Charge Injection Characteristics of Semi-Conductive Composites with Carbon Black-Polymer for HVDC Cable

Abstract

1. Introduction

2. Experimental Method and Setup

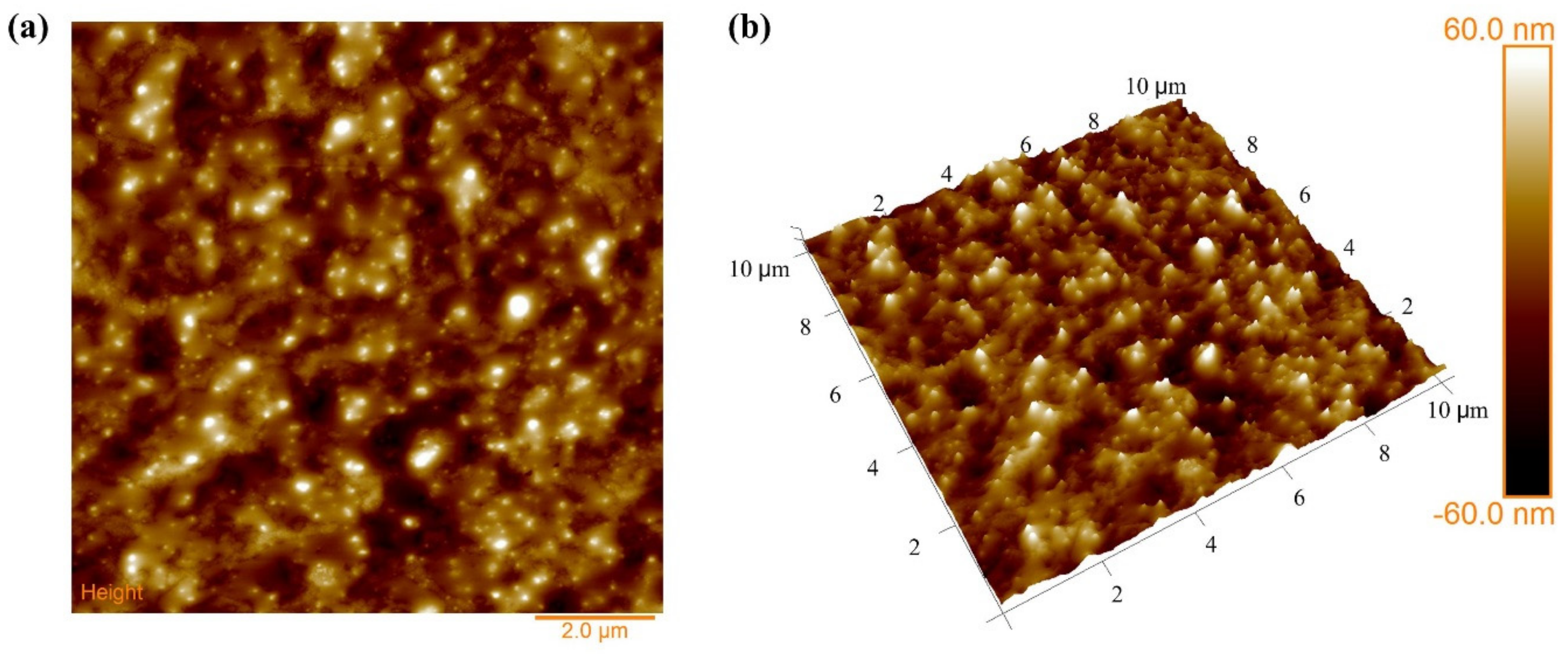

2.1. Preparation of Semi-Conductive Composite

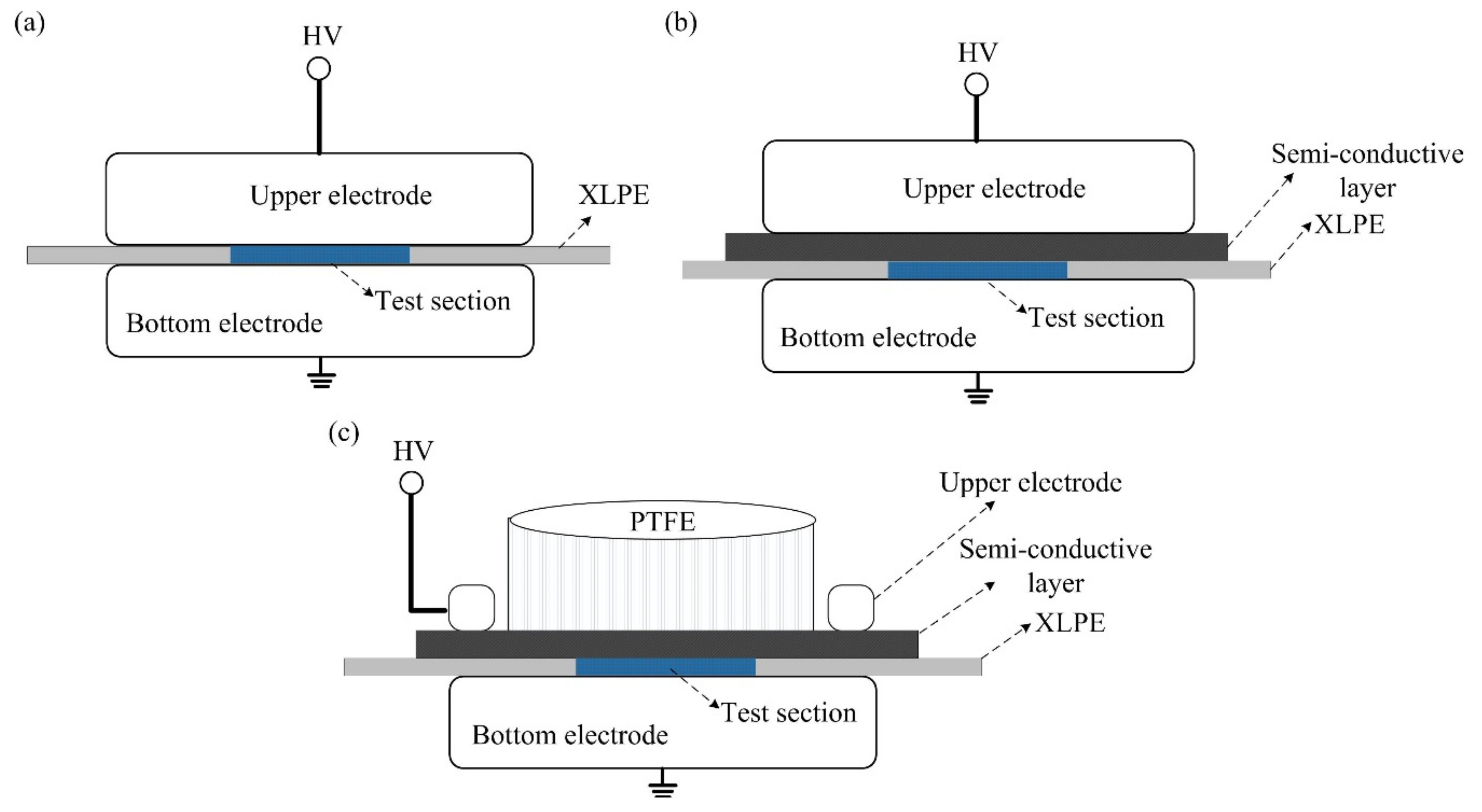

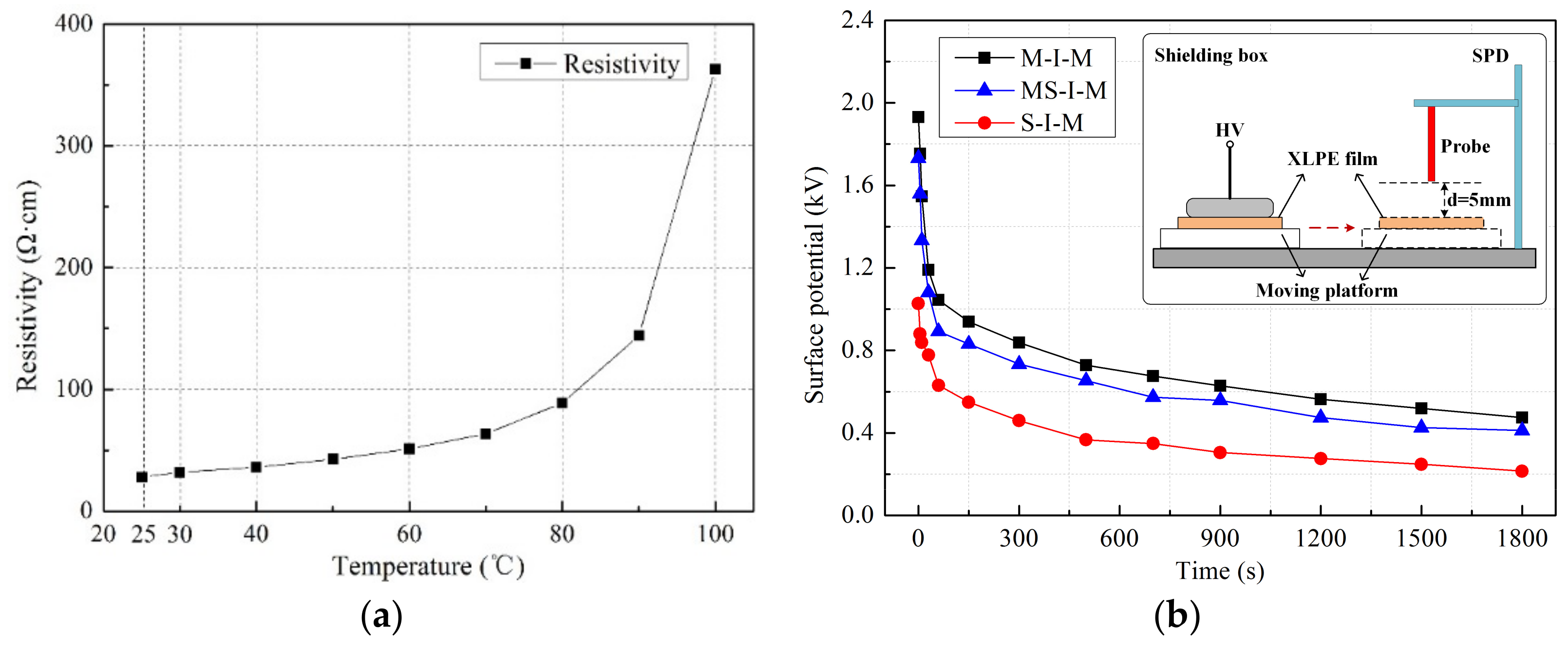

2.2. Test Method and Validation

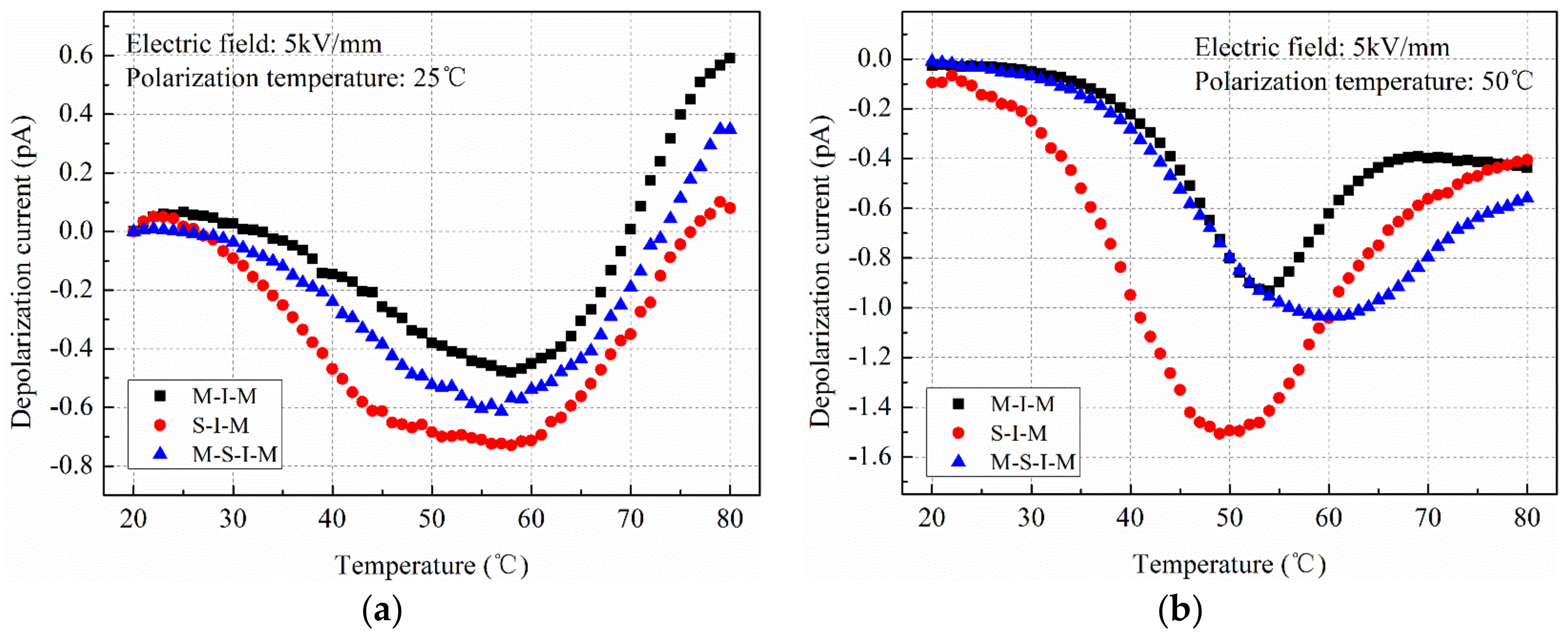

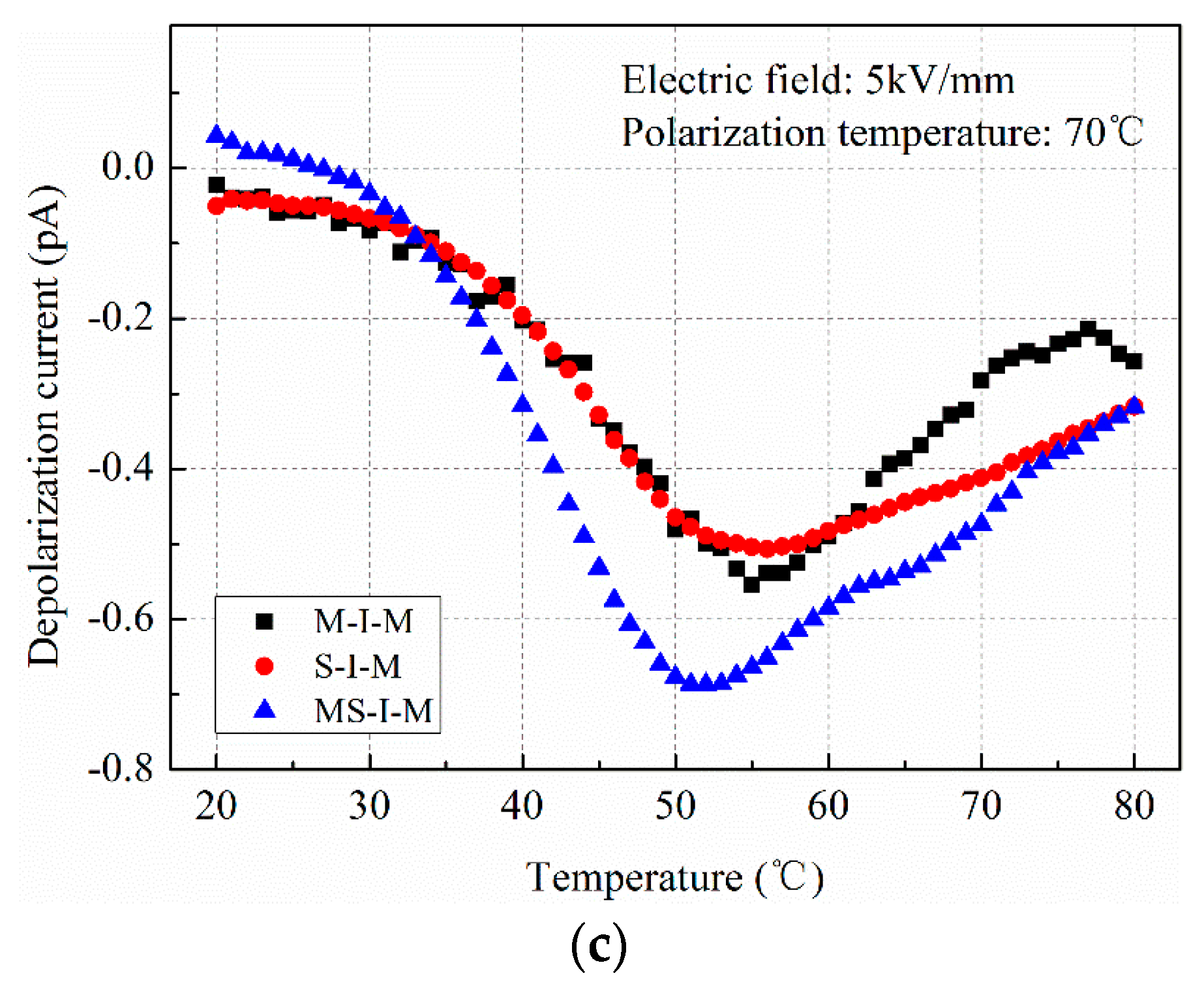

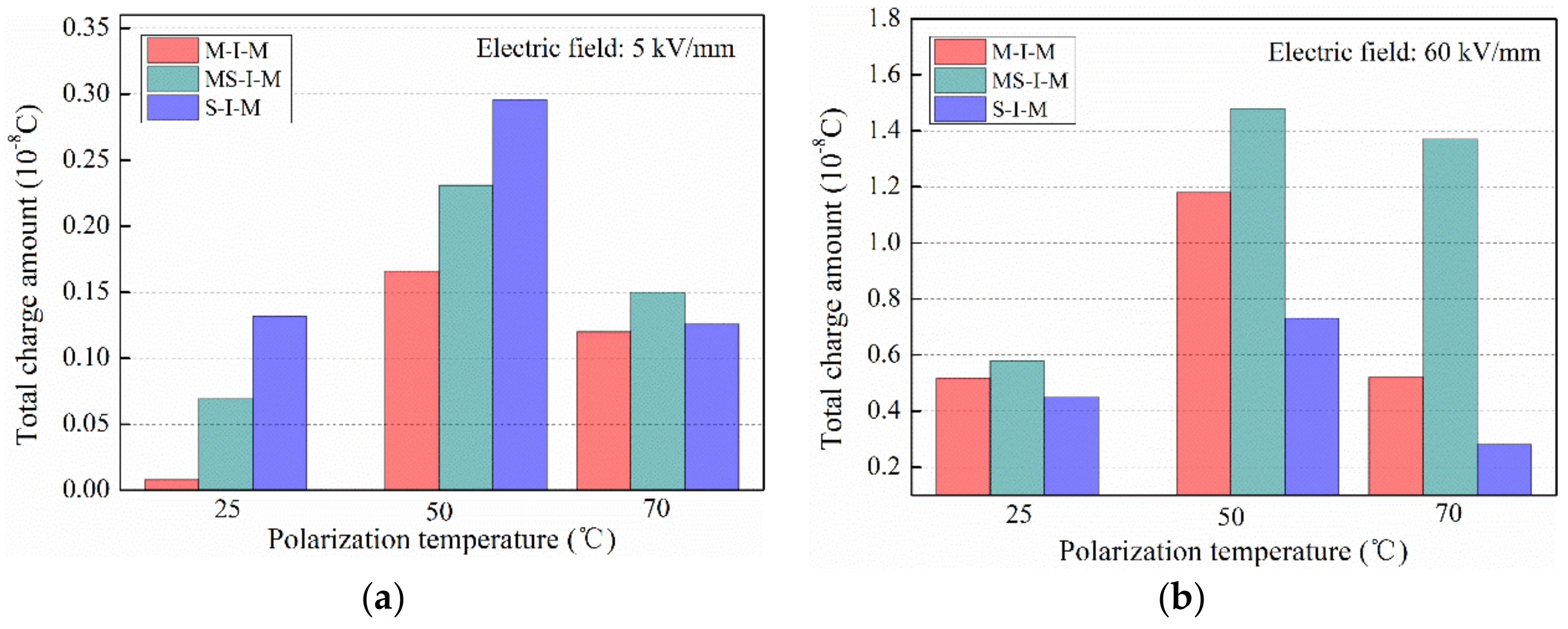

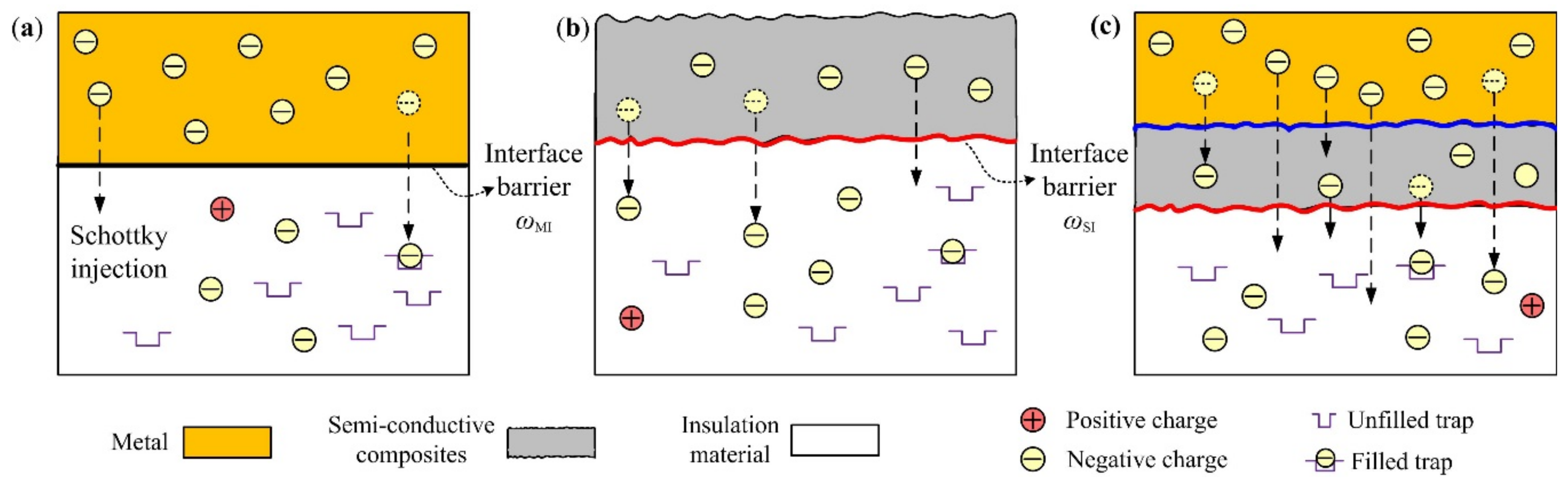

3. Experimental Results and Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Carstensen, P.; Farkas, A.A.; Campus, A.; Nilsson, U.H. Electric characterization of films peeled from the insulation of extruded HVDC cables. IEEE Conf. Electr. Insul. Dielectr. Phenom. 2005, 79–82. [Google Scholar] [CrossRef]

- Rogti, F.; Mekhaldi, A.; Laurent, C. Space charge behavior at physical interfaces in cross-linked polyethylene under DC field. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1478–1485. [Google Scholar] [CrossRef]

- Tanaka, T.; Okamoto, T.; Hozumi, N.; Suzuki, K. Interfacial improvement of XLPE cable insulation at reduced thickness. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 345–350. [Google Scholar] [CrossRef]

- Zhang, Z.; Assala, P.D.S.; Wu, L.H. Residual life assessment of 110 kV XLPE cable. Electr. Power Syst. Res. 2018, 163, 572–580. [Google Scholar] [CrossRef]

- Okamoto, T.; Ishida, M.; Hozumi, N. Dielectric breakdown strength affected by the lamellar configuration in XLPE insulation at a semiconducting interface. IEEE Trans. Dielectr. Electr. Insul. 1989, 24, 599–607. [Google Scholar] [CrossRef]

- Li, L.; Han, B.; Song, W.; Wang, X.; Lei, Q. The effect of the semiconductive screen on space charge suppression in cross-Linked polyethylene. Chin. Phys. Lett. 2014, 31, 112–115. [Google Scholar] [CrossRef]

- Vissouvanadin, B.; Roy, S.L.; Teyssedre, G.; Laurent, C.; Denizet, I.; Mammeri, M.; Poisson, B. Impact of concentration gradient of polarizable species on the electric field distribution in polymeric insulating material for HVDC cable. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 833–839. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, S.M.; Hu, J.; He, J.L. Polymeric insulation materials for HVDC cables: Development, challenges and future perspective. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 308–1318. [Google Scholar] [CrossRef]

- Fu, M.; Chen, G. Space charge measurement in polymer insulated power cables using flat ground electrode PEA system. IEE Proc.-Sci. Meas. Technol. 2003, 150, 89–96. [Google Scholar] [CrossRef]

- Fabiani, D.; Montanari, G.C.; Laurent, C.; Teyssedre, G.; Morshuis, P.H.F.; Bodega, R.; Dissado, L.A. HVDC cable design and space charge accumulation. Part 3: Effect of temperature gradient. IEEE Electr. Insul. Mag. 2008, 24, 5–14. [Google Scholar] [CrossRef]

- Delpino, S.; Fabiani, D.; Montanari, G.C.; Laurent, C.; Teyssedre, G.; Morshuis, P.H.F.; Bodega, R.; Dissado, L.A. Polymeric HVDC cable design and space charge accumulation. Part 2: Insulation interfaces. IEEE Electr. Insul. Mag. 2008, 24, 14–24. [Google Scholar] [CrossRef]

- Tian, F.; Lei, Q.; Wang, X.; Wang, Y. Effect of deep trapping states on space charge suppression in polyethylene/ZnO nanocomposite. Appl. Phys. Lett. 2011, 99, 142903. [Google Scholar] [CrossRef]

- Han, B.; Wang, X.; Sun, Z.; Yang, J.M.; Lei, Q. Space charge suppression induced by deep traps in polyethylene/zeolite Nanocomposite. Appl. Phys. Lett. 2013, 102, 012902. [Google Scholar] [CrossRef]

- Fabiani, D.; Montanari, G.C.; Laurent, C.; Teyssedre, G.; Morshuis, P.H.F.; Bodega, R.; Dissado, L.A. Polymeric HVDC cable design and space charge accumulation. Part 1: Insulation/semicon interface. IEEE Electr. Insul. Mag. 2007, 23, 11–19. [Google Scholar] [CrossRef]

- Suzyoki, Y.; Matsukawa, Y.; Han, S.O.; Fujii, A.; Kim, J.S.; Mizutani, T.; Ieda, M.; Yoshifuji, N. Study of space-charge effects on dielectric breakdown of polymers by direct probing. IEEE Trans. Dielectr. Electr. Insul. 1992, 27, 758–762. [Google Scholar] [CrossRef]

- Hozumi, N.; Suzuki, H.; Okamoto, T.; Watanabe, K.; Watanabe, A. Direct observation of time-dependent space charge profiles in XLPE cable under high electric fields. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 1068–1076. [Google Scholar] [CrossRef]

- Tressaud, A.; Durand, E.; Labrugere, C.; Kharitonov, A.P.; Kharitonova, L.N. Modification of surface properties of carbon-based and polymeric materials through fluorination routes: From fundamental research to industrial applications. J. Fluor. Chem. 2007, 128, 378–391. [Google Scholar] [CrossRef]

- Roy, M.; Nelson, J.K.; Maccrone, R.K.; Schadler, L.S.; Reed, C.W.; Keefe, R.; Zenger, W. Polymer nanocomposite dielectrics-the role of the interface. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 629–643. [Google Scholar] [CrossRef]

- Li, Z.; Du, B.; Han, C.; Xu, H. Trap modulated charge carrier transport in polyethylene/graphene nanocomposites. Sci. Rep. 2017, 7, 4015. [Google Scholar] [CrossRef]

- Nilsson, U.H.; Boström, J.-O. Influence of the semi-conductive material on space charge build-up in extruded HVDC cables. Conf. Rec. IEEE Int. Symp. Electr. Insul. 2010, 1–4. [Google Scholar] [CrossRef]

- Van der Born, D.; Tsekmes, A.; Person, T.J. Evaluation of space charge accumulation processes in small size polymeric cable models. Annu. Rep. Conf. Electr. Insul. Dielectr. Phenom. 2012, 669–672. [Google Scholar] [CrossRef]

- Han, S.J.; Wasserman, S.H. Agglomeration and percolation network behavior of semi-conductive polymer composites with carbon nanotubes. IEEE Int. Symp. Electr. Insul. 2010, 1–4. [Google Scholar] [CrossRef]

- Zhang, Z.; Niu, F.; An, Z.; Zheng, F.; Ma, P.; Lei, Q. Space charge injection in LDPE by semi-conductive electrode with different carbon black filling rates. High Volt. Eng. 2011, 37, 1904–1909. [Google Scholar]

- Xie, K.; Chen, D.; Cai, X.; Hou, B.; Zhang, Z. Study on the practical characterization of the microstructure of polyethylene by infrared spectroscopy. China Synth. Resin Plast. 2005, 1, 48–52. [Google Scholar]

- Ji, J. Characterization of Carbon Black Surface. Carbon 1999, 4, 8–12. [Google Scholar]

- Li, G.; Wang, J.; Han, W.; Wei, Y.; Li, S. Influence of temperature on charge accumulation in low-density polyethylene based on depolarization current and space charge decay. Polymers 2019, 11, 587. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Y.; Liu, M.; Han, W.; Li, G.; Hao, C.; Lei, Q. Charge Injection Characteristics of Semi-Conductive Composites with Carbon Black-Polymer for HVDC Cable. Polymers 2019, 11, 1134. https://doi.org/10.3390/polym11071134

Wei Y, Liu M, Han W, Li G, Hao C, Lei Q. Charge Injection Characteristics of Semi-Conductive Composites with Carbon Black-Polymer for HVDC Cable. Polymers. 2019; 11(7):1134. https://doi.org/10.3390/polym11071134

Chicago/Turabian StyleWei, Yanhui, Mingyue Liu, Wang Han, Guochang Li, Chuncheng Hao, and Qingquan Lei. 2019. "Charge Injection Characteristics of Semi-Conductive Composites with Carbon Black-Polymer for HVDC Cable" Polymers 11, no. 7: 1134. https://doi.org/10.3390/polym11071134

APA StyleWei, Y., Liu, M., Han, W., Li, G., Hao, C., & Lei, Q. (2019). Charge Injection Characteristics of Semi-Conductive Composites with Carbon Black-Polymer for HVDC Cable. Polymers, 11(7), 1134. https://doi.org/10.3390/polym11071134