Impact of Polymer Binders on the Structure of Highly Filled Zirconia Feedstocks

Abstract

1. Introduction

2. Experimental

2.1. Materials

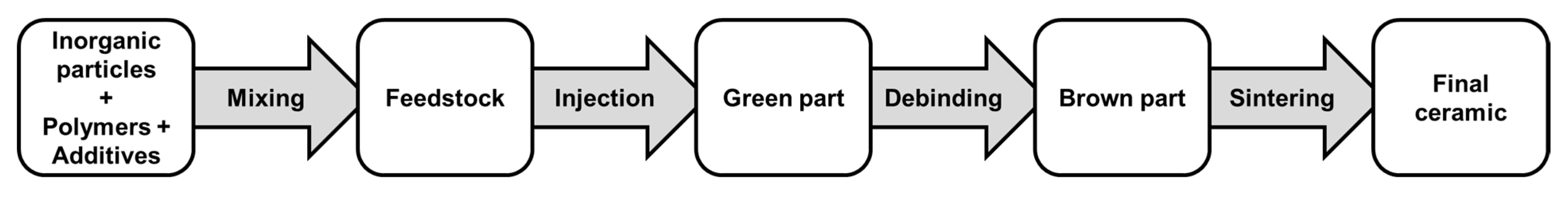

2.2. Processing

2.3. Characterization

2.3.1. Rheological Study

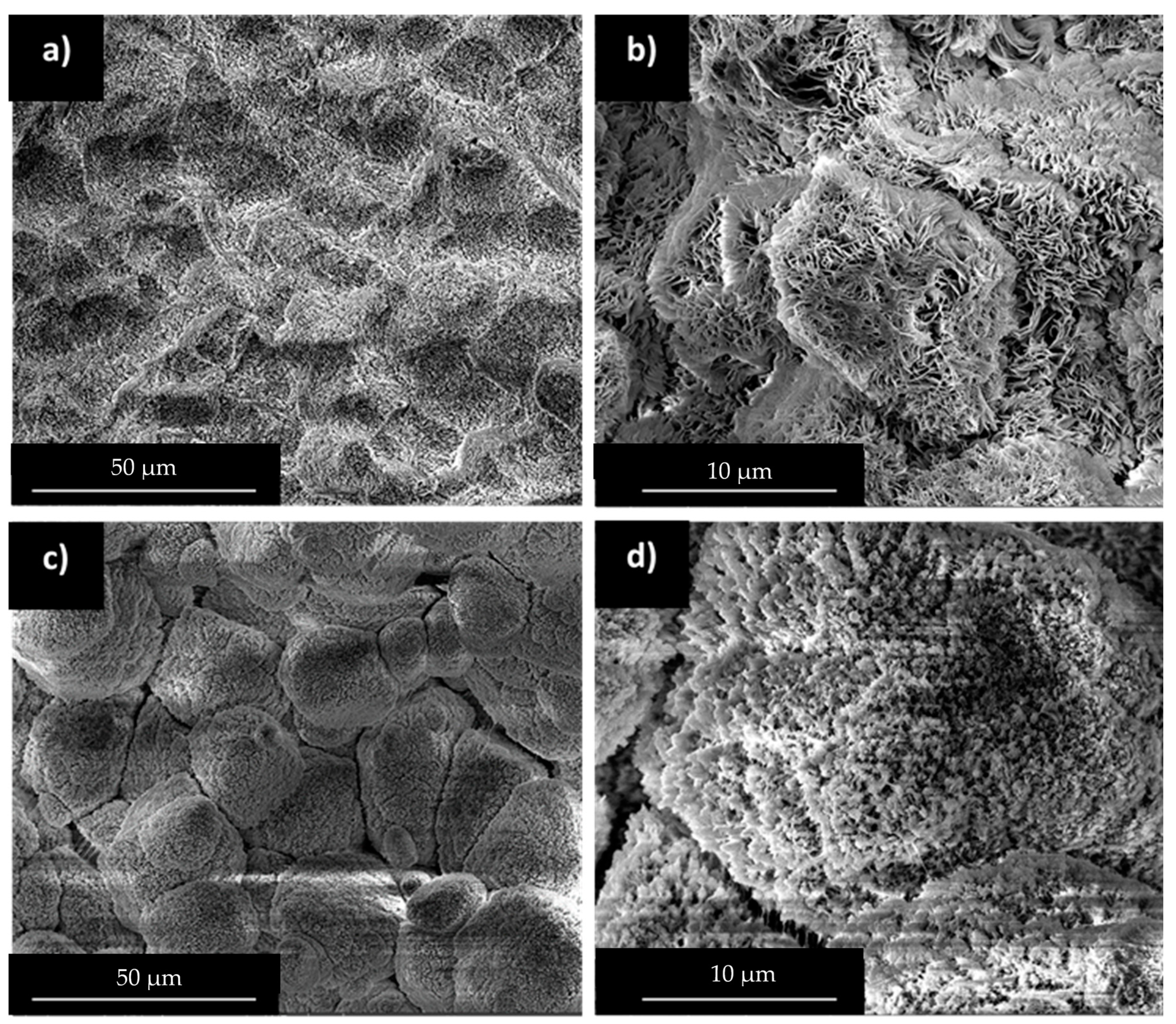

2.3.2. Scanning Electron Microscopy (SEM)

2.3.3. Mercury Injection Porosimetry

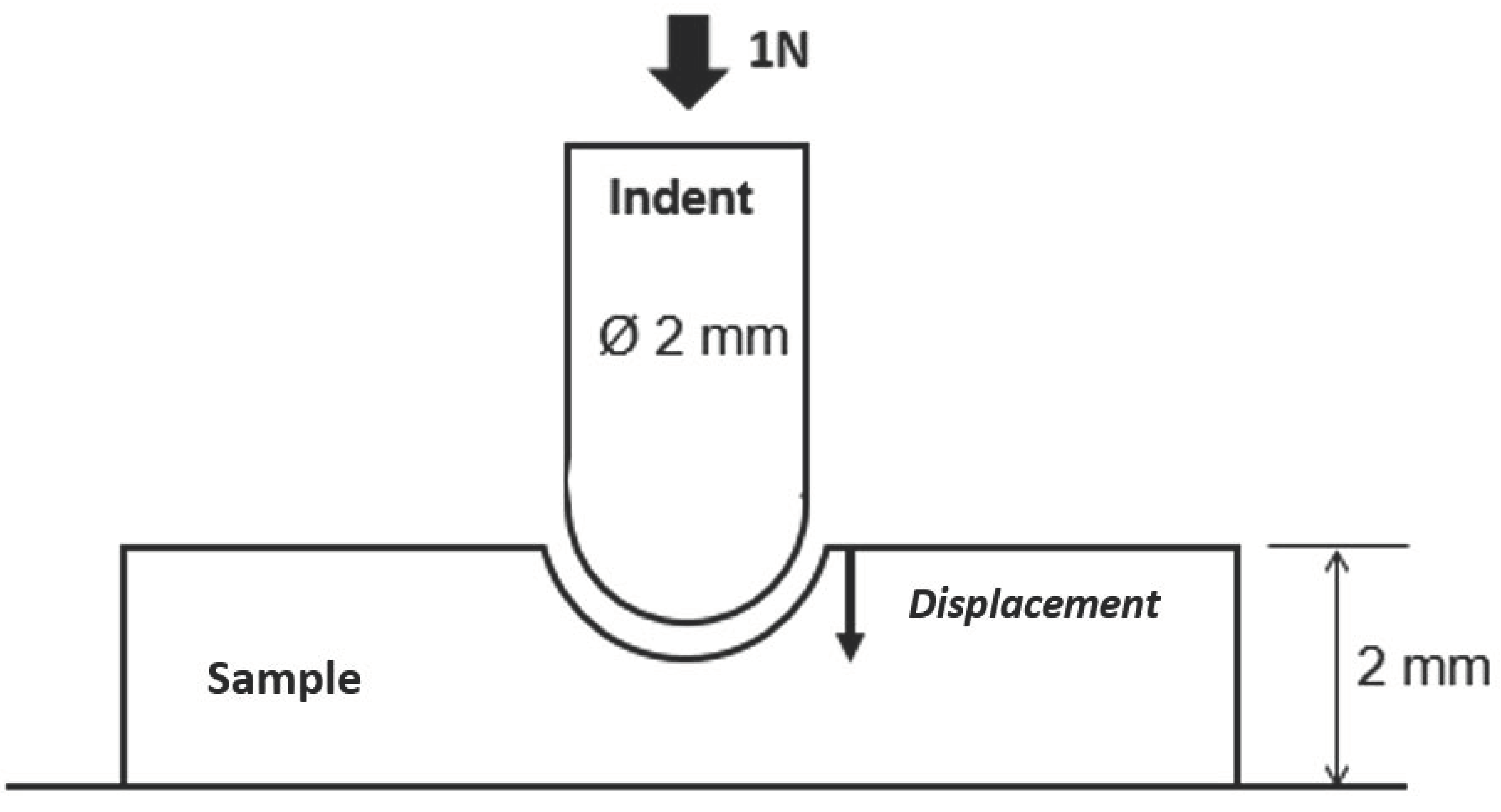

2.3.4. Penetration Tests

2.3.5. Density Measurements

3. Results and Discussions

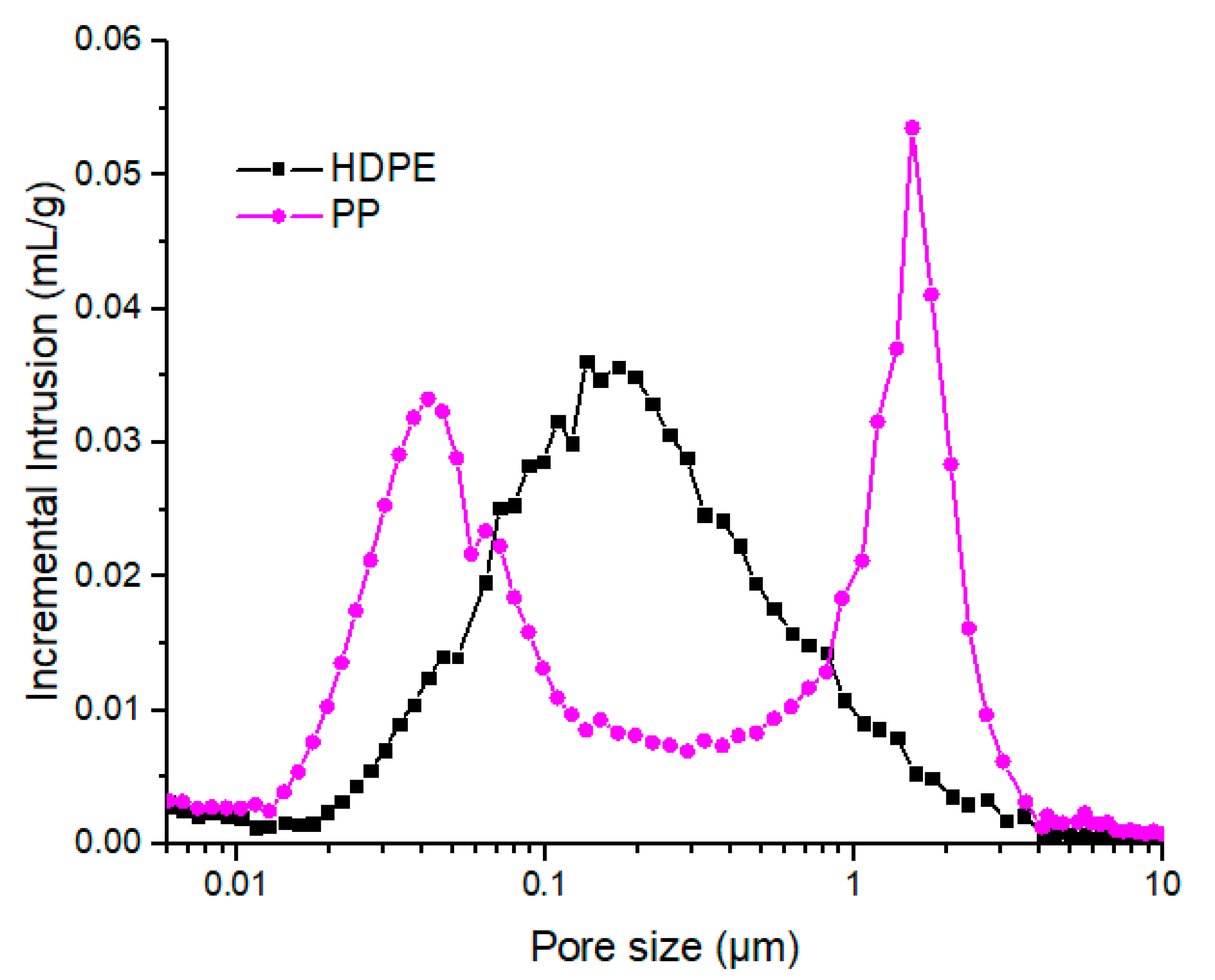

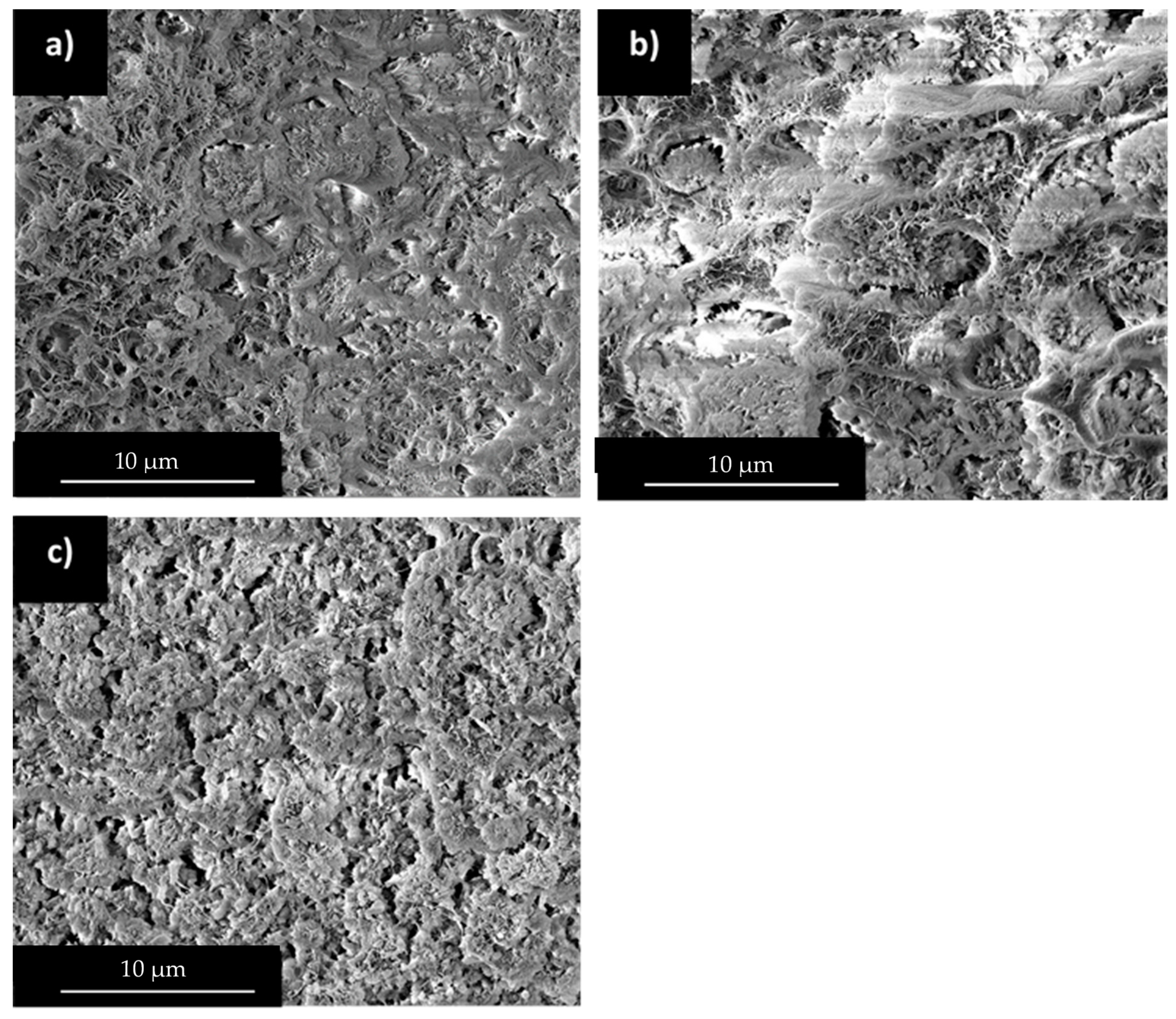

3.1. PP/Wax and PE/Wax Morphologies

3.2. HDPE/PP/wax Blends Morphology

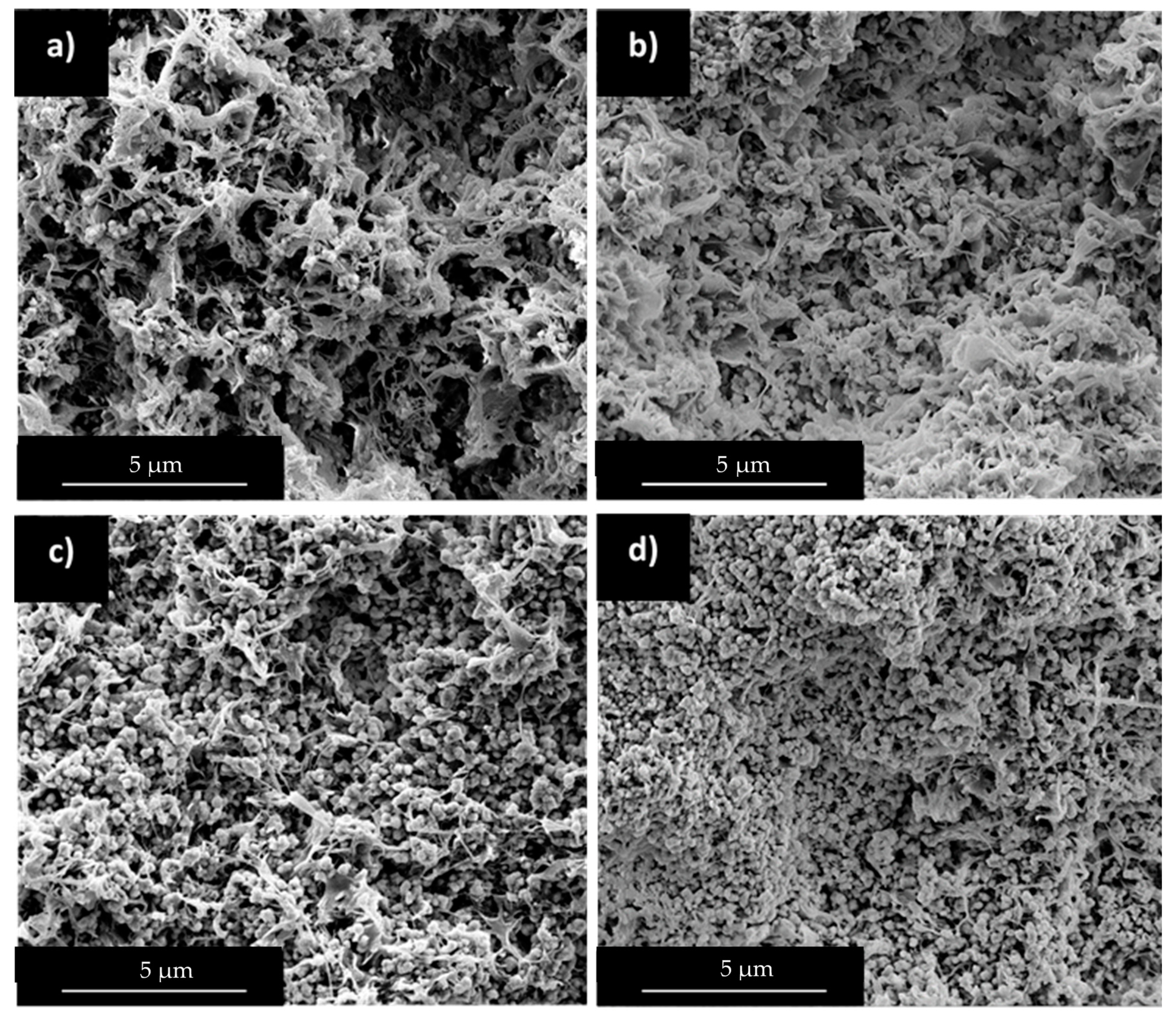

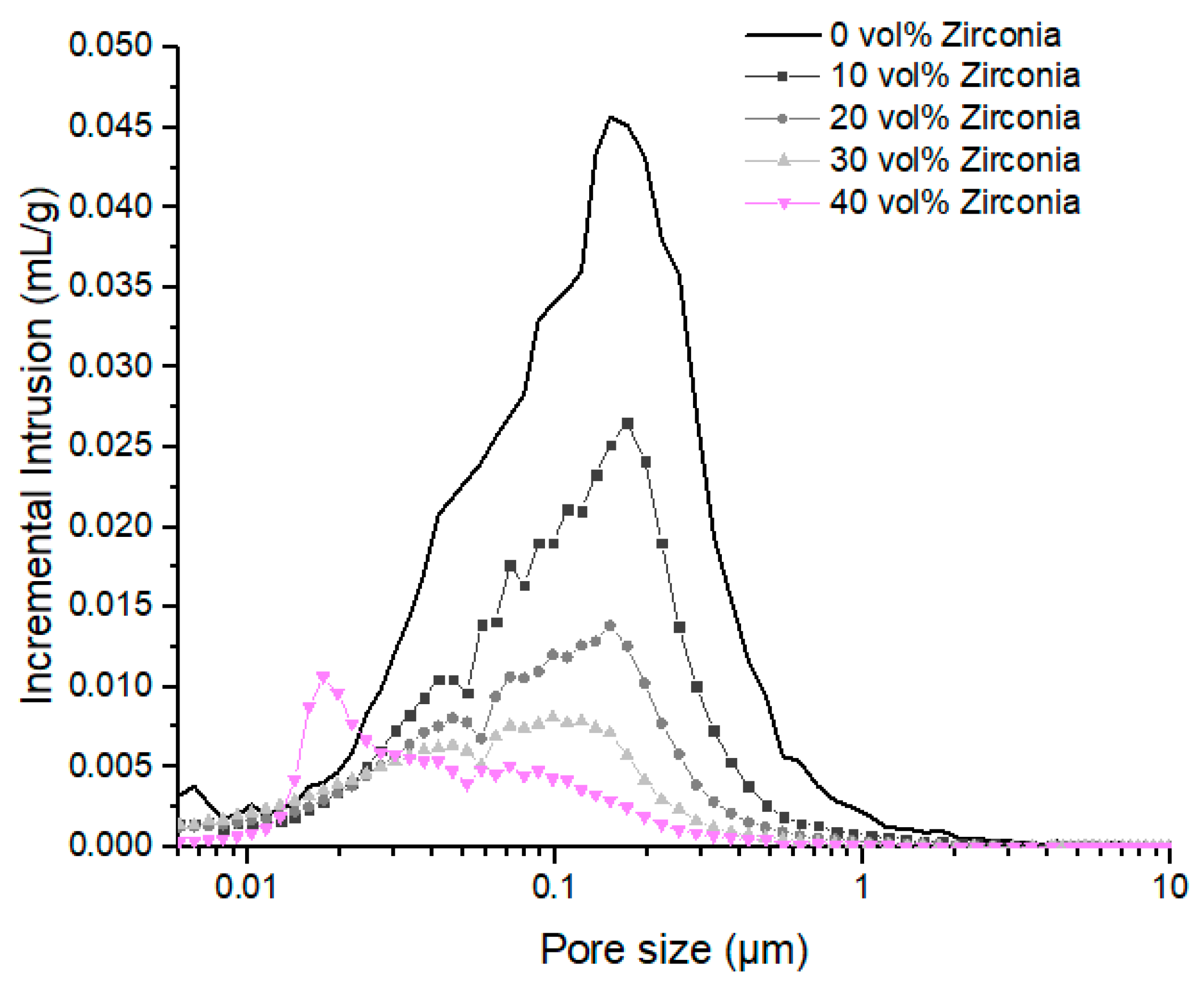

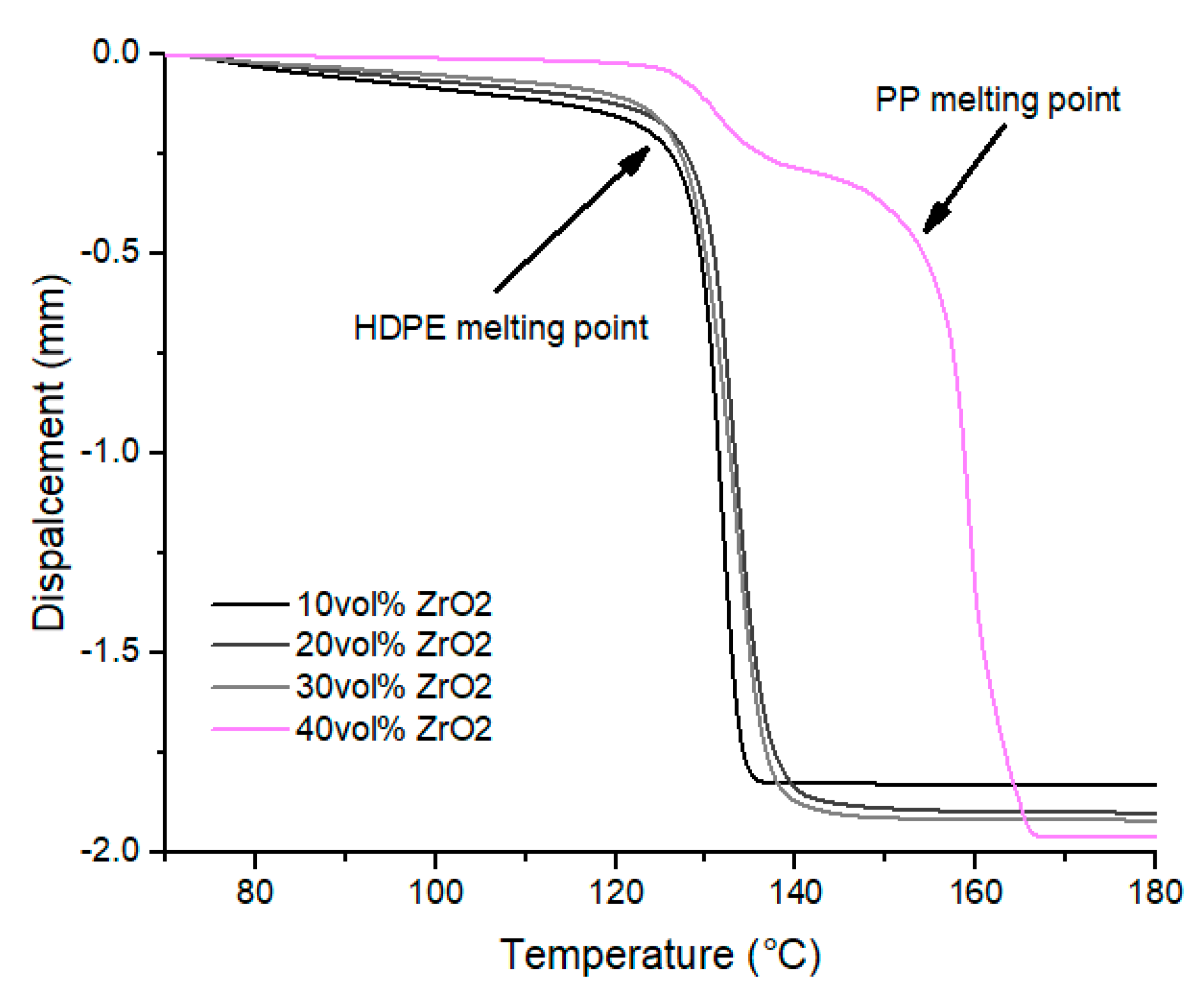

3.3. Zirconia Addition in HDPE/PP/Wax

3.4. Zirconia Addition with Varying HDPE/PP Ratios

4. Conclusions

- ◦

- A high miscibility of plasticizer in backbone binders in the molten state limits phase segregation during crystallization, thus facilitating the creation a finer and more homogeneous wax network in organic matrices.

- ◦

- As solid content increases, interparticle distances are restricted, and the wax network is shifted towards smaller pores. Above 40 vol%, the percolation of fillers induces major modifications in the organization of organic phases and the wax network becomes monomodal and sharp, attesting to blend homogeneity.

- ◦

- As HDPE content in backbone binder increases in 50 vol% loaded feedstocks, a thinner wax network is promoted, restricting diffusion distances and favoring high ceramic densification ability. Using a minimum HDPE content of 70 wt%, sintered densities of 6.065 are obtained.

Author Contributions

Funding

Conflicts of Interest

References

- Davit, B. Binder Systems for Powder Injection Moulding. Ph.D. Thesis, Tomas Bata University in Zlín, Zlín, Czechia, 2015. [Google Scholar]

- Marie-Camille, A. Dispersion of Zirconia Particles in Polyolefins: Rheology and Application to Ceramic Injection Molding. Ph.D. Thesis, Université de Lyon, Lyon, France, 2017. [Google Scholar]

- Auscher, M.-C.; Fulchiron, R.; Périé, T.; Cassagnau, P. Morphological and rheological properties of zirconia filled polyethylene. Polymer 2017, 132, 174–179. [Google Scholar] [CrossRef]

- Wolfrum, S.M.; Ponjee, J.J. Surface modification of powders with carboxylic acids. J. Mater. Sci. Lett. 1989, 8, 667–669. [Google Scholar] [CrossRef]

- Liu, D.-M.; Tseng, W.J. Influence of solids loading on the green microstructure and sintering behaviour of ceramic injection mouldings. J. Mater. Sci. 1997, 32, 6475–6481. [Google Scholar] [CrossRef]

- Liu, D.M.O.; Tseng, W.J. Influence of debinding rate, solid loading and binder formulation on the green microstructure and sintering behavior of ceramic injection mouldings. Ceram. Int. 1998, 24, 471–481. [Google Scholar] [CrossRef]

- Kalyon, D.M.; Aktas, S. Factors Affecting the Rheology and Processability of Highly Filled Suspensions. Annu. Rev. Chem. Biomol. Eng. 2014, 5, 229–254. [Google Scholar] [CrossRef] [PubMed]

- Chartier, T.; Ferrato, M.; Baumard, J.-F. Influence of the debinding method on the mechanical properties of plastic formed ceramics. J. Eur. Ceram. Soc. 1995, 15, 899–903. [Google Scholar] [CrossRef]

- Gorjan, L. Wick Debinding—An Effective Way of Solving Problems in the Debinding Process of Powder Injection Molding. Some Crit. Issues Inject. Molding 2012, 1, 89–104. [Google Scholar]

- Fan, Y.-L.; Hwang, K.S.; Su, S.-C. Improvement of the Dimensional Stability of Powder Injection Molded Compacts by Adding Swelling Inhibitor into the Debinding Solvent. Met. Mater. Trans. A 2007, 39, 395–401. [Google Scholar] [CrossRef]

- Ani, S.M.; Muchtar, A.; Muhamad, N.; Ghani, J.A. Binder removal via a two-stage debinding process for ceramic injection molding parts. Ceram. Int. 2014, 40, 2819–2824. [Google Scholar] [CrossRef]

- Kim, J.; Ahn, S.; Atre, S.V.; Park, S.J.; Kang, T.G.; German, R. Imbalance filling of multi-cavity tooling during powder injection molding. Powder Technol. 2014, 257, 124–131. [Google Scholar] [CrossRef]

- Cima, M.J.; Lewis, J.A.; DeVoe, A.D. Binder Distribution in Ceramic Greenware during Thermolysis. J. Am. Ceram. Soc. 1989, 72, 1192–1199. [Google Scholar] [CrossRef]

- Krug, S.; Evans, J.; Ter Maat, J. Residual stresses and cracking in large ceramic injection mouldings subjected to different solidification schedules. J. Eur. Ceram. Soc. 2000, 20, 2535–2541. [Google Scholar] [CrossRef]

- Krug, S.; Evans, J.R.G.; Maat, J.H.H. Aetiology of Defects in Large Ceramic Moldings. J. Am. Ceram. Soc. 1999, 82, 2094–2100. [Google Scholar] [CrossRef]

- Song, J.H.; Evans, J. Flocculation after injection molding in ceramic suspensions. J. Mater. Res. 1994, 9, 2386–2397. [Google Scholar] [CrossRef]

- Hwang, K.S.; Shu, G.J.; Lee, H.J. Solvent debinding behavior of powder injection molded components prepared from powders with different particle sizes. Met. Mater. Trans. A 2005, 36, 161–167. [Google Scholar] [CrossRef]

- Liu, D.-M.; Tseng, W.J. Porosity development in ceramic injection mouldings via different burnout strategies. J. Mater. Sci. Lett. 1997, 16, 482–484. [Google Scholar] [CrossRef]

- Hwang, K.S.; Hsieh, Y.M. Comparative study of pore structure evolution during solvent and thermal debinding of powder injection molded parts. Met. Mater. Trans. A 1996, 27, 245–253. [Google Scholar] [CrossRef]

- Fan, Y.-L.; Hwang, K.S.; Wu, S.-H.; Liau, Y.-C. Minimum Amount of Binder Removal Required during Solvent Debinding of Powder-Injection-Molded Compacts. Met. Mater. Trans. A 2009, 40, 768–779. [Google Scholar] [CrossRef]

- Hu, S.; Hwang, K. Dilatometric analysis of thermal debinding of injection moulded iron compacts. Powder Met. 2000, 43, 239–244. [Google Scholar] [CrossRef]

- Rueda, M.M.; Auscher, M.-C.; Fulchiron, R.; Périé, T.; Martin, G.; Sonntag, P.; Cassagnau, P. Rheology and applications of highly filled polymers: A review of current understanding. Prog. Polym. Sci. 2017, 66, 22–53. [Google Scholar] [CrossRef]

- Park, J.M.; Han, J.S.; Gal, C.W.; Oh, J.W.; Kate, K.H.; Atre, S.V.; Kim, Y.; Park, S.J. Effect of binder composition on rheological behavior of PMN-PZT ceramic feedstock. Powder Technol. 2018, 330, 19–26. [Google Scholar] [CrossRef]

- Auscher, M.; Fulchiron, R.; Fougerouse, N.; Périé, T.; Cassagnau, P. Zirconia based feedstocks: Influence of particle surface modification on the rheological properties. Ceram. Int. 2017, 43, 16950–16956. [Google Scholar] [CrossRef]

- Dimitri, C.; Mohamed, S.; Thierry, B.; Jean-Claude, G. Influence of particle-size distribution and temperature on the rheological properties of highly concentrated Inconel feedstock alloy. Powder Technol. 2017, 322, 273–289. [Google Scholar] [CrossRef]

- Hsu, K.C.; Lin, C.C.; Lo, G.M. The effect of wax composition on the injection molding of carbonyl iron powder with LDPE. Can. Metall. Q. 1996, 35, 181–187. [Google Scholar] [CrossRef]

- Karatas, C.; Kocer, A.; Unal, H.I.; Saritas, S. Rheological properties of feedstocks prepared with steatite powder and polyethylene-based thermoplastic binders. J. Mater. Process. Technol. 2004, 152, 77–83. [Google Scholar] [CrossRef]

- Ren, S.B.; He, X.B.; Qu, X.H.; Humail, I.S.; Li, Y. Effects of binder compositions on characteristics of feedstocks of microsized SiC ceramic injection moulding. Powder Met. 2007, 50, 255–259. [Google Scholar] [CrossRef]

- Lin, H.-K.; Hwang, K.-S. In situ dimensional changes of powder injection-molded compacts during solvent debinding. Acta Mater. 1998, 46, 4303–4309. [Google Scholar] [CrossRef]

- Huang, M.-S.; Hsu, H.-C. Effect of backbone polymer on properties of 316L stainless steel MIM compact. J. Mater. Process. Technol. 2009, 209, 5527–5535. [Google Scholar] [CrossRef]

- Setasuwon, P.; Bunchavimonchet, A.; Danchaivijit, S. The effects of binder components in wax/oil systems for metal injection molding. J. Mater. Process. Technol. 2008, 196, 94–100. [Google Scholar] [CrossRef]

- Kim, S.; Lee, H.-W.; Song, H. Effect of minor binder on capillary structure evolution during wicking. Ceram. Int. 1999, 25, 671–676. [Google Scholar] [CrossRef]

- Wen, J.; Cao, W.; Yang, X.; Xie, Z. Effects of different backbone binders on the characteristics of zirconia parts using wax-based binder system via ceramic injection molding. J. Adv. Ceram. 2016, 5, 321–328. [Google Scholar] [CrossRef]

- Wen, J.; Liu, W.; Xie, Z.; Lou, C.; Yang, X. Effects of the binder compositions on the homogeneity of ceramic injection molded compacts. Ceram. Int. 2018, 44, 3218–3225. [Google Scholar] [CrossRef]

- Tseng, W.J.; Hsu, C.K. Cracking defect and porosity evolution during thermal debinding in ceramic injection moldings. Ceram. Int. 1999, 25, 461–466. [Google Scholar] [CrossRef]

- Robert, M.; Fulchiron, R.; Cassagnau, P. Rheology and crystallization behavior of polypropylene and high-density polyethylene in the presence of a low molar mass polyethylene. Polym. Cryst. 2019, 2, 1–14. [Google Scholar] [CrossRef]

- Giesche, H. Mercury Porosimetry: A General (Practical) Overview. Part. Part. Syst. Charact. 2006, 23, 1–11. [Google Scholar] [CrossRef]

- Staněk, M.; Géraud, Y. Granite micro-porosity changes due to fracturing and alteration: Secondary mineral phases as proxies for porosity and permeability estimation. Solid Earth 2019, 10, 251–274. [Google Scholar] [CrossRef]

- Ponsard-Fillette, M.; Barres, C.; Cassagnau, P. Viscoelastic study of oil diffusion in molten PP and EPDM copolymer. Polymer 2005, 46, 10256–10268. [Google Scholar] [CrossRef]

- Gimenez, J. Philippe Cassagnau, et Alain Michel, Bulk polymerization of -caprolactone: Rheological predictive laws. J. Rheol. 2000, 43, 527–546. [Google Scholar] [CrossRef]

- Krupa, I.; Luyt, A.S. Physical properties of blends of LLDPE and an oxidized paraffin wax. Polymer 2001, 42, 7285–7289. [Google Scholar] [CrossRef]

- Krupa, I.; Luyt, A.S. Thermal properties of polypropylene/wax blends. Thermochim. Acta 2001, 372, 137–141. [Google Scholar] [CrossRef]

- Montes, P.; Rafiq, Y.; Hill, M. A study of blends of isotactic polypropylene with high density polyethylene by transmission electron microscopy. Polymer 1998, 39, 6669–6672. [Google Scholar] [CrossRef]

- Blackadder, D.A.; Richardson, M.J.; Savill, N.G. Characterization of Blends of High Density Polyethylene with Isotactic Polypropylene. Makromol. Chem. 1981, 182, 1271–1282. [Google Scholar] [CrossRef]

- Noel, O.F.; Carley, J.F. Morphology of polyethylene-polypropylene blends. Polym. Eng. Sci. 1984, 24, 488–492. [Google Scholar] [CrossRef]

- Shivashankar, T.S.; Enneti, R.K.; Park, S.; German, R.; Atre, S.V. The effects of material attributes on powder–binder separation phenomena in powder injection molding. Powder Technol. 2013, 243, 79–84. [Google Scholar] [CrossRef]

- Bernal, J.D.; Mason, J. Packing of Spheres: Co-ordination of Randomly Packed Spheres. Nature 1960, 188, 910–911. [Google Scholar] [CrossRef]

- Barnes, H.A. Review of the rheology of filled viscoelastic systems, Rheology Reviews, The British Society of Rheology. Rheol. Rev. 2003, 1–36. [Google Scholar]

- Liu, D.-M. Influence of solid loading and particle size distribution on the porosity development of green alumina ceramic mouldings. Ceram. Int. 1997, 23, 513–520. [Google Scholar] [CrossRef]

- Yang, W.-W.; Yang, K.-Y.; Wang, M.-C.; Hon, M.-H. Solvent debinding mechanism for alumina injection molded compacts with water-soluble binders. Ceram. Int. 2003, 29, 745–756. [Google Scholar] [CrossRef]

- Yang, X.; Jia, C.; Xie, Z.; Liu, W.; Liu, Q. Water-Soluble Binder System Based on Poly-Methyl Methacrylate and Poly-Ethylene Glycol for Injection Molding of Large-Sized Ceramic Parts. Int. J. Appl. Ceram. Technol. 2012, 10, 339–347. [Google Scholar] [CrossRef]

| Binder | Supplier | Density | Crystallization Temperature | Degradation Temperature |

|---|---|---|---|---|

| Polyethylene | Axalta, Bulle, Swizterland | 0.950 | 115 °C | 460 °C |

| Polypropylene | Total, Paris, France | 0.905 | 120 °C | 430 °C |

| Paraffin wax | Alphawax, Alphen, Neetherlands | 0.785 | 47 °C | 310 °C |

| Stearic acid | Sigma Aldrich, Saint-Louis, MO, US | 0.845 | 65 °C | 250 °C |

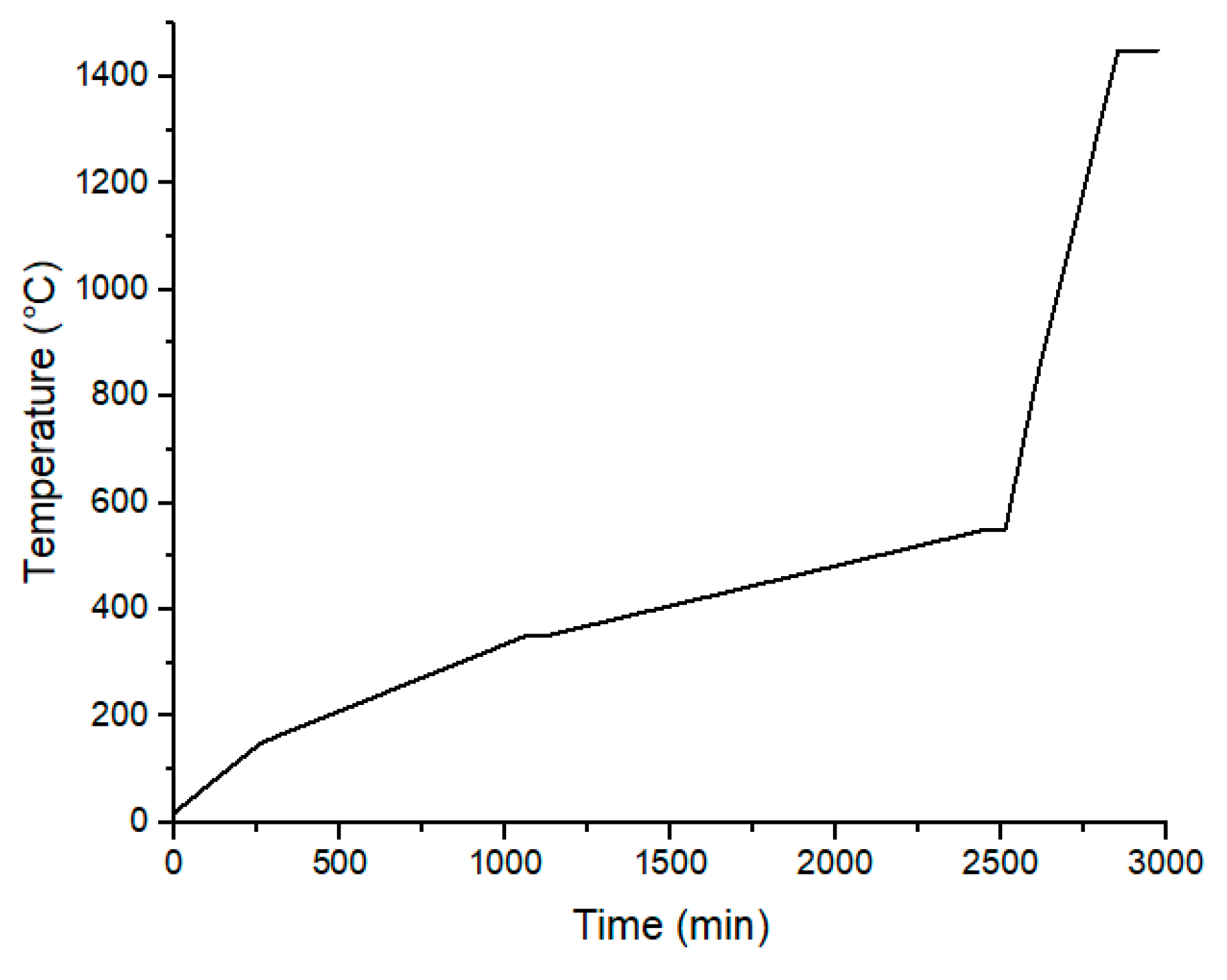

| Temperature (°C) | Speed (°C/h) | Holding Time (min) |

|---|---|---|

| 20 | 0 | 0 |

| 150 | 30 | 0 |

| 350 | 15 | 60 |

| 550 | 9 | 60 |

| 820 | 180 | 0 |

| 1450 | 150 | 120 |

| HDPE (wt%) | PP (wt%) | Wax (wt%) |

|---|---|---|

| 90 | 0 | 10 |

| 80 | 0 | 20 |

| 35 | 0 | 65 |

| 0 | 90 | 10 |

| 0 | 80 | 20 |

| Solid Loading (vol%) | Interspacing Parameter (nm) |

|---|---|

| 10 | 330 |

| 20 | 190 |

| 30 | 120 |

| 40 | 70 |

| 50 | 40 |

| HDPE/PP Ratio | Sintered Density |

|---|---|

| 100/0 | 6.065 |

| 70/30 | 6.065 |

| 50/50 | 6.053 |

| 30/70 | 6.048 |

| 0/100 | 6.040 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delaroa, C.; Fulchiron, R.; Lintingre, E.; Buniazet, Z.; Cassagnau, P. Impact of Polymer Binders on the Structure of Highly Filled Zirconia Feedstocks. Polymers 2020, 12, 2247. https://doi.org/10.3390/polym12102247

Delaroa C, Fulchiron R, Lintingre E, Buniazet Z, Cassagnau P. Impact of Polymer Binders on the Structure of Highly Filled Zirconia Feedstocks. Polymers. 2020; 12(10):2247. https://doi.org/10.3390/polym12102247

Chicago/Turabian StyleDelaroa, Claire, René Fulchiron, Eric Lintingre, Zoé Buniazet, and Philippe Cassagnau. 2020. "Impact of Polymer Binders on the Structure of Highly Filled Zirconia Feedstocks" Polymers 12, no. 10: 2247. https://doi.org/10.3390/polym12102247

APA StyleDelaroa, C., Fulchiron, R., Lintingre, E., Buniazet, Z., & Cassagnau, P. (2020). Impact of Polymer Binders on the Structure of Highly Filled Zirconia Feedstocks. Polymers, 12(10), 2247. https://doi.org/10.3390/polym12102247