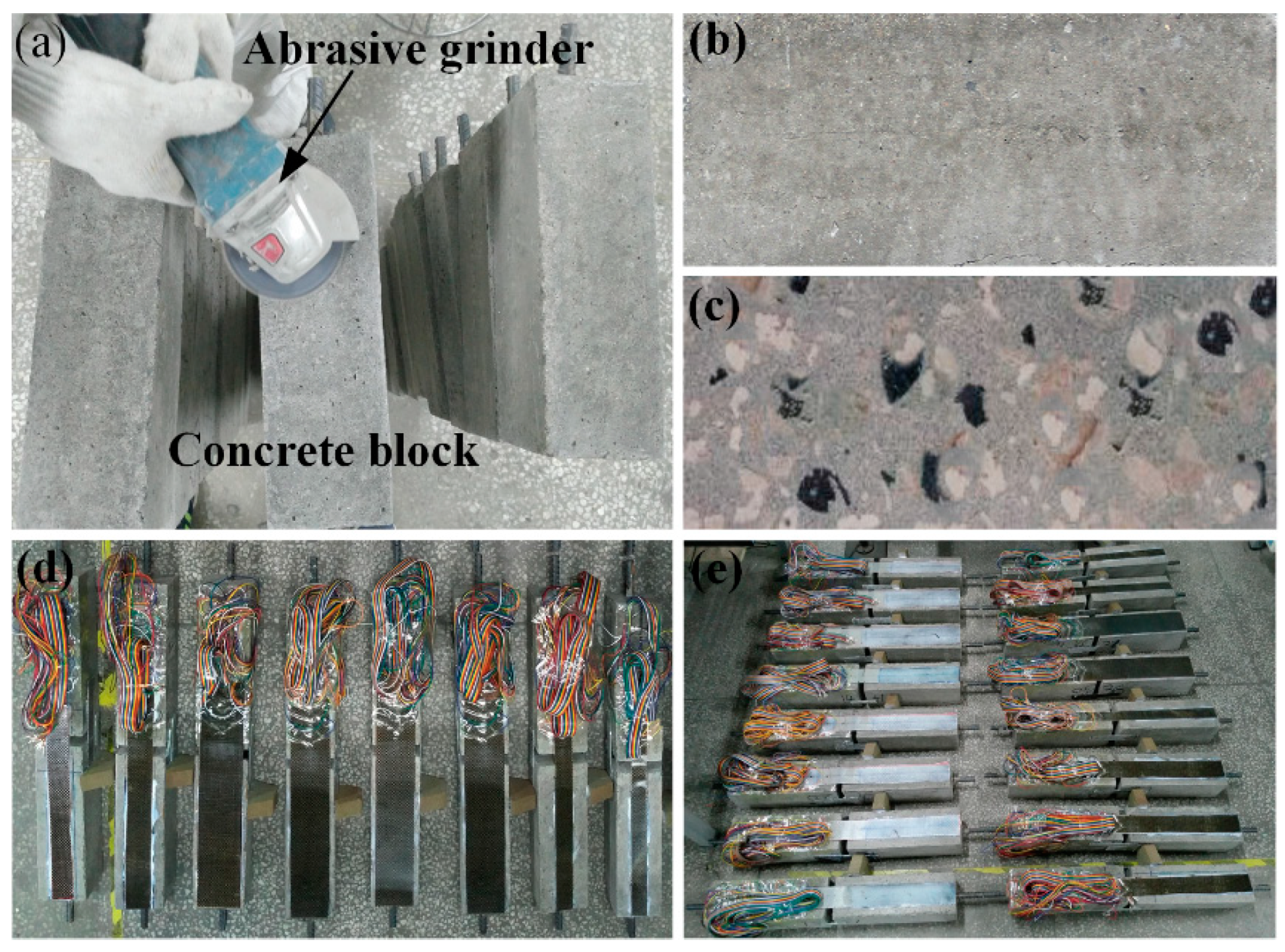

2.2. Specimens Preparation

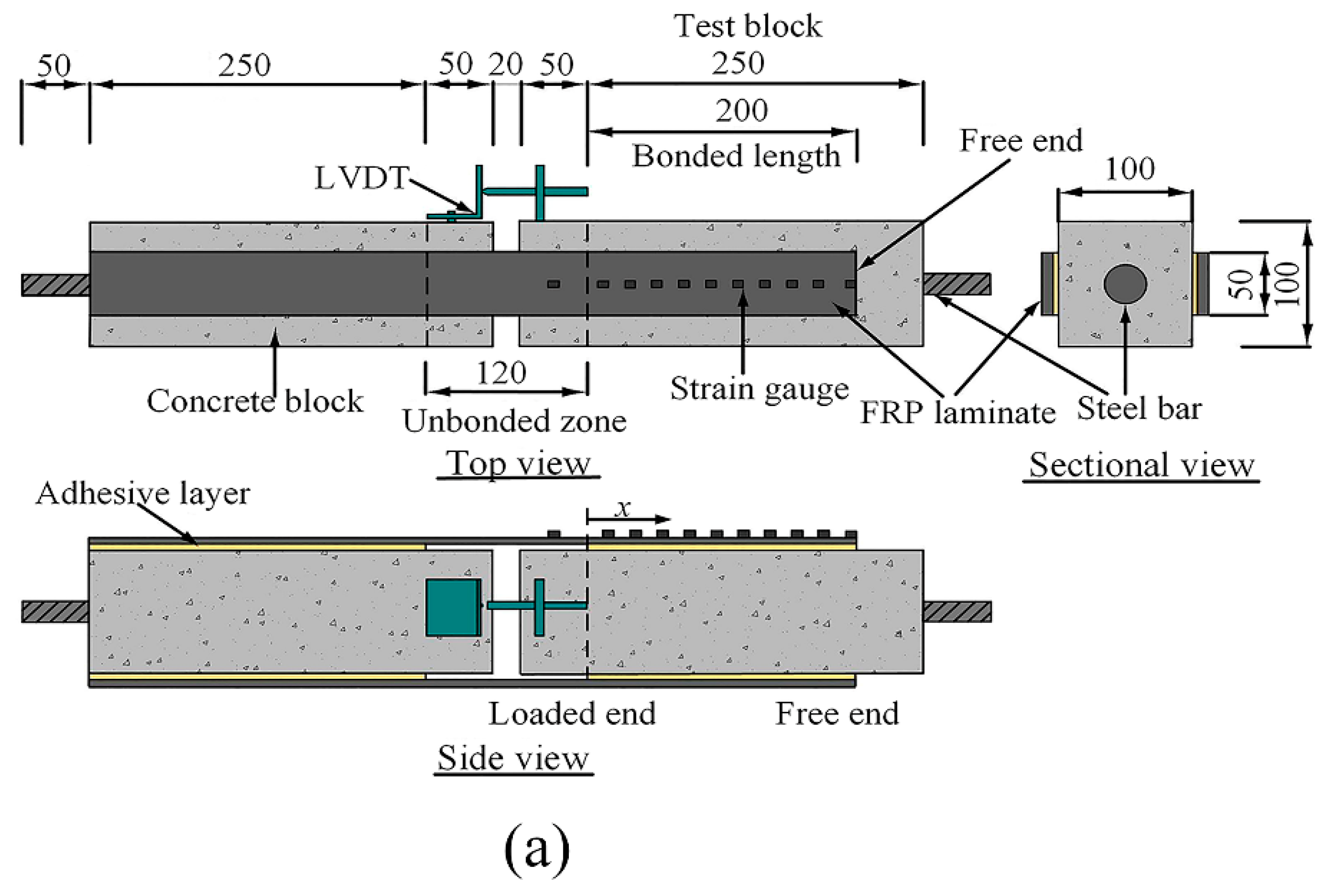

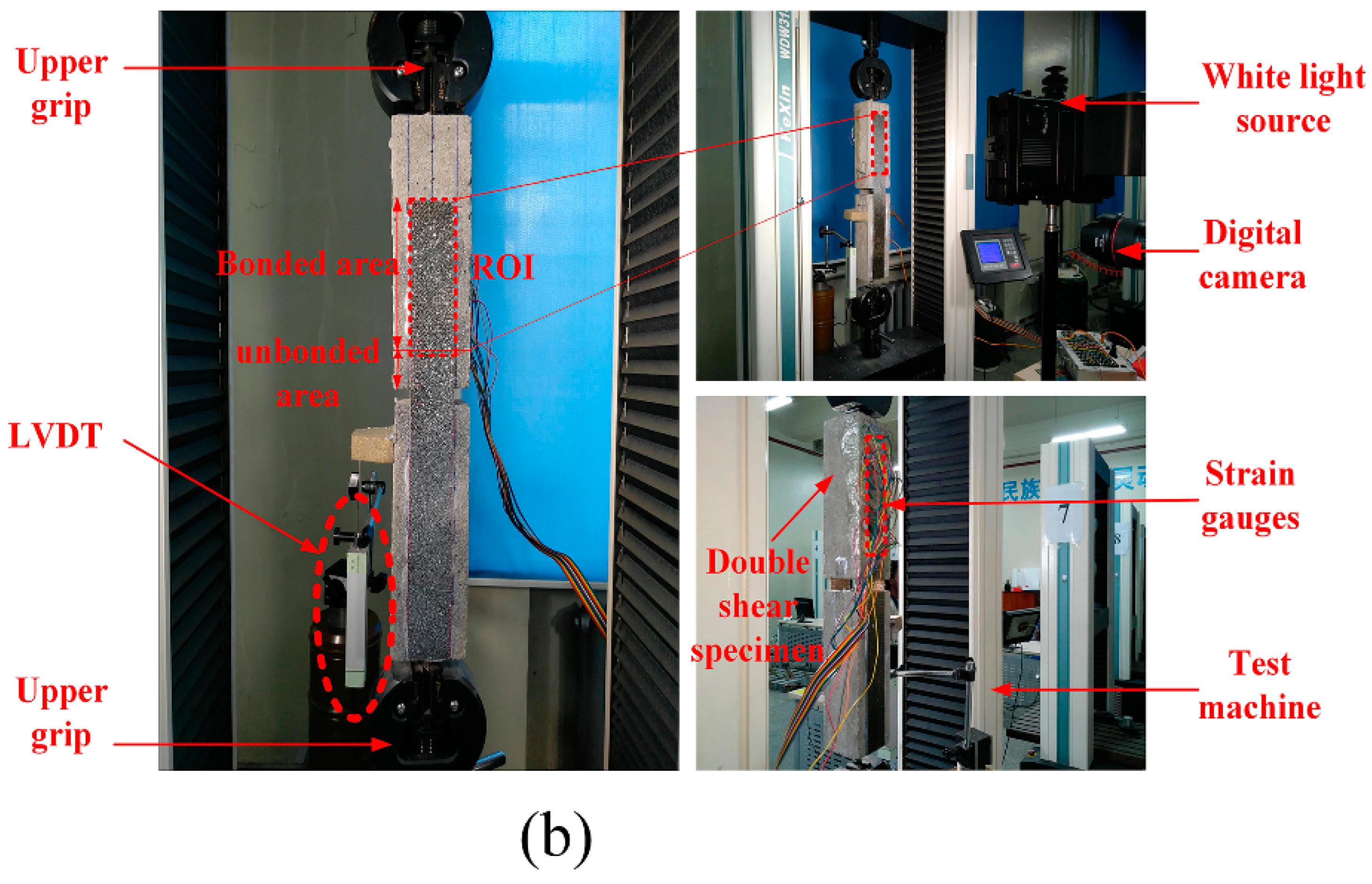

2.3. Double Shear Test Setup and Instrumentation

3. Testing Results and Discussions

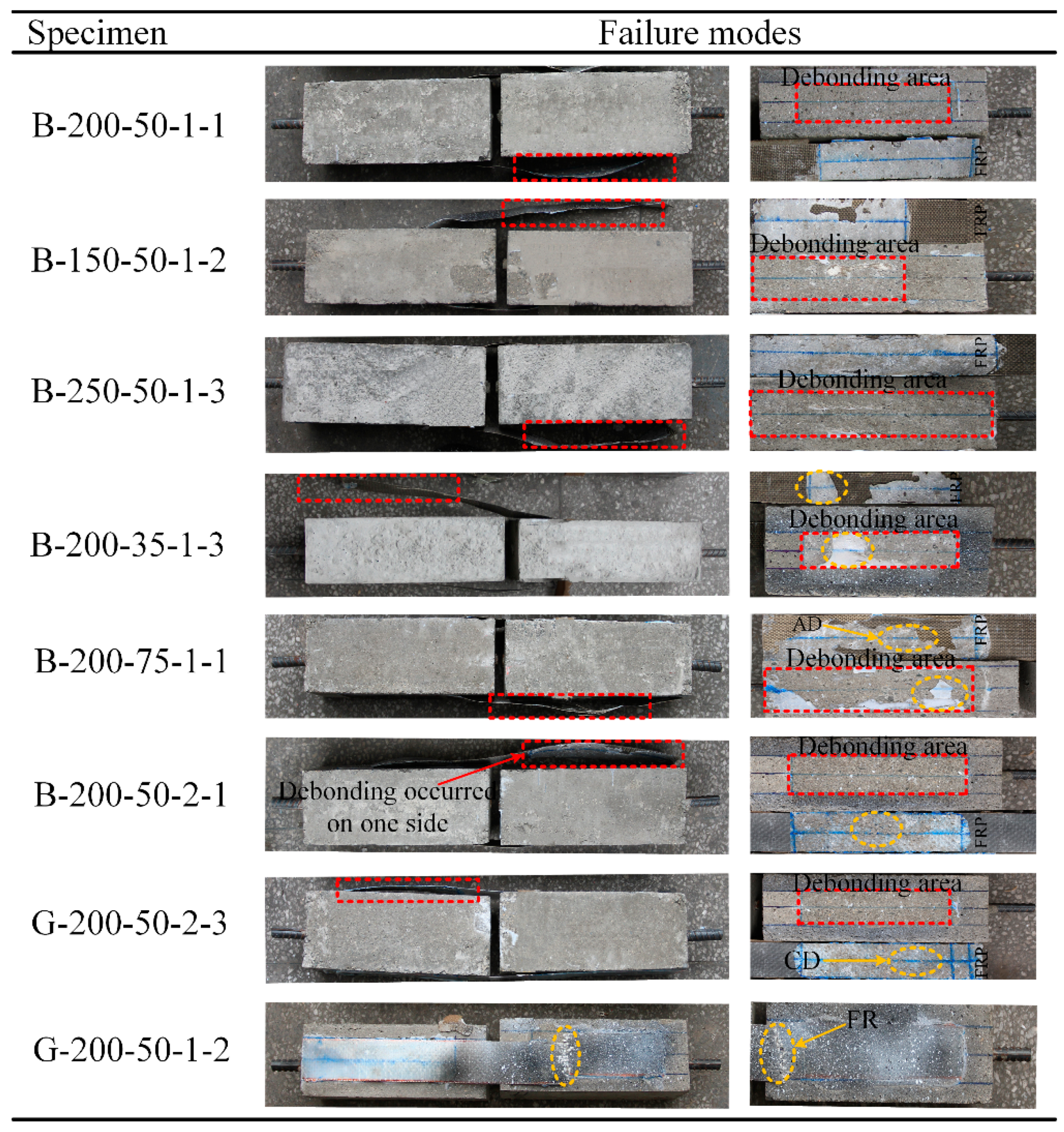

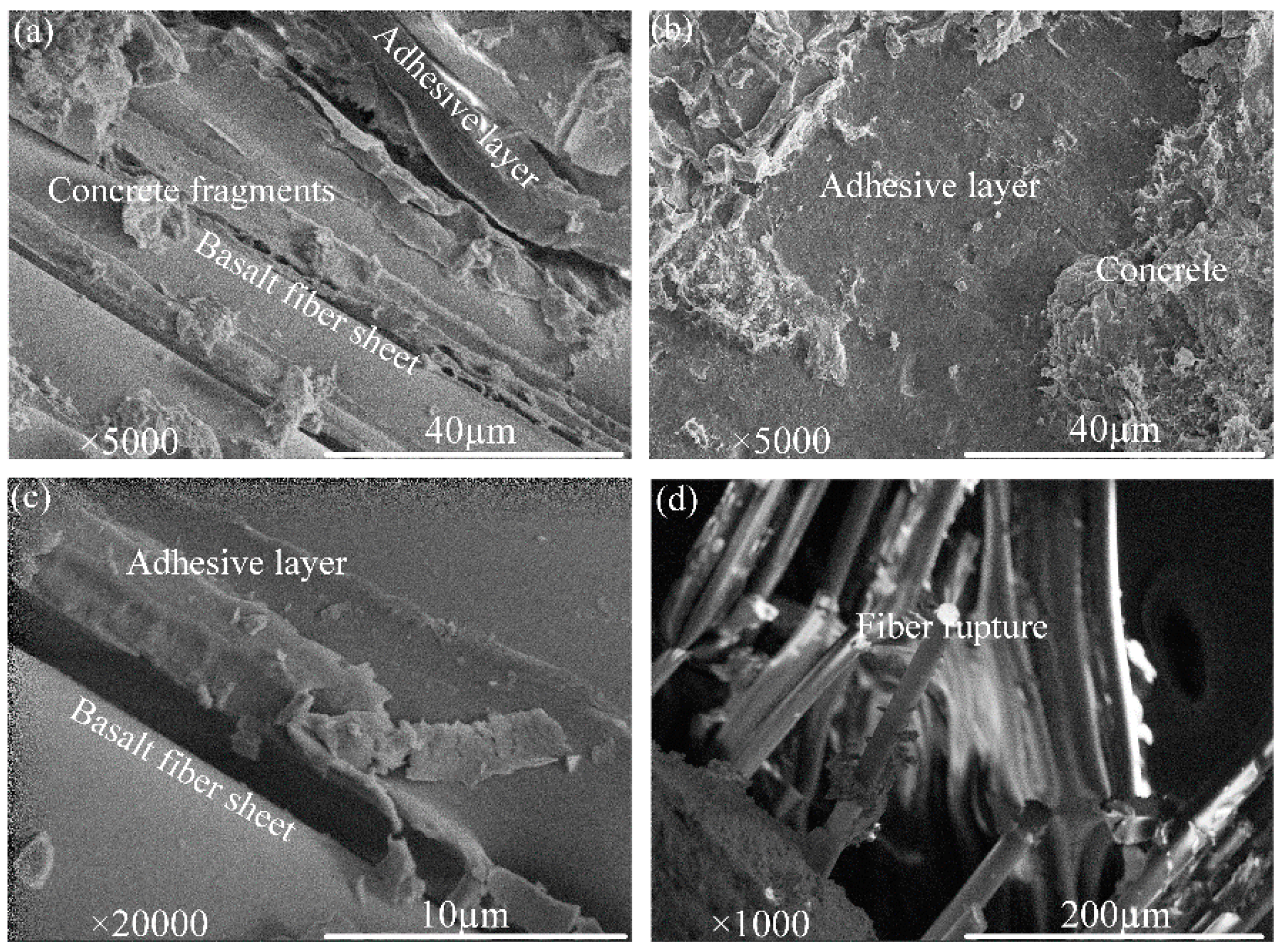

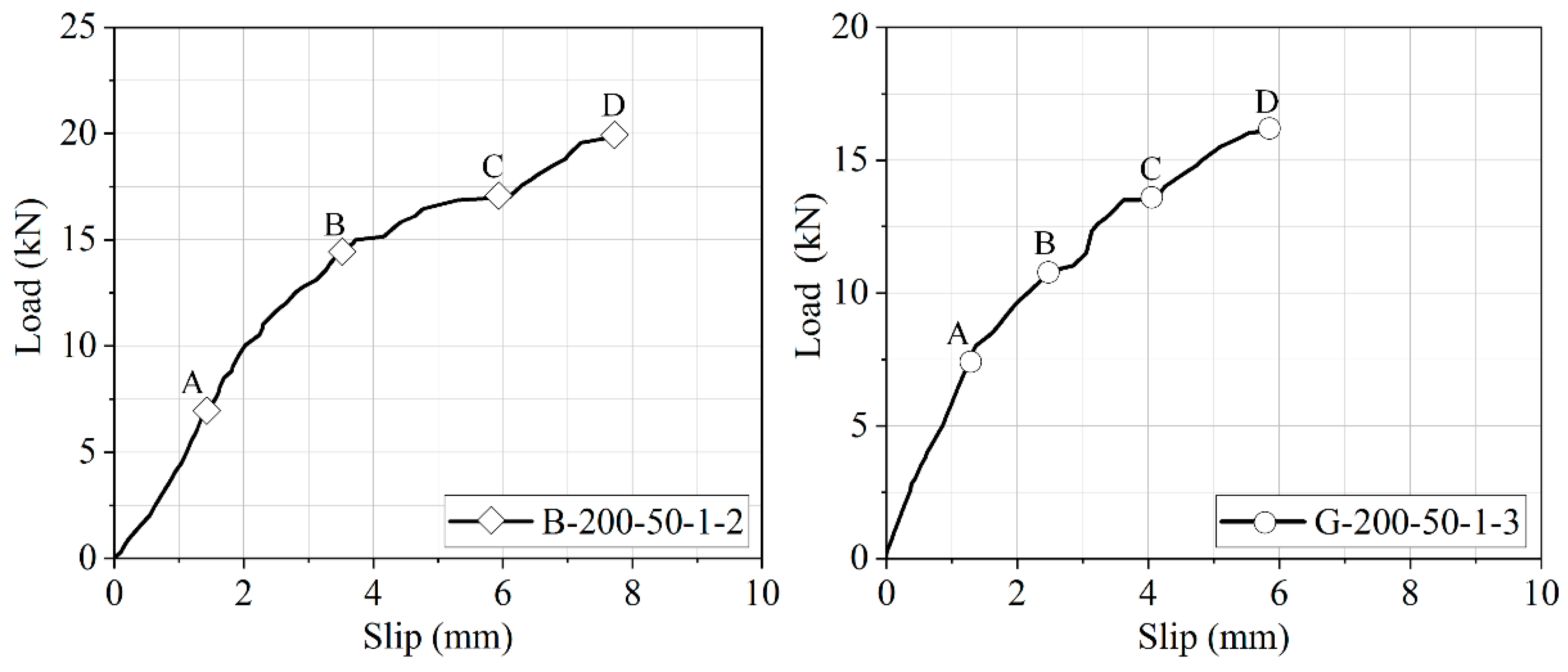

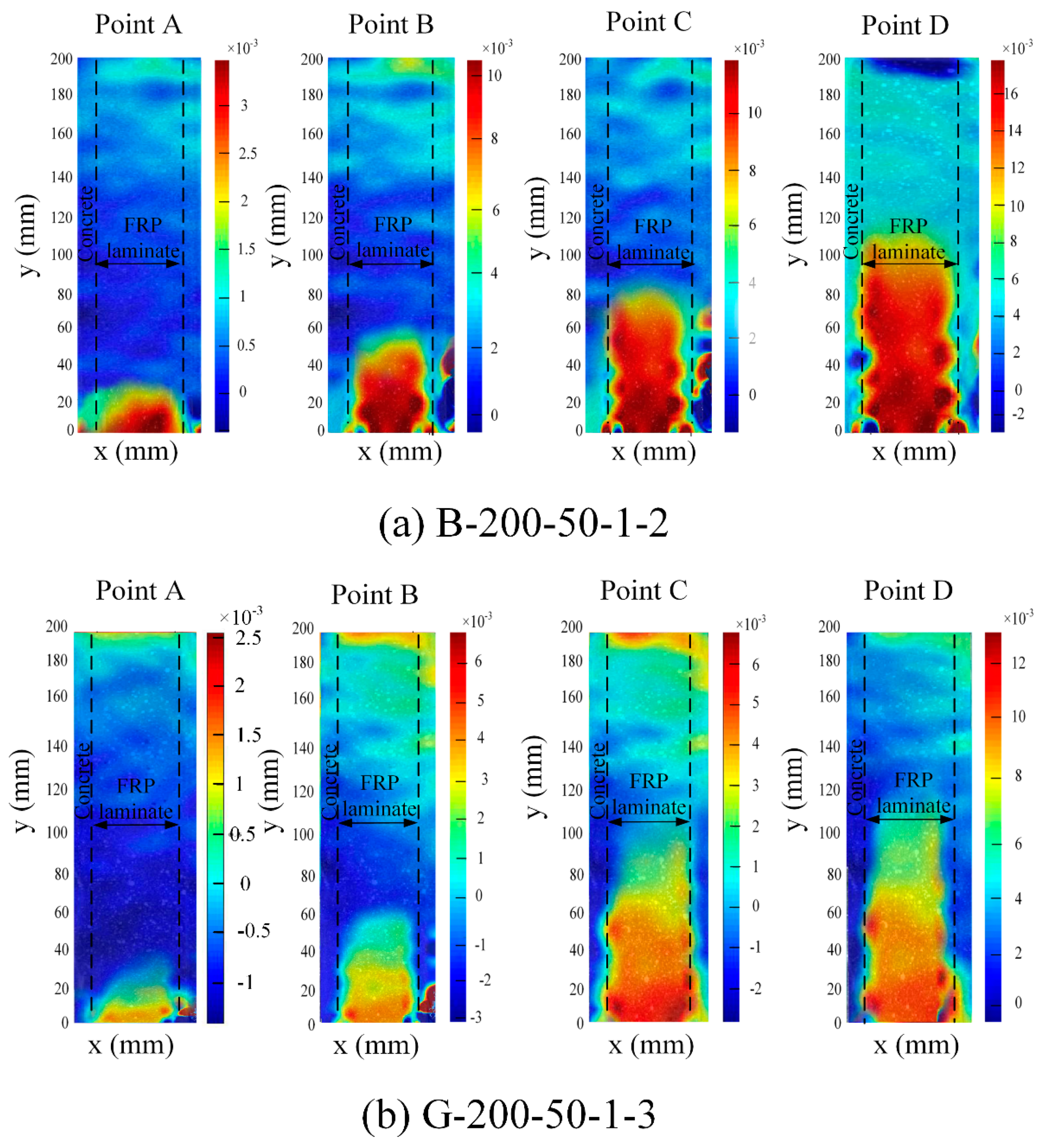

3.1. Failure Modes and Debonding Mechanism

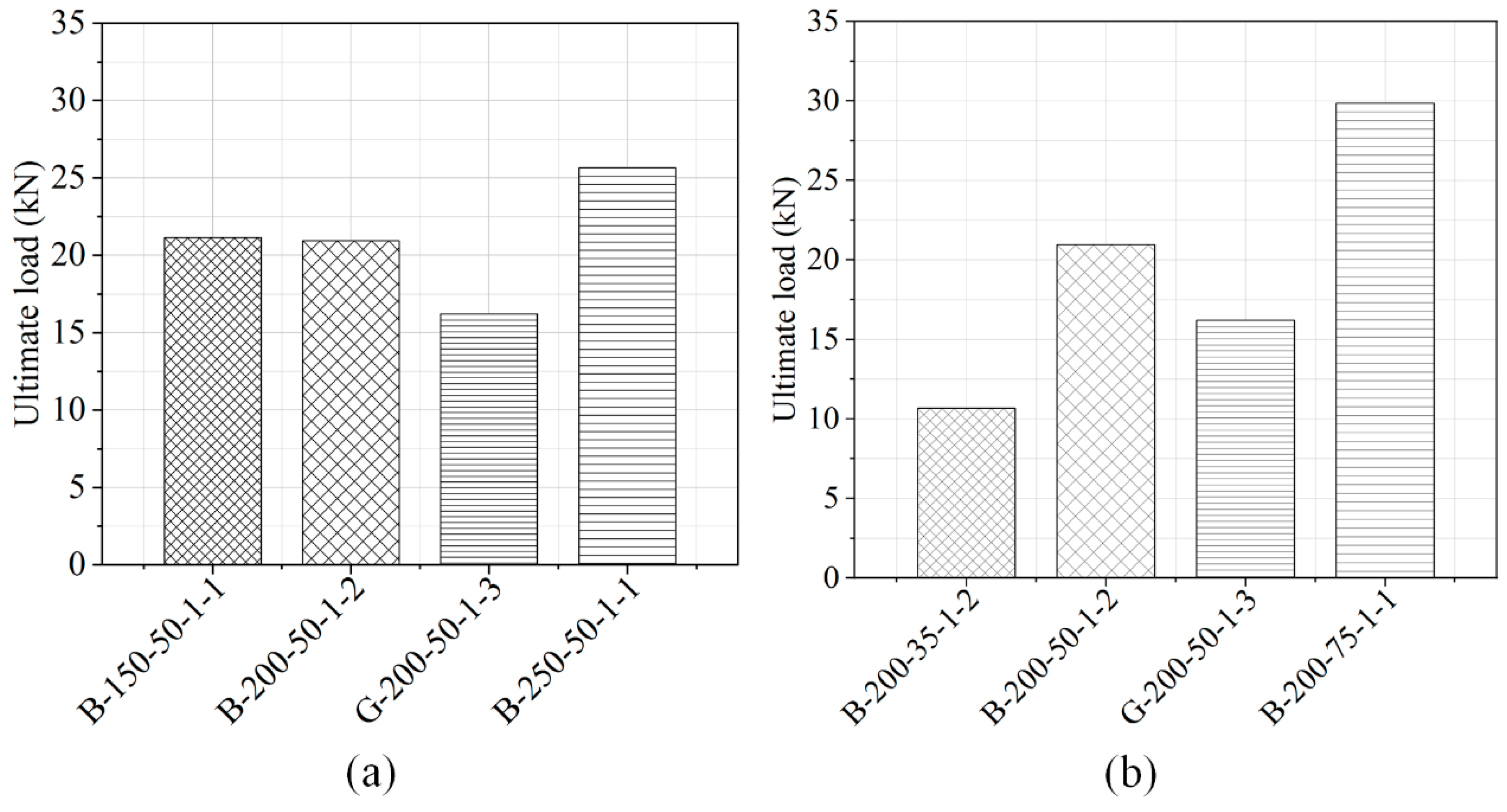

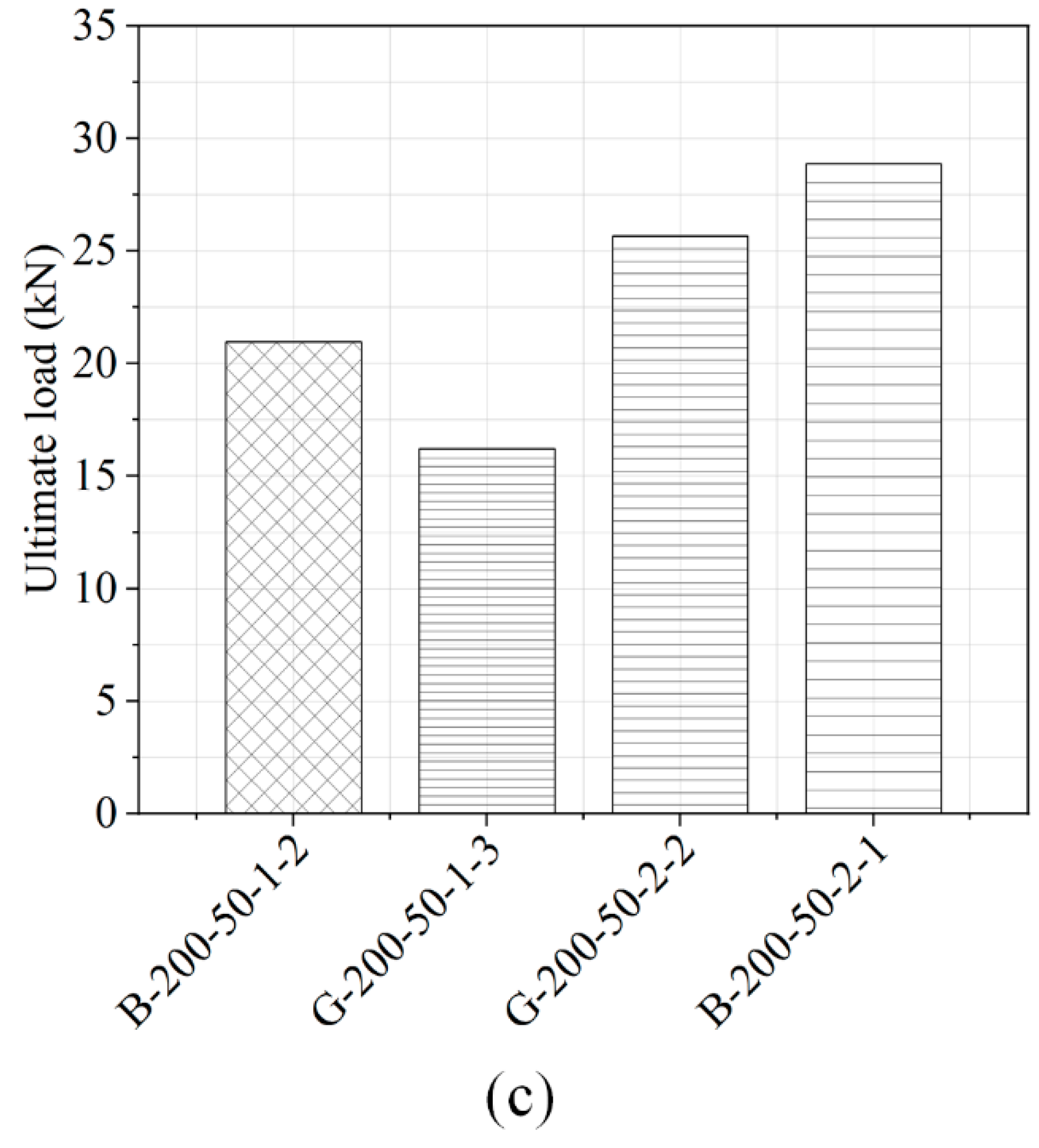

3.2. Ultimate Load and Deformation

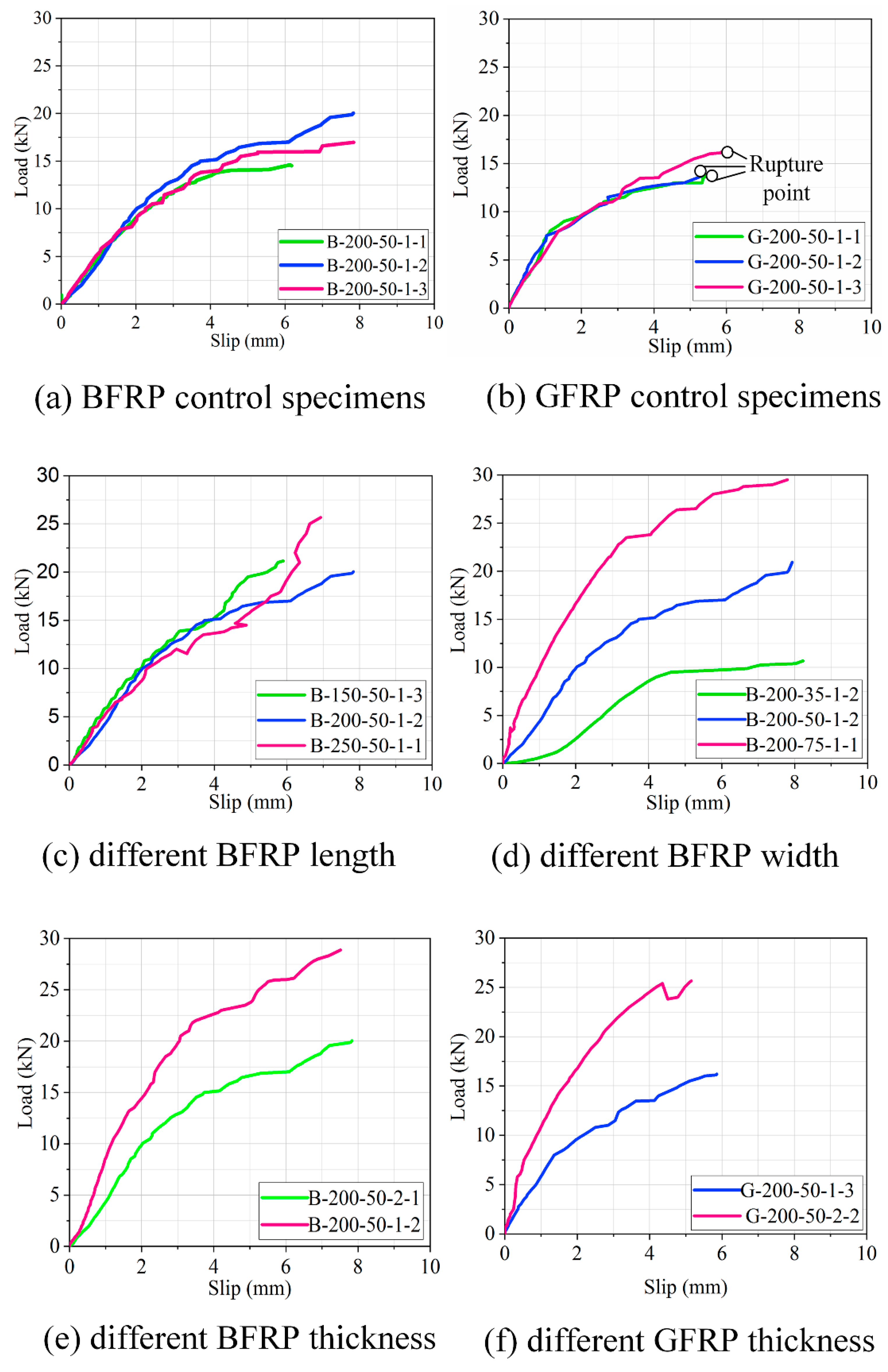

3.3. Load–Slip Relationships of FRP–Concrete Bond

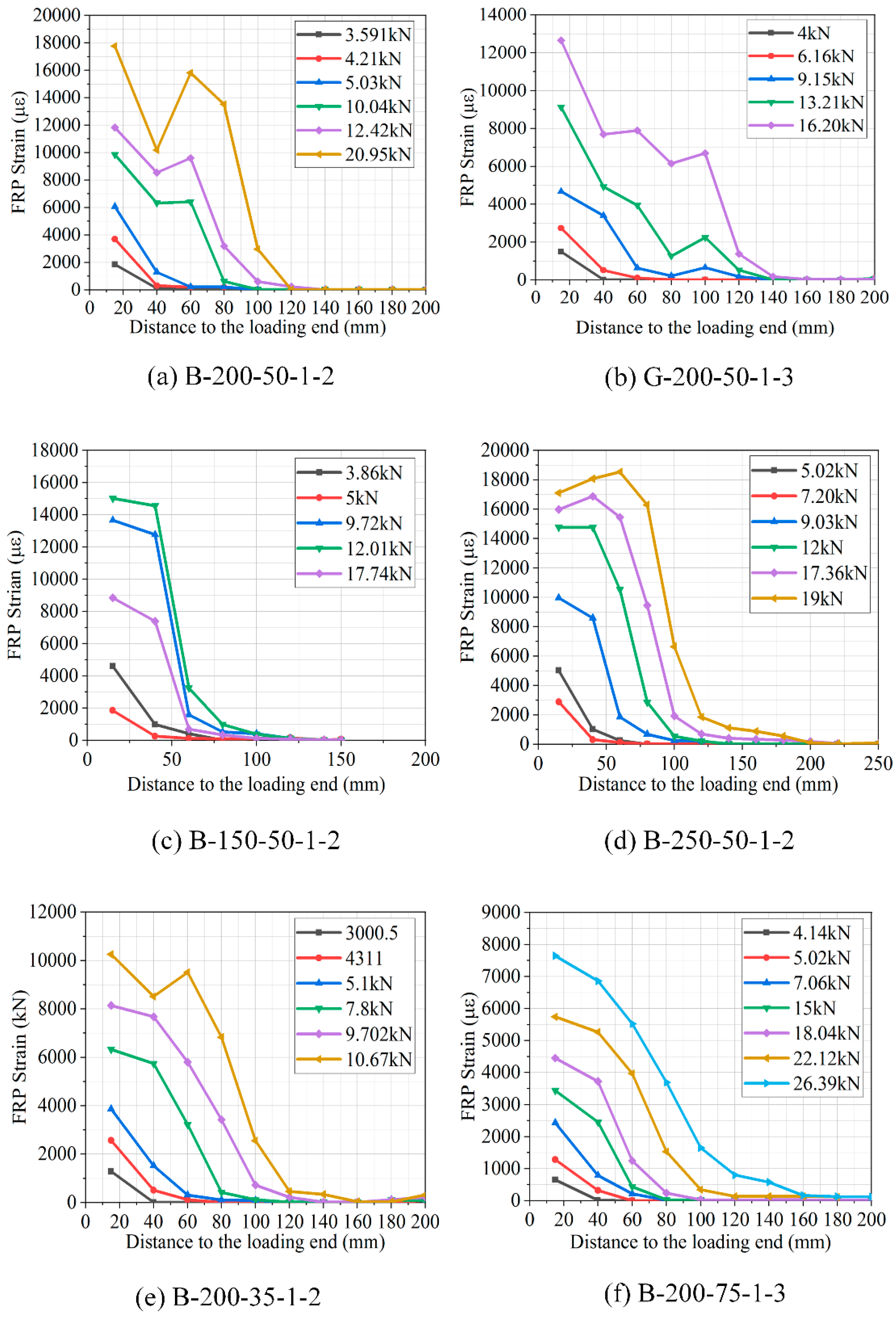

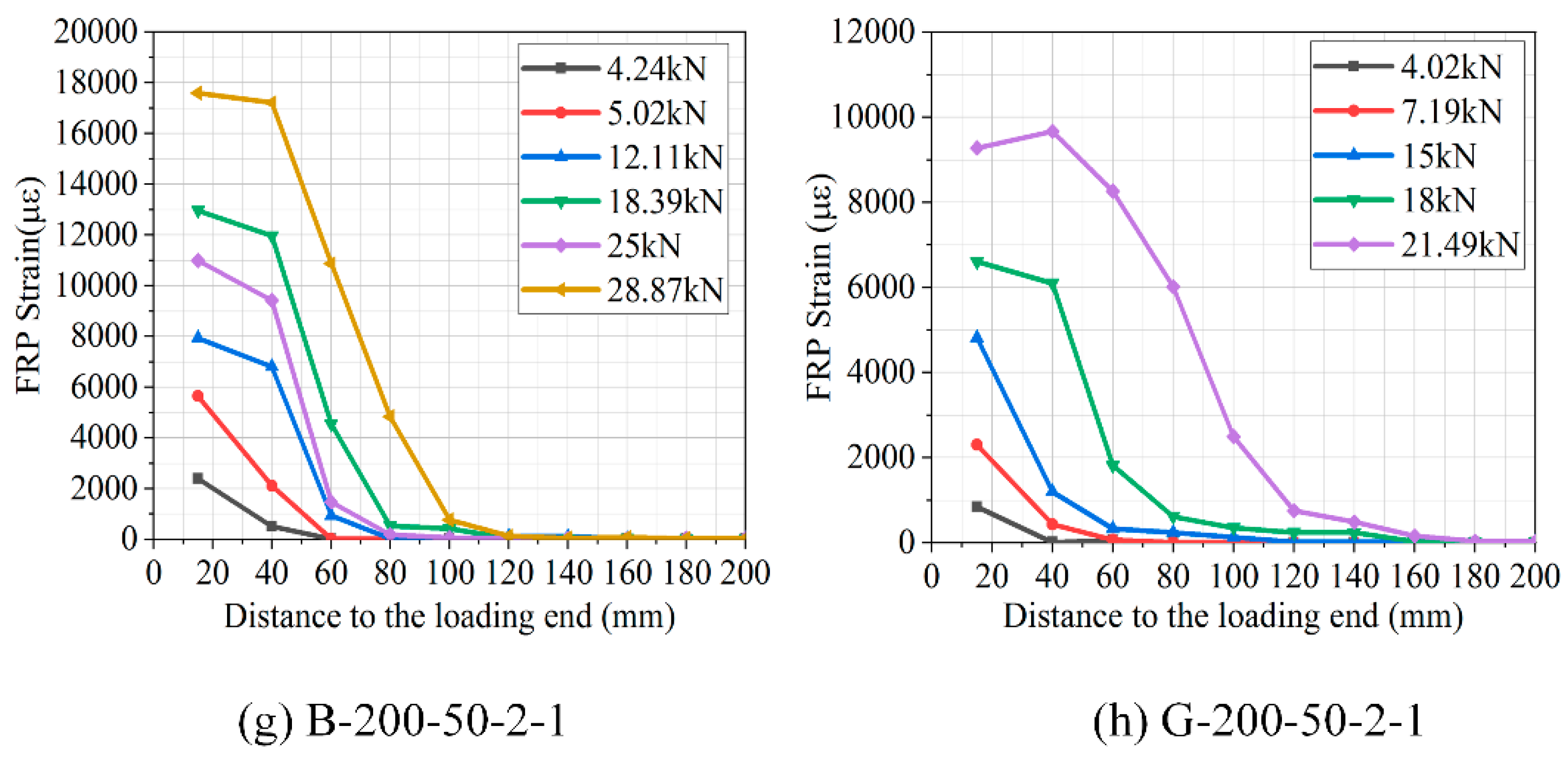

3.4. Strain Distribution in BFRP and GFRP Laminates

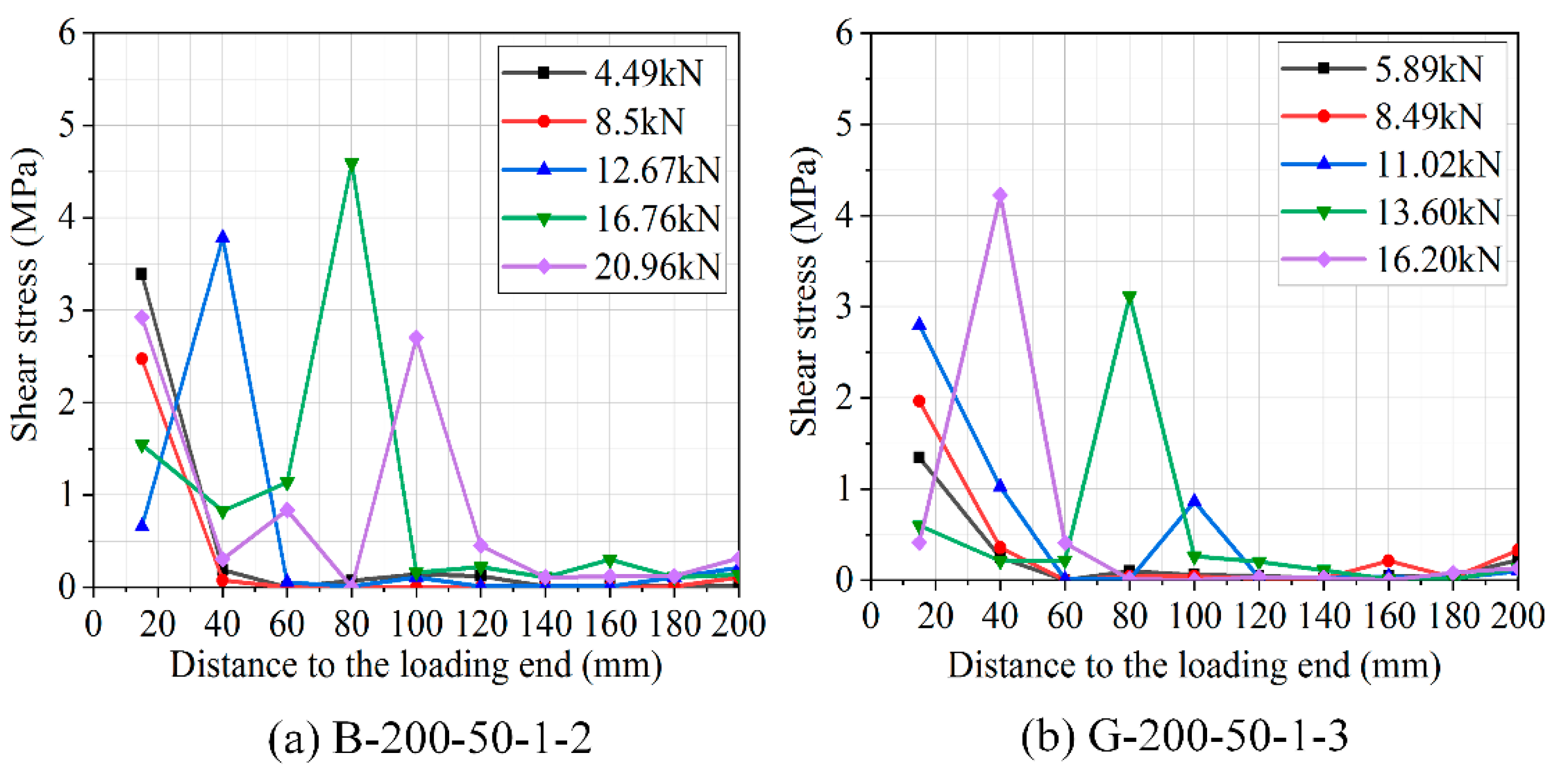

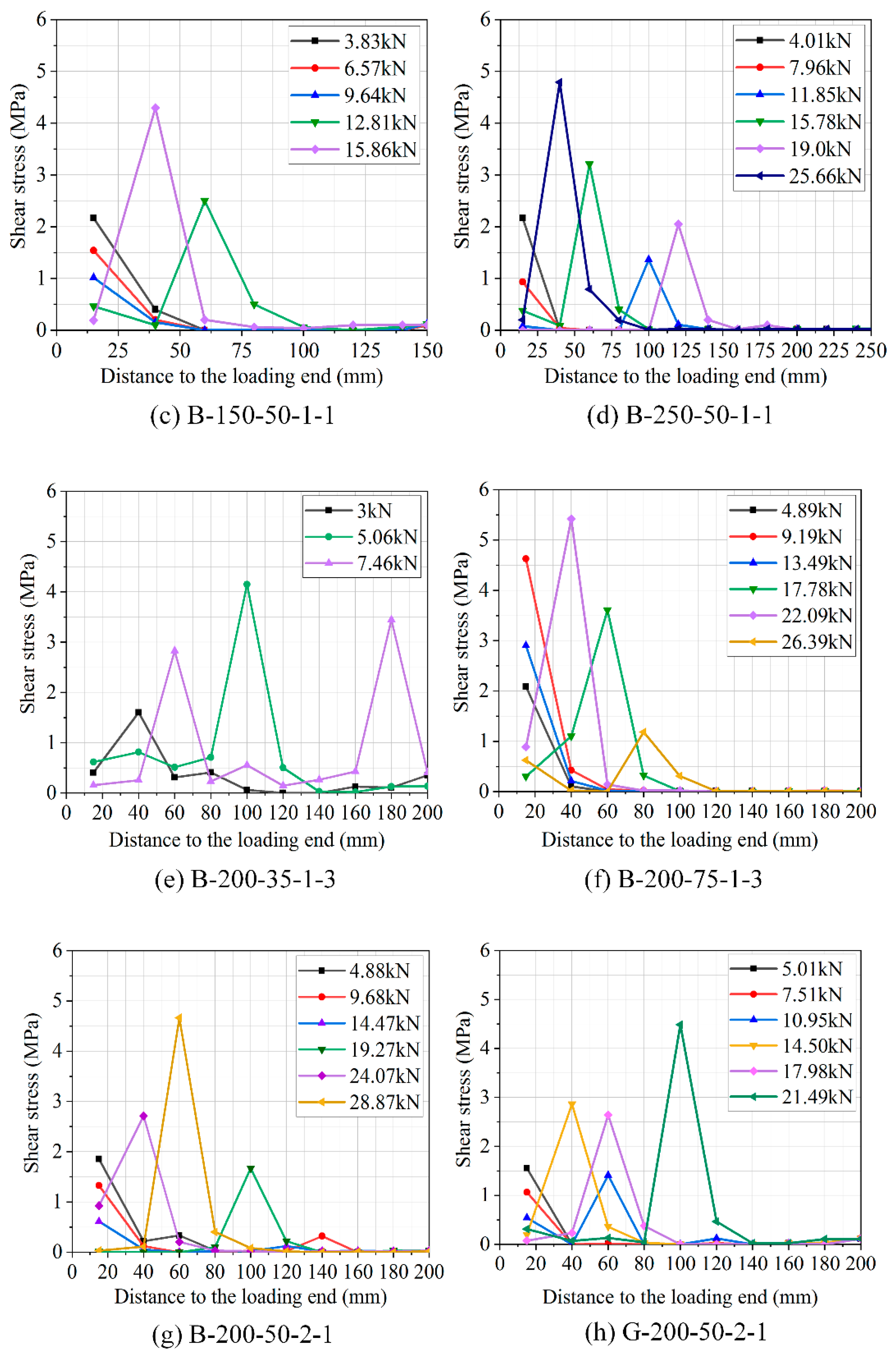

3.5. Shear Stress Distribution along the BFRP and GFRP Bond Length

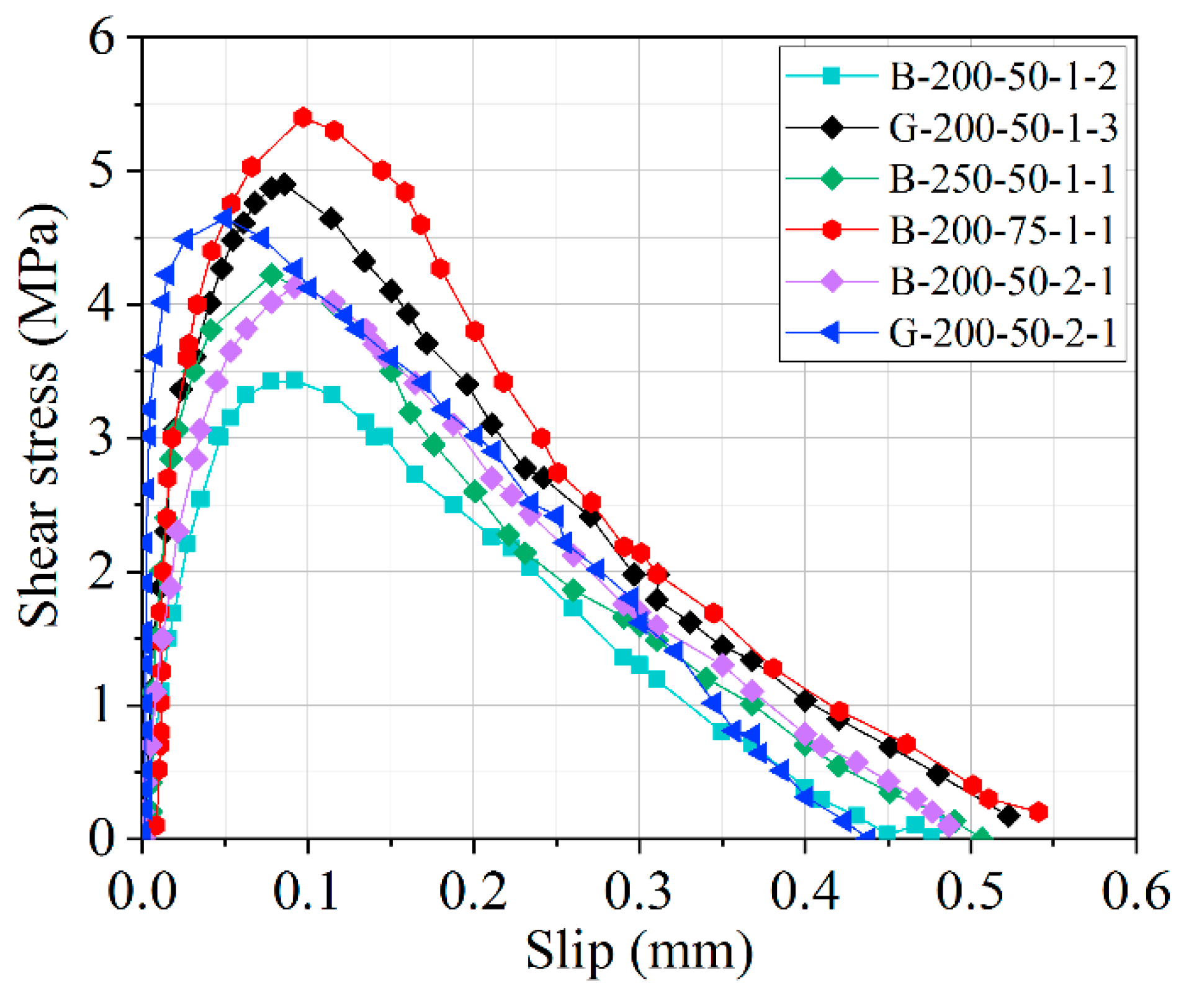

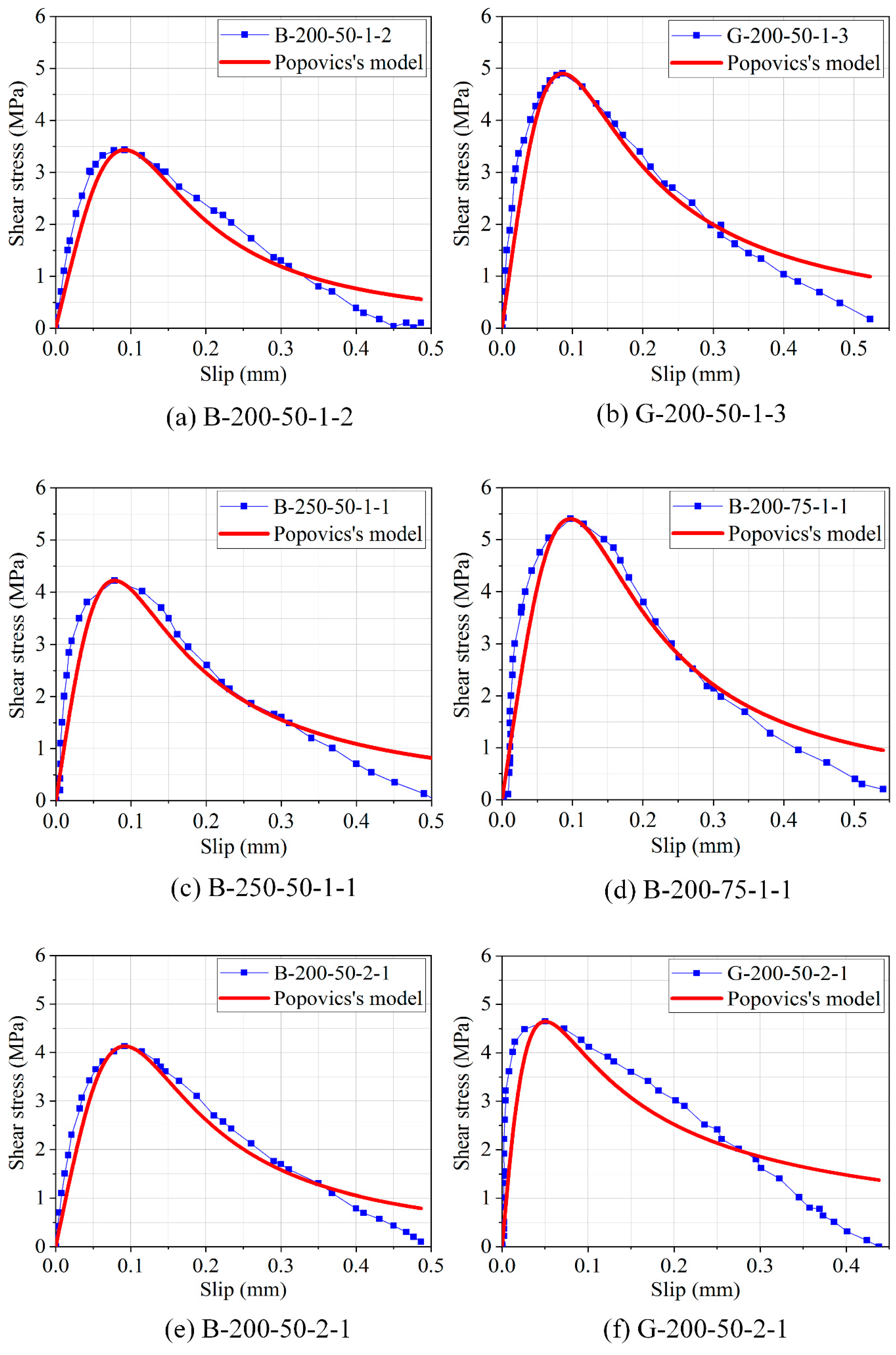

3.6. Bond–Slip Relation

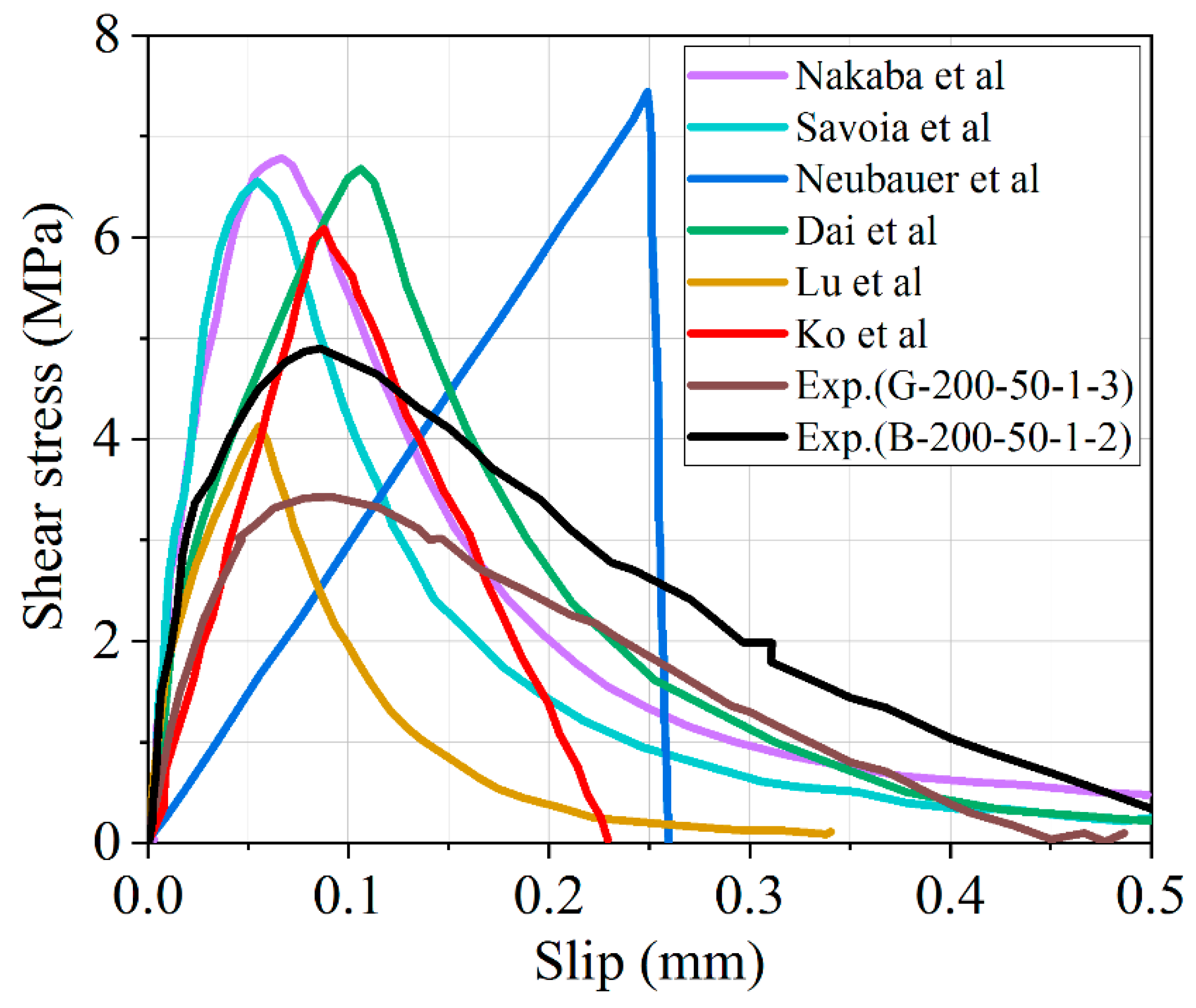

3.7. Comparison of Experimental Results with Selected Bond–Slip Models

4. Conclusions

- The failure mode of BFRP/GFRP–concrete samples from the double shear testing has been attributed mostly to the state of the bonding surface of the concrete block. If the bonding surface of concrete consisted of aggregate and mortar, several debonding modes, such as debonding in concrete, debonding at an adhesive–concrete interface, and debonding at the adhesive–FRP laminate interface can happen. Even though the ultimate load is affected by the characteristics of FRP, concrete, and adhesive, their impact on the bond behavior comparative to one another remains variable and uncertain. In addition, the main debonding mode of samples failure has been associated with the distribution density of aggregate within the bonding surface of FRP and concrete.

- FRP width has a significant impact on the bonding behavior of the BFRP laminate–concrete interface. An increase in FRP width results in improving the maximum load-carrying capacity with higher stiffness and greater ductility. This may be because shear stresses are distributed over a larger bonded area.

- The thickness of FRP laminate has the same influence on the interfacial behavior of BFRP and GFRP samples significantly. Increasing the thickness to double layers of FRP sheet greatly increase the bonding interface of the load-bearing capacity. With the increase in FRP thickness and slip, the ultimate load increased significantly until failure. However, GFRP specimens recorded lower debonding load compared with BFRP specimens.

- The bond length has a distinct influence on the bond behavior. Increasing the length of BFRP laminate above 200 mm results in higher load capacity of the interface between FRP laminate–concrete. The slip can get enhanced with the increasing bond length when the length is less than the maximum effective bonding length.

- The values of peak shear stress and the corresponding maximum shear slip were significantly different because of the various factors’ influences on them.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, J.F.; Teng, J. Anchorage strength models for FRP and steel plates bonded to concrete. J. Struct. Eng. 2001, 127, 784–791. [Google Scholar] [CrossRef]

- Teng, J.; Chen, J.; Smith, S.T.; Lam, L. Behaviour and strength of FRP-strengthened RC structures: A state-of-the-art review. Proc. Inst. Civ. Eng. Struct. Build. 2003, 156, 51–62. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.; Lesko, J.; Machida, A.; Rizkalla, S.; Triantafillou, T. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Chen, W.; Hao, H.; Jong, M.; Cui, J.; Shi, Y.; Chen, L.; Pham, T.M. Quasi-static and dynamic tensile properties of basalt fibre reinforced polymer. Compos. B Eng. 2017, 125, 123–133. [Google Scholar] [CrossRef]

- Dai, J.; Ueda, T.; Sato, Y. Development of the nonlinear bond stress–slip model of fiber reinforced plastics sheet–concrete interfaces with a simple method. J. Compos. Constr. 2005, 9, 52–62. [Google Scholar] [CrossRef]

- Lin, J.-P.; Wu, Y.-F.; Smith, S.T. Width factor for externally bonded FRP-to-concrete joints. Constr. Build. Mater. 2017, 155, 818–829. [Google Scholar] [CrossRef]

- Diab, H.; Wu, Z. Nonlinear constitutive model for time-dependent behavior of FRP-concrete interface. Compos. Sci. Technol. 2007, 67, 2323–2333. [Google Scholar] [CrossRef]

- Ghorbani, M.; Mostofinejad, D.; Hosseini, A. Experimental investigation into bond behavior of FRP-to-concrete under mixed-mode I/II loading. Constr. Build. Mater. 2017, 132, 303–312. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Shameli, S.M.; Materials, B. Externally bonded reinforcement in grooves (EBRIG) technique to postpone debonding of FRP sheets in strengthened concrete beams. Constr. Build. Mater. 2013, 38, 751–758. [Google Scholar] [CrossRef]

- Franco, A.; Royer-Carfagni, G. Effective bond length of FRP stiffeners. Int. J. Non-Linear Mech. 2014, 60, 46–57. [Google Scholar] [CrossRef]

- Smith, S.T.; Teng, J. FRP-strengthened RC beams. II: Assessment of debonding strength models. Eng. Struct. 2002, 24, 397–417. [Google Scholar] [CrossRef]

- Cao, S.; Chen, J.; Pan, J.; Sun, N. ESPI measurement of bond-slip relationships of FRP-concrete interface. J. Compos. Constr. 2007, 11, 149–160. [Google Scholar] [CrossRef]

- Pellegrino, C.; Tinazzi, D.; Modena, C. Experimental study on bond behavior between concrete and FRP reinforcement. J. Compos. Constr. 2008, 12, 180–189. [Google Scholar] [CrossRef]

- Xue, W.; Zeng, L.; Tan, Y. Experimental studies on bond behaviour of high strength CFRP plates. Compos. B Eng. 2008, 39, 592–603. [Google Scholar] [CrossRef]

- Sato, Y.; ASANO, Y.; Ueda, T. Fundamental study on bond mechanism of carbon fiber sheet. Doboku Gakkai Ronbunshu 2000, 2000, 71–87. [Google Scholar] [CrossRef]

- Diab, H.M.; Farghal, O.A. Bond strength and effective bond length of FRP sheets/plates bonded to concrete considering the type of adhesive layer. Compos. B Eng. 2014, 58, 618–624. [Google Scholar] [CrossRef]

- Chajes, M.J.; Finch, W.W.; Thomson, T.A. Bond and force transfer of composite-material plates bonded to concrete. ACI Struct. J. 1996, 93, 209–217. [Google Scholar]

- Pan, J.; Leung, C.K. Debonding along the FRP–concrete interface under combined pulling/peeling effects. Eng. Fract. Mech 2007, 74, 132–150. [Google Scholar] [CrossRef]

- Li, K.; Cao, S.-Y.; Wang, X.-L. Experimental Study on the Fatigue Endurance of the CFRP-Concrete Interface. J. Compos. Constr. 2015, 19, 04014075. [Google Scholar] [CrossRef]

- Mohammadi, T.; Wan, B.; Harries, K.A.; Sweriduk, M.E. Bond behavior of FRP–concrete in presence of intermediate crack debonding failure. J. Compos. Constr. 2017, 21, 04017018. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Shameli, S.M.; Hosseini, A. EBROG and EBRIG methods for strengthening of RC beams by FRP sheets. Eur. J. Environ. Civ. Eng. 2014, 18, 652–668. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2020, 33, 101675. [Google Scholar] [CrossRef]

- Azevedo, A.R.; Marvila, M.T.; Zanelato, E.B.; Alexandre, J.; Xavier, G.C.; Cecchin, D. Development of mortar for laying and coating with pineapple fibers. Revista Brasileira de Engenharia Agrícola e Ambiental 2020, 24, 187–193. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.; Cecchin, D.; Costa, J.M.; Xavier, G.C.; do Carmo, D.d.F.; Monteiro, S.N. Durability of coating mortars containing acai fibers. Case Stud. Constr. Mater. 2020, 13, e00406. [Google Scholar] [CrossRef]

- Amaral, L.F.; Delaqua, G.C.G.; Nicolite, M.; Marvila, M.T.; de Azevedo, A.R.; Alexandre, J.; Vieira, C.M.F.; Monteiro, S.N. Eco-friendly mortars with addition of ornamental stone waste-A mathematical model approach for granulometric optimization. J. Clean. Prod. 2020, 248, 119283. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Jiang, C. Quantification of bond-slip relationship for externally bonded FRP-to-concrete joints. J. Compos. Constr. 2013, 17, 673–686. [Google Scholar] [CrossRef]

- Sun, W.; Peng, X.; Yu, Y. Development of a simplified bond model used for simulating FRP strips bonded to concrete. Compos. Struct. 2017, 171, 462–472. [Google Scholar] [CrossRef]

- Oliveira, P.S.; Antunes, M.L.P.; da Cruz, N.C.; Rangel, E.C.; de Azevedo, A.R.G.; Durrant, S.F. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction. J. Clean. Prod. 2020, 274, 122948. [Google Scholar] [CrossRef]

- De Mendonça Neuba, L.; Pereira Junio, R.F.; Ribeiro, M.P.; Souza, A.T.; de Sousa Lima, E.; Garcia Filho, F.d.C.; Figueiredo, A.B.-H.d.S.; Braga, F.d.O.; Azevedo, A.R.G.d.; Monteiro, S.N. Promising mechanical, thermal, and ballistic properties of novel epoxy composites reinforced with cyperus malaccensis sedge fiber. Polymers 2020, 12, 1776. [Google Scholar] [CrossRef]

- Zheng, X.; Huang, P.; Han, Q.; Chen, G. Bond behavior of interface between CFL and concrete under static and fatigue load. Constr. Build. Mater. 2014, 52, 33–41. [Google Scholar] [CrossRef]

- Yang, Z.; Li, J. Double shear test on bonding mechanical properties of sprayed FRP and concrete substrate. Compos. B Eng. 2019, 162, 388–396. [Google Scholar] [CrossRef]

- Dehghani, E.; Daneshjoo, F.; Aghakouchak, A.; Khaji, N. A new bond-slip model for adhesive in CFRP–steel composite systems. Eng. Struct. 2012, 34, 447–454. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Di Ludovico, M.; Nigro, E.; Pecce, M.; Manfredi, G. Bond efficiency of EBR and NSM FRP systems for strengthening concrete members. J. Compos. Constr. 2011, 15, 757–772. [Google Scholar] [CrossRef]

- Bizindavyi, L.; Neale, K. Transfer lengths and bond strengths for composites bonded to concrete. J. Compos. Constr. 1999, 3, 153–160. [Google Scholar] [CrossRef]

- Mazzotti, C.; Savoia, M.; Ferracuti, B. An experimental study on delamination of FRP plates bonded to concrete. Constr. Build. Mater. 2008, 22, 1409–1421. [Google Scholar] [CrossRef]

- Liu, K.; Wu, Y.-F. Analytical identification of bond–slip relationship of EB-FRP joints. Compos. B Eng. 2012, 43, 1955–1963. [Google Scholar] [CrossRef]

- Ceroni, F.; Pecce, M.; Bilotta, A.; Nigro, E. Bond behavior of FRP NSM systems in concrete elements. Compos. B Eng. 2012, 43, 99–109. [Google Scholar] [CrossRef]

- Cho, K.; Cho, J.-R.; Chin, W.-J.; Kim, B.-S. Bond-slip model for coarse sand coated interface between FRP and concrete from optimization technique. Comput. Struct. 2006, 84, 439–449. [Google Scholar] [CrossRef]

- Mensah, C.; Zhenqing, W.; Bonsu, A.O. Study of the property of lightweight building structure. In Proceedings of the 22nd International Conference on Composites Materials ICCM22, Melbourne, Australia, 11–16 August 2019; pp. 860–871. [Google Scholar]

- GB175-2007. Common Portland Cement. Stand; Press: Beijing, China, 2007. [Google Scholar]

- 50010-2010:, G. Code for Design of Concrete Structures; Building Industry Press: Beijing, China, 2010. [Google Scholar]

- ASTM D3039/D3039, M. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-source 2D digital image correlation matlab software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Teng, J.; Chen, J.-F.; Smith, S.T.; Lam, L. FRP: Strengthened RC Structures; Wiley: Hoboken, NJ, USA, 2002. [Google Scholar]

- Ueda, T.; Sato, Y.; Asano, Y. Experimental study on bond strength of continuous carbon fiber sheet. ACI Spec. Publ. 1999, 188, 407–416. [Google Scholar]

- Zhou, Y.-W.; Wu, Y.-F.; Yun, Y. Analytical modeling of the bond–slip relationship at FRP-concrete interfaces for adhesively-bonded joints. Compos. B Eng. 2010, 41, 423–433. [Google Scholar] [CrossRef]

- Pan, J.; Wu, Y.-F. Analytical modeling of bond behavior between FRP plate and concrete. Compos. B Eng. 2014, 61, 17–25. [Google Scholar] [CrossRef]

- Zheng, X. Study on the Bond-Slip Mechanism of CFL-Concrete Interface under Hot-Wet Environment. Ph.D. Thesis, South China University of Technology, Guangzhou, China, 2014. [Google Scholar]

- Nakaba, K.; Kanakubo, T.; Furuta, T.; Yoshizawa, H. Bond behavior between fiber-reinforced polymer laminates and concrete. ACI Struct. J. 2001, 98, 359–367. [Google Scholar]

- Mazzotti, C.; Savoia, M.; Ferracuti, B. A new single-shear set-up for stable debonding of FRP–concrete joints. Constr. Build. Mater. 2009, 23, 1529–1537. [Google Scholar] [CrossRef]

- Popovics, S. A numerical approach to the complete stress-strain curve of concrete. CEM Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Ko, H.; Matthys, S.; Palmieri, A.; Sato, Y. Development of a simplified bond stress–slip model for bonded FRP–concrete interfaces. Constr. Build. Mater. 2014, 68, 142–157. [Google Scholar] [CrossRef]

- Neubauer, U.; Rostasy, F. Design aspects of concrete structures strengthened with externally bonded CFRP-plates. In Proceedings of the Seventh International Conference on Structural Faults and Repair, Edinburh, UK, 8 July 1997; Volume 2. [Google Scholar]

- Dai, J.; Ueda, T.; Sato, Y. Unified analytical approaches for determining shear bond characteristics of FRP-concrete interfaces through pullout tests. J. Adv. Concr. Technol. 2006, 4, 133–145. [Google Scholar] [CrossRef]

- Lu, X.; Teng, J.; Ye, L.; Jiang, J.J.E.s. Bond–slip models for FRP sheets/plates bonded to concrete. Eng. Struct. 2005, 27, 920–937. [Google Scholar] [CrossRef]

- Neubauer, U.; Rostasy, F. Bond failure of concrete fiber reinforced polymer plates at inclined cracks—Experiments and fracture mechanics model. In Proceedings of the 4th International Symposium on Fiber-Reinforced Polymer Reinforcement for Concrete Structures, Baltimore, MI, USA, 31 October–5 November 1999; ACI Special Publication Special Publication: Farmington Hills, MI, USA, 1999; Volume 188, pp. 369–382. [Google Scholar]

- Savoia, M.; Ferracuti, B.; Mazzotti, C. Non linear bond-slip law for FRP-concrete interface. In Fibre-Reinforced Polymer Reinforcement for Concrete Structures: (In 2 Volumes); World Scientific: Singapore, 2003; pp. 163–172. [Google Scholar] [CrossRef]

| Specimen Name | Type of FRP | No. of Sheets | Bond Length (mm) | Width (mm) | Ultimate Load (kN) | Avg Ultimate Load (kN) | Failure Mode |

|---|---|---|---|---|---|---|---|

| B-200-50-1-1 | BFRP | 1 layer | 200 | 50 | 17.00 | 18.03 | DC |

| B-200-50-1-2 | BFRP | 1 layer | 200 | 50 | 20.96 | DC | |

| B-200-50-1-3 | BFRP | 1 layer | 200 | 50 | 16.05 | DC | |

| B-150-50-1-1 | BFRP | 1 layer | 150 | 50 | 15.86 | 18.25 | DC |

| B-150-50-1-2 | BFRP | 1 layer | 150 | 50 | 17.95 | AD | |

| B-150-50-1-3 | BFRP | 1 layer | 150 | 50 | 21.15 | DC | |

| B-250-50-1-1 | BFRP | 1 layer | 250 | 50 | 25.66 | 22.12 | DC |

| B-250-50-1-2 | BFRP | 1 layer | 250 | 50 | 22.00 | DC | |

| B-250-50-1-3 | BFRP | 1 layer | 250 | 50 | 18.68 | AC | |

| B-200-35-1-1 | BFRP | 1 layer | 200 | 35 | 10.55 | 9.56 | AD |

| B-200-35-1-2 | BFRP | 1 layer | 200 | 35 | 10.67 | AD | |

| B-200-35-1-3 | BFRP | 1 layer | 200 | 35 | 7.47 | DC | |

| B-200-75-1-1 | BFRP | 1 layer | 200 | 75 | 29.86 | 27.94 | DC |

| B-200-75-1-2 | BFRP | 1 layer | 200 | 75 | 27.57 | DC | |

| B-200-75-1-3 | BFRP | 1 layer | 200 | 75 | 26.39 | DC | |

| B-200-50-2-1 | BFRP | 2 layers | 200 | 50 | 28.87 | 24.05 | DC |

| B-200-50-2-2 | BFRP | 2 layers | 200 | 50 | 21.49 | DC | |

| B-200-50-2-3 | BFRP | 2 layers | 200 | 50 | 27.90 | DC | |

| G-200-50-1-1 | GFRP | 1 layer | 200 | 50 | 15.74 | 15.95 | FR+DC |

| G-200-50-1-2 | GFRP | 1 layer | 200 | 50 | 15.93 | FR | |

| G-200-50-1-3 | GFRP | 1 layer | 200 | 50 | 16.20 | FR | |

| G-200-50-2-1 | GFRP | 2 layers | 200 | 50 | 21.49 | 23.17 | DC |

| G-200-50-2-2 | GFRP | 2 layers | 200 | 50 | 25.65 | DC | |

| G-200-50-2-3 | GFRP | 2 layers | 200 | 50 | 25.37 | DC |

| Specimen Number | τmax (MPa) | S0 (mm) | Regression Coefficient n | Correlation Coefficient R2 |

|---|---|---|---|---|

| B-200-50-1-2 | 3.43 | 0.081 | 2.66 | 0.932 |

| B-250-50-1-1 | 4.21 | 0.077 | 2.32 | 0.878 |

| B-200-75-1-3 | 5.40 | 0.097 | 2.54 | 0.901 |

| B-200-50-2-1 | 4.13 | 0.091 | 2.53 | 0.947 |

| G-200-50-1-3 | 4.89 | 0.085 | 2.34 | 0.929 |

| G-200-50-2-1 | 4.64 | 0.050 | 1.83 | 0.648 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mensah, C.; Wang, Z.; Bonsu, A.O.; Liang, W. Effect of Different Bond Parameters on the Mechanical Properties of FRP and Concrete Interface. Polymers 2020, 12, 2466. https://doi.org/10.3390/polym12112466

Mensah C, Wang Z, Bonsu AO, Liang W. Effect of Different Bond Parameters on the Mechanical Properties of FRP and Concrete Interface. Polymers. 2020; 12(11):2466. https://doi.org/10.3390/polym12112466

Chicago/Turabian StyleMensah, Comfort, Zhenqing Wang, Alex Osei Bonsu, and Wenyan Liang. 2020. "Effect of Different Bond Parameters on the Mechanical Properties of FRP and Concrete Interface" Polymers 12, no. 11: 2466. https://doi.org/10.3390/polym12112466

APA StyleMensah, C., Wang, Z., Bonsu, A. O., & Liang, W. (2020). Effect of Different Bond Parameters on the Mechanical Properties of FRP and Concrete Interface. Polymers, 12(11), 2466. https://doi.org/10.3390/polym12112466