Development of Water-Compatible Molecularly Imprinted Polymers Based on Functionalized β-Cyclodextrin for Controlled Release of Atropine

Abstract

1. Introduction

2. Material and Methods

2.1. Chemicals and Materials

2.2. Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) Conditions

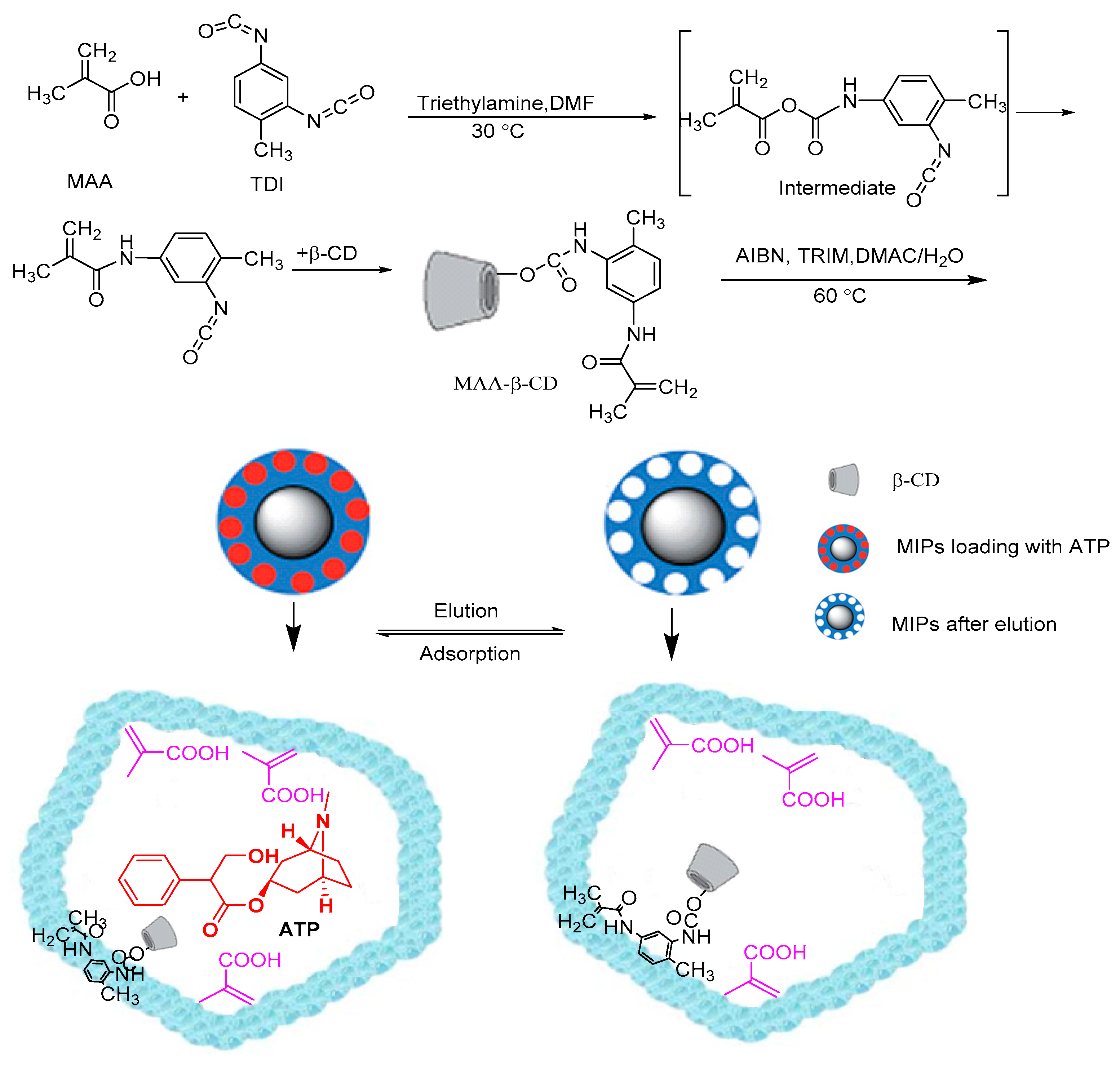

2.3. Synthesis of MAA-β-CD Monomer

2.4. Preparation Molecularly Imprinted Polymers (MIPs) and Non-Molecularly Imprinted Polymers (NIPs) Using Thermally Initiated Precipitation Polymerization

2.5. Polymers Characterization

2.6. Water Swelling Behavior

2.7. Drug Loading Experiment

2.8. In Vitro Drug Release Test

3. Results and Discussion

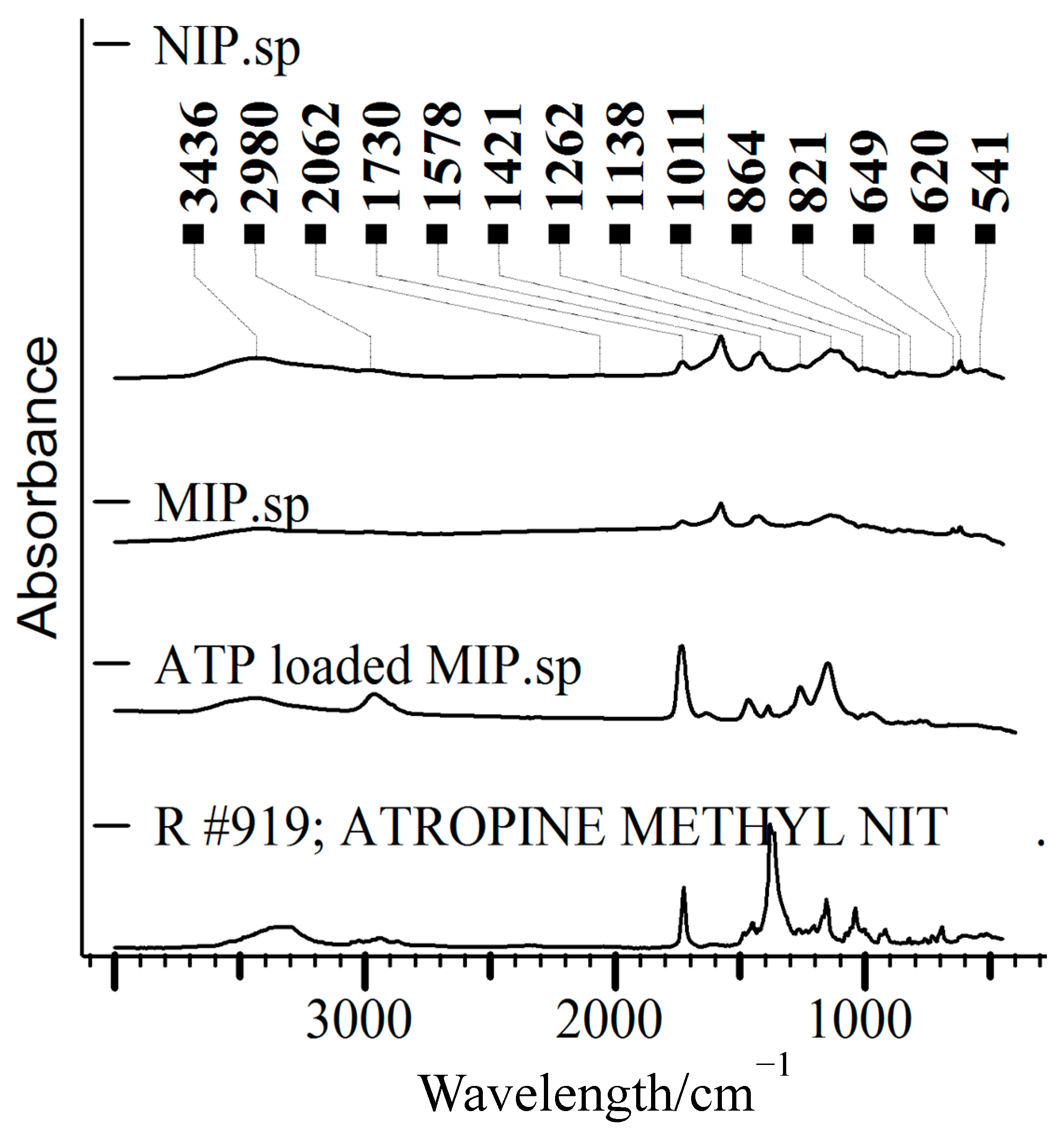

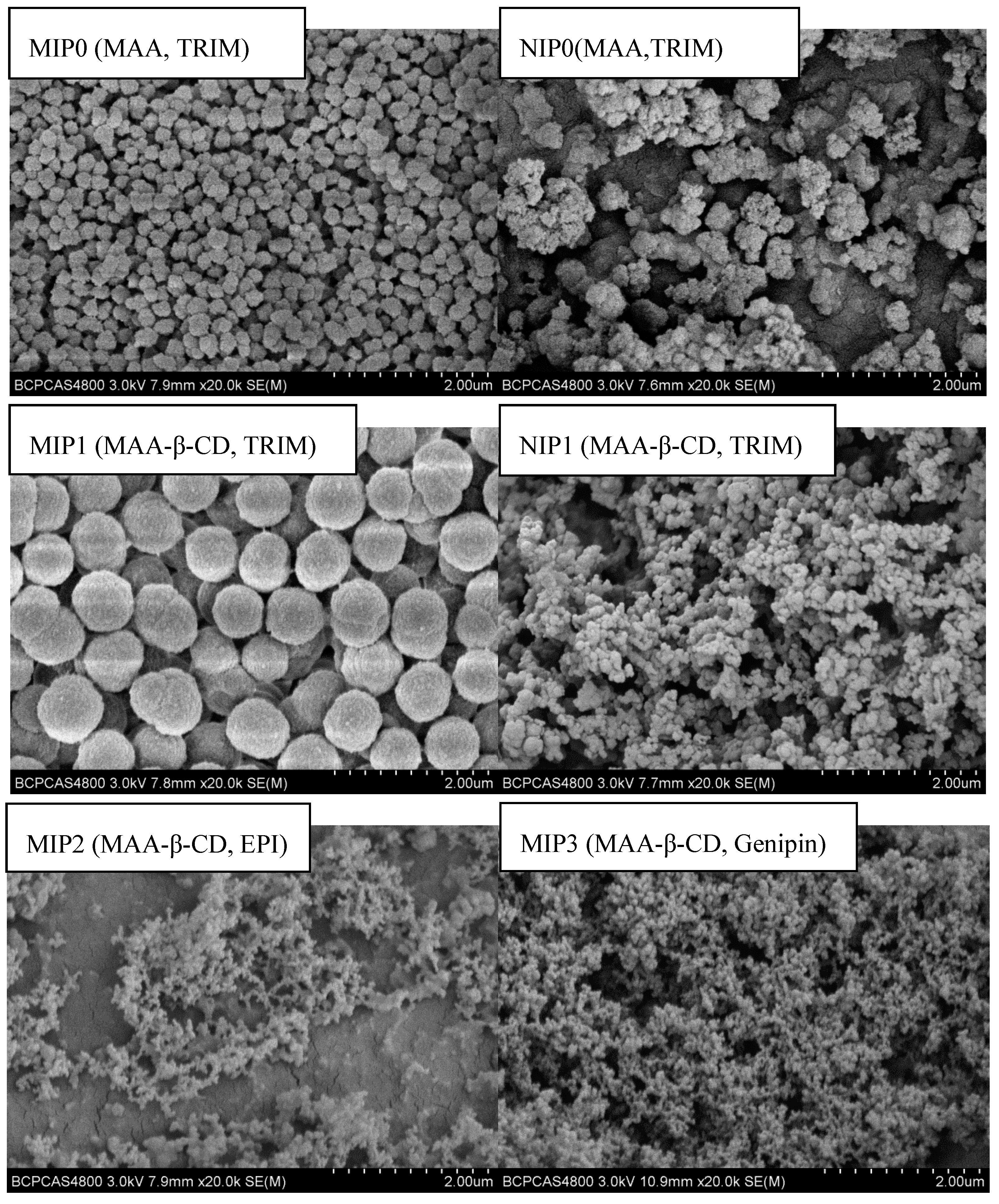

3.1. Characterization and Morphology of the Polymeric Microspheres

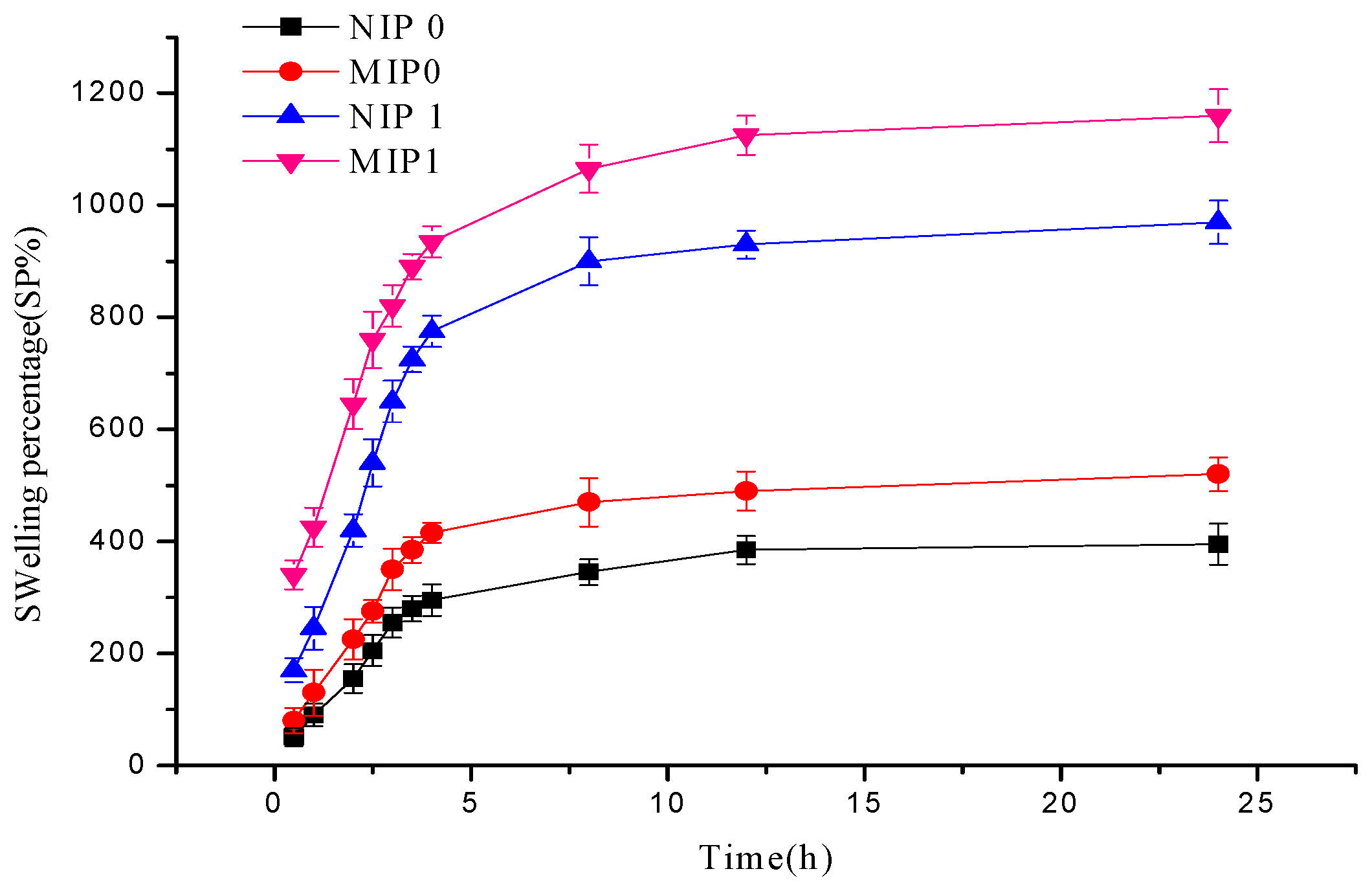

3.2. Swelling Kinetics

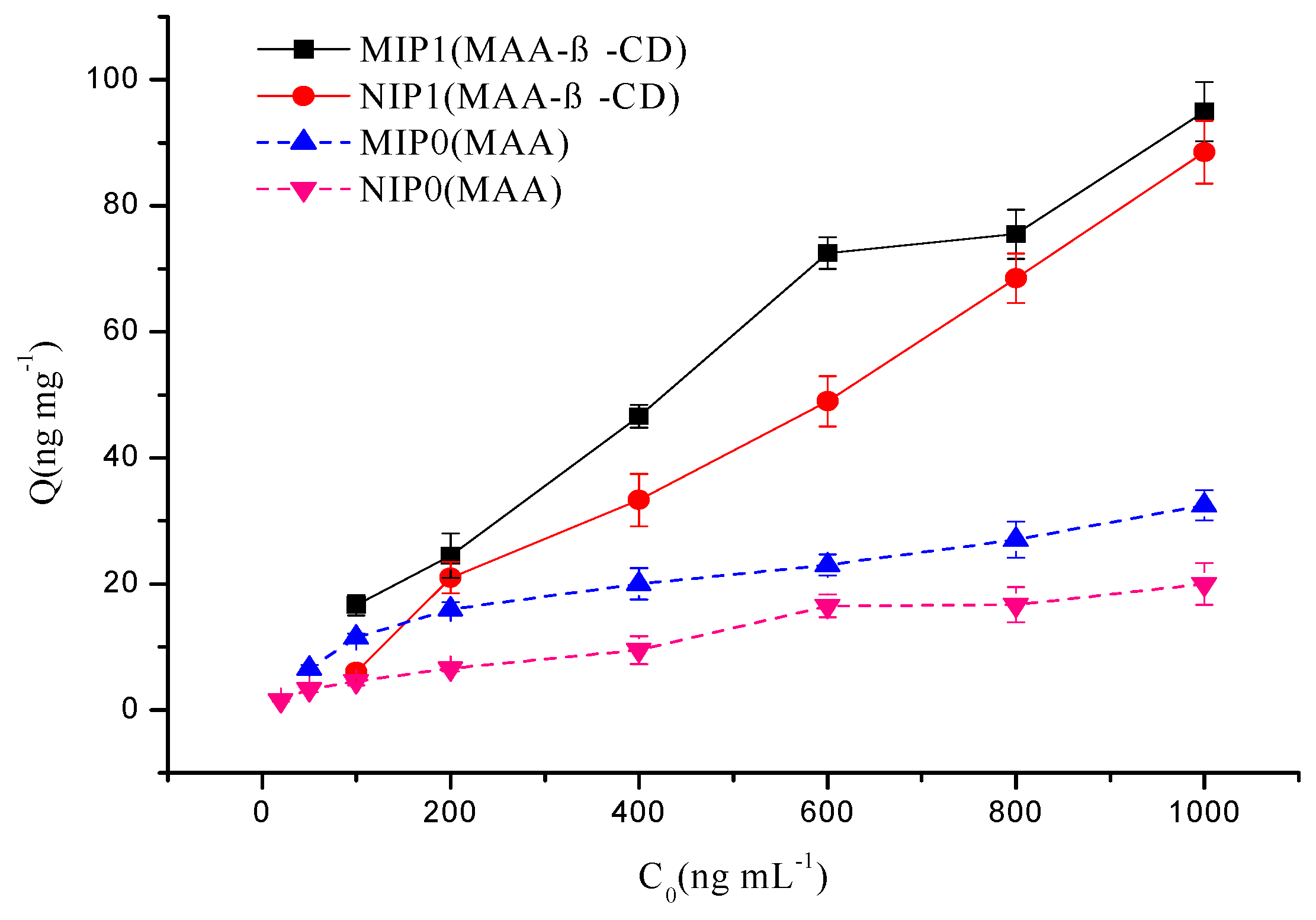

3.3. Binding Behavior of MIPs Prepared from Different Monomers

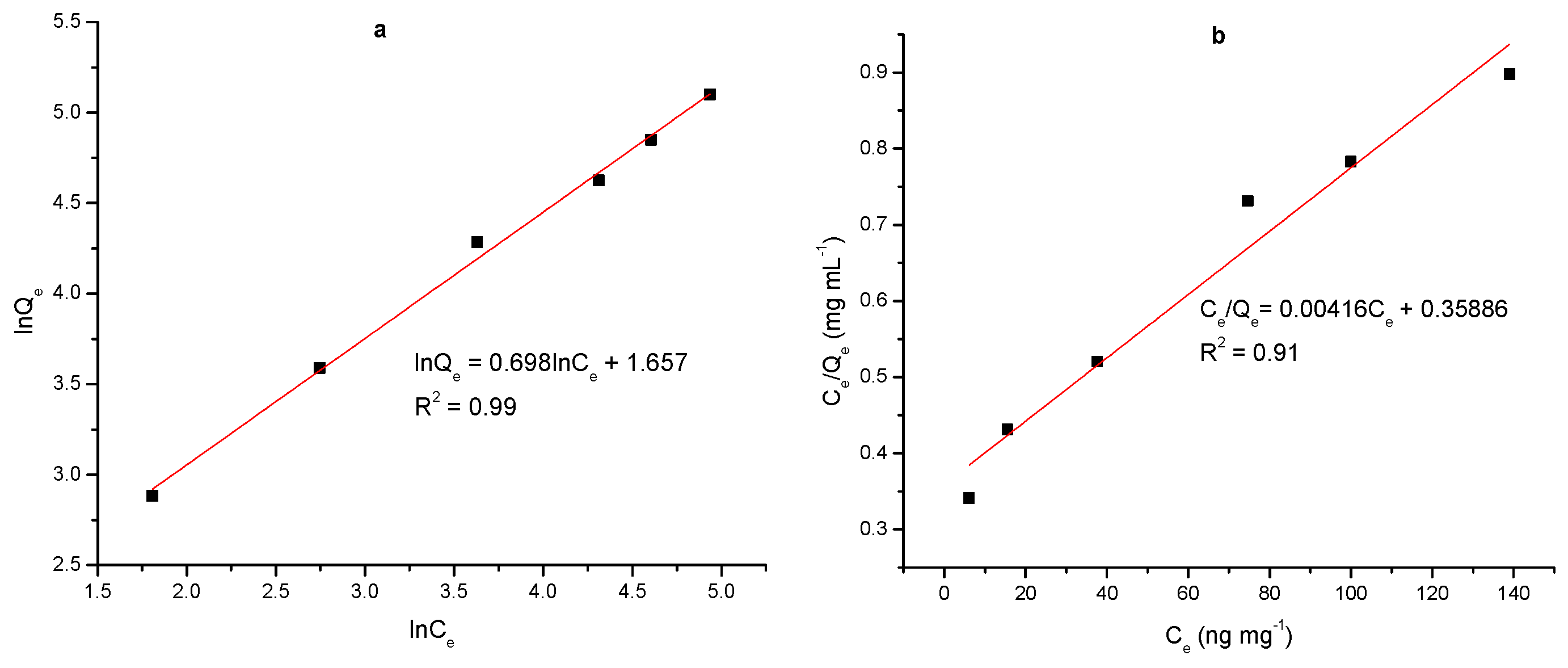

3.4. The Loading Capacity of MIP and NIP Microspheres

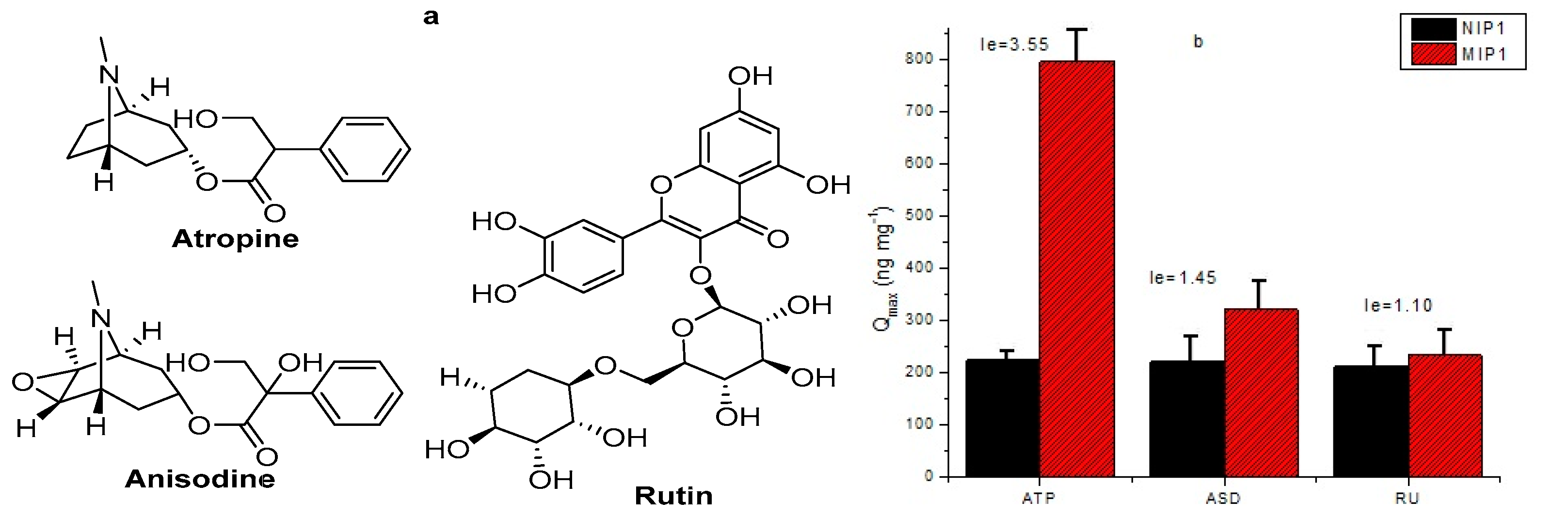

3.5. Selectivity Study

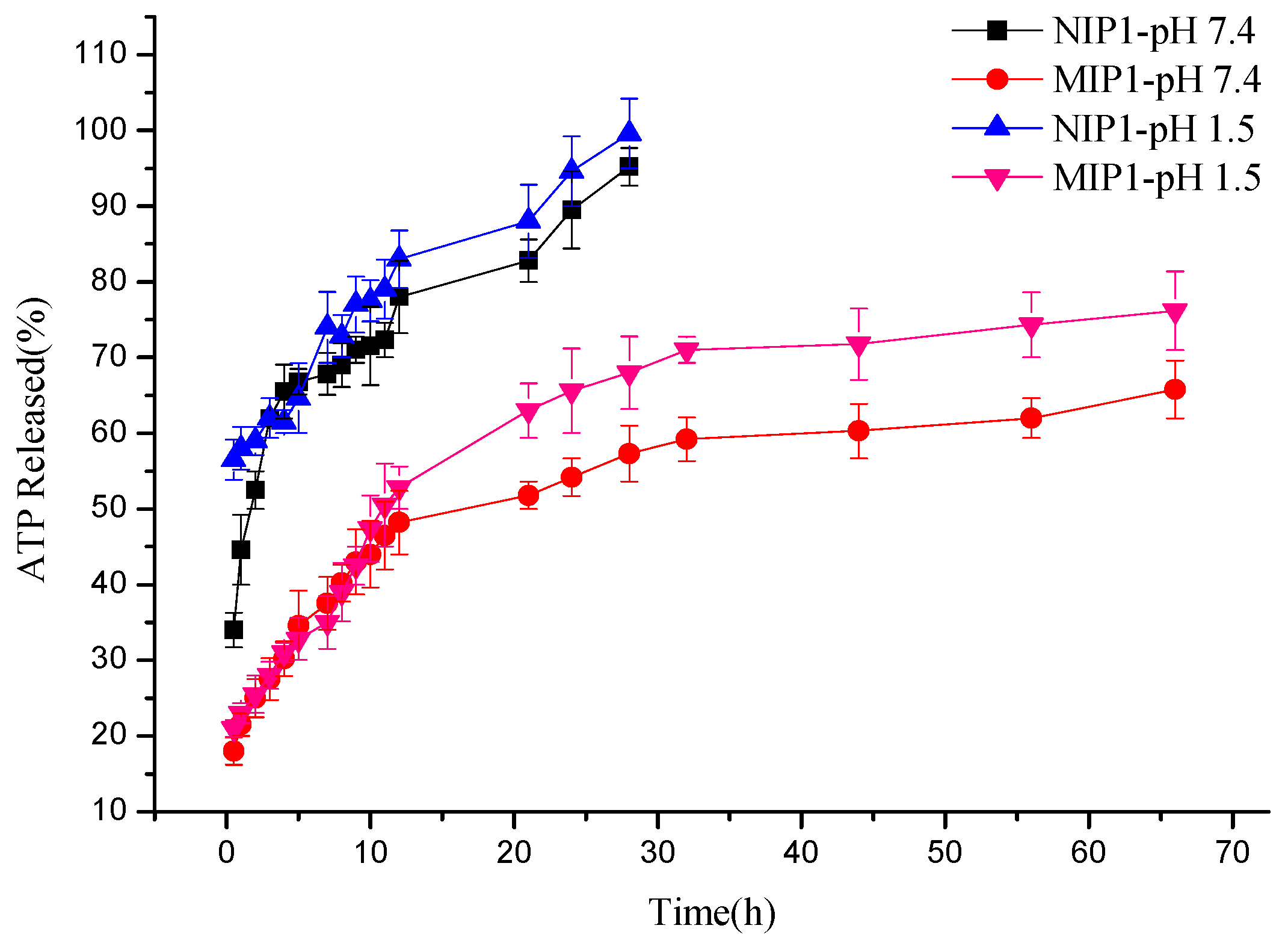

3.6. The Behavior of In Vitro Drug Release at Different pH

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Nakamura, M.; Ono, M.; Nakajima, T.; Ito, Y.; Aketo, T.; Haginaka, J. Uniformly sized molecularly imprinted polymer for atropine and its application to the determination of atropine and scopolamine in pharmaceutical preparations containing Scopolia extract. J. Pharm. Biomed. Anal. 2005, 37, 231–237. [Google Scholar] [CrossRef] [PubMed]

- Chinese Pharmacopoeia Commission. Pharmacopoeia of the People’s Republic of China, 3rd ed.; Chemical Engineering Press: Beijing, China, 1985; Volume 2, p. 542. [Google Scholar]

- Khalsa, K.P.S. Low Dose Herbs. J. Herb. Pharmacother. 2007, 7, 87–98. [Google Scholar] [CrossRef] [PubMed]

- Hedlund, B.; Abens, J.; Bartfai, T. Vasoactive intestinal polypeptide and muscarinic receptors: Supersensitivity induced by long-term atropine treatment. Science 1983, 220, 519–521. [Google Scholar] [CrossRef] [PubMed]

- Addo, R.T.; Yeboah, K.G.; Siwale, R.C.; Siddig, A.; Jones, A.; Ubale, R.V.; Akande, J.; Nettey, H.; Patel, N.J.; Addo, E.; et al. Formulation and Characterization of Atropine Sulfate in Albumin–Chitosan Microparticles for In Vivo Ocular Drug Delivery. J. Pharm. Sci. 2015, 104, 1677–1690. [Google Scholar] [CrossRef]

- Chia, A.; Chua, W.H.; Cheung, Y.B.; Wong, W.L.; Lingham, A.; Fong, A.; Tan, D. Atropine for the treatment of childhood myopia: Safety and efficacy of 0.5%, 0.1%, and 0.01% doses (Atropine for the Treatment of Myopia 2). Ophthalmology 2012, 119, 347–354. [Google Scholar] [CrossRef]

- Repka, M.X.; Kraker, R.T.; Holmes, J.M.; Summers, A.I.; Glaser, S.R.; Barnhardt, C.N.; Tien, D.R. Atropine vs patching for treatment of moderate amblyopia: Follow-up at 15 years of age of a randomized clinical trial. JAMA Ophthalmol. 2014, 132, 799–805. [Google Scholar] [CrossRef]

- Chia, A.; Chua, W.H.; Wen, L.; Fong, A.; Goon, Y.Y.; Tan, D. Atropine for the treatment of childhood myopia: Changes after stopping atropine 0.01%, 0.1% and 0.5%. Am. J. Ophthalmol. 2014, 157, 451–457. [Google Scholar] [CrossRef]

- Deshpande, S.; Sharma, S.; Koul, V.; Singh, N. Core–Shell Nanoparticles as an Efficient, Sustained, and Triggered Drug-Delivery System. ACS Omega 2017, 2, 6455–6463. [Google Scholar] [CrossRef]

- Alvarez-Lorenzo, C.; Concheiro, A. Molecularly imprinted polymers for drug delivery. J. Chromatogr. B 2004, 804, 231–245. [Google Scholar] [CrossRef]

- Shi, Y.; Lv, H.; Lu, X.; Huang, Y.; Zhang, Y.; Xue, W. Uniform molecularly imprinted poly (methacrylic acid) nanospheres prepared by precipitation polymerization: The control of particle features suitable for sustained release of gatifloxacin. J. Mater. Chem. 2012, 22, 3889–3898. [Google Scholar] [CrossRef]

- Chang, P.; Zhang, Z.; Yang, C. Molecularly imprinted polymer-based chemiluminescence array sensor for the detection of proline. Anal. Chim. Acta 2010, 666, 70–75. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Javadi, A.; Ghaffari, M.; Gong, S. A pH-sensitive molecularly imprinted nanospheres/hydrogel composite as a coating for implantable biosensors. Biomaterials 2010, 31, 4944–4951. [Google Scholar] [CrossRef] [PubMed]

- Whitcombe, M.J.; Chianella, I.; Larcombe, L.; Piletsky, S.A.; Noble, J.; Porter, R.; Horgan, A. The rational development of molecularly imprinted polymer-based sensors for protein detection. Chem. Soc. Rev. 2011, 40, 1547–1571. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Bu, Y.; Zhen, Y.; Xu, K.; Ke, R.; Xie, X.; Wang, S. Magnetic carbon nanotubes camouflaged with cell membrane as a drug discovery platform for selective extraction of bioactive compounds from natural products. Chem. Eng. J. 2019, 364, 269–279. [Google Scholar] [CrossRef]

- Ali, M.; Horikawa, S.; Venkatesh, S.; Saha, J.; Hong, J.W.; Byrne, M.E. Zero-order therapeutic release from imprinted hydrogel contact lenses within in vitro physiological ocular tear flow. J. Control. Release 2007, 124, 154–162. [Google Scholar] [CrossRef]

- Adali-Kaya, Z.; Tse Sum Bui, B.; Falcimaigne-Cordin, A.; Haupt, K. Molecularly Imprinted Polymer Nanomaterials and Nanocomposites: Atom-Transfer Radical Polymerization with Acidic Monomers. Angew. Chem. Int. Ed. Engl. 2015, 54, 5192–5195. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, H. Well-defined hydrophilic molecularly imprinted polymer microspheres for efficient molecular recognition in real biological samples by facile RAFT coupling chemistry. Biomacromolecules 2014, 15, 1663–1675. [Google Scholar] [CrossRef]

- Wen, J.; Anderson, S.M.; Du, J.; Yan, M.; Wang, J.; Shen, M.; Lu, Y. Controlled protein delivery based on enzyme-responsive nanocapsules. Adv. Mater. 2011, 23, 4549–4553. [Google Scholar] [CrossRef]

- Piletska, E.V.; Abd, B.H.; Krakowiak, A.S.; Parmar, A.; Pink, D.L.; Wall, K.S.; Wharton, L.; Moczko, E.; Whitcombe, M.J.; Karim, K.; et al. Magnetic high throughput screening system for the development of nano-sized molecularly imprinted polymers for controlled delivery of curcumin. Analyst 2015, 140, 3113–3120. [Google Scholar] [CrossRef]

- Nematollahzadeh, A.; Sun, W.; Aureliano, C.S.; Lutkemeyer, D.; Stute, J.; Abdekhodaie, M.J.; Shojaei, A.; Sellergren, B. High-capacity hierarchically imprinted polymer beads for protein recognition and capture. Angew. Chem. Int. Ed. Engl. 2011, 50, 495–498. [Google Scholar] [CrossRef]

- Hoshino, Y.; Koide, H.; Urakami, T.; Kanazawa, H.; Kodama, T.; Oku, N.; Shea, K. Recognition, neutralization, and clearance of target peptides in the bloodstream of living mice by molecularly imprinted polymer nanoparticles: A plastic antibody. J. Am. Chem. Soc. 2010, 132, 6644–6645. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Chen, H.; Duan, X.; Jia, J.; Kong, J. Molecularly imprinted polymers synthesized using reduction-cleavable hyperbranched polymers for doxorubicin hydrochloride with enhanced loading properties and controlled release. J. Mater. Sci. 2016, 51, 9367–9383. [Google Scholar] [CrossRef]

- Yao, T.; Gu, X.; Li, T.; Zhao, Z.; Li, J.; Wang, J.; Qin, Y.; She, Y. Enhancement of surface plasmon resonance signals using a MIP/GNPs/rGO nano-hybrid film for the rapid detection of ractopamine. Biosens. Bioelectron. 2016, 75, 96–100. [Google Scholar] [CrossRef] [PubMed]

- Shaabani, A.; Afshari, R.; Hooshmand, E.E.; Nejad, M.K. Molecularly Imprinted Polymer as an Eco-Compatible Nanoreactor in Multicomponent Reactions: A Remarkable Synergy for Expedient Access to Highly Substituted Imidazoles. ACS Sustain. Chem. Eng. 2017, 5, 9506–9516. [Google Scholar] [CrossRef]

- Luo, J.; Huang, J.; Cong, J.; Wei, W.; Liu, X. Double Recognition and Selective Extraction of Glycoprotein Based on the Molecular Imprinted Graphene Oxide and Boronate Affi nity. ACS Appl. Mater. Interfaces 2017, 9, 7735–7744. [Google Scholar] [CrossRef]

- Cunliffe, D.; Kirby, A.; Alexander, C. Molecularly imprinted drug delivery systems. Adv. Drug Deliv. Rev. 2005, 57, 1836–1853. [Google Scholar] [CrossRef]

- Alvarez-Lorenzo, C.; Yanez, F.; Barreiro-Iglesias, R.; Concheiro, A. Imprinted soft contact lenses as norfloxacin delivery systems. J. Control. Release 2006, 113, 236–244. [Google Scholar] [CrossRef]

- Ng, S.M.; Narayanaswamy, R. Molecularly imprinted β-cyclodextrin polymer as potential optical receptor for the detection of organic compound. Sens. Actuators B Chem. 2009, 139, 156–165. [Google Scholar] [CrossRef]

- Surikumaran, H.; Mohamad, S.; Muhamad Sarih, N.; Muggundha Raoov, R. β-Cyclodextrin based Molecular Imprinted Solid Phase Extraction for Class Selective Extraction of Priority Phenols in Water Samples. Sep. Sci. Technol. 2015, 50, 2342–2351. [Google Scholar] [CrossRef]

- Gao, S.; Jiang, J.-U.; Liu, Y.-Y.; Fu, Y.; Zhao, L.-X.; Li, C.-Y.; Ye, F. Enhanced Solubility, Stability, and Herbicidal Activity of the Herbicide Diuron by Complex Formation with β-Cyclodextrin. Polymers 2019, 11, 1396. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Shen, M.X.; Cao, G.P.; Deng, J.; Liu, Y. Preparation of bimodal porous copolymer containing β-cyclodextrin and its inclusion adsorption behavior. J. Appl. Polym. Sci. 2010, 118, 2176–2185. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, X.; Wang, Q.; Zhang, R.; Wang, T. Thermo/pH dual responsive β-cyclodextrin magnetic microspheres for anti-cancer drug controlled release. J. Control. Release 2015, 213, e21–e22. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Liu, J.; Zhang, Z.; Wang, L.; Chen, Z.; Xiang, S. The cooperative utilization of imprinting, electro-spinning and a pore-forming agent to synthesise β-cyclodextrin polymers with enhanced recognition of naringin. RSC Adv. 2013, 3, 25396–25402. [Google Scholar] [CrossRef]

- Xu, Z.F.; Wen, G.; Kuang, D.Z.; Zhang, F.X.; Tang, S.P. Selective separation of deltamethrin by molecularly imprinted polymers using a β-cyclodextrin derivative as the functional monomer. J. Environ. Sci. Health B 2013, 48, 336–343. [Google Scholar] [CrossRef]

- Gao, S.; Liu, Y.; Jiang, J.; Ji, Q.; Fu, Y.; Zhao, L.; Li, C.; Ye, F. Physicochemical properties and fungicidal activity of inclusion complexes of fungicide chlorothalonil with β-cyclodextrin and hydroxypropyl-β-cyclodextrin. J. Mol. Liq. 2019, 293, 111513. [Google Scholar] [CrossRef]

- Komiyama, M.; Takeuchi, T.; Mukawa, T.; Asanuma, H. Molecular Imprinting; Wiley-VCH: Weinheim, Germany, 2003; p. 119. [Google Scholar]

- Mao, C.; Xie, X.; Liu, X.; Cui, Z.; Yang, X.; Yeung, K.W.K.; Pan, H.; Chu, P.K.; Wu, S. The controlled drug release by pH-sensitive molecularly imprinted nanospheres for enhanced antibacterial activity. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 77, 84–91. [Google Scholar] [CrossRef]

- Wu, W.; Shen, J.; Banerjee, P.; Zhou, S. Chitosan-based responsive hybrid nanogels for integration of optical pH-sensing, tumor cell imaging and controlled drug delivery. Biomaterials 2010, 31, 8371–8381. [Google Scholar] [CrossRef]

- Takehiro, N.; Kazunari, A.; Junzo, S. Macromolecular Complexation between Bovine Serum Albumin and the Self-Assembled Hydrogel Nanoparticle of Hydrophobized Polysaccharides. J. Am. Chem. Soc. 1996, 118, 6110–6115. [Google Scholar]

- Sreenivasan, K. Grafting of β-cyclodextrin-modified 2-hydroxyethyl methacrylate onto polyurethane. J. Appl. Polym. Sci. 1996, 60, 2245–2249. [Google Scholar] [CrossRef]

- She, Y.X.; Cao, W.Q.; Shi, X.M.; Lv, X.L.; Liu, J.J.; Wang, R.Y.; Jin, F.; Wang, J.; Xiao, H. Class-specific molecularly imprinted polymers for the selective extraction and determination of sulfonylurea herbicides in maize samples by high-performance liquid chromatography–tandem mass spectrometry. J. Chromatogr. B 2010, 878, 2047–2053. [Google Scholar] [CrossRef]

- Ma, X.; Chen, Z.; Chen, R.; Zheng, X.; Chen, X.; Lan, R. Imprinted β-cyclodextrin polymers using naringin as template. Polym. Int. 2011, 60, 1455–1460. [Google Scholar] [CrossRef]

- Li, C.; Jia, J.; Guo, Y.; Liu, Y.; Zhu, P. Preparation and characterization of IPN hydrogels composed of chitosan and gelatin cross-linked by genipin. Carbohydr. Polym. 2014, 99, 31–38. [Google Scholar]

- Chen, F.F.; Xie, X.Y.; Shi, Y.P. Preparation of magnetic molecularly imprinted polymer for selective recognition of resveratrol in wine. J. Chromatogr. A. 2013, 1300, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Langmuir, I. The constitution and fundamental properties of solids and liquids. Part 1 Solids. J. Am. Chem. Soc. 1916, 38, 2221–2295. [Google Scholar] [CrossRef]

- Herbert, F. Colloid and Capillary; E. P. Dutton and Co.: New York, NY, USA, 1928. [Google Scholar]

- Milojevic, S.; Newton, J.M.; Cummings, J.H.; Gibson, G.R.; Botham, R.L.; Ring, S.G.; Stockham, M.; Allwood, M.C. Amylose as a coating for drug delivery to the colon: Preparation and in vitro evaluation using 5-aminosalicylic acid pellets. J. Control. Release 1996, 38, 75–84. [Google Scholar] [CrossRef]

- Asman, S.; Mohamad, S.; Sarih, N.M. Exploiting β-cyclodextrin in molecular imprinting for achieving recognition of benzylparaben in aqueous media. Int. J. Mol. Sci. 2015, 16, 3656–3676. [Google Scholar] [CrossRef]

- Kayaci, F.; Aytac, Z.; Uyar, T. Surface modification of electrospun polyester nanofibers with cyclodextrin polymer for the removal of phenanthrene from aqueous solution. J. Hazard. Mater. 2013, 261, 286–294. [Google Scholar] [CrossRef]

- Byrne, M.E.; Park, K.; Peppas, N.A. Biomimetic networks for selective recognition of biomolecules. Mater. Res. Soc. Symp. Proc. 2002, 724, 193–198. [Google Scholar] [CrossRef]

- Siemoneit, U.; Schmitt, C.; Alvarez-Lorenzo, C.; Luzardo, A.; Otero-Espinar, F.; Concheiro, A.; Blanco-Méndez, J. Acrylic/cyclodextrin hydrogels with enhanced drug loading and sustained release capability. Int. J. Pharm. 2006, 312, 66–74. [Google Scholar] [CrossRef]

- Umpleby, R.J.; Baxter, S.C.; Chen, Y.; Shah, R.N.; Shimizu, K.D. Characterization of molecularly imprinted polymers with the Langmuir-Freundlich isotherm. Anal. Chem. 2001, 73, 4584–4591. [Google Scholar] [CrossRef]

- Marcelo, G.; Ferreira, I.C.; Viveiros, R.; Casimiro, T. Development of itaconic acid-based molecular imprinted polymers using supercritical fluid technology for ph-triggered drug delivery. Int. J. Pharm. 2018, 542, 125–131. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Nanaki, S.G.; Koltsakidou, A.; Papageorgiou, M.; Kechagia, M.; Bikiaris, D.N.; Lambropoulou, D.A. Effectively designed molecularly imprinted polymers for selective isolation of the antidiabetic drug metformin and its transformation product guanylurea from aqueous media. Anal. Chim. Acta 2015, 866, 27–40. [Google Scholar] [CrossRef]

- Rampey, A.M.; UmplebyIi, R.J.; Rushton, G.T.; Iseman, J.C.; Shah, R.N.; Shimizu, K.D. Characterization of the imprint effect and the influence of imprinting conditions on affinity, capacity, and heterogeneity in molecularly imprinted polymers using the Freundlich isotherm-affinity distribution analysis. Anal. Chem. 2004, 76, 1123–1133. [Google Scholar] [CrossRef]

| Compounds | Parent mass (m/z) | Daughter mass (m/z) | Declustering potential (V) | Collision energy (eV) |

|---|---|---|---|---|

| ATP | 290.2 | 124.1 * | 69 | 36 |

| 93.0 | 47 | |||

| ASD | 320.0 | 156.0 * | 69 | 27 |

| 138.1 | 33 | |||

| 119.1 | 35 |

| Microspheres name | Template (ATP) | Functional monomer | Cross-linker | ATP: monomer molar ratio | Yield (%) | Saturated swelling (%) |

|---|---|---|---|---|---|---|

| NIP0 | - | MAA (0.4 mmol) | TRIM (2 mmol) | - | 74 | 394 |

| MIP0 | 0.1 mmol | MAA (0.4 mmol) | TRIM (2 mmol) | 1/4 | 71 | 502 |

| NIP1 | - | MAA-β-CD (0.4 mmol) | TRIM (2 mmol) | - | 72 | 983 |

| MIP1 | 0.1 mmol | MAA-β-CD (0.4 mmol) | TRIM (2 mmol) | 1/4 | 74 | 1154 |

| MIP2 | 0.1 mmol | MAA-β-CD (0.4 mmol) | EPI (2 mmol) | 1/4 | 12 | - |

| MIP3 | 0.1 mmol | MAA-β-CD (0.4 mmol) | Genipin (2 mmol) | 1/4 | 50 | - |

| Langmuir model | Freundlich model | ||

|---|---|---|---|

| Qm (ng·mg−1) | 240.8 | Kf | 5.24 |

| b | 0.012 | n | 1.42 |

| R2 | 0.91 | R2 | 0.99 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Zeng, S.; Abd El-Aty, A.M.; Hacımüftüoğlu, A.; Kalekristos Yohannes, W.; Khan, M.; She, Y. Development of Water-Compatible Molecularly Imprinted Polymers Based on Functionalized β-Cyclodextrin for Controlled Release of Atropine. Polymers 2020, 12, 130. https://doi.org/10.3390/polym12010130

He Y, Zeng S, Abd El-Aty AM, Hacımüftüoğlu A, Kalekristos Yohannes W, Khan M, She Y. Development of Water-Compatible Molecularly Imprinted Polymers Based on Functionalized β-Cyclodextrin for Controlled Release of Atropine. Polymers. 2020; 12(1):130. https://doi.org/10.3390/polym12010130

Chicago/Turabian StyleHe, Yahui, Shaomei Zeng, A. M. Abd El-Aty, Ahmet Hacımüftüoğlu, Woldemariam Kalekristos Yohannes, Majid Khan, and Yongxin She. 2020. "Development of Water-Compatible Molecularly Imprinted Polymers Based on Functionalized β-Cyclodextrin for Controlled Release of Atropine" Polymers 12, no. 1: 130. https://doi.org/10.3390/polym12010130

APA StyleHe, Y., Zeng, S., Abd El-Aty, A. M., Hacımüftüoğlu, A., Kalekristos Yohannes, W., Khan, M., & She, Y. (2020). Development of Water-Compatible Molecularly Imprinted Polymers Based on Functionalized β-Cyclodextrin for Controlled Release of Atropine. Polymers, 12(1), 130. https://doi.org/10.3390/polym12010130