Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling

Abstract

1. Introduction

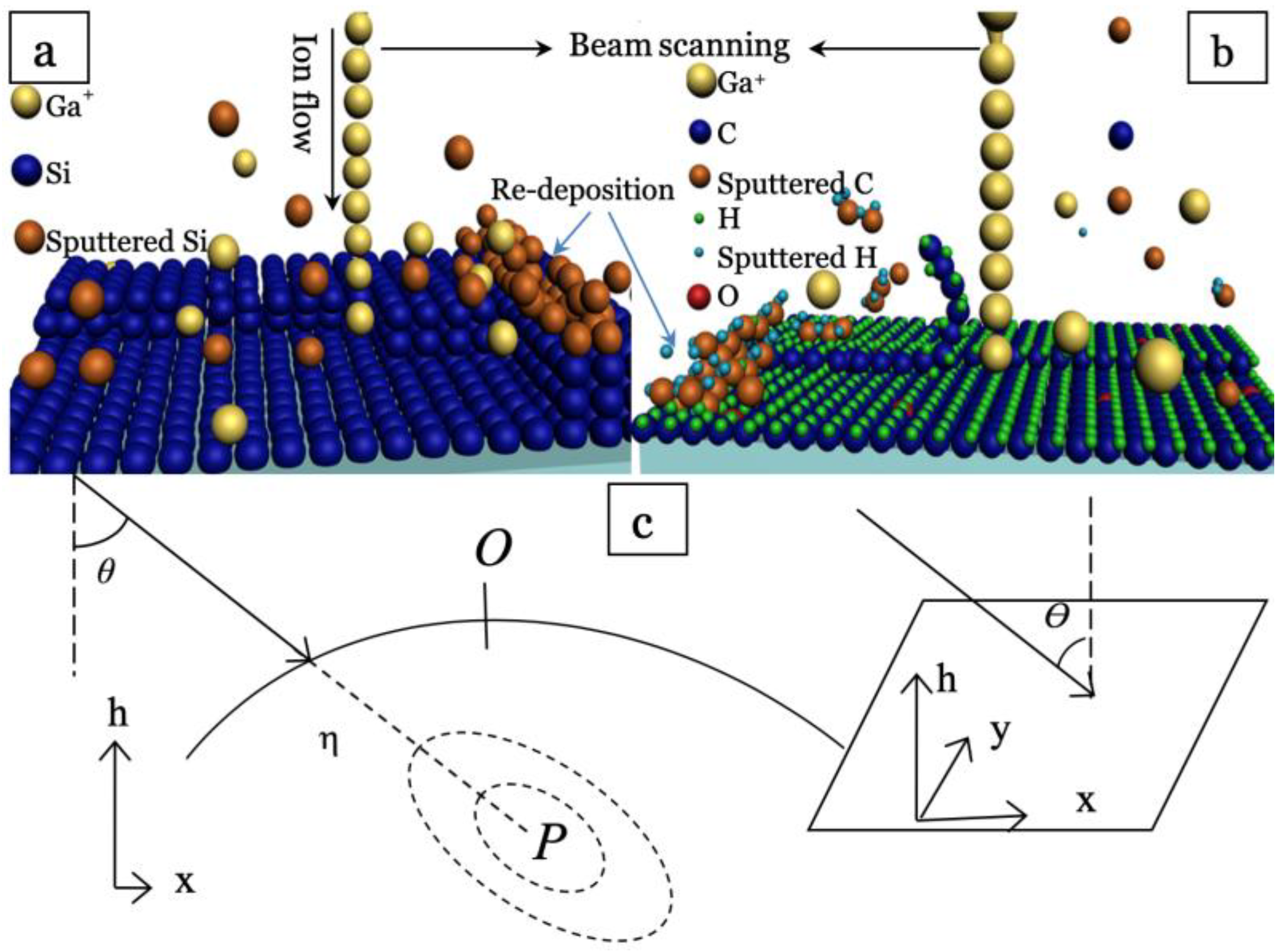

2. Theoretical Background

3. Experimental Methods

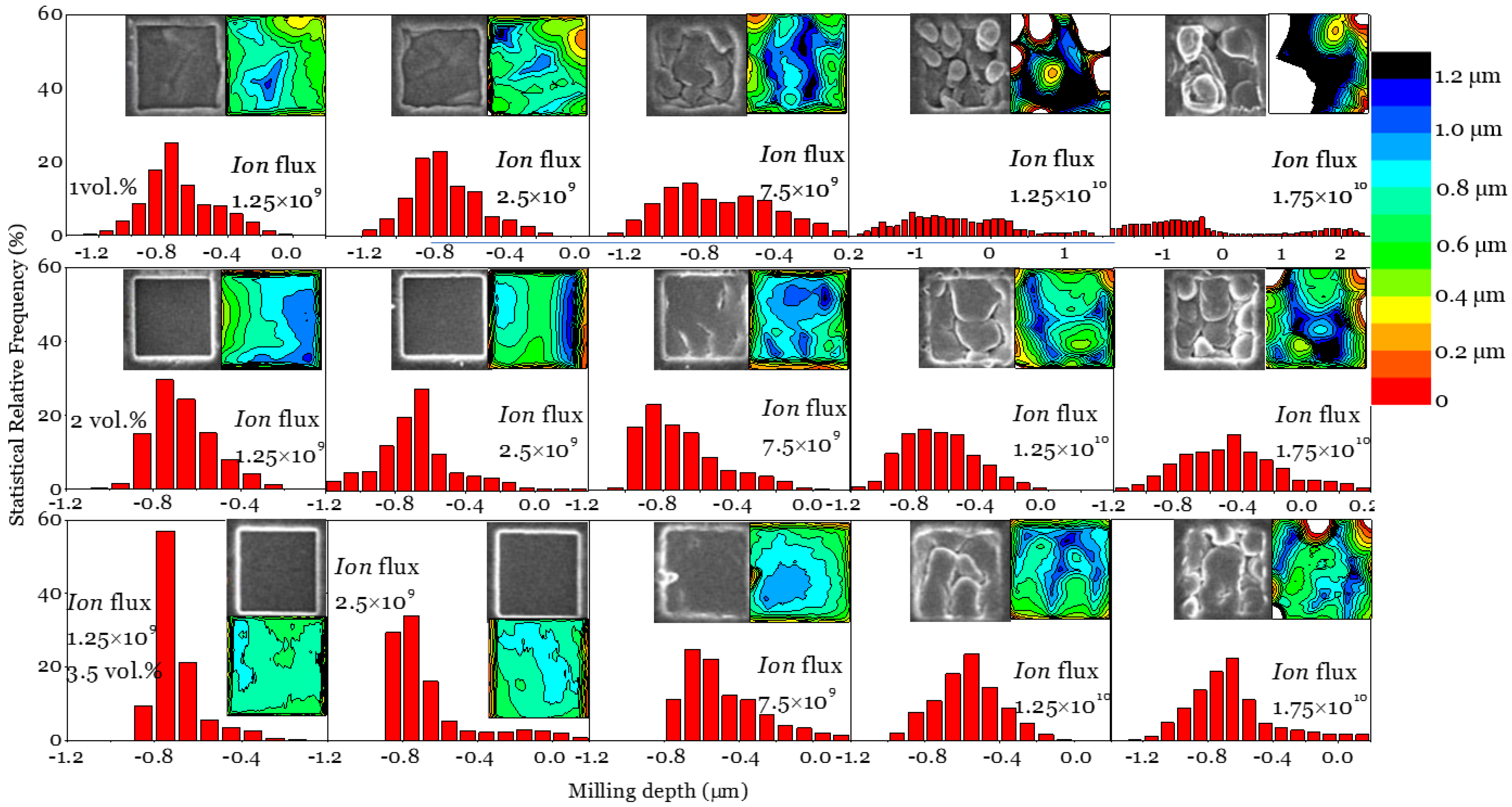

4. Results and Discussion

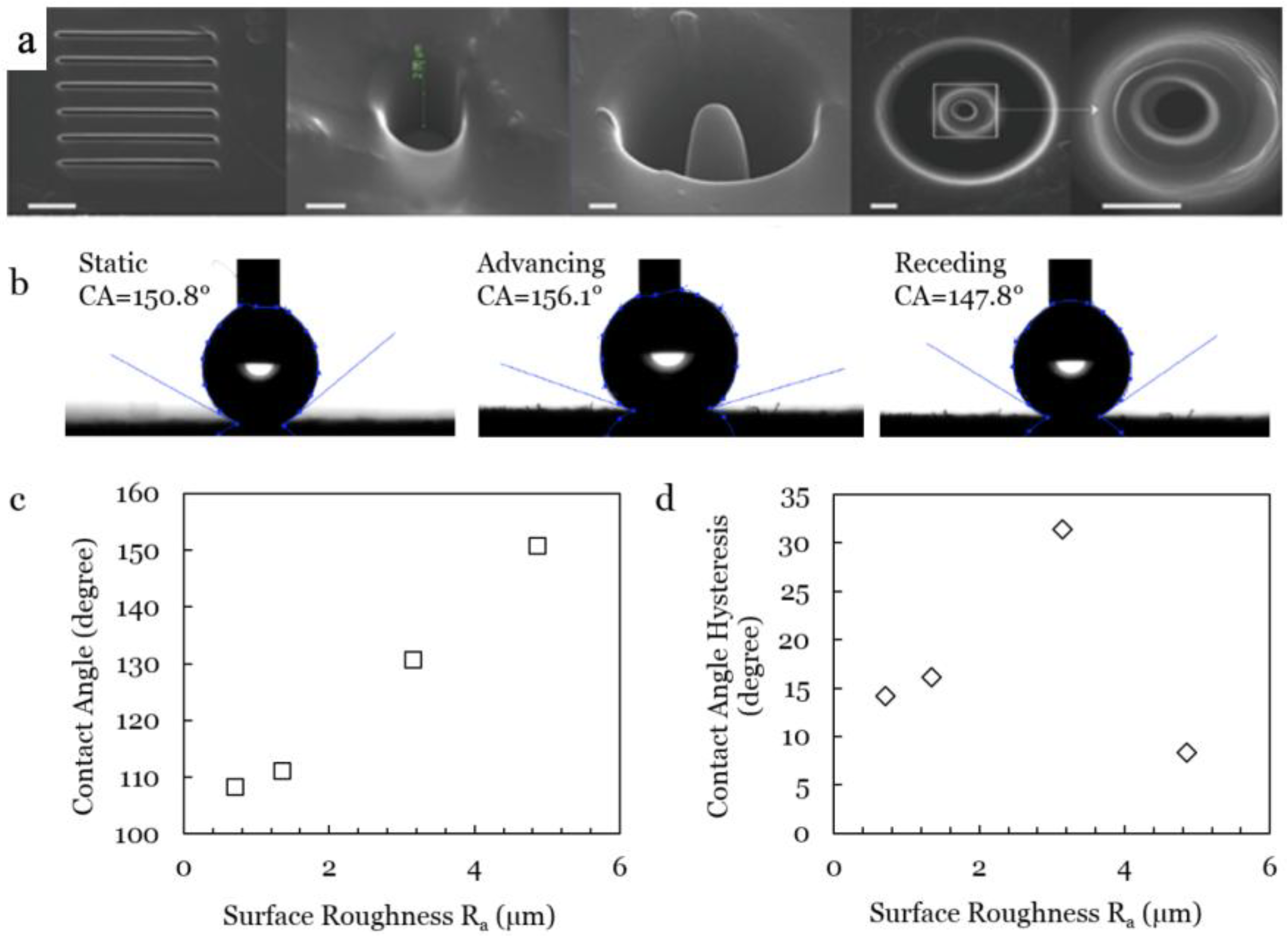

5. Application Demonstration

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Simpson, J.T.; Hunter, S.R.; Aytug, T. Superhydrophobic materials and coatings: A review. Rep. Prog. Phys. 2015, 78, 086501. [Google Scholar] [CrossRef] [PubMed]

- Yilgör, E.; Söz, C.K.; Yilgör, I. Wetting behavior of superhydrophobic poly(methyl methacrylate). Prog. Org. Coat. 2018, 125, 530–536. [Google Scholar] [CrossRef]

- Bhushan, B.; Jung, Y.C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 2011, 56, 1–108. [Google Scholar] [CrossRef]

- Wang, S.; Liu, K.; Yao, X.; Jiang, L. Bioinspired Surfaces with Superwettability: New Insight on Theory, Design, and Applications. Chem. Rev. 2015, 115, 8230–8293. [Google Scholar] [CrossRef]

- Kochkodan, V.; Hilal, N. A comprehensive review on surface modified polymer membranes for biofouling mitigation. Desalination 2015, 356, 187–207. [Google Scholar] [CrossRef]

- Kreder, M.J.; Alvarenga, J.; Kim, P.; Aizenberg, J. Design of anti-icing surfaces: Smooth, textured or slippery? Nat. Rev. Mater. 2016, 1, 15003. [Google Scholar] [CrossRef]

- Zhang, C.; McAdams, D.A.; Grunlan, J.C. Nano/Micro-Manufacturing of Bioinspired Materials: A Review of Methods to Mimic Natural Structures. Adv. Mater. 2016, 28, 6292–6321. [Google Scholar] [CrossRef]

- Zhang, P.; Lin, L.; Zang, D.; Guo, X.; Liu, M. Designing Bioinspired Anti-Biofouling Surfaces based on a Superwettability Strategy. Small 2017, 13, 1503334. [Google Scholar] [CrossRef]

- Wang, D.; Cheewaruangroj, N.; Li, Y.; McHale, G.; Jiang, Y.; Wood, D.; Biggins, J.S.; Xu, B.B. Spatially configuring wrinkle pattern and multiscale surface evolution with structural confinement. Adv. Funct. Mater. 2018, 28, 1704228. [Google Scholar] [CrossRef]

- Huang, X.; Sun, Y.; Soh, S. Stimuli-Responsive Surfaces for Tunable and Reversible Control of Wettability. Adv. Mater. 2015, 27, 4062–4068. [Google Scholar] [CrossRef]

- Rhee, D.; Lee, W.K.; Odom, T.W. Crack-Free, Soft Wrinkles Enable Switchable Anisotropic Wetting. Angew. Chem. Int. Ed. 2017, 56, 6523–6527. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Liu, Y.; Xu, B.; Hui, D.; Fu, Y.Q. Spontaneous biaxial pattern generation and autonomous wetting switching on the surface of gold/shape memory polystyrene bilayer. Compos. Part B Eng. 2017, 122, 9–15. [Google Scholar] [CrossRef]

- Liu, Y.; Genzer, J.; Dickey, M.D. “2D or not 2D”: Shape-programming polymer sheets. Prog. Polym. Sci. 2016, 52, 79–106. [Google Scholar] [CrossRef]

- Xu, B.; Huang, W.; Pei, Y.; Chen, Z.; Kraft, A.; Reuben, R.; De Hosson, J.; Fu, Y. Mechanical properties of attapulgite clay reinforced polyurethane shape-memory nanocomposites. Eur. Polym. J. 2009, 45, 1904–1911. [Google Scholar] [CrossRef]

- Moon, M.W.; Lee, S.H.; Sun, J.Y.; Oh, K.H.; Vaziri, A.; Hutchinson, J.W. Wrinkled hard skins on polymers created by focused ion beam. Proc. Natl. Acad. Sci. USA 2007, 104, 1130–1133. [Google Scholar] [CrossRef]

- Xu, B.; Fu, Y.Q.; Huang, W.M.; Pei, Y.T.; Chen, Z.G.; De Hosson, J.T.; Kraft, A.; Reuben, R.L. Thermal-Mechanical Properties of Polyurethane-Clay Shape Memory Polymer Nanocomposites. Polymers 2010, 2, 31–39. [Google Scholar] [CrossRef]

- Giannuzzi, L.A.; Utlaut, M. A review of Ga+ FIB/SIMS. Surf. Interface Anal. 2011, 43, 475. [Google Scholar] [CrossRef]

- Roediger, P.; Wanzenboeck, H.D.; Waid, S.; Hochleitner, G.; Bertagnolli, E. Focused-ion-beam-inflicted surface amorphization and gallium implantation—New insights and removal by focused-electron-beam-induced etching. Nanotechnology 2011, 22, 235302. [Google Scholar] [CrossRef]

- Völlner, J.; Ziberi, B.; Frost, F.; Rauschenbach, B. Topography evolution mechanism on fused silica during low-energy ion beam sputtering. J. Appl. Phys. 2011, 109, 43501. [Google Scholar]

- Oehrlein, G.S.; Phaneuf, R.J.; Graves, D.B. Plasma-polymer interactions: A review of progress in understanding polymer resist mask durability during plasma etching for nanoscale fabrication. J. Vac. Sci. Technol. B 2011, 29, 10801. [Google Scholar] [CrossRef]

- Cahill, D.G. Morphological instabilities in thin-film growth and etching. J. Vac. Sci. Technol. A 2003, 21, S110–S116. [Google Scholar] [CrossRef]

- Brostow, W.; Gorman, B.P.; Olea-Mejia, O. Focused ion beam milling and scanning electron microscopy characterization of polymer+ metal hybrids. Mater. Lett. 2007, 61, 1333. [Google Scholar] [CrossRef]

- Brunner, S.; Gasser, P.; Simmler, H.; Wakili, K.G. Investigation of multilayered aluminium-coated polymer laminates by focused ion beam (FIB) etching. Surf. Coat. Technol. 2006, 200, 5908. [Google Scholar] [CrossRef]

- Pialat, E.; Trigaud, T.; Bernical, V.; Moliton, J.P. Milling of polymeric photonic crystals by focused ion beam. Mater. Sci. Eng. C 2005, 25, 618. [Google Scholar] [CrossRef]

- Mulders, J.; De Winter, D.; Duinkerken, W.; De Winter, M. Measurements and calculations of FIB milling yield of bulk metals. Microelectron. Eng. 2007, 84, 1540–1543. [Google Scholar] [CrossRef]

- Muñoz-Garcia, J.; Gago, R.; Vazquez, L.; Sánchez-García, J.A.; Cuerno, R. Observation and Modeling of Interrupted Pattern Coarsening: Surface Nanostructuring by Ion Erosion. Phys. Rev. Lett. 2010, 104, 026101. [Google Scholar] [CrossRef]

- Muñoz-Garcia, J.; Castro, M.; Cuerno, R. Nonlinear Ripple Dynamics on Amorphous Surfaces Patterned by Ion Beam Sputtering. Phys. Rev. Lett. 2006, 96, 086101. [Google Scholar] [CrossRef] [PubMed]

- Bradley, R.M. Theory of ripple topography induced by ion bombardment. J. Vac. Sci. Technol. A 1988, 6, 2390–2395. [Google Scholar] [CrossRef]

- Eklund, E.A.; Bruinsma, R.; Rudnick, J.; Williams, R.S. Submicron-Scale Surface Roughening Induced by Ion Bombardment. Phys. Rev. Lett. 1991, 67, 1759. [Google Scholar] [CrossRef]

- Mitsui, T.; Stein, D.; Kim, Y.R.; Hoogerheide, D.; Golovchenko, J.A. Nanoscale Volcanoes: Accretion of Matter at Ion-Sculpted Nanopores. Phys. Rev. Lett. 2006, 96, 036102. [Google Scholar] [CrossRef]

- Rodríguez-Laguna, J.; Santalla, S.N.; Cuerno, R. Intrinsic geometry approach to surface kinetic roughening. J. Stat. Mech. Theory Exp. 2011, 2011, 05032. [Google Scholar] [CrossRef]

- Kardar, M.; Parisi, G.; Zhang, Y.C. Dynamic Scaling of Growing Interfaces. Phys. Rev. Lett. 1986, 56, 889–892. [Google Scholar] [CrossRef] [PubMed]

- Makeev, M.A.; Barabási, A.L. Effect of surface roughness on the secondary ion yield in ion sputtering. Appl. Phys. Lett. 1998, 73, 2209–2211. [Google Scholar] [CrossRef]

- Cuerno, R.; Barabasi, A.L. Dynamic Scaling of Ion-Sputtered Surfaces. Phys. Rev. Lett. 1995, 74, 4746–4749. [Google Scholar] [CrossRef] [PubMed]

- Sigmund, P. Theory of Sputtering. I. Sputtering Yield of Amorphous and Polycrystalline Targets. Phys. Rev. 1969, 184, 383–416. [Google Scholar] [CrossRef]

- Castro, M.; Cuerno, R.; Vazquez, L.; Gago, R. Self-Organized Ordering of Nanostructures Produced by Ion-Beam Sputtering. Phys. Rev. Lett. 2005, 94, 016102. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-Garcia, J.; Cuerno, R.; Castro, M. Coupling of morphology to surface transport in ion-beam-irradiated surfaces: Normal incidence and rotating targets. J. Phys. Condens. Matter 2009, 21, 224020. [Google Scholar] [CrossRef]

- Walmann, T.; Malthe-Sørenssen, A.; Feder, J.; Jøssang, T.; Hardy, H.H.; Meakin, P. Scaling Relations for the Lengths and Widths of Fractures. Phys. Rev. Lett. 1996, 77, 5393–5396. [Google Scholar] [CrossRef]

- Mullins, W.W. Theory of thermal grooving. J. Appl. Phys. 1957, 28, 333. [Google Scholar] [CrossRef]

- Herring, C. Effect of Change of Scale on Sintering Phenomena. J. Appl. Phys. 1950, 21, 301–303. [Google Scholar] [CrossRef]

- Mullins, J.F.; Lettieri, M.F. Chemosurgery of facial wrinkles. Tex. State J. Med. 1963, 59, 488. [Google Scholar] [PubMed]

- Jain, H.; Mundy, J. Analysis of ac conductivity of glasses by a power law relationship. J. Non-Cryst. Solids 1987, 91, 315–323. [Google Scholar] [CrossRef]

- Voss, S.; Imre, Á.W.; Mehrer, H. Mixed-alkali effect in Na–Rb borate glasses: A tracer diffusion and electrical conductivity study. Phys. Chem. Chem. Phys. 2004, 6, 3669–3675. [Google Scholar] [CrossRef]

- Makeev, M.A.; Cuerno, R.; Barabási, A.L. Morphology of ion-sputtered surfaces. Nuclear Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2002, 197, 185. [Google Scholar] [CrossRef]

- Makeev, M.A.; Barabási, A.L. Secondary ion yield changes on rippled interfaces. Appl. Phys. Lett. 1998, 72, 906–908. [Google Scholar] [CrossRef][Green Version]

- Muñoz-García, J.; Cuerno, R.; Castro, M. Short-range stationary patterns and long-range disorder in an evolution equation for one-dimensional interfaces. Phys. Rev. E 2006, 74, 050103. [Google Scholar] [CrossRef]

- Kim, J.H.; Ha, N.B.; Kim, J.S.; Joe, M.; Lee, K.R.; Cuerno, R. One-dimensional pattern of Au nanodots by ion-beam sputtering: Formation and mechanism. Nanotechnology 2011, 22, 285301. [Google Scholar] [CrossRef]

- Lu, H.; Wang, X.; Yao, Y.; Gou, J.; Hui, D.; Xu, B.; Fu, Y. Synergistic effect of siloxane modified aluminum nanopowders and carbon fiber on electrothermal efficiency of polymeric shape memory nanocomposite. Compos. Part B Eng. 2015, 80, 1–6. [Google Scholar] [CrossRef]

- Dai, X.; Du, Y.; Yang, J.; Wang, D.; Gu, J.; Li, Y.; Wang, S.; Xu, B.B.; Kong, J. Recoverable and self-healing electromagnetic wave absorbing nanocomposites. Compos. Sci. Technol. 2019, 174, 27–32. [Google Scholar] [CrossRef]

- Hood, P.J.; Havens, D.E. Structural and optical applications for shape memory polymers (SMP. Polymer Patches). U.S. Patent US6986855B1, 24 1 2002. [Google Scholar]

- Hood, P.J.; Garrigan, S.; Auffinger, F. Method of Making and Using Shape Memory. U.S. Patent US8808479B2, 15 12 2006. [Google Scholar]

- Xu, B.; Zhang, L.; Pei, Y.T.; Luom, J.K.; Tao, S.W.; de Hosson, J.T.M.; Fu, Y.Q. Electro-responsive polystyrene shape memory polymer nanocomposites. Nanosci. Nanotechnol. Lett. 2012, 4, 814–820. [Google Scholar] [CrossRef]

- Lei, M.; Xu, B.; Pei, Y.; Lu, H.; Fu, Y.Q. Micro-mechanics of nanostructured carbon/shape memory polymer hybrid thin film. Soft Matter 2016, 12, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Fu, Y.Q.; Ahmad, M.; Luo, J.K.; Huang, W.M.; Kraft, A.; Reuben, R.; Pei, Y.T.; Chen, Z.G.; De Hosson, J.T.M. Thermo-mechanical properties of polystyrene-based shape memory nanocomposites. J. Mater. Chem. 2010, 20, 3442–3448. [Google Scholar] [CrossRef]

- Barna, A.; Kotis, L.; Labar, J.L.; Osvath, Z.; Toth, A.L.; Menyhard, M.; Zalar, A.; Panjan, P. Producing metastable nanophase with sharp interface by means of focused ion beam irradiation. J. Appl. Phys. 2007, 102, 044305. [Google Scholar] [CrossRef]

- Roush, M.; Andreadis, T.; Davarya, F.; Goktepe, O. Dynamic simulation of changes in near-surface composition during ion bombardment. Appl. Surf. Sci. 1982, 11, 235–242. [Google Scholar] [CrossRef]

- Möller, W.; Eckstein, W.; Biersack, J. Tridyn-binary collision simulation of atomic collisions and dynamic composition changes in solids. Comput. Phys. Commun. 1988, 51, 355–368. [Google Scholar] [CrossRef]

- Sun, J.; Luo, X.; Ritchie, J.M.; Chang, W.; Wang, W. An investigation of redeposition effect for deterministic fabrication of nanodots by focused ion beam. Precis. Eng. 2012, 36, 31. [Google Scholar] [CrossRef]

- Dang, Z.M.; Lin, Y.H.; Nan, C.W. Novel ferroelectric polymer composites with high dielectric constants. Adv. Mater. 2003, 15, 1625. [Google Scholar] [CrossRef]

- Pecharroman, C.; Esteban-Betegon, F.; Bartolome, J.F.; Lopez-Esteban, S.; Moya, J.S. New Percolative BaTiO3–Ni Composites with a High and Frequency-Independent Dielectric Constant. Adv. Mater. 2001, 13, 1541. [Google Scholar] [CrossRef]

- Pötschke, P.; Dudkin, S.M.; Alig, I. Dielectric spectroscopy on melt processed polycarbonate—Multiwalled carbon nanotube composites. Polymer 2003, 44, 5023–5030. [Google Scholar] [CrossRef]

- Regev, O.; ElKati, P.N.B.; Loos, J.; Koning, C.E. Preparation of Conductive Nanotube–Polymer Composites Using Latex Technology. Adv. Mater. 2004, 16, 284. [Google Scholar] [CrossRef]

- Dang, Z.M.; Wang, L.; Yin, Y.; Zhang, Q.; Lei, Q.Q. Giant dielectric permittivities in functionalized carbon-nanotube/electroactive-polymer nanocomposites. Adv. Mater. 2007, 19, 852. [Google Scholar] [CrossRef]

- Kolb, M.; Botet, R.; Jullien, R. Scaling of Kinetically Growing Clusters. Phys. Rev. Lett. 1983, 51, 1123–1126. [Google Scholar] [CrossRef]

- Karásek, L.; Meissner, B.; Asai, S.; Sumita, M. Percolation Concept: Polymer-Filler Gel Formation, Electrical Conductivity and Dynamic Electrical Properties of Carbon-Black-Filled Rubbers. Polym. J. 1996, 28, 121–126. [Google Scholar] [CrossRef]

- Jonscher, A.K. New interpretation of dielectric loss peaks. Nature 1975, 256, 566–568. [Google Scholar] [CrossRef]

- Mehrer, H. (Ed.) Series in Solid-State Sciences; Springer: Berlin, Germany, 2007; p. 221. [Google Scholar]

- Nicoli, M.; Cuerno, R.; Castro, M. Unstable Nonlocal Interface Dynamics. Phys. Rev. Lett. 2009, 102, 256102. [Google Scholar] [CrossRef] [PubMed]

- Ishitani, T.; Ohnishi, T.; Madokoro, Y.; Kawanami, Y. Focused-ion-beam “cutter” and “attacher” for micromachining and device transplantation. J. Vac. Sci. Technol. B 1991, 9, 2633. [Google Scholar] [CrossRef]

- Roy, X.; Sarazin, P.; Favis, B.D. Ultraporous nanosheath materials by layer-by-layer deposition onto co-continuous polymer-blend templates. Adv. Mater. 2006, 18, 1015. [Google Scholar] [CrossRef]

- Cuerno, R.; Vazquez, L.; Gago, R.; Castro, M. Surface nanopatterns induced by ion-beam sputtering. J. Phys. Condens. Matter 2009, 21, 220301. [Google Scholar] [CrossRef][Green Version]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, A.; Wang, D.; Zhou, H.; Li, Y.; Connor, C.; Kong, J.; Sun, J.; Xu, B.B. Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling. Polymers 2019, 11, 1229. https://doi.org/10.3390/polym11071229

Sun A, Wang D, Zhou H, Li Y, Connor C, Kong J, Sun J, Xu BB. Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling. Polymers. 2019; 11(7):1229. https://doi.org/10.3390/polym11071229

Chicago/Turabian StyleSun, Ansu, Ding Wang, Honghao Zhou, Yifan Li, Chris Connor, Jie Kong, Jining Sun, and Ben Bin Xu. 2019. "Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling" Polymers 11, no. 7: 1229. https://doi.org/10.3390/polym11071229

APA StyleSun, A., Wang, D., Zhou, H., Li, Y., Connor, C., Kong, J., Sun, J., & Xu, B. B. (2019). Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling. Polymers, 11(7), 1229. https://doi.org/10.3390/polym11071229