Fabrication and Characterization of Carbon-Fiber-Reinforced Polymer–FeSi Composites with Enhanced Magnetic Properties

Abstract

1. Introduction

2. Materials and Methods

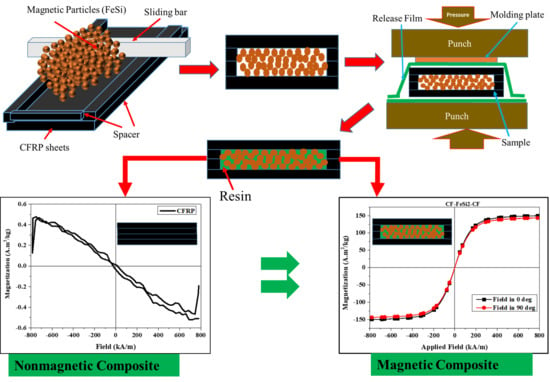

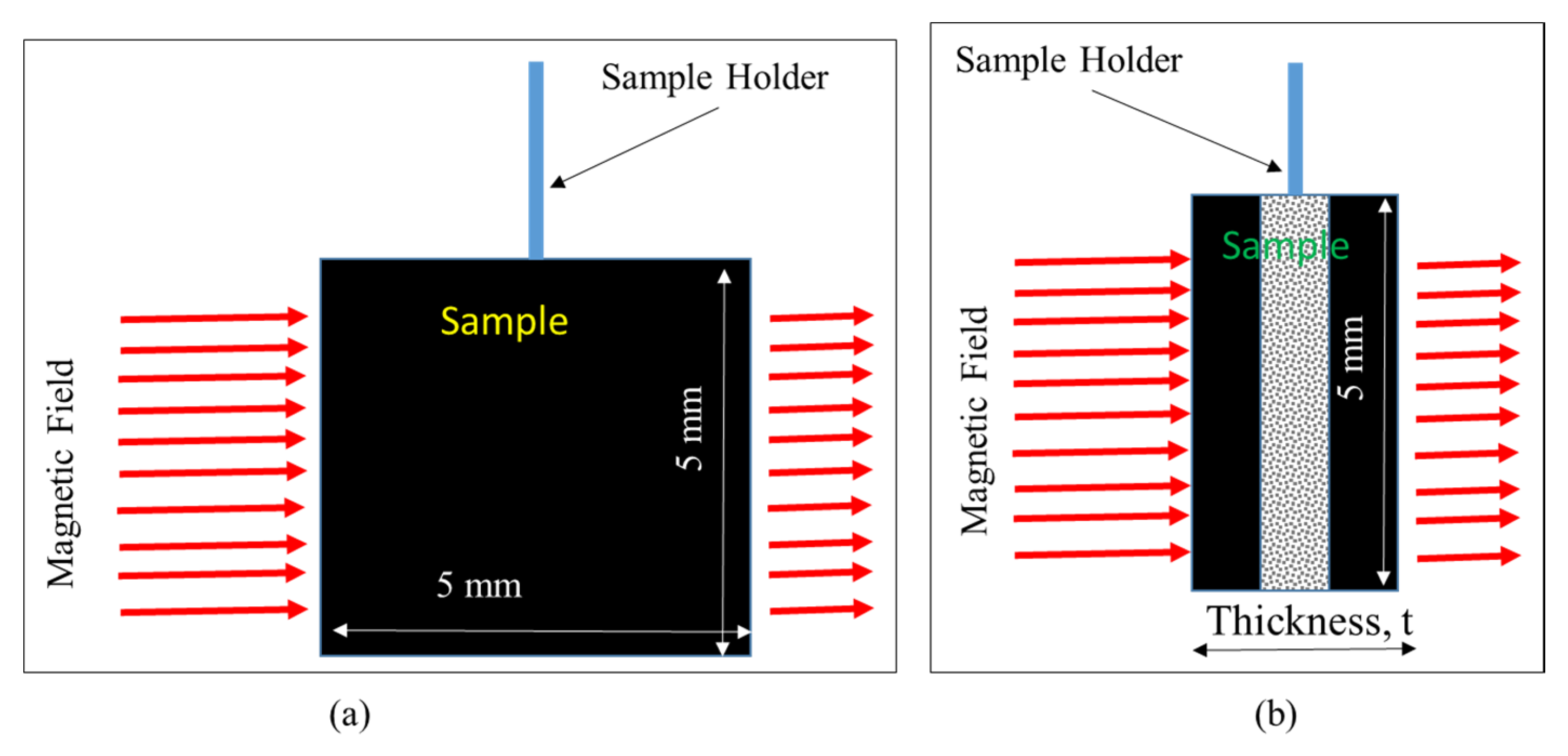

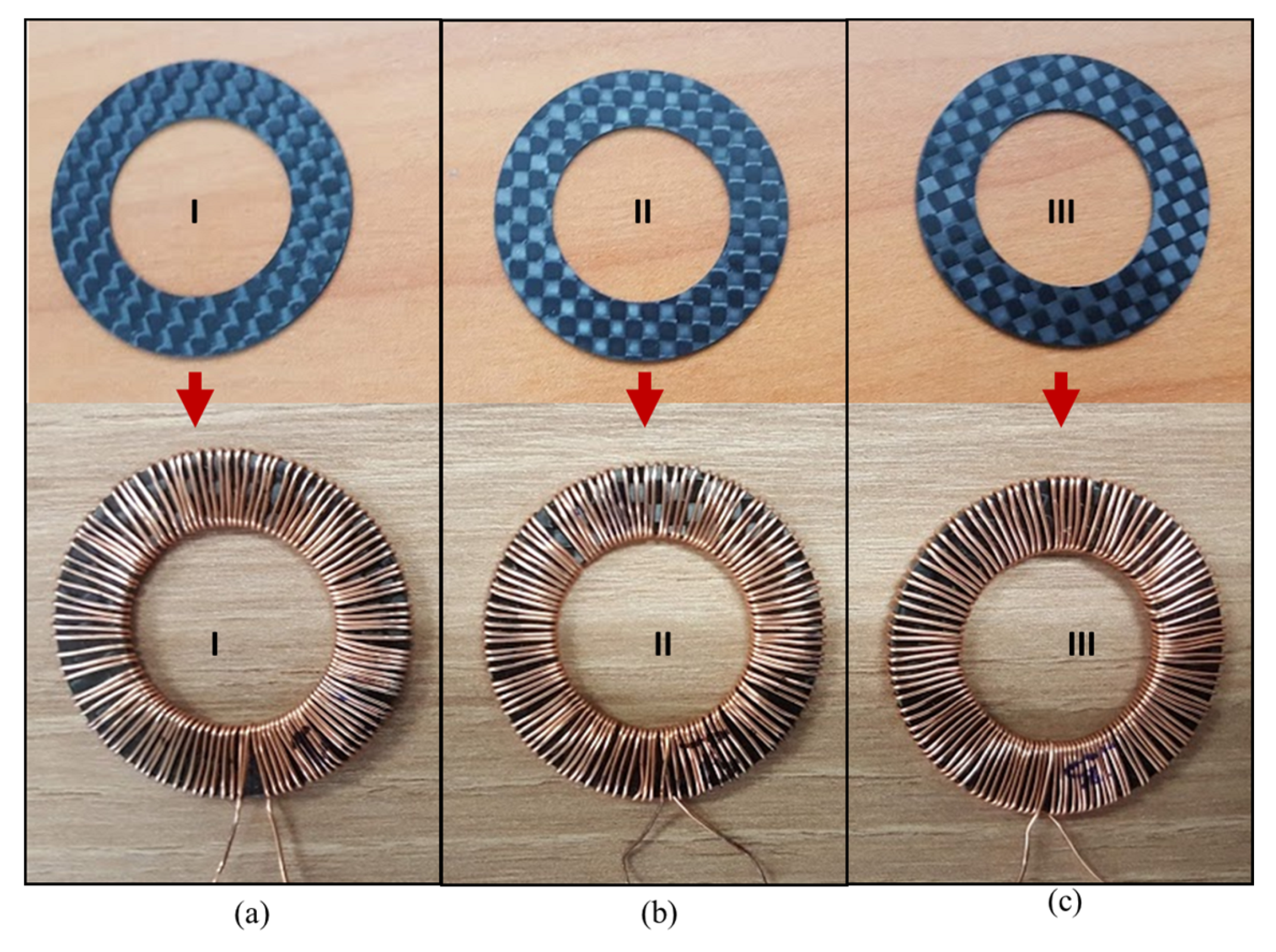

2.1. The Preparation and Design of the Composites

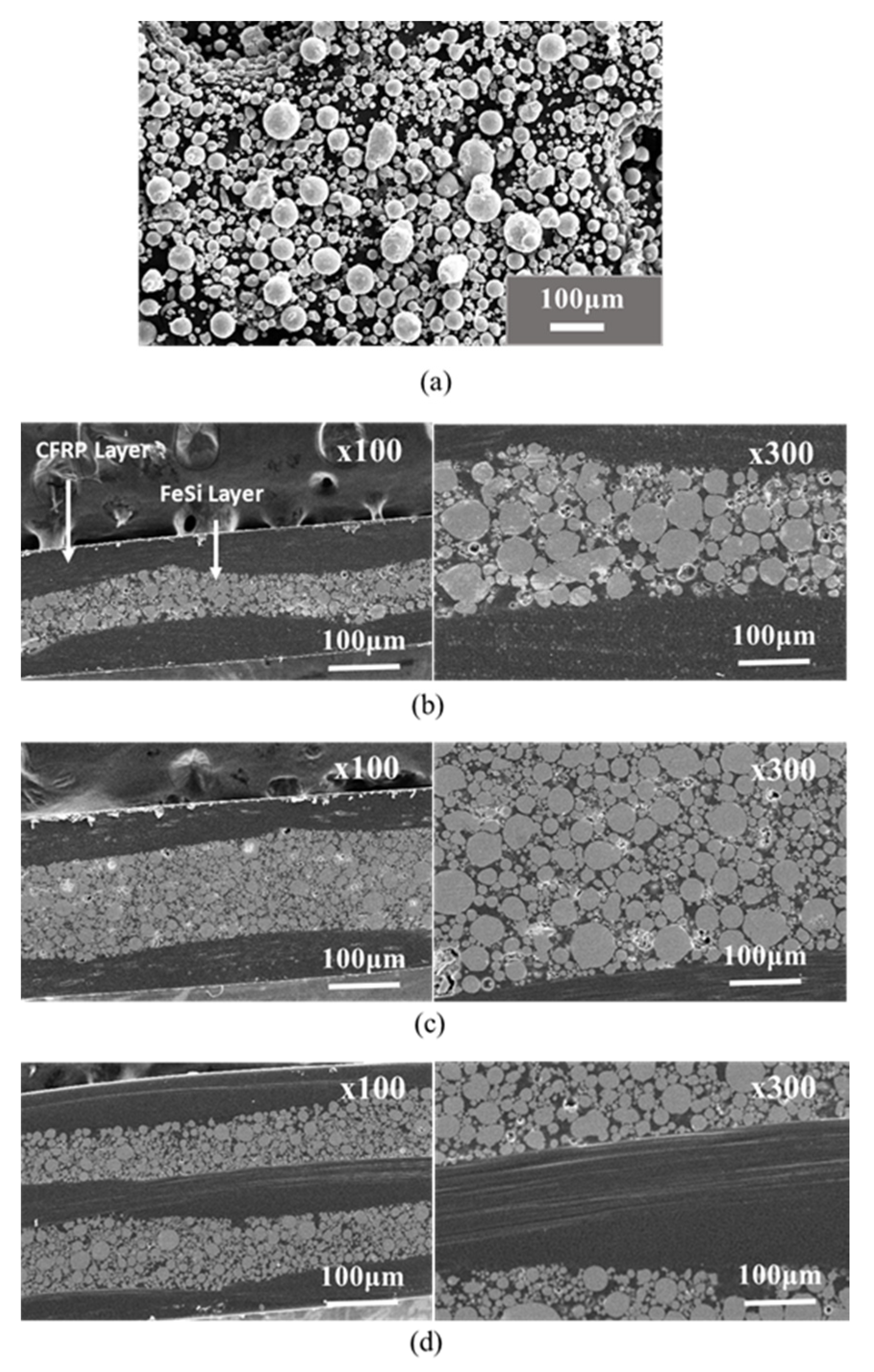

2.2. The Characterization of the Composites

3. Results and Discussion

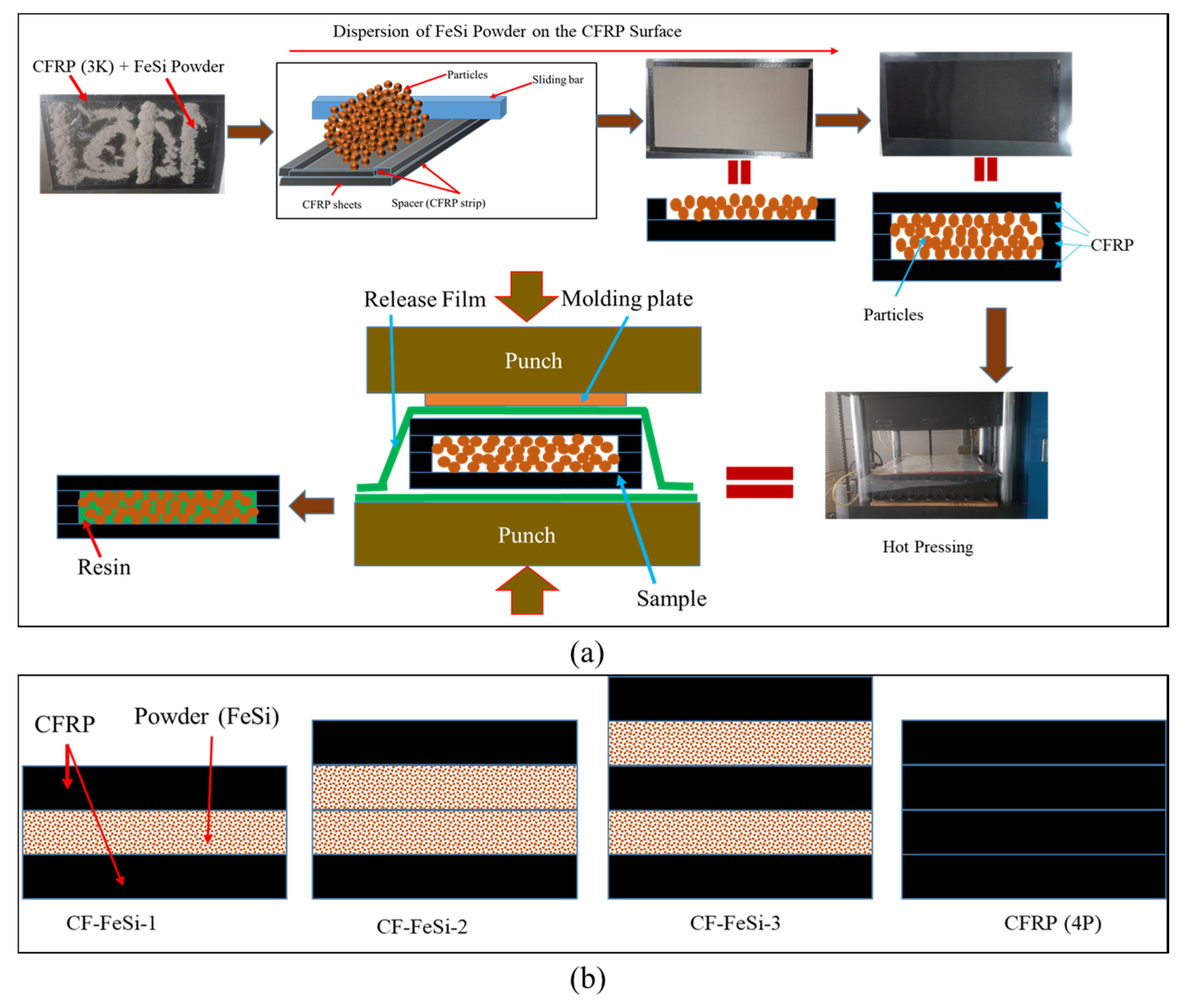

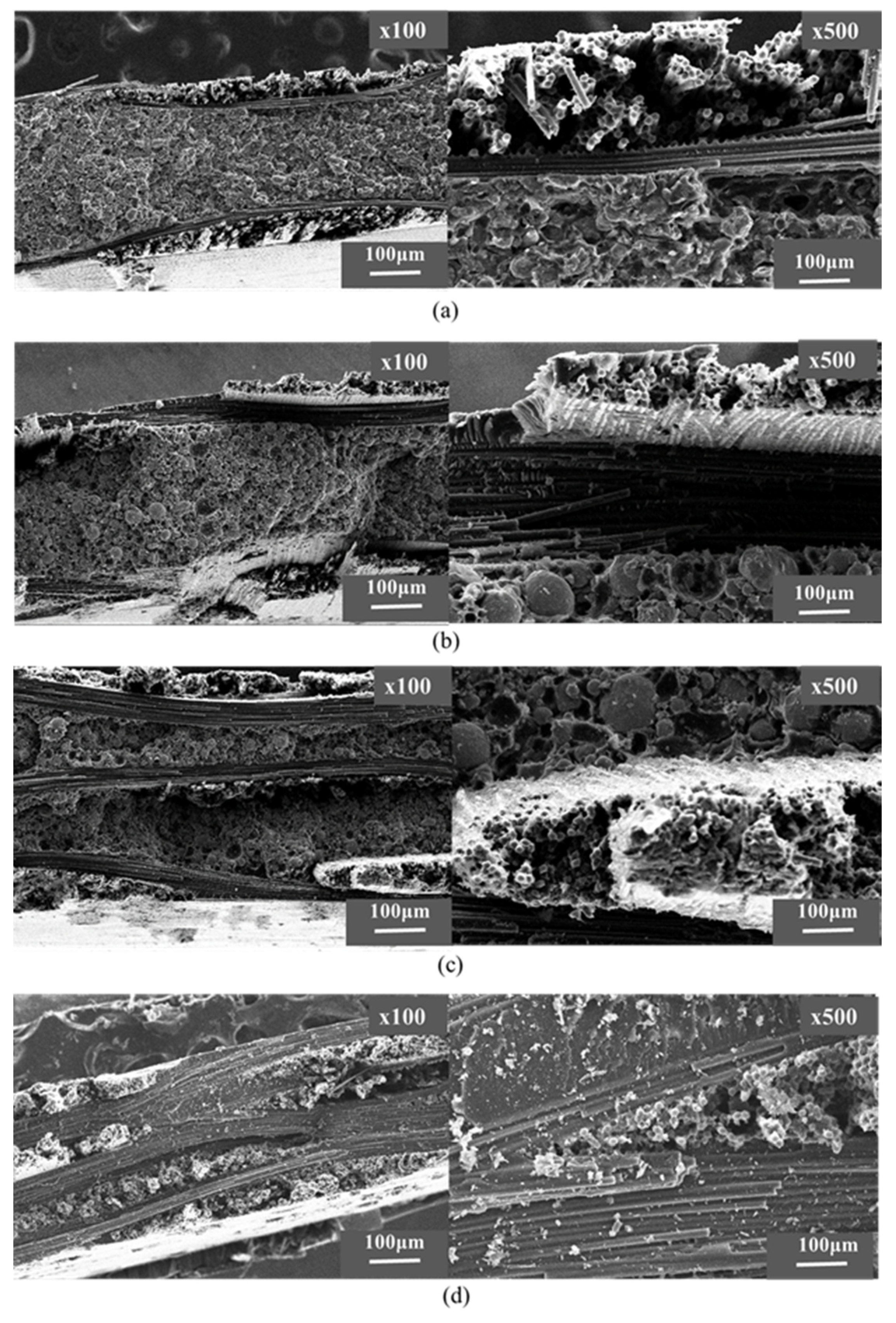

3.1. The Density and Morphology of the Composites

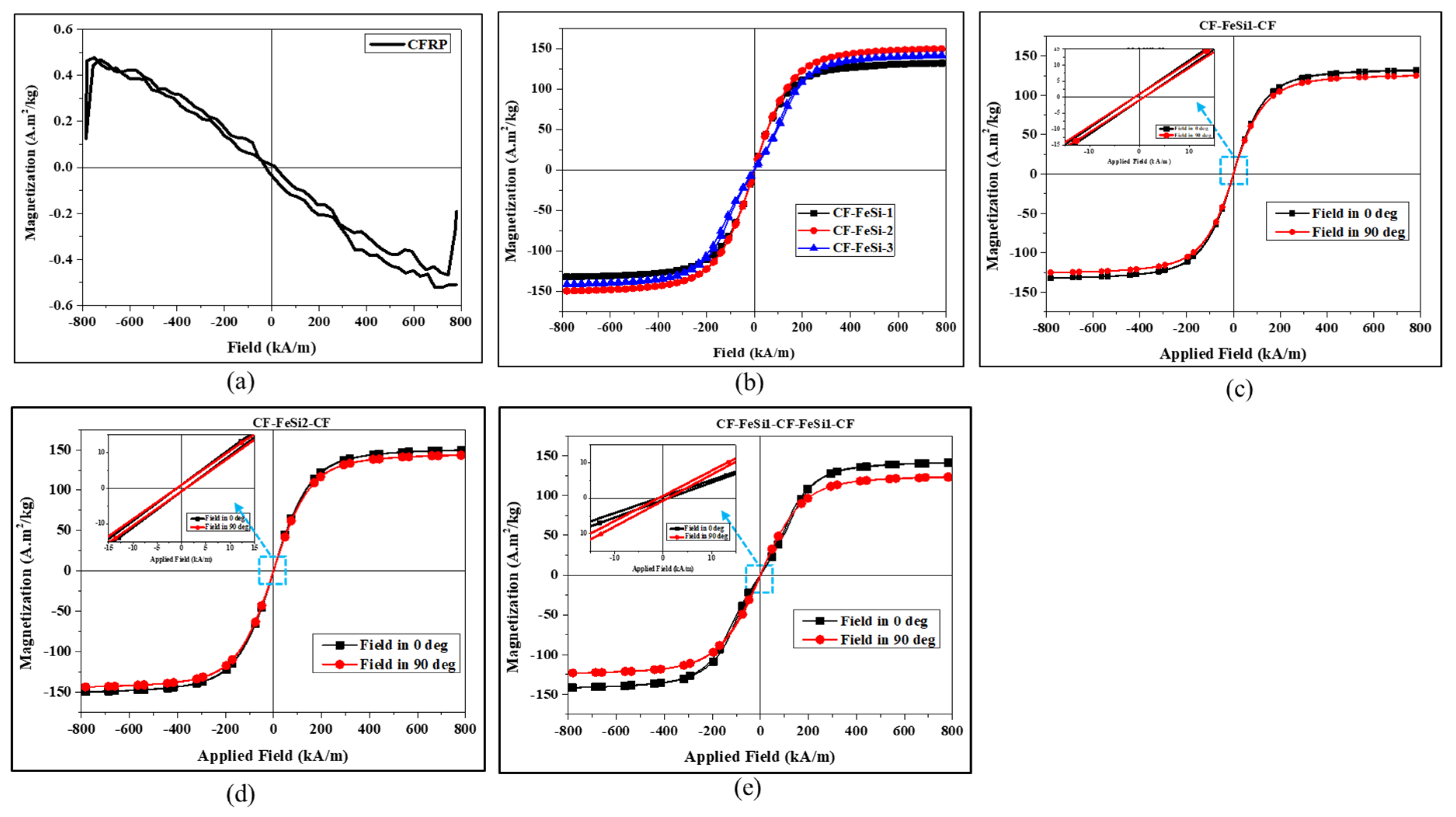

3.2. The Magnetic Properties of the CFRP-FeSi Composites

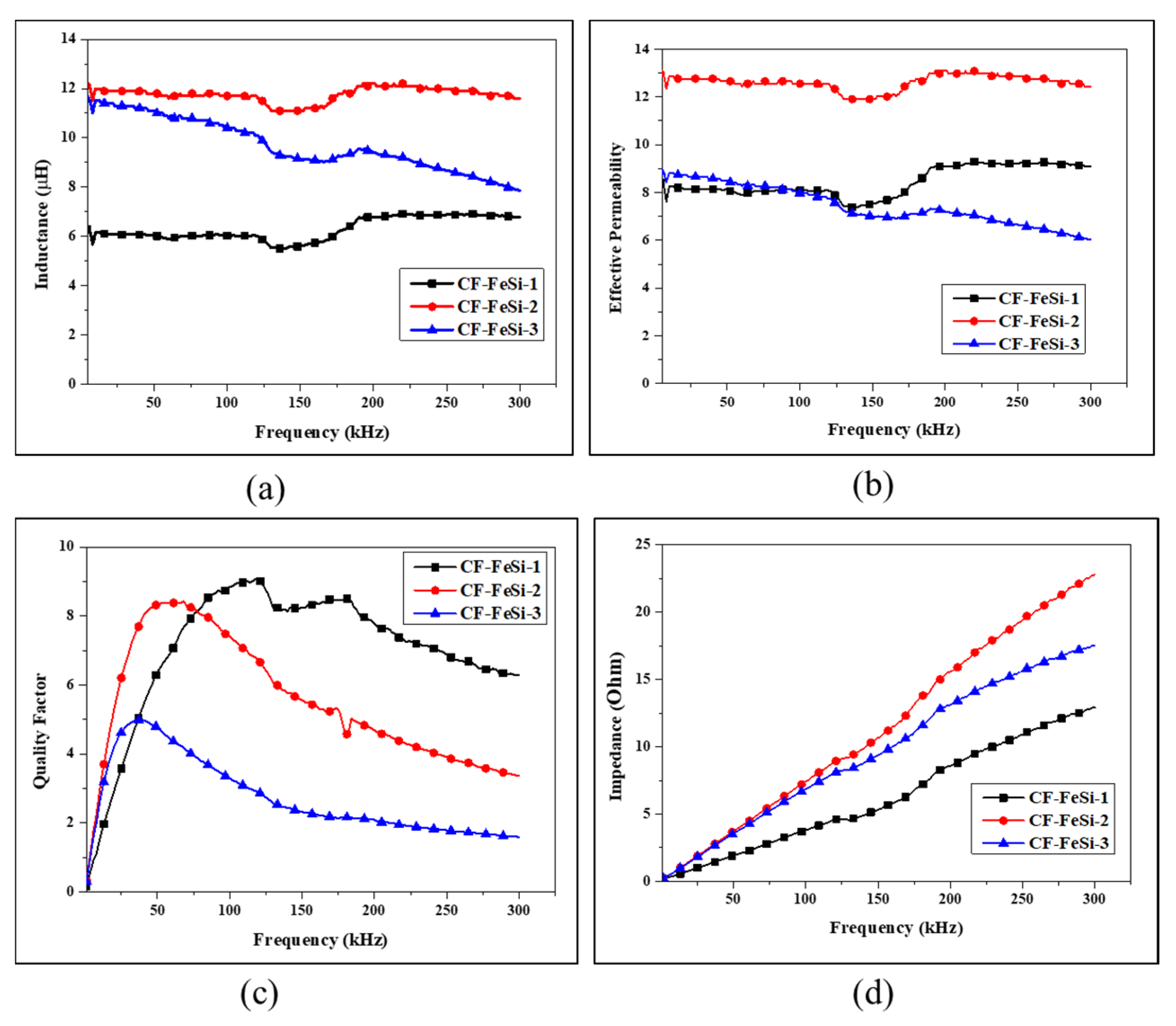

3.3. Inductance, Permeability, Impedance and Quality Factor of CFRP-FeSi Composites

3.4. The Electrical Resistivity of CFRP-FeSi Composites

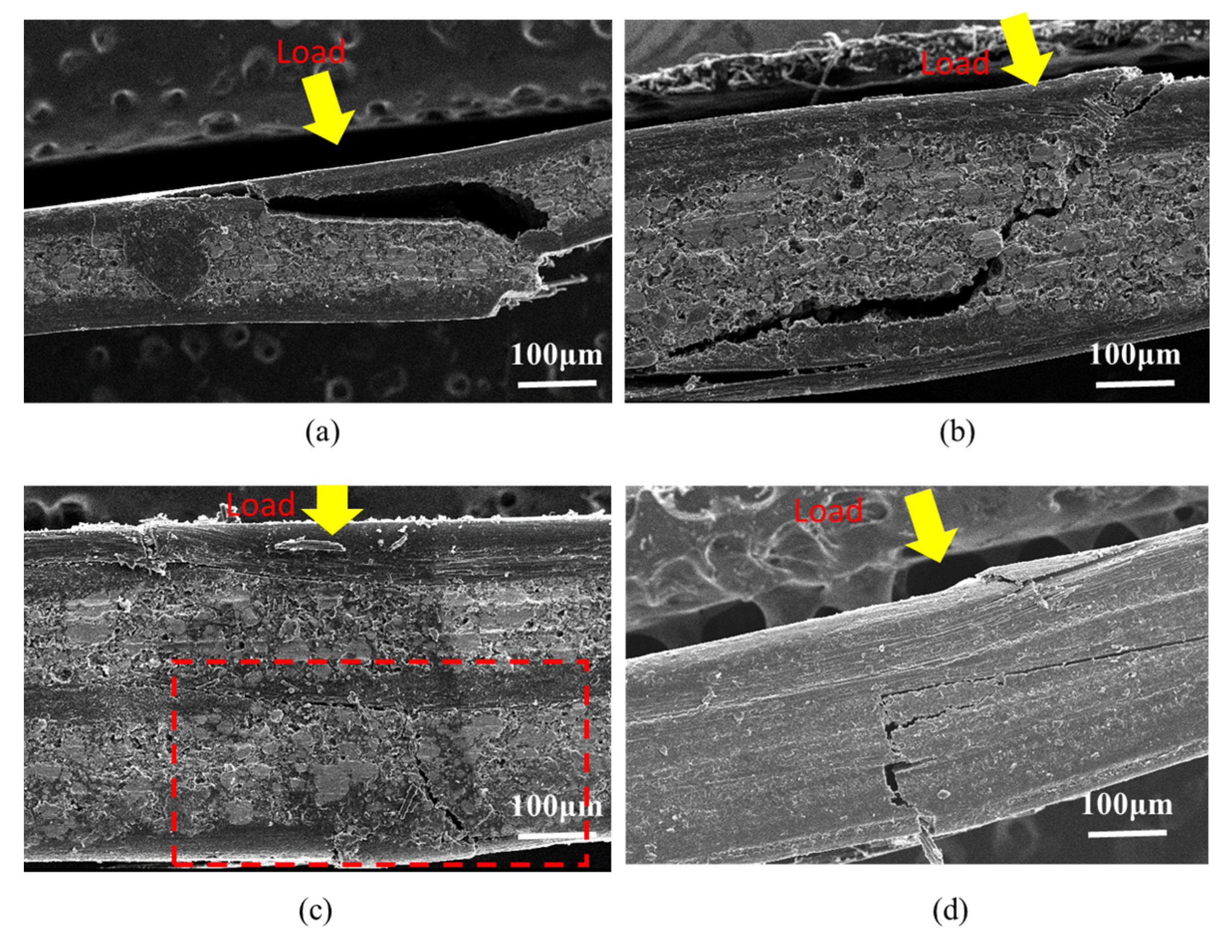

3.5. The Flexural and Tensile Properties of CFRP-FeSi Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Karataş, M.A.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Edwards, K.L. An overview of the technology of fibre-reinforced plastics for design purposes. Mater. Des. 1998, 19, 1–10. [Google Scholar] [CrossRef]

- Usman, M.; Farooq, S.H.; Umair, M.; Hanif, A. Axial compressive behavior of confined steel fiber reinforced high strength concrete. Constr. Build. Mater. 2020, 230, 117043. [Google Scholar] [CrossRef]

- Forintos, N.; Czigany, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers—A short review. Compos. Part B Eng. 2019, 162, 331–343. [Google Scholar] [CrossRef]

- Koumoulos, E.P.; Trompeta, A.-F.; Santos, R.-M.; Martins, M.; dos Santos, C.M.; Iglesias, V.; Böhm, R.; Gong, G.; Chiminelli, A.; Verpoest, I.; et al. Research and Development in Carbon Fibers and Advanced High-Performance Composites Supply Chain in Europe: A Roadmap for Challenges and the Industrial Uptake. J. Compos. Sci. 2019, 3, 86. [Google Scholar] [CrossRef]

- Rajak, D.; Pagar, D.; Menezes, P.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Li, Y.; Li, R.; Lu, L.; Huang, X. Experimental study of damage characteristics of carbon woven fabric/epoxy laminates subjected to lightning strike. Compos. Part A Appl. Sci. Manuf. 2015, 79, 164–175. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, Z.; Zhang, H.; Huang, D.; Gu, J.; Huang, Z.; Kang, F.; Hatton, T.A.; Rutledge, G.C. Electrospun magnetic carbon composite fibers: Synthesis and electromagnetic wave absorption characteristics. J. Appl. Polym. Sci. 2013, 127, 4288–4295. [Google Scholar] [CrossRef]

- Guo, H.; Chen, Z.; Li, J.; Li, L. Study of Fe/Ni alloy coated carbon fibres prepared by electroplating. Surf. Eng. 2019, 35, 841–847. [Google Scholar] [CrossRef]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. Electromagnetic shielding effectiveness of carbon fibre reinforced composites. Compos. Part B Eng. 2019, 173, 106906. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Hamim, S.U.; Akbari, M.K.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H.; Ghasali, E.; Zabet, M.; Munir, K.S.; Jia, S.; et al. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties. Compos. Part A Appl. Sci. Manuf. 2017, 92, 70–96. [Google Scholar] [CrossRef]

- Hegde, S.; Shenoy, B.S.; Chethan, K.N. Review on carbon fiber reinforced polymer (CFRP) and their mechanical performance. Mater. Today Proc. 2019, 19, 658–662. [Google Scholar] [CrossRef]

- Yokozeki, T.; Iwahori, Y.; Ishiwata, S.; Enomoto, K. Mechanical properties of CFRP laminates manufactured from unidirectional prepregs using CSCNT-dispersed epoxy. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2121–2130. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, F.; Ji, Y.; Yuan, B.; Hu, X. Effect of aramid pulp on low temperature flexural properties of carbon fibre reinforced plastics. Compos. Sci. Technol. 2020, 192. [Google Scholar] [CrossRef]

- Patel, K.; Potluri, P.; Yousaf, Z.; Wilkinson, A. Multi-scale reinforcement of epoxy composites—Use of carbon fibre fabrics coated with an epoxy binder containing MWCNTs for improved interlaminar fracture resistance. Compos. Part B Eng. 2019, 165, 109–119. [Google Scholar] [CrossRef]

- Choi, H.; Huang, H.; Kim, D.; Joe, C. Fracture behavior of carbon/epoxy laminated composite reinforced by iron powder. Korean J. Chem. Eng. 2008, 25, 1208–1211. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H.; Demir, O.; Şahin, Ö.S.; Avcı, A. Effects of alumina nanoparticles on dynamic impact responses of carbon fiber reinforced epoxy matrix nanocomposites. Eng. Sci. Technol. Int. J. 2018, 21, 399–407. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H.; Ahmet, A. Characterization of Tensile Properties And Toughness Mechanisms on Nano-Al2O3 Epoxy Nanocomposites. Int. J. Innov. Res. Sci. Eng. Technol. 2016, 5, 74–79. [Google Scholar]

- Kandola, B.; Sarker, F.; Luangtriratana, P.; Myler, P. Thermal protection of carbon fiber-reinforced composites by ceramic particles. Coatings 2016, 6, 22. [Google Scholar] [CrossRef]

- Bulut, M.; Alsaadi, M.; Erkliğ, A. A comparative study on the tensile and impact properties of Kevlar, carbon, and S-glass/epoxy composites reinforced with SiC particles. Mater. Res. Express 2018, 5, 025301. [Google Scholar] [CrossRef]

- Vedrtnam, A. Novel method for improving fatigue behavior of carbon fiber reinforced epoxy composite. Compos. Part B Eng. 2019, 157, 305–321. [Google Scholar] [CrossRef]

- Justo, J.; Osuna, S.; París, F. Design of composite materials with improved impact properties. Compos. Part B Eng. 2015, 76, 229–234. [Google Scholar] [CrossRef]

- Wang, R.; He, F.; Wan, Y.; Qi, Y. Preparation and characterization of a kind of magnetic carbon fibers used as electromagnetic shielding materials. J. Alloys Compd. 2012, 514, 35–39. [Google Scholar] [CrossRef]

- Slosarczyk, A.; Klapiszewski, L.; Buchwald, T.; Krawczyk, P.; Kolanowski, L.; Lota, G. Carbon fiber and nickel coated carbon fiber-silica aerogel nanocomposite as low-frequency microwave absorbing materials. Materials 2020, 13, 400. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Pasha, S.K.K. Recent advances in electromagnetic interference shielding properties of metal and carbon filler reinforced flexible polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 49–71. [Google Scholar] [CrossRef]

- Park, K.Y.; Han, J.H.; Lee, S.B.; Yi, J.W. Microwave absorbing hybrid composites containing Ni-Fe coated carbon nanofibers prepared by electroless plating. Compos. Part A Appl. Sci. Manuf. 2011, 42, 573–578. [Google Scholar] [CrossRef]

- Singh, A.P.; Garg, P.; Alam, F.; Singh, K.; Mathur, R.B.; Tandon, R.P.; Chandra, A.; Dhawan, S.K. Phenolic resin-based composite sheets filled with mixtures of reduced graphene oxide, γ-Fe2O3 and carbon fibers for excellent electromagnetic interference shielding in the X-band. Carbon N. Y. 2012, 50, 3868–3875. [Google Scholar] [CrossRef]

- Jalali, M.; Dauterstedt, S.; Michaud, A.; Wuthrich, R. Electromagnetic shielding of polymer-matrix composites with metallic nanoparticles. Compos. Part B Eng. 2011, 42, 1420–1426. [Google Scholar] [CrossRef]

- Yang, W.; Fu, Y.; Xia, A.; Zhang, K.; Wu, Z. Microwave absorption property of Ni-Co-Fe-P-coated flake graphite prepared by electroless plating. J. Alloys Compd. 2012, 518, 6–10. [Google Scholar] [CrossRef]

- Liao, F.; Han, X.; Zhang, Y.; Xu, C.; Chen, H. Carbon fabrics coated with nickel film through alkaline electroless plating technique. Mater. Lett. 2017, 205, 165–168. [Google Scholar] [CrossRef]

- Wang, L.; He, F.; Wan, Y. Facile synthesis and electromagnetic wave absorption properties of magnetic carbon fiber coated with Fe-Co alloy by electroplating. J. Alloys Compd. 2011, 509, 4726–4730. [Google Scholar] [CrossRef]

- Electroless (Autocatalytic) vs. Electrolytic Plating—Sharretts Plating Company. Available online: https://www.sharrettsplating.com/blog/electroless-autocatalytic-vs-electrolytic-plating/ (accessed on 26 September 2020).

- What Are the Advantages and Disadvantages of Electroplating?|eNotes. Available online: https://www.enotes.com/homework-help/what-advantages-disadvantages-electroplating-627911?__cf_chl_jschl_tk__=4215d0da00d01ed653fe0431986fb8d86628753a-1601111449-0-AXmODq1T49OoKIzV-wA72CRWHRUS8EcZHXj7Lf-J1VT2qjp6qxDjag-Ac-wc4AVT-XSviiHGFWv1W_IDdEcZ50BNRuWIa4ffDN9-O9wm_KzD1wDIvRua7F83gEDJn4MbhDdRyFkN6YhSVM9eJzC69wECQ3LUHGOiP5GaEAMC35VozeKlLuwCTyBQzK8cFT05ir7idd7HQTlexASgJWUgOYVgpPIE68I33TW63ydmKsuHv8sjt6rIHlRHNpMDePZvmG9VbBkx_9UBvBX0oJcJPWpDk5H0lynh0dEJCL0Pn56MoW3jz6WLyjAAdXYo0VCsC7cMZRHwaeQ46a4Rb2kUnDzdS03MyWOLggHY1WTE5X3DoyNOXcYeAejSQoWnHZZjxvZetviYatUhEthuVkWCaAvG9eOjJ0j-blTWs5YuO2-X (accessed on 26 September 2020).

- Sabeen, A.H.; Kamaruddin, S.N.B.; Noor, Z.Z. Environmental impacts assessment of industrial wastewater treatment system using electroless nickel plating and life cycle assessment approaches. Int. J. Environ. Sci. Technol. 2019, 16, 3171–3182. [Google Scholar] [CrossRef]

- Luangtriratana, P.; Kandola, B.K.; Myler, P. Ceramic particulate thermal barrier surface coatings for glass fibre-reinforced epoxy composites. Mater. Des. 2015, 68, 232–244. [Google Scholar] [CrossRef]

- ASTM International. ASTM D790-03-Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulation Materials. In ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM International. ASTM D3039, Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. In ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- BK Precision. 300 kHz Bench LCR Meter (Model 891) User Manual; BK Precision: Yorba Linda, CA, USA, 2015. [Google Scholar]

- MPC Technical Information of Samwha Electronics—Magentic Design Formulas. Available online: http://www.samwha.com/electronics/product/product_mpc_tech11.aspx (accessed on 20 April 2020).

- Wang, J.; Fan, X.; Wu, Z.; Li, G. Intergranular insulated Fe/SiO2 soft magnetic composite for decreased core loss. Adv. Powder Technol. 2016, 27, 1189–1194. [Google Scholar] [CrossRef]

- The Calculation of Inductance and Core. Available online: http://www.pocomagnetic.com/html/2014/03/06/2014030605592122540691.html (accessed on 20 April 2020).

- Magnetic Powder Core. Available online: http://changsung.com/_new/wp-content/uploads/2018/11/core_1809_small.pdf (accessed on 30 September 2020).

- Soft Magnetic Powder Core, Chang Sung Corporation. Available online: http://changsung.com/_new/wp-content/uploads/2018/11/core_1809_small.pdf (accessed on 20 April 2020).

- Zhao, G.; Wu, C.; Yan, M. Fabrication and growth mechanism of iron oxide insulation matrix for Fe soft magnetic composites with high permeability and low core loss. J. Alloys Compd. 2017, 710, 138–143. [Google Scholar] [CrossRef]

- Heck, C. Magnetic Materials and Their Applications; Heck, C., Ed.; Butterworth Co: London, UK, 1974; ISBN 9780408703994. [Google Scholar]

- Leng, W. Design-Oriented Modeling and Optimization of On-Chip Inductors. Master’s Thesis, University of California, Oakland, CA, USA, 2015. [Google Scholar]

- Massarini, A. Analytical Approach to the Calculation of Parasitic Capacitance between Winding Turns. In Proceedings of the 2018 IEEE 4th International Forum on Research and Technology for Society and Industry (RTSI), Palermo, Italy, 10–13 September 2018. [Google Scholar]

- Pasko, S.W.; Kazimierczuk, M.K.; Grzesik, B. Self-capacitance of coupled toroidal inductors for EMI filters. IEEE Trans. Electromagn. Compat. 2015, 57, 216–223. [Google Scholar] [CrossRef]

- Sudhoff, S.D.; Singh, H.; Duppalli, V.S.; Swanson, R.R. Capacitance of UR-Core and C-Core Common Mode Inductors. IEEE Power Energy Technol. Syst. J. 2019, 6, 113–121. [Google Scholar] [CrossRef]

- Legg, V.E. Analysis of Quality Factor of Annular Core Inductors. Bell Syst. Tech. J. 1960, 39, 105–126. [Google Scholar] [CrossRef]

- Morgan, V.T.; Findlay, R.D. The effect of frequency on the resistance and internal inductance of bare ACSR conductors. IEEE Trans. Power Deliv. 1991, 6, 1319–1326. [Google Scholar] [CrossRef]

- Frequency-Impedance Characteristics of Inductors and Determination of Inductor’s Resonance Frequency. Available online: https://techweb.rohm.com/knowledge/emc/s-emc/04-s-emc/8136 (accessed on 28 September 2020).

| Thickness (mm) | Fiber Areal Weight (g/m2) | Weave Density (Warf/Fill) | Resin Content | Fiber Strength (MPa) |

|---|---|---|---|---|

| 0.227 | 204 | 12.5/13.5 | 40% | 4900 |

| Composites | Materials ID | Thickness (mm) | Density (g/cm3) |

|---|---|---|---|

| CFRP-FeSi1-CFRP | CF-FeSi-1 | 0.62 | 3.38 |

| CFRP-FeSi2-CFRP | CF-FeSi-2 | 0.83 | 3.76 |

| CFRP-FeSi-CFRP-FeSi-CFRP | CF-FeSi-3 | 1.06 | 3.72 |

| CFPR (four-ply) | CFRP (4P) | 0.78 | 1.54 |

| Composites | Material ID | Coercivity, Hc (kA/m) | Saturation Magnetization, Ms (A.m2/kg) | Remanence, Mr (A.m2/kg) | |||

|---|---|---|---|---|---|---|---|

| Field In 0° | Field in 90° | Field in 0° | Field in 90° | Field in 0° | Field in 90° | ||

| CFRP-FeSi1-CFRP | CF-FeSi-1 | 0.92 | 0.92 | 132.22 | 125.11 | 0.97 | 0.92 |

| CFRP-FeSi2-CFRP | CF-FeSi-2 | 0.92 | 0.94 | 149.71 | 143.55 | 0.93 | 0.89 |

| CFRP-FeSi-CFRP-FeSi-CFRP | CF-FeSi-3 | 1.04 | 0.94 | 141.63 | 123.47 | 0.47 | 0.66 |

| CFRP (4P) | CFRP (4P) | - | - | - | - | - | - |

| Composites | Materials ID | Electrical Resistivity (mΩ.cm) |

|---|---|---|

| CFRP-FeSi1-CFRP | CF-FeSi-1 | 18.88 |

| CFRP-FeSi2-CFRP | CF-FeSi-2 | 25.84 |

| CFRP-FeSi-CFRP-FeSi-CFRP | CF-FeSi-3 | 29.74 |

| CFPR (four-ply) | CFRP (4P) | 6.90 |

| Materials | Flexural Strength (MPa) | Tangent Modulus of Elasticity (GPa) | Chord Modulus (0.2%–0.6% Strain) (GPa) | ||||

|---|---|---|---|---|---|---|---|

| Samples | Specimen No | Each Specimen | Average | Each Specimen | Average | Each Specimen | Average |

| CF-FeSi-1 | 1 | 1233.09 | 1178.11 | 67.68 | 64.96 | 67.29 | 64.65 |

| 2 | 1083.25 | 67.00 | 66.70 | ||||

| 3 | 1079.21 | 61.22 | 60.75 | ||||

| 4 | 1316.09 | 67.70 | 67.37 | ||||

| 5 | 1178.94 | 61.22 | 61.14 | ||||

| CF-FeSi-2 | 1 | 944.48 | 855.53 | 62.25 | 64.79 | 62.28 | 64.81 |

| 2 | 773.67 | 64.40 | 64.57 | ||||

| 3 | 823.47 | 60.90 | 60.96 | ||||

| 4 | 857.54 | 63.67 | 63.70 | ||||

| 5 | 878.51 | 72.72 | 72.55 | ||||

| CF-FeSi-3 | 1 | 1006.84 | 934.57 | 62.70 | 60.07 | 62.49 | 59.95 |

| 2 | 850.80 | 58.34 | 58.38 | ||||

| 3 | 994.25 | 58.32 | 58.04 | ||||

| 4 | 841.16 | 61.00 | 60.98 | ||||

| 5 | 979.80 | 59.97 | 59.85 | ||||

| CFRP(4P) | 1 | 1574.26 | 1429.90 | 81.23 | 76.91 | 81.22 | 76.90 |

| 2 | 1463.20 | 74.31 | 74.37 | ||||

| 3 | 1349.85 | 77.24 | 77.13 | ||||

| 4 | 1425.96 | 73.17 | 73.18 | ||||

| 5 | 1336.24 | 78.63 | 78.60 | ||||

| Specimen No | Flexural Toughness (J/mm3) | |||

|---|---|---|---|---|

| CF-FeSi-1 | CF-FeSi-2 | CF-FeSi-3 | CFRP (4P) | |

| 1 | 11.14 | 7.41 | 8.39 | 15.07 |

| 2 | 8.33 | 5.51 | 7.29 | 13.67 |

| 3 | 9.28 | 5.87 | 9.00 | 12.74 |

| 4 | 12.47 | 7.37 | 6.75 | 13.27 |

| 5 | 13.28 | 6.34 | 8.49 | 11.18 |

| Average | 10.90 | 6.50 | 7.99 | 13.19 |

| Materials | Tensile Strength (MPa) | Tensile Chord Modulus of Elasticity (GPa) | Poisson’s Ratio by Chord Method | ||||

|---|---|---|---|---|---|---|---|

| Samples | Specimen No | Each Specimen | Average | Each Specimen | Average | Each Specimen | Average |

| CF-FeSi-1 | 1 | 495.73 | 475.28 | 48.85 | 48.90 | 0.08 | 0.09 |

| 2 | 506.06 | 48.09 | 0.08 | ||||

| 3 | 424.05 | 49.77 | 0.11 | ||||

| CF-FeSi-2 | 1 | 329.34 | 306.98 | 31.66 | 33.84 | 0.07 | 0.07 |

| 2 | 294.65 | 33.65 | 0.07 | ||||

| 3 | 296.95 | 36.21 | 0.08 | ||||

| CF-FeSi-3 | 1 | 365.09 | 380.12 | 44.02 | 42.80 | 0.10 | 0.10 |

| 2 | 378.11 | 41.75 | 0.09 | ||||

| 3 | 397.16 | 42.64 | 0.09 | ||||

| CFRP (4P) | 1 | 774.97 | 775.59 | 65.37 | 65.17 | 0.05 | 0.06 |

| 2 | 780.51 | 65.44 | 0.05 | ||||

| 3 | 771.28 | 64.68 | 0.06 | ||||

| Specimen No | Tensile Toughness (J/mm3) | |||

|---|---|---|---|---|

| CF-FeSi-1 | CF-FeSi-2 | CF-FeSi-3 | CFRP (4P) | |

| 1 | 282.35 | 271.74 | 175.27 | 449.46 |

| 2 | 302.11 | 165.47 | 196.25 | 448.93 |

| 3 | 197.13 | 162.93 | 216.96 | 436.66 |

| Average | 260.53 | 200.04 | 196.16 | 445.02 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tugirumubano, A.; Go, S.H.; Shin, H.J.; Kwac, L.K.; Kim, H.G. Fabrication and Characterization of Carbon-Fiber-Reinforced Polymer–FeSi Composites with Enhanced Magnetic Properties. Polymers 2020, 12, 2325. https://doi.org/10.3390/polym12102325

Tugirumubano A, Go SH, Shin HJ, Kwac LK, Kim HG. Fabrication and Characterization of Carbon-Fiber-Reinforced Polymer–FeSi Composites with Enhanced Magnetic Properties. Polymers. 2020; 12(10):2325. https://doi.org/10.3390/polym12102325

Chicago/Turabian StyleTugirumubano, Alexandre, Sun Ho Go, Hee Jae Shin, Lee Ku Kwac, and Hong Gun Kim. 2020. "Fabrication and Characterization of Carbon-Fiber-Reinforced Polymer–FeSi Composites with Enhanced Magnetic Properties" Polymers 12, no. 10: 2325. https://doi.org/10.3390/polym12102325

APA StyleTugirumubano, A., Go, S. H., Shin, H. J., Kwac, L. K., & Kim, H. G. (2020). Fabrication and Characterization of Carbon-Fiber-Reinforced Polymer–FeSi Composites with Enhanced Magnetic Properties. Polymers, 12(10), 2325. https://doi.org/10.3390/polym12102325