Economic Evaluation and Techno-Economic Sensitivity Analysis of a Mass Integrated Shrimp Biorefinery in North Colombia

Abstract

1. Introduction

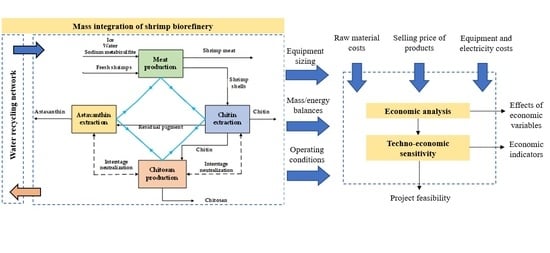

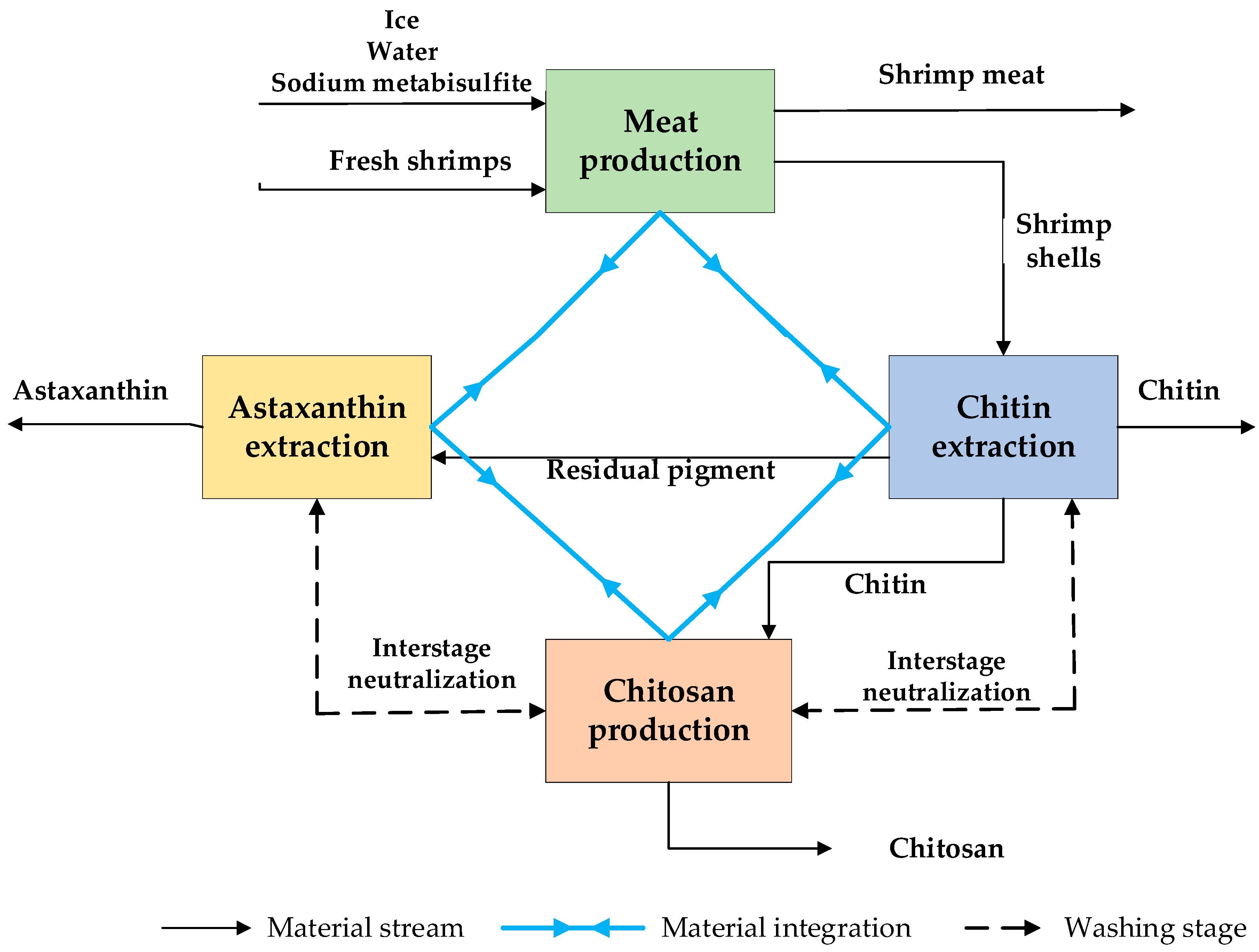

2. Materials and Methods

2.1. Process Description

2.2. Economic Evaluation

3. Results and Discussion

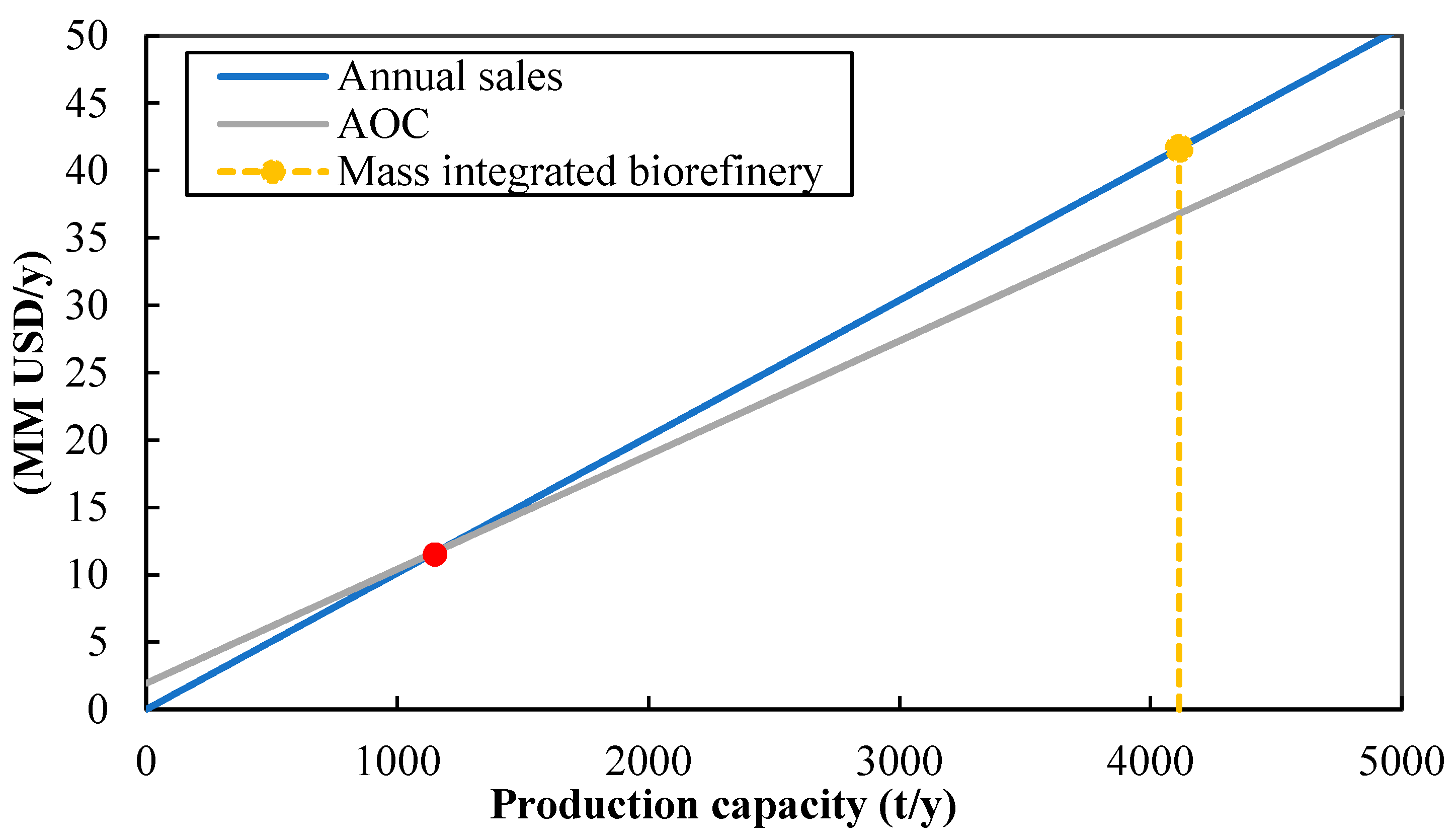

3.1. Economic Evaluation

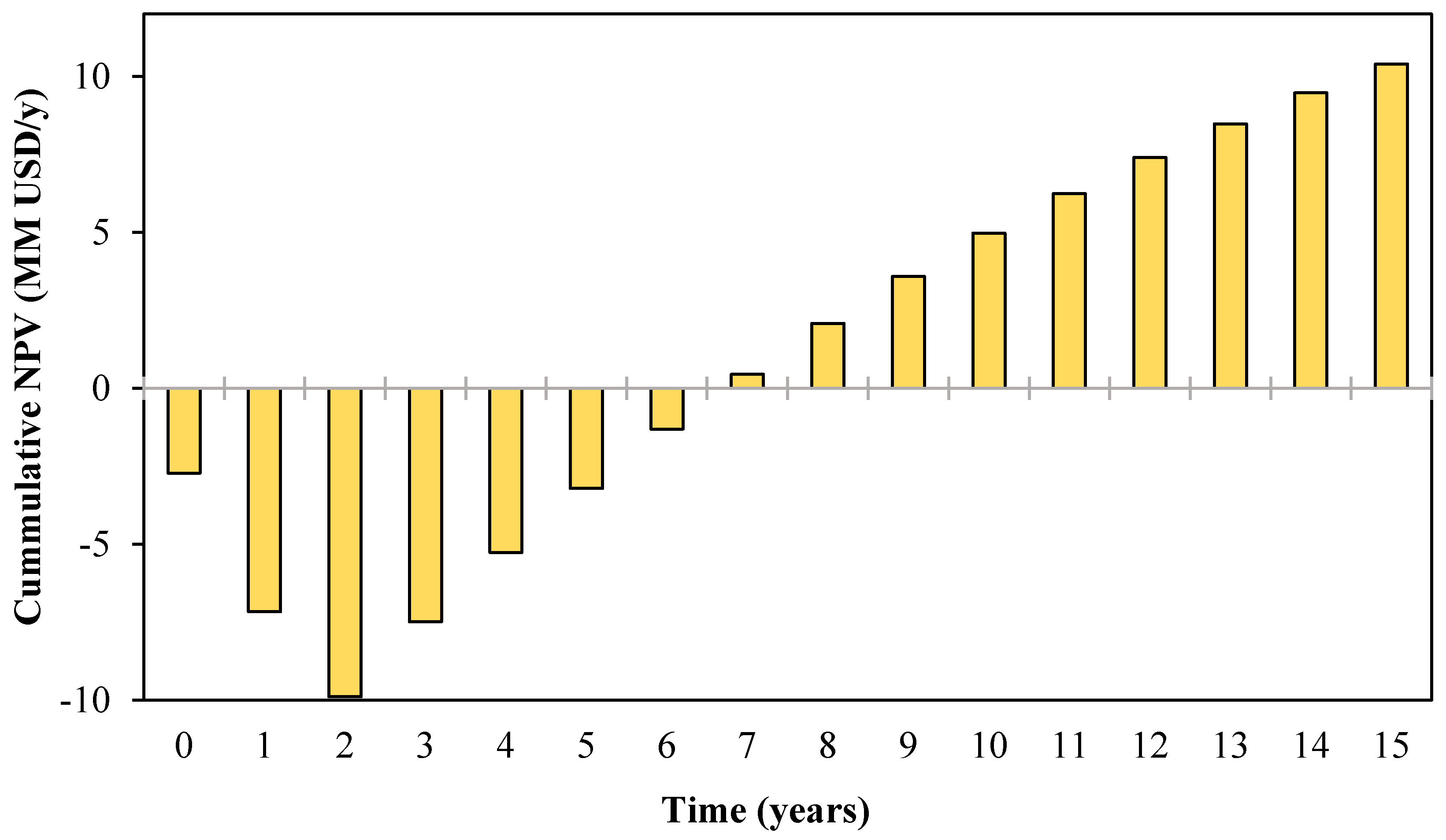

3.2. Economic Indicators

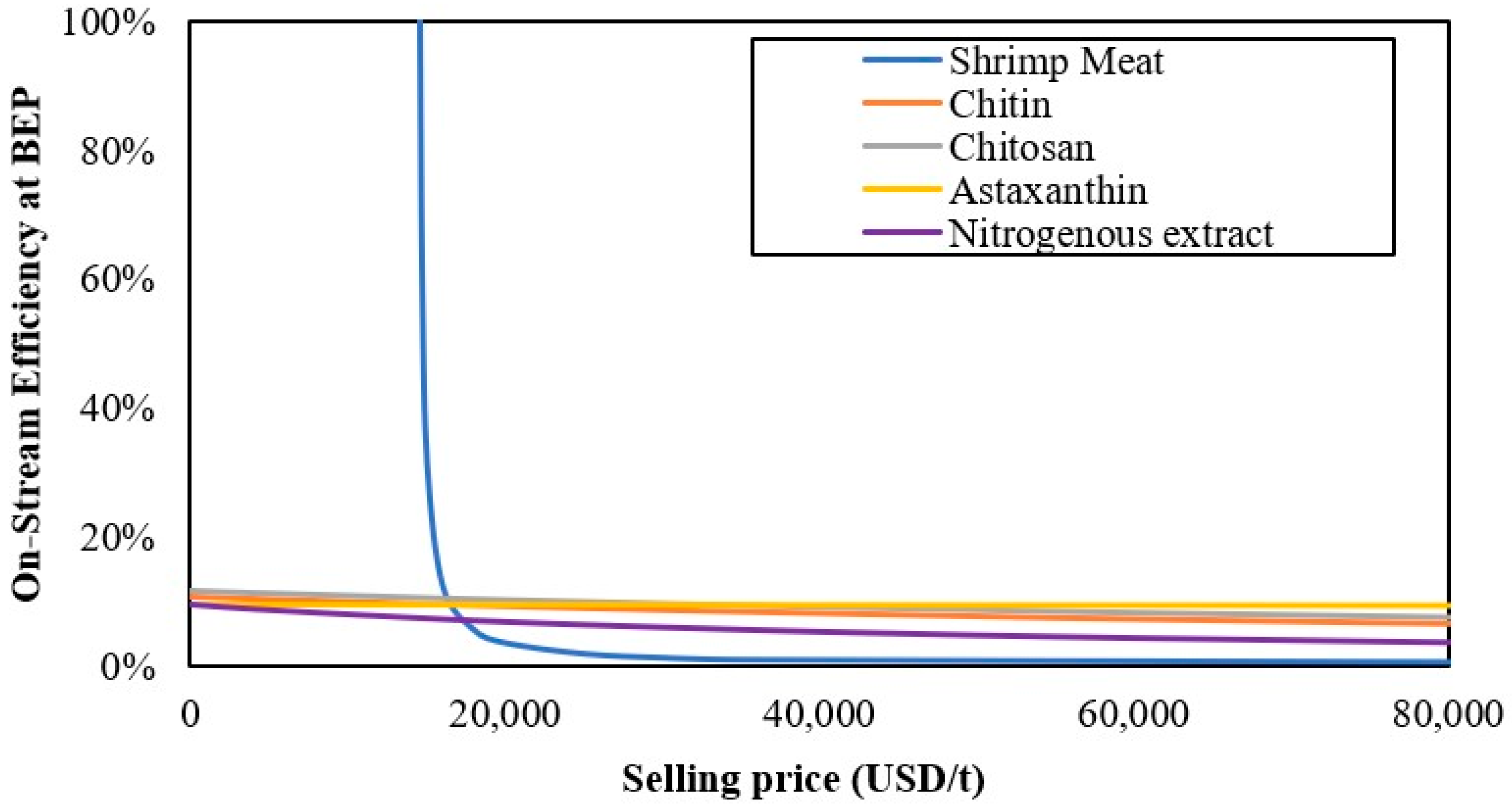

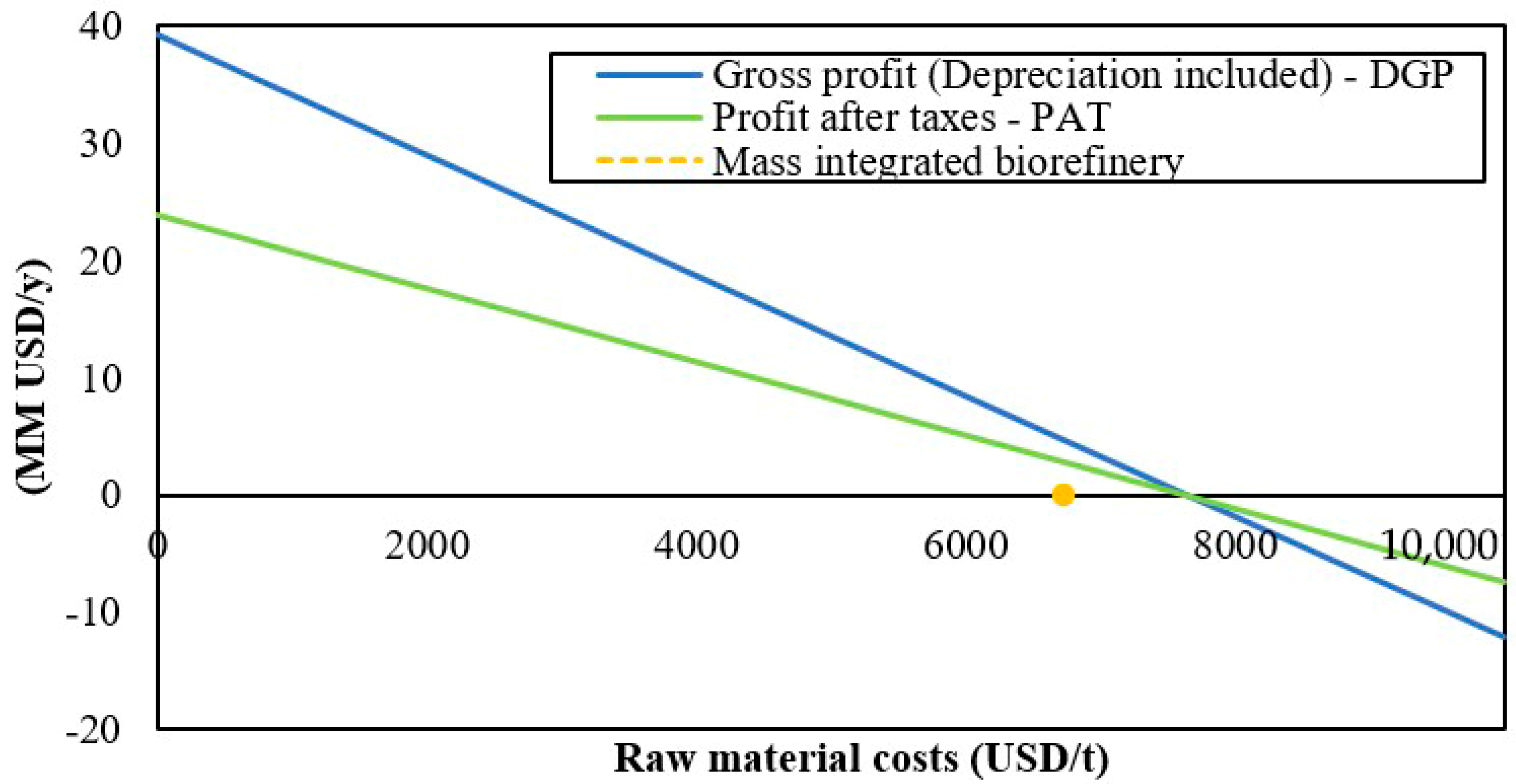

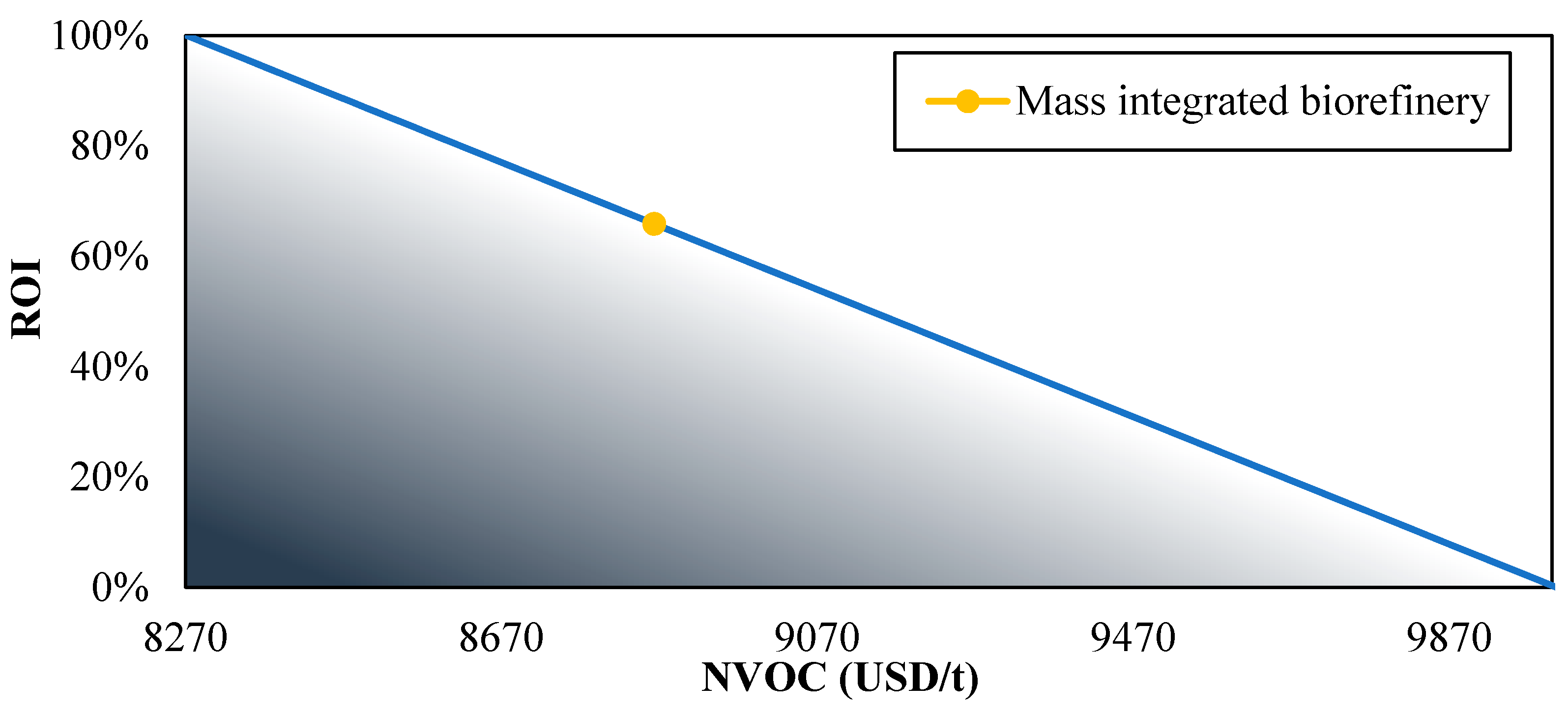

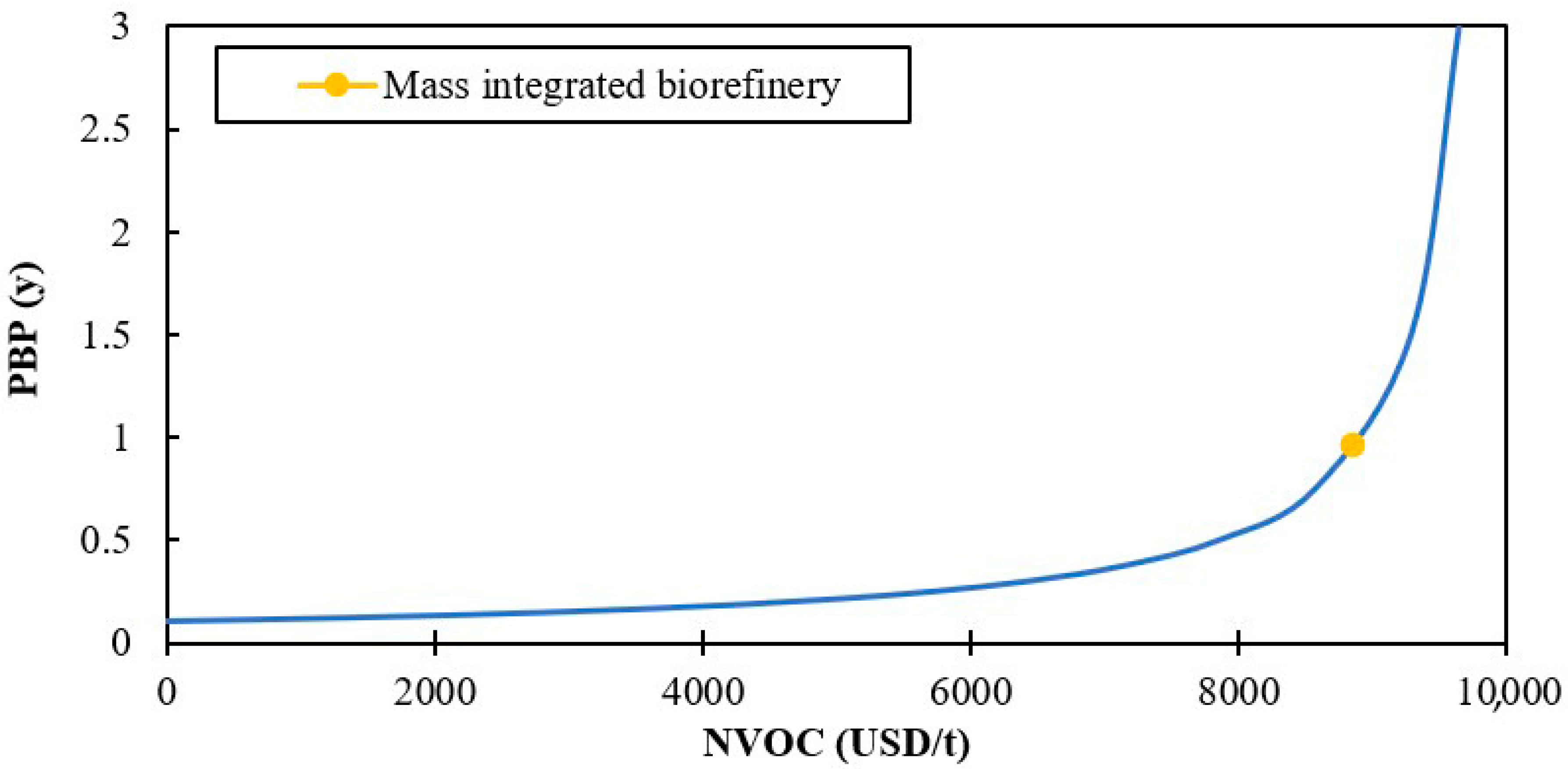

3.3. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sagheer, F.A.; Al-Sughayer, M.A.; Muslim, S.; Elsabee, M.Z. Extraction, and characterization of chitin and chitosan from marine sources in Arabian Gulf. Carbohydr Polym. 2009, 77, 410–419. [Google Scholar] [CrossRef]

- IMARC. Shrimp market: Global industry trends, share, size, growth, opportunity, and forecast 2020-2025. Available online: https://www.imarcgroup.com/prefeasibility-report-shrimp-processing-plant (accessed on 16 August 2020).

- Zhao, D.; Huang, W.C.; Guo, N.; Zhang, S.; Xue, C.; Mao, X. Two-step separation of chitin from shrimp shells using citric acid and deep eutectic solvents with the assistance of microwave. Polymers 2019, 11, 409. [Google Scholar] [CrossRef] [PubMed]

- Mao, X.; Guo, N.; Sun, J.; Xue, C. Comprehensive utilization of shrimp waste based on biotechnological methods: A review. J. Clean. Prod. 2017, 143, 814–823. [Google Scholar] [CrossRef]

- Pillai, C.K.S.; Paul, W.; Sharma, C.P. Chitin and chitosan polymers: Chemistry, solubility, and fiber formation. Prog. Polym. Sci. 2009, 34, 641–678. [Google Scholar] [CrossRef]

- Song, Z.; Li, G.; Guan, F.; Liu, W. Application of chitin/chitosan and their derivatives in the papermaking industry. Polymers 2018, 10, 389. [Google Scholar] [CrossRef]

- Moreno-Sader, K.; Meramo-Hurtado, S.I.; González-Delgado, A.D. Environmental sustainability analysis of chitosan microbeads production for pharmaceutical applications via computer-aided simulation, WAR, and TRACI assessments. Sustain. Chem. Pharm. 2019, 15. [Google Scholar] [CrossRef]

- Wang, W.T.; Shu, J.; Wang, X.L.; Huang, Y.; Wang, Y.Z. Dissolution behavior of chitin in ionic liquids. J. Macromol. Sci. Part B Phys. 2010, 49, 528–541. [Google Scholar] [CrossRef]

- Majeti, M.; Kumar, R. Review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar]

- Mujtaba, M.; Morsi, R.E.; Kerch, G.; Elsabee, M.Z.; Kaya, M.; Labidi, J.; Khawar, K.M. Current advancements in chitosan-based film production for food technology; A review. Int. J. Biol. Macromol. 2019, 121, 889–904. [Google Scholar] [CrossRef]

- Kaya, M.; Salaberria, A.M.; Mujtaba, M.; Labidi, J.; Baran, T. An inclusive physicochemical comparison of natural and synthetic chitin films. Int. J. Biol. Macromol. 2018, 106, 1062–1070. [Google Scholar] [CrossRef]

- Akyuz, L.; Kaya, M.; Koc, B.; Mujtaba, M.; Ilk, S.; Labidi, J.; Salaberria, A.M.; Cakmak, Y.S.; Yildiz, A. Diatomite as a novel composite ingredient for chitosan film with enhanced physicochemical properties. Int. J. Biol. Macromol. 2017, 105, 1401–1411. [Google Scholar] [CrossRef]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Sharif, R.; Mujtaba, M.; Rahman, M.; Shalmani, A.; Ahmad, H.; Anwar, T.; Tiachan, D.; Wang, X. The Multifunctional Role of Chitosan in Horticultural. Molecules 2018, 23, 872. [Google Scholar] [CrossRef]

- Gulzar, S.; Raju, N.; Chandragiri, R.; Benjakul, S. Oil and pigments from shrimp processing by-products: Extraction, composition, bioactivities and its application—A review. Trends Food Sci. Technol. 2020, 100, 307–319. [Google Scholar] [CrossRef]

- Ambati, R.R.; Phang, S.M.; Ravi, S.; Aswathanarayana, R.G. Astaxanthin: Sources, Extraction, Stability, Biological Activities and Its Commercial Applications—A Review. Mar. Drugs 2014, 12, 128–152. [Google Scholar] [CrossRef] [PubMed]

- Jyonouchi, H.; Sun, S.; Iijima, K.; Gross, M.D. Antitumor activity of astaxanthin and its mode of action. Nutr. Cancer. 2000, 36, 59–65. [Google Scholar] [CrossRef]

- Park, S.Y.; Binkley, R.M.; Kim, W.J.; Lee, M.H.; Lee, S.Y. Metabolic engineering of Escherichia coli for high-level astaxanthin production with high productivity. Metab. Eng. 2018, 49, 105–115. [Google Scholar] [CrossRef]

- Abdou, E.S.; Nagy, K.S.A.; Elsabee, M.Z. Extraction and characterization of chitin and chitosan from local sources. Bioresour. Technol. 2008, 99, 1359–1367. [Google Scholar] [CrossRef]

- Winsock, T.; Ghazouani, S.; Le Bourdieu, S. A methodology for designing thermodynamic energy conversion systems in industrial mass/heat integration problems based on MILP models. Energy. 2019, 185, 121–135. [Google Scholar] [CrossRef]

- Barlow, J.; Sims, R.C.; Quinn, J.C. Techno-economic and life-cycle assessment of an attached growth algal biorefinery. Bioresour. Technol. 2016, 220, 360–368. [Google Scholar] [CrossRef]

- Yu, B.Y.; Tsai, C.C. Rigorous simulation, and techno-economic analysis of a bio-jet-fuel intermediate production process with various integration strategies. Chem. Eng. Res. Des. 2020, 159, 47–65. [Google Scholar] [CrossRef]

- Romero, J.C.; Vergara, L.A.; Peralta-Ruiz, Y.Y.; González-Delgado, A.D. A techno-economic sensitivity approach for development of a palm-based biorefineries in Colombia. Chem. Eng. Trans. 2017, 57, 13–18. [Google Scholar] [CrossRef]

- Meramo-Hurtado, S.I.; Sanchez-Tuiran, E.; Ponce-Ortega, J.M.; El-Halwagi, M.M.; Ojeda-Delgado, K.A. Synthesis and Sustainability Evaluation of a Lignocellulosic Multifeedstock Biorefinery Considering Technical Performance Indicators. ACS Omega 2020, 5, 9259–9275. [Google Scholar] [CrossRef]

- Nirmal, N.P.; Benjakul, S. Retardation of quality changes of Pacific white shrimp by green tea extract treatment and modified atmosphere packaging during refrigerated storage. Int. J. Food Microbiol. 2011, 149, 247–253. [Google Scholar] [CrossRef]

- Bonfante-Alvarez, H.; De Avila-Montiel, G.; Herrera-Barros, A.; Torrenegra-Alarcón, M.; González-Delgado, A.D. Valuation of five chitosan production routes with astaxanthin recovery from shrimp exoskeletons. Chem. Eng. Trans. 2018, 70, 1969–1974. [Google Scholar] [CrossRef]

- Dave, D.; Liu, Y.; Pohling, J.; Trenholm, S.; Murphy, W. Astaxanthin recovery from Atlantic shrimp (Pandalus borealis) processing materials. Bioresour. Technol. Rep. 2020, 11. [Google Scholar] [CrossRef]

- Srinivasan, H.; Kanayairam, V.; Ravichandran, R. Chitin and chitosan preparation from shrimp shells Penaeus monodon and its human ovarian cancer cell line, PA-1. Int. J. Biol. Macromol. 2018, 107, 662–667. [Google Scholar] [CrossRef]

- Meramo-Hurtado, S.; Alarcón-Suesca, C.; González-Delgado, A.D. Exergetic sensitivity analysis and environmental evaluation of chitosan production from shrimp exoskeleton in Colombia. J. Clean. Prod. 2020, 248. [Google Scholar] [CrossRef]

- Jane, J.; Shen, L.; Wang, L.; Maningat, C.C. Preparation, and Properties of Small-Particle Corn Starch. Cereal Chem 1992, 69, 280–283. [Google Scholar]

- Kandra, P.; Challa, M.M. Efficient use of shrimp waste: Present and future trends. Appl. Microbiol. Biotechnol. 2012, 93, 17–29. [Google Scholar] [CrossRef]

- Salman, D.D.; Ulaiwi, W.S.; Qais, A. Preparation of chitosan from Iraqi shrimp shell by autoclave, studying some physicochemical properties and antioxidant activity. J. Pharm. Sci. Res. 2018, 10, 3120–3123. [Google Scholar]

- De Queiroz Antonino, R.S.C.M.; Lia Fook, B.R.P.; De Oliveira Lima, V.A.; De Farias Rached, R.Í.; Lima, E.P.N.; Da Silva Lima, R.J.; Peniche Covas, C.A.; Lia Fook, M.V. Preparation and Characterization of Chitosan Obtained from Shells of Shrimp (Litopenaeus vannamei Boone). Mar. Drugs. 2017, 15, 141. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez Bell, J. Producción local de camarón. La República. 2019. Available online: https://www.agronegocios.co/agricultura/produccion-local-de-camaron-completo-cuatro-anos-al-alza-aumento-de-21-comparado-con-2017-2827251 (accessed on 9 August 2020).

- Herrera-Rodriguez, T.; Parejo-Palacio, V.; González-Delgado, A.D. Technoeconomic sensitivity analysis of industrial agar production from red algae. Chem. Eng. Trans. 2018, 70, 029–2034. [Google Scholar] [CrossRef]

- El-Halwagi, M.M. Overview of Process Economics. Sustain. Des. Through Process Integr. 2012, 15–61. [Google Scholar] [CrossRef]

- Perez Zúñiga, D.L.; Luna Barrios, E.J.; Peralta-Ruiz, Y.Y.; González-Delgado, A.D. Techno-economic sensitivity of bio-hydrogen production from empty palm fruit bunches under colombian conditions. Chem. Eng. Trans. 2016, 52, 1117–1122. [Google Scholar] [CrossRef]

- Alibaba.com: Manufacturers, Suppliers, Exporters & Importers from the world’s largest online B2B marketplace. Available online: https://spanish.alibaba.com/ (accessed on 24 August 2020).

- Peters, M.S.; Timmerhaus, K.D.; West, R. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2003; p. 988. [Google Scholar]

- El-Halwagi, M.M. Sustainable Design through Process Integration: Fundamentals and Applications to Industrial Pollution Prevention, Resource Conservation, and Profitability Enhancement; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Ninõ-Villalobos, A.; Puello-Yarce, J.; González-Delgado, A.D.; Ojeda, K.A.; Sánchez-Tuirán, E. Biodiesel and Hydrogen Production in a Combined Palm and Jatropha Biomass Biorefinery: Simulation, Techno-Economic, and Environmental Evaluation. ACS Omega. 2020, 5, 7074–7084. [Google Scholar] [CrossRef]

- Gómez-Ríos, D.; Barrera-Zapata, R.; Ríos-Estepa, R. Comparison of process technologies for chitosan production from shrimp shell waste: A techno-economic approach using Aspen Plus®. Food Bioprod. Process. 2017, 103, 49–57. [Google Scholar] [CrossRef]

- Zuorro, A.; Lavecchia, R. Polyphenols and energy recovery from spent coffee grounds. Chem. Eng. Trans. 2011, 25, 285–290. [Google Scholar] [CrossRef]

- Zuorro, A.; Lavecchia, R.; Medici, F.; Piga, L. Use of cell wall degrading enzymes for the production of high-quality functional products from tomato processing waste. Chem. Eng. Trans. 2014, 38, 355–360. [Google Scholar] [CrossRef]

- Zuorro, A. Response surface methodology analysis of polyphenol recovery from artichoke waste. Am. J. Appl. Sci. 2014, 11, 1463–1471. [Google Scholar] [CrossRef]

- Zuorro, A.; Lavecchia, R.; Maffei, G. Enhanced lipid extraction from unbroken microalgal cells using enzymes. Chem. Eng. Trans. 2015, 43, 211–216. [Google Scholar] [CrossRef]

- Panusa, A.; Petrucci, R.; Lavecchia, R.; Zuorro, A. UHPLC-PDA-ESI-TOF/MS metabolic profiling and antioxidant capacity of arabica and robusta coffee silverskin: Antioxidants vs phytotoxins. Food Res. Int. 2017, 99, 155–165. [Google Scholar] [CrossRef]

- Cogollo-Herrera, K.; Bonfante-Álvarez, H.; De Ávila-Montiel, G. Herrera- Barros, A.; González-Delgado, A.D.Techno-economic sensitivity analysis of large scale chitosan production process from shrimp shell wastes. Chem. Eng. Trans. 2018, 70, 2179–2184. [Google Scholar] [CrossRef]

| Streams | Fresh Shrimp | Shells | Meat | Astaxanthin | Nitrogenous Extract | Chitin | Chitosan |

|---|---|---|---|---|---|---|---|

| Temperature (K) | 286.38 | 282.15 | 298.15 | 363.15 | 373.15 | 298.16 | |

| Pressure (kPa) | 101.32 | 101.32 | 101.32 | 101.32 | 101.32 | 101.32 | 101.32 |

| Components mass flow (kg/h) | |||||||

| L-Alanine | 16.64 | 1.76 | 9.75 | 0.00 | 1.76 | 0.00 | 0.00 |

| L-Glutamic-acid | 28.68 | 3.04 | 16.81 | 0.00 | 3.04 | 0.00 | 0.00 |

| L-phenylalanine | 10.80 | 1.15 | 6.33 | 0.00 | 1.15 | 0.00 | 0.00 |

| Methionine | 9.70 | 1.03 | 5.68 | 0.00 | 1.03 | 0.00 | 0.00 |

| Lysine | 31.35 | 3.32 | 18.37 | 0.00 | 3.32 | 0.00 | 0.00 |

| Calcium Carbonate | 8.31 | 1.40 | 2.83 | 0.00 | 0.00 | 0.00 | 0.00 |

| Calcium phosphate | 20.86 | 3.52 | 7.11 | 0.00 | 0.00 | 0.00 | 0.00 |

| Sodium carbonate | 4.24 | 0.72 | 1.44 | 0.00 | 0.00 | 0.00 | 0.00 |

| Magnesium carbonate | 2.45 | 0.41 | 0.83 | 0.00 | 0.00 | 0.00 | 0.00 |

| D-N-acetylglucosamine | 32.00 | 8.20 | 0.00 | 0.00 | 0.00 | 4.01 | 0.00 |

| Methyl-palmitate | 57.73 | 14.36 | 1.67 | 0.00 | 0.00 | 0.00 | 0.00 |

| Astaxanthin | 0.44 | 0.11 | 0.00 | 0.11 | 0.00 | 0.00 | 0.00 |

| Water | 246.01 | 9.91 | 204.97 | 0.00 | 443.27 | 0.00 | 0.09 |

| Carbon dioxide | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Magnesium chloride | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Calcium chloride | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Hydrogen chloride | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Orthophosphoric- acid | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Ethanol | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Sodium hydroxide | 0.00 | 0.00 | 0.00 | 0.00 | 6.88 | 0.00 | 0.00 |

| Sodium chloride | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| hydroxypropylammoniun | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 3.25 |

| Sodium acetate | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Sodium metabisulfite | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Sodium hypochlorite | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Acetone | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Total | 469.21 | 48.93 | 275.80 | 0.11 | 460.44 | 4.01 | 3.33 |

| Assumptions | Value |

|---|---|

| Processing capacity (t/y) | 4113.09 |

| Main product flowrate (t/y) | 2417.66 |

| Raw material cost (USD/t) | 6724.27 |

| Plant life (y) | 15 |

| Salvage value | 10% of depreciable FCI |

| Construction time of the plant (y) | 3 |

| Location | Colombia |

| Tax rate | 39% |

| Discount rate | 8% |

| Subsidies (USD/y) | 0 |

| Type of process | New and unproven |

| Process control | Digital |

| Project type | Plant on non-built land |

| Percentage of contingency | 20% |

| Salary per operator (USD/h) | 30 |

| Utilities | Electricity, steam, water |

| Process fluids | Solid-liquid-gas |

| Product | Selling Price (USD/t) |

|---|---|

| Shrimp meat | 16,500 |

| Chitin | 17,000 |

| Chitosan | 35,000 |

| Nitrogenous extract | 1000 |

| Astaxanthin | 40,000 |

| Cost of Capital Investment | Total (USD) |

|---|---|

| Fixed Capital investment (FCI) | 2,718,282.60 |

| Working Capital (WCI) | 1,359,141.30 |

| Start-up Costs (SUC) | 271,828.26 |

| Operating Costs | Total (USD/y) |

|---|---|

| Direct Production Cost (DPC) | 28,762,035.14 |

| Fixed Charge (FCH) | 330,588.83 |

| Plant Overhead (POH) | 336,960.00 |

| General Expenses (GE) | 7,357,395.99 |

| Primary Costs | Total | Unit |

|---|---|---|

| Total Capital Investment (TCI) | 4.35 | MM USD |

| Operating Cost (OC) | 36.79 | MM USD/y |

| Revenues | 41.65 | MM USD/y |

| Economic Indicator | Value | Units |

|---|---|---|

| Gross Profit (depreciation not included) (GP) | 4.88 | MM USD |

| Gross Profit (depreciation included) (DGP) | 4.70 | MM USD |

| Profit After taxes (PAT) | 2.87 | MM USD |

| Economic Potential 1 ($/y) | 13.99 | MM USD/y |

| Economic Potential 2 ($/y) | 13.77 | MM USD/y |

| Economic Potential 3 ($/y) | 4.86 | MM USD/y |

| Cumulative Cash Flow | 1.12 | (1/y) |

| Payback Period (depreciation included) (DPBP) | 6.00 | y |

| ROI | 65.88 | % |

| Net present value (NPV) | 10.40 | MM USD |

| Annual Cost/Revenue | 1.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuorro, A.; Moreno-Sader, K.A.; González-Delgado, Á.D. Economic Evaluation and Techno-Economic Sensitivity Analysis of a Mass Integrated Shrimp Biorefinery in North Colombia. Polymers 2020, 12, 2397. https://doi.org/10.3390/polym12102397

Zuorro A, Moreno-Sader KA, González-Delgado ÁD. Economic Evaluation and Techno-Economic Sensitivity Analysis of a Mass Integrated Shrimp Biorefinery in North Colombia. Polymers. 2020; 12(10):2397. https://doi.org/10.3390/polym12102397

Chicago/Turabian StyleZuorro, Antonio, Kariana Andrea Moreno-Sader, and Ángel Darío González-Delgado. 2020. "Economic Evaluation and Techno-Economic Sensitivity Analysis of a Mass Integrated Shrimp Biorefinery in North Colombia" Polymers 12, no. 10: 2397. https://doi.org/10.3390/polym12102397

APA StyleZuorro, A., Moreno-Sader, K. A., & González-Delgado, Á. D. (2020). Economic Evaluation and Techno-Economic Sensitivity Analysis of a Mass Integrated Shrimp Biorefinery in North Colombia. Polymers, 12(10), 2397. https://doi.org/10.3390/polym12102397