Electrospun Combination of Peppermint Oil and Copper Sulphate with Conducive Physico-Chemical properties for Wound Dressing Applications

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of PU, Composite Solution and Electrospinning process

2.3. Morphological and Structural Characterization

2.4. Mechanical Characterization

2.5. Coagulation Assays

2.5.1. Activated Partial Thromboplastin Time (APTT) and Prothrombin Time (PT) Assay

2.5.2. Hemolysis Assay

2.6. Characterization of In Vitro Biocompatibility

2.7. Statistical Analysis

3. Result and discussion

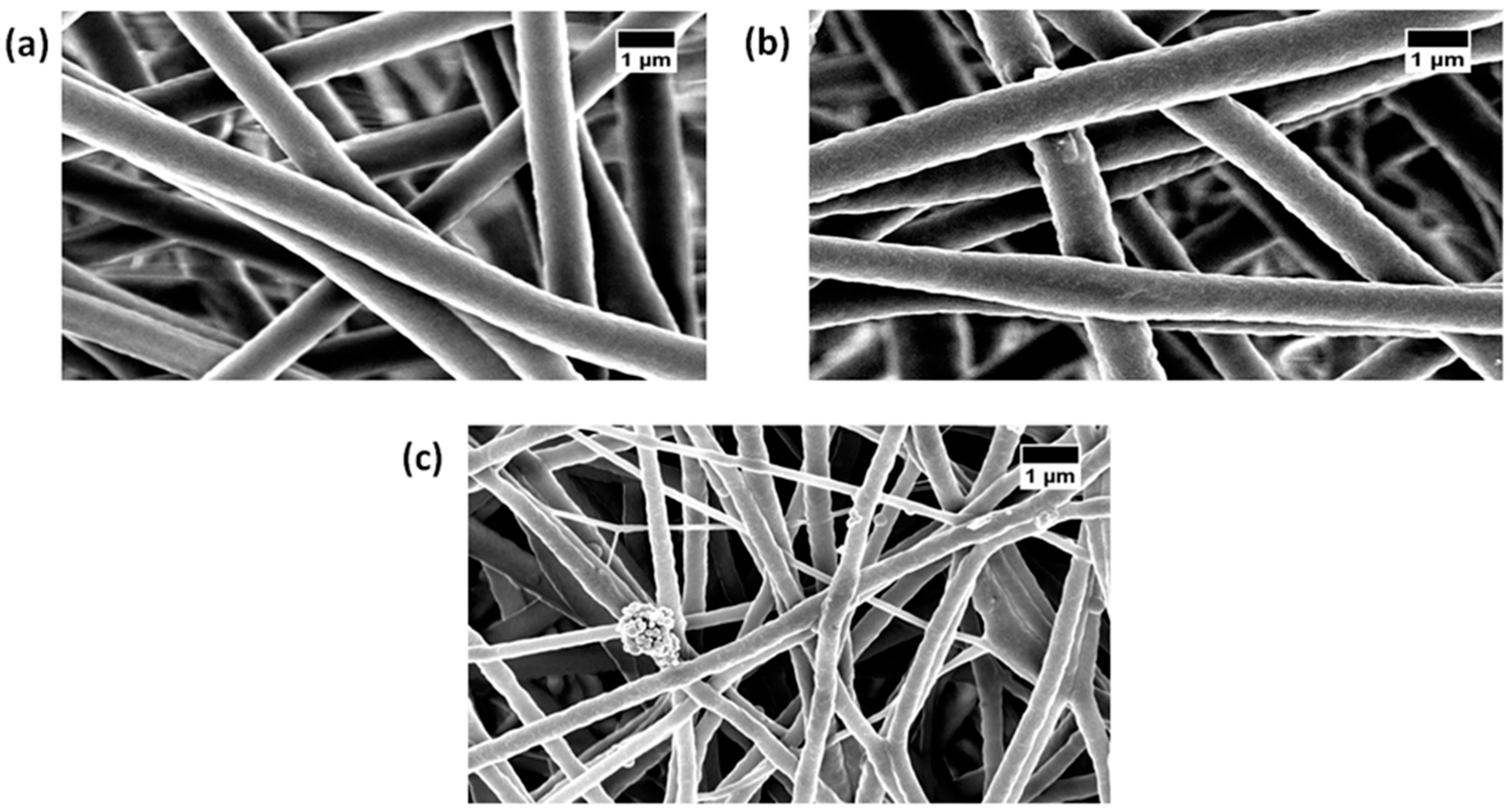

3.1. FESEM Investigation

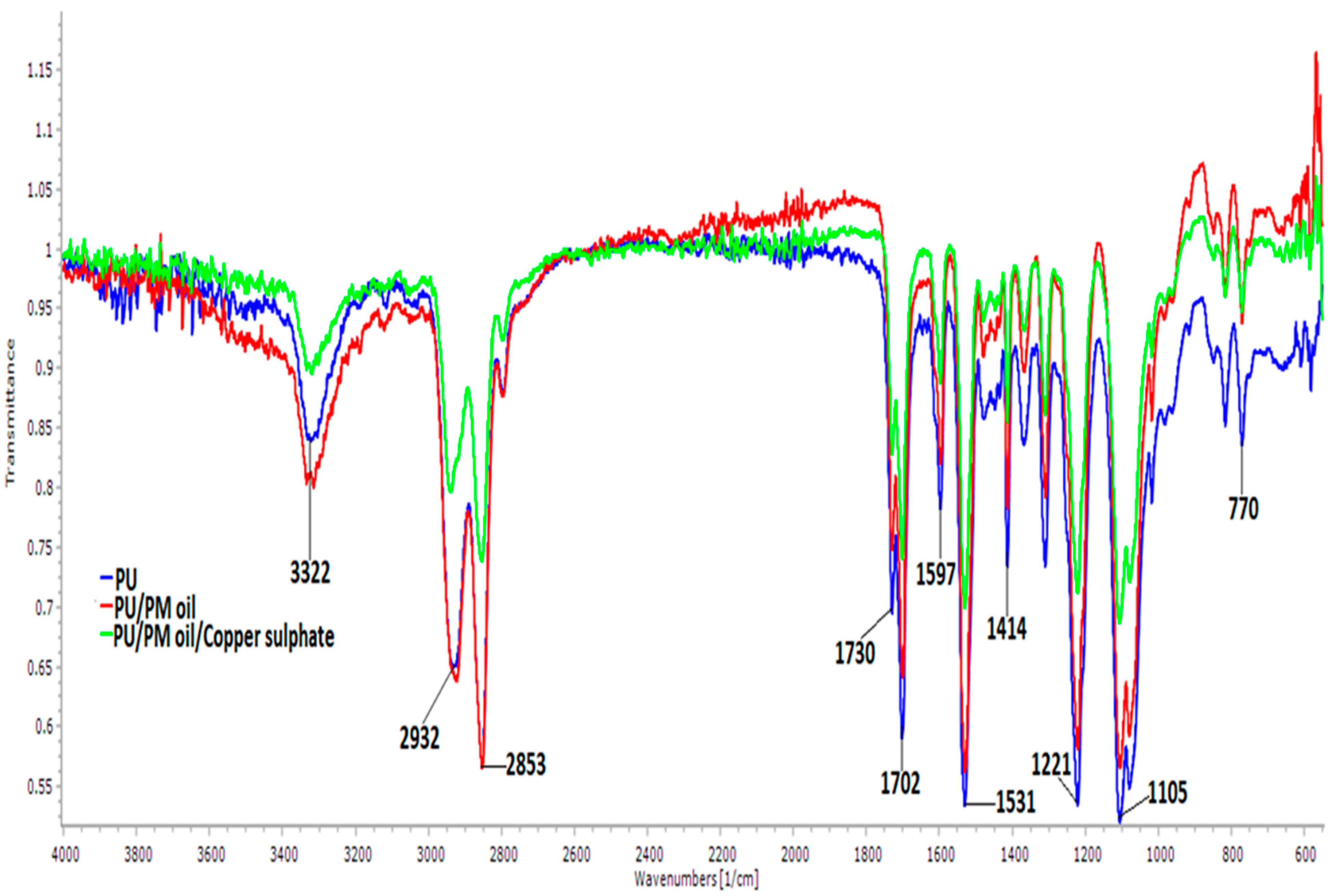

3.2. FTIR Analysis

3.3. Wettability Measurements

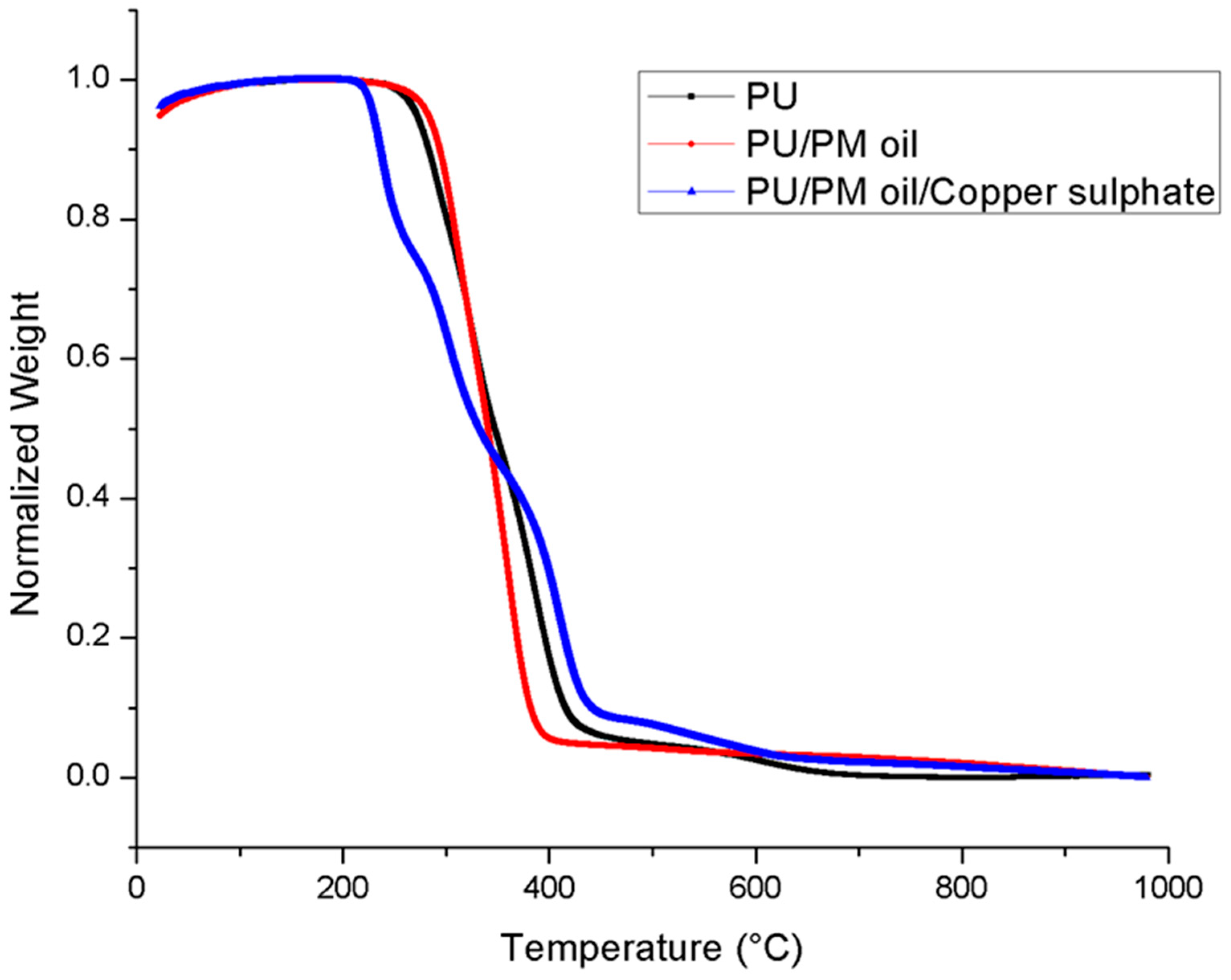

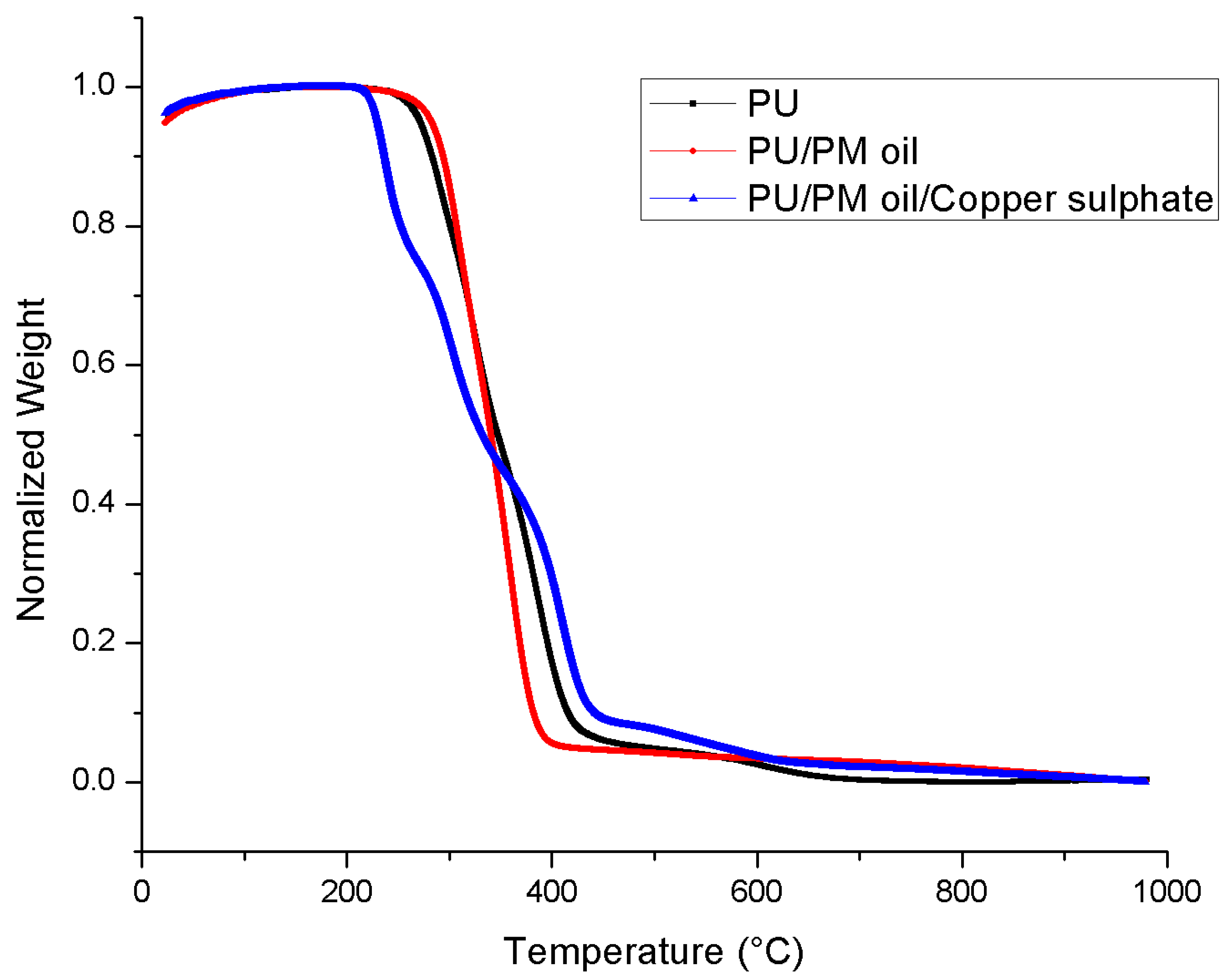

3.4. TGA Analysis

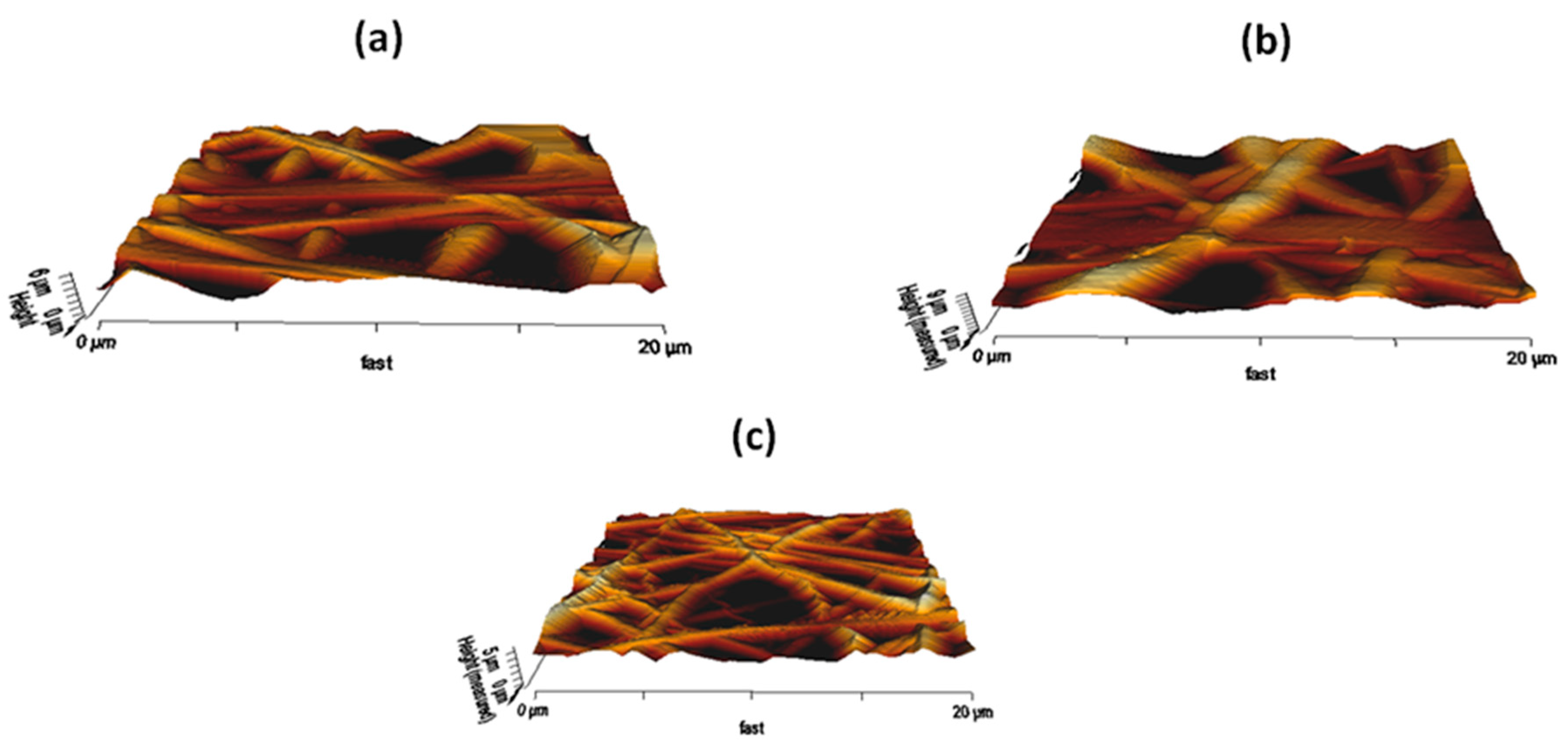

3.5. AFM Analysis

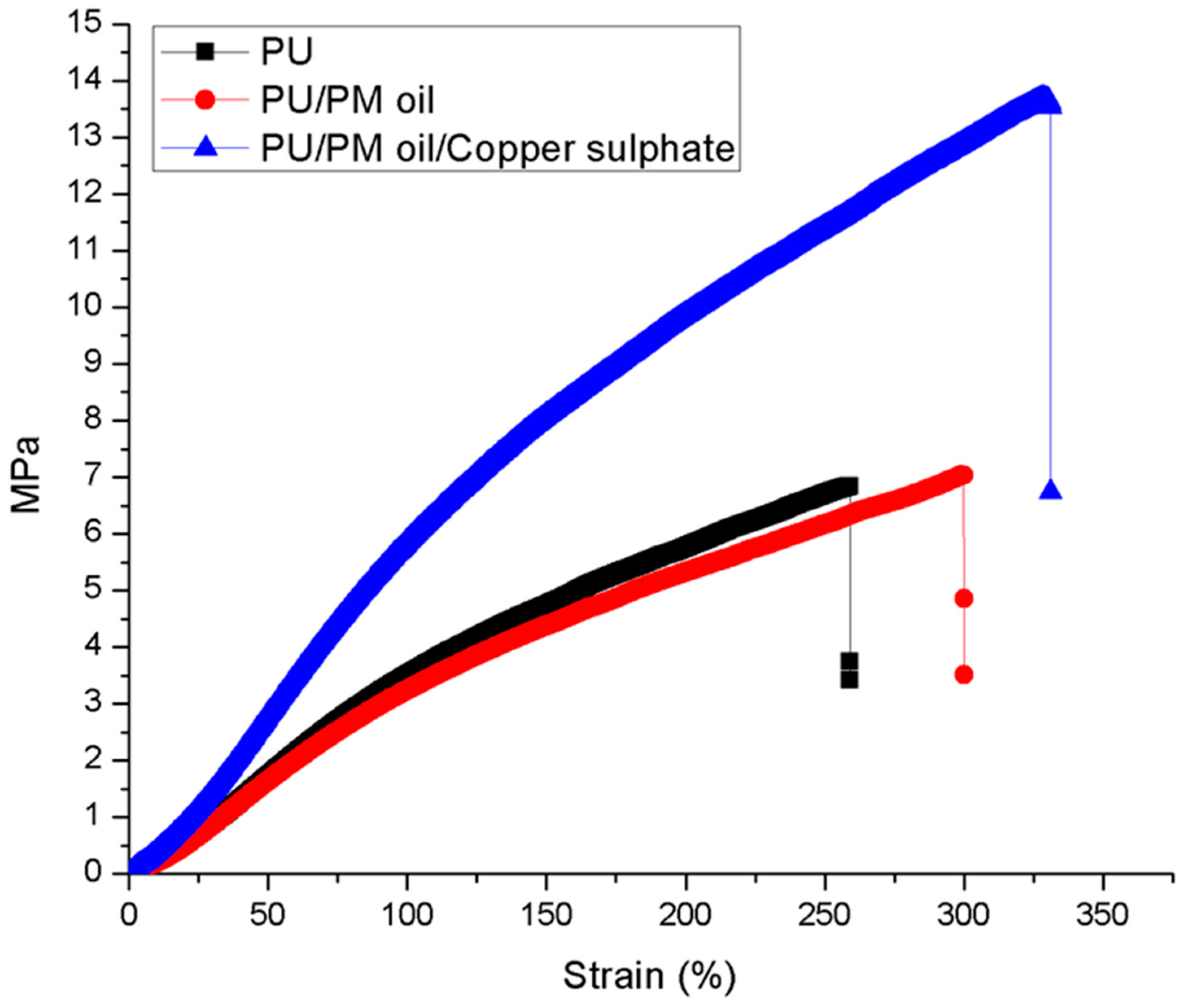

3.6. Tensile Testing

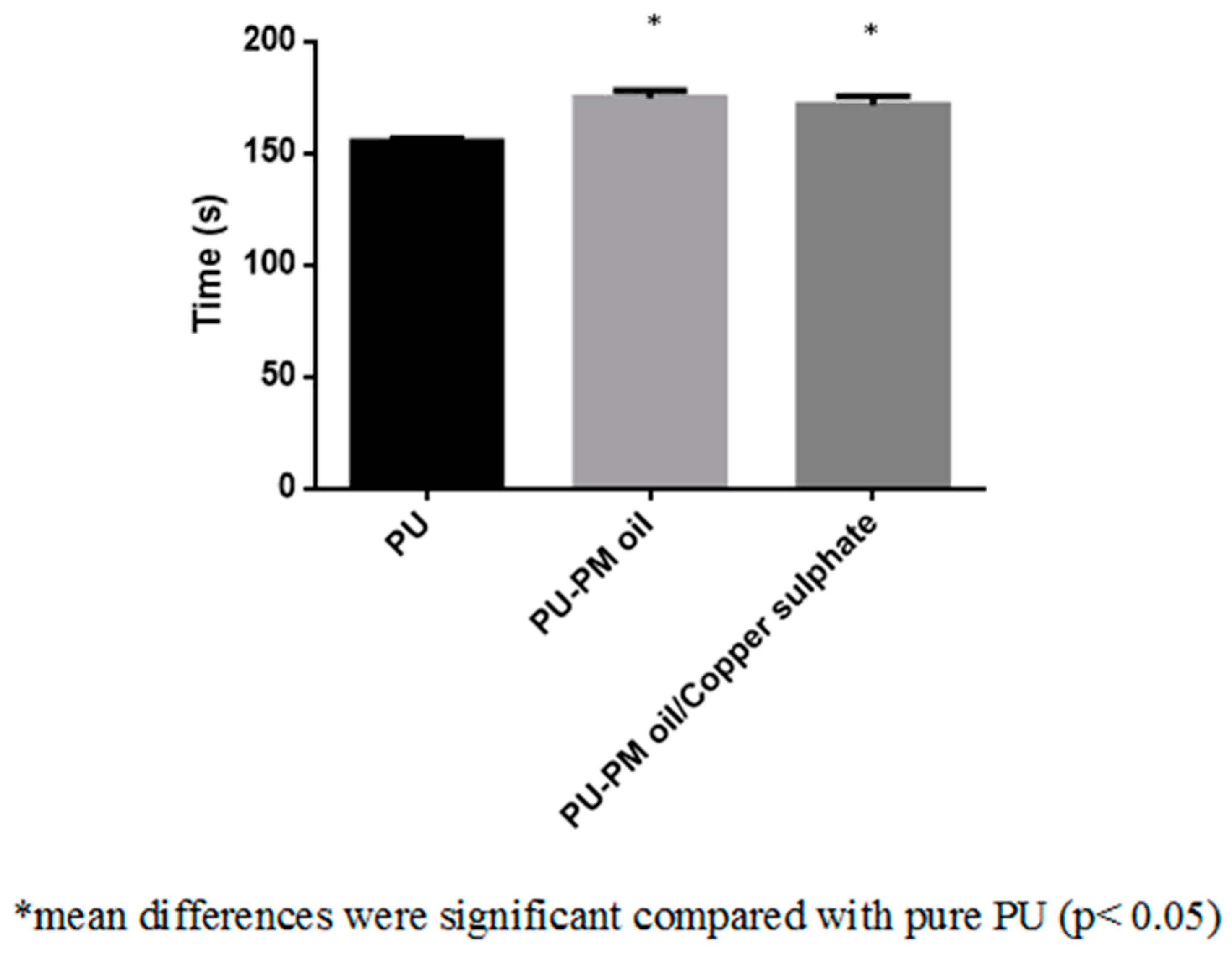

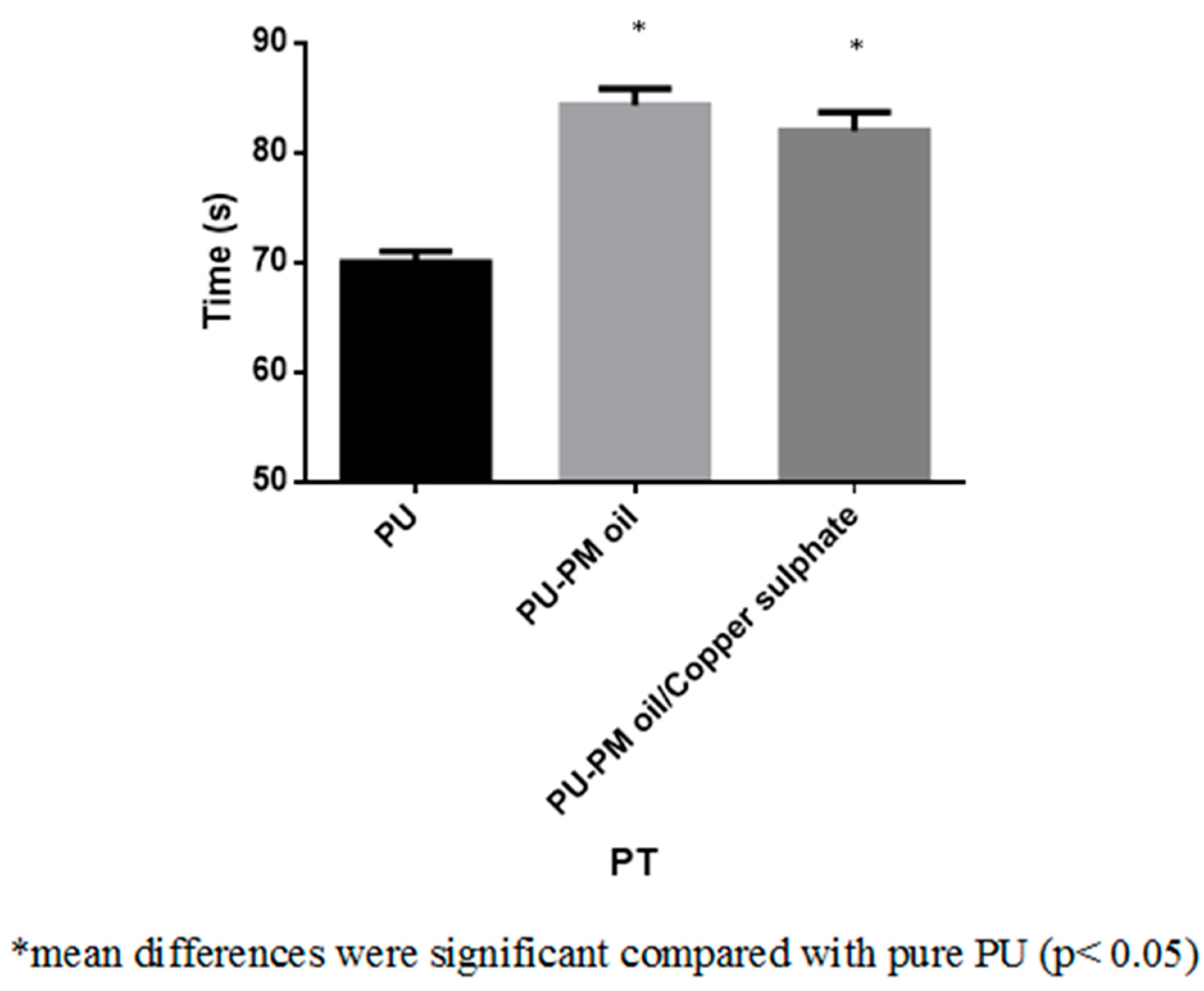

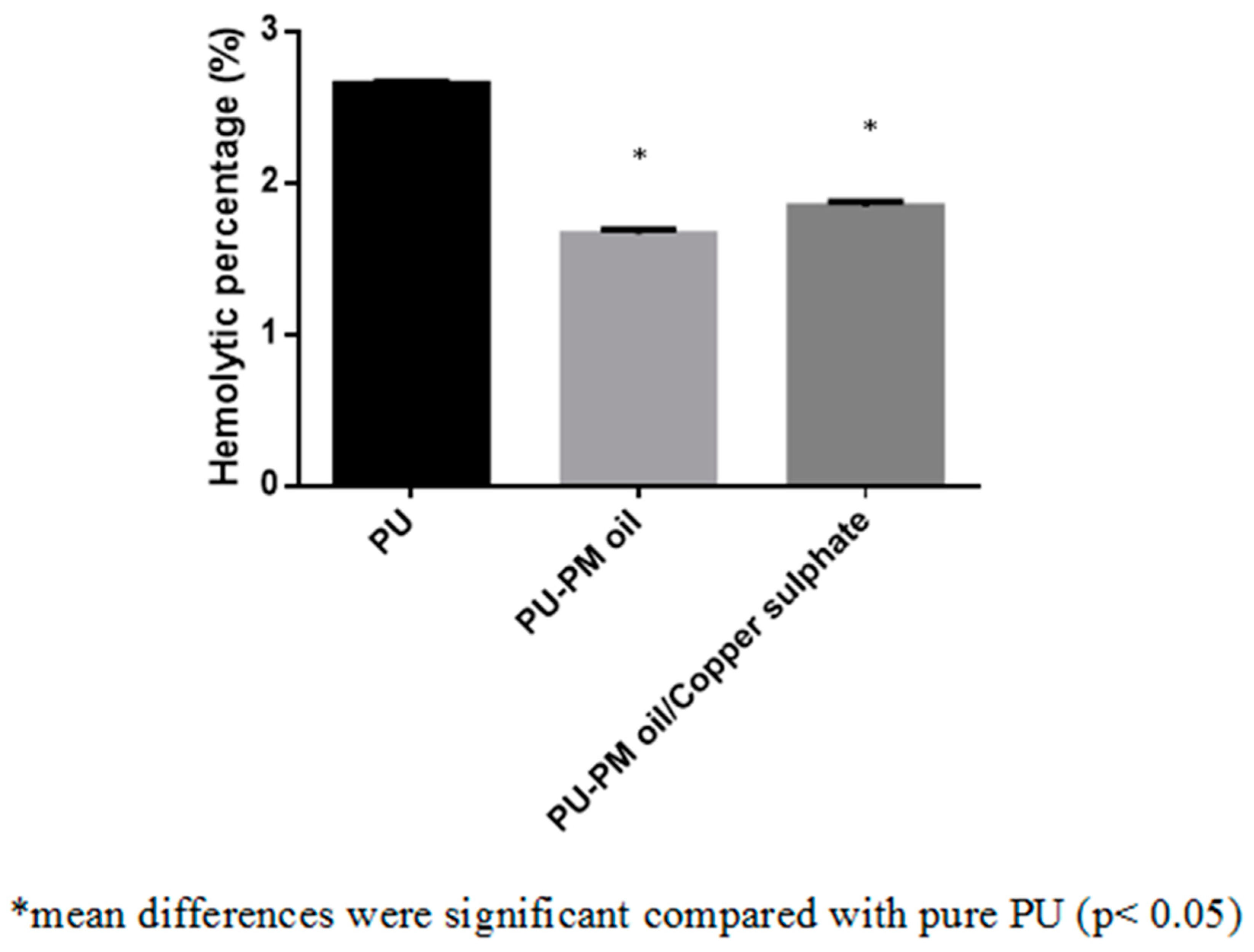

3.7. Blood Compatibility Measurements

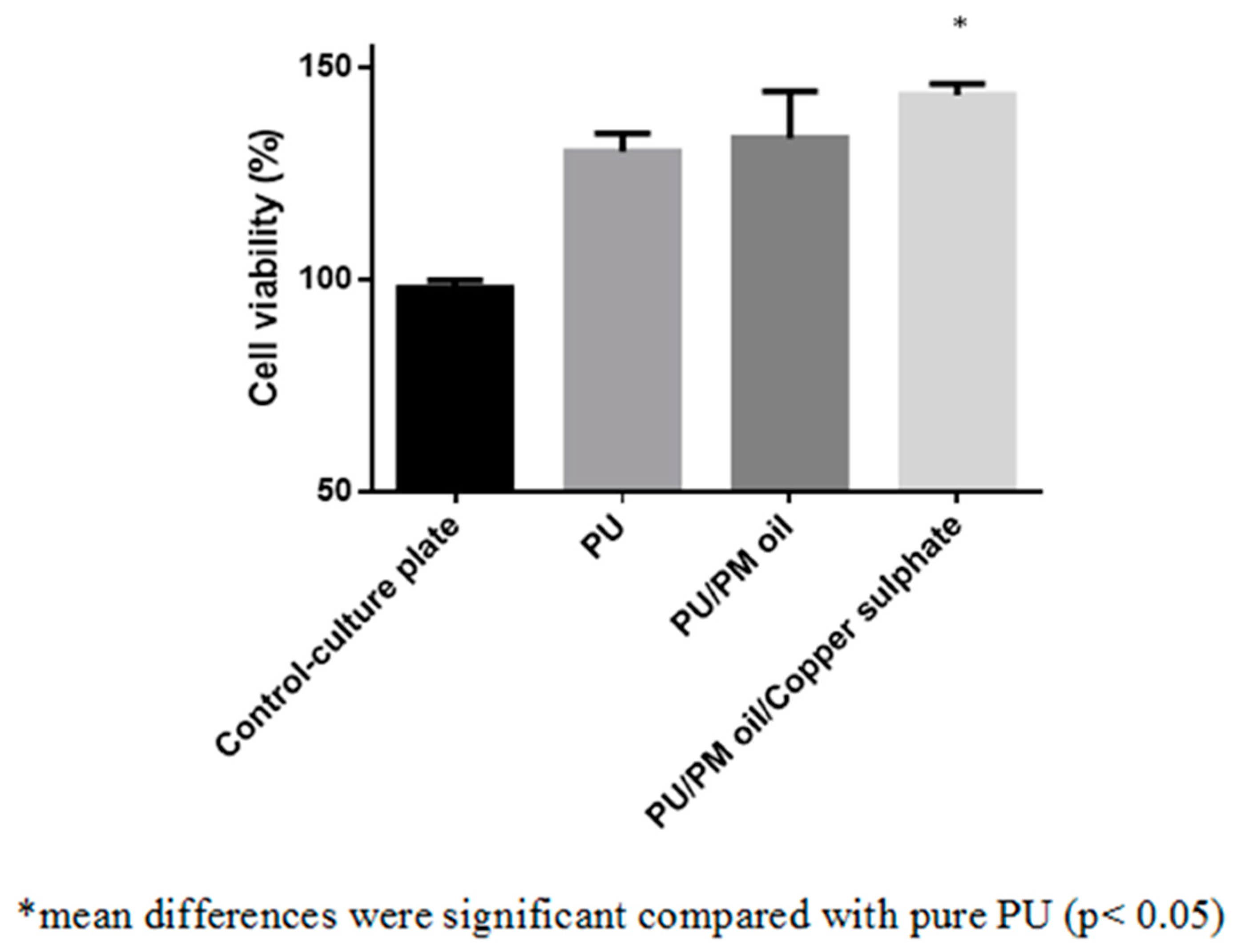

3.8. Cytocompatibility Measurements

4. Conclusion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, X.; Wang, C.; Yang, S.; Liu, P.; Zhang, B. Electrospun Pcl/mupirocin and chitosan/lidocaine hydrochloride multifunctional double layer nanofibrous scaffolds for wound dressing applications. Int. J. Nanomed. 2018, 13, 5287. [Google Scholar] [CrossRef] [PubMed]

- Dhivya, S.; Padma, V.V.; Santhini, E. Wound dressings—A review. Bio Med. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhao, R.; Wang, X.; Li, X.; Peng, F.; Jin, Z.; Gao, X.; Yu, J.; Wang, C. Electrospun mupirocin loaded polyurethane fiber mats for anti-infection burn wound dressing application. J. Biomater. Sci. Polym. 2017, 28, 162–176. [Google Scholar] [CrossRef] [PubMed]

- Yildirimer, L.; Thanh, N.T.; Seifalian, A.M. Skin regeneration scaffolds: A multimodal bottom-up approach. Trends Biotechnol. 2012, 30, 638–648. [Google Scholar] [CrossRef]

- Fu, K.; Lu, Y.; Dirican, M.; Chen, C.; Yanilmaz, M.; Shi, Q.; Bradford, P.D.; Zhang, X. Chamber-confined silicon–carbon nanofiber composites for prolonged cycling life of Li-ion batteries. Nanoscale 2014, 6, 7489–7495. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; He, X.; Zhang, W.; Zhang, X.; Lu, C. In situ synthesis of MnO2 coated cellulose nanofibers hybrid for effective removal of methylene blue. Carbohydr. Polym. 2014, 110, 302–308. [Google Scholar] [CrossRef]

- Lim, C.T. Nanofiber technology: Current status and emerging developments. Prog. Polym. Sci. 2017, 1, 70:1–70:7. [Google Scholar]

- Rasouli, R.; Barhoum, A.; Bechelany, M.; Dufresne, A. Nanofibers for Biomedical and Healthcare Applications. Macromol. Biosci. 2018, 28, 1800256. [Google Scholar] [CrossRef]

- Ali, I.H.; Khalil, I.A.; El-Sherbiny, I.M. Single-dose electrospun nanoparticles-in-nanofibers wound dressings with enhanced epithelialization; collagen deposition, and granulation Properties. ACS Appl. Mater. Interface 2016, 8, 14453–14469. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, S.; Wendorff, J.H.; Greiner, A. Use of electrospinning technique for biomedical applications. Polymer 2008, 49, 5603–5621. [Google Scholar] [CrossRef]

- Rnjak-Kovacina, J.; Weiss, A.S. Increasing the pore size of electrospun scaffolds. Tissue Eng. Part B Rev. 2011, 17, 365–372. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Si, N.; Xu, L.; Liu, H. Effect of flow rate on diameter of electrospun nanoporous fibers. Therm. Sci. 2014, 18, 1447–1449. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, X.; Wu, L.; Han, Y.; Sheng, J. Study on morphology of electrospun poly (vinyl alcohol) mats. Eur. Polym. J. 2005, 41, 423–432. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, Y.; Dong, C.; Sheng, J. Morphology of ultrafine polysulfone fibers prepared by electrospinning. Polym. Int. 2004, 53, 1704–1710. [Google Scholar] [CrossRef]

- Tarus, B.; Fadel, N.; Al-Oufy, A.; El-Messiry, M. Effect of polymer concentration on the morphology and mechanical characteristics of electrospun cellulose acetate and poly (vinyl chloride) nanofiber mats. Alex. Eng. J. 2016, 55, 2975–2984. [Google Scholar] [CrossRef]

- Abrigo, M.; McArthur, S.L.; Kingshott, P. Electrospun nanofibers as dressings for chronic wound care: Advances, challenges, and future prospects. Macromol. Biosci. 2014, 14, 772–792. [Google Scholar] [CrossRef] [PubMed]

- Tecoflex™ TPU - Lubrizol. Available online: https://www.lubrizol.com/Life-Sciences/products/Tecoflex-TPU (accessed on 13 March 2019).

- Jaganathan, S.K.; Mani, M.P.; Palaniappan, S.K.; Rathanasamy, R. Fabrication and characterisation of nanofibrous polyurethane scaffold incorporated with corn and neem oil using single stage electrospinning technique for bone tissue engineering applications. J. Polym. Res. 2018, 25, 146. [Google Scholar] [CrossRef]

- Detta, N.; Errico, C.; Dinucci, D.; Puppi, D.; Clarke, D.A.; Reilly, G.C.; Chiellini, F. Novel electrospun polyurethane/gelatin composite meshes for vascular grafts. J. Mater. Sci. Mater. Med. 2010, 21, 1761–1769. [Google Scholar] [CrossRef]

- Unnithan, A.R.; Pichiah, P.T.; Gnanasekaran, G.; Seenivasan, K.; Barakat, N.A.; Cha, Y.S.; Jung, C.H.; Shanmugam, A.; Kim, H.Y. Emu oil-based electrospun nanofibrous scaffolds for wound skin tissue engineering. Colloids. Surf. A Phys. Eng. Asp. 2012, 415, 454–460. [Google Scholar] [CrossRef]

- Chao, C.Y.; Mani, M.P.; Jaganathan, S.K. Engineering electrospun multicomponent polyurethane scaffolding platform comprising grapeseed oil and honey/propolis for bone tissue regeneration. PLoS ONE 2018, 13, e0205699. [Google Scholar] [CrossRef]

- Singh, R.; Shushni, M.A.; Belkheir, A. Antibacterial and antioxidant activities of Mentha piperita L. Arab. J. Chem. 2015, 8, 322–328. [Google Scholar] [CrossRef]

- Karuza, L.; Blazevic, N.; Soljic, Z. Isolation and structure of flavonoids from peppermint (Mentha piperita) leaves. Acta Pharm. 1996, 46, 315–320. [Google Scholar]

- Shimada, K.; Fujikawa, K.; Yahara, K.; Nakamura, T. Antioxidative properties of xanthan on the autooxidation of soybean oil in cyclodextrin. J. Agric. Food Chem. 1992, 40, 945–948. [Google Scholar] [CrossRef]

- Sokovic, M.D.; Vukojevic, J.; Marin, P.D.; Brkic, D.D.; Vajs, V.; van Griensven, L.J.L.D. Chemical composition of essential oils of Thymus and Mentha species and their antifungal activities. Molecules 2009, 14, 238–249. [Google Scholar] [CrossRef]

- Grigore, A. Plant phenolic compounds as immunomodulatory agents. In Phenolic Compounds-Biological Activity; InTech: London, UK, 2017. [Google Scholar]

- Zhang, Y.J.; Gan, R.Y.; Li, S.; Zhou, Y.; Li, A.N.; Xu, D.P.; Li, H.B. Antioxidant phytochemicals for the prevention and treatment of chronic diseases. Molecules 2015, 20, 21138–21156. [Google Scholar] [CrossRef] [PubMed]

- Amna, T.; Hassan, M.S.; Yang, J.; Khil, M.S.; Song, K.D.; Oh, J.D.; Hwang, I. Virgin olive oil blended polyurethane micro/nanofibers ornamented with copper oxide nanocrystals for biomedical applications. Int. J. Nanomed. 2014, 9, 891. [Google Scholar] [CrossRef] [PubMed]

- Jaganathan, S.K.; Mani, M.P. Electrospun polyurethane nanofibrous composite impregnated with metallic copper for wound-healing application. 3 Biotech 2018, 8, 327. [Google Scholar] [CrossRef] [PubMed]

- Jaganathan, S.K.; Mani, M.P. Single-stage synthesis of electrospun polyurethane scaffold impregnated with zinc nitrate nanofibers for wound healing applications. J. Appl. Polym. Sci. 2019, 136, 46942. [Google Scholar] [CrossRef]

- Kim, H.H.; Kim, M.J.; Ryu, S.J.; Ki, C.S.; Park, Y.H. Effect of fiber diameter on surface morphology, mechanical property, and cell behavior of electrospun poly (ε-caprolactone) mat. Fibers Polym. 2016, 17, 1033–1042. [Google Scholar] [CrossRef]

- Chou, S.H.; Don, T.M.; Lai, W.C.; Cheng, L.P. Formation of microporous poly (hydroxybutyric acid) membranes for culture of osteoblast and fibroblast. Polym. Adv. Technol. 2009, 20, 1082–1090. [Google Scholar]

- Sharifi, F.; Irani, S.; Zandi, M.; Soleimani, M.; Atyabi, S.M. Comparative of fibroblast and osteoblast cells adhesion on surface modified nanofibrous substrates based on polycaprolactone. Prog. Biomater. 2016, 5, 213–222. [Google Scholar] [CrossRef]

- Vernon, B. (Ed.) Injectable Biomaterials: Science and Applications; Elsevier: Amsterdam, The Netherlands, 24 January 2011. [Google Scholar]

- Balaji, A.; Jaganathan, S.K.; Ismail, A.F.; Rajasekar, R. Fabrication and hemocompatibility assessment of novel polyurethane-based bio-nanofibrous dressing loaded with honey and carica papaya extract for the management of burn injuries. Int. J. Nanomed. 2016, 11, 4339. [Google Scholar]

- Huang, N.; Yang, P.; Leng, Y.X.; Chen, J.Y.; Sun, H.; Wang, J.; Wang, G.J.; Ding, P.D.; Xi, T.F.; Leng, Y. Hemocompatibility of titanium oxide films. Biomaterials 2003, 24, 2177–2187. [Google Scholar] [CrossRef]

- Jaganathan, S.; Mani, M.; Ismail, A.; Ayyar, M. Manufacturing and characterization of novel electrospun composite comprising polyurethane and mustard oil scaffold with enhanced blood compatibility. Polymers 2017, 9, 163. [Google Scholar] [CrossRef]

- Ayyar, M.; Mani, M.P.; Jaganathan, S.K.; Rathanasamy, R. Preparation, characterization and blood compatibility assessment of a novel electrospun nanocomposite comprising polyurethane and ayurvedic-indhulekha oil for tissue engineering applications. Biomed. Eng./Biomed. Tech. 2018, 63, 245–253. [Google Scholar] [CrossRef] [PubMed]

- Jaganathan, S.K.; Mani, M.P.; Ayyar, M.; Supriyanto, E. Engineered electrospun polyurethane and castor oil nanocomposite scaffolds for cardiovascular applications. J. Mater. Sci. 2017, 52, 10673–10685. [Google Scholar] [CrossRef]

- Pitz, H.D.; Pereira, A.; Blasius, M.B.; Voytena, A.P.; Affonso, R.C.; Fanan, S.; Trevisan, A.C.; Ribeiro-do-Valle, R.M.; Maraschin, M. In vitro evaluation of the antioxidant activity and wound healing properties of Jaboticaba (Plinia peruviana) fruit peel Hydroalcoholic extract. Oxidative Med. Cell. Longev. 2016, 2016. [Google Scholar] [CrossRef] [PubMed]

- Tian, F.; Hosseinkhani, H.; Hosseinkhani, M.; Khademhosseini, A.; Yokoyama, Y.; Estrada, G.G.; Kobayashi, H. Quantitative analysis of cell adhesion on aligned micro-and nanofibers. J. Biomed. Mater. Res. Part A 2008, 84, 291–299. [Google Scholar] [CrossRef]

- Nandakumar, V.; Suresh, G.; Chittaranjan, S.; Doble, M. Synthesis and Characterization of Hydrophilic High Glycolic Acid–Poly (dl-Lactic-co-Glycolic Acid)/Polycaprolactam/Polyvinyl Alcohol Blends and Their Biomedical Application as a Ureteral Material. Ind. Eng. Chem. Res. 2012, 52, 751–760. [Google Scholar] [CrossRef]

| Membrane | Carbon | Oxygen | Copper |

|---|---|---|---|

| PU | 78.9 ± 0.8 | 21.1 ± 0.8 | - |

| PU/PM | 79.1 ± 1.2 | 20.9 ± 1.2 | - |

| PU/PM/CuSO4 | 75.6 ± 0.3 | 23 ± 0.3 | 1.5 ± 0.2 |

| Peaks | Band name |

|---|---|

| 3322 cm−1 | N–H |

| 2932 and 2853 cm−1 | C–H |

| 1730 and 1702 cm−1 | C=O |

| 1531 and 1597 cm−1 | Vibrations of N–H |

| 1414 cm−1 | Vibrations of C–H |

| 1221, 1105, and 770 cm−1 | C–O corresponding to the alcohol group |

| S.NO | PU | PU/PM | PU/PM/CuSO4 |

|---|---|---|---|

| First weight loss | 210 °C to 302 °C | 228 °C to 327 °C | 206 °C to 270 °C |

| Second weight loss | 302 °C to 353 °C | 327 °C to 434 °C | 270 °C to 353 °C |

| Third weight loss | 353 °C to 494 °C | - | 353 °C to 476 °C |

| Fourth weight loss | 494 °C to 760 °C | - | 476 °C to 664 °C |

| Membrane | Tensile strength MPa | Elastic Modulus MPa | Elongation at break (%) |

|---|---|---|---|

| PU | 6.83 | 3.51 | 259.16 |

| PU/PM | 7.04 | 2.95 | 300.10 |

| PU/PM/CuSO4 | 13.60 | 5.37 | 331.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaganathan, S.K.; Mani, M.P.; Khudzari, A.Z.M. Electrospun Combination of Peppermint Oil and Copper Sulphate with Conducive Physico-Chemical properties for Wound Dressing Applications. Polymers 2019, 11, 586. https://doi.org/10.3390/polym11040586

Jaganathan SK, Mani MP, Khudzari AZM. Electrospun Combination of Peppermint Oil and Copper Sulphate with Conducive Physico-Chemical properties for Wound Dressing Applications. Polymers. 2019; 11(4):586. https://doi.org/10.3390/polym11040586

Chicago/Turabian StyleJaganathan, Saravana Kumar, Mohan Prasath Mani, and Ahmad Zahran Md Khudzari. 2019. "Electrospun Combination of Peppermint Oil and Copper Sulphate with Conducive Physico-Chemical properties for Wound Dressing Applications" Polymers 11, no. 4: 586. https://doi.org/10.3390/polym11040586

APA StyleJaganathan, S. K., Mani, M. P., & Khudzari, A. Z. M. (2019). Electrospun Combination of Peppermint Oil and Copper Sulphate with Conducive Physico-Chemical properties for Wound Dressing Applications. Polymers, 11(4), 586. https://doi.org/10.3390/polym11040586