Modulating Carrier Type for Enhanced Thermoelectric Performance of Single-Walled Carbon Nanotubes/Polyethyleneimine Composites

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Flexible p- and n-Type Single-Walled Carbon Nanotube/Polyethyleneimine (SWCNT/PEI) Films

2.3. Thermoelectric Device Fabrication

2.4. Characterization

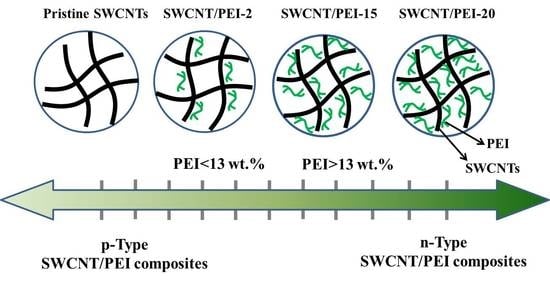

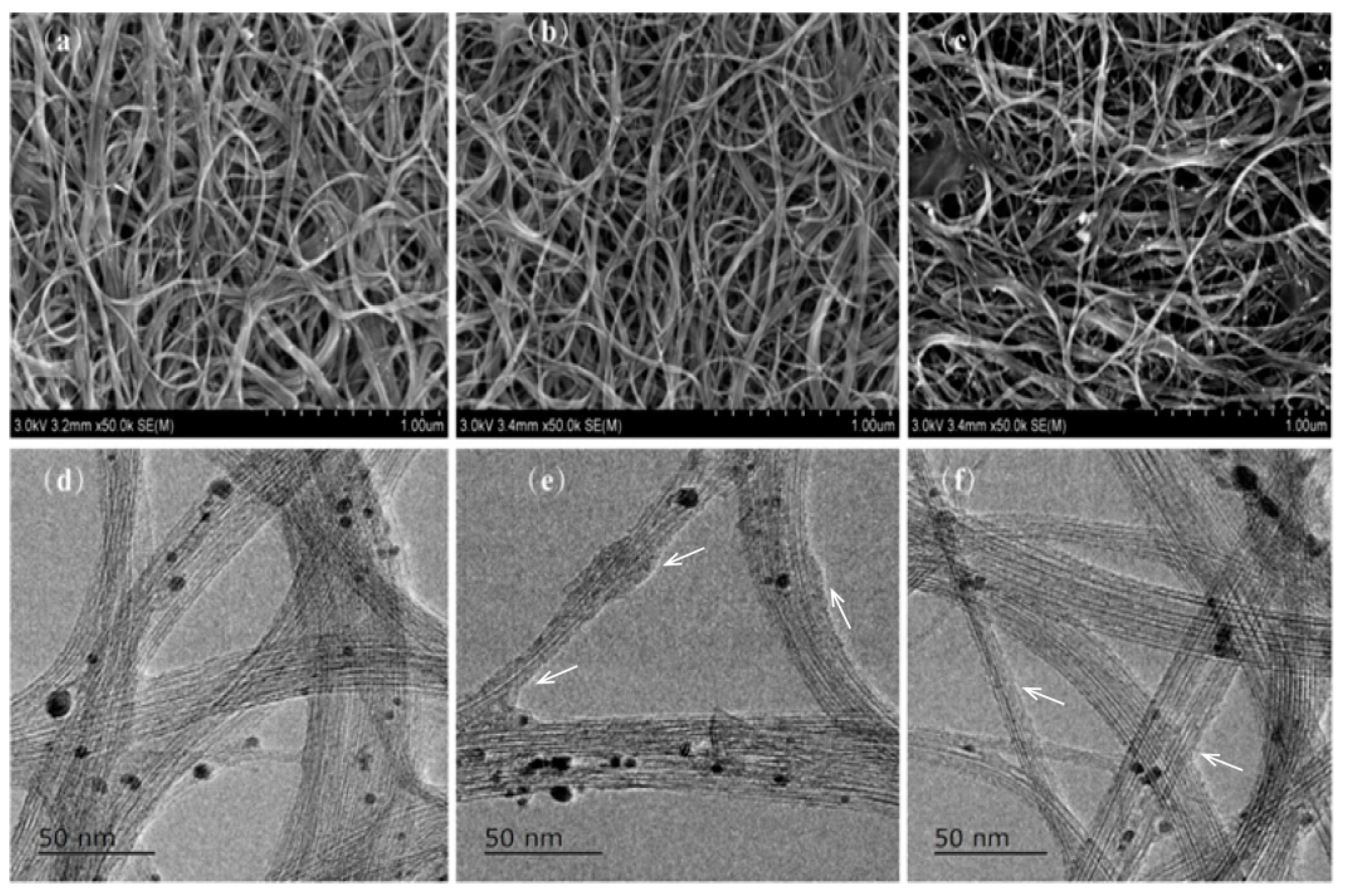

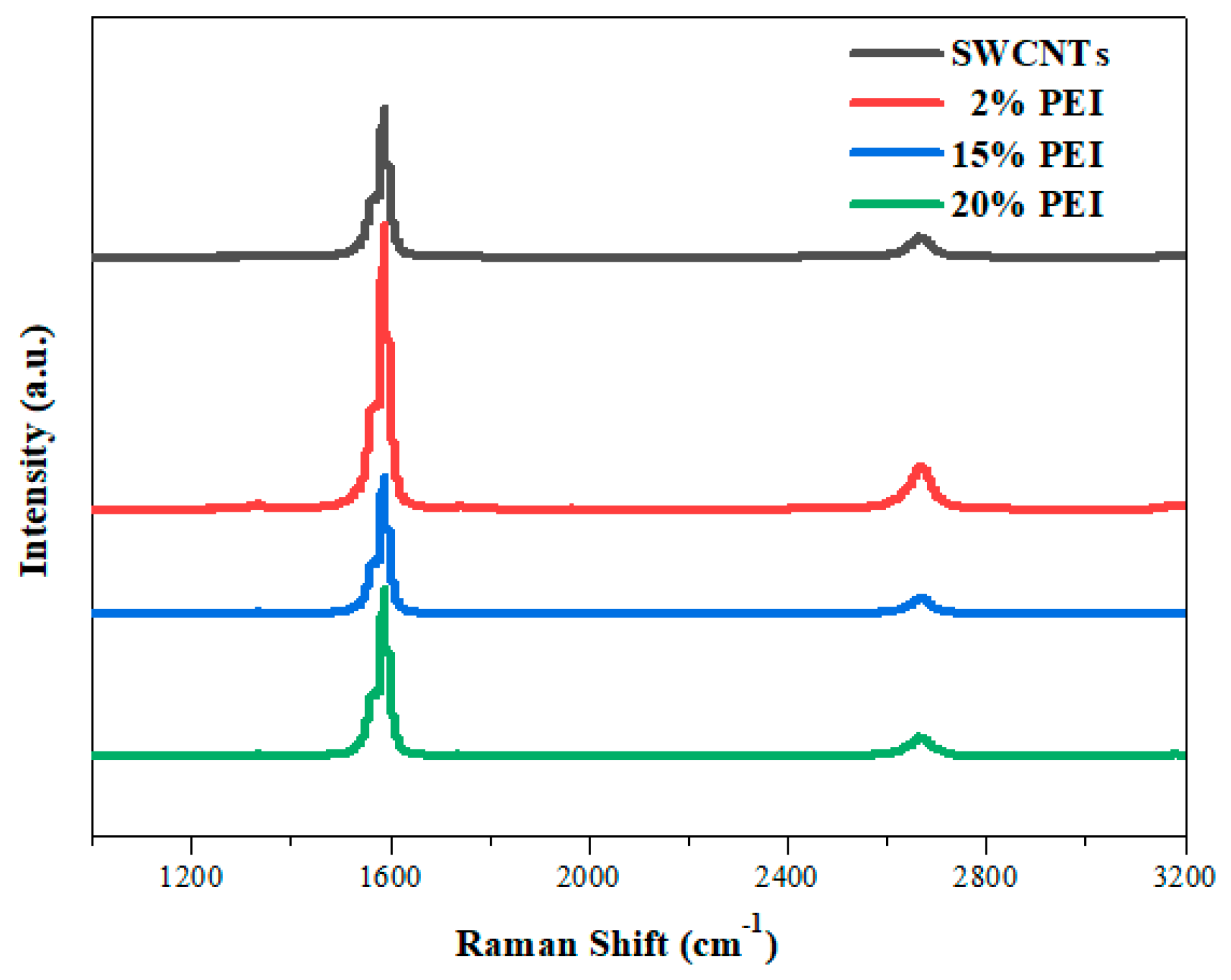

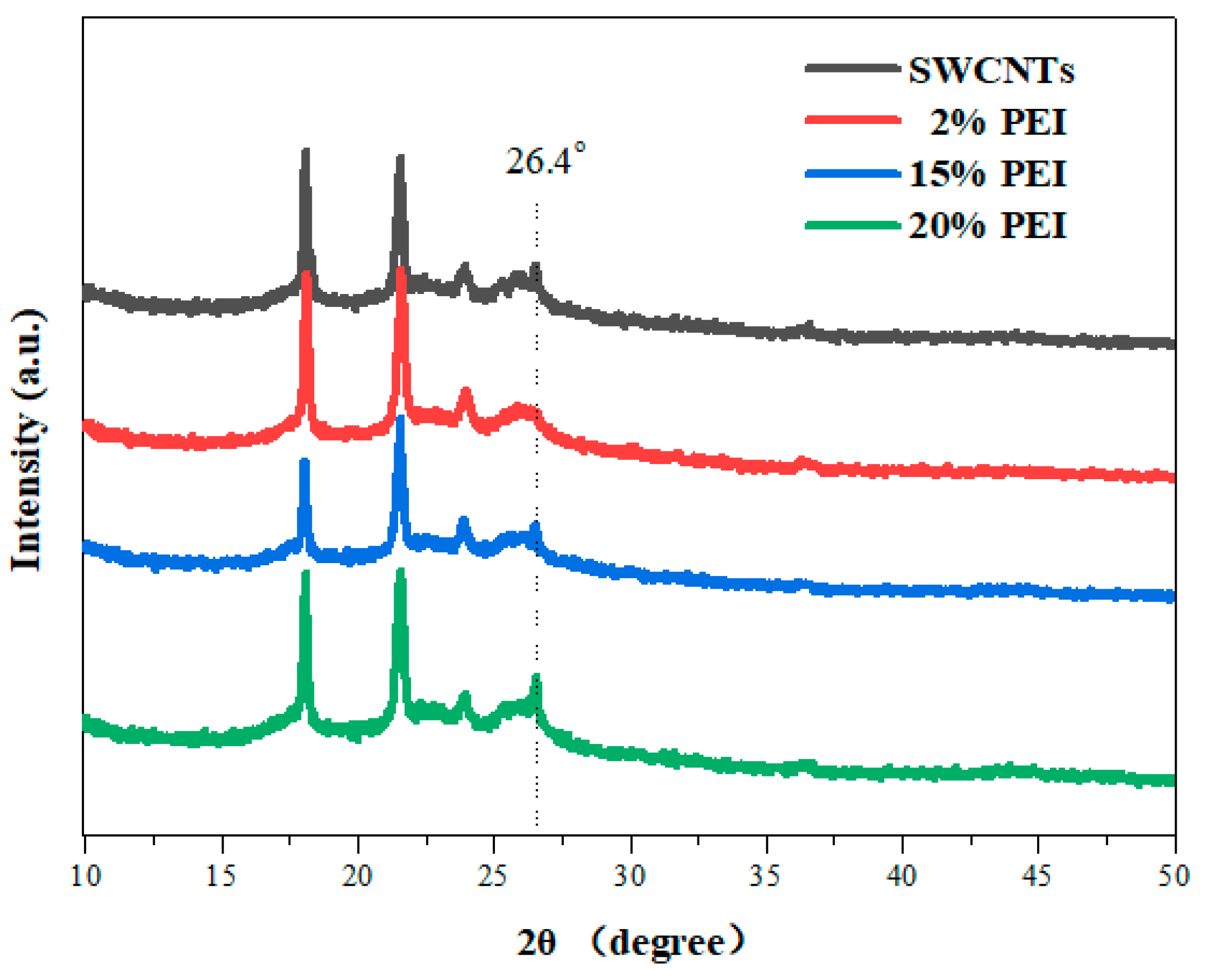

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Meng, Q.; Cai, K.; Du, Y.; Chen, L. Preparation and thermoelectric properties of SWCNT/PEDOT: PSS coated tellurium nanorod composite films. J. Alloys Compd. 2019, 778, 163–169. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Park, S.J. Flexible organic thermoelectric materials and devices for wearable green energy harvesting. Polymers 2019, 11. [Google Scholar] [CrossRef] [PubMed]

- Du, F.P.; Cao, N.N.; Zhang, Y.F.; Fu, P.; Wu, Y.G.; Lin, Z.D.; Shi, R.; Amini, A.; Cheng, C. PEDOT:PSS/graphene quantum dots films with enhanced thermoelectric properties via strong interfacial interaction and phase separation. Sci. Rep. 2018, 8, 6441. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Du, D.; Guan, X.; Ouyang, J. Polymer films with ultrahigh thermoelectric properties arising from significant seebeck coefficient enhancement by ion accumulation on surface. Nano Energy 2018, 51, 481–488. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, C.; Jiang, F.; Xu, J.; Liu, E. Effective treatment methods on PEDOT: PSS to enhance its thermoelectric performance. Synth. Met. 2017, 225, 31–40. [Google Scholar] [CrossRef]

- Ding, Y.; Qiu, Y.; Cai, K.; Yao, Q.; Chen, S.; Chen, L.; He, J. High performance n-type ag2se film on nylon membrane for flexible thermoelectric power generator. Nat. Commun. 2019, 10, 841. [Google Scholar] [CrossRef]

- Luo, J.; Cerretti, G.; Krause, B.; Zhang, L.; Otto, T.; Jenschke, W.; Ullrich, M.; Tremel, W.; Voit, B.; Poetschke, P. Polypropylene-based melt mixed composites with singlewalled carbon nanotubes for thermoelectric applications: Switching from p-type to n-type by the addition of polyethylene glycol. Polymer 2017, 108, 513–520. [Google Scholar] [CrossRef]

- Dörling, B.; Ryan, J.; Craddock, J. Photoinduced p- to n- type switching in thermoelectric polymer-carbon nanotube composites. Adv. Mater. 2016, 28, 2782–2789. [Google Scholar] [CrossRef]

- Cheng, X.L.; Zhang, Y.F.; Wu, Y.G.; Fu, P.; Lin, Z.D.; Du, F.P.; Cheng, C. Thermally sensitive n-type thermoelectric aniline oligomer-block-polyethylene glycol-block-aniline oligomer aba triblock copolymers. Macromol. Chem. Phys. 2018, 219. [Google Scholar] [CrossRef]

- Yao, C.J.; Zhang, H.L.; Zhang, Q.C. Recent progress in thermoelectric materials based on conjugated polymers. Polymers 2019, 11. [Google Scholar] [CrossRef]

- Xue, Y.F.; Gao, C.M.; Liang, L.R.; Wang, X.; Chen, G.M. Nanostructure controlled construction of high-performance thermoelectric materials of polymers and their composites. J. Mater. Chem. A 2018, 6, 22381–22390. [Google Scholar] [CrossRef]

- Du, F.P.; Qiao, X.; Wu, Y.G.; Fu, P.; Liu, S.P.; Zhang, Y.F.; Wang, Q.Y. Fabrication of porous polyvinylidene fluoride/multi-walled carbon nanotube nanocomposites and their enhanced thermoelectric performance. Polymers 2018, 10. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Heo, Y.J.; Park, M.; Park, S.J. Recent advances in organic thermoelectric materials: Principle mechanisms and emerging carbon-based green energy materials. Polymers 2019, 11. [Google Scholar] [CrossRef]

- Pan, C.J.; Wang, L.H.; Zhou, W.Q.; Cai, L.R.; Xie, D.X.; Chen, Z.M.; Wang, L. Preparation and thermoelectric properties study of bipyridine-containing polyfluorene derivative/swcnt composites. Polymers 2019, 11. [Google Scholar] [CrossRef]

- Aghelinejad, M.; Zhang, Y.C.; Leung, S.N. Processing parameters to enhance the electrical conductivity and thermoelectric power factor of polypyrrole/multi-walled carbon nanotubes nanocomposites. Synth. Met. 2019, 247, 59–66. [Google Scholar] [CrossRef]

- He, P.; Shimano, S.; Salikolimi, K.; Isoshima, T.; Kakefuda, Y.; Mori, T.; Taguchi, Y.; Ito, Y.; Kawamoto, M. Noncovalent modification of single-walled carbon nanotubes using thermally cleavable polythiophenes for solution-processed thermoelectric films. ACS Appl. Mater. Inter. 2019, 11, 4211–4218. [Google Scholar] [CrossRef]

- Kim, J.Y.; Mo, J.H.; Kang, Y.H.; Cho, S.Y.; Jang, K.S. Thermoelectric fibers from well-dispersed carbon nanotube/poly (vinyliedene fluoride) pastes for fiber-based thermoelectric generators. Nanoscale 2018, 10, 19766–19773. [Google Scholar] [CrossRef]

- Yao, Q.; Wang, Q.; Wang, L.; Chen, L. Abnormally enhanced thermoelectric transport properties of SWNT/PANI hybrid films by the strengthened PANI molecular ordering. Energy Environ. Sci. 2014, 7, 3801–3807. [Google Scholar] [CrossRef]

- Okhay, O.; Gonçalves, G.; Dias, C.; Ventura, J.; Vieira, E.M.F.; Gonçalves, L.M.V.; Tkach, A. Tuning electrical and thermoelectric properties of freestanding graphene oxide papers by carbon nanotubes and heat treatment. J. Alloys Compd. 2019, 781, 196–200. [Google Scholar] [CrossRef]

- Yao, Q.; Chen, L.; Zhang, W.; Liufu, S.; Chen, X. Enhanced thermoelectric performance of single-walled carbon nanotubes/polyaniline hybrid nanocomposites. ACS Nano 2010, 4, 2445–2451. [Google Scholar] [CrossRef]

- Nonoguchi, Y.; Nakano, M.; Murayama, T.; Hagino, H.; Hama, S.; Miyazaki, K.; Matsubara, R.; Nakamura, M.; Kawai, T. Simple salt-coordinated n-type nanocarbon materials stable in air. Adv. Funct. Mater. 2016, 26, 3021–3028. [Google Scholar] [CrossRef]

- Song, H.; Qiu, Y.; Wang, Y.; Cai, K.; Li, D.; Deng, Y.; He, J. Polymer/carbon nanotube composite materials for flexible thermoelectric power generator. Compos. Sci. Technol. 2017, 153, 71–83. [Google Scholar] [CrossRef]

- Yu, C.; Murali, A.; Choi, K.; Ryu, Y. Air-stable fabric thermoelectric modules made of n- and p-type carbon nanotubes. Energy Environ. Sci. 2012, 5, 9481–9486. [Google Scholar] [CrossRef]

- Wang, H.; Hsu, J.H.; Yi, S.I.; Kim, S.L.; Choi, K.; Yang, G.; Yu, C. Thermally driven large n-type voltage responses from hybrids of carbon nanotubes and poly(3,4-ethylenedioxythiophene) with tetrakis(dimethylamino) ethylene. Adv. Mater. 2015, 27, 6855–6861. [Google Scholar] [CrossRef]

- Sarabia-Riquelme, R.; Craddock, J.; Morris, E.A.; Eaton, D.; Andrews, R.; Anthony, J.; Weisenberger, M.C. Simple, low-cost, water-processable n-type thermoelectric composite films from multiwall carbon nanotubes in polyvinylpyrrolidone. Synth. Met. 2017, 225, 86–92. [Google Scholar] [CrossRef]

- Oshima, K.; Yanagawa, Y.; Asano, H.; Shiraishi, Y.; Toshima, N. Improvement of stability of n-type super growth cnts by hybridization with polymer for organic hybrid thermoelectrics. Synth. Met. 2017, 225, 81–85. [Google Scholar] [CrossRef]

- Liu, J.; Jia, Y.; Jiang, Q.; Jiang, F.; Li, C.; Wang, X.; Liu, P.; Liu, P.; Hu, F.; Du, Y.; et al. Highly conductive hydrogel polymer fibers toward promising wearable thermoelectric energy harvesting. ACS Appl. Mater. Inter. 2018, 10, 44033–44040. [Google Scholar] [CrossRef]

- Wang, P.C.; Liao, Y.C.; Lai, Y.L.; Lin, Y.C.; Su, C.Y.; Tsai, C.H.; Hsu, Y.J. Conversion of pristine and p-doped sulfuric-acid-treated single-walled carbon nanotubes to n-type materials by a facile hydrazine vapor exposure process. Mater. Chem. Phys. 2012, 134, 325–332. [Google Scholar] [CrossRef]

- Cho, C.; Culebras, M.; Wallace, K.L.; Song, Y.X.; Holder, K.; Hsu, J.H.; Yu, C.; Grunlan, J.C. Stable n-type thermoelectric multilayer thin films with high power factor from carbonaceous nanofillers. Nano Energy 2016, 28, 426–432. [Google Scholar] [CrossRef]

- Wang, X.; Liu, P.; Jiang, Q.; Zhou, W.; Xu, J.; Liu, J.; Jia, Y.; Duan, X.; Liu, Y.; Du, Y.; et al. Efficient dmso-vapor annealing for enhancing thermoelectric performance of PEDOT:PSS-based aerogel. ACS Appl. Mater. Inter. 2019, 11, 2408–2417. [Google Scholar] [CrossRef]

- Li, H.; Liang, Y.; Liu, S.; Qiao, F.; Li, P.; He, C. Modulating carrier transport for the enhanced thermoelectric performance of carbon nanotubes/polyaniline composites. Org. Electron. 2019, 69, 62–68. [Google Scholar] [CrossRef]

- Gebhardt, B.; Hof, F.; Backes, C.; Muller, M.; Plocke, T.; Maultzsch, J.; Thomsen, C.; Hauke, F.; Hirsch, A. Selective polycarboxylation of semiconducting single-walled carbon nanotubes by reductive sidewall functionalization. J. Am. Chem. Soc. 2011, 133, 19459–19473. [Google Scholar] [CrossRef]

- Ryu, Y.; Yu, C.H. The influence of incorporating organic molecules or inorganic nanoparticles on the optical and electrical properties of carbon nanotube films. Sol. State Commun. 2011, 151, 1932–1935. [Google Scholar] [CrossRef]

- Dillon, E.P.; Crouse, C.A.; Barron, A.R. Synthesis, characterization, and carbon dioxide adsorption of covalently attached polyethyleneimine-functionalized single-wall carbon nanotubes. ACS Nano 2008, 2, 156–164. [Google Scholar] [CrossRef]

- Ludvigsson, M.; Tegenfeldt, J. Crystallinity in cast nafion. J. Electrochem. Soc. 2000, 147, 1303–1305. [Google Scholar] [CrossRef]

- Devrim, Y. Preparation and testing of nafion/titanium dioxide nanocomposite membrane electrode assembly by ultrasonic coating technique. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Jia, Y.; Liu, C.; Liu, J.; Liu, C.; Xu, J.; Li, X.; Shen, L.; Jiang, Q.; Wang, X.; Yang, J.; et al. Efficient enhancement of the thermoelectric performance of vapor phase polymerized poly(3,4-ethylenedioxythiophene) films with poly(ethyleneimine). J. Polym. Sci. Pol. Phys. 2019, 57, 257–265. [Google Scholar] [CrossRef]

- Piao, M.; Na, J.; Choi, J.; Kim, J.; Kennedy, G.P.; Kim, G.; Roth, S.; Dettlaff-Weglikowska, U. Increasing the thermoelectric power generated by composite films using chemically functionalized single-walled carbon nanotubes. Carbon 2013, 62, 430–437. [Google Scholar] [CrossRef]

- Minnich, A.J.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Bulk nanostructured thermoelectric materials: Current research and future prospects. Energ. Environ. Sci. 2009, 2, 466–479. [Google Scholar] [CrossRef]

- Liu, S.Y.; Deng, H.; Zhao, Y.; Ren, S.J.; Fu, Q. The optimization of thermoelectric properties in a PEDOT: PSS thin film through post-treatment. RSC Adv. 2015, 5, 1910–1917. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiu, J.; Wang, S. Roll-to-roll printing of flexible thin-film organic thermoelectric devices. Manuf. Lett. 2016, 8, 6–10. [Google Scholar] [CrossRef]

- Hong, C.T.; Kang, Y.H.; Ryu, J.; Cho, S.Y.; Jang, K.S. Spray-printed CNT/P3HT organic thermoelectric films and power generators. J. Mater. Chem. A 2015, 3, 21428–21433. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, W.; Kang, Y.H.; Cho, S.Y.; Jang, K.S. Wet-spinning and post-treatment of CNT/PEDOT: PSS composites for use in organic fiber-based thermoelectric generators. Carbon 2018, 133, 293–299. [Google Scholar] [CrossRef]

- Jia, Y.H.; Shen, L.L.; Liu, J.; Zhou, W.Q.; Du, Y.K.; Xu, J.K.; Liu, C.C.; Zhang, G.; Zhang, Z.S.; Jiang, F.X. An efficient PEDOT coated textile for wearable thermoelectric generators and strain sensors. J. Mater. Chem. C 2019, 7, 3496–3502. [Google Scholar] [CrossRef]

- Zhao, X.; Han, W.; Zhao, C.; Wang, S.; Kong, F.; Ji, X.; Li, Z.; Shen, X. Fabrication of transparent paper-based flexible thermoelectric generator for wearable energy harvester using modified distributor printing technology. ACS Appl. Mater. Inter. 2019, 11, 10301–10309. [Google Scholar] [CrossRef]

- Pires, A.L.; Cruz, I.F.; Silva, J.; Oliveira, G.N.P.; Ferreira-Teixeira, S.; Lopes, A.M.L.; Araujo, J.P.; Fonseca, J.; Pereira, C.; Pereira, A.M. Printed flexible mu-thermoelectric device based on hybrid Bi2Te3/PVA composites. ACS Appl. Mater. Inter. 2019, 11, 8969–8981. [Google Scholar] [CrossRef]

- Bharti, M.; Jha, P.; Singh, A.; Chauhan, A.K.; Misra, S.; Yamazoe, M.; Debnath, A.K.; Marumoto, K.; Muthe, K.P.; Aswal, D.K. Scalable free-standing polypyrrole films for wrist-band type flexible thermoelectric power generator. Energy 2019, 176, 853–860. [Google Scholar] [CrossRef]

- Ni, D.; Song, H.; Chen, Y.; Cai, K. Free-standing highly conducting pedot films for flexible thermoelectric generator. Energy 2019, 170, 53–61. [Google Scholar] [CrossRef]

- Park, K.T.; Choi, J.; Lee, B.; Ko, Y.; Jo, K.; Lee, Y.M.; Lim, J.A.; Park, C.R.; Kim, H. High-performance thermoelectric bracelet based on carbon nanotube ink printed directly onto a flexible cable. J. Mater. Chem. A 2018, 6, 19727–19734. [Google Scholar] [CrossRef]

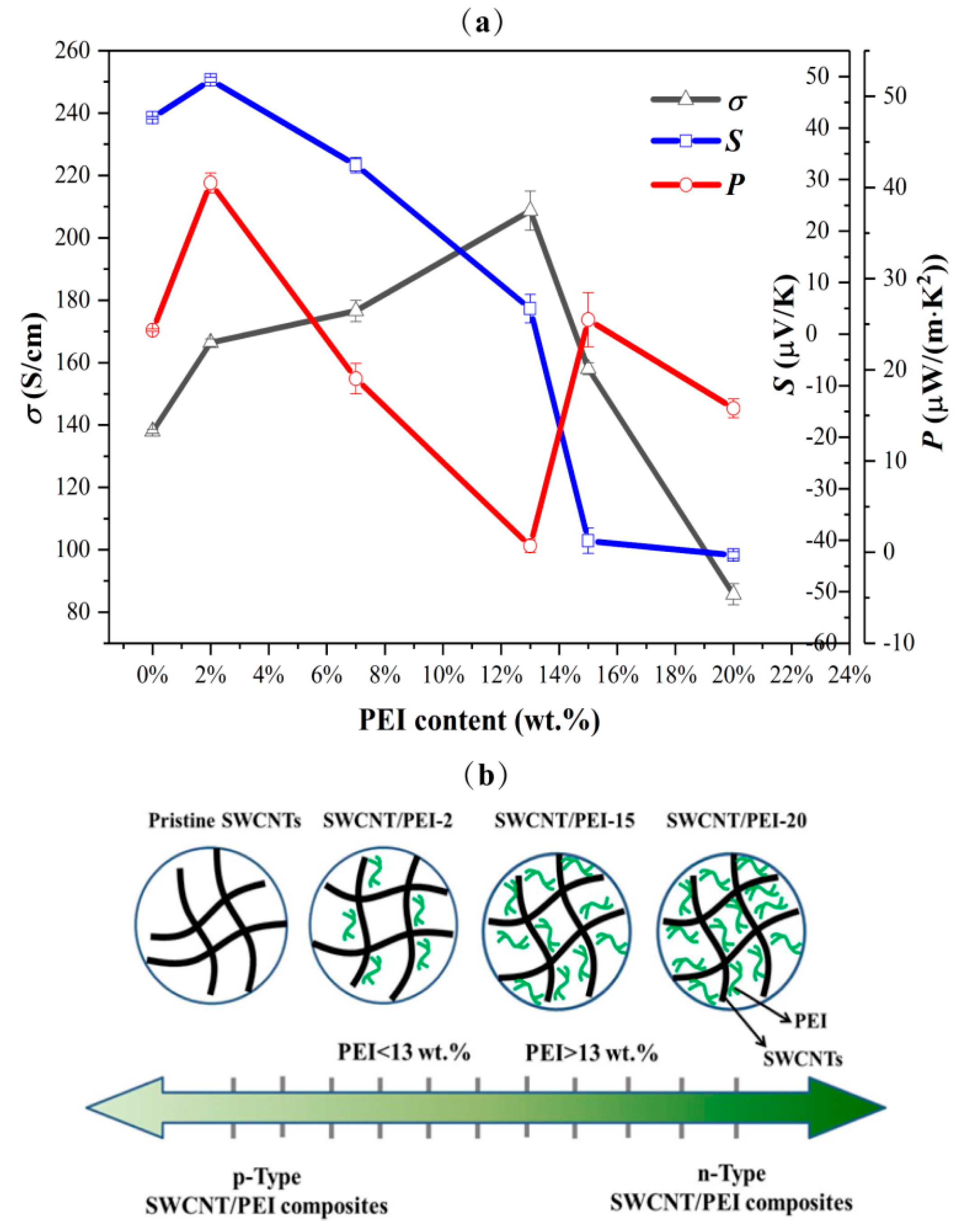

| Sample | Carrier Type | Carrier Concentration (n/(cm³)) | Carrier Mobility (μ/(cm²/V·s)) |

|---|---|---|---|

| SWCNT/PEI-0 | p | 4.6 × 1020 | 5.314 |

| SWCNT/PEI-2 | p | 3.7 × 1021 | 0.252 |

| SWCNT/PEI-15 | n | 9.3 × 1020 | 0.814 |

| SWCNT/PEI-20 | n | 2.6 × 1022 | 0.057 |

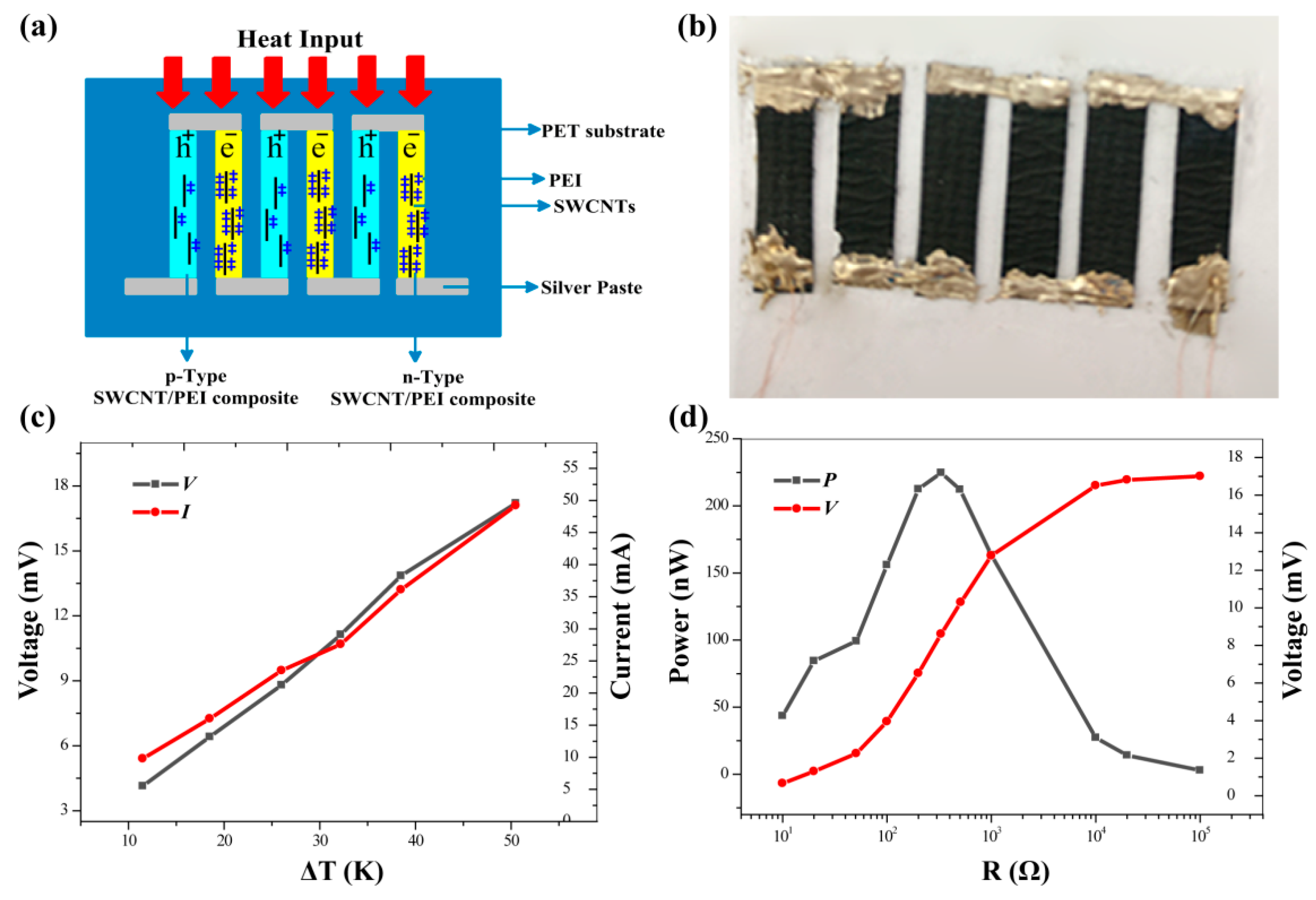

| TE Units | Device Dimensions | ΔT | Output Voltage | Output Power | Comment | Ref. |

|---|---|---|---|---|---|---|

| p-type: poly(3,4-ethylenedioxythiophene):polystyrenesulfonate (PEDOT:PSS) | 14 thermocouples | 50 | 12 mV | 16.8 µW | Parallel connected single-leg structure; screening printing; paper substrate. | [40] |

| p-type: PEDOT:PSS n-type: N-doped graphene | 8 cm × 10 cm | 10 K | 3 mV | ≈0.24 mW·m−2 | Roll-to roll printing. | [41] |

| p-type: carbon nanotubes (CNTs)/poly(3-hexyl thiophene) | 41 p-type stripes (0.1 cm × 1.5 cm) | 10 K | ≈32 mV | 32.7 nW | Spray-printing; polyimide substrate. | [42] |

| p-type: CNTs/PEDOT:PSS n-type: CNTs/PEDOT:PSS treated by hydrazine | 14 thermocouples | 10 K | 8 mV | 0.43 µW | Wet-spinning process. | [43] |

| p-type: PEDOT-coated textiles n-type: n-type CNTs | 5 thermocouples | 100 K | ≈22 mV | 62 nW | Vapor phase polymerization; wearable thermoelectric strain sensor. | [44] |

| p-type: Bi0.5Sb1.5Te3 pastes infiltrated paper; n-type: Bi2Se0.3Te2.7 pastes infiltrated paper; | 10 thermocouples | 35 K | 8.3 mV | 10 nW | Impregnating method; transparent paper-based thermoelectric generator. | [45] |

| n-type: Bi2Te3/polyvinyl alcohol hybrid composites | 10 stripes (0.2 cm × 2.5 cm) | 46 K | 24 mV | ≈9 µW·cm−2 | Solid-state reaction and ball milling method. | [46] |

| p-type: polypyrrole film n-type: copper tape | 7 thermocouples | 80 K | 336 µV | 6.4 pW | Flexible scaleable free-standing polypyrrole films; interfacial chemical polymerization. | [47] |

| p-type: PEDOT film | 6 stripes (0.7 cm × 3 cm) | 51.6 K | ≈5.6 mV | 157.2 nW | Simple self-assembled micellar soft-template method; vacuum-assisted filtration; ultrafine PEDOT nanowires. | [48] |

| p-type: poly(acrylic acid)/CNTs n-type: PEI/CNTs | 30 thermocouples | 10 K | 21 mV | 131 nW | A flexible thermoelectric generator prepared by printing the p-type and n-type CNTs ink on a curved surface. | [49] |

| p-type: PEI/SWCNTs n-type: PEI/SWCNTs | 6 stripes (0.5 cm × 2 cm) | 50 K | 8.6 mV | 224 nW | Flexible scaleable PEI/SWCNTs films; simple mixing techniques. | Our work |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, X.-X.; Qiao, X.; Luo, S.; Yao, J.-A.; Zhang, Y.-F.; Du, F.-P. Modulating Carrier Type for Enhanced Thermoelectric Performance of Single-Walled Carbon Nanotubes/Polyethyleneimine Composites. Polymers 2019, 11, 1295. https://doi.org/10.3390/polym11081295

Peng X-X, Qiao X, Luo S, Yao J-A, Zhang Y-F, Du F-P. Modulating Carrier Type for Enhanced Thermoelectric Performance of Single-Walled Carbon Nanotubes/Polyethyleneimine Composites. Polymers. 2019; 11(8):1295. https://doi.org/10.3390/polym11081295

Chicago/Turabian StylePeng, Xiao-Xi, Xuan Qiao, Shuai Luo, Jun-An Yao, Yun-Fei Zhang, and Fei-Peng Du. 2019. "Modulating Carrier Type for Enhanced Thermoelectric Performance of Single-Walled Carbon Nanotubes/Polyethyleneimine Composites" Polymers 11, no. 8: 1295. https://doi.org/10.3390/polym11081295

APA StylePeng, X.-X., Qiao, X., Luo, S., Yao, J.-A., Zhang, Y.-F., & Du, F.-P. (2019). Modulating Carrier Type for Enhanced Thermoelectric Performance of Single-Walled Carbon Nanotubes/Polyethyleneimine Composites. Polymers, 11(8), 1295. https://doi.org/10.3390/polym11081295