PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties

Abstract

1. Introduction

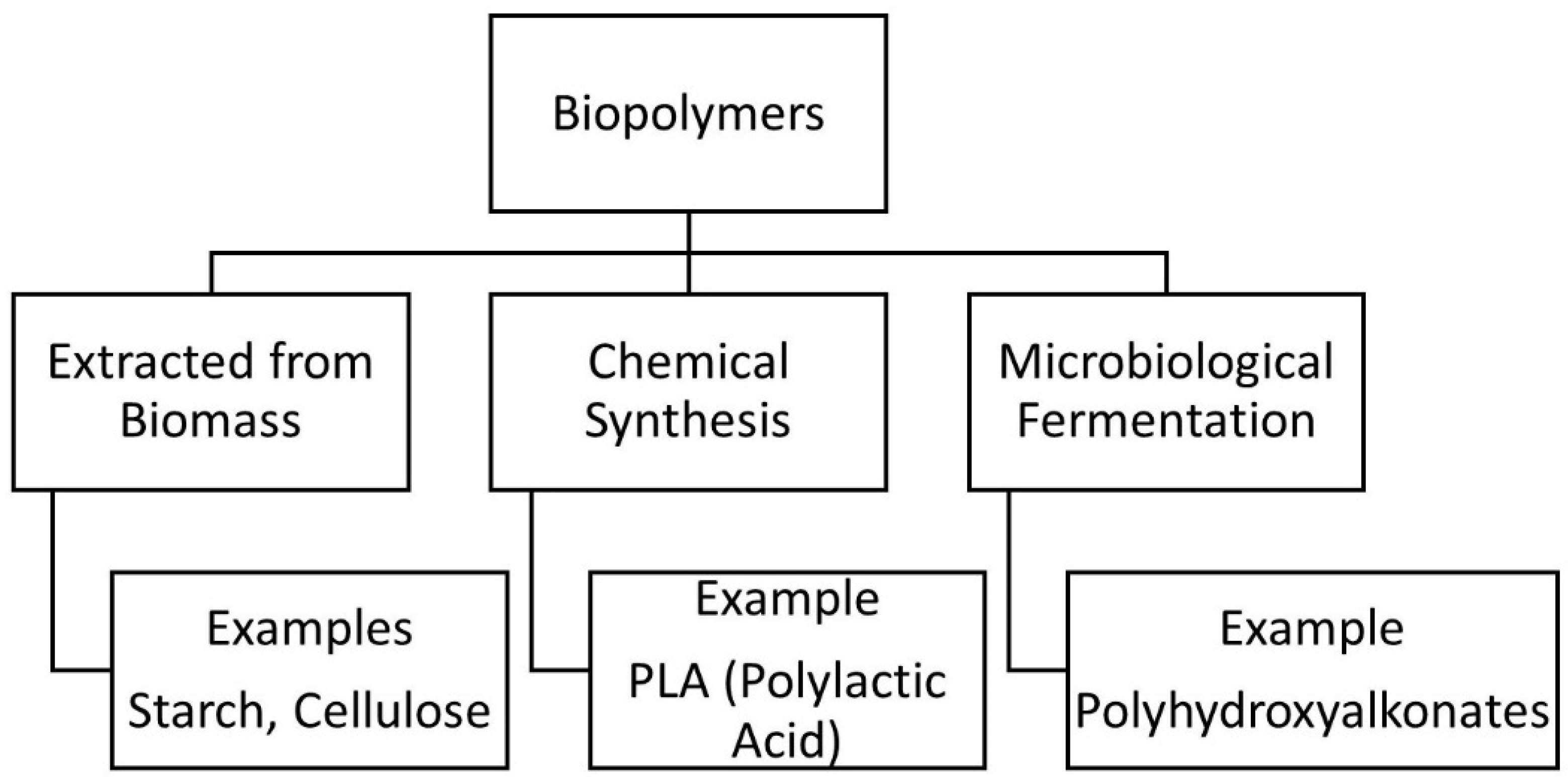

2. Green Composites—Historical Perspective

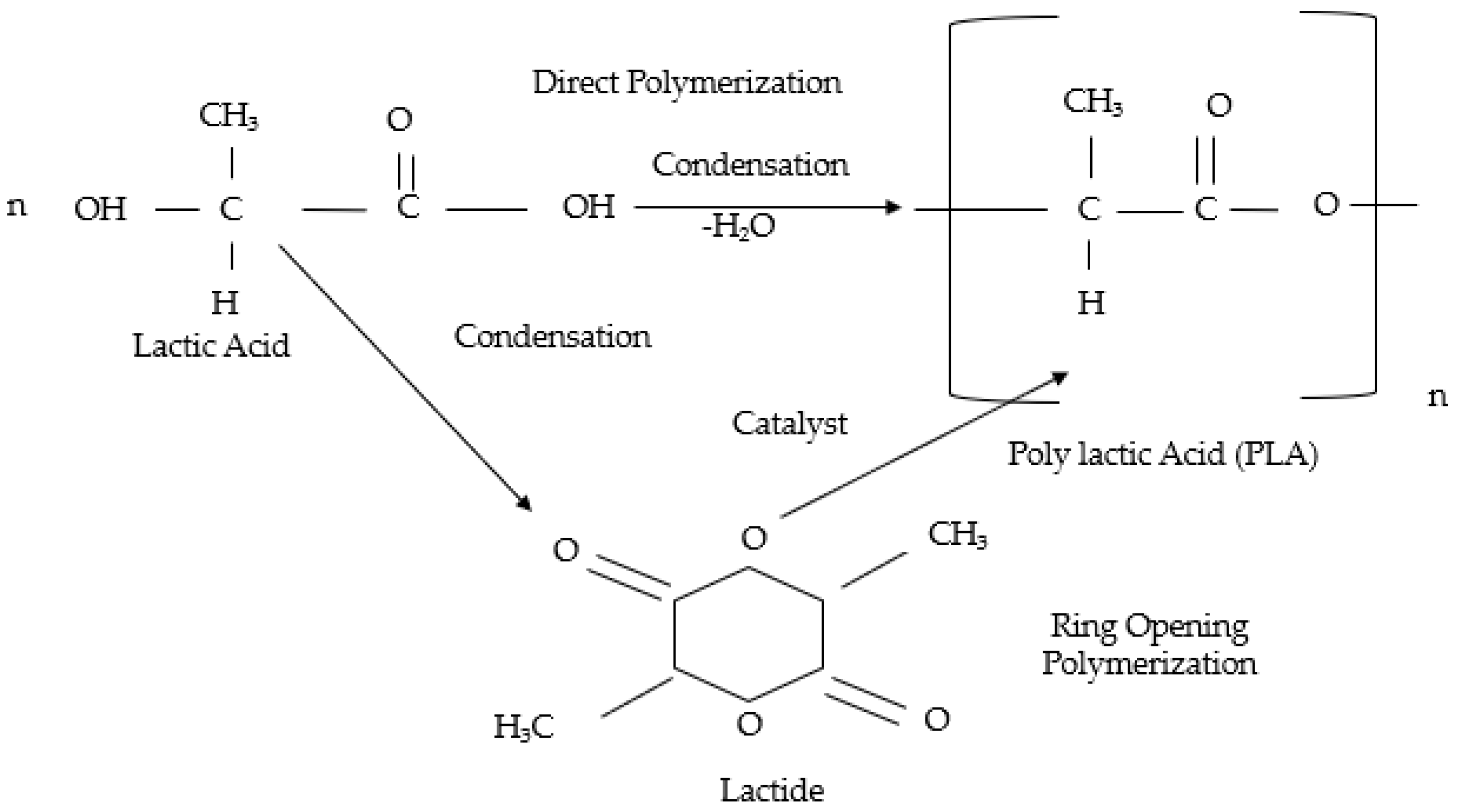

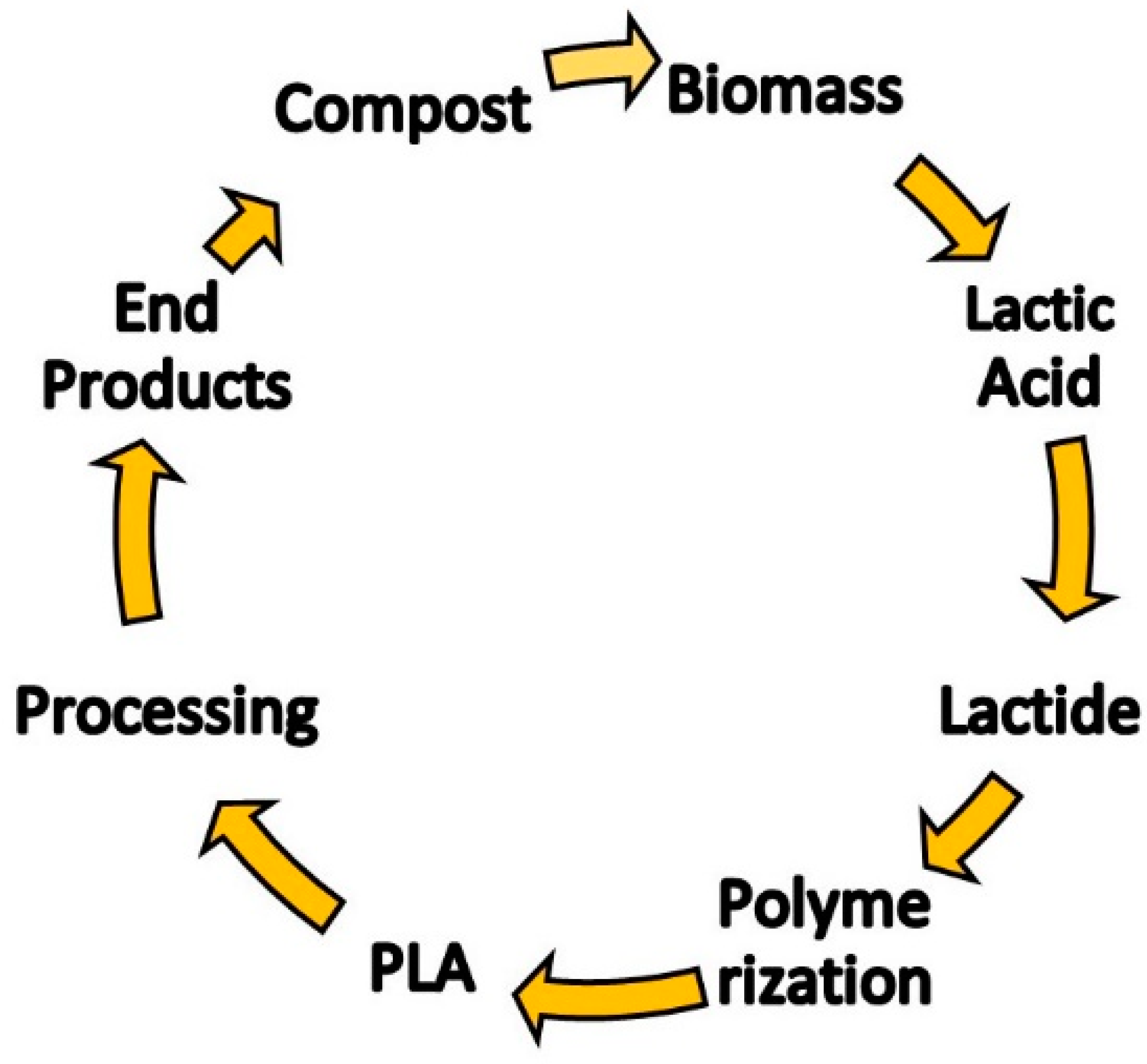

3. Biopolymers

PLA

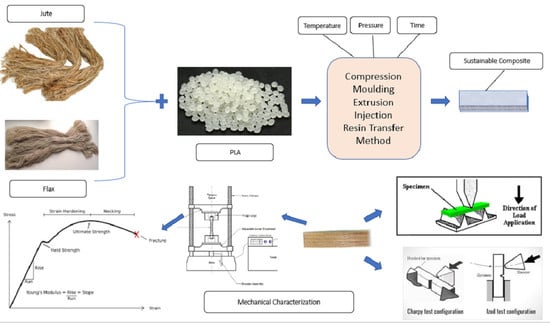

4. Natural Fibers

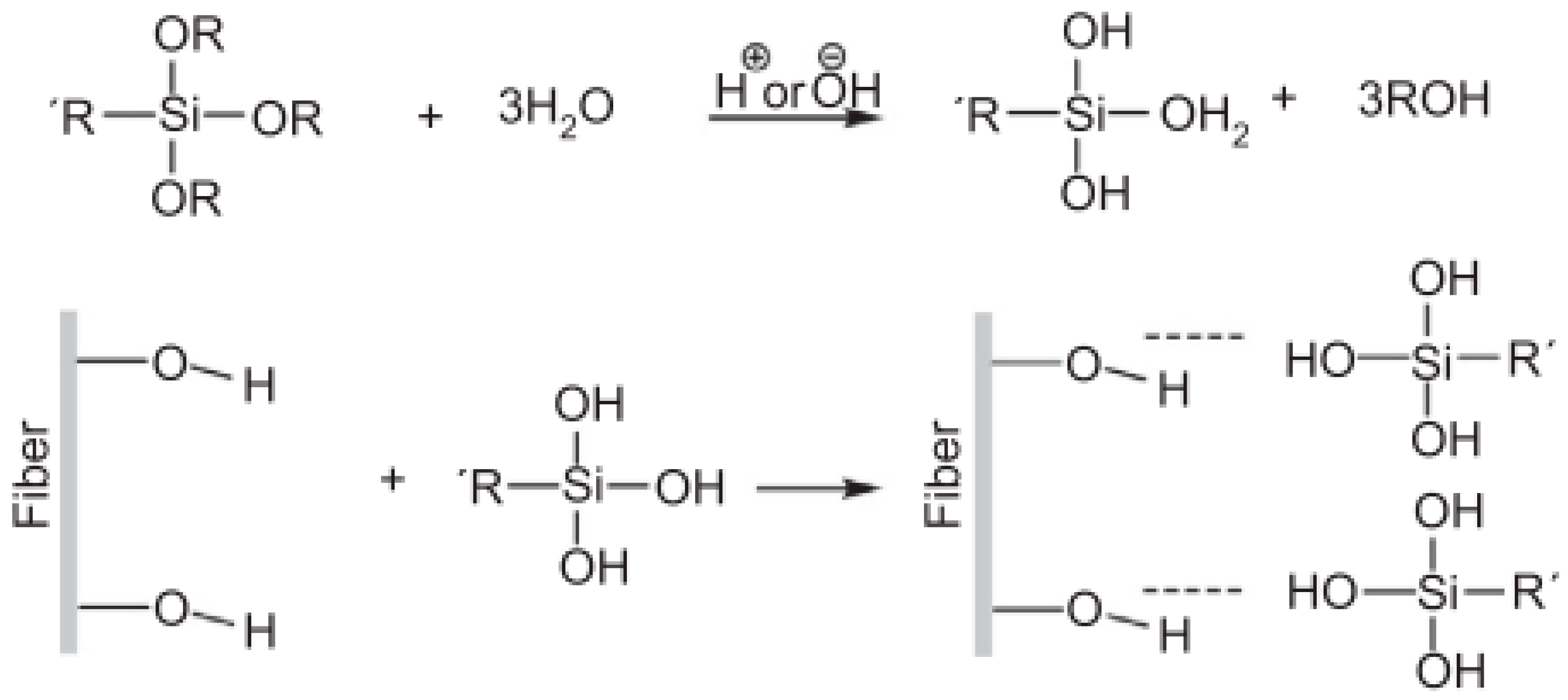

5. Treatment of Natural Fibers

6. Composite Processing

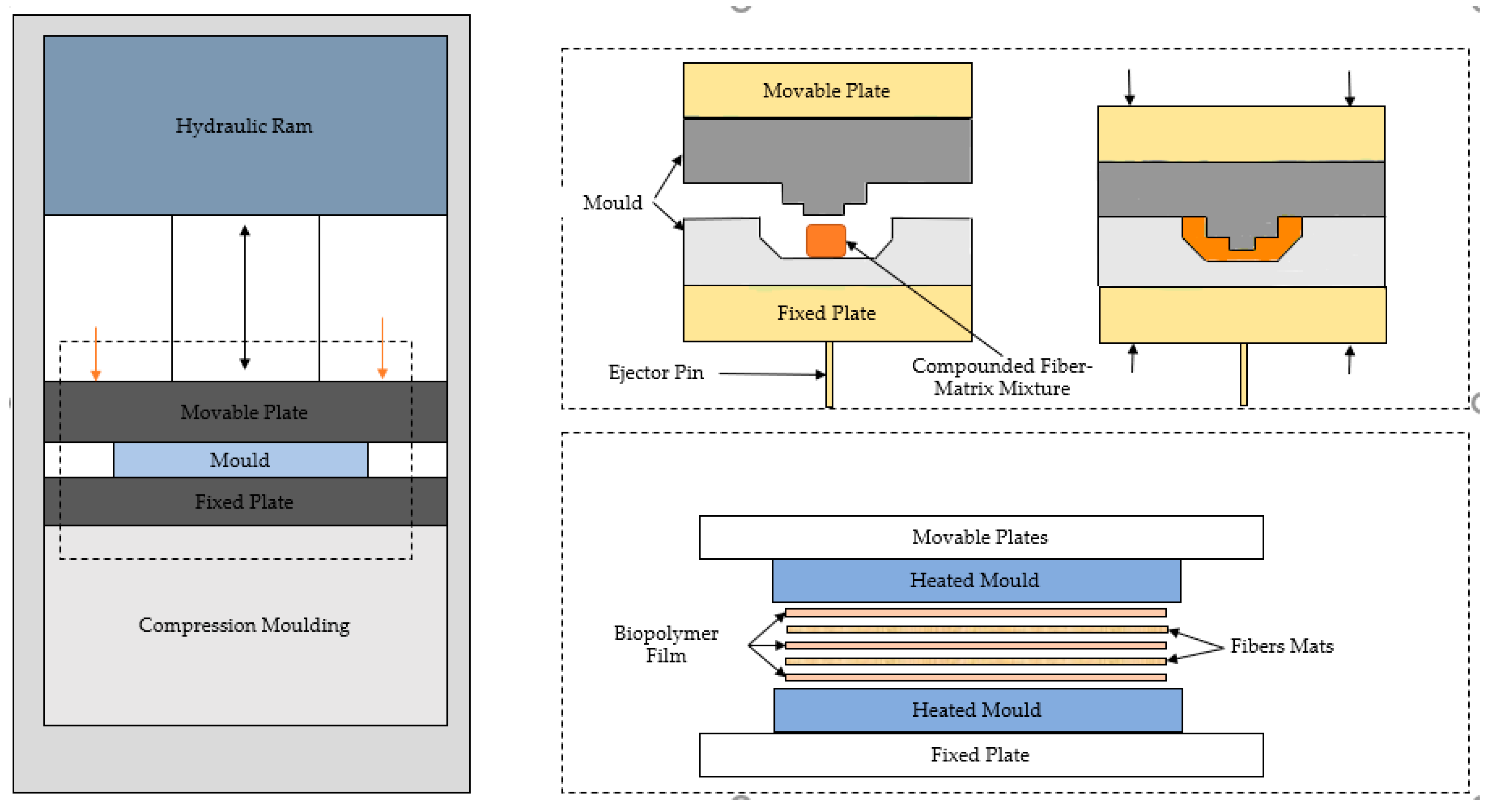

6.1. Compression Moulding

6.2. Compression Moulding of Precompounded Mixture

6.3. Film Stacking

6.4. Fiber Orientaiton and Distribution

7. PLA/Flax Composites

8. PLA/Jute Composites

9. Trends in Green Composites

10. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Sarapure, S. Nano Green Composites—An Overview. Int. J. Appl. Eng. Res. 2018, 13, 115–116. [Google Scholar]

- Jagadeesh, D.; Kanny, K.; Prashantha, K. A review on research and development of green composites from plant protein-based polymers. Polym. Compos. 2017, 38, 1504–1518. [Google Scholar] [CrossRef]

- Shekar, H.S.; Ramachandra, M. Green Composites: A Review. Mater. Today Proc. 2018, 5, 2518–2526. [Google Scholar] [CrossRef]

- Mulhaupt, R. The Use of Renewable Resources—Possibilities and Limitations. Chim. J. Int. Chem. 1996, 50, 191–198. [Google Scholar]

- Gordon, J.E. The New Science of Strong Materials, 2nd ed.; Penguin Books: London, UK, 1976. [Google Scholar]

- Muthu, S.S. (Ed.) Textile Science and Clothing Technology Green Composites Processing, Characterisation and Applications for Textiles; Springer Nature Sinapore Pte. Ltd.: Singapore, 2019. [Google Scholar] [CrossRef]

- McMullen, P. Fiber/resin composites for aircraft primary structures: A short history, 1936–1984. Composites 1984, 15, 222–230. [Google Scholar] [CrossRef]

- Dai, D.; Fan, M. Wood Fibers as Reinforcements in Natural Fiber Composites: Structure, Properties, Processing and Applications; Woodhead Publishing Ltd.: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Jha, K.; Kataria, R.; Verma, J.; Pradhan, S. Potential biodegradable matrices and fiber treatment for green composites: A review. AIMS Mater. Sci. 2019, 6, 119–138. [Google Scholar] [CrossRef]

- Mann, G.S.; Singh, L.P.; Kumar, P.; Singh, S. Green composites: A review of processing technologies and recent applications. J. Thermoplast. Compos. Mater. 2018, 33, 1145–1171. [Google Scholar] [CrossRef]

- Chen, J. Global Markets and Technologies for Bioplastics; BCC Research Report PLS050E; BCC Research: Wellesley, MA, USA, 2019. [Google Scholar]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2018, 40, 446–463. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Development and characterization of PLA-based green composites: A review. J. Thermoplast. Compos. Mater. 2014, 27, 52–81. [Google Scholar] [CrossRef]

- Jem, K.J.; Tan, B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv. Ind. Eng. Polym. Res. 2020, 3, 60–70. [Google Scholar] [CrossRef]

- Qi, X.; Ren, Y.; Wang, X. New advances in the biodegradation of Poly(lactic) acid. Int. Biodeterior. Biodegrad. 2017, 117, 215–223. [Google Scholar] [CrossRef]

- Babu, R.P.; O’Connor, K.E.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [PubMed]

- Rincon Lasprilla, A.J.; Rueda Martinez, G.A.; Lunelli, B.H.; Jaimes Figueroa, J.E.; Jardini, A.L.; Filho, R.M. Synthesis and Characterization of Poly (Lactic Acid) for Use in Biomedical Field. Chem. Eng. Trans. 2011, 24, 985–990. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Auras, R.; Lim, L.-T.; Selke, S.E.M.; Tsuji, H. Poly Lactic Acid: Synthesis, Strucutes, Properties, Processing and Applications; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Lasprilla, A.J.; Martinez, G.A.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly-lactic acid synthesis for application in biomedical devices—A review. Biotechnol. Adv. 2012, 30, 321–328. [Google Scholar] [CrossRef]

- Iannace, S.; Sorrentino, L.; Di Maio, E. Biodegradable biomedical foam scaffolds. In Biomedical Foams for Tissue Engineering Applications; Woodhead Publishing Ltd.: Cambridge, UK, 2014. [Google Scholar] [CrossRef]

- Hart, A.; Summerscales, J. Effect of time at temperature for natural fibers. Procedia Eng. 2017, 200, 269–275. [Google Scholar] [CrossRef]

- Van De Velde, K.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2001, 99, 483. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Composites: Part B Flax Fibre and Its Composites—A Review. Compos. PART B 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Luo, Y.; Lin, Z.; Guo, G. Biodegradation Assessment of Poly (Lactic Acid) Filled with Functionalized Titania Nanoparticles (PLA/TiO2) under Compost Conditions. Nanoscale Res. Lett. 2019, 14, 1–10. [Google Scholar] [CrossRef]

- Sáez, A. Industrial Applications of Natural Gas; InTech Open: London, UK, 2010. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Progress Report on Natural Fiber Reinforced Composites. Macromol. Mater. Eng. 2013, 299, 9–26. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Gupta, R.K. Review: Raw Natural Fiber–Based Polymer Composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Asim, M.; Abdan, K.; Jawaid, M.; Nasir, M.; Dashtizadeh, Z.; Ishak, M.R.; Hoque, M.E.; Deng, Y. A Review on Pineapple Leaves Fiber and Its Composites. Int. J. Polym. Sci. 2015, 2015, 1–16. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibers: A review. Constr. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef]

- Girijappa, Y.G.T.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibers and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Khiari, R.; Mhenni, M.F.; Belgacem, M.N.; Mauret, E. Chemical composition and pulping of date palm rachis and Posidonia oceanica—A comparison with other wood and non-wood fiber sources. Bioresour. Technol. 2010, 101, 775–780. [Google Scholar] [CrossRef]

- Madakadze, I.C.; Masamvu, T. Evaluation of Pulp and Paper Making Characteristics of Elephant Grass (Pennisetum purpureum Schum) and Switchgrass (Panicum virgatum L.). Afr. J. Environ. Sci. Technol. 2010, 4, 465–470. [Google Scholar] [CrossRef]

- Ishak, M.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.; Anwar, U.M.K. Characterization of Sugar Palm (Arenga pinnata) Fibers Tensile and Thermal Properties. J. Therm. Anal. Calorim. 2012, 109, 981–989. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fiber reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Fazita, M.N.; Jayaraman, K.; Bhattacharyya, D.; Haafiz, M.M.; Saurabh, C.K.; Hussin, M.H.; Khalil, H.A. Green Composites Made of Bamboo Fabric and Poly (Lactic) Acid for Packaging Applications—A Review. Materials 2016, 9, 435. [Google Scholar] [CrossRef]

- De Araujo, M.A.M.; de Sena Neto, A.R.; Hage, E., Jr.; Mattoso, L.H.C.; Marconcini, J.M. Curaua leaf fiber (Ananas comosus var. erectifolius) reinforcing poly(lactic acid) biocomposites: Formulation and performance. Polym. Compos. 2015, 36, 1520–1530. [Google Scholar] [CrossRef]

- Pickering, K.; Efendy, M.A. Preparation and mechanical properties of novel bio-composite made of dynamically sheet formed discontinuous harakeke and hemp fiber mat reinforced PLA composites for structural applications. Ind. Crop. Prod. 2016, 84, 139–150. [Google Scholar] [CrossRef]

- Khan, M.A.; Rahaman, M.S.; Jubayer, A.A.l.; Islam, J.M.M. Modification of Jute Fibers by Radiation-Induced Graft Copolymerization and Their Applications. Cellul. Graft Copolym. Struct. Chem. 2015, 209–234. [Google Scholar] [CrossRef]

- Cruz, J.; Fangueiro, R. Surface Modification of Natural Fibers: A Review. Procedia Eng. 2016, 155, 285–288. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Dreal, L.T. Surface Modifications of Natural Fibers and Peformance of the Resulting Biocomposite. Compos. Interfaces 2001, 8, 313–343. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Cho, D.; Lee, H.S.; Han, S.O. Effect of Fiber Surface Modification on the Interfacial and Mechanical Properties of Kenaf Fiber-Reinforced Thermoplastic and Thermosetting Polymer Composites. Compos. Interfaces 2009, 16, 711–729. [Google Scholar] [CrossRef]

- Asumani, O.; Reid, R.; Paskaramoorthy, R. The effects of alkali–silane treatment on the tensile and flexural properties of short fiber non-woven kenaf reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- Ferreira, D.P.; Cruz, J.; Fangueiro, R. Surface Modification of Natural Fibers in Polymer Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Ho, M.-P.; Wang, H.; Lee, J.-H.; Ho, C.-K.; Lau, K.-T.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fiber composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fiber be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Herrmann, A.; Nickel, J.; Riedel, U. Construction materials based upon biologically renewable resources—From components to finished parts. Polym. Degrad. Stab. 1998, 59, 251–261. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fiber composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Khan, M.A.; Sahoo, S.; Hinrichsen, G. Effect of chemical modification on the performance of biodegradable jute yarn-Biopol® composites. J. Mater. Sci. 2000, 35, 2589–2595. [Google Scholar] [CrossRef]

- Van De Velde, K.; Kiekens, P. Effect of material and process parameters on the mechanical properties of unidirectional and multidirectional flax/polypropylene composites. Compos. Struct. 2003, 62, 443–448. [Google Scholar] [CrossRef]

- Van Voorn, B.; Smit, H.; Sinke, R.; De Klerk, B. Natural fiber reinforced sheet moulding compound. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1271–1279. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Bajwa, D.S.; Bajwa, S.G. Mechanical properties of polylactic acid composites reinforced with cotton gin waste and flax fibers. Procedia Eng. 2017, 200, 370–376. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Kontou, E.; Georgousis, G. Effect of silane treatment loading on the flexural properties of PLA/flax unidirectional composites. Compos. Commun. 2018, 10, 6–10. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Pan, Y.-T.; Yáñez, A.P.; Hu, S.; Zhang, X.-Q.; Wang, R.; Wang, D.-Y. Polydopamine induced natural fiber surface functionalization: A way towards flame retardancy of flax/poly(lactic acid) biocomposites. Compos. Part B Eng. 2018, 154, 56–63. [Google Scholar] [CrossRef]

- Prasad, V.; Joseph, M.; Sekar, K. Investigation of mechanical, thermal and water absorption properties of flax fiber reinforced epoxy composite with nano TiO2 addition. Compos. Part A Appl. Sci. Manuf. 2018, 115, 360–370. [Google Scholar] [CrossRef]

- Akonda, M.; Alimuzzaman, S.; Shah, D.U.; Rahman, A.M. Physico-Mechanical, Thermal and Biodegradation Performance of Random Flax/Polylactic Acid and Unidirectional Flax/Polylactic Acid Biocomposites. Fibers 2018, 6, 98. [Google Scholar] [CrossRef]

- Bayart, M.; Gauvin, F.; Foruzanmehr, M.R.; Elkoun, S.; Robert, M. Mechanical and moisture absorption characterization of PLA composites reinforced with nano-coated flax fibers. Fibers Polym. 2017, 18, 1288–1295. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Christopoulos, A.; Koutsoumpis, S.; Kontou, E. The effect of surface treatment on the performance of flax/biodegradable composites. Compos. Part B Eng. 2016, 106, 88–98. [Google Scholar] [CrossRef]

- Xia, X.; Liu, W.; Zhou, L.; Hua, Z.; Liu, H.; He, S. Modification of flax fiber surface and its compatibilization in polylactic acid/flax composites. Iran. Polym. J. 2016, 25, 25–35. [Google Scholar] [CrossRef]

- Couture, A.; Lebrun, G.; Laperrière, L. Mechanical properties of polylactic acid (PLA) composites reinforced with unidirectional flax and flax-paper layers. Compos. Struct. 2016, 154, 286–295. [Google Scholar] [CrossRef]

- Foruzanmehr, M.; Vuillaume, P.Y.; Elkoun, S.; Robert, M. Physical and mechanical properties of PLA composites reinforced by TiO 2 grafted flax fibers. Mater. Des. 2016, 106, 295–304. [Google Scholar] [CrossRef]

- Bax, B.; Müssig, J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef]

- Kodal, M.; Topuk, Z.D.; Ozkoc, G. Dual Effect of Chemical Modification and Polymer Precoating of Flax Fibers on the Properties of Short Flax Fiber/Poly(Lactic Acid) Composites. J. Appl. Polym. Sci. 2015, 132, 42564. [Google Scholar] [CrossRef]

- Regazzi, A.; Léger, R.; Corn, S.; Ienny, P. Modeling of hydrothermal aging of short flax fiber reinforced composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 559–566. [Google Scholar] [CrossRef]

- Xia, X.; Shi, X.; Liu, W.; Zhao, H.; Li, H.; Zhang, Y. Effect of flax fiber content on polylactic acid (PLA) crystallization in PLA/flax fiber composites. Iran. Polym. J. 2017, 26, 693–702. [Google Scholar] [CrossRef]

- Memon, A.; Nakai, A. Fabrication and Mechanical Properties of Jute Spun Yarn/PLA Unidirection Composite by Compression Molding. Energy Procedia 2013, 34, 830–838. [Google Scholar] [CrossRef]

- Ji, S.G.; Hwang, J.H.; Cho, D.; Kim, H.-J. Influence of electron beam treatment of jute on the thermal properties of random and two-directional jute/poly(lactic acid) green composites. J. Adhes. Sci. Technol. 2013, 27, 1359–1373. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Singh, S.; Dhawan, V. Effect of Curing Temperature on Mechanical Properties of Natural Fiber Reinforced Polymer Composites. J. Nat. Fibers 2018, 15, 687–696. [Google Scholar] [CrossRef]

- Du, S.; Peng, X.; Gu, H. Experimental investigation on fabrication and thermal-stamping of woven jute/polylactic acid biocomposites. J. Compos. Mater. 2019, 53, 851–861. [Google Scholar] [CrossRef]

- Rahman, M.M.; Afrin, S.; Haque, P.; Islam, M.M.; Islam, M.S.; Gafur, M.A. Preparation and Characterization of Jute Cellulose Crystals-Reinforced Poly(L-lactic acid) Biocomposite for Biomedical Applications. Int. J. Chem. Eng. 2014, 2014, 1–7. [Google Scholar] [CrossRef]

- Chen, J.-C.; Lin, J.-C. Manufacturing and properties of cotton and jute fabrics reinforced epoxy and PLA composites. Int. J. Mod. Phys. B 2018, 32, 1840084. [Google Scholar] [CrossRef]

- Fujiura, T.; Sakamoto, K.; Tanaka, T.; Imaida, Y. A Study on Preparation and Mechanical Properties of Long Jute Fiber Reinforced Polylactic Acid by the Injection Molding Process. WIT Trans. Built Environ. 2008, 97, 231–240. [Google Scholar] [CrossRef]

- Arao, Y.; Fujiura, T.; Itani, S.; Tanaka, T. Strength improvement in injection-molded jute-fiber-reinforced polylactide green-composites. Compos. Part B Eng. 2015, 68, 200–206. [Google Scholar] [CrossRef]

- Yu, T.; Ding, D.; Sheng, C.; Tuerhongjiang, T.; Li, Y. Enhanced mechanical properties and flame retardancy of short jute fiber/poly(lactic acid) composites with phosphorus-based compound. Sci. China Technol. Sci. 2017, 60, 1716–1723. [Google Scholar] [CrossRef]

- Yu, T.; Tuerhongjiang, T.; Sheng, C.; Li, Y. Phosphorus-containing diacid and its application in jute/poly(lactic acid) composites: Mechanical, thermal and flammability properties. Compos. Part A Appl. Sci. Manuf. 2017, 97, 60–66. [Google Scholar] [CrossRef]

- Jiang, N.; Yu, T.; Li, Y.; Pirzada, T.J.; Marrow, T.J. Hygrothermal aging and structural damage of a jute/poly (lactic acid) (PLA) composite observed by X-ray tomography. Compos. Sci. Technol. 2019, 173, 15–23. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, A.P.; Singh, I. Processing of Lignocellulosic Fiber-Reinforced Biodegradable Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Yu, T.; Li, Y.; Ren, J. Preparation and properties of short natural fiber reinforced poly(lactic acid) composites. Trans. Nonferrous Met. Soc. China 2009, 19 (Suppl. 3), s651–s655. [Google Scholar] [CrossRef]

- Dong, Y.; Ghataura, A.; Takagi, H.; Haroosh, H.J.; Nakagaito, A.N.; Lau, K.-T. Polylactic acid (PLA) biocomposites reinforced with coir fibers: Evaluation of mechanical performance and multifunctional properties. Compos. Part A Appl. Sci. Manuf. 2014, 63, 76–84. [Google Scholar] [CrossRef]

- Plackett, D.; Andersen, T.L.; Pedersen, W.B.; Nielsen, L. Biodegradable composites based on l-polylactide and jute fibers. Compos. Sci. Technol. 2003, 63, 1287–1296. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Improvement of mechanical performance of industrial hemp fiber reinforced polylactide biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 310–319. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Flexural properties of hemp fiber reinforced polylactide and unsaturated polyester composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 519–526. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Comparative studies of mechanical and morphological properties of polylactic acid and polypropylene based natural fiber composites. J. Reinf. Plast. Compos. 2012, 31, 1712–1724. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Tribological behavior of natural fiber reinforced PLA composites. Wear 2013, 297, 829–840. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly(lactic acid) (PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Hu, R.-H.; Sun, M.-Y.; Lim, J.-K. Moisture absorption, tensile strength and microstructure evolution of short jute fiber/polylactide composite in hygrothermal environment. Mater. Des. 2010, 31, 3167–3173. [Google Scholar] [CrossRef]

- Ben Amor, I.; Rekik, H.; Kaddami, H.; Raihane, M.; Arous, M.; Kallel, A. Effect of Palm Tree Fiber Orientation on Electrical Properties of Palm Tree Fiber-reinforced Polyester Composites. J. Compos. Mater. 2010, 44, 1553–1568. [Google Scholar] [CrossRef]

- Joseph, P.V.; Joseph, K.; Sabu, T. Effect of Processing Variables on the Mechanical Properties of Sisal Fiber-Polypropylene Composites. Compos. Sci. 1999, 59, 1625–1640. [Google Scholar] [CrossRef]

- Brahim, S.B.; Cheikh, R.B. Influence of Fiber Orientation and Volume Fraction on the Tensile Properties of Unidirectional Alfo-Polyester Composite. Compos. Sci. Technol. 2007, 67, 140–147. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanen, M.; Nousiainen, P. Novel aligned hemp fiber reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Oliver-Ortega, H.; Alberto Méndez, J.; Camps, J.; Espinach, F.X.; Mutjé, P. The role of lignin on the mechanical performance of polylactic acid and jute composites. Int. J. Biol. Macromol. 2018, 116, 299–304. [Google Scholar] [CrossRef] [PubMed]

- Russo, P.; Simeoli, G.; Papa, I.; Acierno, D.; Lopresto, V.; Langella, A. Low-Velocity Impact Behavior of Woven Jute/Poly(Lactic Acid) Composites. AIP Conf. Proc. 2016, 1736, 020025. [Google Scholar] [CrossRef]

- Jiang, N.; Yu, T.; Li, Y. Effect of Hydrothermal Aging on Injection Molded Short Jute Fiber Reinforced Poly(Lactic Acid) (PLA) Composites. J. Polym. Environ. 2018, 26, 3176–3186. [Google Scholar] [CrossRef]

- Ma, H.; Joo, C.W. Structure and mechanical properties of jute—Polylactic acid biodegradable composites. J. Compos. Mater. 2011, 45, 1451–1460. [Google Scholar] [CrossRef]

- Rajesh, G.; Prasad, A.V.R. Tensile Properties of Successive Alkali Treated Short Jute Fiber Reinforced PLA Composites. Procedia Mater. Sci. 2014, 5, 2188–2196. [Google Scholar] [CrossRef]

- Gunti, R.; Ratna Prasad, A.V.; Gupta, A.V.S.S.K.S. Preparation and properties of successive alkali treated completely biodegradable short jute fiber reinforced PLA composites. Polym. Compos. 2015, 37, 2160–2170. [Google Scholar] [CrossRef]

- Zafar, M.T.; Maiti, S.N.; Ghosh, A.K. Effect of surface treatments of jute fibers on the microstructural and mechanical responses of poly(lactic acid)/jute fiber biocomposites. RSC Adv. 2016, 6, 73373–73382. [Google Scholar] [CrossRef]

- Yu, T.; Hu, C.; Li, Y. Functionalization of Graphene and Its Influence on Mechanical Properties and Flame Retardancy of Jute/Poly(lactic acid) Composite. J. Nanosci. Nanotechnol. 2019, 19, 7074–7082. [Google Scholar] [CrossRef]

- Baheti, V.; Militky, J.; Marsalkova, M. Mechanical Properties of Poly Lactic Acid Composite Films Reinforced with Wet Milled Jute Nanofibers. Polym. Compos. 2015, 38, 96–104. [Google Scholar] [CrossRef]

- Baheti, V.; Mishra, R.; Militky, J.; Behera, B.K. Influence of noncellulosic contents on nano scale refinement of waste jute fibers for reinforcement in polylactic acid films. Fibers Polym. 2014, 15, 1500–1506. [Google Scholar] [CrossRef]

- He, H.; Tay, T.E.; Wang, Z.; Duan, Z. The strengthening of woven jute fiber/polylactide biocomposite without loss of ductility using rigid core–Soft shell nanoparticles. J. Mater. Sci. 2018, 54, 4984–4996. [Google Scholar] [CrossRef]

- Zafar, M.T.; Maiti, S.N.; Ghosh, A.K. Effect of surface treatment of jute fibers on the interfacial adhesion in poly(lactic acid)/jute fiber biocomposites. Fibers Polym. 2016, 17, 266–274. [Google Scholar] [CrossRef]

- Netravali, A.N.; Huang, X.; Mizuta, K. Advanced “Green” Composites, 1st ed.; Netravali, A., Ed.; Scrivener Publications: Beverly, CA, USA, 2018. [Google Scholar] [CrossRef]

- Netravali, A.N. Advanced green composites: New directions. Mater. Today Proc. 2019, 8, 832–838. [Google Scholar] [CrossRef]

- Chow, W.S.; Ishak, Z.A.M. Smart polymer nanocomposites: A review. Express Polym. Lett. 2020, 14, 416–435. [Google Scholar] [CrossRef]

- Zhang, N.; Khan, T.; Guo, H.; Shi, S.; Zhong, W.; Zhang, W. Functionally Graded Materials: An Overview of Stability, Buckling and Free Vibration Analysis. Adv. Mater. Sci. Eng. 2019, 2019, 1–18. [Google Scholar] [CrossRef]

- Singh, R.; Bhavar, V.; Kattire, P.; Thakare, S.; Patil, S.; Singh, R.K.P. A Review on Functionally Gradient Materials (FGMs) and Their Applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 229, 012021. [Google Scholar] [CrossRef]

- Pereira, J.F.; Ferreira, D.P.; Pinho, E.; Fangueiro, R. Chemical and Biological Warfare Protection and Self-Decontaminating Flax Fabrics Based on CaO Nanoparticles. Key Eng. Mater. 2019, 812, 75–83. [Google Scholar] [CrossRef]

- Costa, S.M.; Ferreira, D.P.; Ferreira, A.; Vaz, F.; Fangueiro, R. Multifunctional Flax Fibers Based on the Combined Effect of Silver and Zinc Oxide (Ag/ZnO) Nanostructures. Nanomaterials 2018, 8, 1069. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, D.P.; Costa, S.M.; Felgueiras, H.P.; Fangueiro, R. Smart and Sustainable Materials for Military Applications Based on Natural Fibers and Silver Nanoparticles. Key Eng. Mater. 2019, 812, 66–74. [Google Scholar] [CrossRef]

- Ferreira, D.P.; Ferreira, A.; Fangueiro, R. Searching for Natural Conductive Fibrous Structures via a Green Sustainable Approach Based on Jute Fibers and Silver Nanoparticles. Polymers 2018, 10, 63. [Google Scholar] [CrossRef]

- Boticas, I.; Dias, D.; Ferreira, D.P.; Magalhães, P.; Silva, R.; Fangueiro, R. Superhydrophobic cotton fabrics based on ZnO nanoparticles functionalization. SN Appl. Sci. 2019, 1, 1–9. [Google Scholar] [CrossRef]

- Todor, P.; Bulei, C.; Kiss, I. An Overview on Key Trends in Composite Materials Continuous Innovation and Improvements with Focus on Composites Based on Cellulose Fibers. Acta Tech. Corviniensis-Bull. Eng. 2018, 11, 107–112. [Google Scholar]

- Diestel, O.; Hausding, J. Pre-impregnated textile semi-finished products (prepregs). In Textile Materials for Lightweight Constructions: Technologies—Methods—Materials—Properties; Springer: Berlin, Germany, 2016; Chapter 11; pp. 1–677. [Google Scholar] [CrossRef]

- Todor, M.P.; Bulei, C.; Hepuţ, T.; Kiss, I. Researches on the development of new composite materials complete / partially biodegradable using natural textile fibers of new vegetable origin and those recovered from textile waste. IOP Conf. Ser. Mater. Sci. Eng. 2018, 294, 12021. [Google Scholar] [CrossRef]

- Ecélino, A.; Efreour, S.; Ejacquemin, F.; Ecasari, P. The hygroscopic behavior of plant fibers: A review. Front. Chem. 2014, 1, 1–12. [Google Scholar] [CrossRef]

| Biopolymers | Density (g/cm3) | Tensile Strength (MPa) | Youngs Modulus (GPa) | Glass Transition Temperature (°C) | Melting Temperature (°C) |

|---|---|---|---|---|---|

| PLA | 1.21–1.25 | 21–60 | 0.35–3.5 | 45–60 | 150–162 |

| PLLA | 1.24–1.30 | 15.5–150 | 2.7–4.14 | 55–65 | 170–200 |

| Biopolymers | Tensile Strength (MPa) | Youngs Modulus (GPa) | Elongation at Break (%) | Reference |

|---|---|---|---|---|

| PLA | 53 | 2.4 | 5 | [15] |

| Polypropylene | 31 | 1.5–2 | 80-350 | [15] |

| HDPE | 14.5–38 | 0.4–1.5 | 2.0–130 | [25] |

| Polystyrene | 25–69 | 4–5 | 1–2.5 | [25] |

| Polyamide | 56–90 | 2 | 70 | [15] |

| Bio Fibers | Sources | Examples |

|---|---|---|

| Animal Fiber | Wool/hair—sheep, camel, rabbit hair goat hair, yak, horsehair, Silk Asbestos | |

| Mineral | Asbestos, wollastonite | |

| Plant fiber | Stalk fiber | Bamboo, wheat, rice, grass, barley, corn, maize, oat |

| Fruit fiber | Coconut, betelnut | |

| Seed fiber | Cotton, oil palm, kapok, alfalfa | |

| Leaf fiber | Sisal, banana, palm, date palm, pineapple, henequen, agave | |

| Bast fiber | Hemp, jute, banana, flax, kenaf sugarcane, ramie, roselle |

| Fibers | Cellulose (wt %) | HC (wt %) | Lignin (wt %) | Pectin (wt %) | Ash (wt %) | Waxes (wt %) | MC (%) | MFA (Deg) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Abaca | 56–63 | 20–25 | 7–9 | - | 3 | 3 | 5–10 | - | [31] |

| Bagasse | 55.2 | 16.8 | 25.3 | - | 1.5–5 | - | 8.8 | - | [33] |

| Bamboo | 73.83 | 12.49 | 10.15 | 0.37 | 9.6 | - | 3.16 | - | [31] |

| Banana | 60–65 | 6–8 | 5–10 | - | 2.7–10.2 | - | 10–15 | 11 | [34] |

| Coir | 32–43 | 0.15–0.25 | 40–45 | - | - | - | 10–12 | 30–39 | [33] |

| Cotton | 82.7 | 5.7 | - | - | - | - | 1 | 20–30 | [31] |

| Curauá | 73.6 | 9.9 | 7.5 | - | 3.9–9.6 | - | - | - | [33] |

| Date-palm | 30.3–33.5 | 59.5 | 27–31.2 | - | 5 | - | - | - | [35] |

| Elephant Grass Grass | 45.6 | - | 17.7 | - | - | - | - | - | [36] |

| Flax | 71 | 18.6–20.6 | 2.2 | 2.3 | - | 1.7 | 8–12 | 5–10 | [33] |

| Hemp | 68 | 15 | 10 | 1 | 0.8 | 0.8 | 6.2–12 | 2–6.2 | [33] |

| Henequen | 77.6 | 4–8 | 13.1 | - | - | - | - | - | [29] |

| Jute | 61–71 | 14–20 | 12–13 | - | 0.8 | 0.5 | 12.5–13.7 | 8 | [33] |

| Kenaf | 45–57 | 21.5 | 8–13 | 3–5 | 2–5 | - | - | - | [29] |

| Oil-palm | 65 | - | 29 | - | 2.4 | - | - | 46 | [33] |

| Pineapple | 70–80 | 18.8 | 12.7 | 1.1–1.2 | 0.9–1.2 | 3.2–4.2 | 11.8 | 8–15 | [29] |

| Ramie | 68.6–76.2 | 13–16 | 0.6–0.7 | 1.9 | - | 0.3 | 7.5–1.7 | 7.5 | [29] |

| Rice Husk | 35–45 | 19–25 | 20 | - | - | 14–17 | - | - | [33] |

| Rice Straw | 41–57 | 33 | 8–19 | - | 14–20 | 8–35 | 6.5 | - | [33] |

| Sisal | 65 | 12 | 9.9 | 10 | 0.6–1 | 2 | 10–12 | 10–22 | [33] |

| Sugar Palm | 53.41 | 7.45 | 24.92 | - | 4.27 | - | 8.7 | - | [37] |

| Wheat Straw | 38–45 | 15–31 | 12–20 | - | 6.8 | - | 10 | - | [33] |

| Fibers | Density (g/cm3) | Tensile Strength (MPa) | Youngs Modulus (GPa) | Elongation (%) | Moisture Absorption | Ref. |

|---|---|---|---|---|---|---|

| Abaca | 1.5 | 410–810 | 41 | 1.6 | - | [13] |

| Banana | 1.35 | 721.5–910 | 29 | 2 | - | [33] |

| Chicken Feathers | 0.89 | 100–200 | 3–10 | - | - | [13] |

| Coconut | 1.15 | 131–175 | 4–6 | 15 | - | [13] |

| Coir | 1.2 | 175–220 | 4–6 | 15–30 | 10 | [13] |

| Cotton | 1.5–1.6 | 287–597 | 5.5–12.6 | 3–10 | 8–25 | [13] |

| Curaua Leaf | - | 1250–3000 | 30–80 | - | - | [40] |

| Flax | 1.4–1.5 | 345–1500 | 27.6–80 | 1.2–3.2 | 7 | [13] |

| Harakeke | - | 440–990 | 14–33 | - | - | [41] |

| Hemp | 1.48 | 550–900 | 70 | 1.6 | 8 | [13] |

| Henequen | 1.4 | 500 | 13.2 | 4.8 | - | [33] |

| Jute | 1.3–1.46 | 393–800 | 10–30 | 1.5–1.8 | 12 | [13] |

| Nettle | 1.51 | 650 | 38 | 1.7 | - | [33] |

| Pineapple Leaf | 1.07–1.50 | 413–1627 | 34.5–82.5 | 11.8 | [13] | |

| Ramie | 1.5 | 220–938 | 44–128 | 2.0–3.8 | 12–17 | [13] |

| Sisal | 1.33–1.5 | 400–700 | 9–38 | 2–14 | 11 | [13] |

| Spartium Juncem L | 1.55 | 986.46 | 17.86 | - | - | [41] |

| Softwood | 1.5 | 1000 | 40.0 | - | - | [13] |

| E-Glass | 2.5 | 2000–3500 | 70.0 | 2.5–3 | - | [13] |

| S-Glass | 2.5 | 4570 | 86.0 | 2.8 | - | [13] |

| Aramide (normal) | 1.4 | 3000–3150 | 63–67 | 3.3–3.7 | - | [13] |

| Carbon (standard) | 1.4 | 4000 | 230–400 | 1.4–1.8 | - | [13] |

| Advantages | Disadvantages |

|---|---|

| Lower specific weight results in a higher specific and stiffness than glass | Low mechanical properties especially impact resistance |

| Renewable resource | Moisture sensitivity |

| Production with low investment | Low thermal stability |

| Low abrasion and hence less tool wear | Low durability |

| Abundantly available | Poor fire resistance |

| Biodegradable | Poor fiber-matrix adhesion |

| Method | Rotation Speed (RPM) | Temperature (°C) | Process | Mold Temp (°C) | Pressure (MPa) | Time (Min) | wt % | Ref. |

|---|---|---|---|---|---|---|---|---|

| TSE | 150 | 154–171 | CM | 185 | - | - | 30 | [56] |

| FS | - | - | CM | 185 | 4 | - | 22 | [57] |

| MC | 100 | 180 | CM | 180 | 30 | 10 | 30 | [58] |

| SC | - | - | CM | 100 | 5 | 30 | - | [59] |

| CS | - | - | CM | 180 | 2 | 5 | 49.5 | [60] |

| AL | - | - | CM | 180 | 4 | 5 | 48 | [60] |

| FS | - | - | HP | 180 | 0T, 2T, 1T, 0.5T, 6T | 5, 1.5, 1, 0.5, | 30 | [61] |

| FS | - | - | HP | 124 | 5 | 6 h | 22 | [62] |

| TSE | 150 | 170–175 | - | - | - | - | - | [63] |

| SC | - | - | HP | 180 | - | 5 | 49.3 | [64] |

| SC | - | - | HP | 180 | - | 5 | 60.7 | [64] |

| SC | - | - | HP | 180 | 34 | 5 | 34 | [65] |

| Process | Temperature (°C) | Pressure (MPa) | Process | Temperature (°C) | Pressure (MPa) | wt % | Ref. |

|---|---|---|---|---|---|---|---|

| HP | 170 | 18 | IM | 170, 175, 180 | 10 | 10, 20, 30 | [66] |

| HP | 170 | 18 | IM | 170, 175, 180 | 12 | 40 | [66] |

| Equipment | Rotation Speed (RPM) | Temperature (°C) | Process | Melting Temperature (°C) | Mold Temperature (°C) | wt % | Ref. |

|---|---|---|---|---|---|---|---|

| TSC | 100 | 180 | IM | 180 | 25 | 25 | [67] |

| TSE | - | 180 | IM | 200 | 25 | 10, 30 | [68] |

| TSE | 150 | 172–177 | IM | 177–182 | 55 | 2.5–12.5 | [69] |

| Method | Rotation Speed (RPM) | Temperature (°C) | Process | Mold Temperature (°C) | Pressure (MPa) | Time (Min) | wt % | Ref. |

|---|---|---|---|---|---|---|---|---|

| WM | - | - | CM | 185 | 1.33 | 8 | 37.3 | [70] |

| - | - | - | CM | 180 | 6.89 | 40 | 50 | [71] |

| FS | - | - | CM | 180 | 13.79 | 40 | 50 | [71] |

| - | - | - | CM | 80–130 | 350 KN | 180 | - | [72] |

| CM | 150 | 0.6 | 10 | 40 | [73] | |||

| Extrusion | 25 | 75 and 80 | HP | 165 | - | 2–3 | 3–15 | [74] |

| - | - | - | HP | 110 | 50 | 180 | [75] |

| Method | Rotation Speed (RPM) | Temperature (°C) | Process | Temperature (°C) | Mold Temperature (°C) | wt % | Ref. |

|---|---|---|---|---|---|---|---|

| - | - | - | IM | 160 | 25 | 50 | [76] |

| TSE | 150 | 180 | IM | 180 | - | - | [77] |

| TSCE | 80 | 155–170 | IM | 170–190 | 40–50 | 15 | [78] |

| TSCE | 80 | 155–170 | IM | 170 | 30 | 15 | [79] |

| TSE | 100 | 160–170 | IM | 175–180 | - | 10 | [80] |

| Fiber Content wt (%) | Process | Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Strength (kJ/m2) | Young’s Modulus (GPa) | Additional Information | Ref. |

|---|---|---|---|---|---|---|---|

| IM | 74.3 | - | 12.7 | - | ST and PC | [67] | |

| 22 | FS | 99.0 | 140 | - | 16.0 | UT | [62] |

| 22 | FS | 102.5 | 117 | - | 12.5 | ST | [62] |

| 22 | FS | 63.0 | 83 | - | 12.7 | TBCT | [62] |

| 22 | FS | 35.0 | 63 | - | 25.0 | MAHT | [62] |

| 30 | HP | 177 | - | - | 10.8 | Before conditioning | [61] |

| 30 | HP | 187 | -- | 12.2 | Nano silica coated and before conditioning | [61] | |

| 30 | HP | 89 | - | - | 4.68 | After conditioning | [61] |

| 30 | HP | 114 | - | - | 6.2 | Nano Silica coated and after conditioning | [61] |

| 30 | CM | 55.4 | - | 2.90 | Coated with PDA film | [58] | |

| 30 | CM | 60.1 | - | - | 3.40 | - | [58] |

| 48 | CM | 83.0 | 130.0 | 9.3 | Random | [60] | |

| 48 | CM | 151.0 | 215.0 | 18.5 | Aligned | [60] |

| Fiber Content wt (%) | Process | Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Strength (kJ/m2) | Young’s Modulus (GPa) | Additional Information | Ref. |

|---|---|---|---|---|---|---|---|

| 50 | IM | 62.2 | 98.8 | 2.21 | - | - | [76] |

| - | IM | 90.7 | - | 4.22 (kJ/m) | 12.3 | Short Fiber Pellet mix | [77] |

| - | CM | 32.3 | 41.8 | 3.5 J | 2.11 | Woven Jute Fabric | [72] |

| 30 | IM | 71.7 | - | - | 9.15 | Lignin 4% | [95] |

| - | RFM | 53.16 | 128.3 | - | 8.11 | - | [75] |

| 20 | IM | 55 | 110 | 1.6 | 1.7 | 10% NaOH + H2O2 | [99,100] |

| 25 | IM | 54 | 80 | 2.5 | 2.7 | 05% NaOH + H2O2 | [99,100] |

| 30 | IM | 70 | - | 26 (J/m) | - | Alkali Treated | [101] |

| 30 | IM | 80 | - | 28(J/m) | - | Alkali + Silane Treated | [101] |

| 15 | IM | 50 | 78 | 4.8 | 4.8 | Treated with DOPO-ICN | [78] |

| 10 | - | 61.71 | 93.68 | 19.26 | 4.2 | Graphene Modified with DOPO | [102] |

| 5 | SC | 70.30 | - | - | 3.30 | PLA Composite Films with Jute Nano Fibers | [103] |

| 3 | SC | 69.80 | - | - | 3.20 | NaOH Treated Jute Nano Fibers | [104] |

| 40 | HP | 77.5 | 115.3 | 3.67 | Core Shell Nanoparticles (SiO2–PBA–NH2) | [105] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanivada, U.K.; Mármol, G.; Brito, F.P.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymers 2020, 12, 2373. https://doi.org/10.3390/polym12102373

Sanivada UK, Mármol G, Brito FP, Fangueiro R. PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymers. 2020; 12(10):2373. https://doi.org/10.3390/polym12102373

Chicago/Turabian StyleSanivada, Usha Kiran, Gonzalo Mármol, F. P. Brito, and Raul Fangueiro. 2020. "PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties" Polymers 12, no. 10: 2373. https://doi.org/10.3390/polym12102373

APA StyleSanivada, U. K., Mármol, G., Brito, F. P., & Fangueiro, R. (2020). PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymers, 12(10), 2373. https://doi.org/10.3390/polym12102373