Investigation on Mode I Fracture Toughness of Woven Carbon Fiber-Reinforced Polymer Composites Incorporating Nanomaterials

Abstract

1. Introduction

2. Experimental Program

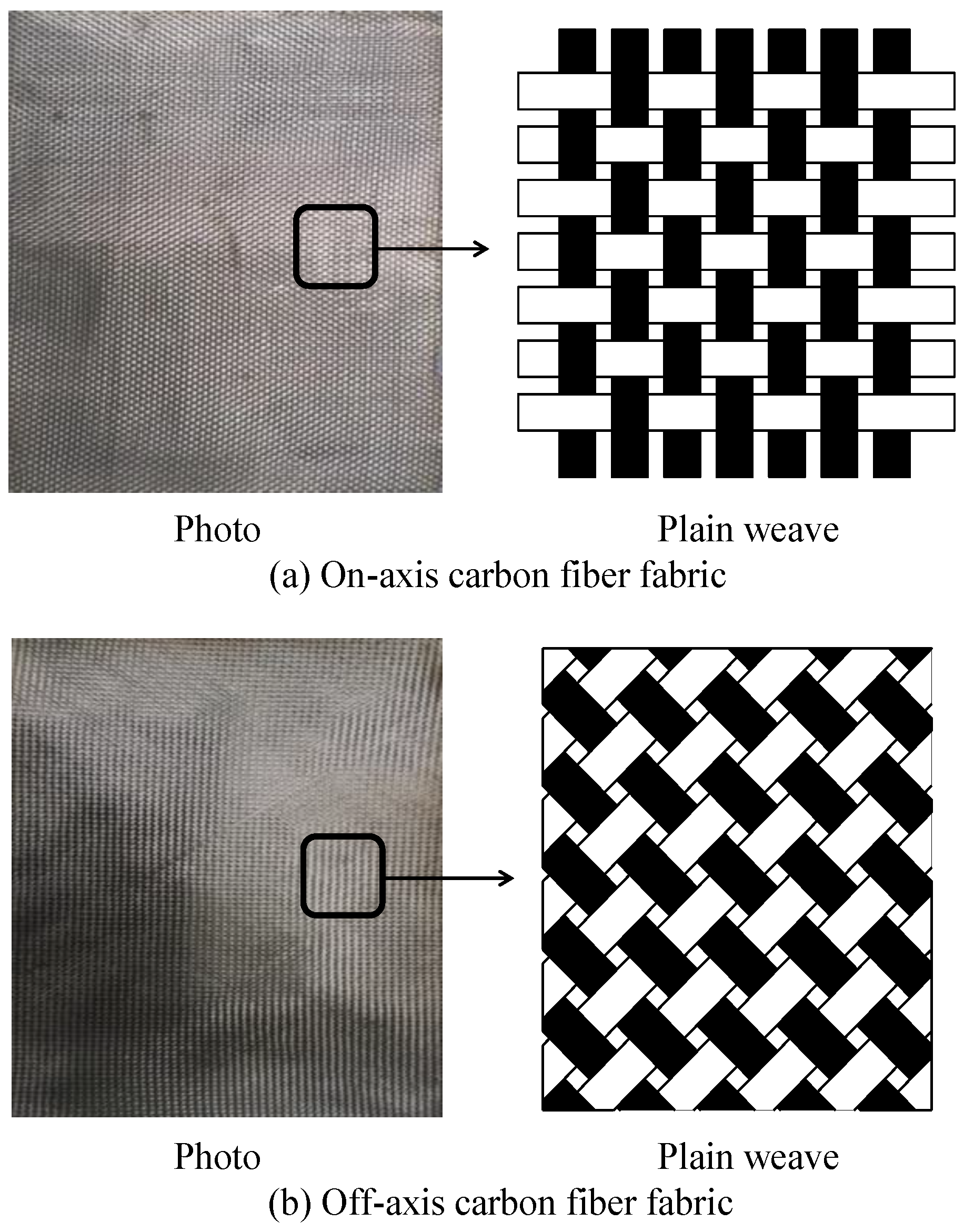

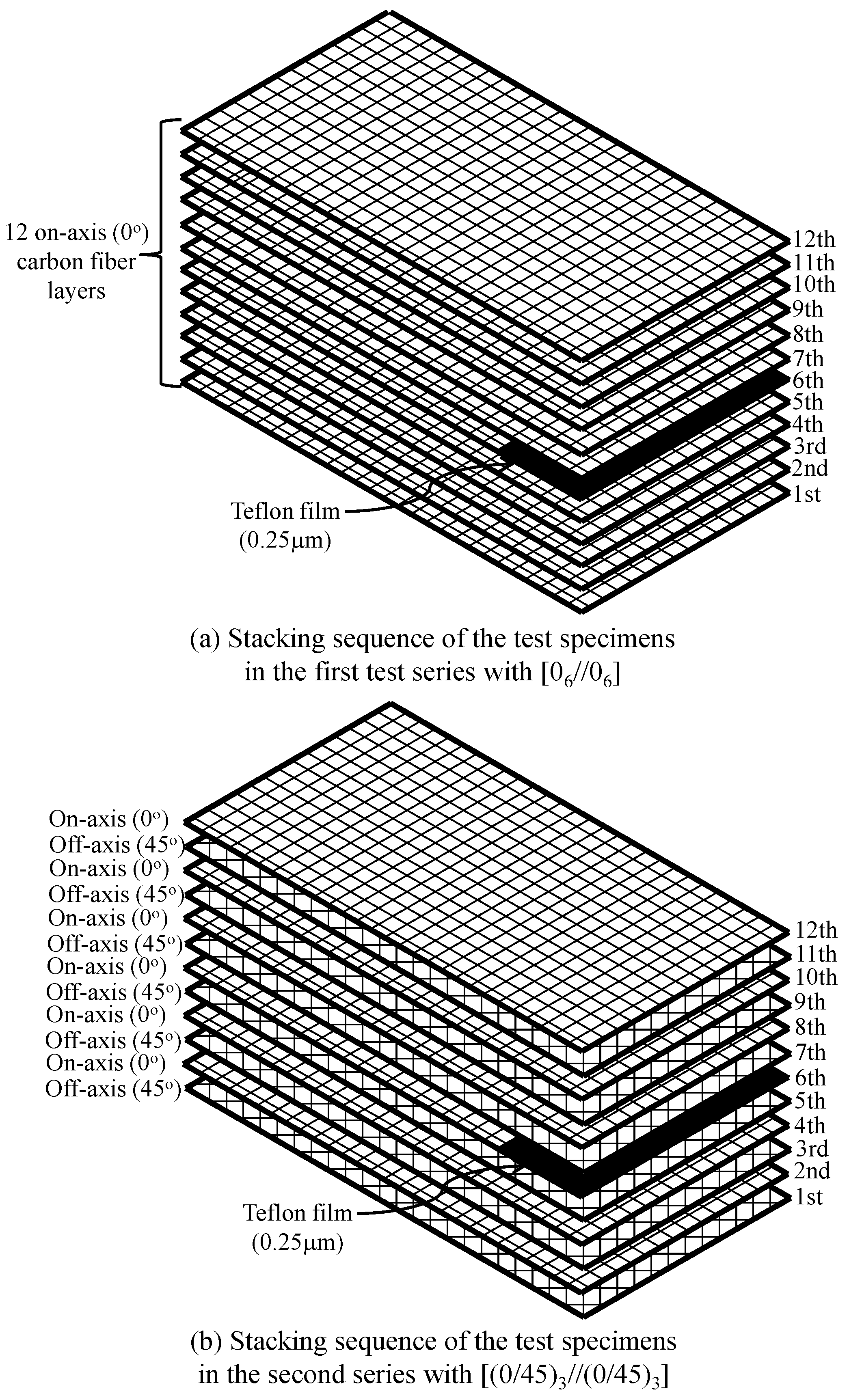

2.1. Material Properties

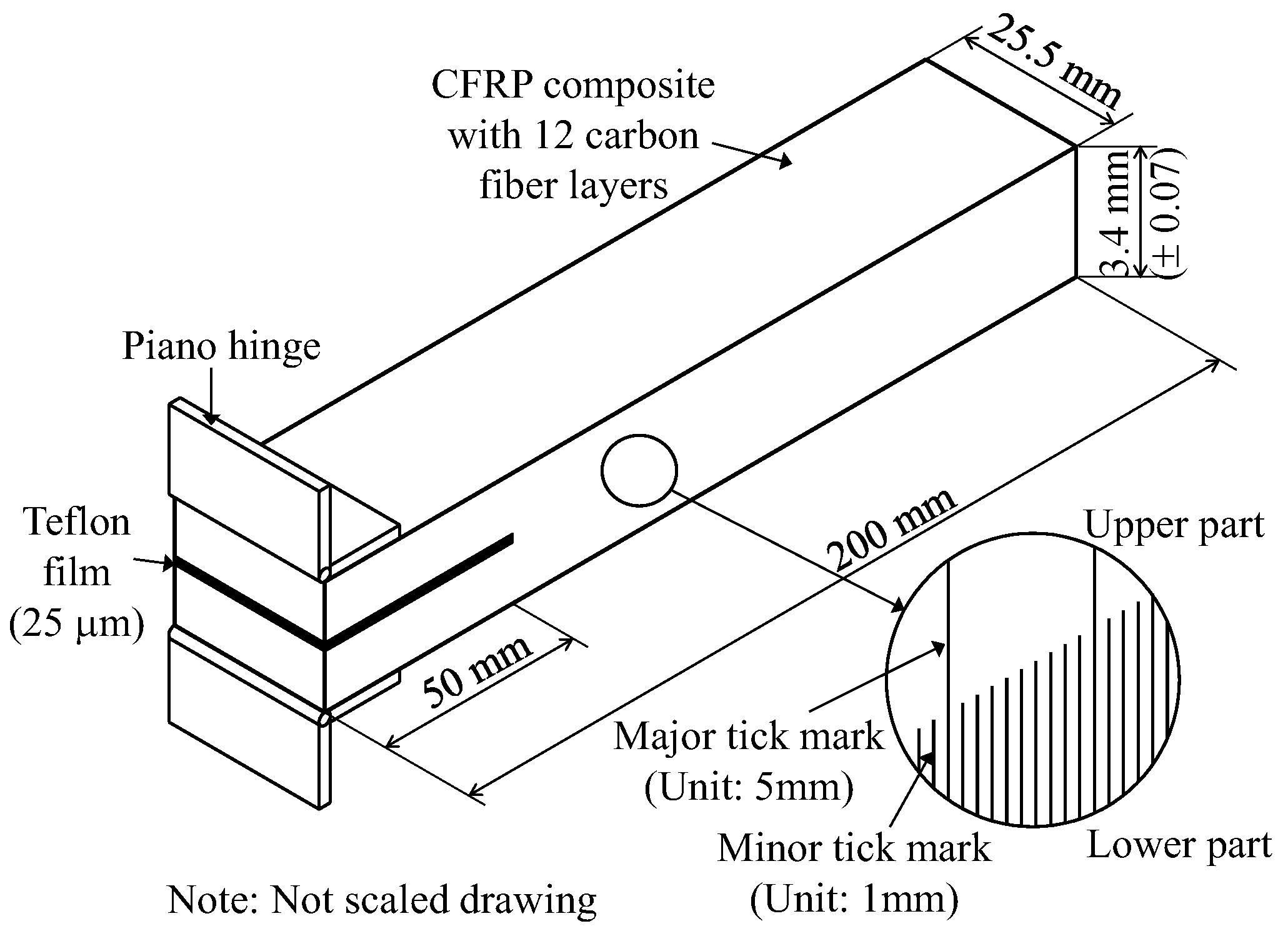

2.2. Manufacture of the Test Specimen

2.3. Carbon-Fiber Volume Fraction

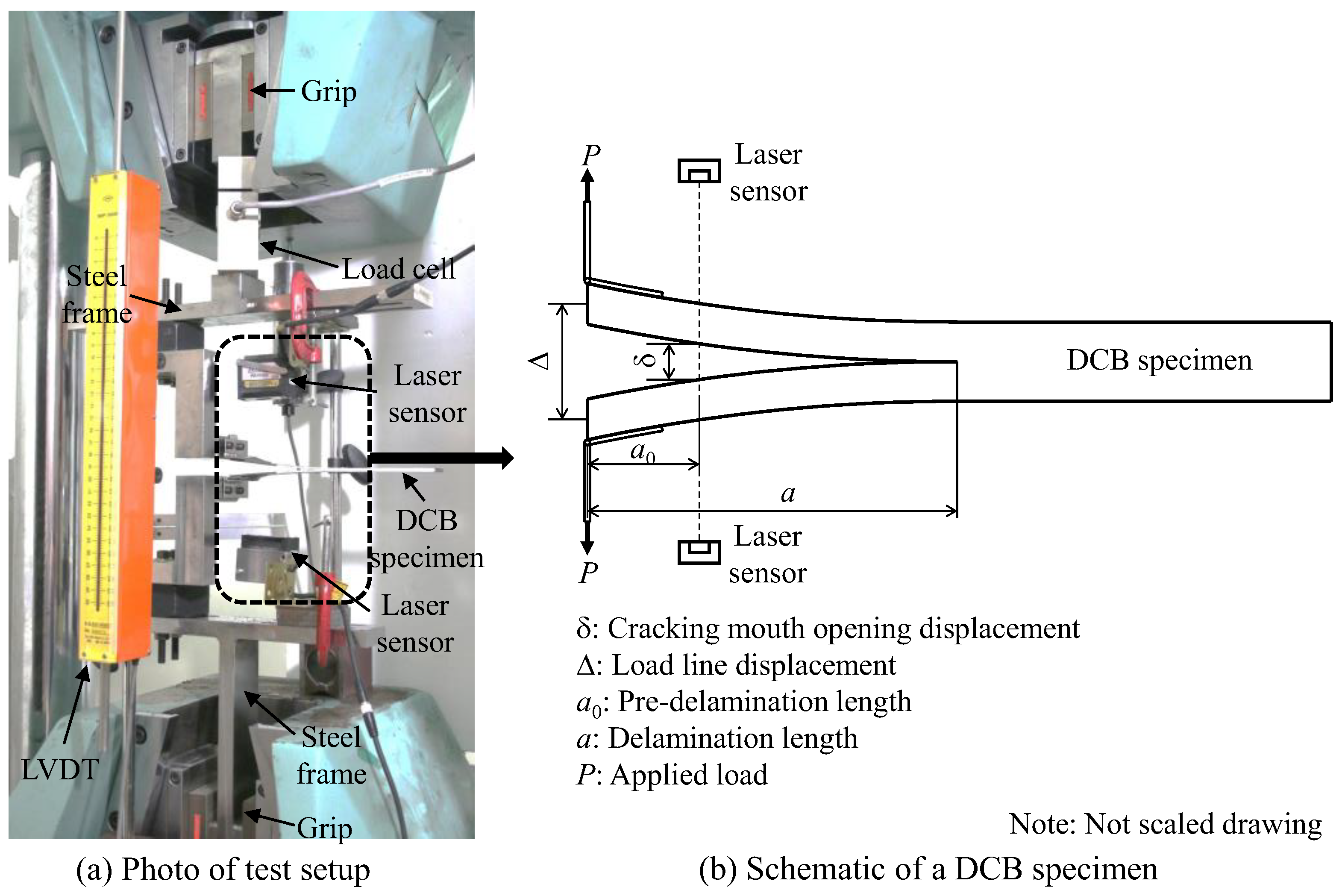

2.4. Test Setup for Mode I Fracture Toughness

3. Test Results and Discussions

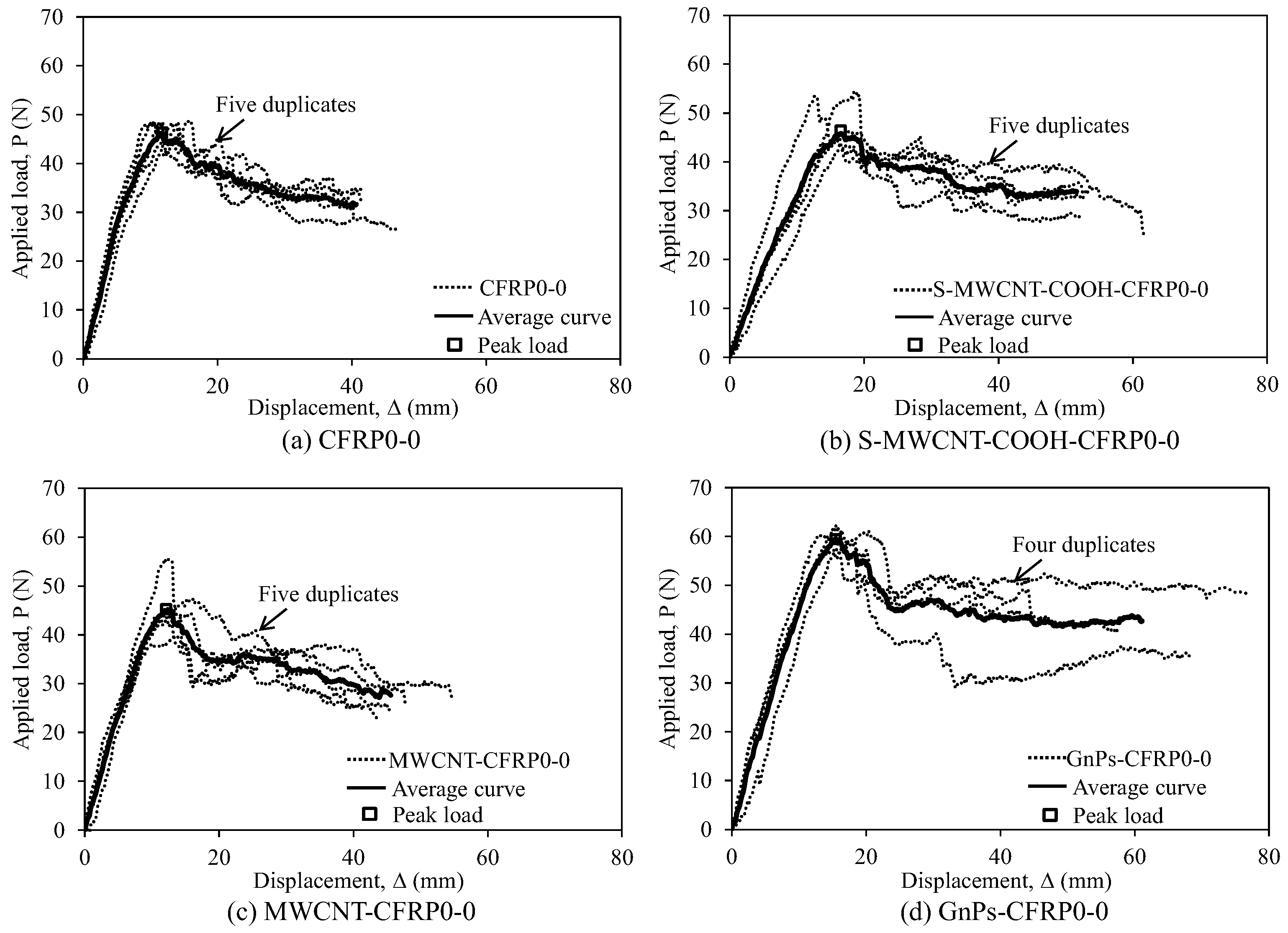

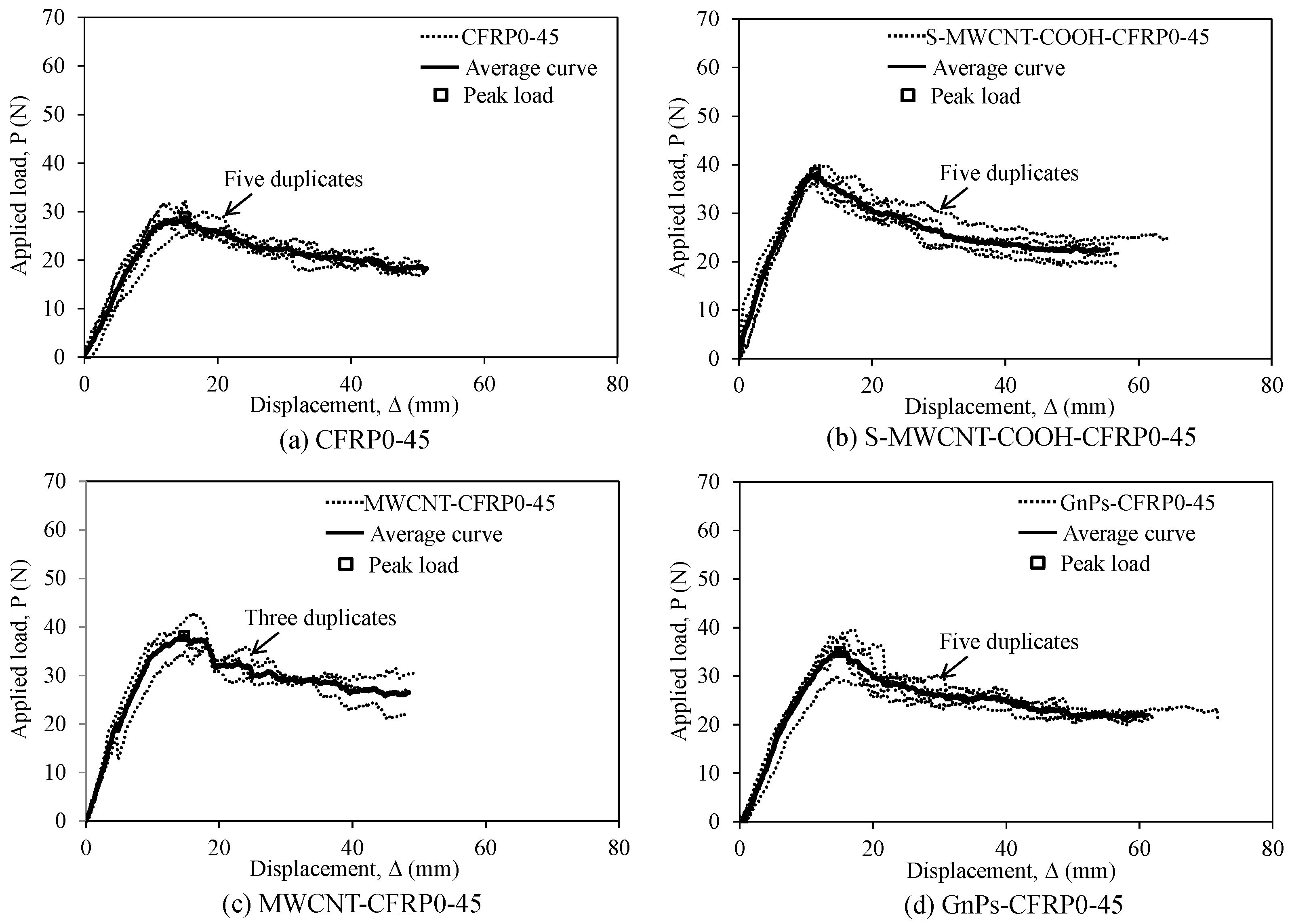

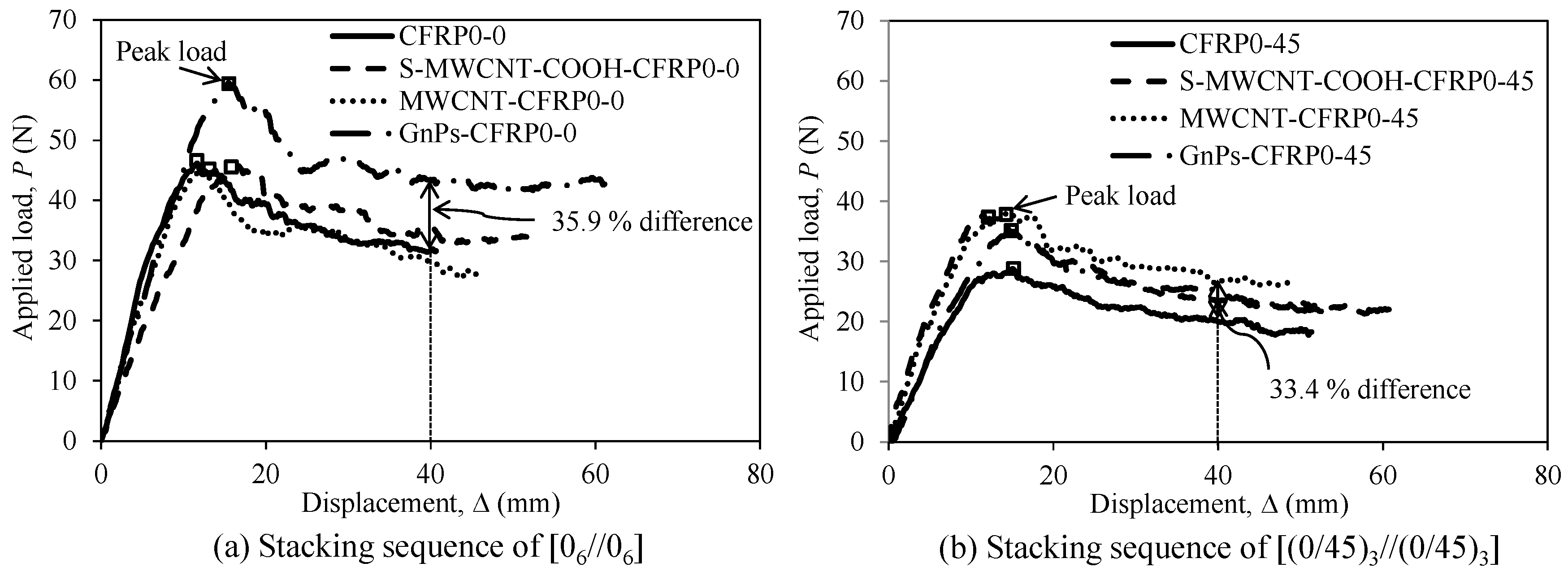

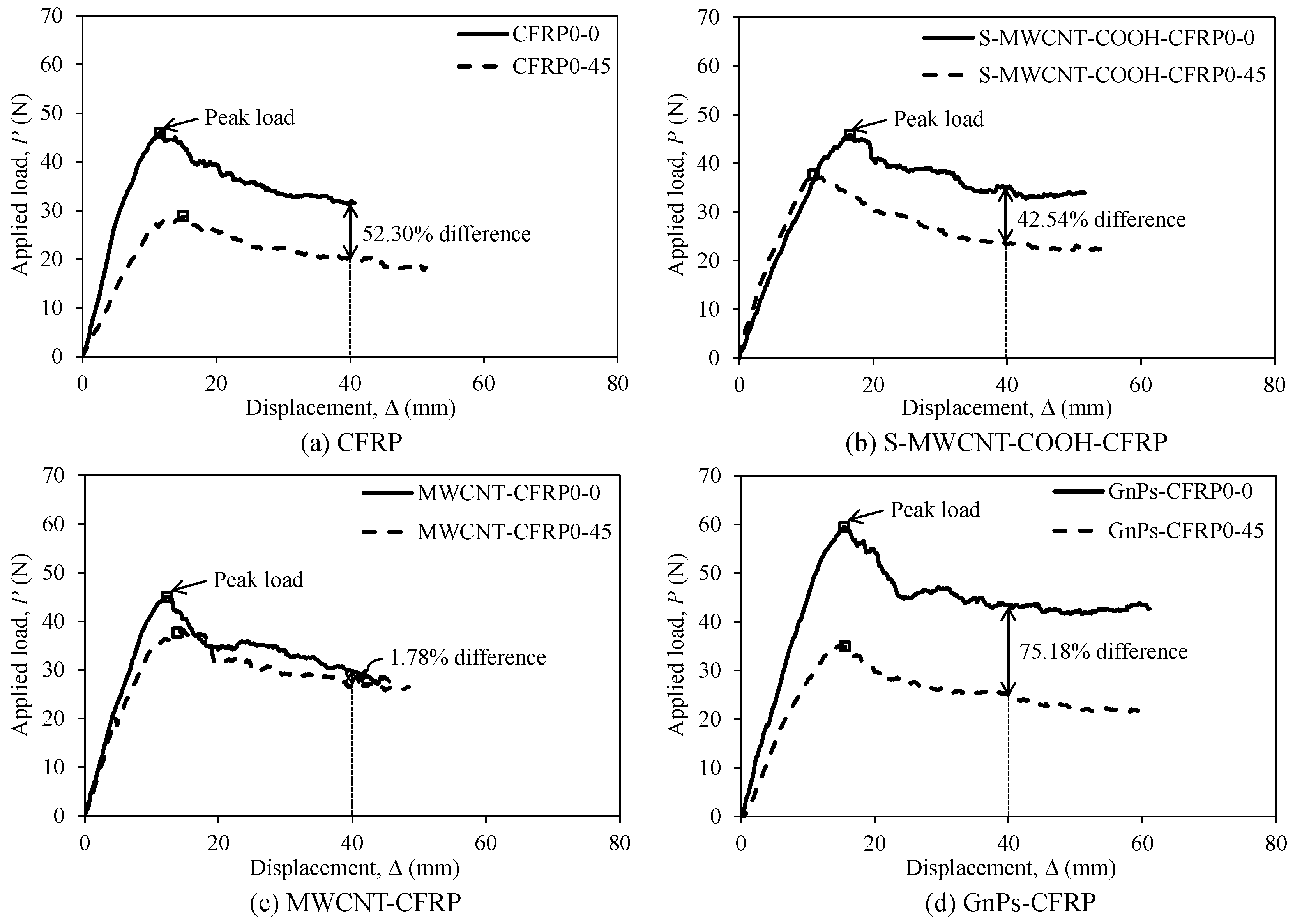

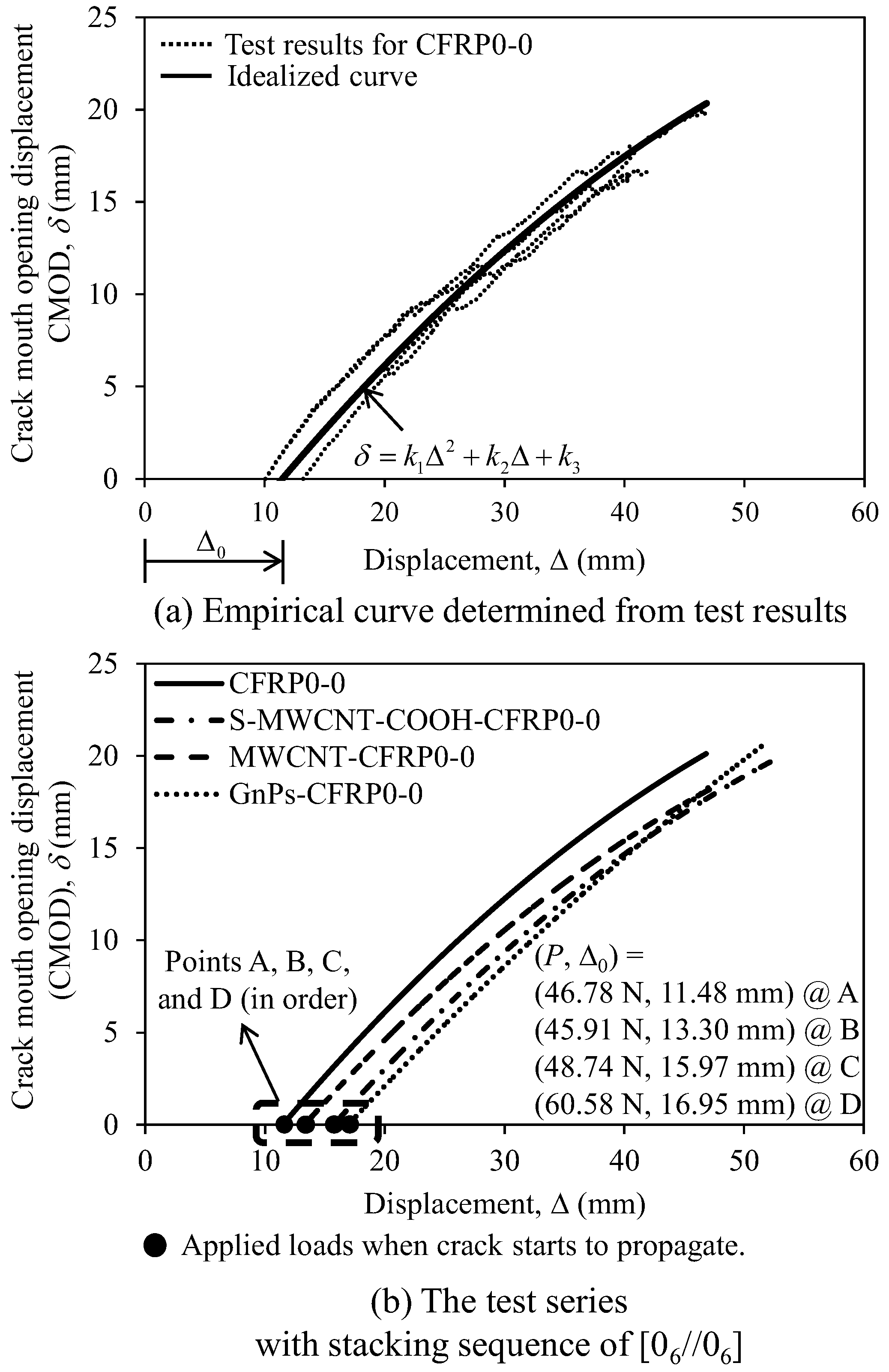

3.1. Load–Displacement Curve

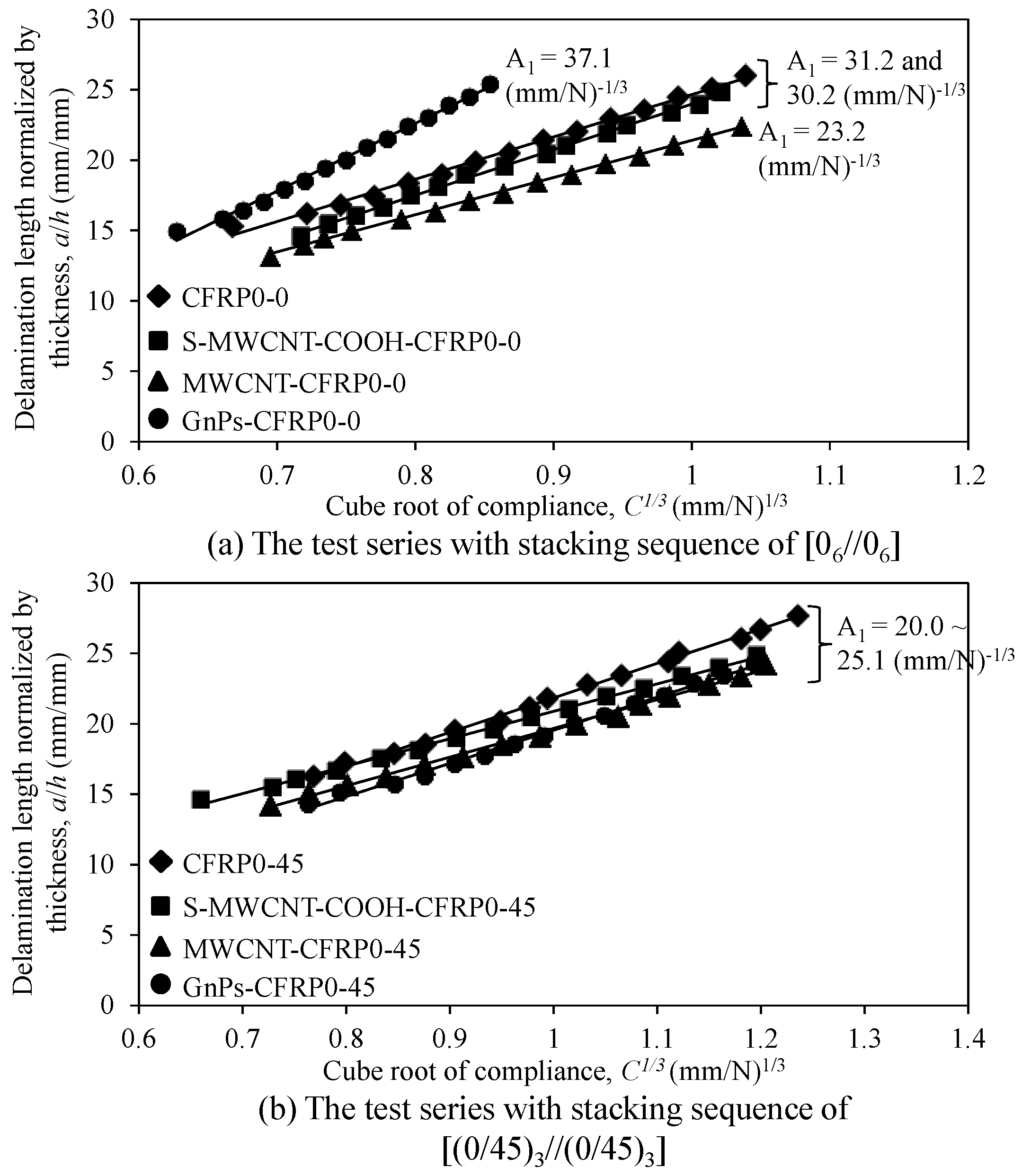

3.2. Data Reduction Factor (A1)

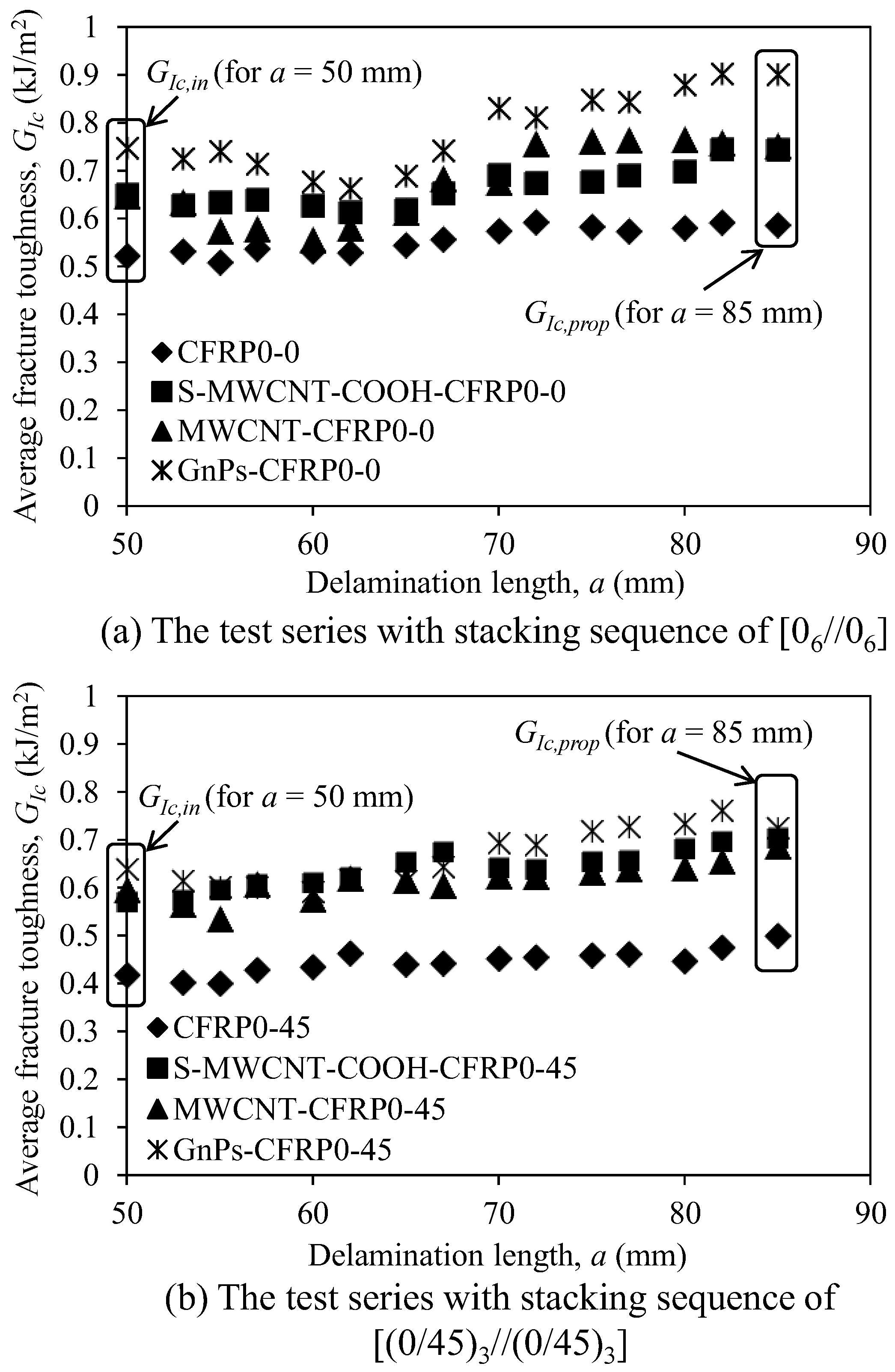

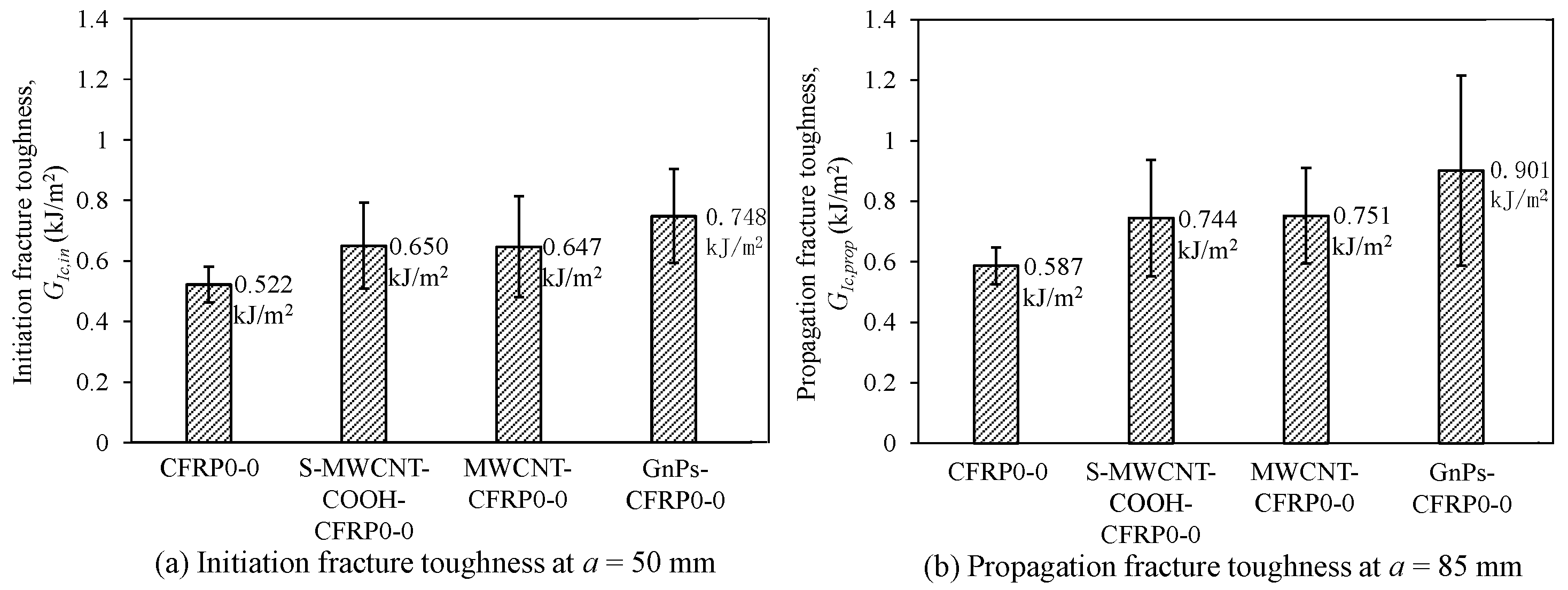

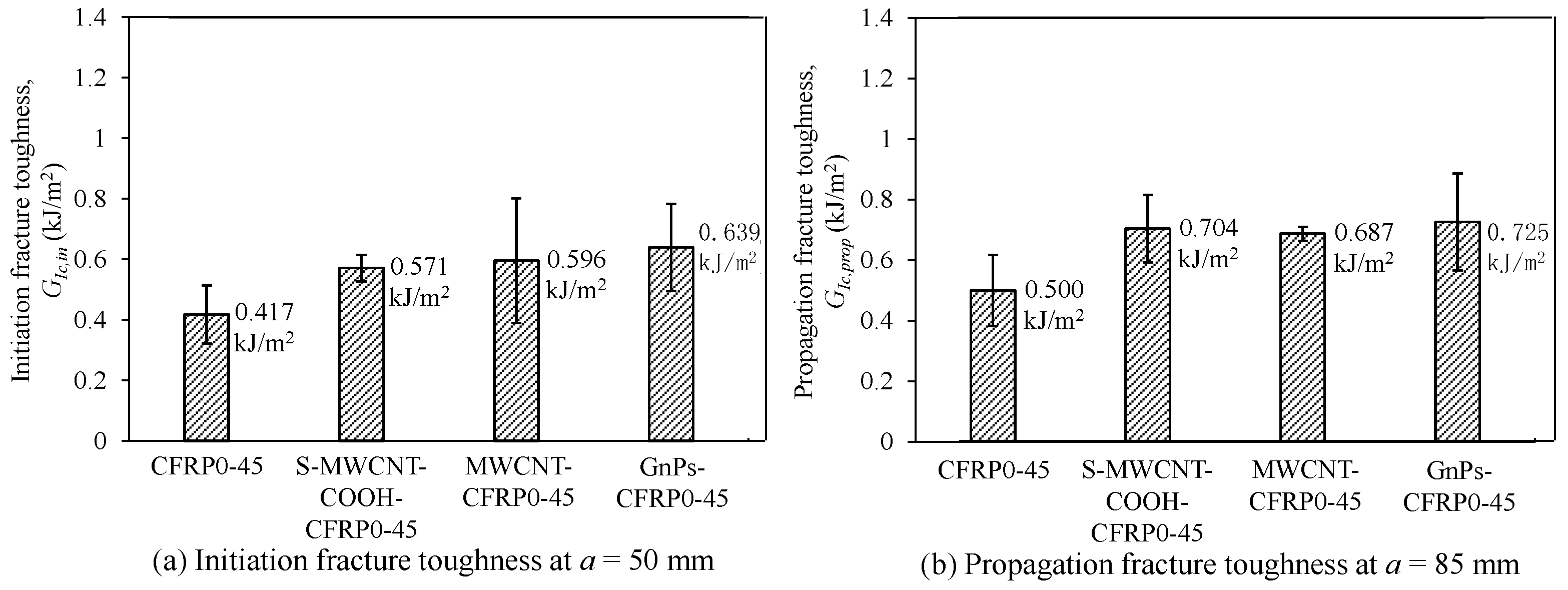

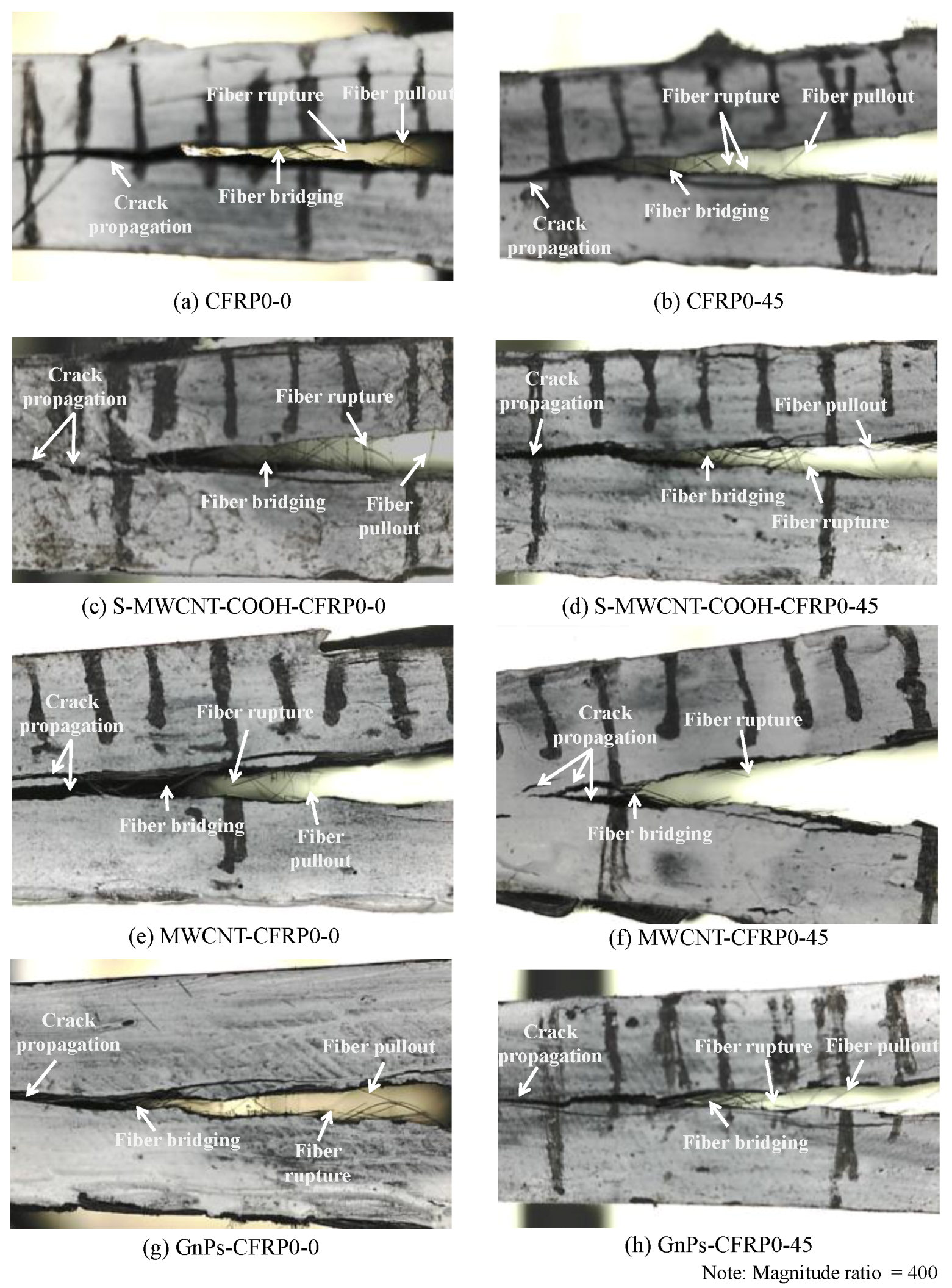

3.3. Effect of Nanomaterials on Mode I Fracture Toughness

3.4. Effect of Interface Fiber Angle

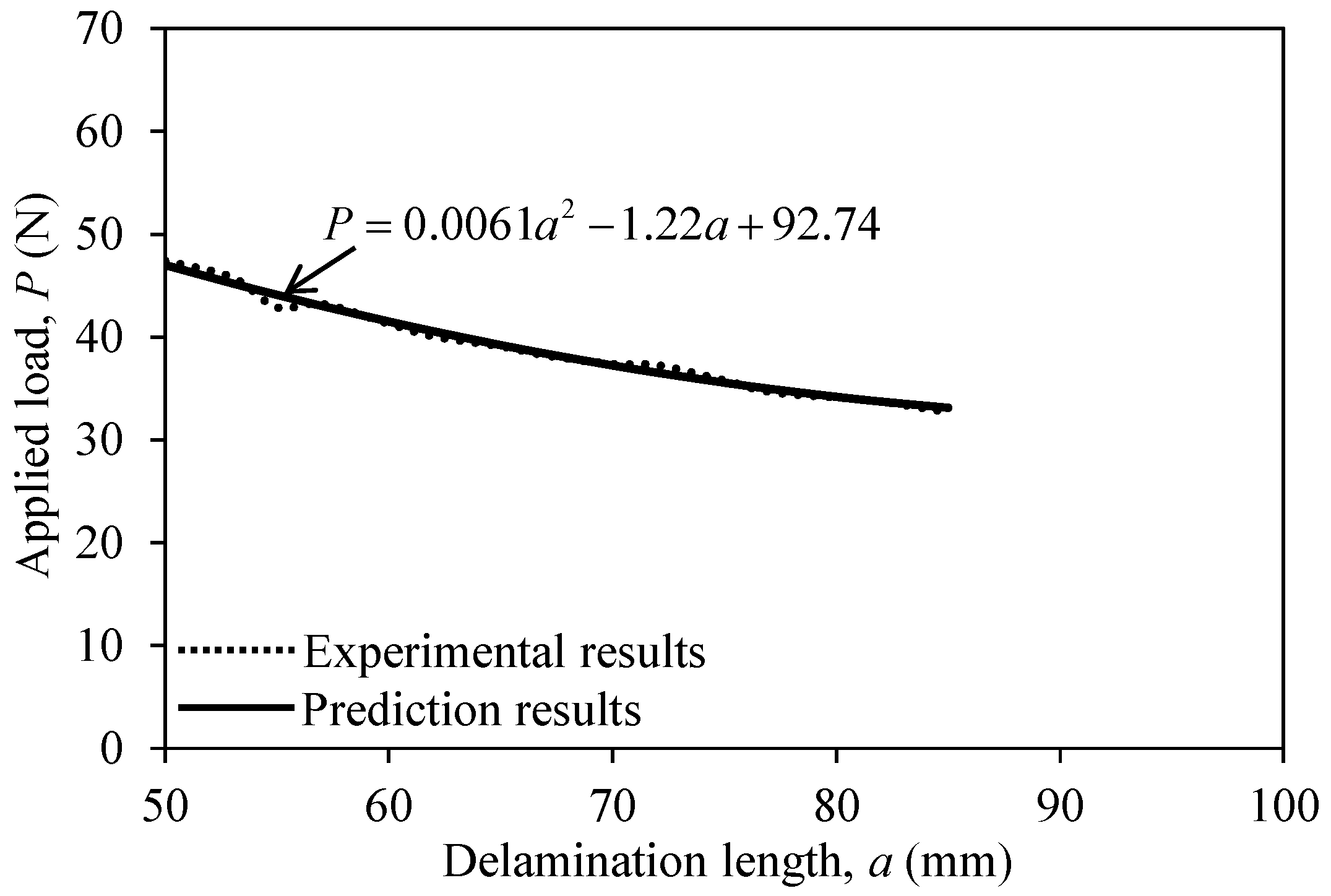

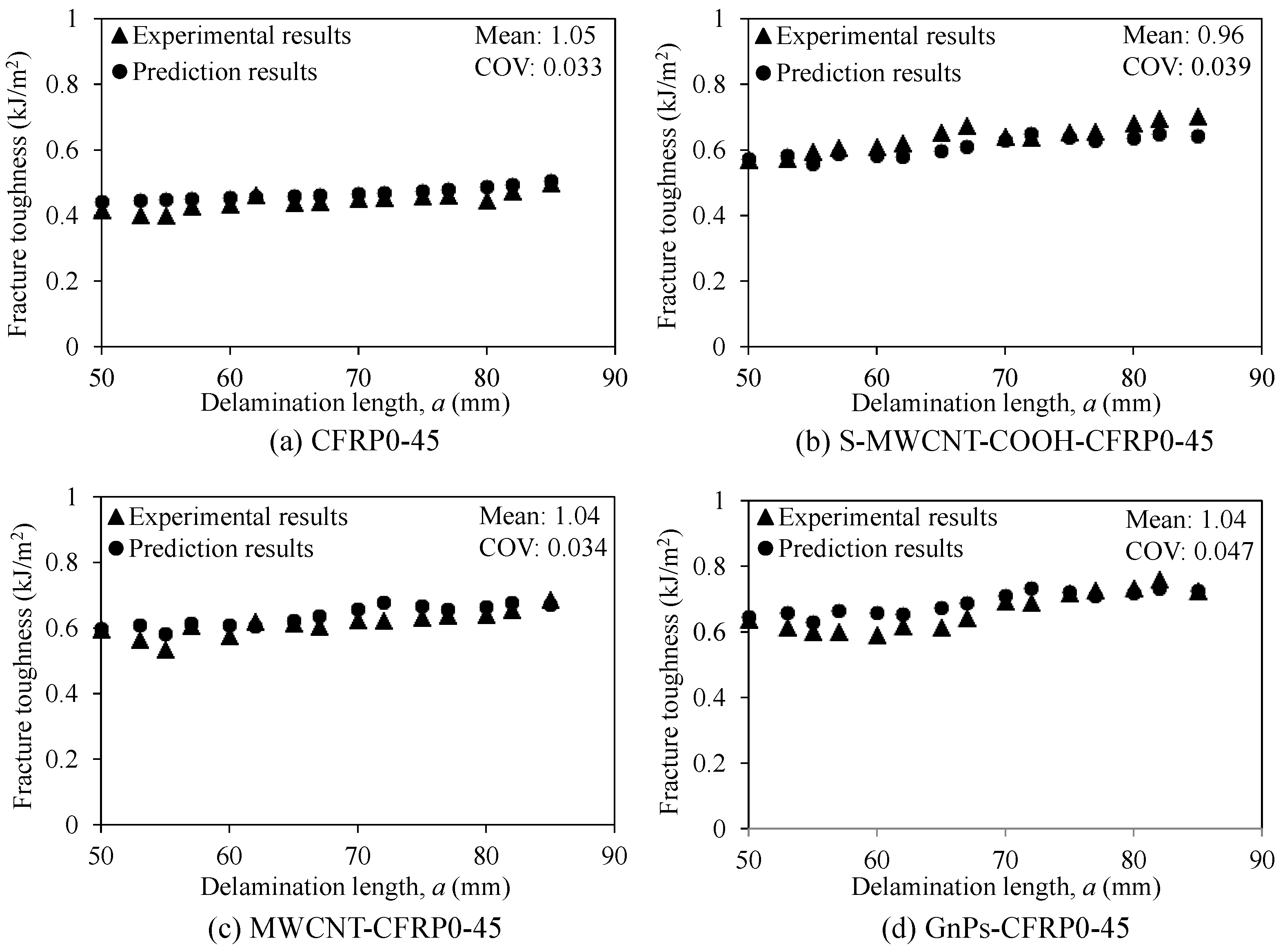

3.5. Prediction Model for Evaluating the Fracture Toughness of CFRP Composites with 0//45 Interface Fiber Angle and Nanomaterials

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, W.-X.; Nakata, M.; Takao, Y.; Matsubara, T. Experimental investigation on test methods for mode II interlaminar fracture testing of carbon fiber reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1447–1455. [Google Scholar] [CrossRef]

- Koloor, S.R.; Tamin, M.N. Mode-II interlaminar fracture and crack-jump phenomenon in CFRP composite laminate materials. Compos. Struct. 2018, 204, 594–606. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Karimizadeh, H. Experimental study of RC deep beams with opening and FRP composites installed by means of EBR and EBROG methods. Constr. Build. Mater. 2019, 208, 780–791. [Google Scholar] [CrossRef]

- Wroblewski, L.; Hristozov, D.; Sadeghian, P. Durability of bond between concrete beams and FRP composites made of flax and glass fibers. Constr. Build. Mater. 2016, 126, 800–811. [Google Scholar] [CrossRef]

- Sun, W.; Liu, H.; Pan, C.; He, T. Modelling of a novel strong and ductile FRP composite. Constr. Build. Mater. 2019, 217, 73–83. [Google Scholar] [CrossRef]

- Noël, M. Probabilistic fatigue life modelling of FRP composites for construction. Constr. Build. Mater. 2019, 206, 279–286. [Google Scholar] [CrossRef]

- Prusty, R.K.; Rathore, D.K.; Singh, B.P.; Mohanty, S.C.; Mahato, K.K.; Ray, B.C. Experimental optimization of flexural behaviour through inter-ply fibre hybridization in FRP composite. Constr. Build. Mater. 2016, 118, 327–336. [Google Scholar] [CrossRef]

- Yun, K.; Kwak, S.; Wang, Z.; Chang, M.; Kim, J.; Liu, J.; Ri, C. A Damage Model Reflecting the Interaction between Delamination and Intralaminar Crack for Failure Analysis of FRP Laminates. Appl. Sci. 2019, 9, 314. [Google Scholar] [CrossRef]

- Jollivet, T.; Peyrac, C.; Lefebvre, F. Damage of Composite Materials. Procedia Eng. 2013, 66, 746–758. [Google Scholar] [CrossRef]

- Alizadeh, F.; Soares, C.G. Experimental and numerical investigation of the fracture toughness of Glass/Vinylester composite laminates. Eur. J. Mech. A/Solid 2019, 73, 204–211. [Google Scholar] [CrossRef]

- De Cicco, D.; Asaee, Z.; Taheri, F. Use of Nanoparticles for Enhancing the Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints—A Review. Nanomaterials 2017, 7, 360. [Google Scholar] [CrossRef]

- Tsai, J.L.; Huang, H.B.; Cheng, Y.L. Enhancing fracture toughness of glass/epoxy composites for wind blades using silica nanoparticles and rubber particles. Procedia Eng. 2011, 14, 1982–1987. [Google Scholar] [CrossRef]

- Grabowski, K.; Zbyrad, P.; Uhl, T.; Staszewski, W.J.; Packo, P. Multiscale electro-mechanical modeling of carbon nanotube composites. Comput. Mater. Sci. 2017, 135, 169–180. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Mode I fracture toughness and fractographic investigation of carbon fibre composites with liquid Methylmethacrylate thermoplastic matrix. Compos. Part B Eng. 2018, 134, 246–253. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Neisiany, R.E.; Khorasani, S.N.; Ramakrishna, S.; Berto, F. Effect of neat and reinforced polyacrylonitrile nanofibers incorporation on interlaminar fracture toughness of carbon/epoxy composite. Theor. Appl. Mech. Lett. 2018, 8, 126–131. [Google Scholar] [CrossRef]

- Ognibene, G.; Latteri, A.; Mannino, S.; Saitta, L.; Recca, G.; Scarpa, F.; Cicala, G. Interlaminar Toughening of Epoxy Carbon Fiber Reinforced Laminates: Soluble Versus Non-Soluble Veils. Polymers 2019, 11, 1029. [Google Scholar] [CrossRef] [PubMed]

- Akasheh, F.; Aglan, H. Fracture toughness enhancement of carbon fiber–reinforced polymer composites utilizing additive manufacturing fabrication. J. Elastomers Plast. 2018, 51, 698–711. [Google Scholar] [CrossRef]

- Quan, D.; Carolan, D.; Rouge, C.; Murphy, N.; Ivankovic, A. Mechanical and fracture properties of epoxy adhesives modified with graphene nanoplatelets and rubber particles. Int. J. Adhes. Adhes. 2018, 81, 21–29. [Google Scholar] [CrossRef]

- Cholake, S.T.; Moran, G.; Joe, B.; Bai, Y.; Raman, R.K.S.; Zhao, X.; Rizkalla, S.; Bandyopadhyay, S. Improved Mode I fracture resistance of CFRP composites by reinforcing epoxy matrix with recycled short milled carbon fibre. Constr. Build. Mater. 2016, 111, 399–407. [Google Scholar] [CrossRef]

- Ozdemir, N.G.; Zhang, T.; Aspin, I.; Scarpa, F.; Hadavinia, H.; Song, Y.; Ozdemir, N.G. Toughening of carbon fibre reinforced polymer composites with rubber nanoparticles for advanced industrial applications. Express Polym. Lett. 2016, 10, 394–407. [Google Scholar] [CrossRef]

- Carolan, D.; Kinloch, A.J.; Sprenger, S.; Taylor, A.C.; Ivanković, A. Toughened carbon fibre-reinforced polymer composites with nanoparticle-modified epoxy matrices. J. Mater. Sci. 2016, 52, 1767–1788. [Google Scholar] [CrossRef]

- Hanemann, T.; Szabó, D.V. Polymer-Nanoparticle Composites: From Synthesis to Modern Applications. Materials 2010, 3, 3468–3517. [Google Scholar] [CrossRef]

- Quan, D.; Urdániz, J.L.; Ivanković, A. Enhancing mode-I and mode-II fracture toughness of epoxy and carbon fibre reinforced epoxy composites using multi-walled carbon nanotubes. Mater. Des. 2018, 143, 81–92. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Taylor, A.C.; Kinloch, I.A. The effect of carbon nanotubes on the fracture toughness and fatigue performance of a thermosetting epoxy polymer. J. Mater. Sci. 2011, 46, 7525–7535. [Google Scholar] [CrossRef]

- Boroujeni, A.Y.; Al-Haik, M.S. Interlaminar fracture toughness of hybrid carbon fiber-carbon nanotubes-reinforced polymer composites. Polym. Compos. 2018, 40, E1470–E1478. [Google Scholar] [CrossRef]

- Hamer, S.; Leibovich, H.; Green, A.; Avrahami, R.; Zussman, E.; Siegmann, A.; Sherman, D. Mode I and Mode II fracture energy of MWCNT reinforced nanofibrilmats interleaved carbon/epoxy laminates. Compos. Sci. Technol. 2014, 90, 48–56. [Google Scholar] [CrossRef]

- Wicks, S.S.; Wang, W.; Williams, M.R.; Wardle, B.L. Multi-scale interlaminar fracture mechanisms in woven composite laminates reinforced with aligned carbon nanotubes. Compos. Sci. Technol. 2014, 100, 128–135. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Gries, T.; Veit, D.; Quadflieg, T.; Mohr, B.; Kolloch, M. Effect of nanomaterial on mode I and mode II interlaminar fracture toughness of woven carbon fabric reinforced polymer composites. Eng. Fract. Mech. 2017, 180, 73–86. [Google Scholar] [CrossRef]

- Di Leonardo, S.; Nistal, A.; Catalanotti, G.; Hawkins, S.C.; Falzon, B. Mode I interlaminar fracture toughness of thin-ply laminates with CNT webs at the crack interface. Compos. Struct. 2019, 225, 111178. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, Y.; Zhang, J.; Gong, Y.; Lu, Z.; Hu, N.; Xu, J. An interface-dependent model of plateau fracture toughness in multidirectional CFRP laminates under mode I loading. Compos. Part B Eng. 2017, 131, 196–208. [Google Scholar] [CrossRef]

- Batra, R.; Sears, A. Continuum models of multi-walled carbon nanotubes. Int. J. Solids Struct. 2007, 44, 7577–7596. [Google Scholar] [CrossRef]

- Wang, C.; Ji, X.; Roy, A.; Silberschmidt, V.V.; Chen, Z. Shear strength and fracture toughness of carbon fibre/epoxy interface: Effect of surface treatment. Mater. Des. 2015, 85, 800–807. [Google Scholar] [CrossRef]

- Lim, J.I.; Rhee, K.Y.; Kim, H.J.; Jung, D.H. Effect of stacking sequence on the flexural and fracture properties of carbon/basalt/epoxy hybrid composites. Carbon Lett. 2014, 15, 125–128. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Liu, B.; Zhang, J. Effects of geometrical and mechanical properties of fiber and matrix on composite fracture toughness. Compos. Struct. 2015, 122, 496–506. [Google Scholar] [CrossRef]

- Bilisik, K.; Sapanci, E. Experiemntal determination of fracture toughness properties of nanostiched and nanoprepreg carbon/epoxy composites. Eng. Fract. Mech. 2018, 189, 293–306. [Google Scholar] [CrossRef]

- Mujika, F.; Vargas-Silva, G.; Ibarretxe, J.; De Gracia, J.; Arrese, A. Influence of the modification with MWCNT on the interlaminar fracture properties of long carbon fiber composites. Compos. Part B Eng. 2012, 43, 1336–1340. [Google Scholar] [CrossRef]

- Truong, G.T.; Van Tran, H.; Choi, K.-K. Tensile Behavior of Carbon Fiber-Reinforced Polymer Composites Incorporating Nanomaterials after Exposure to Elevated Temperature. J. Nanomater. 2019, 2019, 1–14. [Google Scholar] [CrossRef]

- Lukaszewicz, D.H.-J.; Ward, C.; Potter, K.D. The engineering aspects of automated prepreg layup: History, present and future. Compos. Part B Eng. 2012, 43, 997–1009. [Google Scholar] [CrossRef]

- Kim, D.-W.; Hennigan, D.J.; Beavers, K.D. Effect of fabrication processes on mechanical properties of glass fiber reinforced polymer composites for 49 meter (160 foot) recreational yachts. Int. J. Nav. Archit. Ocean Eng. 2010, 2, 45–56. [Google Scholar] [CrossRef]

- ASTM D5528-13. Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fibre Reinforced Polymer Matrix Composites; ASTM International: West Conshohocken, PA, USA, 2013; Available online: https://www.astm.org (accessed on 10 January 2013).

- Hsiao, K.-T.; Scruggs, A.M.; Brewer, J.S.; Hickman, G.J.; McDonald, E.E.; Henderson, K. Effect of carbon nanofiber z-threads on mode-I delamination toughness of carbon fiber reinforced plastic laminates. Compos. Part A Appl. Sci. Manuf. 2016, 91, 324–335. [Google Scholar] [CrossRef]

- Almuhammadi, K.; Alfano, M.; Yang, Y.; Lubineau, G. Analysis of interlaminar fracture toughness and damage mechanisms in composite laminates reinforced with sprayed multi-walled carbon nanotubes. Mater. Des. 2014, 53, 921–927. [Google Scholar] [CrossRef]

- Rehan, M.S.B.M.; Rousseau, J.; Fontaine, S.; Gong, X.-J. Experimental study of the influence of ply orientation on DCB mode-I delamination behavior by using multidirectional fully isotropic carbon/epoxy laminates. Compos. Struct. 2017, 161, 1–7. [Google Scholar] [CrossRef]

- Truong, G.T.; Choi, K.-K. Effect of short multi-walled carbon nanotubes on the mode I fracture toughness of woven carbon fiber reinforced polymer composites. Constr. Build. Mater. 2020, 259, 119696. [Google Scholar] [CrossRef]

- Woldemariam, M.H.; Belingardi, G.; Koricho, E.G.; Reda, D.T. Effects of nanomaterials and particles on mechanical properties and fracture toughness of composite materials: A short review. AIMS Mater. Sci. 2019, 6, 1191–1212. [Google Scholar] [CrossRef]

- Faul, F.; Erdfelder, E.; Buchner, A.; Lang, A.-G. Statistical power analyses using G*Power 3.1: Tests for correlation and regression analyses. Behav. Res. Methods 2009, 41, 1149–1160. [Google Scholar] [CrossRef]

- Biau, D.J.; Kernéis, S.; Porcher, R. Statistics in Brief: The Importance of Sample Size in the Planning and Interpretation of Medical Research. Clin. Orthop. Relat. Res. 2008, 466, 2282–2288. [Google Scholar] [CrossRef]

- Borowski, E.; Soliman, E.; Kandil, U.F.; Taha, M.M.R. Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes. Polymers 2015, 7, 1020–1045. [Google Scholar] [CrossRef]

- Davis, D.C.; Whelan, B.D. An experimental study of interlaminar shear fracture toughness of a nanotube reinforced composite. Compos. Part B Eng. 2011, 42, 105–116. [Google Scholar] [CrossRef]

- Li, M.; Gu, Y.; Liu, Y.; Li, Y.; Zhang, Z. Interfacial improvement of carbon fiber/epoxy composites using a simple process for depositing commercially functionalized carbon nanotubes on the fibers. Carbon 2013, 52, 109–121. [Google Scholar] [CrossRef]

- Kharratzadeh, M.; Shokrieh, M.; Salamat-Talab, M. Effect of interface fiber angle on the mode I delamination growth of plain woven glass fiber-reinforced composites. Theor. Appl. Fract. Mech. 2018, 98, 1–12. [Google Scholar] [CrossRef]

- Gong, X.; Hurez, A.; Verchery, G. On the determination of delamination toughness by using multidirectional DCB specimens. Polym. Test. 2010, 29, 658–666. [Google Scholar] [CrossRef]

- Suo, Z.; Bao, G.; Fan, B. Delamination R-curve phenomena due to damage. J. Mech. Phys. Solids 1992, 40, 1–16. [Google Scholar] [CrossRef]

- Yue, L.; Pircheraghi, G.; Monemian, S.A.; Manas-Zloczower, I. Epoxy composites with carbon nanotubes and graphene nanoplatelets—Dispersion and synergy effects. Carbon 2014, 78, 268–278. [Google Scholar] [CrossRef]

| Nanomaterials | Carbon Purity (wt%) | Sizes |

|---|---|---|

| Multi-walled carbon nanotubes (MWCNTs) | >95 | Outside diameter: (30–50) nm |

| Inside diameter: (5–12) nm | ||

| Length: (10–20) μm | ||

| Specific surface area > 60 m2/g | ||

| Density: 2.1 g/cm3 | ||

| Graphene nanoplatelets (GnPs) | >95 | Average number of layers: 6 |

| Max. number of layer: 32 | ||

| Diameter: (4–12) μm | ||

| Thickness: 2–18 nm | ||

| Specific surface area: 500–1200 m2/g | ||

| Density: 2.1 g/cm3 | ||

| COOH-functionalized short multi-walled carbon nanotubes (S-MWCNT-COOH) | >95 | Outside diameter: (5–15) nm |

| Inside diameter: (3–5) nm | ||

| Length: (0.5–2) μm | ||

| Specific surface area > 233 m2/g | ||

| Density: 2.1 g/cm3 |

| Specimens | Stacking Sequence | Flexural Rigidity, K (N/mm) | SD (1) | Peak Load, Pu (N) | SD (1) | Residual Load (2), PR (N) | SD (1) |

|---|---|---|---|---|---|---|---|

| CFRP0-0 | [06//06] | 5.15 | 1.21 | 46.78 | 2.48 | 31.95 | 2.59 |

| S-MWCNT-COOH-CFRP0-0 | 3.79 | 1.01 | 48.74 | 4.75 | 35.19 | 4.17 | |

| MWCNT-CFRP0-0 | 5.39 | 1.76 | 45.91 | 5.82 | 29.82 | 5.11 | |

| GnPs-CFRP0-0 | 5.06 | 1.67 | 60.58 | 2.32 | 43.41 | 8.49 | |

| CFRP0-45 | [(0/45)3// (0/45)3] | 2.95 | 1.00 | 29.72 | 2.64 | 20.06 | 1.48 |

| S-MWCNT-COOH-CFRP0-45 | 4.67 | 1.21 | 38.54 | 1.14 | 23.35 | 2.39 | |

| MWCNT-CFRP0-45 | 4.10 | 0.49 | 39.21 | 3.47 | 26.76 | 3.34 | |

| GnPs-CFRP0-45 | 2.59 | 0.65 | 35.98 | 3.74 | 25.06 | 1.43 |

| Specimens | Factors | (mm) | ||

|---|---|---|---|---|

| CFRP0-0 | −0.0054 | 0.89 | −9.50 | 11.48 |

| S-MWCNT-COOH-CFRP0-0 | −0.0053 | 0.90 | −12.86 | 15.97 |

| MWCNT-CFRP0-0 | −0.0055 | 0.87 | −10.60 | 13.30 |

| GnPs-CFRP0-0 | −0.0030 | 0.80 | −12.70 | 16.95 |

| CFRP0-45 | −0.0044 | 0.82 | −10.00 | 13.12 |

| S-MWCNT-COOH-CFRP0-45 | −0.0044 | 0.75 | −8.10 | 11.59 |

| MWCNT-CFRP0-45 | −0.0047 | 0.84 | −12.86 | 16.91 |

| GnPs-CFRP0-45 | −0.0037 | 0.78 | −11.00 | 15.21 |

| Specimens | ((mm/N)−1/3) | SD (2) | ((mm/N)−1/3) |

|---|---|---|---|

| CFRP0-0 | 31.2 | 1.47 | 30.0 |

| S-MWCNT-COOH-CFRP0-0 | 30.2 | 3.75 | 30.0 |

| MWCNT-CFRP0-0 | 23.2 | 3.86 | 23.0 |

| GnPs-CFRP0-0 | 37.1 | 7.43 | 37.0 |

| CFRP0-45 | 25.11 | 4.19 | 25.0 |

| S-MWCNT-COOH-CFRP0-45 | 20.8 | 3.87 | 20.0 |

| MWCNT-CFRP0-45 | 25.1 | 4.43 | 25.0 |

| GnPs-CFRP0-45 | 20.0 | 2.93 | 20.0 |

| Specimens | Stacking Sequence | Interface Fiber Angle | Amount of Nanomaterials (by Weight, wt%) | ||||

|---|---|---|---|---|---|---|---|

| Initiation, GIc,in | SD (1) | Propagation, GIc,prop | SD (1) | ||||

| CFRP0-0 | [06//06] | 0//0 | 0 | 0.522 | 0.058 | 0.587 | 0.061 |

| S-MWCNT-COOH-CFRP0-0 | 1 | 0.650 | 0.142 | 0.744 | 0.192 | ||

| MWCNT-CFRP0-0 | 0.647 | 0.167 | 0.751 | 0.158 | |||

| GnPs-CFRP0-0 | 0.748 | 0.156 | 0.901 | 0.315 | |||

| CFRP0-45 | [(0/45)3// (0/45)3] | 0//45 | 0 | 0.417 | 0.100 | 0.500 | 0.117 |

| S-MWCNT-COOH-CFRP0-45 | 1 | 0.571 | 0.044 | 0.704 | 0.112 | ||

| MWCNT-CFRP0-45 | 0.596 | 0.206 | 0.687 | 0.023 | |||

| GnPs-CFRP0-45 | 0.639 | 0.143 | 0.725 | 0.160 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truong, G.T.; Tran, H.V.; Choi, K.-K. Investigation on Mode I Fracture Toughness of Woven Carbon Fiber-Reinforced Polymer Composites Incorporating Nanomaterials. Polymers 2020, 12, 2512. https://doi.org/10.3390/polym12112512

Truong GT, Tran HV, Choi K-K. Investigation on Mode I Fracture Toughness of Woven Carbon Fiber-Reinforced Polymer Composites Incorporating Nanomaterials. Polymers. 2020; 12(11):2512. https://doi.org/10.3390/polym12112512

Chicago/Turabian StyleTruong, Gia Toai, Hai Van Tran, and Kyoung-Kyu Choi. 2020. "Investigation on Mode I Fracture Toughness of Woven Carbon Fiber-Reinforced Polymer Composites Incorporating Nanomaterials" Polymers 12, no. 11: 2512. https://doi.org/10.3390/polym12112512

APA StyleTruong, G. T., Tran, H. V., & Choi, K.-K. (2020). Investigation on Mode I Fracture Toughness of Woven Carbon Fiber-Reinforced Polymer Composites Incorporating Nanomaterials. Polymers, 12(11), 2512. https://doi.org/10.3390/polym12112512