A Numerical and Experimental Study of Adhesively-Bonded Polyethylene Pipelines

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Characterisation

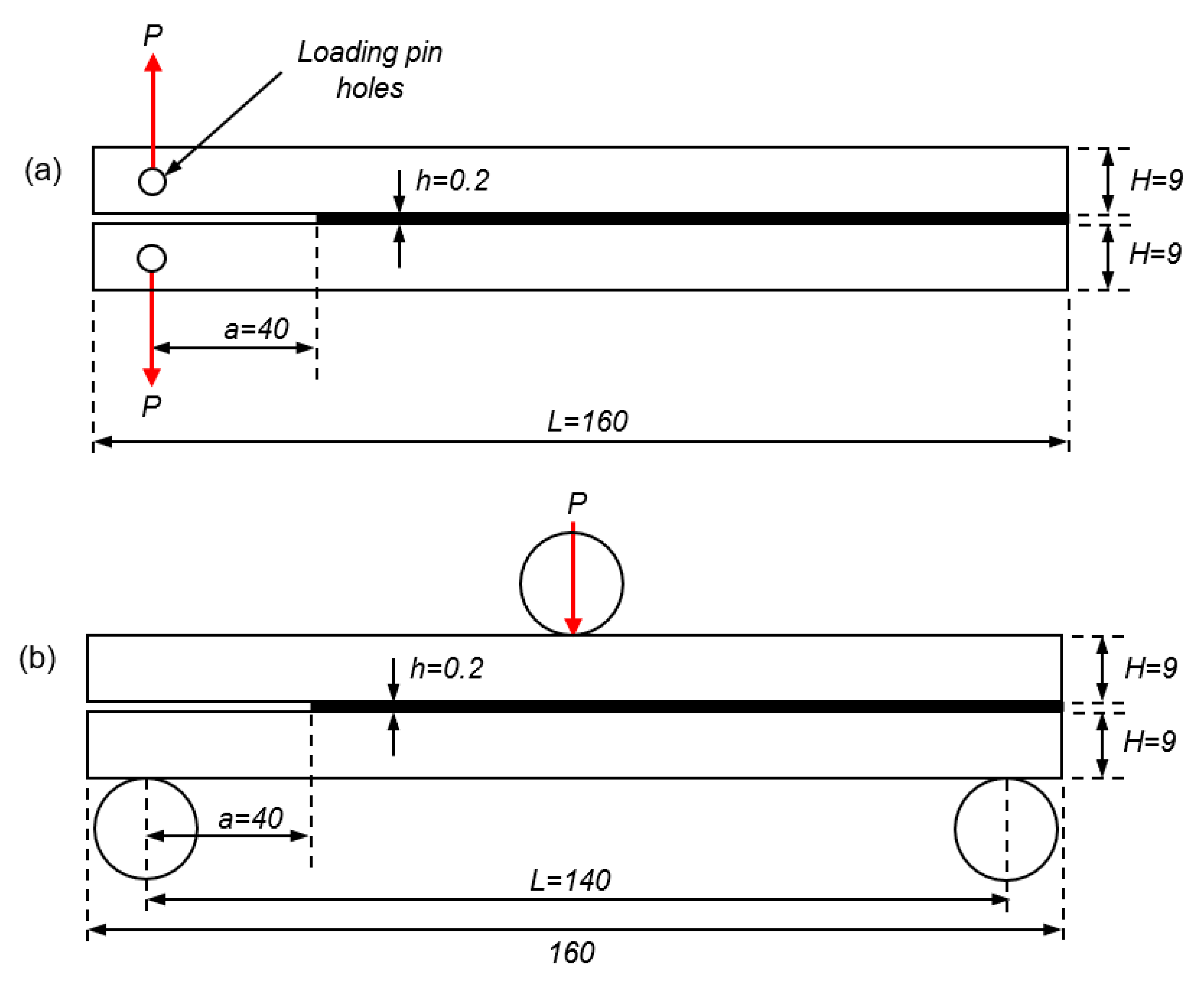

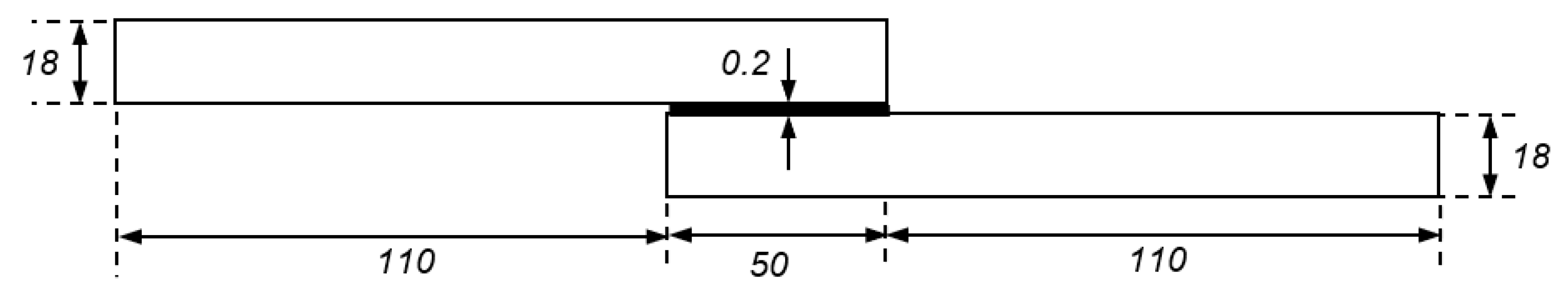

2.2. Tensile Lap-Shear Testing

3. Numerical Analysis

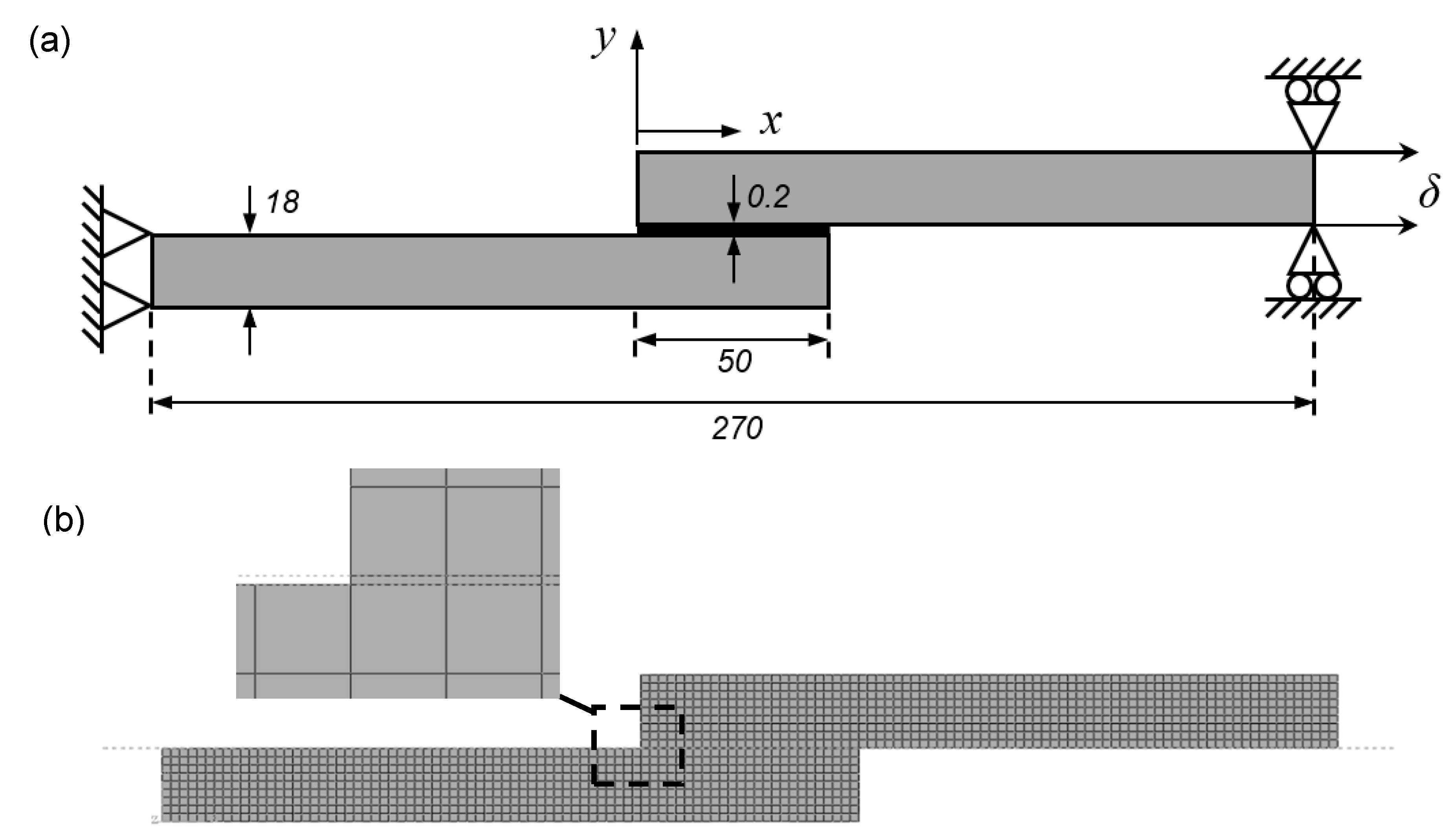

3.1. Analysis Conditions

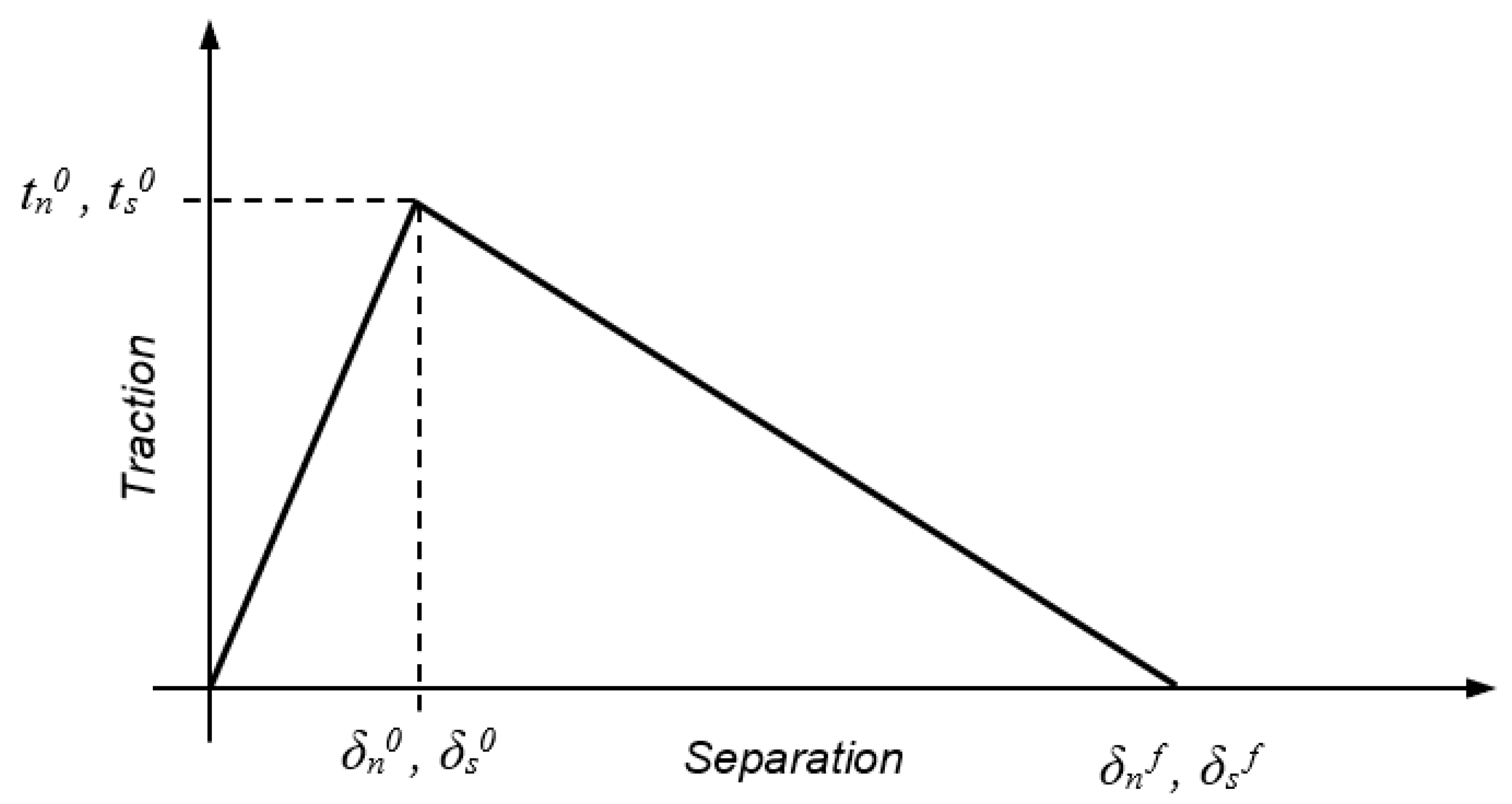

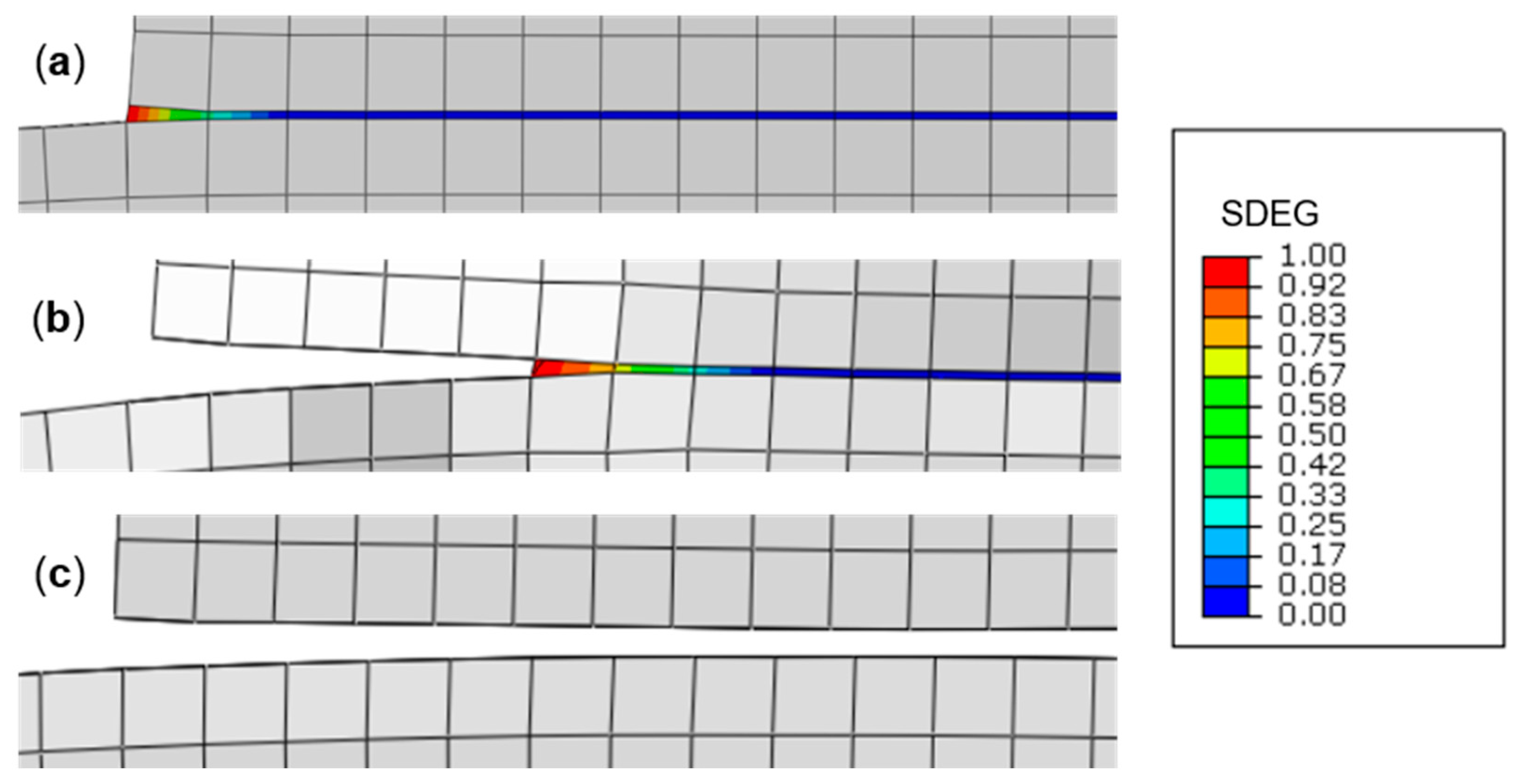

3.2. Cohesive Zone Model

4. Results and Discussion

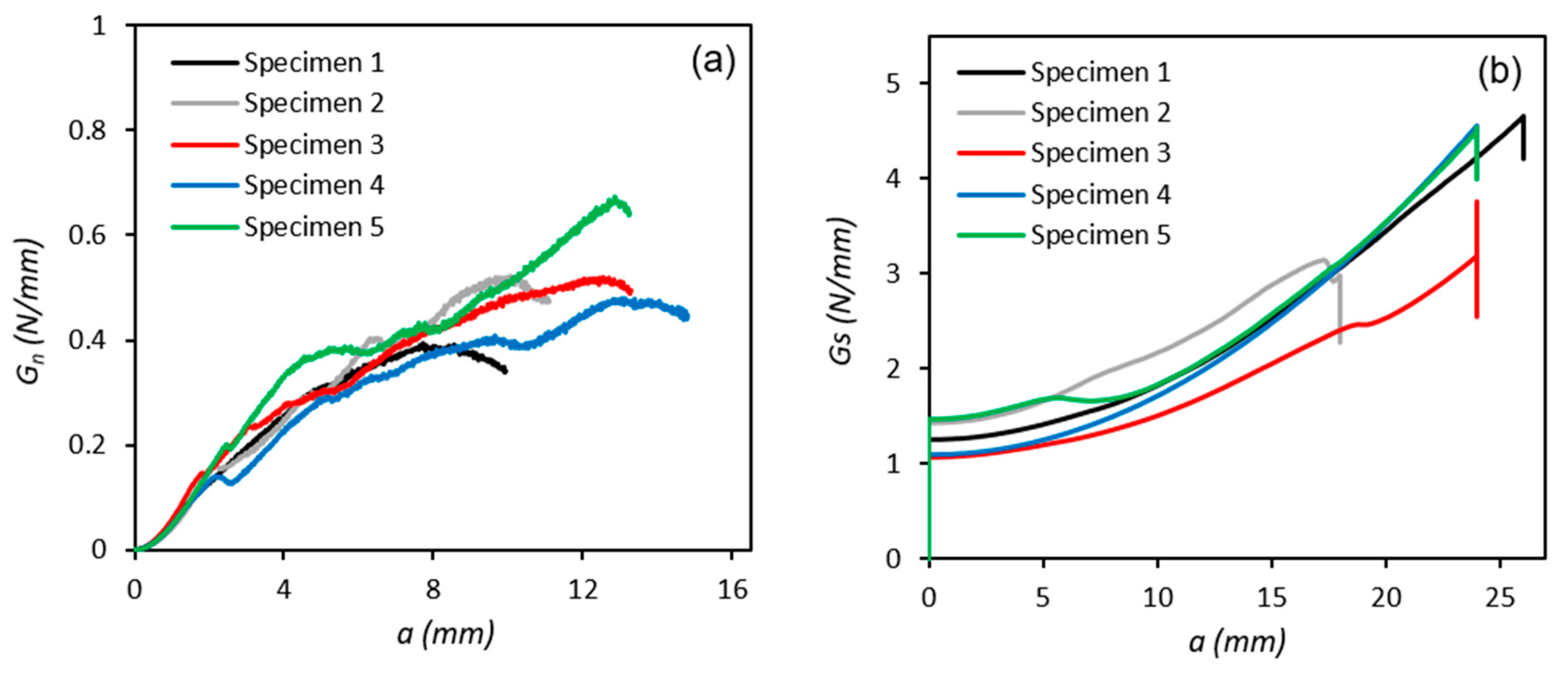

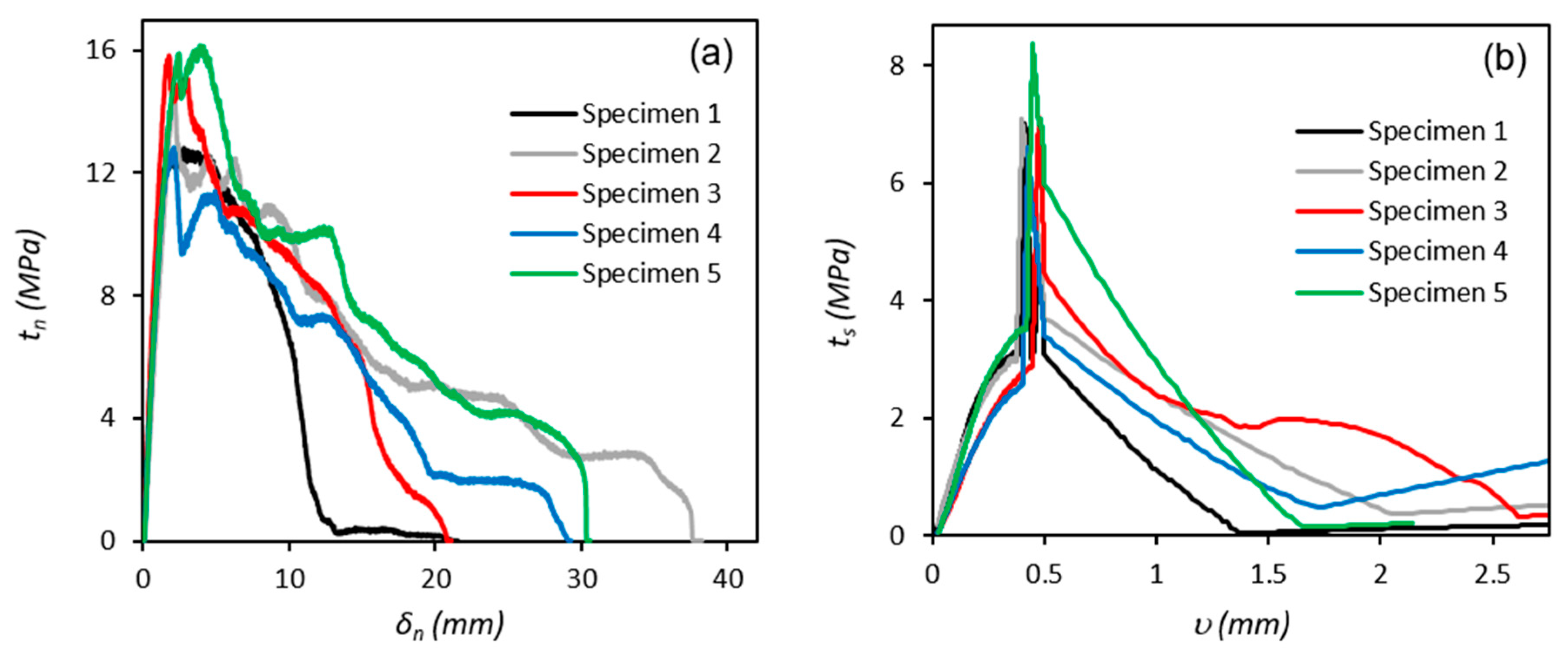

4.1. Materials Characterisation

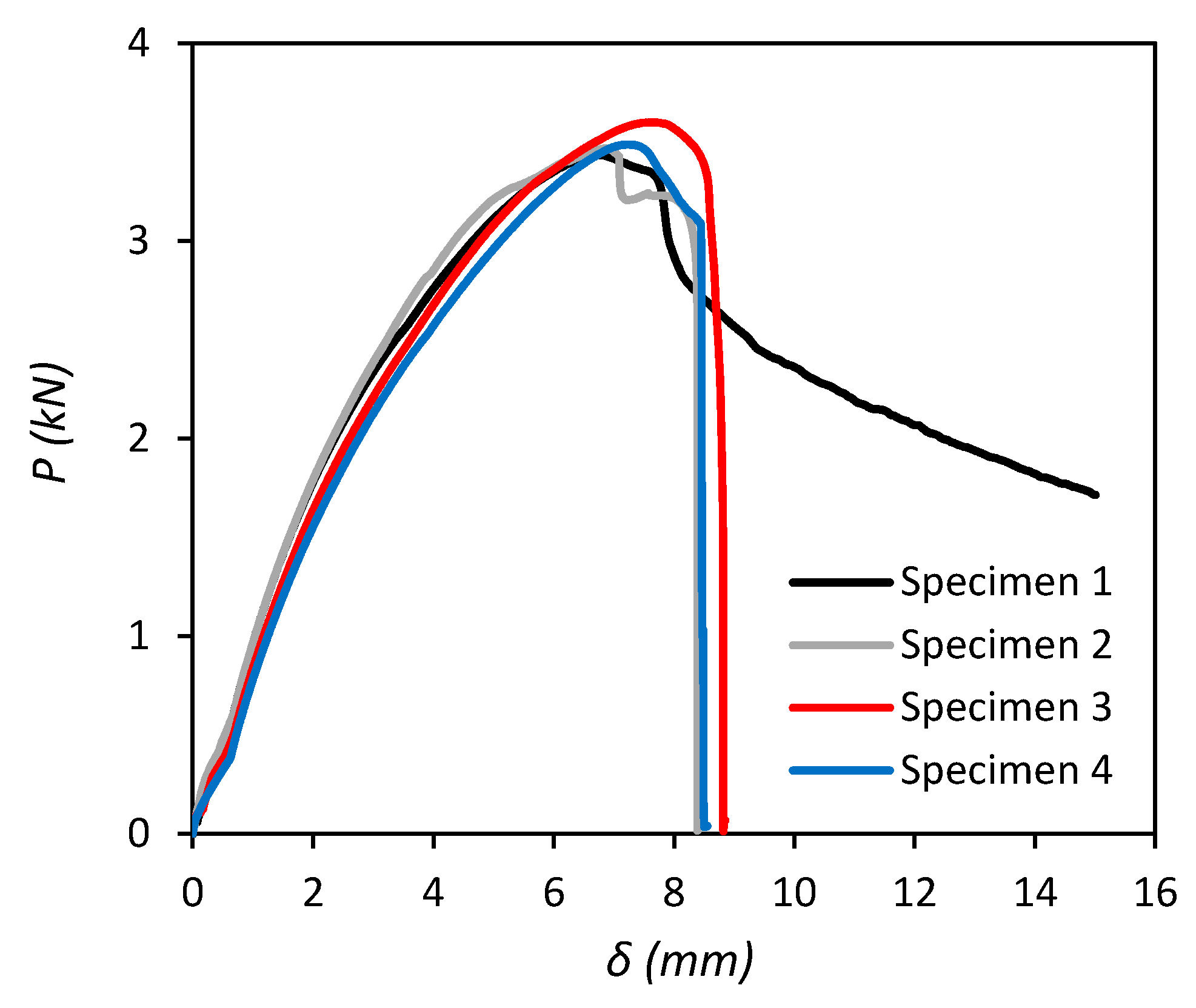

4.2. Tensile Lap-Shear Tests

4.3. Numerical Model

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Frank, A.; Pinter, G.; Lang, R.W. Prediction of the remaining lifetime of polyethylene pipes after up to 30 years in use. Polym. Test. 2009, 28, 737–745. [Google Scholar] [CrossRef]

- Leskovics, K.; Kollar, M.; Barczy, P. A study of structure and mechanical properties of welded joints in polyethylene pipes. Mater. Sci. Eng. A 2006, 419, 138–143. [Google Scholar] [CrossRef]

- Hoang, E.; Lowe, D. Lifetime prediciton of a blue PE100 water pipe. Polym. Degrad. Stabil. 2008, 93, 1496–1503. [Google Scholar] [CrossRef]

- Bhowmik, S.; Ghaki, T.K.; Ray, S.; Hoffman, F.; Dorn, L. Experimental investigation into the effect of DC glow discharge pre-treatment of HDPE on tensile lap shear strength. Int. J. Adhes. Adhes. 2004, 24, 461–470. [Google Scholar] [CrossRef]

- Wang, H. Improving the adhesion of polyethylene by UV grafting. J. Adhes. 2006, 82, 731–745. [Google Scholar] [CrossRef]

- Navaneetha Pandiyaraj, K.; Selvarajan, V.; Deshmukh, R.R.; Changyou, G. Adhesion properties of polypropylene (PP) and polyethylene trephthalate (PET) film surfaces treated by DC glow discharge plasma. Vacuum 2009, 83, 332–339. [Google Scholar] [CrossRef]

- O’Connor, C.; Denton, G.L.N. Polyethylene pipeline systems: Avoiding the pitfalls of fusion welding. In Proceedings of the 7th Pipeline Technology Conference, Hannover, Germany, 28–30 March 2012. [Google Scholar]

- Shi, J.; Zheng, J.; Guo, W.; Qin, Y. Defects classification and failure modes of electrofusion joints for connecting polyethylene pipes. J. Appl. Polym. Sci. 2012, 124, 4070–4080. [Google Scholar] [CrossRef]

- Plastic Pipe Database Committee. Plastic Piping Data Collection Initiative Status Report (3 May, 2018); American Gas Association: Washington, DC, USA, 2018; pp. 1–69. [Google Scholar]

- Barton, L.; Birkett, M. Mechanical behaviour of adhesively bonded polyethylene tapping tees. Int. J. Adhes. Adhes. 2016, 66, 1–8. [Google Scholar] [CrossRef][Green Version]

- LeBono, J.; Barton, L.; Birkett, M. Low temperature tensile lap-shear testing of adhesively bonded polyethylene pipe. Int. J. Adhes. Adhes. 2017, 74, 57–63. [Google Scholar] [CrossRef]

- Wooley, G.R.; Carver, D.R. Stress concentration factors for bonded lap joint. J. Aircr. 1971, 8, 817–820. [Google Scholar]

- Harris, J.A.; Adams, R.D. Strength pridiction of bonded single-lap joints by non-linear finite element methods. Int. J. Adhes. Adhes. 1984, 4, 65–78. [Google Scholar] [CrossRef]

- Bigwood, D.A.; Crocombe, A.D. Non-linear adhesive bonded joint design analyses. Int. J. Adhes. Adhes. 1990, 10, 31–41. [Google Scholar] [CrossRef]

- Qian, Z.Q.; Akisanya, A.R. An investigation of the stress singularity near the free edge of scarf joints. Eur. J. Mech. A-Solid. 1999, 18, 443–463. [Google Scholar] [CrossRef]

- Dragoni, E.; Mauri, P. Intrinsic static strength of friction interfaces augmented with anearobic adhesives. Int. J. Adhes. Adhes. 2000, 20, 315–321. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; Banea, M.D.; Pinto, A.M.G.; da Silva, L.F.M.; de Jesus, A.M.P. Strength prediction of single- and double-lap joints by standard and extended finite element modelling. Int. J. Adhes. Adhes. 2011, 31, 363–372. [Google Scholar] [CrossRef]

- Feraren, P.; Jensen, H.M. Cohesive zone modelling of of interface fracture near flaws in adhesive joints. Eng. Fract. Mech. 2004, 71, 2125–2141. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Campilho, R.D.S.G. Advances in Numerical Modelling of Adhesive Joints. In Advances in Numerical Modelling of Adhesive Joints; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–93. [Google Scholar]

- Barenblatt, G.I. The mathematical theory of equilibrium cracks in brittle fracture. Adv. Appl. Mech. 1962, 7, 55–129. [Google Scholar]

- Dugdale, D.S. Yielding of sheets containing slits. J. Mech. Phys. Solids. 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modeer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Crocombe, A.D.; Richardson, G.; Smith, P.A. A unified approach for predicting the strength of cracked and non-cracked adhesive joints. J. Adhes. 1995, 49, 211–244. [Google Scholar] [CrossRef]

- Paroissien, E.; Lachaud, F.; Morlier, J.; Schwartz, S. A direct method for the assessment of cohesive zone models for thin adhesive layers loaded in mode I, Mode II, and mixed-mode I/II. Rev. Adhes. Adhes. 2019. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; Banea, M.D.; Neto, J.A.B.P.; da Silva, L.F.M. Modelling adhesive joints with cohesive zone models: Effect of the cohesive law shape of the adhesive layer. Int. J. Adhes. Adhes. 2013, 44, 48–56. [Google Scholar] [CrossRef]

- Gheibi, M.R.; Shojaeefard, M.H.; Saeidi Googarchin, H. Direct determination of a new mode-dependent cohesive zone model to simulate metal-to-metal adhesive joints. J. Adhes. 2019, 10, 943–970. [Google Scholar] [CrossRef]

- de Moura, M.F.S.F.; Campilho, R.D.S.G.; Gonclaves, J.P.M. Crack equivalent concept applied to the fracture characterization of bonded joints under pure mode I loading. Compos. Sci. Technol. 2008, 68, 2224–2230. [Google Scholar] [CrossRef]

- Andersson, T.; Stigh, U. The stress-elongation relation for an adhesive layer loaded in peel using equilibrium of energetic forces. Int. J. Solids Struct. 2004, 41, 413–434. [Google Scholar] [CrossRef]

- Carlberger, T.; Stigh, U. Influence of layer thickness on cohesive properties of an epoxy based adhesive—An experimental study. J. Adhes. 2010, 86, 816–835. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; de Moura, M.F.S.F.; Domingues, J.J.M.S. Using a cohesive damage model to predict the tensile behaviour of CFRP single-strap repairs. Int. J. Solids Struct. 2008, 45, 1497–1512. [Google Scholar] [CrossRef]

- Kafkalidis, M.S.; Thouless, M.D. The effect of geometry and material properties on th fracture of single lap-shear joints. Int. J. Solids Struct. 2002, 39, 4367–4383. [Google Scholar] [CrossRef]

- ASTM D638-14. Standard Test Method for Tensile Properties of Plastics. 2014. Available online: https://www.astm.org/Standards/D638 (accessed on 15 September 2019).

- ASTM D3433-99. Stanard Test Method for Fracture Strength in Clevage of Adhesives in Bonded Metal Joints. 1999. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/D3433-99.htm (accessed on 15 September 2019).

- BS ISO 25217:2009. Adhesives-Determination of the Mode 1 Fracture energy of Structural Adhesive Joints Using Double Cantilver Beam and Tapered Double Cantilever Beam Specimens. 2009. Available online: https://www.iso.org/obp/ui/#iso:std:iso:25217:ed-1:v1:en (accessed on 15 September 2019).

- Yang, Q.D.; Thouless, M.D.; Ward, S.M. Elastic-plastic mode-II fracture of adhesive joints. Int. J. Solids Struct. 2001, 38, 3251–3262. [Google Scholar] [CrossRef]

- Lee, M.; Yeo, E.; Blacklock, M.; Janardhana, M.; Feih, S.; Wang, C.H. Predicting the strength of adhesively bonded joints of variable thickness using a cohesive element approach. Int. J. Adhes. Adhes. 2015, 58, 44–52. [Google Scholar] [CrossRef]

- Sekiguchi, Y.; Katano, M.; Sato, C. Exoerimental study of the mode I adhesive fracture ebergy in DCB specimens bonded with a polyurethane adhesive. J. Adhes. 2017, 93, 235–255. [Google Scholar] [CrossRef]

- Anyfantis, K.N.; Tsouvalis, N.G. Experiment and numerical investigation of Mode II fracture in fibrous reinforced composites. J. Reinf. Plast. Comp. 2011, 30, 473–487. [Google Scholar] [CrossRef]

- Zhu, Y.; Liechti, K.; Ravi-Chandar, K. Direct extraction of rate-dependent traction-separation laws for polyurea/steel interfaces. Int. J. Solids Struct. 2006, 46, 31–51. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; de Moura, M.F.S.F.; Pinto, A.M.G.; Morais, J.J.L.; Domingues, J.J.M.S. Modelling the tensile fracture behaviour of CFRP scarf repairs. Compos. Part. B-Eng. 2009, 40, 149–157. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; de Moura, M.F.S.F.; Domingues, J.J.M.S. Computational modelling of the residual strength of repaired composite laminates using a cohesive damage model. J. Adhes. Sci. Technol. 2008, 22, 1565–1591. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; de Moura, M.F.S.F.; Domingues, J.J.M.S. Numercial prediction on the tensile residual strength of repaired CFRP under different geometric changes. Int. J. Adhes. Adhes. 2009, 29, 195–205. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Ferreira, J.A.M.; Antunes, F. Effect of adherend’s rigidity on the shear strength of single lap adhesive joints. Int. J. Adhes. Adhes. 2011, 31, 193–201. [Google Scholar] [CrossRef]

- Pinto, A.M.G.; Campilho, R.D.S.G.; Mendes, I.R.; Baptista, A.P.M. Numerical and experimental analysis of balanced and unbalanced adhesive single-lap joints between aluminium adherends. J. Adhes. 2014, 90, 89–103. [Google Scholar] [CrossRef]

- ABAQUS Analysis User’s Guide, version 6.13; Dassault Systèmes. 2013. Available online: http://dsk.ippt.pan.pl/docs/abaqus/v6.13/books/usb/default.htm (accessed on 15 September 2019).

- Jing, J.; Gao, F.; Johnson, J.; Liang, F.; Williams, R.; Qu, J. Simulation of dynamic fracture along solder-pad interfaces using a cohesive zone model. Eng. Fail. Anal. 2009, 16, 1579–1586. [Google Scholar] [CrossRef]

- Desai, C.K.; Basu, S.; Parameswaran, V. Determination of traction separation law for interfacial failure in adhesive joints at different loading rates. J. Adhes. 2016, 92, 819–839. [Google Scholar] [CrossRef]

- Alfredsson, K.S.; Salimi, A.B.S. Shear testing of thick adhesive layers using the ENF-specimen. Int. J. Adhes. Adhes. 2015, 62, 130–138. [Google Scholar] [CrossRef]

- Hesebeck, O. Consideration of th restriction of lateral contraction in the elastic behaviour of cohesive zone models. Int J. Adhes. Adhes. 2015, 62, 165–171. [Google Scholar] [CrossRef][Green Version]

| MDPE Substrate (PE80 Yellow Gas Pipeline) | |

| Dimensions | 250 mm diameter, 18 mm thick |

| Density | 0.93–0.95 g/cm3 |

| Molecular Weight | 16 × 104 |

| Polydispersity index | 16 |

| Melt flow rate (190 °C/5 kg) | 1.0 g/10 min |

| Tensile strength | 14–22.8 MPa |

| Acrylic Adhesive (Weicon Easy-Mix PE-PP 45) | |

| Mixing ratio by volume | 10:1 (resin/hardener) |

| Density | 1.07 g/cm3 |

| Viscosity at +20 °C | 45 mPa.s |

| Pot life (10 mL at +20 °C) | 2–3 min |

| Glass transistion temperature (Tg) | 35 °C |

| Processing temperature (optimal) | +20 to +25 °C |

| Curing Temperature | +15 to +70 °C |

| Curing time at 20 °C (for PP substrates) | 2–3 h—handling strength (35% of final) |

| 6 h—mechanical strength (50% of final) | |

| 24 h—final strength (100% cured) | |

| Specimen No. | Mode I (DCB) | Mode II (ENF) | ||

|---|---|---|---|---|

| Gnc (N/mm) | tn0 (MPa) | Gsc (N/mm) | ts0 (MPa) | |

| 1 | 0.39 | 12.83 | 4.65 | 10.02 |

| 2 | 0.52 | 14.67 | 3.14 | 9.47 |

| 3 | 0.52 | 15.84 | 3.76 | 9.50 |

| 4 | 0.48 | 12.83 | 4.56 | 8.45 |

| 5 | 0.67 | 16.16 | 4.53 | 10.07 |

| Average | 0.52 | 14.46 | 4.13 | 9.50 |

| Std Dev. | 0.10 | 1.60 | 0.66 | 0.65 |

| Property | Weicon PE-PP 45 |

|---|---|

| E (MPa) | 1850 |

| G (MPa) | 560 |

| tn0 (MPa) | 14.46 |

| ts0 (MPa) | 9.50 |

| Gn0 (N/mm) | 0.52 |

| Gs0 (N/mm) | 4.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guilpin, A.; Franciere, G.; Barton, L.; Blacklock, M.; Birkett, M. A Numerical and Experimental Study of Adhesively-Bonded Polyethylene Pipelines. Polymers 2019, 11, 1531. https://doi.org/10.3390/polym11091531

Guilpin A, Franciere G, Barton L, Blacklock M, Birkett M. A Numerical and Experimental Study of Adhesively-Bonded Polyethylene Pipelines. Polymers. 2019; 11(9):1531. https://doi.org/10.3390/polym11091531

Chicago/Turabian StyleGuilpin, Antoine, Geoffrey Franciere, Lewis Barton, Matthew Blacklock, and Martin Birkett. 2019. "A Numerical and Experimental Study of Adhesively-Bonded Polyethylene Pipelines" Polymers 11, no. 9: 1531. https://doi.org/10.3390/polym11091531

APA StyleGuilpin, A., Franciere, G., Barton, L., Blacklock, M., & Birkett, M. (2019). A Numerical and Experimental Study of Adhesively-Bonded Polyethylene Pipelines. Polymers, 11(9), 1531. https://doi.org/10.3390/polym11091531