Properties of Biodegradable Films Based on Poly(butylene Succinate) (PBS) and Poly(butylene Adipate-co-Terephthalate) (PBAT) Blends †

This paper is dedicated to the memory of Prof. Eduardo Luís Canedo and Maria Rossella Nobile.

This paper is an extended version of paper presented in the 9th International Conference on “Times of Polymers and Composites”: From Aerospace to Nanotechnology, Ischia, Italy, 17–21 June 2018 (AIP Conf. Proc. 2018, 1981, 020180, doi:10.1063/1.5046042).

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Characterization Methods

3. Results and Discussion

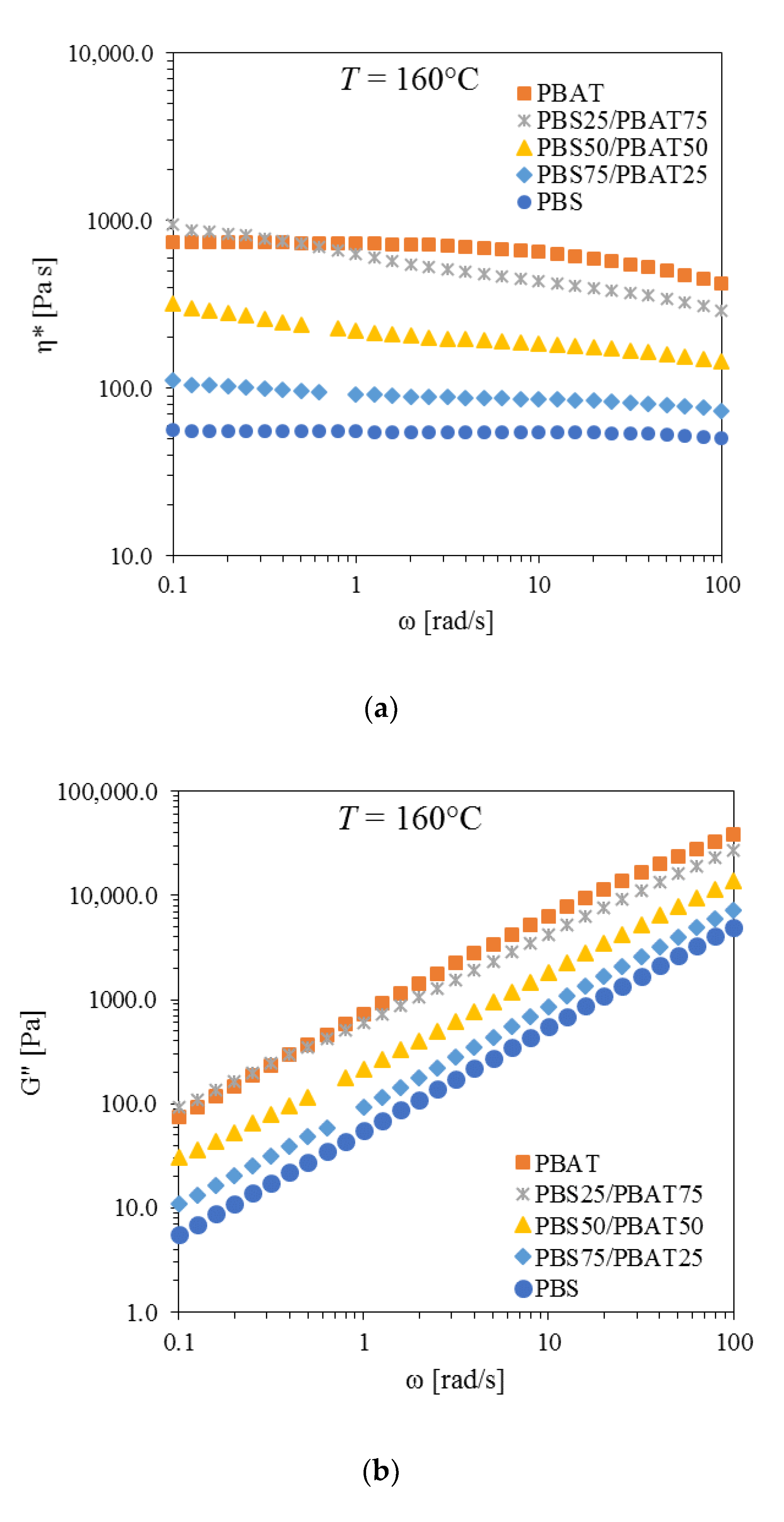

3.1. Rheological Properties of the Melts

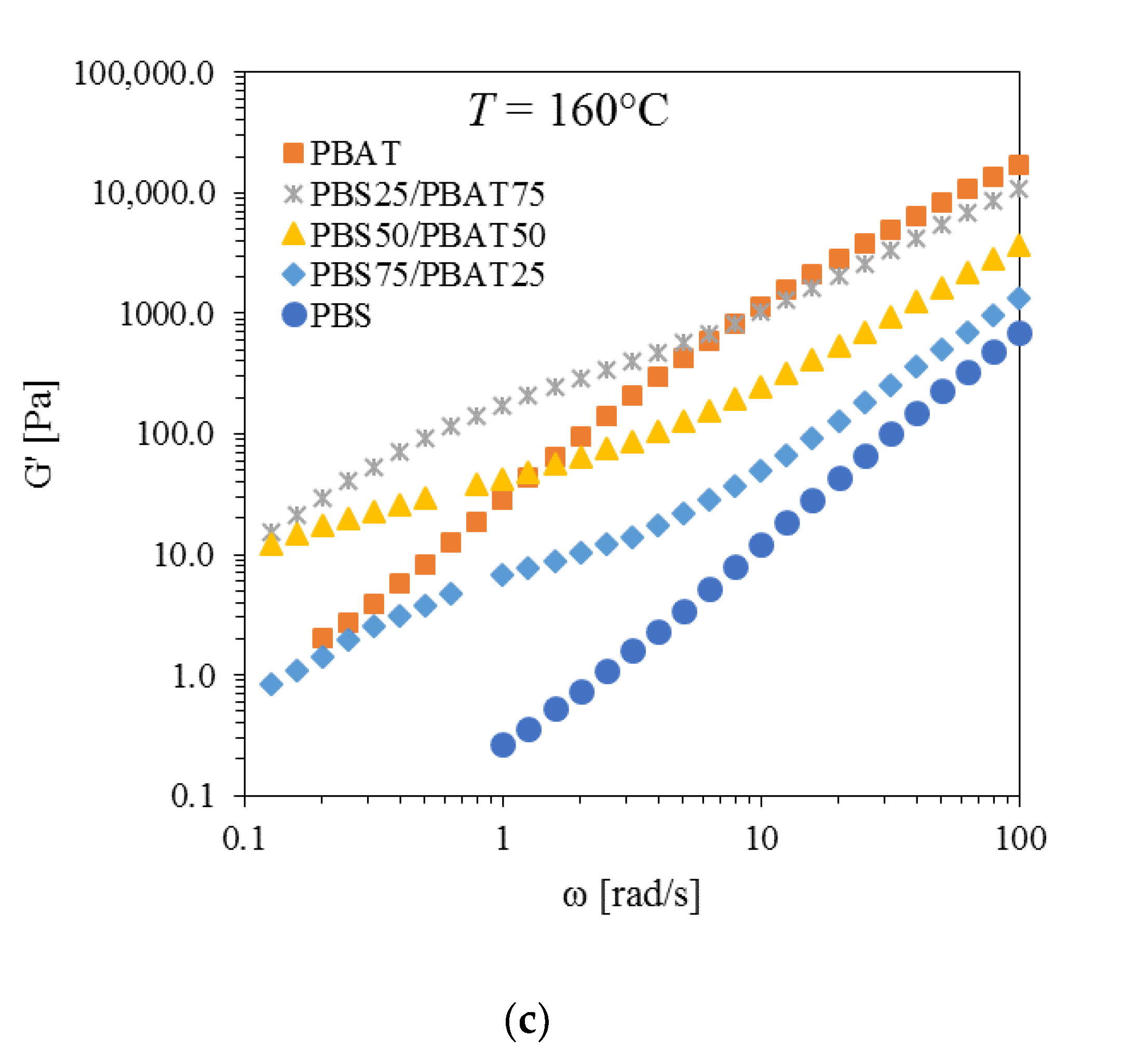

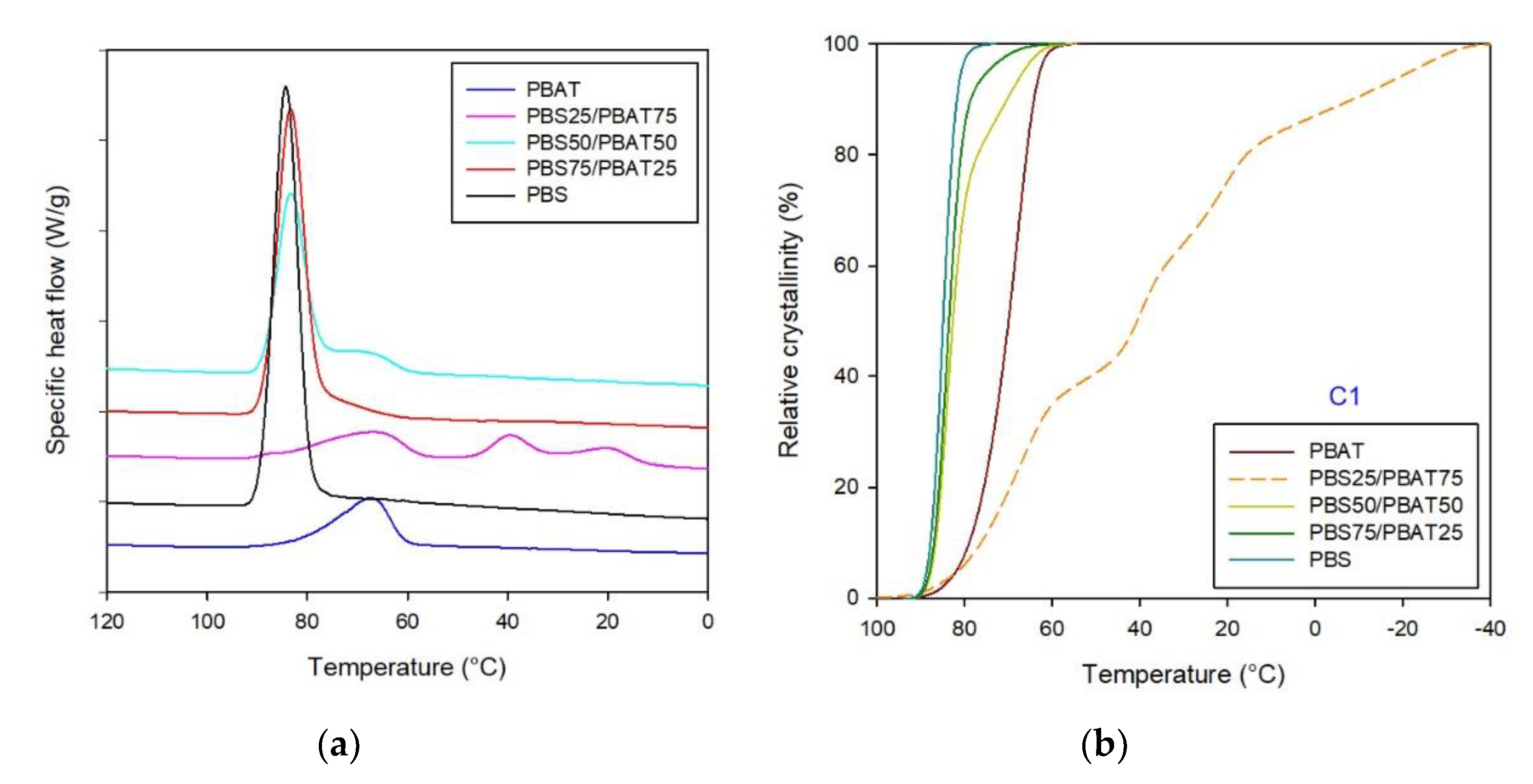

3.2. Differential Scanning Calorimetry (DSC) of Films

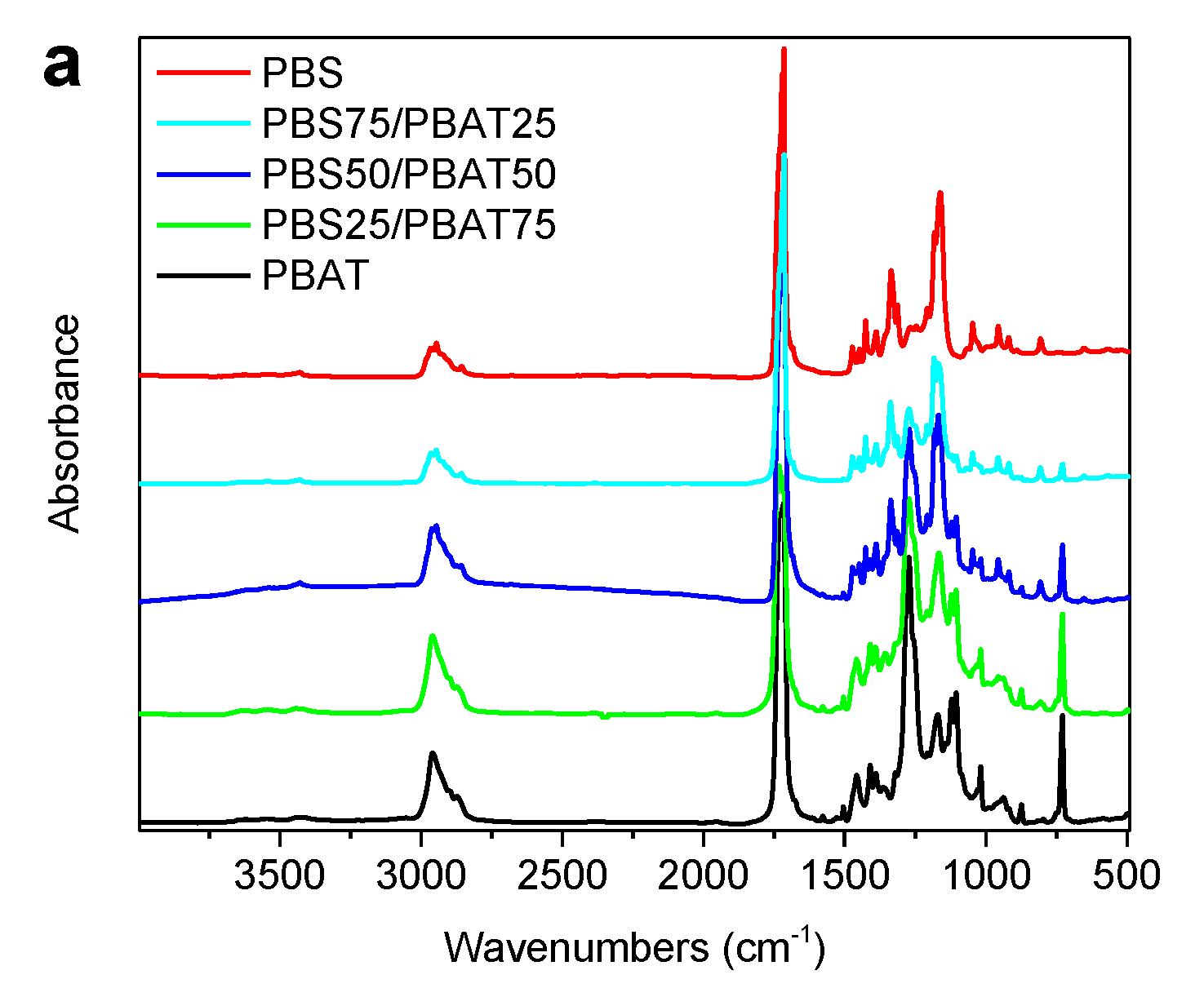

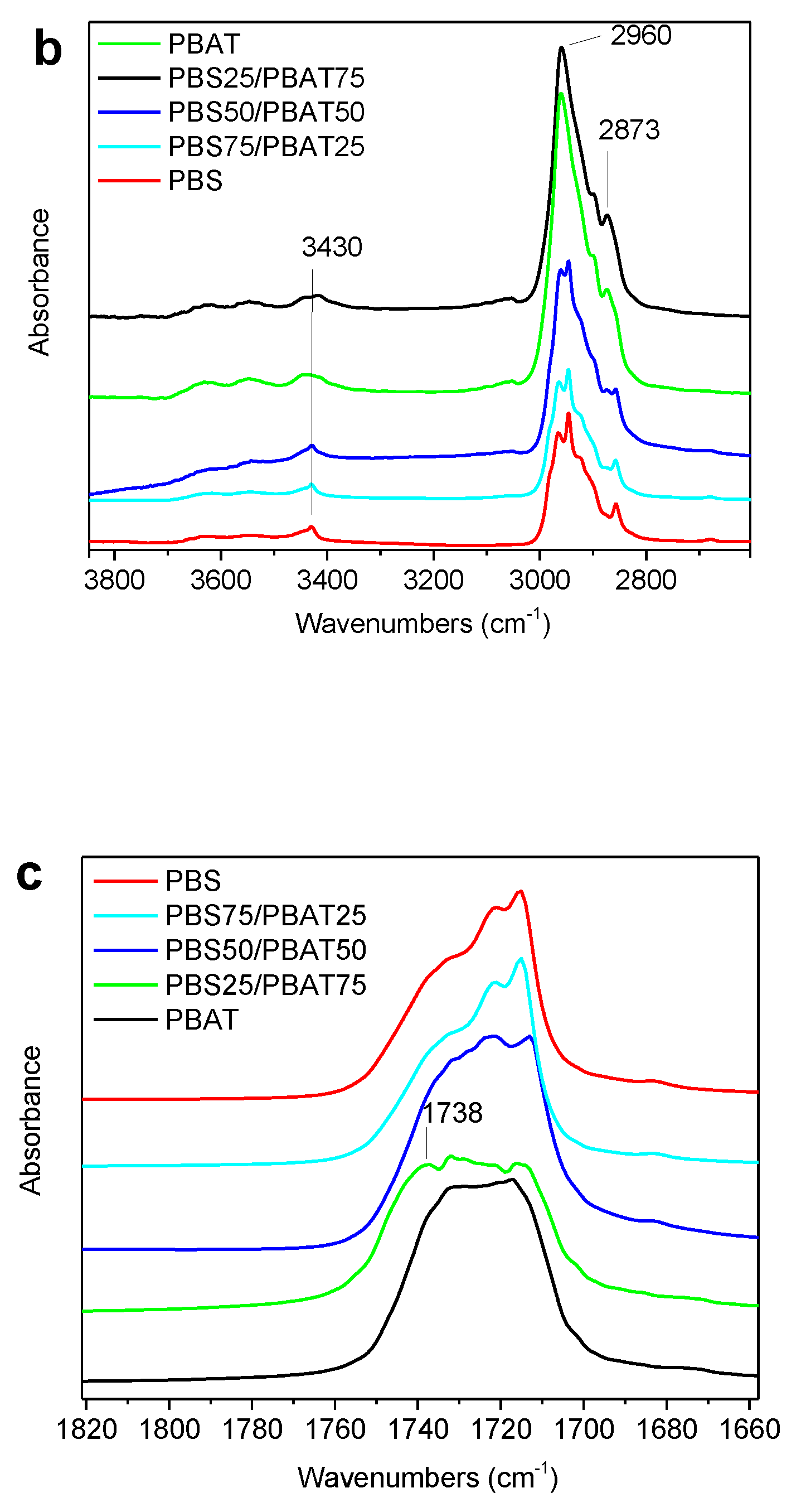

3.3. FTIR Spectroscopy of Films

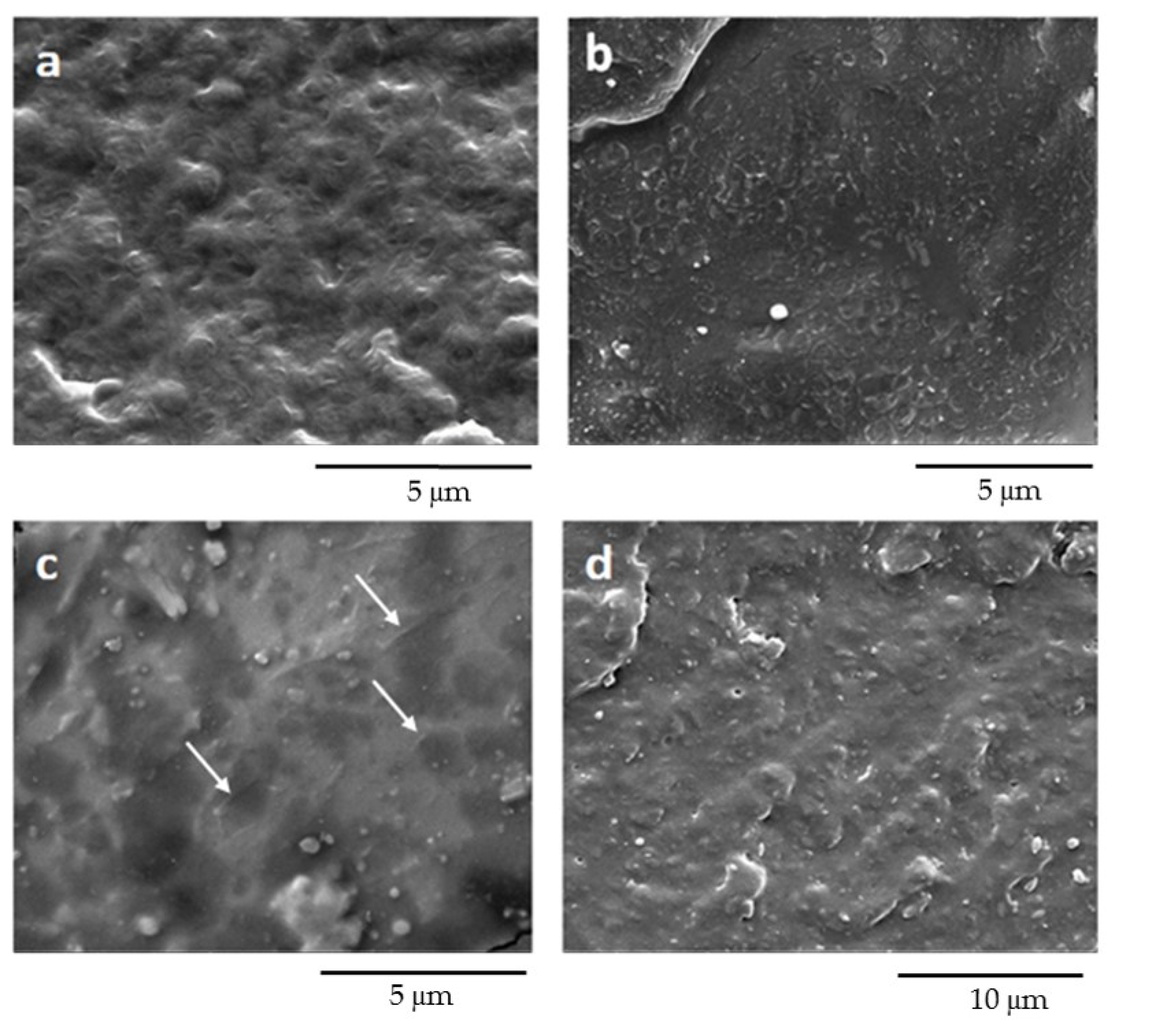

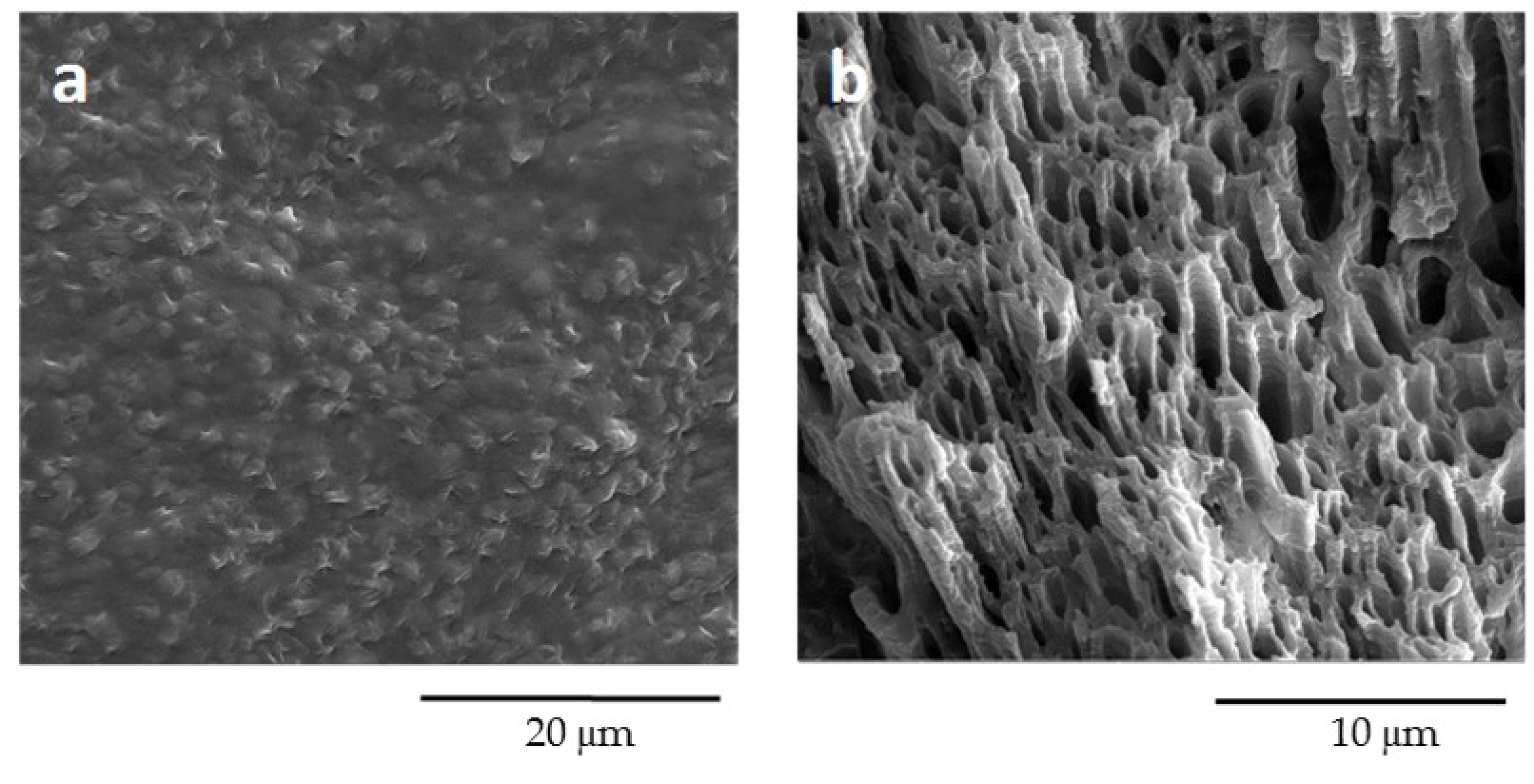

3.4. Scanning Electron Microscopy (SEM) of Films

3.5. Thermogravimetric Analysis (TGA) of Films

3.6. Mechanical Properties of Films

3.7. Water Vapor and Oxygen Permeability of Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Xu, J.; Guo, B.H. Poly(butylene succinate) and its copolymers: Research, development and industrialization. Biotechnol. J. 2010, 5, 1149–1163. [Google Scholar] [CrossRef] [PubMed]

- Guidotti, G.; Soccio, M.; Siracusa, V.; Gazzano, M.; Salatelli, E.; Munari, A.; Lotti, N. Novel random PBS-based copolymers containing aliphatic side chains for sustainable flexible food packaging. Polymers 2017, 9, 724. [Google Scholar] [CrossRef] [PubMed]

- De Santis, F.; Volpe, V.; Pantani, R. Effect of molding conditions on crystallization kinetics and mechanical properties of poly(lactic acid). Polym. Eng. Sci. 2017, 57, 306–311. [Google Scholar] [CrossRef]

- Scarfato, P.; di Maio, L.; Milana, M.R.; Giamberardini, S.; di Maio, L.; Denaro, M.; Incarnato, L. Performance properties, lactic acid specific migration and swelling by simulant of biodegradable poly(lactic acid)/nanoclay multilayer films for food packaging. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess 2017. [Google Scholar] [CrossRef]

- Jost, V. Packaging related properties of commercially available biopolymers—An overview of the status quo. eXPRESS Polym. Lett. 2018, 12, 429–435. [Google Scholar] [CrossRef]

- Coltelli, M.; Aliotta, L.; Gigante, V.; Bellusci, M.; Cinelli, P.; Bugnicourt, E.; Schmid, M.; Staebler, A.; Lazzeri, A. Protein Isolate Based Blends. Molecules 2020, 25, 3313. [Google Scholar] [CrossRef] [PubMed]

- Mallegni, N.; Phuong, T.; Coltelli, M.-B.; Cinelli, P.; Lazzeri, A. Poly(lactic acid) (PLA) Based Tear Resistant and Biodegradable Flexible Films by Blown Film Extrusion. Materials 2018, 11, 148. [Google Scholar] [CrossRef] [PubMed]

- Nobile, M.R.; Cerruti, P.; Malinconico, M.; Pantani, R. Processing and properties of biodegradable compounds based on aliphatic polyesters. J. Appl. Polym. Sci. 2015, 132, 42481. [Google Scholar] [CrossRef]

- Charlon, S.; Follain, N.; Soulestin, J.; Sclavons, M.; Marais, S. Water transport properties of poly(butylene succinate) and poly[(butylene succinate)-co-(butylene adipate)] Nanocomposite films: Influence of the water-assisted extrusion process. J. Phys. Chem. C 2017, 121, 918–930. [Google Scholar] [CrossRef]

- Yao, S.F.; Chen, X.T.; Ye, H.M. Investigation of Structure and Crystallization Behavior of Poly(butylene succinate) by Fourier Transform Infrared Spectroscopy. J. Phys. Chem. B 2017, 121, 9476–9485. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and characterization of PLA/PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crops Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- John, J.; Mani, R.; Bhattacharya, M. Evaluation of compatibility and properties of biodegradable polyester blends. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 2003–2014. [Google Scholar] [CrossRef]

- Qiu, T.Y.; Song, M.; Zhao, L.G. Testing, characterization and modelling of mechanical behaviour of poly (lactic-acid) and poly (butylene succinate) blends. Mech. Adv. Mater. Mod. Process. 2016, 2, 7. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.; Shi, J.; Ye, H.; Zhou, Q. Distinctive Tensile Properties of the Blends of Poly(l-lactic acid) (PLLA) and Poly(butylene succinate) (PBS). J. Polym. Environ. 2018, 26, 1737–1744. [Google Scholar] [CrossRef]

- Tan, F.T.; Cooper, D.G.; Marić, M.; Nicell, J.A. Biodegradation of a synthetic co-polyester by aerobic mesophilic microorganisms. Polym. Degrad. Stab. 2008, 93, 1479–1485. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Cividanes, L.S.; Gouveia, R.F.; Lona, L.M.F. An overview on properties and applications of poly(butylene adipate- co -terephthalate)-PBAT based composites. Polym. Eng. Sci. 2019, 59, E7–E15. [Google Scholar] [CrossRef]

- Dil, E.J.; Carreau, P.J.; Favis, B.D. Morphology, miscibility and continuity development in poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. Polymer (Guildf) 2015, 68, 202–212. [Google Scholar] [CrossRef]

- Arruda, L.C.; Magaton, M.; Bretas, R.E.S.; Ueki, M.M. Influence of chain extender on mechanical, thermal and morphological properties of blown films of PLA/PBAT blends. Polym. Test. 2015, 43, 27–37. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Rheological, morphological, and interfacial properties of compatibilized PLA/PBAT blends. Rheol. Acta. 2014, 53, 501–517. [Google Scholar] [CrossRef]

- Dong, W.; Zou, B.; Yan, Y.; Ma, P.; Chen, M. Effect of chain-extenders on the properties and hydrolytic degradation behavior of the poly(lactide)/ poly(butylene adipate-co-terephthalate) blends. Int. J. Mol. Sci. 2013, 14, 20189–20203. [Google Scholar] [CrossRef]

- Dammak, M.; Fourati, Y.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P.; Boufi, S. Blends of PBAT with plasticized starch for packaging applications: Mechanical properties, rheological behaviour and biodegradability. Ind. Crops Prod. 2020, 144, 112061. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biocomposite consisting of miscanthus fiber and biodegradable binary blend matrix: Compatibilization and performance evaluation. RSC Advances 2017, 7, 27538–27548. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable Poly(butylene succinate) and Poly(butylene adipate-co-terephthalate) Blends: Reactive Extrusion and Performance Evaluation. J. Polym. Environ. 2014, 22, 336–349. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W. Effect of organo-modified montmorillonite on poly (butylene succinate)/poly (butylene adipate-co-terephthalate) nanocomposites. Express Polym. Lett. 2010, 4, 404–414. [Google Scholar] [CrossRef]

- Nobile, M.R.; Crocitti, A.; Malinconico, M.; Santagata, G.; Cerruti, P. Preparation and characterization of poly(butylene succinate) (PBS) and polybutylene adipate-terephthalate (PBAT) biodegradable blends. AIP Conf. Proc. 2018, 1981, 020180. [Google Scholar] [CrossRef]

- Pérez-Camargo, R.A.; Fernández-D’Arlas, B.; Cavallo, D.; Debuissy, T.; Pollet, E.; Avérous, L.; Müller, A.J. Tailoring the structure, morphology, and crystallization of isodimorphic poly(butylene succinate-ran-butylene adipate) random copolymers by changing composition and thermal history. Macromolecules 2017, 50, 597–608. [Google Scholar] [CrossRef]

- Fukushima, K.; Wu, M.H.; Bocchini, S.; Rasyida, A.; Yang, M.C. PBAT based nanocomposites for medical and industrial applications. Mater. Sci. Eng. C 2012, 32, 1331–1351. [Google Scholar] [CrossRef]

- Yokohara, T.; Yamaguchi, M. Structure and properties for biomass-based polyester blends of PLA and PBS. Eur. Polym. J. 2008, 44, 677–685. [Google Scholar] [CrossRef]

- Nofar, M.; Maani, A.; Sojoudi, H.; Heuzey, M.C.; Carreau, P.J. Interfacial and rheological properties of PLA/PBAT and PLA/PBSA blends and their morphological stability under shear flow. J. Rheol 2015, 59, 317–333. [Google Scholar] [CrossRef]

- Chen, R.; Zou, W.; Zhang, H.; Zhang, G.; Qu, J. Crystallization behavior and thermal stability of poly(butylene succinate)/poly(propylene carbonate) blends prepared by novel vane extruder. In Proceedings of the 31st International Conference of the Polymer Processing Society, Jeju Island, Korea, 7–11 June 2016; p. 050002. [Google Scholar] [CrossRef]

- Pivsa-Art, S.; Thumsorn, S.; Pavasupree, S.; O-Charoen, N.; Pivsa-Art, W.; Yamane, H.; Ohara, H. Effect of additive on crystallization and mechanical properties of polymer blends of poly(lactic acid) and poly[(butylene succinate)-co-adipate]. Energ. Proc. 2013, 34, 563–571. [Google Scholar] [CrossRef]

- Ma, P.M.; Wang, R.Y.; Wang, S.F.; Zhang, Y.; Zhang, Y.X.; Hristova, D. Effects of fumed silica on the crystallization behavior and thermal properties of poly(hydroxybutyrate-co-hydroxyvalerate). J. Appl. Polym. Sci. 2008, 108, 1770–1777. [Google Scholar] [CrossRef]

- Song, L.; Qiu, Z. Crystallization behavior and thermal property of biodegradable poly(butylene succinate)/functional multi-walled carbon nanotubes nanocomposite. Polym. Degrad. Stab. 2009, 94, 632–637. [Google Scholar] [CrossRef]

- Ray, S.S.; Bandyopadhyay, J.; Bousmina, M. Thermal and thermomechanical properties of poly[(butylene succinate)-co-adipate] nanocomposite. Polym. Degrad. Stab. 2007, 92, 802–812. [Google Scholar] [CrossRef]

- Mallardo, S.; de Vito, V.; Malinconico, M.; Volpe, M.G.; Santagata, G.; di Lorenzo, M.L. Poly(butylene succinate)-based composites containing β-cyclodextrin/d-limonene inclusion complex. Eur. Polym. J. 2016, 79, 82–96. [Google Scholar] [CrossRef]

- Dong, T.; He, Y.; Shin, K.M.; Inoue, Y. Formation and characterization of inclusion complexes of poly(butylene succinate) with α- and γ-cyclodextrins. Macromol. Biosci. 2004, 4, 1084–1091. [Google Scholar] [CrossRef]

- Hexig, A.; Hexig, B. Characterization of Compositional Gradient Structure of Polymeric Materials by FTIR Technology. In Infrared Spectrosc; IntechOpen Limited: London, UK, 2012. [Google Scholar] [CrossRef]

- Dos Santos Rosa, B.; Merlini, C.; Livi, S.; de Oliviera Barra, G.M. Development of poly (butylene adipate-co-terephthalate) filled with montmorillonite-polypyrrole for pressure sensor applications. Mater. Res. 2019, 22, 20180541. [Google Scholar] [CrossRef]

- Tavares, L.B.; Ito, N.M.; Salvadori, M.C.; Santos, D.J.d.; Rosa, D.S. PBAT/kraft lignin blend in flexible laminated food packaging: Peeling resistance and thermal degradability. Polym. Test. 2018, 67, 169–176. [Google Scholar] [CrossRef]

- Herrera, R.; Franco, L.; Rodríguez-Galán, A.; Puiggalí, J. Characterization and degradation behavior of poly(butylene adipate-co-terephthalate)s. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 4141–4157. [Google Scholar] [CrossRef]

- Murphy, S.H.; Leeke, G.A.; Jenkins, M.J. A Comparison of the use of FTIR spectroscopy with DSC in the characterisation of melting and crystallisation in polycaprolactone. J. Therm. Anal. Calorim. 2012, 107, 669–674. [Google Scholar] [CrossRef]

- Dou, Q.; Cai, J. Investigation on Polylactide (PLA)/Poly(butylene adipate-co-terephthalate) (PBAT)/Bark Flour of Plane Tree (PF) Eco-Composites. Materials 2016, 9, 393. [Google Scholar] [CrossRef]

- Gigante, V.; Coltelli, M.-B.; Vannozzi, A.; Panariello, L.; Fusco, A.; Trombi, L.; Donnarumma, G.; Danti, S.; Lazzeri, A. Flat Die Extruded Biocompatible Poly(Lactic Acid) (PLA)/Poly(Butylene Succinate) (PBS) Based Films. Polymers 2019, 11, 1857. [Google Scholar] [CrossRef] [PubMed]

- Wenyong, D.; Xu, W.; Yongjin, L. Formation of co-continuous PLLA/PC blends with significantly improved physical properties by reactive comb polymers. J. Appl. Polym. Sci. 2018, 135, 46047. [Google Scholar] [CrossRef]

- Tan, L.; Chen, Y.; Zhou, W.; Nie, H.; Li, F.; He, X. Novel poly(butylene succinate-co-lactic acid) copolyesters: Synthesis, crystallization, and enzymatic degradation. Polym. Degrad. Stab. 2010, 95, 1920–1927. [Google Scholar] [CrossRef]

- Lee, S.H.; Lim, S.W.; Lee, K.H. Properties of potentially biodegradable copolyesters of (succinic acid-1,4-butanediol)/(dimethyl terephthalate-1,4-butanediol). Polym. Int. 1999, 48, 861–867. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Huang, H.-D.; Ji, X.; Yan, D.-X.; Zhong, G.-J.; Hsiao, B.S.; Li, Z.-M. Super-Robust Polylactide Barrier Films by Building Densely Oriented Lamellae Incorporated with Ductile in Situ Nanofibrils of Poly(butylene adipate-co-terephthalate). ACS Appl. Mater. Interf. 2016, 8, 8096–8109. [Google Scholar] [CrossRef] [PubMed]

- Číhal, P.; Vopička, O.; Lanč, M.; Kludský, M.; Velas, J.; Hrdlička, Z.; Michalcová, A.; Dendisová, M.; Friess, K. Poly(butylene succinate)-cellulose triacetate blends: Permeation, pervaporation, sorption and physical structure. Polym. Test. 2018, 65, 468–479. [Google Scholar] [CrossRef]

| Sample | T0.1% (°C) | T99% (°C) | Tc PBAT (°C) | Tc PBS (°C) | ΔHc PBAT (J/g) | ΔHc PBS (J/g) |

|---|---|---|---|---|---|---|

| PBAT | 91.4 | 56.8 | 67.4 | - | 21.0 | - |

| PBS25-PBAT75- | 99.3 | −38 | 66.6 | 40.0 (Tc1), 21.3 (Tc2) | 17.5 (23.3) | 15.6 (62.4) |

| PBS50/PBAT50 | 91.2 | 58.3 | 69.2 | 83.3 | 9.5 (19) | 33.4 (66.8) |

| PBS75/PBAT25 | 91.4 | 62.4 | N.D. | 83.3 | 6.1 (24.4) | 52.5 (70) |

| PBS | 91.8 | 75.2 | - | 84.3 | - | 72.3 |

| Sample | T0.1% (°C) | T99% (°C) | Tm PBAT (°C) | Tm PBS (°C) | ΔHm PBAT (J/g) | ΔHm PBS (J/g) | ΔXPBAT (%) | ΔXPBS (%) |

|---|---|---|---|---|---|---|---|---|

| PBAT | 84.3 | 140.2 | 120.9 | - | 22.2 | - | 19.5 | - |

| PBS25/PBAT75 | 89.7 | 143.6 | 122.5 | 114.0 | 8.3 (11.1) | 16.7 (66.8) | 9.7 | 60.7 |

| PBS50/PBAT50 | 90.8 | 133.8 | 122.8 | 101.1 (Tm1), 113.1 (Tm2) | 3.9 (7.8) | 28.4 (56.8) | 6.8 | 51.6 |

| PBS75/PBAT25 | 105.4 | 120.3 | N.D. | 101.2 (Tm1), 113.0 (Tm2) | 1.9 (7.6) | 54.1 (72.1) | 6.7 | 65.6 |

| PBS | 106.0 | 119.4 | - | 101.8 (Tm1), 113.6 (Tm2) | - | 72.2 | - | 65.6 |

| Sample | T5% (°C) | Tmax (°C) | Char600 (%) |

|---|---|---|---|

| PBAT | 373 | 407 | 5.0 |

| PBS25/PBAT75 | 354 | 406 | 4.7 |

| PBS50/PBAT50 | 349 | 404 | 3.4 |

| PBS75/PBAT25 | 343 | 400 | 4.2 |

| PBS | 343 | 402 | 0.6 |

| Sample | Elastic Modulus E | Strain at Break ε | Stress at Break σR |

|---|---|---|---|

| MPa | % | MPa | |

| PBAT | 81.0 ± 2.5 | 689.5 ± 110.3 | 20.1 ± 2.4 |

| PBS25/PBAT75 | 134.9 ± 1.1 | 393.1 ± 13.0 | 22.7 ± 1.1 |

| PBS50/PBAT50 | 299.8 ± 4.0 | 16.4 ± 0.3 | 15.2 ± 0.0 |

| PBS75/PBAT25 | 488.8 ± 7.2 | 10.2 ± 0.3 | 10.2 ± 0.2 |

| PBS | 725.6 ± 15.6 | 7.1 ± 0.3 | 29.6 ± 1.5 |

| Samples | Water Vapor | Oxygen |

|---|---|---|

| PWV × 1012 [mol/m·s·Pa] | PO × 1016 [mol/m·s·Pa] | |

| PBAT | 7.09 ± 0.08 | 4.41 ± 0.01 |

| PBS25/PBAT75 | 6.49 ± 0.03 | 3.13 ± 0.01 |

| PBS50/PBAT50 | 3.83 ± 0.04 | 1.23 ± 0.01 |

| PBS75/PBAT25 | 2.90 ± 0.02 | 0.68 ± 0.01 |

| PBS | 2.74 ± 0.01 | 0.98 ± 0.01 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Matos Costa, A.R.; Crocitti, A.; Hecker de Carvalho, L.; Carroccio, S.C.; Cerruti, P.; Santagata, G. Properties of Biodegradable Films Based on Poly(butylene Succinate) (PBS) and Poly(butylene Adipate-co-Terephthalate) (PBAT) Blends. Polymers 2020, 12, 2317. https://doi.org/10.3390/polym12102317

de Matos Costa AR, Crocitti A, Hecker de Carvalho L, Carroccio SC, Cerruti P, Santagata G. Properties of Biodegradable Films Based on Poly(butylene Succinate) (PBS) and Poly(butylene Adipate-co-Terephthalate) (PBAT) Blends. Polymers. 2020; 12(10):2317. https://doi.org/10.3390/polym12102317

Chicago/Turabian Stylede Matos Costa, Anna Raffaela, Andrea Crocitti, Laura Hecker de Carvalho, Sabrina Carola Carroccio, Pierfrancesco Cerruti, and Gabriella Santagata. 2020. "Properties of Biodegradable Films Based on Poly(butylene Succinate) (PBS) and Poly(butylene Adipate-co-Terephthalate) (PBAT) Blends" Polymers 12, no. 10: 2317. https://doi.org/10.3390/polym12102317

APA Stylede Matos Costa, A. R., Crocitti, A., Hecker de Carvalho, L., Carroccio, S. C., Cerruti, P., & Santagata, G. (2020). Properties of Biodegradable Films Based on Poly(butylene Succinate) (PBS) and Poly(butylene Adipate-co-Terephthalate) (PBAT) Blends. Polymers, 12(10), 2317. https://doi.org/10.3390/polym12102317