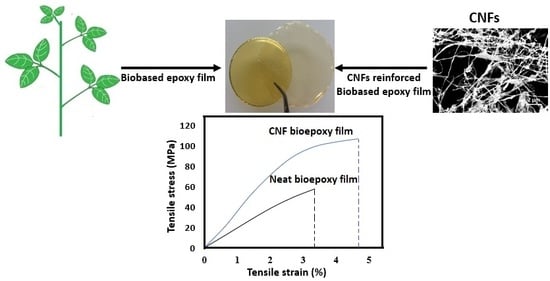

Highly Toughened and Transparent Biobased Epoxy Composites Reinforced with Cellulose Nanofibrils

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cellulose Nanofibril Sheet Preparation

2.3. Production of CNF/Epoxy Composites

2.4. Mechanical Properties

2.5. Thermogravimetric Analysis (TGA)

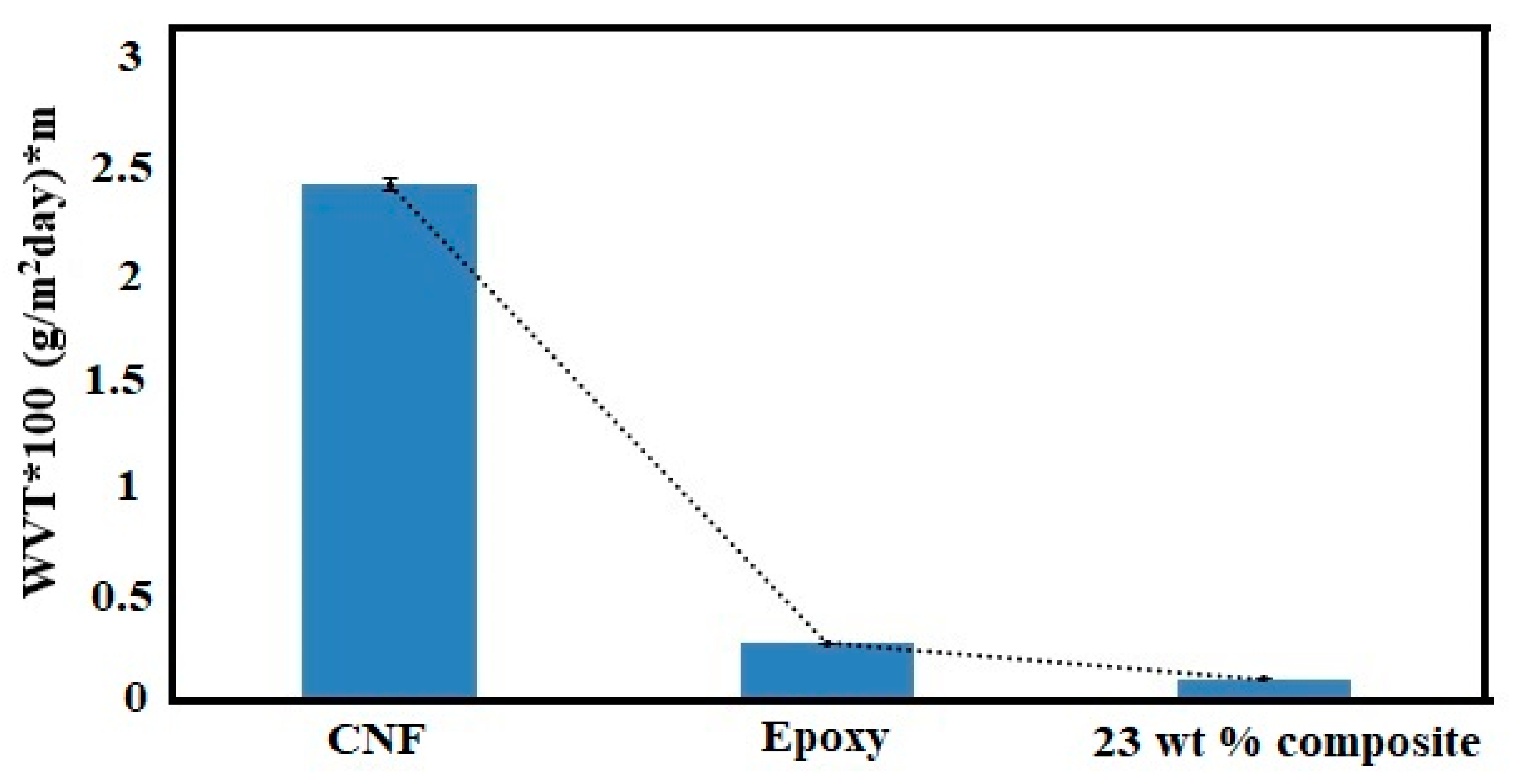

2.6. Water Vapour Transmission (WVT)

2.7. Other Characterizations

2.8. Statistical Analysis

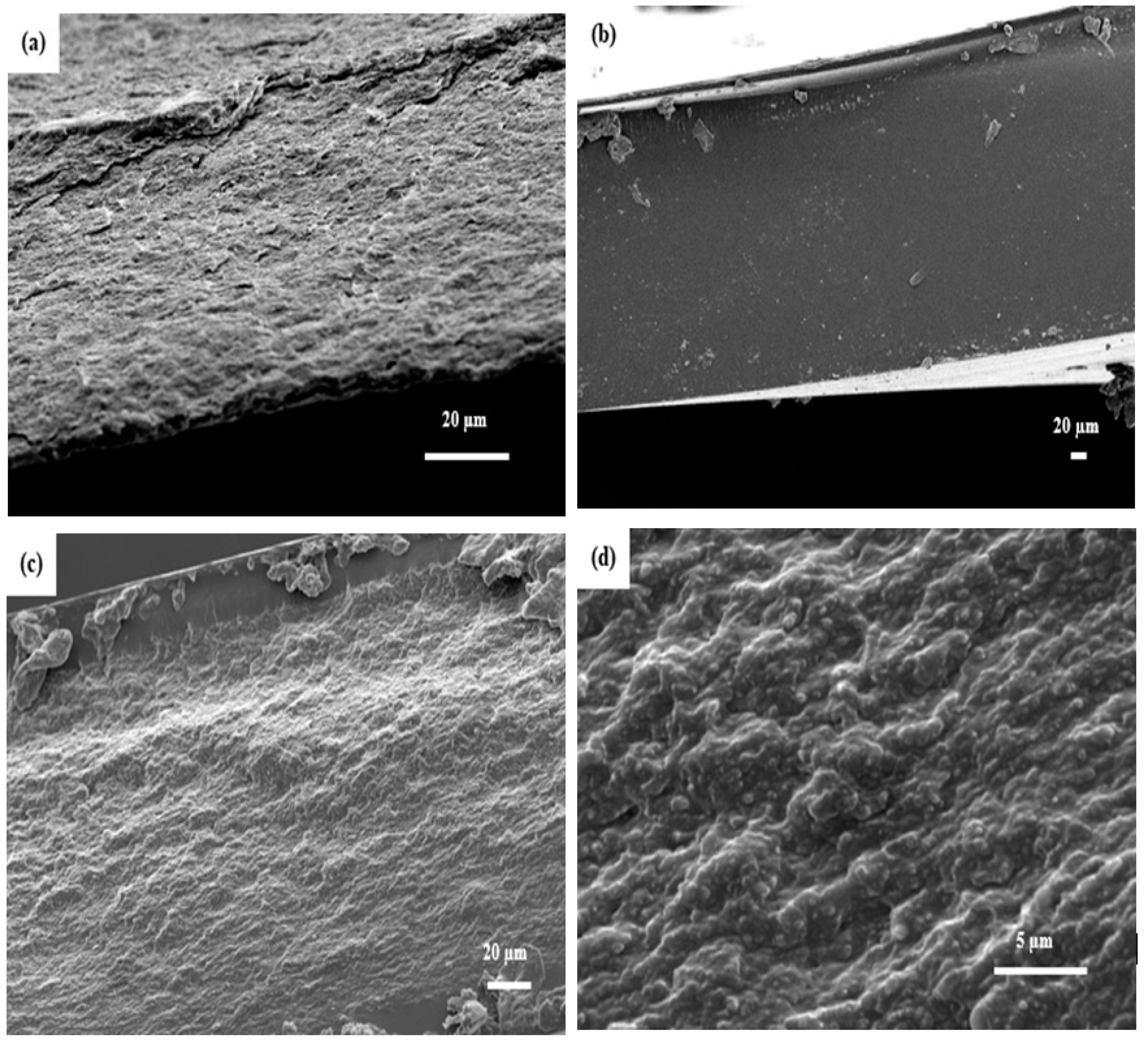

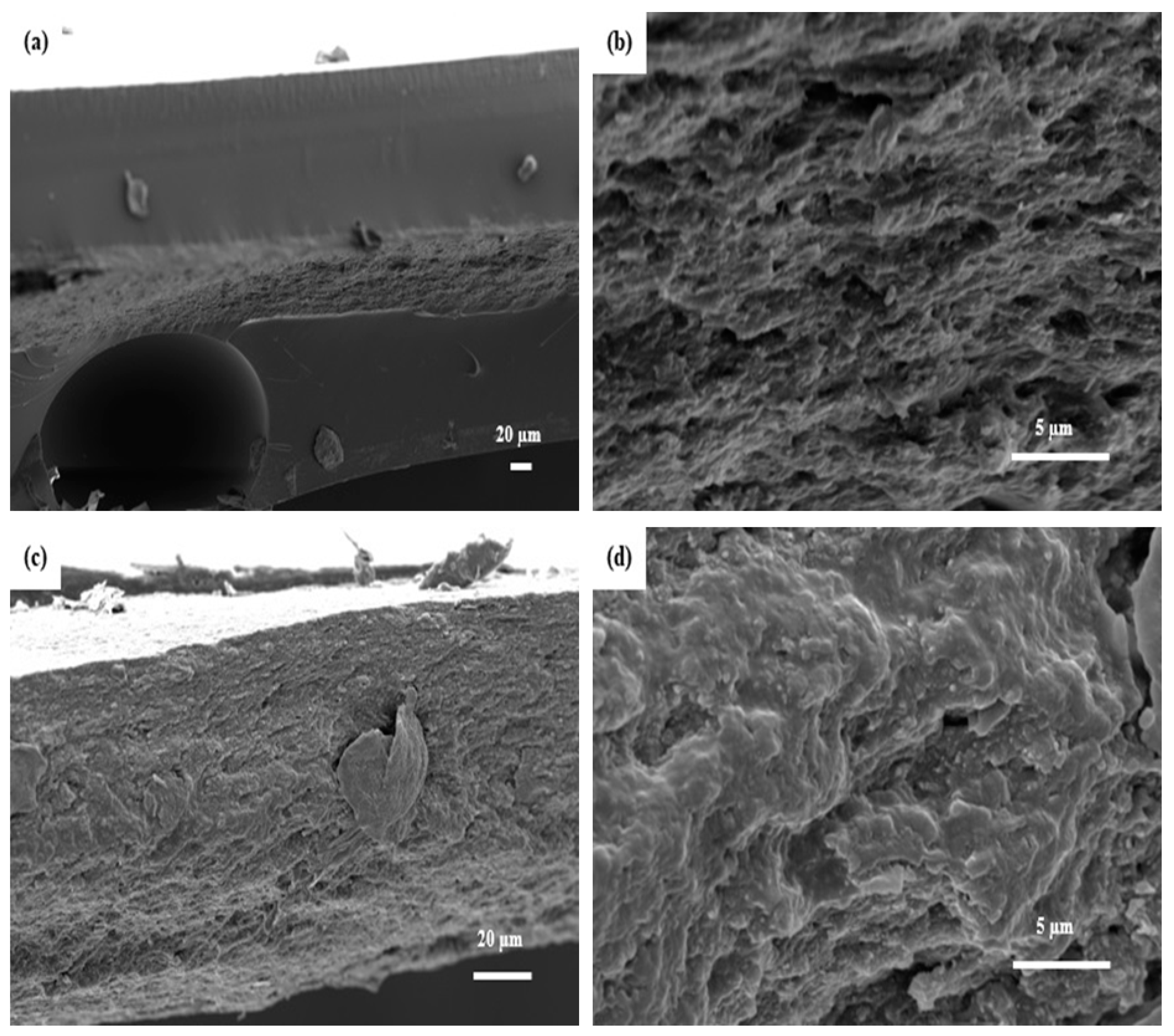

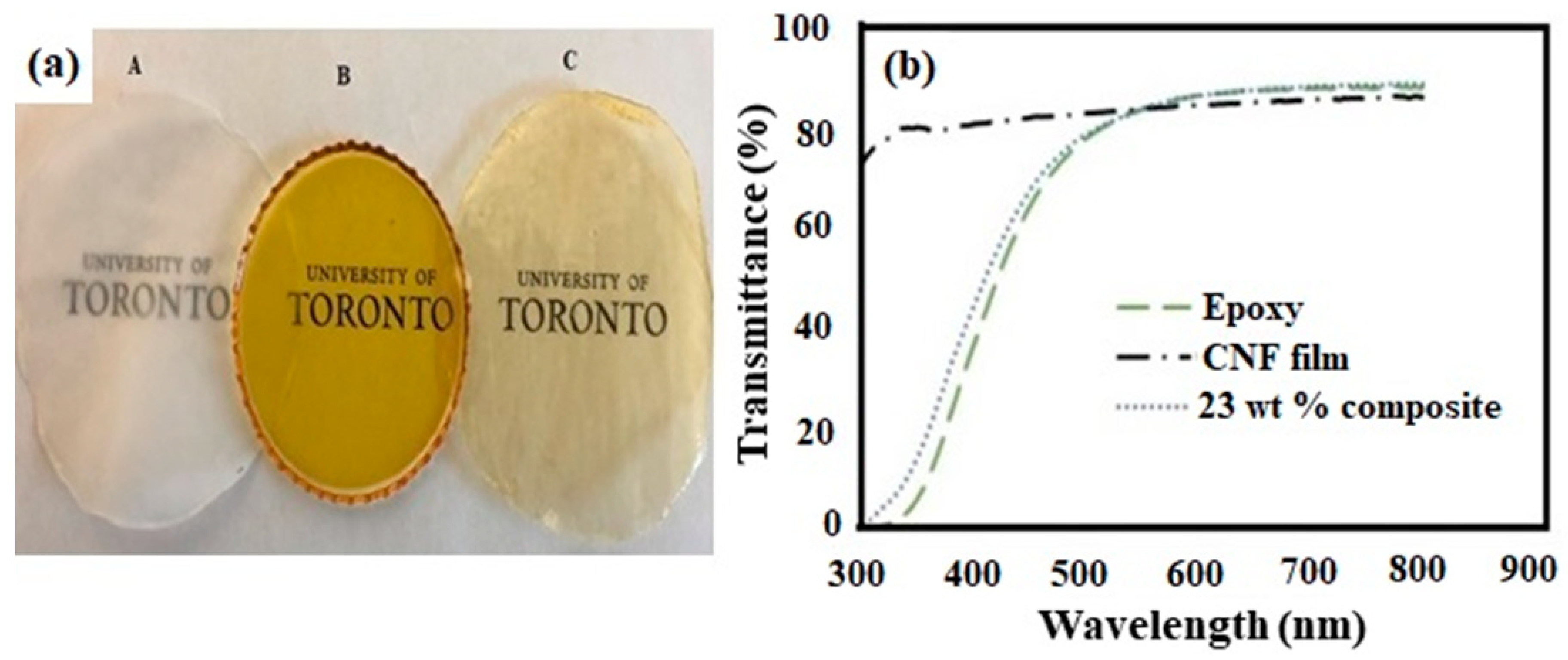

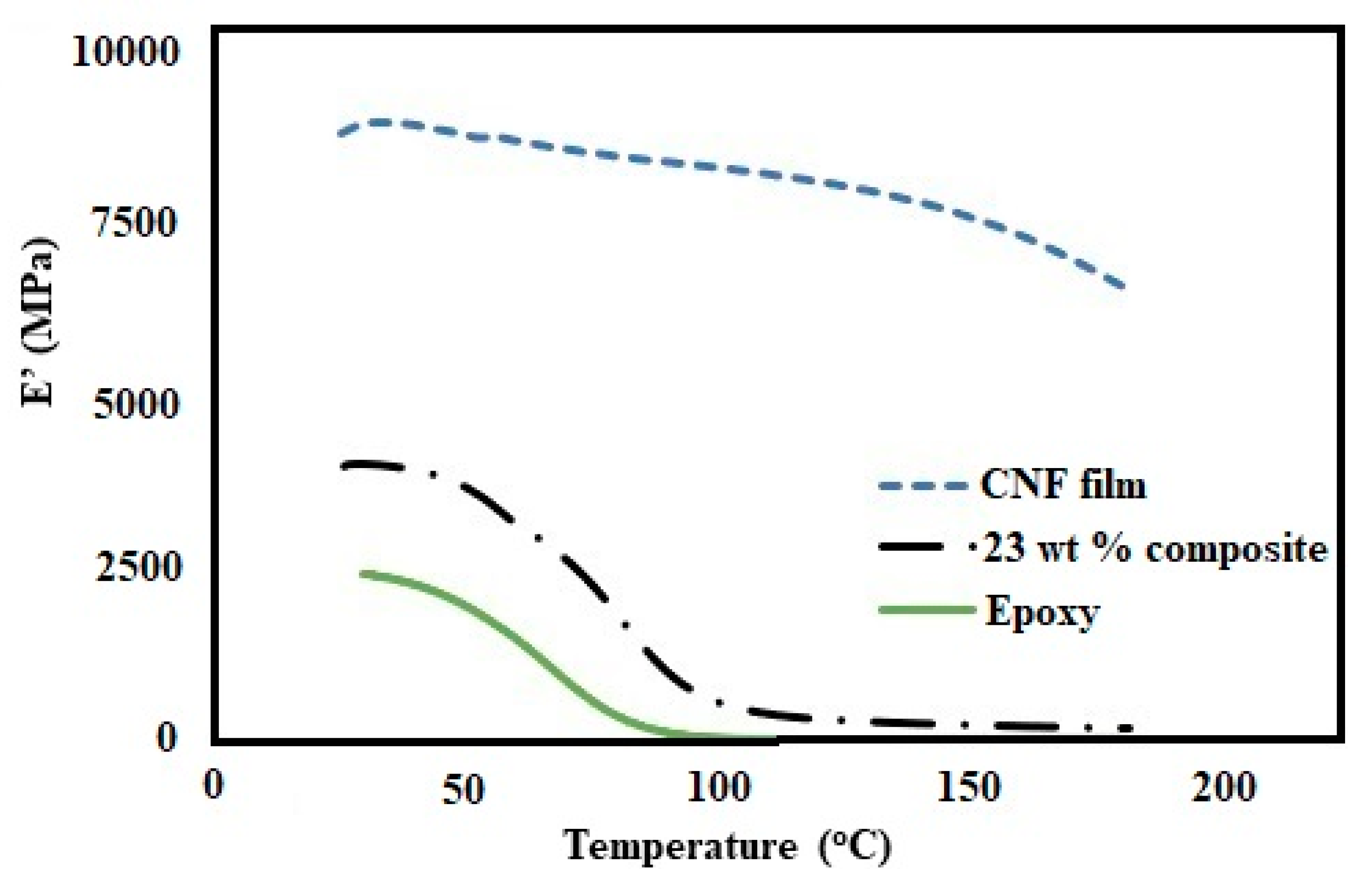

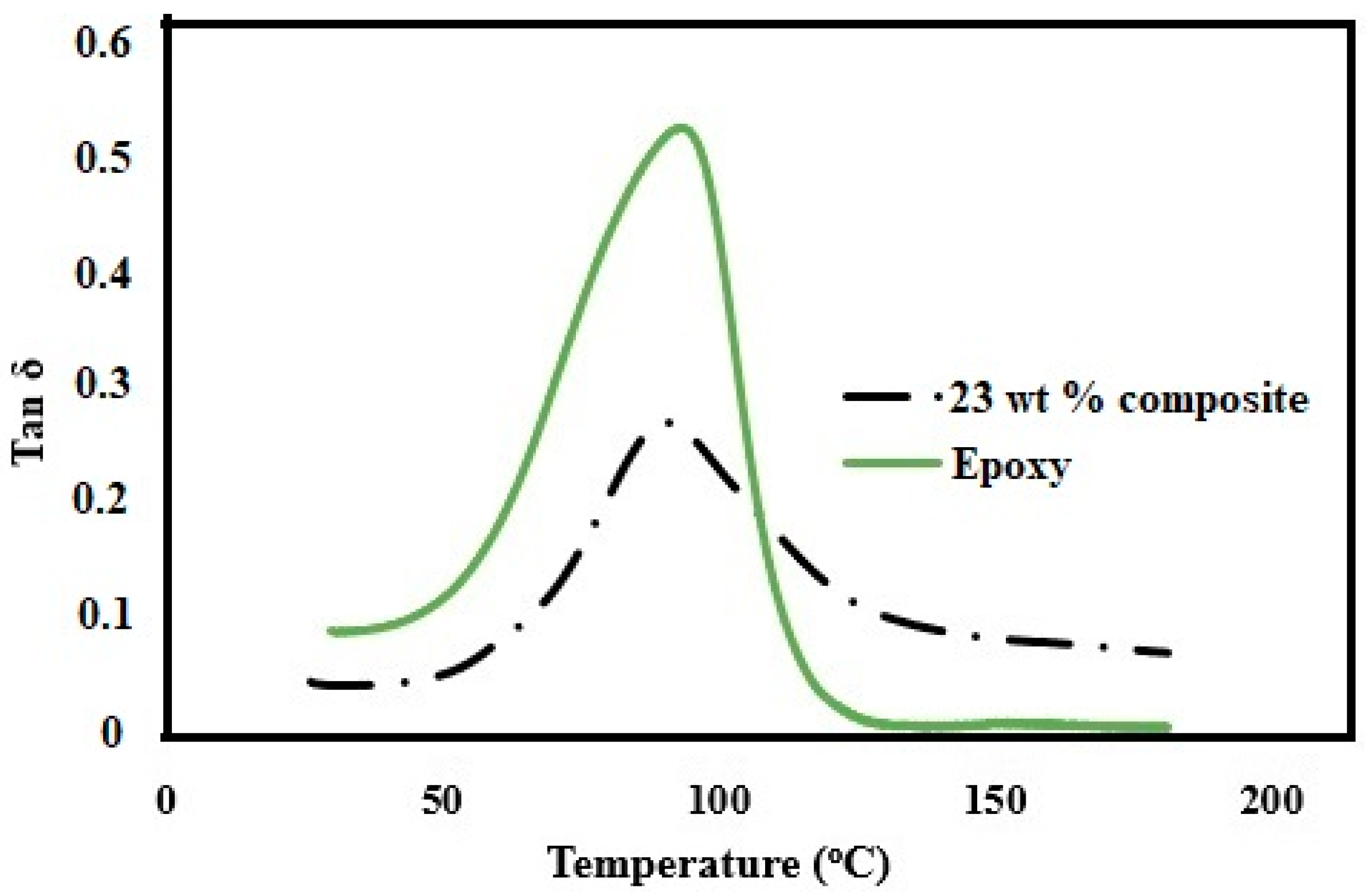

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Auvergne, R.; Caillol, S.; David, G.; Boutevin, B.; Pascault, J.P. Biobased thermosetting epoxy: Present and future. Chem. Rev. 2014, 114, 1082–1115. [Google Scholar] [CrossRef] [PubMed]

- Roudsari, G.M.; Mohanty, A.K.; Misra, M. Green Approaches to Engineer Tough Biobased Epoxies: A Review. ACS Sustain. Chem. Eng. 2017, 5, 9528–9541. [Google Scholar] [CrossRef]

- Shen, L.; Haufe, J.; Patel, M.K. Product Overview and Market Projection of Emerging Bio-Based Plastics PRO-BIP 2009; Report for European Polysaccharide Network of Excellence (EPNOE) and European Bioplastics; European Polysaccharide Network of Excellence (EPNOE) and European Bioplastics: Utrecht, The Netherlands, 2009. [Google Scholar]

- Celikbag, Y.; Meadows, S.; Barde, M.; Adhikari, S.; Buschle-Diller, G.; Auad, M.L.; Via, B.K. Synthesis and characterization of bio-oil-based self-curing epoxy resin. Ind. Eng. Chem. Res. 2017, 57, 9389–9400. [Google Scholar] [CrossRef]

- Unnikrishnan, K.P.; Thachil, E.T. Toughening of epoxy resins. Des. Monomers Polym. 2006, 9, 129–152. [Google Scholar] [CrossRef]

- Day, R.; Lovell, P.; Pierre, D. Toughening of epoxy resins using particles prepared by emulsion polymerization: Effects of particle surface functionality, size and morphology on impact fracture properties. Polym. Int. 1997, 44, 288–299. [Google Scholar] [CrossRef]

- Kishi, H.; Uesawa, K.; Matsuda, S.; Murakami, A. Adhesive strength and mechanisms of epoxy resins toughened with pre-formed thermoplastic polymer particles. J. Adhes. Sci. Technol. 2005, 19, 1277–1290. [Google Scholar] [CrossRef]

- Spanoudakis, J.; Young, R.J. Crack propagation in a glass particle-filled epoxy resin. J. Mater. Sci. 1984, 19, 473–486. [Google Scholar] [CrossRef]

- Boogh, L.; Pettersson, B.; Månson, J.A.E. Dendritic hyperbranched polymers as tougheners for epoxy resins. Polymer 1999, 40, 2249–2261. [Google Scholar] [CrossRef]

- Könczöl, L.; Döll, W.; Buchholz, U.; Mülhaupt, R. Ultimate properties of epoxy resins modified with a polysiloxane–polycaprolactone block copolymer. J. Appl. Polym. Sci. 1994, 54, 815–826. [Google Scholar] [CrossRef]

- Bagheri, R.; Marouf, B.T.; Pearson, R.A. Rubber-toughened epoxies: A critical review. Polym. Rev. 2009, 49, 201–225. [Google Scholar] [CrossRef]

- Chen, M.C.; Hourston, D.J.; Sun, W.B. The morphology and fracture behaviour of a miscible epoxy resin-polyetherimide blend. Eur. Polym. J. 1995, 31, 199–201. [Google Scholar] [CrossRef]

- Mezzenga, R.; Boogh, L.; Månson, J.A.E. A review of dendritic hyperbranched polymer as modifiers in epoxy composites. Compos. Sci. Technol. 2001, 61, 787–795. [Google Scholar] [CrossRef]

- Miyagawa, H.; Misra, M.; Drzal, L.T.; Mohanty, A.K. Fracture toughness and impact strength of anhydride-cured biobased epoxy. Polym. Eng. Sci. 2005, 45, 487–495. [Google Scholar] [CrossRef]

- Kuo, P.Y.; de Assis Barrosb, L.; Yan, N.; Sain, M.; Qing, Y.; Wu, Y. Nanocellulose composites with enhanced interfacial compatibility and mechanical properties using a hybrid-toughened epoxy matrix. Carbohydr. Polym. 2017, 177, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Girouard, N.; Schueneman, G.; Shofner, M.L.; Meredith, J.C. Mechanical and thermal properties of waterborne epoxy composites containing cellulose nanocrystals. Polymer 2013, 54, 6589–6598. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose—Its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.P.S.A.; Bhat, A.H.; Yusra, A.F.I. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Spence, K.L.; Venditti, R.A.; Rojas, O.J.; Habibi, Y.; Pawlak, J.J. A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 2011, 18, 1097–1111. [Google Scholar] [CrossRef]

- Nair, S.S.; Zhu, J.Y.; Deng, Y.; Ragauskas, A.J. Characterization of cellulose nanofibrillation by micro grinding. J. Nanopart. Res. 2014, 16, 2349. [Google Scholar] [CrossRef]

- Saito, T.; Kuramae, R.; Wohlert, J.; Berglund, L.A.; Isogai, A. An ultrastrong nanofibrillar biomaterial: The strength of single cellulose nanofibrils revealed via sonication-induced fragmentation. Biomacromolecules 2013, 14, 248–253. [Google Scholar] [CrossRef] [PubMed]

- Matsuo, M.; Sawatari, C.; Iwai, Y.; Ozaki, F. Effect of Orientation Distribution and Crystallinity on the Measurement by x-ray Diffraction of the Crystal Lattice Moduli of Cellulose I and II. Macromolecules 1990, 23, 3266–3275. [Google Scholar] [CrossRef]

- Nair, S.S.; Kuo, P.-Y.; Chen, H.; Yan, N. Investigating the effect of lignin on the mechanical, thermal, and barrier properties of cellulose nanofibril reinforced epoxy composite. Ind. Crops Prod. 2017, 100, 208–217. [Google Scholar] [CrossRef]

- Chen, H.; Nair, S.S.; Chauhan, P.; Yan, N. Lignin containing cellulose nanofibril application in pMDI wood adhesives for drastically improved gap-filling properties with robust bondline interfaces. Chem. Eng. J. 2019, 360, 393–401. [Google Scholar] [CrossRef]

- Nair, S.S.; Chen, H.; Peng, Y.; Huang, Y.; Yan, N. Polylactic Acid Biocomposites Reinforced with Nanocellulose Fibrils with High Lignin Content for Improved Mechanical, Thermal, and Barrier Properties. ACS Sustain. Chem. Eng. 2018, 6, 10058–10068. [Google Scholar] [CrossRef]

- Teixeira, E.d.M.; Pasquini, D.; Curvelo, A.A.S.; Corradini, E.; Belgacem, M.N.; Dufresne, A. Cassava bagasse cellulose nanofibrils reinforced thermoplastic cassava starch. Carbohydr. Polym. 2009, 78, 422–431. [Google Scholar] [CrossRef]

- Nair, S.S.; Zhu, J.; Deng, Y.; Ragauskas, A.J. High performance green barriers based on nanocellulose. Sustain. Chem. Process. 2014, 2, 1–7. [Google Scholar] [CrossRef]

- Ansari, F.; Galland, S.; Johansson, M.; Plummer, C.J.G.; Berglund, L.A. Cellulose nanofiber network for moisture stable, strong and ductile biocomposites and increased epoxy curing rate. Compos. Part A Appl. Sci. Manuf. 2014, 63, 35–44. [Google Scholar] [CrossRef]

- Lee, K.Y.; Tammelin, T.; Schulfter, K.; Kiiskinen, H.; Samela, J.; Bismarck, A. High performance cellulose nanocomposites: Comparing the reinforcing ability of bacterial cellulose and nanofibrillated cellulose. ACS Appl. Mater. Interfaces 2012, 4, 4078–4086. [Google Scholar] [CrossRef]

- Lu, J.; Askeland, P.; Drzal, L.T. Surface modification of microfibrillated cellulose for epoxy composite applications. Polymer 2008, 49, 1285–1296. [Google Scholar] [CrossRef]

- Nair, S.S.; Wang, S.; Hurley, D.C. Nanoscale characterization of natural fibers and their composites using contact-resonance force microscopy. Compos. Part A Appl. Sci. Manuf. 2010, 41, 624–631. [Google Scholar] [CrossRef]

- Bruce, D.M.; Hobson, R.N.; Farrent, J.W.; Hepworth, D.G. High-performance composites from low-cost plant primary cell walls. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1486–1493. [Google Scholar] [CrossRef]

- Asadi, A.; Miller, M.; Moon, R.J.; Kalaitzidou, K. Improving the Interfacial and Mechanical Properties of Short Glass fiber/Epoxy Composites by Coating the Glass Fibers with Cellulose Nanocrystals. Express Polym. Lett. 2016, 10, 587–597. [Google Scholar] [CrossRef]

- Miwa, M.; Ohsawa, T.; Tahara, K. Effects of Fiber Length on the Tensile Strength of Epoxy-Glass Fiber and Polyester-Glass Fiber Composites. J. Appl. Polym. Sci. 1980, 25, 795–807. [Google Scholar] [CrossRef]

- Karumuri, S.; Hiziroglu, S.; Kalkan, A.K. Thermoset-cross-linked lignocellulose: A moldable plant biomass. ACS Appl. Mater. Interfaces 2015, 7, 6596–6604. [Google Scholar] [CrossRef]

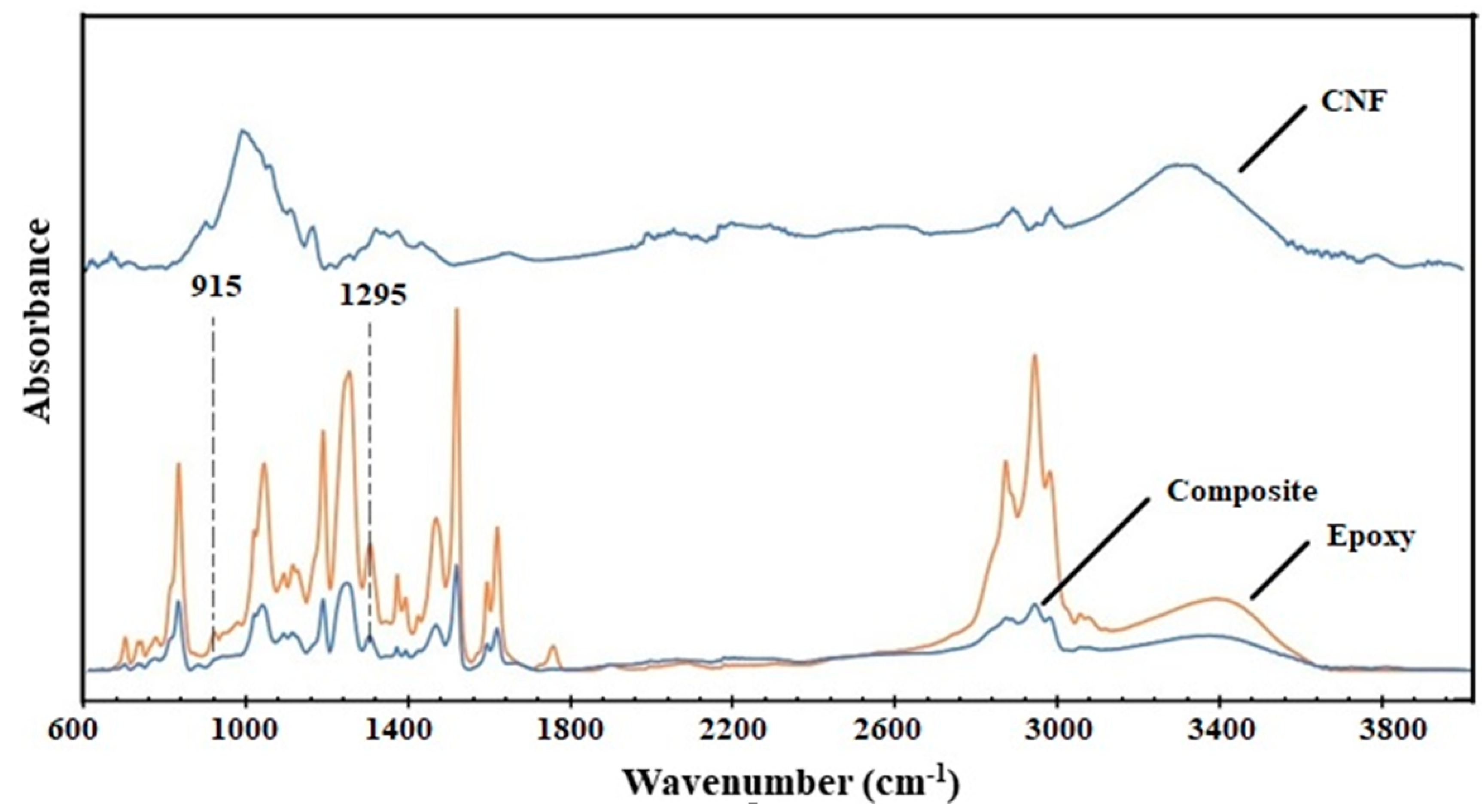

- Pandey, K.K. A study of chemical structure of soft and harwood and wood polymers by FTIR spectrscopy. J. Appl. Polym. Sci. 1999, 71, 1969–1975. [Google Scholar] [CrossRef]

- Varma, A.J.; Jamdade, Y.K.; Nadkarni, V.M. Curing Characteristics of Epoxy-Resins Filled with Cellulose and Oxidized Cellulose. Angew. Makromol. Chem. 1984, 122, 211–218. [Google Scholar] [CrossRef]

- Mertzel, E.; Koenig, J. Application of FT-IR and NMR to epoxy resins. In Epoxy Resins and Composites II; Springer: Berlin, Germany, 1986; pp. 73–112. [Google Scholar]

- Kuo, P.Y.; Yan, N.; Sain, M. Influence of cellulose nanofibers on the curing behavior of epoxy/amine systems. Eur. Polym. J. 2013, 49, 3778–3787. [Google Scholar] [CrossRef]

- Partansky, A.M. A study of accelerators for epoxy-amine condensation reaction. Adv. Chem. 1970, 92, 29–47. [Google Scholar]

- Abe, K.; Iwamoto, S.; Yano, H. Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 2007, 8, 3276–3278. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Forte, M.M.C.; Santana, R.M.C. Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour. Technol. 2012, 109, 148–153. [Google Scholar] [CrossRef]

- Yasuda, H.; Stannett, V. Permeation, solution, and diffusion of water in some high polymers. J. Polym. Sci. 1962, 57, 907. [Google Scholar] [CrossRef]

- Soles, C.L.; Yee, A.F. Discussion of the molecular mechanisms of moisture transport in epoxy resins. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 792–802. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Sorrentino, A.; Raimondo, M.; Naddeo, C.; Vittoria, V.; Iannuzzo, G.; Calvi, E.; Russo, S. Mechanical and barrier properties of epoxy resin filled with multi-walled carbon nanotubes. Carbon 2009, 47, 2419–2430. [Google Scholar] [CrossRef]

- Sangermano, M.; Periolatto, M.; Signore, V.; Russo Spena, P. Improvement of the water-vapor barrier properties of an uv-cured epoxy coating containing graphite oxide nanoplatelets. Prog. Org. Coat. 2017, 103, 152–155. [Google Scholar] [CrossRef]

- Steven, M.D.; Hotchkiss, J.H. Comparison of flat film to total package water vapour transmission rates for several commercial food wraps. Packag. Technol. Sci. 2002, 15, 17–27. [Google Scholar] [CrossRef]

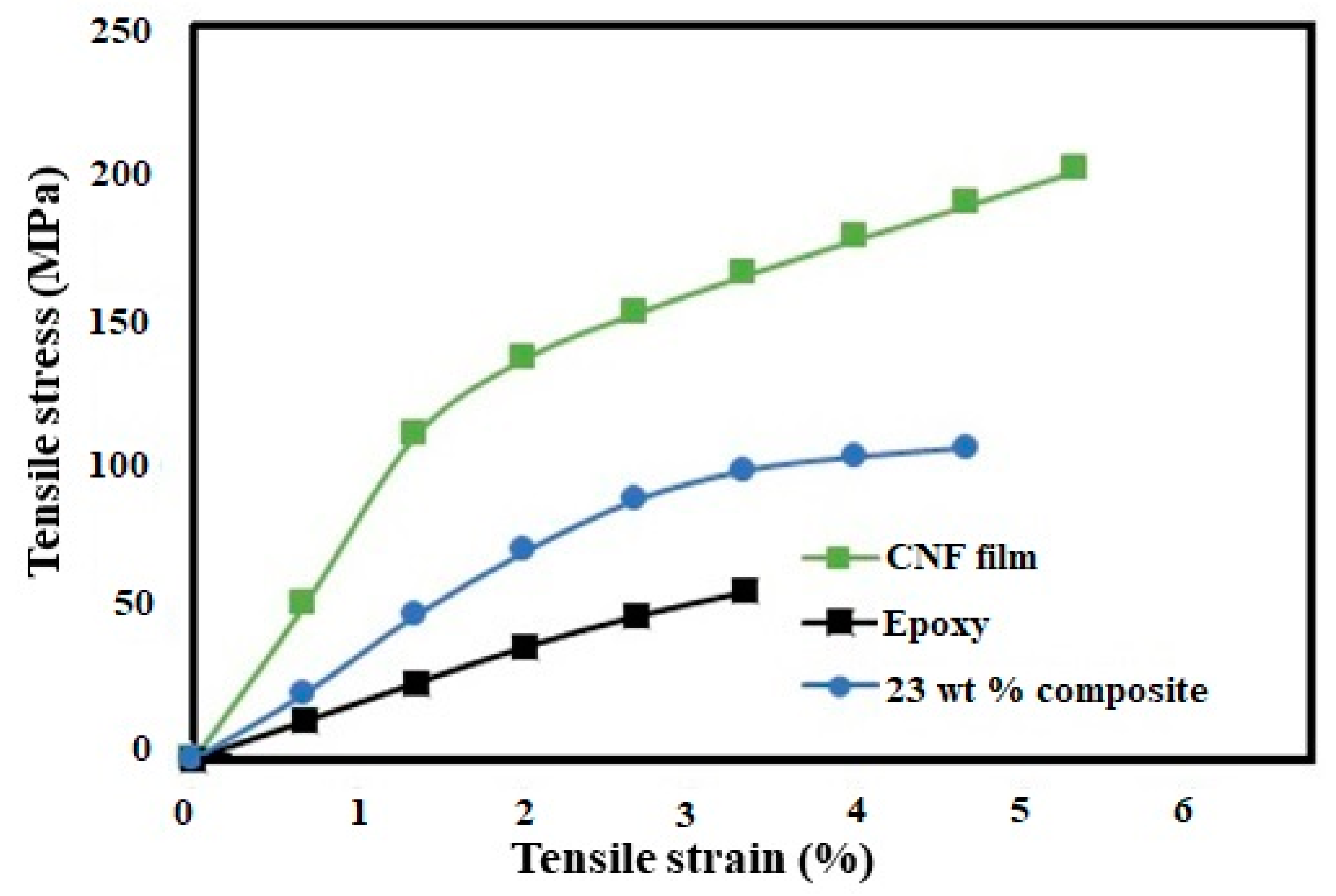

| Sample | Tensile Strength (MPa) | Tensile Modulus (GPa) | Tensile Strain (%) | Strain Energy Density (MPa) |

|---|---|---|---|---|

| Pure CNF film | 220 ± 21.7 | 7.7 ± 0.85 | 5.0 ± 0.47 | 7.53 ± 0.4 |

| Epoxy | 62.5 ± 5.86 | 2.28 ± 0.41 | 2.92 ± 0.33 | 0.98 ± 0.06 |

| Composite (18–23 wt % CNF) | 108.5 ± 8.43 | 3.56 ± 0.28 | 4.81 ± 1.04 | 2.79 ± 0.49 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nair, S.S.; Dartiailh, C.; Levin, D.B.; Yan, N. Highly Toughened and Transparent Biobased Epoxy Composites Reinforced with Cellulose Nanofibrils. Polymers 2019, 11, 612. https://doi.org/10.3390/polym11040612

Nair SS, Dartiailh C, Levin DB, Yan N. Highly Toughened and Transparent Biobased Epoxy Composites Reinforced with Cellulose Nanofibrils. Polymers. 2019; 11(4):612. https://doi.org/10.3390/polym11040612

Chicago/Turabian StyleNair, Sandeep S., Christopher Dartiailh, David B. Levin, and Ning Yan. 2019. "Highly Toughened and Transparent Biobased Epoxy Composites Reinforced with Cellulose Nanofibrils" Polymers 11, no. 4: 612. https://doi.org/10.3390/polym11040612

APA StyleNair, S. S., Dartiailh, C., Levin, D. B., & Yan, N. (2019). Highly Toughened and Transparent Biobased Epoxy Composites Reinforced with Cellulose Nanofibrils. Polymers, 11(4), 612. https://doi.org/10.3390/polym11040612