Biocomposites Based on Plasticized Wheat Flours: Effect of Bran Content on Thermomechanical Behavior

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Milled Products, Their Plasticization and Blending

2.3. Characterization of Flours and TPWF-Based Composites

2.3.1. Alveographic Properties

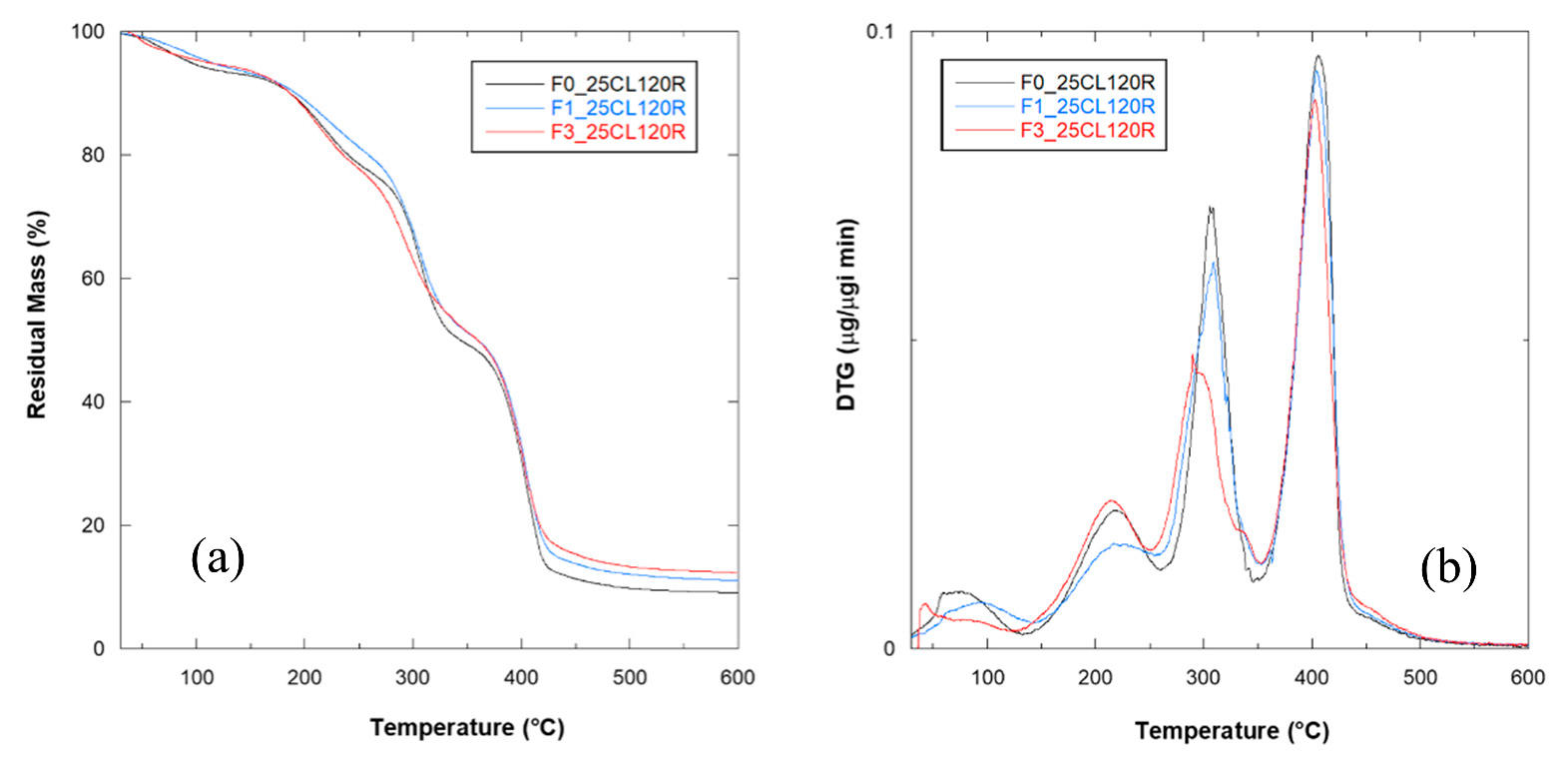

2.3.2. Thermogravimetric Analysis

2.3.3. Tensile Tests

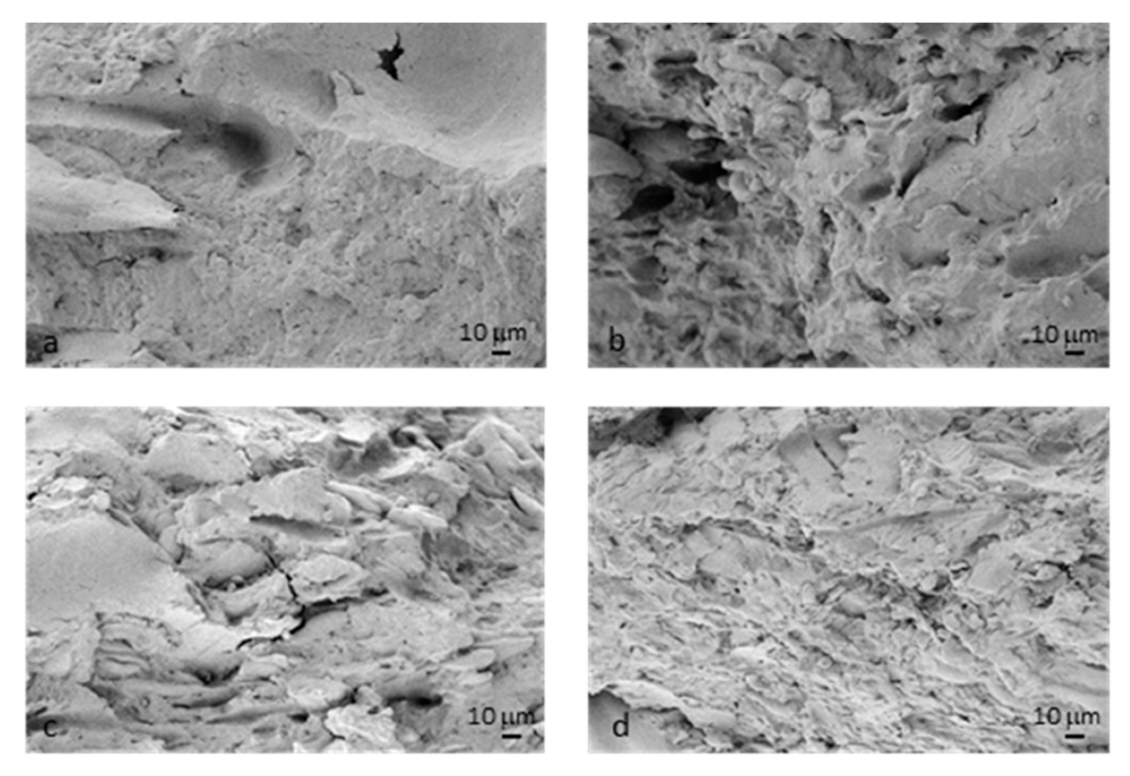

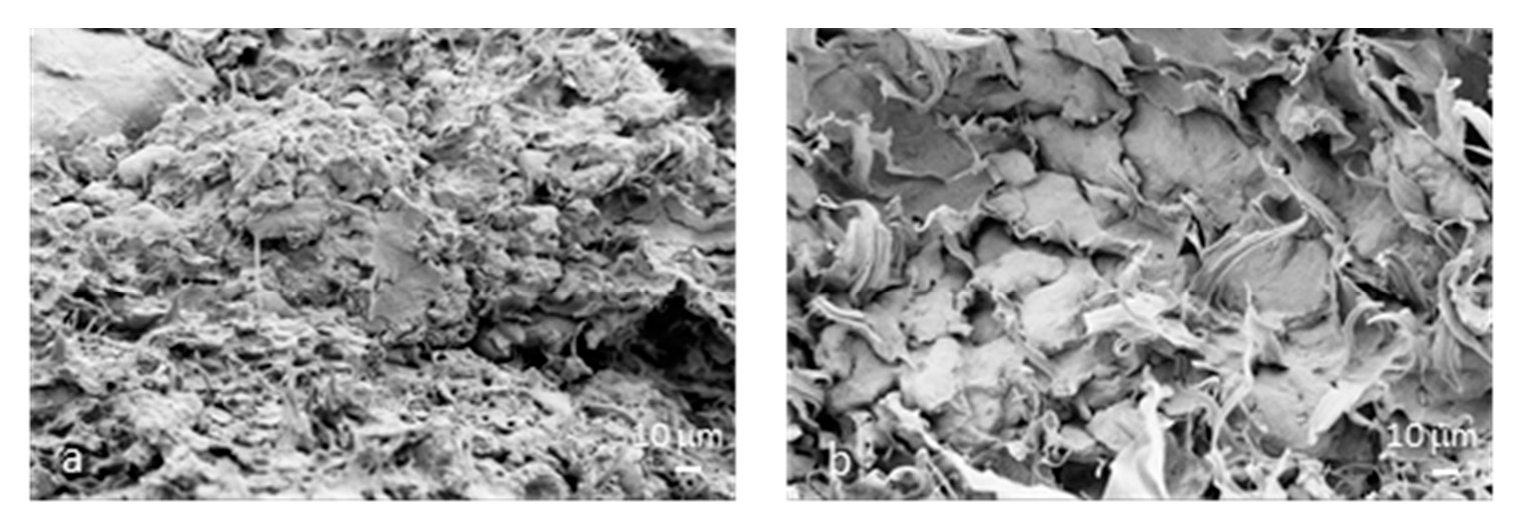

2.3.4. Morphological Evaluation

2.3.5. Disintegration in Compost

2.3.6. Evaluation of Phytotoxicity

- Gc = average number of germinated seeds in the sample

- Gt = average number of seeds germinated in the control

- Lc = average root length in the sample

- Lt = average root length in the control

2.3.7. Statistical Analysis

3. Results and Discussion

Wheat Flour Characterization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Leblanc, N.; Saiah, R.; Beucher, E.; Gattin, R.; Castandet, M.; Saiter, J.-M. Structural investigation and thermal stability of new extruded wheat flour based polymeric materials. Carbohyd. Polym. 2008, 73, 548–557. [Google Scholar] [CrossRef] [PubMed]

- Soccio, M.; Dominici, F.; Quattrosoldi, S.; Luzi, F.; Munari, A.; Torre, L.; Puglia, D. PBS-based green copolymer as efficient compatibilizer in Thermoplastic inedible Wheat Flour/Poly (Butylene Succinate) Blends. Biomacromolecules 2020, 21, 3254–3269. [Google Scholar] [CrossRef] [PubMed]

- Benincasa, P.; Dominici, F.; Bocci, L.; Governatori, C.; Panfili, I.; Tosti, G.; Torre, L.; Puglia, D. Relationships between wheat flour baking properties and tensile characteristics of derived thermoplastic films. Ind. Crop. Prod. 2017, 100, 138–145. [Google Scholar] [CrossRef]

- Puglia, D.; Dominici, F.; Kenny, J.M.; Santulli, C.; Governatori, C.; Tosti, G.; Benincasa, P. Tensile behavior of thermoplastic films from wheat flours as function of raw material baking properties. J. Polym. Environ. 2016, 24, 37–47. [Google Scholar] [CrossRef]

- Cano, A.; Jiménez, A.; Cháfer, M.; Gónzalez, C.; Chiralt, A. Effect of amylose:amylopectin ratio and rice bran addition on starch films properties. Carbohyd. Polym. 2014, 111, 543–555. [Google Scholar] [CrossRef]

- Prückler, M.; Siebenhandl-Ehn, S.; Apprich, S.; Höltinger, S.; Haas, C.; Schmid, E.; Kneifel, W. Wheat bran-based biorefinery 1: Composition of wheat bran and strategies of functionalization. LWT-Food Sci. Technol. 2014, 56, 211–221. [Google Scholar] [CrossRef]

- ElMekawy, A.; Diels, L.; De Wever, H.; Pant, D. Valorization of Cereal Based Biorefinery Byproducts: Reality and Expectations. Environ. Sci. Technol. 2013, 47, 9014–9027. [Google Scholar] [CrossRef]

- Bressiani, J.; Oro, T.; Da Silva, P.; Montenegro, F.; Bertolin, T.; Gutkoski, L.; Gularte, M. Influence of milling whole wheat grains and particle size on thermo-mechanical properties of flour using Mixolab. Czech. J. Food Sci. 2019, 37, 276–284. [Google Scholar] [CrossRef]

- Liu, N.; Ma, S.; Li, L.; Wang, X. Study on the effect of wheat bran dietary fiber on the rheological properties of dough. Grain Oil Sci. Technol. 2019, 2, 1–5. [Google Scholar] [CrossRef]

- De Bondt, Y.; Liberloo, I.; Roye, C.; Goos, P.; Courtin, C.M. The impact of wheat (Triticum aestivum L.) bran on wheat starch gelatinization: A differential scanning calorimetry study. Carbohyd. Polym. 2020, 241, 116262. [Google Scholar] [CrossRef]

- Dobircau, L.; Sreekumar, P.A.; Saiah, R.; Leblanc, N.; Terrié, C.; Gattin, R.; Saiter, J.M. Wheat flour thermoplastic matrix reinforced by waste cotton fibre: Agro-green-composites. Compos. Part A-Appl. S. 2009, 40, 329–334. [Google Scholar]

- Pérez-Pacheco, E.; Canto-Pinto, J.C.; Moo-Huchin, V.M.; Estrada-Mota, I.A.; Estrada-León, R.J.; Chel-Guerrero, L. Thermoplastic Starch (TPS)-Cellulosic Fibers Composites: Mechanical Properties and Water Vapor Barrier: A Review. Compos. Renew. Sustain. Mater. 2016, 85–105. [Google Scholar]

- Hanis-Syazwani, M.; Bolarinwa, I.F.; Lasekan, O.; Muhammad, K. Influence of starter culture on the physicochemical properties of rice bran sourdough and physical quality of sourdough bread. Food Res. 2018, 2, 340–349. [Google Scholar]

- Roozendaal, H.; Madian, A.; Frazier, R.A. Thermogravimetric analysis of water release from wheat flour and wheat bran suspensions. J. Food Eng. 2012, 111, 606–611. [Google Scholar] [CrossRef]

- El-Sayed, S. Thermal decomposition, kinetics and combustion parameters determination for two different sizes of rice husk using TGA. Eng. Agric. Environ. Food 2019, 12, 460–469. [Google Scholar]

- Yu, A.-N.; Li, Y.; Yang, Y.; Yu, K. The browning kinetics of the non-enzymatic browning reaction in L-ascorbic acid/basic amino acid systems. Food Sci. Technol. 2018, 38, 537–542. [Google Scholar]

- Edoardo Capuano, E.; Ferrigno, A.; Acampa, I.; Ait-Ameur, L.; Fogliano, V. Characterization of the Maillard reaction in bread crisps. Eur. Food Res. Technol. 2008, 228, 311–319. [Google Scholar]

- Rosell, C.M. The Science of Doughs and Bread Quality. In Flour and Breads and Their Fortification in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2011; pp. 3–14. [Google Scholar]

- Majewsky, L.; Cunha, A.G. Evaluation of Suitability of Wheat Bran as a Natural Filler in Polymer Processing. Bioresources 2018, 13, 7037–7052. [Google Scholar]

- Follain, N.; Joly, C.; Dole, P.; Roge, B.; Mathlouthi. M. Quaternary starch based blends: Influence of a fourth component addition to the starch/water/glycerol system. Carbohydr. Polym. 2006, 63, 400–407. [Google Scholar] [CrossRef]

- Dominici, F.; Gigli, M.; Armentano, I.; Genovese, L.; Luzi, F.; Torre, L.; Munari, A.; Lotti, N. Improving the flexibility and compostability of starch/poly(butylene cyclohexanedicarboxylate)-based blends. Carbohydr. Polym. 2020, 246, 116631. [Google Scholar] [CrossRef]

- Carvalho, A.J.F.; Zambon, M.D.; da Silva Curvelo, A.A.; Gandini, A. Thermoplastic starch modification during melt processing: Hydrolysis catalyzed by carboxylic acids. Carbohydr. Polym. 2005, 62, 387–390. [Google Scholar] [CrossRef]

- Genovese, L.; Dominici, F.; Gigli, M.; Armentano, I.; Lotti, N.; Torre, L.; Munari, A. Processing, thermo-mechanical characterization and gas permeability of thermoplastic starch/poly(butylene trans-1,4-cyclohexanedicarboxylate) blends. Polym. Degr. Stab. 2018, 157, 100–107. [Google Scholar] [CrossRef]

- Olivato, J.B.; Grossmann, M.V.E.; Yamashita, F.; Eiras, D.; Pessan, L.A. Citric acid and maleic anhydride as compatibilizers in starch/poly(butylene adipate-co-terephthalate) blends by one-step reactive extrusion. Carbohydr. Polym. 2012, 87, 2614–2618. [Google Scholar] [CrossRef]

- Jiugao, Y.; Ning, W.; Xiaofei, M. The Effects of Citric Acid on the Properties of Thermoplastic Starch Plasticized by Glycerol. Starch/Stärke 2005, 57, 494–504. [Google Scholar] [CrossRef]

- Lagrain, B.; Thewissen, B.G.; Brijs, K.; Delcour, J.A. Mechanism of gliadin–glutenin cross-linking during hydrothermal treatment. Food Chem. 2008, 107, 753–760. [Google Scholar] [CrossRef]

- Basiak, E.; Lenart, A.; Debeaufort, F. How Glycerol and Water Contents Affect the Structural and Functional Properties of Starch-Based Edible Films. Polymers 2018, 10, 412. [Google Scholar] [CrossRef]

- Khamthong, P.; Lumdubwong, N. Effects of heat-moisture treatment on normal and waxy rice flours and production of thermoplastic flour materials. Carbohydr. Polym. 2012, 90, 340–347. [Google Scholar] [CrossRef]

- Jbilou, F.; Ayadi, F.; Galland, S.; Joly, C.; Dole, P.; Belard, L.; Degraeve, P. Effect of Shear Stress Extrusion Intensity on Plasticized Corn Flour Structure: Proteins Role and Distribution. J. Appl. Polym. Sci. 2012, 123, 2177–2186. [Google Scholar] [CrossRef]

- Sasimowski, E.; Majewski, L.; Grochowicz, M. Influence of the Design Solutions of Extruder Screw Mixing Tip on Selected Properties of Wheat Bran-Polyethylene Biocomposite. Polymers 2019, 11, 2120. [Google Scholar] [CrossRef]

- Carmona, V.B.; Corrêa, A.C.; Marconcini, J.M.; Mattoso, L.H.C. Properties of a Biodegradable Ternary Blend of Thermoplastic Starch (TPS), Poly(ε-Caprolactone) (PCL) and Poly(Lactic Acid) (PLA). J. Polym. Environ. 2014, 23, 83–89. [Google Scholar] [CrossRef]

- Sin, L.T.; Rahman, W.A.W.A.; Rahmat, A.R.; Mokhtar, M. Determination of thermal stability and activation energy of polyvinyl alcohol-cassava starch blends. Carbohydr. Polym. 2011, 83, 303–305. [Google Scholar] [CrossRef]

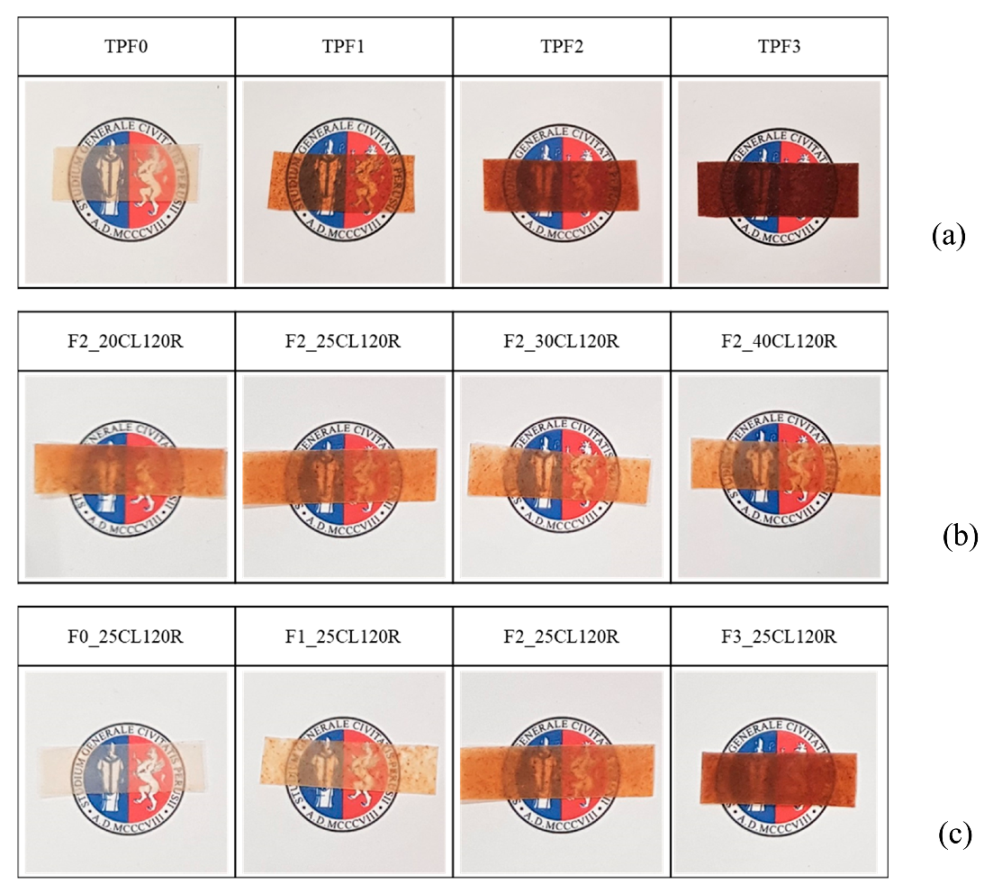

| Sample | Flour * | Bran ** | Plasticizable Fraction (PF) | Unplasticizable Fraction (UF) |

|---|---|---|---|---|

| F0 | 100 | 0 | 100.0 | 0.0 |

| F1 | 80 | 20 | 86 | 14 |

| F2 | 65 | 35 | 75.5 | 24.5 |

| F3 | 50 | 50 | 65.0 | 35.0 |

| Sample | Flour | Glycerol (% wt.) | Biopolymer (% wt.) | Citric Acid (% wt.) | Tset * | Screw Speed (Rpm) |

|---|---|---|---|---|---|---|

| TPF0 | F0 | 23 | 0 | 0 | 2 | 30 |

| TPF1 | F1 | 23 | 0 | 0 | 2 | 30 |

| TPF2 | F2 | 23 | 0 | 0 | 2 | 30 |

| TPF3 | F3 | 23 | 0 | 0 | 2 | 30 |

| TPF2_CA | F2 | 23 | 0 | 0.8 | 2 | 30 |

| TPF2_20BAT | F2 | 23 | 20 PBAT | 0 | 2 | 30 |

| TPF2_20CL | F2 | 23 | 20 PCL | 0 | 2 | 30 |

| TPF2_CA20BAT | F2 | 23 | 20 PBAT | 0.8 | 2 | 30 |

| TPF2_CA20CL | F2 | 23 | 20 PCL | 0.8 | 2 | 30 |

| F0_CA2 | F0 | 17 | 0 | 0.8 | 2 | 30 |

| F0_CA3 | F0 | 17 | 0 | 0.8 | 3 | 30 |

| F0_CA20CL2 | F0 | 17 | 20 PCL | 0.8 | 2 | 30 |

| F0_CA20CL3 | F0 | 17 | 20 PCL | 0.8 | 3 | 30 |

| F2_CA20CL2 | F2 | 17 | 20 PCL | 0.8 | 2 | 30 |

| F2_CA20CL3 | F2 | 17 | 20 PCL | 0.8 | 3 | 30 |

| F2_20CL | F2 | 17 | 20 PCL | 0.8 | 2 | 30 |

| F2_20CL120R | F2 | 17 | 20 PCL | 0.8 | 2 | 120 |

| F2_25CL | F2 | 17 | 25 PCL | 0.8 | 2 | 30 |

| F2_25CL120R | F2 | 17 | 25 PCL | 0.8 | 2 | 120 |

| F2_30CL | F2 | 17 | 30 PCL | 0.8 | 2 | 30 |

| F2_30CL120R | F2 | 17 | 30 PCL | 0.8 | 2 | 120 |

| F2_40CL | F2 | 17 | 40 PCL | 0.8 | 2 | 30 |

| F2_40CL120R | F2 | 17 | 40 PCL | 0.8 | 2 | 120 |

| F0_25CL120R | F0 | 17 | 25 PCL | 0.8 | 2 | 120 |

| F1_25CL120R | F1 | 17 | 25 PCL | 0.8 | 2 | 120 |

| F3_25CL120R | F3 | 17 | 25 PCL | 0.8 | 2 | 120 |

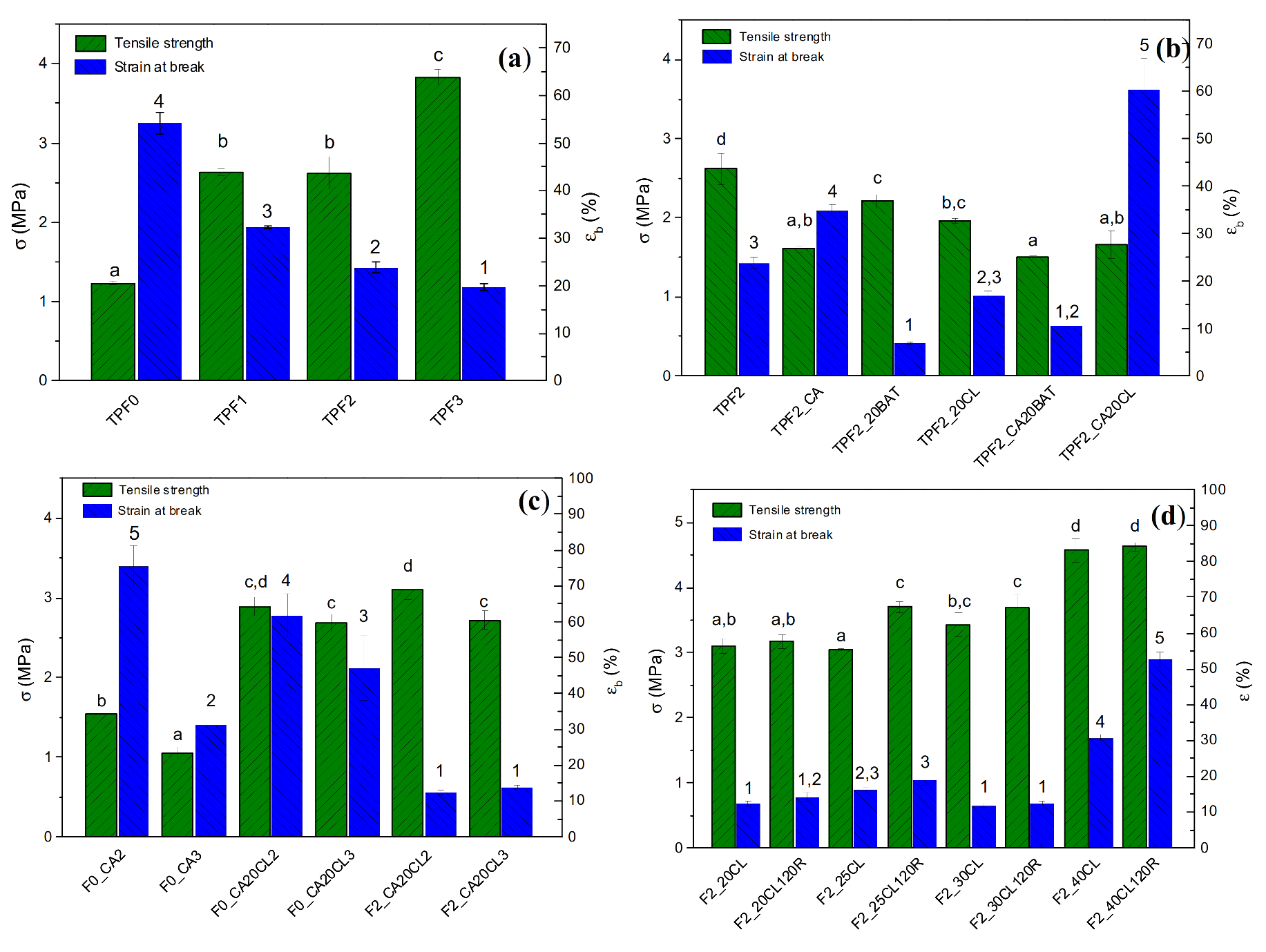

| Sample | Flour | Glycerol (% wt.) | Biopolymer (% wt.) | Citric Acid (% wt.) | Tset * | Screw Speed (rpm) | Ultimate Tensile Strength (MPa) | Strain at Break (%) |

|---|---|---|---|---|---|---|---|---|

| TPF0 | F0 | 23 | 0 | 0 | 2 | 30 | 1.23 ± 0.05 | 54.13 ± 4.39 |

| TPF1 | F1 | 23 | 0 | 0 | 2 | 30 | 2.63 ± 0.10 | 32.23 ± 0.64 |

| TPF2 | F2 | 23 | 0 | 0 | 2 | 30 | 2.62 ± 0.40 | 23.84 ± 2.45 |

| TPF3 | F3 | 23 | 0 | 0 | 2 | 30 | 3.83 ± 0.20 | 19.64 ± 1.60 |

| TPF2_CA | F2 | 23 | 0 | 0.8 | 2 | 30 | 1.61 ± 0,08 | 34.89 ± 2.44 |

| TPF2_20BAT | F2 | 23 | 20 PBAT | 0 | 2 | 30 | 2.21 ± 0,17 | 6.93 ± 0.47 |

| TPF2_20CL | F2 | 23 | 20 PCL | 0 | 2 | 30 | 1.96 ± 0.06 | 16.80 ± 1.98 |

| TPF2_CA20BAT | F2 | 23 | 20 PBAT | 0.8 | 2 | 30 | 1.50 ± 0.05 | 10.44 ± 0.17 |

| TPF2_CA20CL | F2 | 23 | 20 PCL | 0.8 | 2 | 30 | 1.66 ± 0.34 | 60.39 ± 13.00 |

| F0_CA2 | F0 | 17 | 0 | 0.8 | 2 | 30 | 1.54 ± 0.02 | 75.47 ± 11.66 |

| F0_CA3 | F0 | 17 | 0 | 0.8 | 3 | 30 | 1.05 ± 0.14 | 31.08 ± 6.07 |

| F0_CA20CL2 | F0 | 17 | 20 PCL | 0.8 | 2 | 30 | 2.89 ± 0.23 | 61.80 ± 11,87 |

| F0_CA20CL3 | F0 | 17 | 20 PCL | 0.8 | 3 | 30 | 2.69 ± 0.22 | 47.04 ± 18.15 |

| F2_CA20CL2 | F2 | 17 | 20 PCL | 0.8 | 2 | 30 | 3,10 ± 0,24 | 12,42 ± 1,43 |

| F2_CA20CL3 | F2 | 17 | 20 PCL | 0.8 | 3 | 30 | 2,72 ± 0,23 | 13,83 ± 1,12 |

| F2_20CL | F2 | 17 | 20 PCL | 0.8 | 2 | 30 | 3.10 ± 0.24 | 12.42 ± 1.43 |

| F2_20CL120R | F2 | 17 | 20 PCL | 0.8 | 2 | 120 | 3.17 ± 0.20 | 14.15 ± 2.46 |

| F2_25CL | F2 | 17 | 25 PCL | 0.8 | 2 | 30 | 3.05 ± 0.03 | 16.27 ± 1.47 |

| F2_25CL120R | F2 | 17 | 25 PCL | 0.8 | 2 | 120 | 3.70 ± 0.16 | 18.87 ± 2.77 |

| F2_30CL | F2 | 17 | 30 PCL | 0.8 | 2 | 30 | 3.69 ± 0.43 | 12.49 ± 1.03 |

| F2_30CL120R | F2 | 17 | 30 PCL | 0.8 | 2 | 120 | 3.43 ± 0.36 | 11.73 ± 0.99 |

| F2_40CL | F2 | 17 | 40 PCL | 0.8 | 2 | 30 | 4,57 ± 0.36 | 30.75 ± 1.97 |

| F2_40CL120R | F2 | 17 | 40 PCL | 0.8 | 2 | 120 | 4,63 ± 0.13 | 52.64 ± 4.02 |

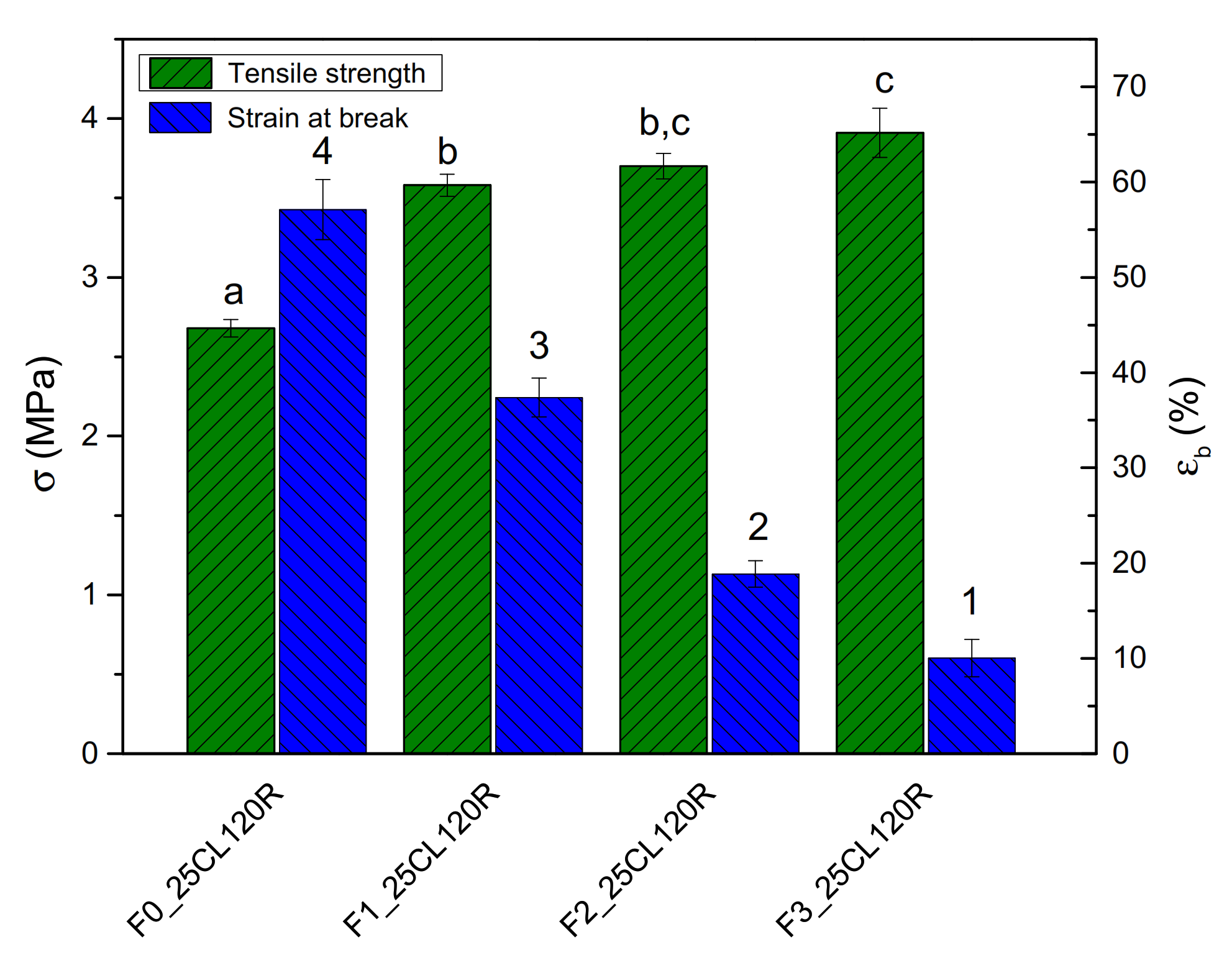

| F0_25CL120R | F0 | 17 | 25 PCL | 0.8 | 2 | 120 | 2.68 ± 0.11 | 57.11 ± 6.29 |

| F1_25CL120R | F1 | 17 | 25 PCL | 0.8 | 2 | 120 | 3.58 ± 0.14 | 37.39 ± 4.07 |

| F3_25CL120R | F3 | 17 | 25 PCL | 0.8 | 2 | 120 | 3.91 ± 0.31 | 10.04 ± 3.92 |

| 40 Days | 60 Days | |||

|---|---|---|---|---|

| Samples | G×L | Ig (%) | G×L | Ig (%) |

| C | 37.0 | 233 | ||

| TPF3_50 | 20.0 | 54 | 229 | 98 |

| TPF1_50 | 21.0 | 57 | 251 | 108 |

| TPF0_50 | 9.5 | 26 | 183 | 79 |

| TPF3_75 | 13.3 | 36 | 197 | 85 |

| TPF1_75 | 12.5 | 34 | 213 | 91 |

| TPF0_75 | 1.9 | 5 | 171 | 73 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dominici, F.; Luzi, F.; Benincasa, P.; Torre, L.; Puglia, D. Biocomposites Based on Plasticized Wheat Flours: Effect of Bran Content on Thermomechanical Behavior. Polymers 2020, 12, 2248. https://doi.org/10.3390/polym12102248

Dominici F, Luzi F, Benincasa P, Torre L, Puglia D. Biocomposites Based on Plasticized Wheat Flours: Effect of Bran Content on Thermomechanical Behavior. Polymers. 2020; 12(10):2248. https://doi.org/10.3390/polym12102248

Chicago/Turabian StyleDominici, Franco, Francesca Luzi, Paolo Benincasa, Luigi Torre, and Debora Puglia. 2020. "Biocomposites Based on Plasticized Wheat Flours: Effect of Bran Content on Thermomechanical Behavior" Polymers 12, no. 10: 2248. https://doi.org/10.3390/polym12102248

APA StyleDominici, F., Luzi, F., Benincasa, P., Torre, L., & Puglia, D. (2020). Biocomposites Based on Plasticized Wheat Flours: Effect of Bran Content on Thermomechanical Behavior. Polymers, 12(10), 2248. https://doi.org/10.3390/polym12102248