Fabrication of Cotton Linter-Based Adsorbents by Radiation Grafting Polymerization for Humic Acid Removal from Aqueous Solution

Abstract

1. Introduction

2. Experimental

2.1. Materials

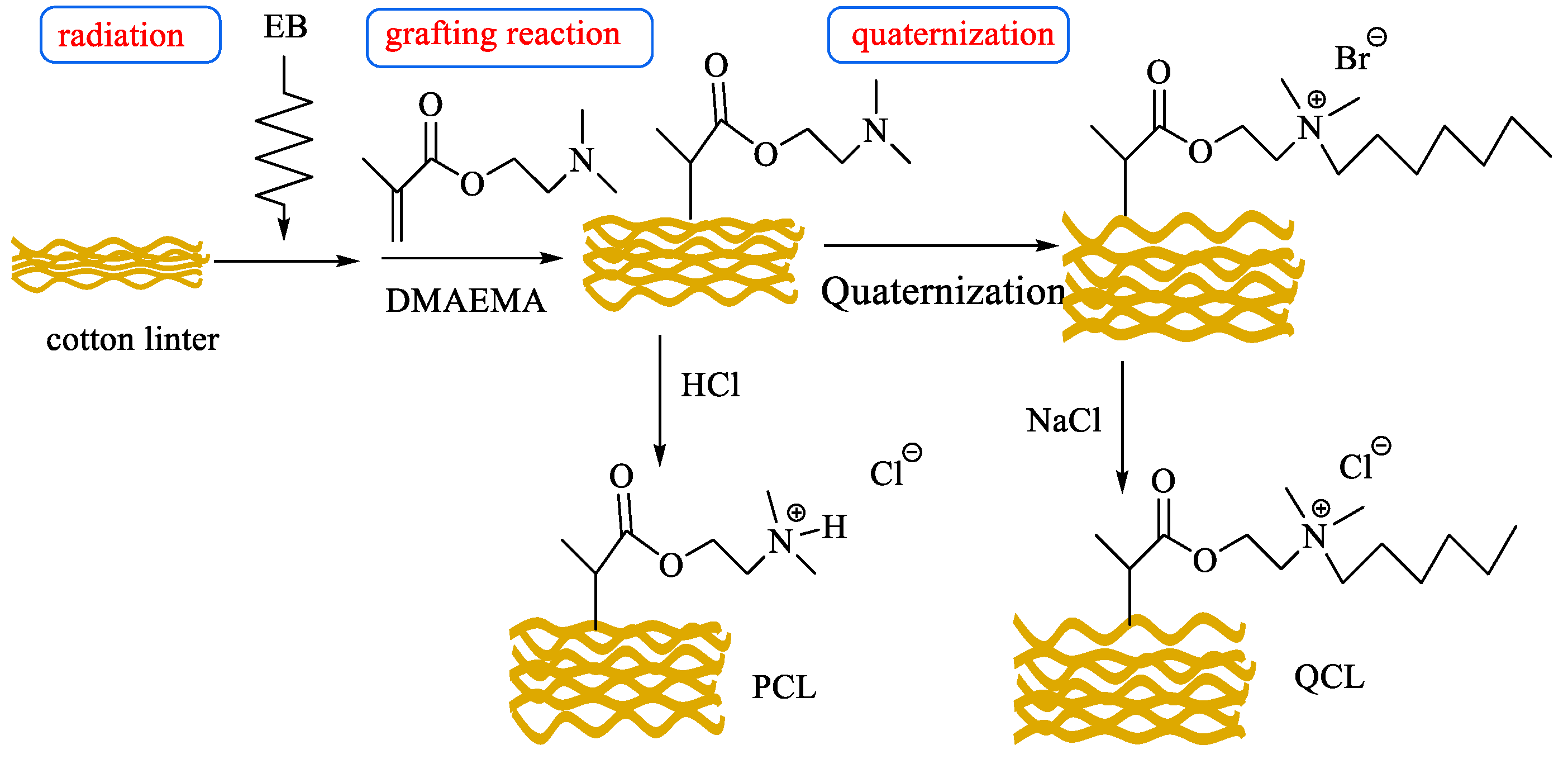

2.2. Preparation of Cotton Linter-Based Adsorbents

2.3. Characterization

2.4. Analysis of HA Concentration in Test Solution

2.5. Batch Experiments

3. Results and Discussion

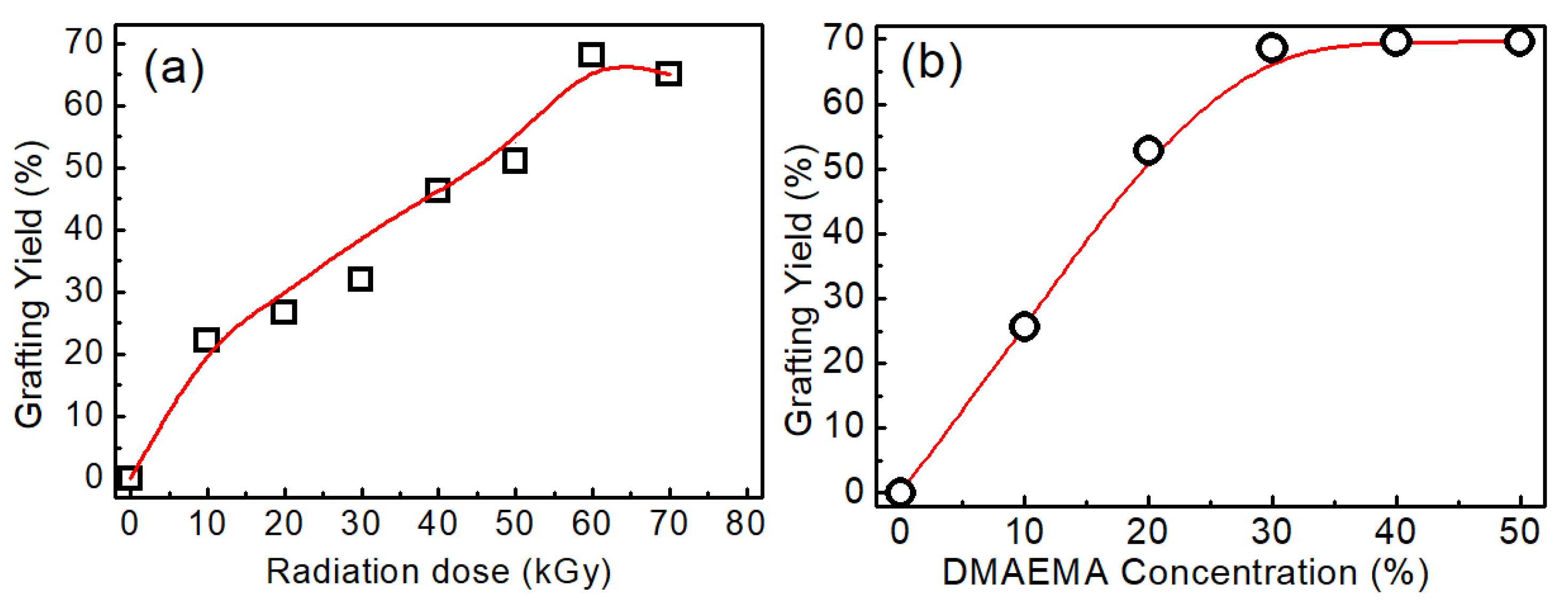

3.1. Preparation

3.2. Characterization

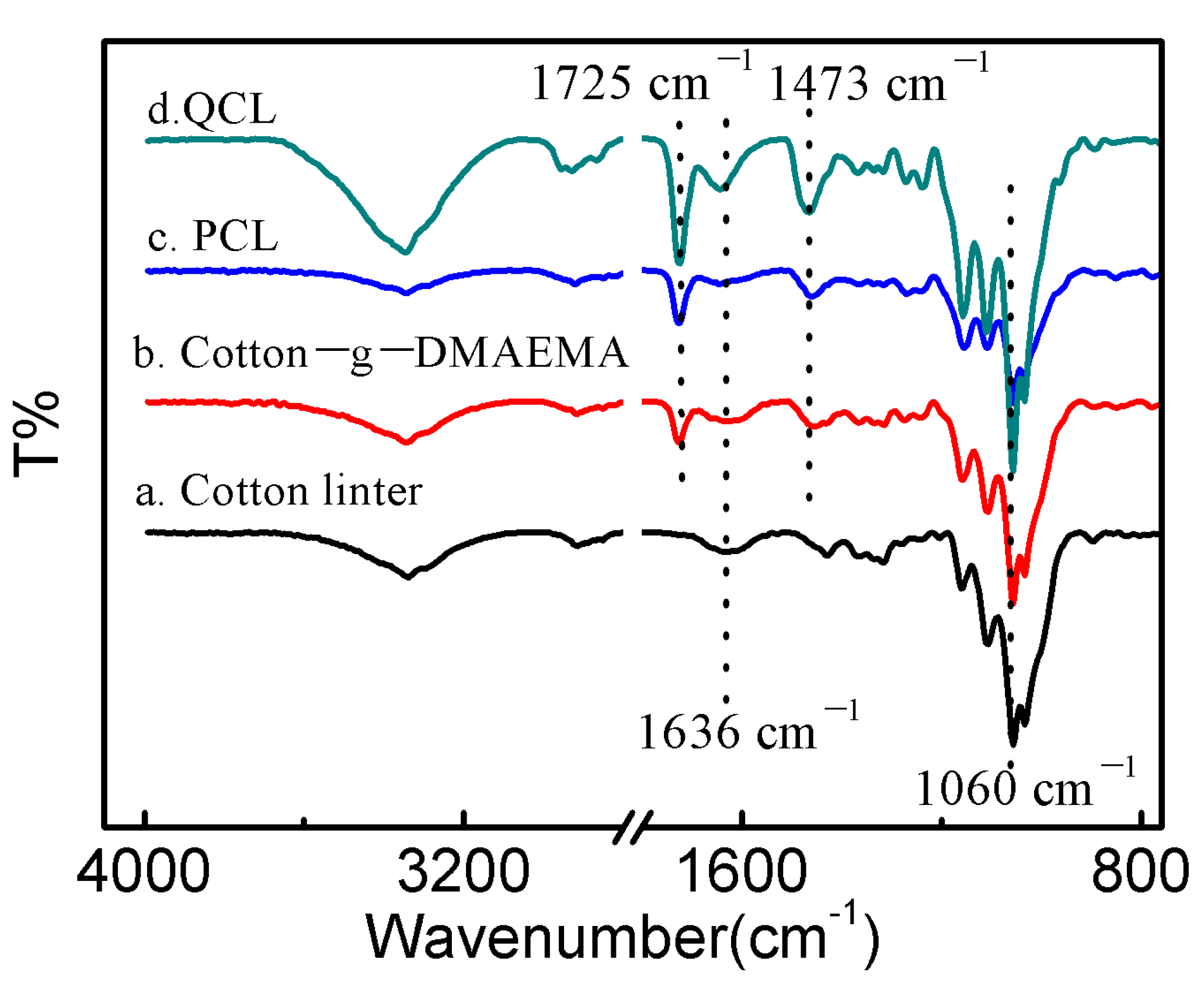

3.2.1. FTIR Analysis

3.2.2. Thermal Analysis

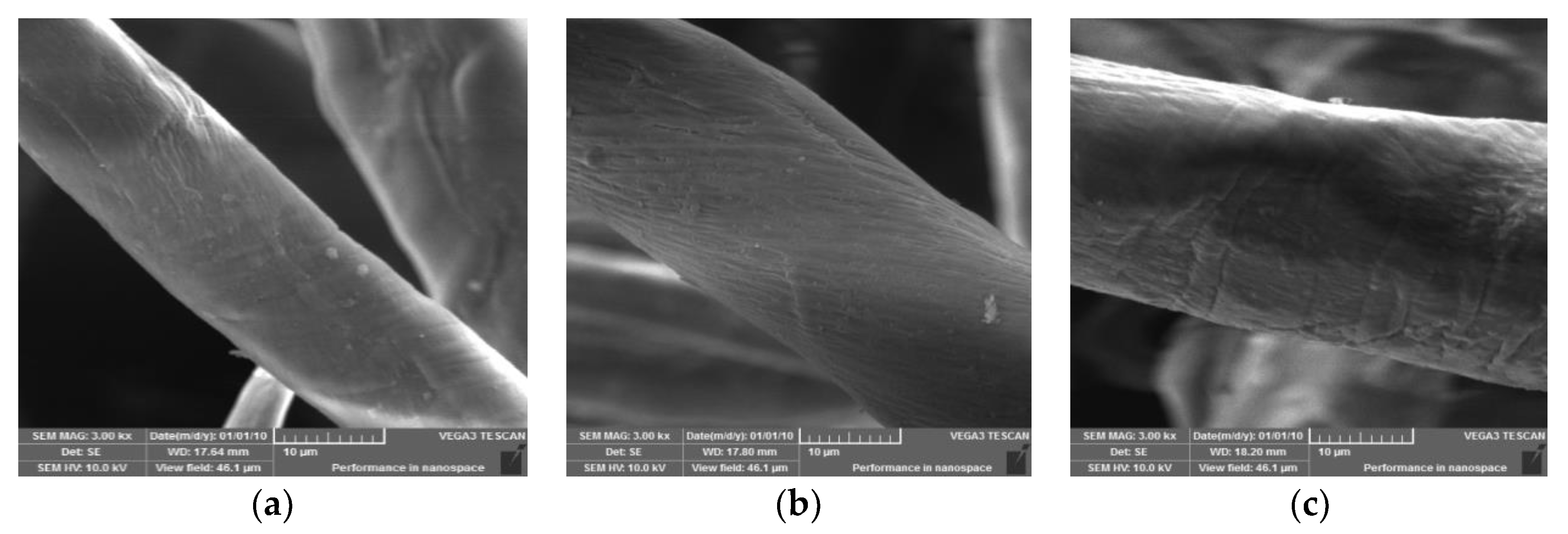

3.2.3. SEM Morphologies

3.3. Batch Experiments

3.3.1. Effect of pH and Point of Zero Charge

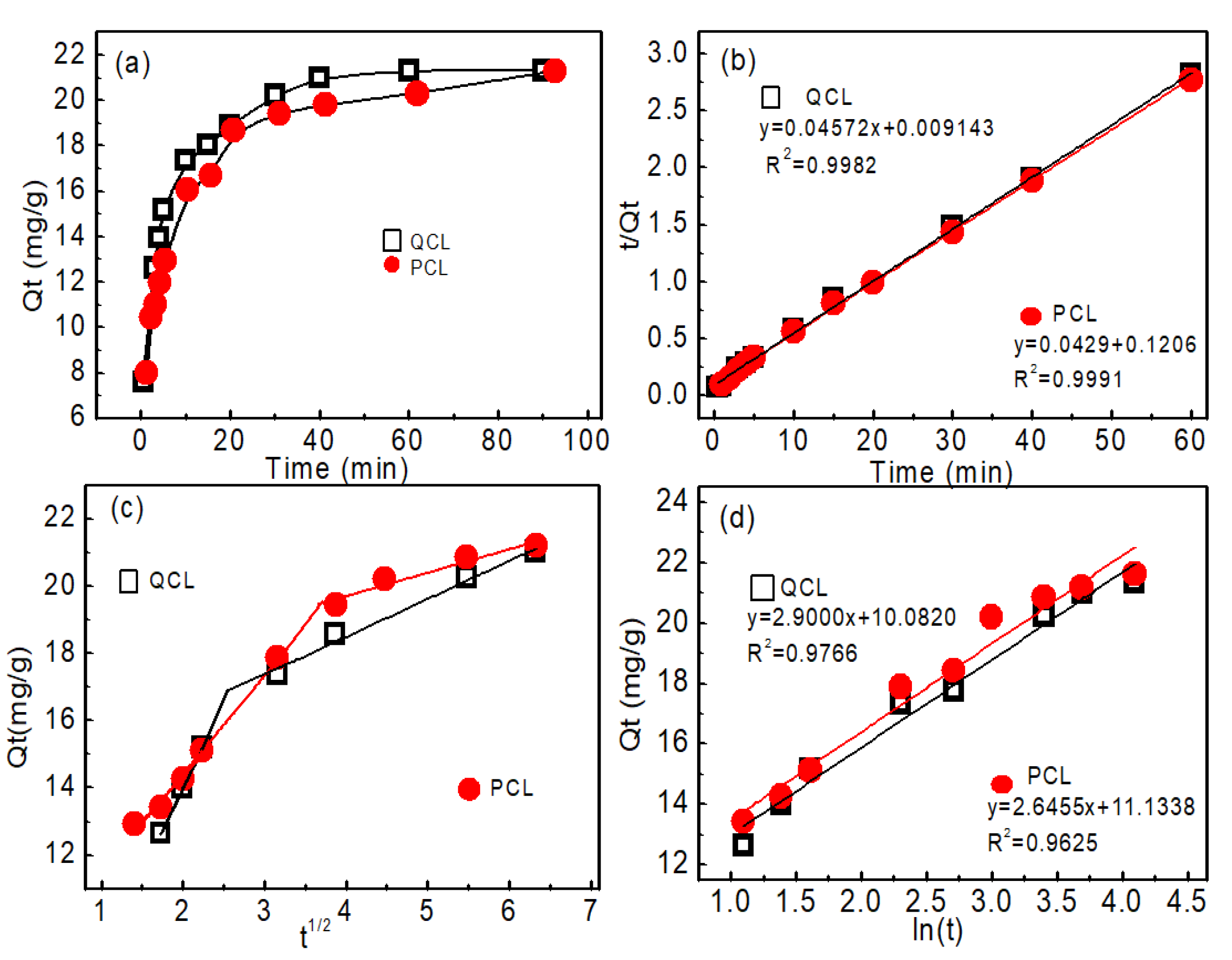

3.3.2. Adsorption Kinetics

3.3.3. Adsorption Isotherms

3.3.4. Desorption Experiments

3.4. XPS Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anirudhan, T.S.; Suchithra, P.S.; Rijith, S. Amine–modified polyacrylamide–bentonite composite for the adsorption of humic acid in aqueous solutions. Colloid Surf. A 2008, 326, 147–156. [Google Scholar] [CrossRef]

- Bousba, S.; Bougdah, N.; Messikh, N.; Magric, P. Adsorption Removal of Humic Acid from Water Using a Modified Algerian Bentonite. Phys. Chem. Res. 2018, 6, 613–625. [Google Scholar] [CrossRef]

- Tan, X.W.; Zhou, X.L.; Hua, R.; Zhang, Y.Y. Technologies for the Removal of Humic Acid from Water: A Short Review of Recent Developments. In Proceedings of the International Conference on Bioinformatics & Biomedical Engineering, Chengdu, China, 10–12 June 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Elham, D.; Ali, N. Optimization of humic acid removal by adsorption onto bentonite and montmorillonite nanoparticles. J. Mol. Liuids 2018, 259, 76–81. [Google Scholar] [CrossRef]

- Hartono, T.; Wang, S.B.; Ma, Q. Layer structured graphite oxide as a novel adsorbent for humic acid removal from aqueous solution. J. Colloid Interface Sci. 2009, 333, 114–119. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Luo, F.; Wasikiewicz, J.M. Adsorption of humic acid from aqueous solution onto irradiation-cross-linked carboxymethylchitosan. Bioresource Technol. 2008, 99, 1911–1917. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Liu, J.; Yuan, W.; Yi, Y.; Zhao, L. Recovery of Au(III) by radiation synthesized aminomethyl pyridine functionalized adsorbents based on cellulose. Chem. Eng. J. 2016, 283, 504–513. [Google Scholar] [CrossRef]

- Moigne, N.L.; Sonnier, R.; Hage, R.E.; Rouif, S. Radiation-induced modifications in natural fibres and their biocomposites: Opportunities for controlled physico-chemical modification pathways? Ind. Crop. Prod. 2017, 109, 199–213. [Google Scholar] [CrossRef]

- Hayashi, N.; Chen, J.H.; Seko, N. Nitrogen-Containing Fabric Adsorbents Prepared by Radiation Grafting for Removal of Chromium from Wastewater. Polymers 2018, 10, 744. [Google Scholar] [CrossRef]

- Du, J.F.; Dong, Z.; Yang, X.; Zhao, L. Facile fabrication of sodium styrene sulfonate-grafted ethylene- vinyl alcohol copolymer as adsorbent for ammonium removal from aqueous solution. Environ. Sci. Polluti. Res. 2018, 25, 27235–27244. [Google Scholar] [CrossRef]

- Du, J.F.; Dong, Z.; Xie, C.; Yang, X.; Yang, L.; Zhao, L.; Zhai, M.L. Application of radiation grafting technique in preparation of adsorption materials. Acta Polym. Sin. 2016, 6, 698–705. [Google Scholar] [CrossRef]

- Chattopadhyay, D.; Umrigar, K. Chemical Modification of Waste Cotton Linters for Oil Spill Cleanup Application. J. Inst. Eng. India Ser. E. 2017, 98, 103–120. [Google Scholar] [CrossRef]

- Wang, Y.F.; He, L.; Yu, B.; Chen, Y.; Shen, Y.Q.; Cong, H.L. ZnO Quantum Dots Modified by pH-Activated Charge-Reversal Polymer for Tumor Targeted Drug Delivery. Polymers 2018, 10, 1272. [Google Scholar] [CrossRef] [PubMed]

- Kavakli, C.; Kavakli, P.A.; Turan, B.D.; Hamurcu, A.; Guven, O. Quaternized dimethyl- aminoethyl methacrylate strong base anion exchange fibers for As(V) adsorption. Radiat. Phys. Chem. 2014, 102, 84–95. [Google Scholar] [CrossRef]

- Huang, S.J.; Ma, C.Z.; Li, C.; Min, C.G.; Du, P.; Xia, Y.; Yang, C.F.; Huang, Q.L. Facile Synthesis, Characterization of Poly-2-mercapto-1,3,4-thiadiazole Nanoparticles for Rapid Removal of Mercury and Silver Ions from Aqueous Solutions. Polymers 2018, 10, 150. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.Y.; Liu, H.Y.; Xiong, T.H.; Xu, A.; Pan, B.L.; Tang, K.R. Graphene Oxide Reinforced Alginate/PVA Double Network Hydrogels for Efficient Dye Removal. Polymers 2018, 10, 835. [Google Scholar] [CrossRef] [PubMed]

- Shaban, M.; Abukhadra, M.R.; Khan, A.A.P.; Jibali, B.M. Removal of Congo red, methylene blue and Cr(VI) ions from water using natural serpentine. J. Taiwan Inst. Chem. E 2018, 82, 102–116. [Google Scholar] [CrossRef]

- Pang, L.J.; Hu, J.T.; Zhang, M.J.; Yang, C.J.; Wu, G.Z. An efficient and reusable quaternary ammonium fabric adsorbent prepared by radiation grafting for removal of Cr(VI) from wastewater. Environ. Sci. Pollut. Res. 2018, 25, 11045–11053. [Google Scholar] [CrossRef]

- Tunc, O.; Tanaci, H.; Aksu, Z. Potential Use of Cotton Plant Waste for the Removal of Ramazol Black B Reactive Dye. J. Hazard. Mater. 2009, 163, 187–198. [Google Scholar] [CrossRef]

- Zulfikar, M.A.; Afrita, S.; Wahyuningrum, D.; Ledyastuti, M. Preparation of Fe3O4-chitosan hybrid nano-particles used for humic acid adsorption. Environ. Nanotechnol. Monit. Manag. 2016, 6, 64–75. [Google Scholar] [CrossRef]

- Lin, K.-Y.A.; Chang, H.-A. Efficient adsorptive removal of humic acid from water using zeolitic imidazole framework-8 (ZIF-8). Water. Air. Soil Pollut. 2015, 226, 10. [Google Scholar] [CrossRef]

- Daifullah, A.A.M.; Girgis, B.S.; Gad, H.M.H. A study of the factors affecting the removal of humic acid by activated carbon prepared from biomass material. Colloid Surf. A 2004, 235, 1–10. [Google Scholar] [CrossRef]

- Salman, M.; El-Eswed, B.; Khalili, F. Adsorption of humic acid on bentonite. Appl. Clay Sci. 2007, 38, 51–56. [Google Scholar] [CrossRef]

- Wu, F.C.; Tseng, R.L.; Juang, R.S. Adsorption of dyes and humic acid from water using chitosan-encapsulated activated carbon. J. Chem. Technol. Biotechnol. 2002, 77, 1269. [Google Scholar] [CrossRef]

- Anirudhan, T.S.; Ramachandran, M. Surfactant-modified bentonite as adsorbent for the removal of humic acid from wastewaters. Appl. Clay Sci. 2007, 35, 276–281. [Google Scholar] [CrossRef]

- Wang, L.; Han, C.; Nadagouda, M.N.; Dionysiou, D.D. An innovative zinc oxide-coated zeolite adsorbent for removal of humic acid. J. Hazard. Mater. 2016, 313, 283–290. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.W.; Wang, Y.; Ma, J.; Qiu, J.Y.; Peng, J.; Li, J.Q.; Zhai, M.L. A novel amphoteric ion exchange membrane synthesized by radiation-induced graftingα-methylstyrene and N,N-dimethylaminoethyl methacrylate for vanadium redox flow battery application. J. Membr. Sci. 2012, 407–408, 184–192. [Google Scholar] [CrossRef]

| Model | Parameters | QCL | PCL |

|---|---|---|---|

| pseudo-first-order kinetics | k1(h−1) | 0.3809 | 0.3833 |

| qe (mg/g) | 19.4410 | 20.5938 | |

| R2 | 0.7772 | 0.7207 | |

| pseudo-second-order kinetics | k2 (g/(mg·min)) | 0.0229 | 0.0153 |

| qe (mg/g) | 21.8723 | 23.3046 | |

| R2 | 0.9982 | 0.9991 | |

| h0 | 10.955 | 8.3095 | |

| Weber and Morris | Kp1 | 5.0313 | 2.9340 |

| C1 | 3.9268 | 8.5383 | |

| R2 | 0.9999 | 0.9905 | |

| Kp2 | 1.1318 | 0.6968 | |

| C2 | 13.9619 | 16.908 | |

| R2 | 0.9822 | 0.9191 | |

| Elovich model | β (g/mg) | 0.3448 | 0.3780 |

| α (mg/g·min) | 93.8163 | 177.9421 | |

| R2 | 0.9766 | 0.9625 |

| Langmuir | Freundlich | Temkin | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Adsorbents | Qm (mg/g) | KL (L/mg) | R2 | KF (mg/g) | n | R2 | BT | KT | R2 |

| QCL | 250.0 | 0.0084 | 0.9910 | 14.22 | 2.347 | 0.9914 | 45.07 | 0.1353 | 0.9111 |

| PCL | 333.3 | 0.0042 | 0.9827 | 9.331 | 1.939 | 0.9832 | 69.24 | 0.0468 | 0.9212 |

| Adsorbents | Qm (mg/g) | pH | Temperature | Ref. |

|---|---|---|---|---|

| Fe3O4-chitosan hybrid nano-particles | 44.84 | 4 | RT | [20] |

| Zeolitic Imidazole Framework-8 (ZIF-8) | 45 | 3 | 20 °C | [21] |

| Activated carbon | 45.4 | -- | -- | [22] |

| bentonite | 53 | 5 | 25 °C | [23] |

| Natural Algerian bentonite | 54.8 | 3.2 | 20 °C | [2] |

| cross-linked carboxymethyl chitosan | 57.14 | 3.5 | RT | [6] |

| chitosan-encapsulated activated carbon | 84 | 6.4 | 30 °C | [24] |

| Modified HDTMA-bentonite | 104.77 | 3.0 | 30 °C | [25] |

| ZnO-30N-zeolite | 120 | -- | 21 °C | [26] |

| QCL | 250.0 | 6 | 30 °C | This paper |

| Modified HDTMA-bentonite | 330.3 | 3.2 | 20 °C | [2] |

| PCL | 333.3 | 6 | 30 °C | This paper |

| Elution Reagent | Desorption Efficiency (%) | ||

|---|---|---|---|

| PCL | QCL | ||

| 1 mol/L HCl | 3.268 | 33.12 | |

| 3 mol/L HCl | 7.631 | 35.98 | |

| 1 mol/L NaOH | 55.04 | 37.14 | |

| 3 mol/L NaOH | 75.98 | 30.86 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Dong, Z.; Pi, Y.; Yang, X.; Zhao, L. Fabrication of Cotton Linter-Based Adsorbents by Radiation Grafting Polymerization for Humic Acid Removal from Aqueous Solution. Polymers 2019, 11, 962. https://doi.org/10.3390/polym11060962

Du J, Dong Z, Pi Y, Yang X, Zhao L. Fabrication of Cotton Linter-Based Adsorbents by Radiation Grafting Polymerization for Humic Acid Removal from Aqueous Solution. Polymers. 2019; 11(6):962. https://doi.org/10.3390/polym11060962

Chicago/Turabian StyleDu, Jifu, Zhen Dong, Yuxuan Pi, Xin Yang, and Long Zhao. 2019. "Fabrication of Cotton Linter-Based Adsorbents by Radiation Grafting Polymerization for Humic Acid Removal from Aqueous Solution" Polymers 11, no. 6: 962. https://doi.org/10.3390/polym11060962

APA StyleDu, J., Dong, Z., Pi, Y., Yang, X., & Zhao, L. (2019). Fabrication of Cotton Linter-Based Adsorbents by Radiation Grafting Polymerization for Humic Acid Removal from Aqueous Solution. Polymers, 11(6), 962. https://doi.org/10.3390/polym11060962