Synthesis of Lignin-Based Polyacid Catalyst and Its Utilization to Improve Water Resistance of Urea–formaldehyde Resins

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hydroxymethylation of Lignin

2.3. Synthesis of Lignin-Based Polyacid Catalyst

2.4. Model Reaction

2.5. Synthesis of UF Resin

2.6. Properties of UF Resins

2.7. Preparation of Five-Plywood Panels

2.8. MDF Panel Manufacture

2.9. Plywood Bonding Strength Test

2.10. MDF Mechanical and Physical Test

2.11. Plywood and MDF Formaldehyde Emission Test

2.12. Characterization

3. Results and Discussion

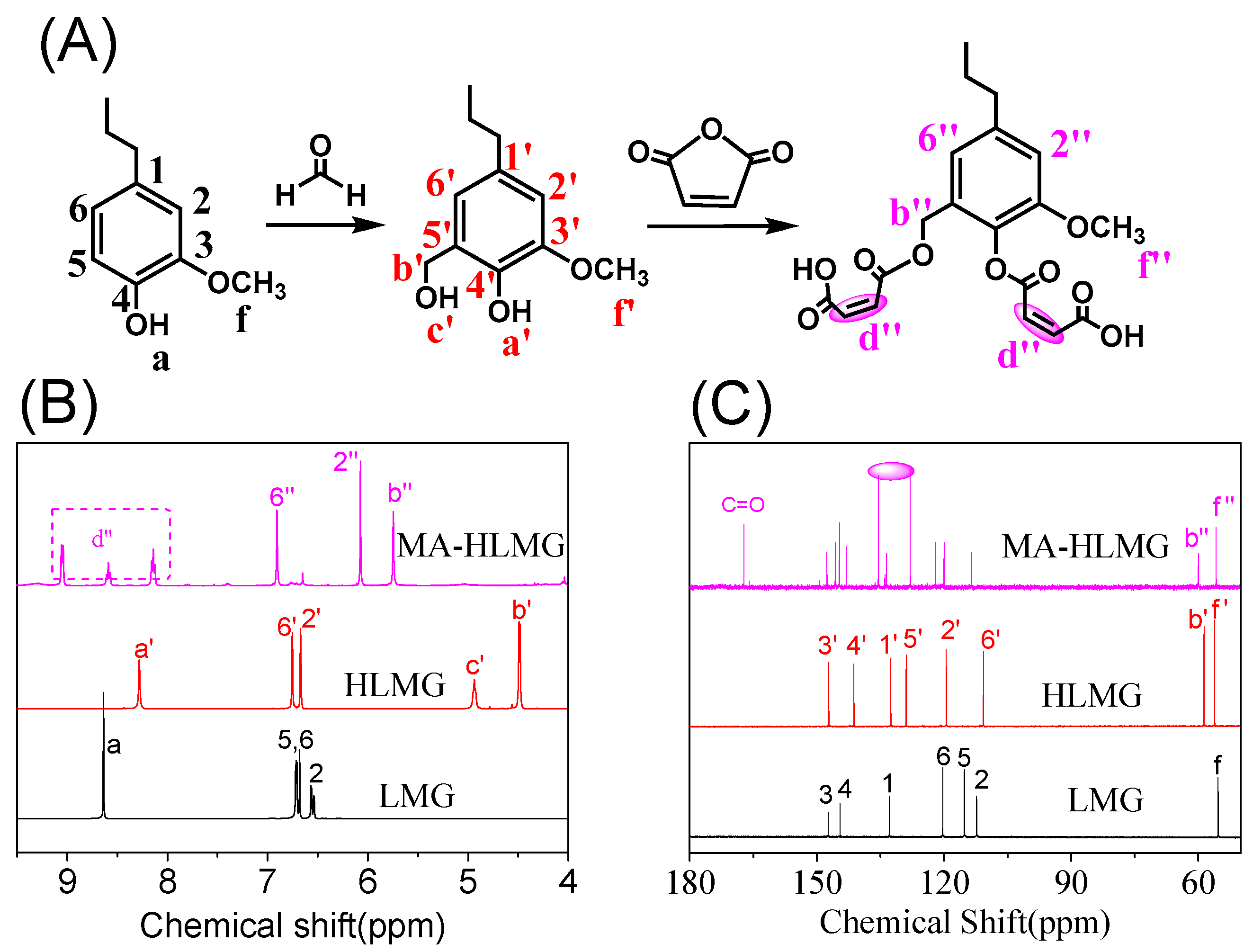

3.1. Model Reaction

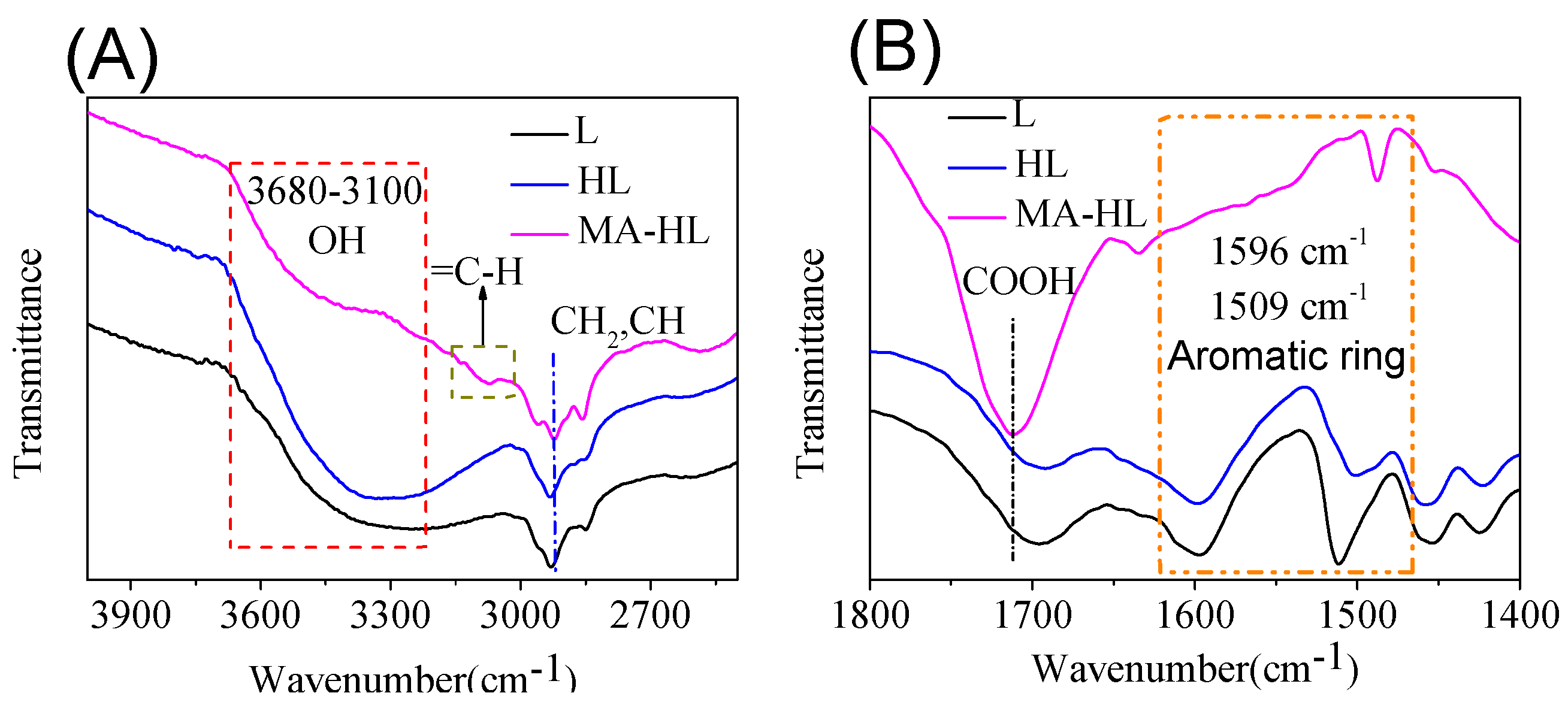

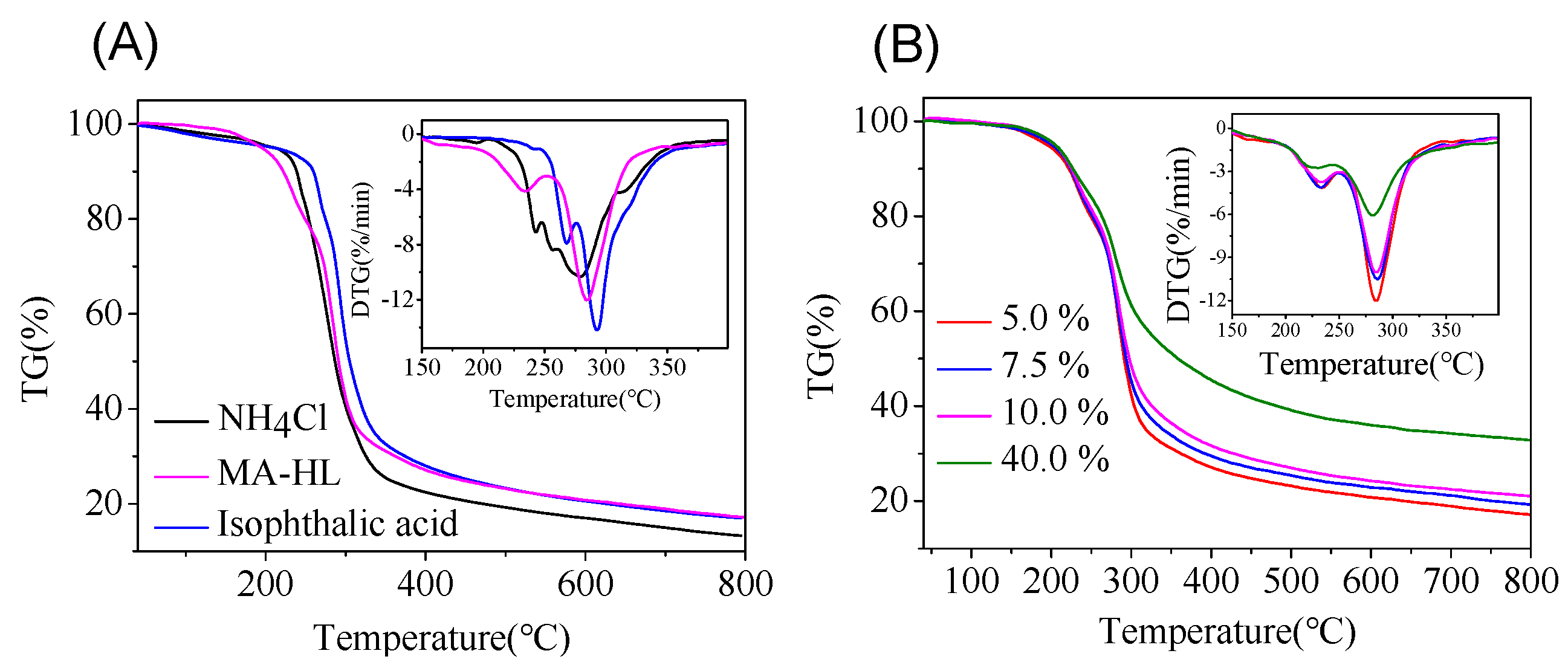

3.2. Synthesis of Lignin-Based Catalysts

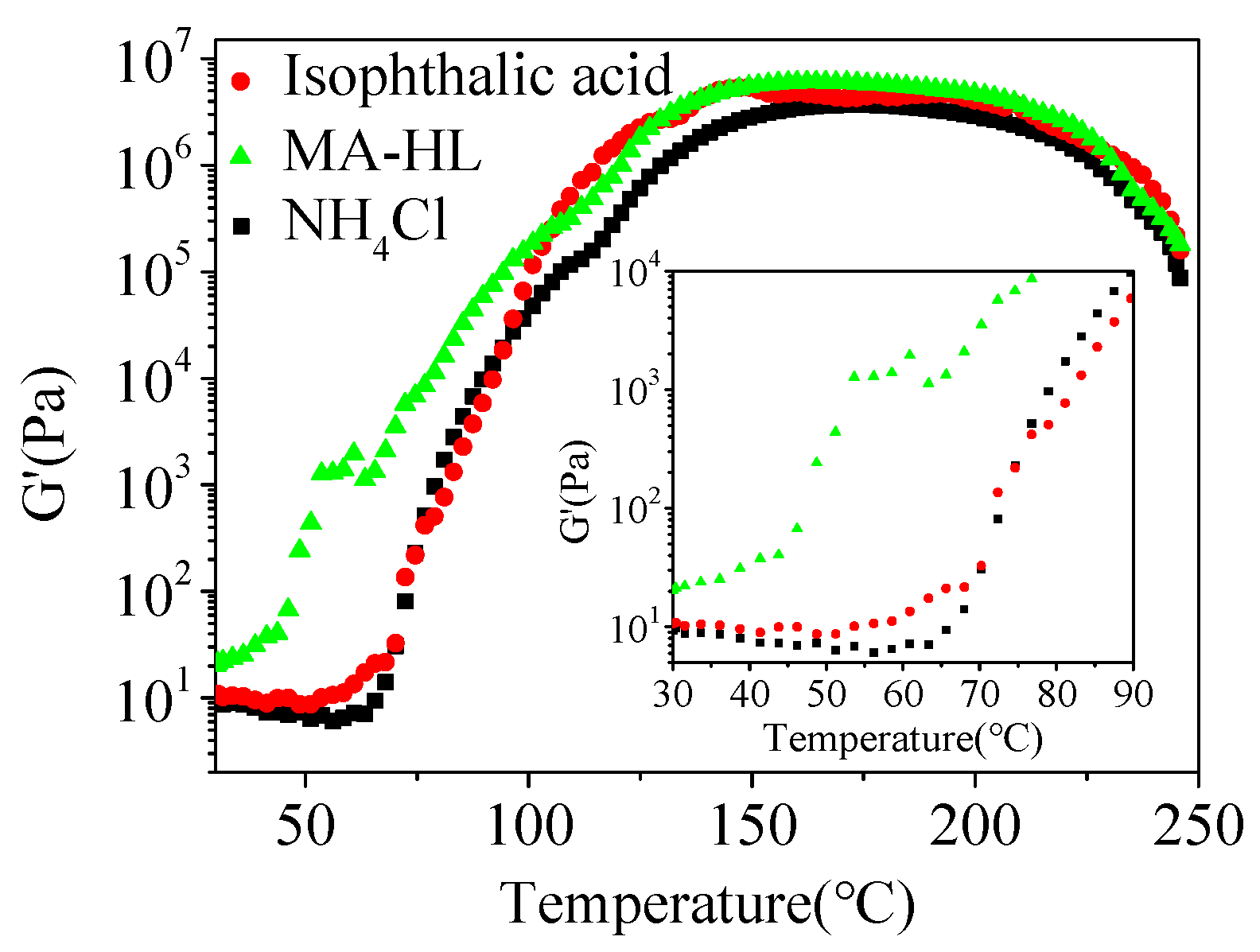

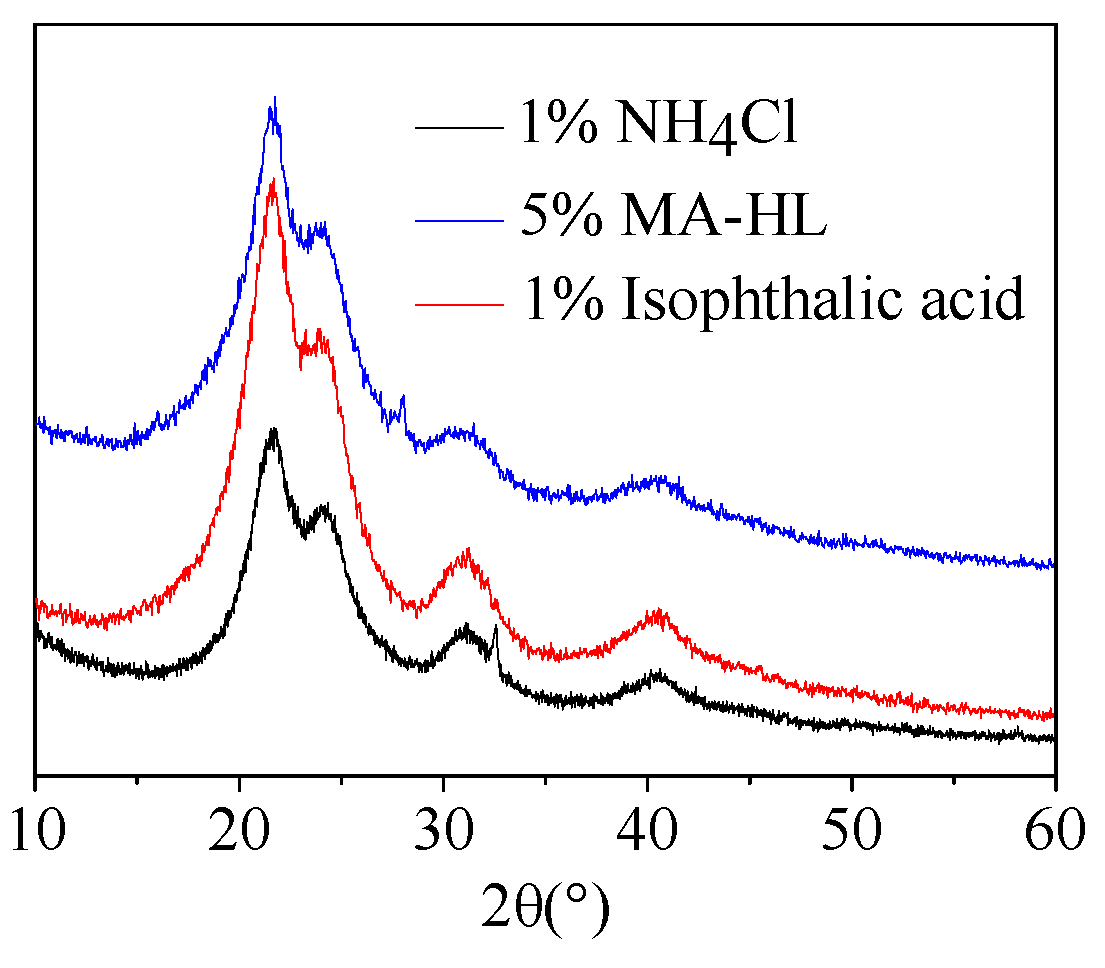

3.3. Utilization of Lignin-Based Catalyst for UF Resins Synthesis

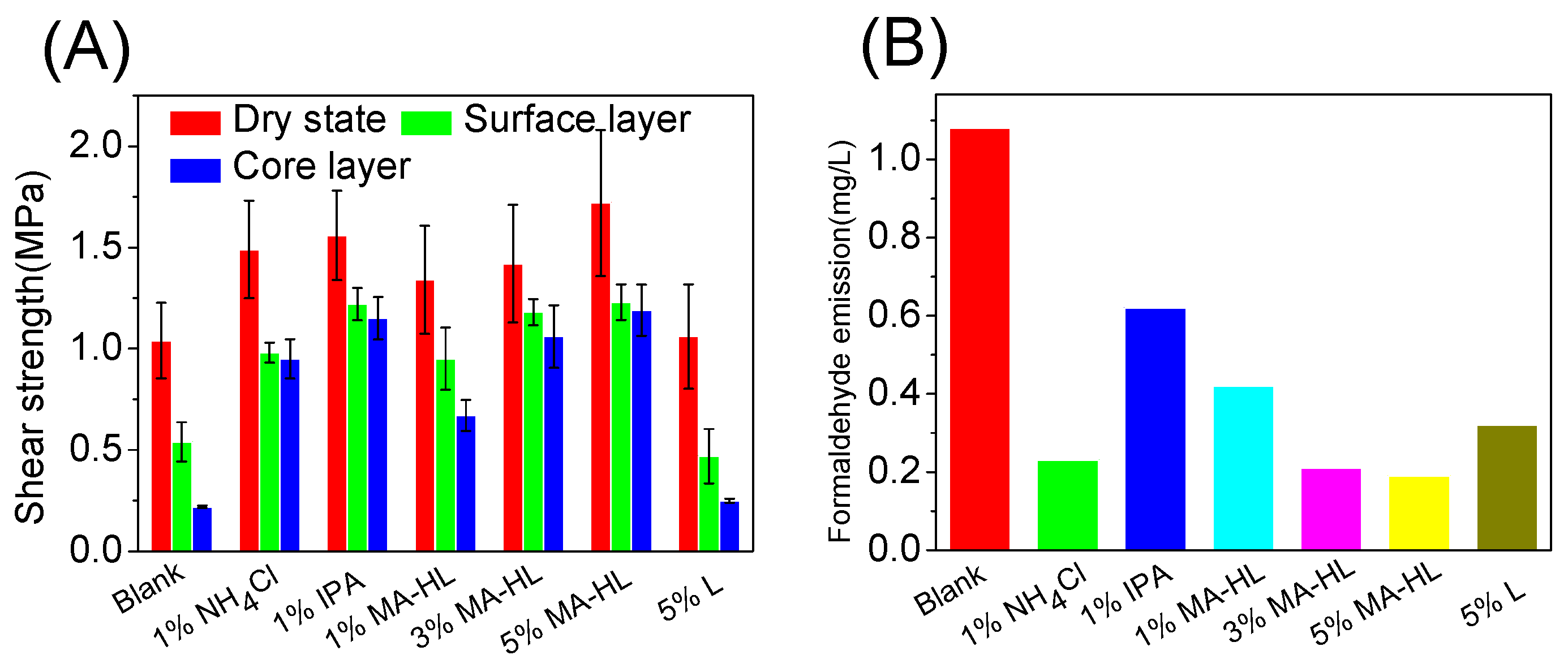

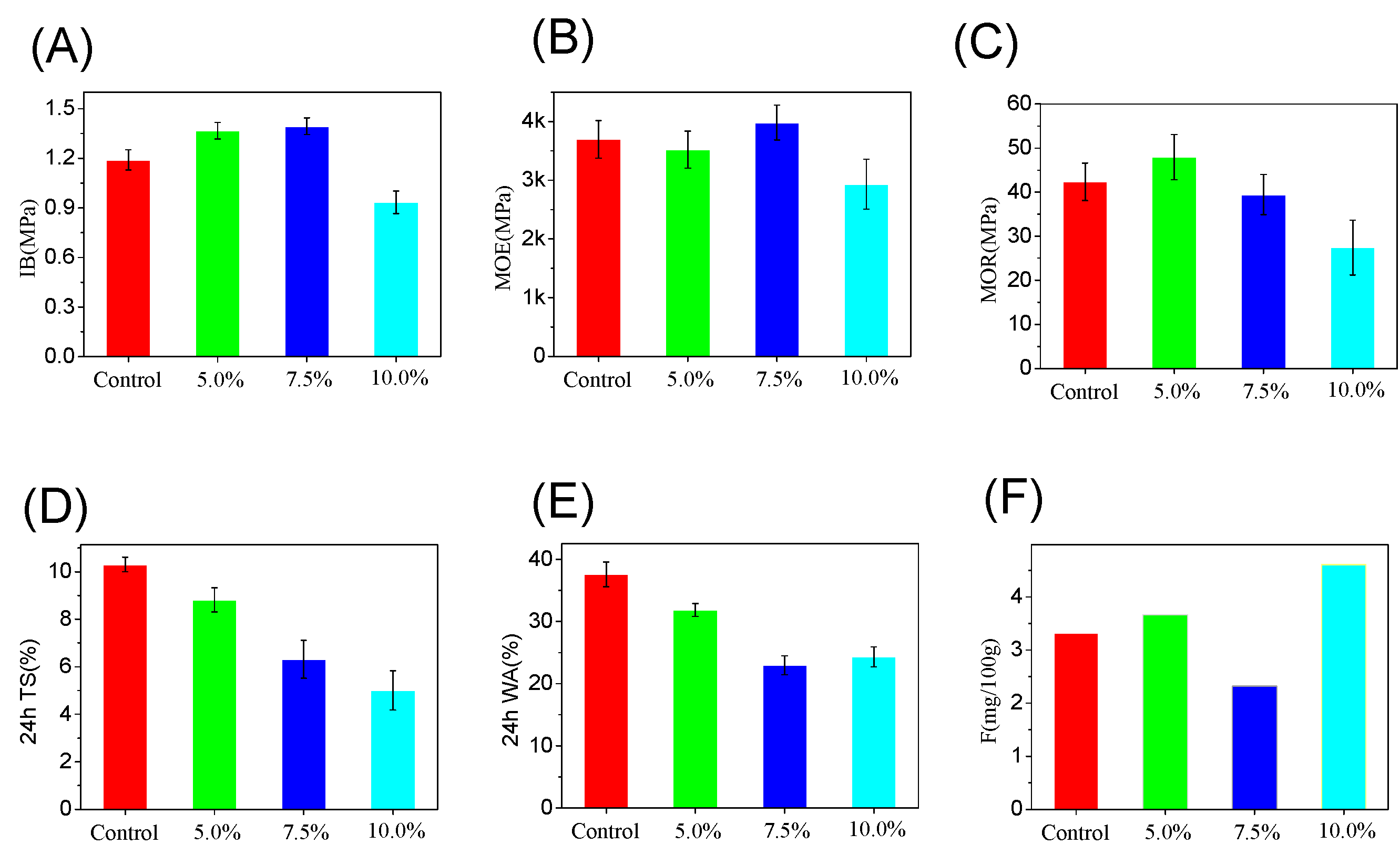

3.4. Mechanical Properties Using Lignin-Based Polyacid Catalysts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, Z.; Zhang, B.; Zhou, X.; Li, L.; Yu, L.; Liao, J.; Du, G. Influence of Single/Collective Use of Curing Agents on the Curing Behavior and Bond Strength of Soy Protein-Melamine-Urea-Formaldehyde (SMUF) Resin for Plywood Assembly. Polymers 2019, 11, 1995. [Google Scholar] [CrossRef]

- Li, X.; Gao, Q.; Xia, C.; Li, J.; Zhou, X. Urea Formaldehyde Resin Resultant Plywood with Rapid Formaldehyde Release Modified by Tunnel-Structured Sepiolite. Polymers 2019, 11, 1286. [Google Scholar] [CrossRef]

- Lei, H.; Frazier, C.E. Curing behavior of melamine-urea-formaldehyde (MUF) resin adhesive. Int. J. Adhes. Adhes. 2015, 62, 40–44. [Google Scholar] [CrossRef]

- Liu, C.; Luo, J.; Li, X.; Gao, Q.; Li, J. Effects of compounded curing agents on properties and performance of urea formaldehyde resin. J. Polym. Environ. 2018, 26, 158–165. [Google Scholar] [CrossRef]

- Singh, A.P.; Causin, V.; Nuryawan, A.; Park, B.-D. Morphological, chemical and crystalline features of urea–formaldehyde resin cured in contact with wood. Eur. Polym. J. 2014, 56, 185–193. [Google Scholar] [CrossRef]

- Chen, S.; Lu, X.; Wang, T.; Zhang, Z. Preparation and characterization of urea-formaldehyde resin/reactive kaolinite composites. Particuology 2016, 24, 203–209. [Google Scholar] [CrossRef]

- Paiva, N.T.; Ferra, J.M.; Pereira, J.; Martins, J.; Carvalho, L.; Magalhães, F.D. Production of water tolerant melamine–urea–formaldehyde resin by incorporation of sodium metabisulphite. Int. J. Adhes. Adhes. 2016, 70, 160–166. [Google Scholar] [CrossRef]

- Nuryawan, A.; Park, B.D. Quantification of hydrolytic degradation of cured urea-formaldehyde resin adhesives using confocal laser scanning microscopy. Int. J. Adhes. Adhes. 2017, 74, 1–5. [Google Scholar] [CrossRef]

- Nuryawan, A.; Singh, A.P.; Zanetti, M.; Park, B.-D.; Causin, V. Insights into the development of crystallinity in liquid urea-formaldehyde resins. Int. J. Adhes. Adhes. 2017, 72, 62–69. [Google Scholar] [CrossRef]

- Park, B.-D.; Jeong, H.-W. Hydrolytic stability and crystallinity of cured urea–formaldehyde resin adhesives with different formaldehyde/urea mole ratios. Int. J. Adhes. Adhes. 2011, 31, 524–529. [Google Scholar] [CrossRef]

- Weinstabl, A.; Binder, W.H.; Gruber, H.; Kantner, W. Melamine salts as hardeners for urea formaldehyde resins. J. Appl. Polym. Sci. 2001, 81, 1654–1661. [Google Scholar] [CrossRef]

- Pizzi, A. Advanced Wood Adhesives Technology; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Španić, N.; Jambreković, V.; Radmanović, K.; Mihulja, G.; Kljak, J. Effect of Tartaric Acid Addition to Catalyst on Curing Behaviour of Urea-Formaldehyde Resin. In Proceedings of the 28th International Conference on Wood Science and Technology (ICWST)-Implementation of Wood Science in Woodworking Sector, Zagreb, Croatia, 7–8 December 2017. [Google Scholar]

- Cui, H.-W.; Du, G.-B. Development of a novel polyvinyl acetate type emulsion curing agent for urea formaldehyde resin. Wood Sci. Technol. 2013, 47, 105–119. [Google Scholar] [CrossRef]

- Williams, C.K.; Hillmyer, M.A. Polymers from renewable resources: A perspective for a special issue of polymer reviews. Polym. Rev. 2008, 48, 1–10. [Google Scholar] [CrossRef]

- Shan, R.; Lu, L.; Shi, Y.; Yuan, H.; Shi, J. Catalysts from renewable resources for biodiesel production. Energy Convers. Manag. 2018, 178, 277–289. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Recent advances in green hydrogels from lignin: A review. Int. J. Biol. Macromol. 2015, 72, 834–847. [Google Scholar] [CrossRef] [PubMed]

- Kai, D.; Low, Z.W.; Liow, S.S.; Karim, A.A.; Ye, H.; Jin, G.; Li, K.; Loh, X.J. Development of lignin supramolecular hydrogels with mechanically responsive and self-healing properties. ACS Sustain. Chem. Eng. 2015, 3, 2160–2169. [Google Scholar] [CrossRef]

- Wang, S.; Shuai, L.; Saha, B.; Vlachos, D.G.; Epps, T.H., III. From tree to tape: Direct synthesis of pressure sensitive adhesives from depolymerized raw lignocellulosic biomass. ACS Cent. Sci. 2018, 4, 701–708. [Google Scholar] [CrossRef]

- Huang, W.; Wu, M.; Liu, W.; Hua, Z.; Wang, Z.; Zhou, L. Value-adding of organosolv lignin: Designing mechanically robust UV-resistant polymeric glass via ARGET ATRP. Appl. Surf. Sci. 2019, 475, 302–311. [Google Scholar] [CrossRef]

- Over, L.C. Sustainable Derivatization of Lignin and Subsequent Synthesis of Cross-Linked Polymers. Ph.D. Thesis, KIT, Karlsruhe, Germany, 26 July 2017. [Google Scholar]

- Cui, M.; Nguyen, N.A.; Bonnesen, P.V.; Uhrig, D.; Keum, J.K.; Naskar, A.K. Rigid Oligomer from Lignin in Designing of Tough, Self-Healing Elastomers. ACS Macro Lett. 2018, 7, 1328–1332. [Google Scholar] [CrossRef]

- Ding, C.; Matharu, A.S. Recent developments on biobased curing agents: A review of their preparation and use. ACS Sustain. Chem. Eng. 2014, 2, 2217–2236. [Google Scholar] [CrossRef]

- Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Yan, N.; Zhang, R.; Li, J. Demethylation of wheat straw alkali lignin for application in phenol formaldehyde adhesives. Polymers 2016, 8, 209. [Google Scholar] [CrossRef] [PubMed]

- Younesi-Kordkheili, H.; Pizzi, A. A comparison between lignin modified by ionic liquids and glyoxalated lignin as modifiers of urea-formaldehyde resin. J. Adhes. 2017, 93, 1120–1130. [Google Scholar] [CrossRef]

- Liu, C.-F.; Sun, R.-C.; Qin, M.-H.; Zhang, A.-P.; Ren, J.-L.; Xu, F.; Ye, J.; Wu, S.-B. Chemical modification of ultrasound-pretreated sugarcane bagasse with maleic anhydride. Ind. Crop. Prod. 2007, 26, 212–219. [Google Scholar] [CrossRef]

- Thielemans, W.; Wool, R.P. Lignin esters for use in unsaturated thermosets: Lignin modification and solubility modeling. Biomacromolecules 2005, 6, 1895–1905. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, G.; González, J.; Freire, S.; Antorrena, G. Effect of chemical modification of lignin on the gluebond performance of lignin-phenolic resins. Bioresour. Technol. 1997, 60, 191–198. [Google Scholar] [CrossRef]

- Mansouri, N.E.E.; Pizzi, A.; Salvado, J. Lignin-based polycondensation resins for wood adhesives. J. Appl. Polym. Sci. 2007, 103, 1690–1699. [Google Scholar] [CrossRef]

- Levendis, D.; Pizzi, A.; Ferg, E. The correlation of strength and formaldehyde emission with the crystalline/amorphous structure of UF resins. Holzforsch. Int. J. Biol. Chem. Phys. Technol. Wood 1992, 46, 263–269. [Google Scholar] [CrossRef]

- Hao, Z.; Guo, Y.; Mansuer, M.; Zhu, J.; Zhu, Z. Role of the Excess Monomer in the Growth of UF Resin deposit Particles. J. Colloid Interface Sci. 2014, 430, 239–248. [Google Scholar] [CrossRef]

| Curing Agent Species | Curing Time | Shear Strength/MPa | Formaldehyde Emission/mg/L | ||

|---|---|---|---|---|---|

| Dry State | Surface Layer | Core Layer | |||

| Blank | >15 min | 1.04 | 0.54 | 0.22 | 1.08 |

| 1% NH4Cl | 2 min 45 s | 1.49 | 0.98 | 0.95 | 0.23 |

| 1% IPA | 3 min 10 s | 1.56 | 1.22 | 1.15 | 0.62 |

| 1% MA-HL | 6 min 42 s | 1.34 | 0.95 | 0.67 | 0.42 |

| 3% MA-HL | 3 min 56 s | 1.42 | 1.18 | 1.06 | 0.21 |

| 5% MA-HL | 2 min 50 s | 1.72 | 1.23 | 1.19 | 0.19 |

| 5% L | >15 min | 1.06 | 0.47 | 0.25 | 0.32 |

| Maleic acid | Gelling at room temperature in a few minutes | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, S.; Liu, Y.; Wang, C.; Chu, F.; Xu, F.; Zhang, D. Synthesis of Lignin-Based Polyacid Catalyst and Its Utilization to Improve Water Resistance of Urea–formaldehyde Resins. Polymers 2020, 12, 175. https://doi.org/10.3390/polym12010175

Gao S, Liu Y, Wang C, Chu F, Xu F, Zhang D. Synthesis of Lignin-Based Polyacid Catalyst and Its Utilization to Improve Water Resistance of Urea–formaldehyde Resins. Polymers. 2020; 12(1):175. https://doi.org/10.3390/polym12010175

Chicago/Turabian StyleGao, Shishuai, Yupeng Liu, Chunpeng Wang, Fuxiang Chu, Feng Xu, and Daihui Zhang. 2020. "Synthesis of Lignin-Based Polyacid Catalyst and Its Utilization to Improve Water Resistance of Urea–formaldehyde Resins" Polymers 12, no. 1: 175. https://doi.org/10.3390/polym12010175

APA StyleGao, S., Liu, Y., Wang, C., Chu, F., Xu, F., & Zhang, D. (2020). Synthesis of Lignin-Based Polyacid Catalyst and Its Utilization to Improve Water Resistance of Urea–formaldehyde Resins. Polymers, 12(1), 175. https://doi.org/10.3390/polym12010175