Using an Ionic Liquid to Reduce the Electrical Percolation Threshold in Biobased Thermoplastic Polyurethane/Graphene Nanocomposites

Abstract

1. Introduction

2. Materials and Methods

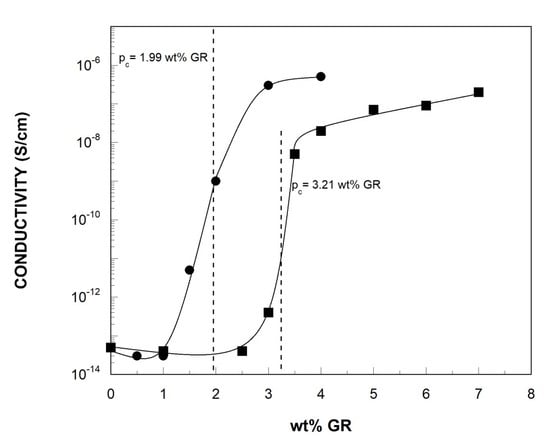

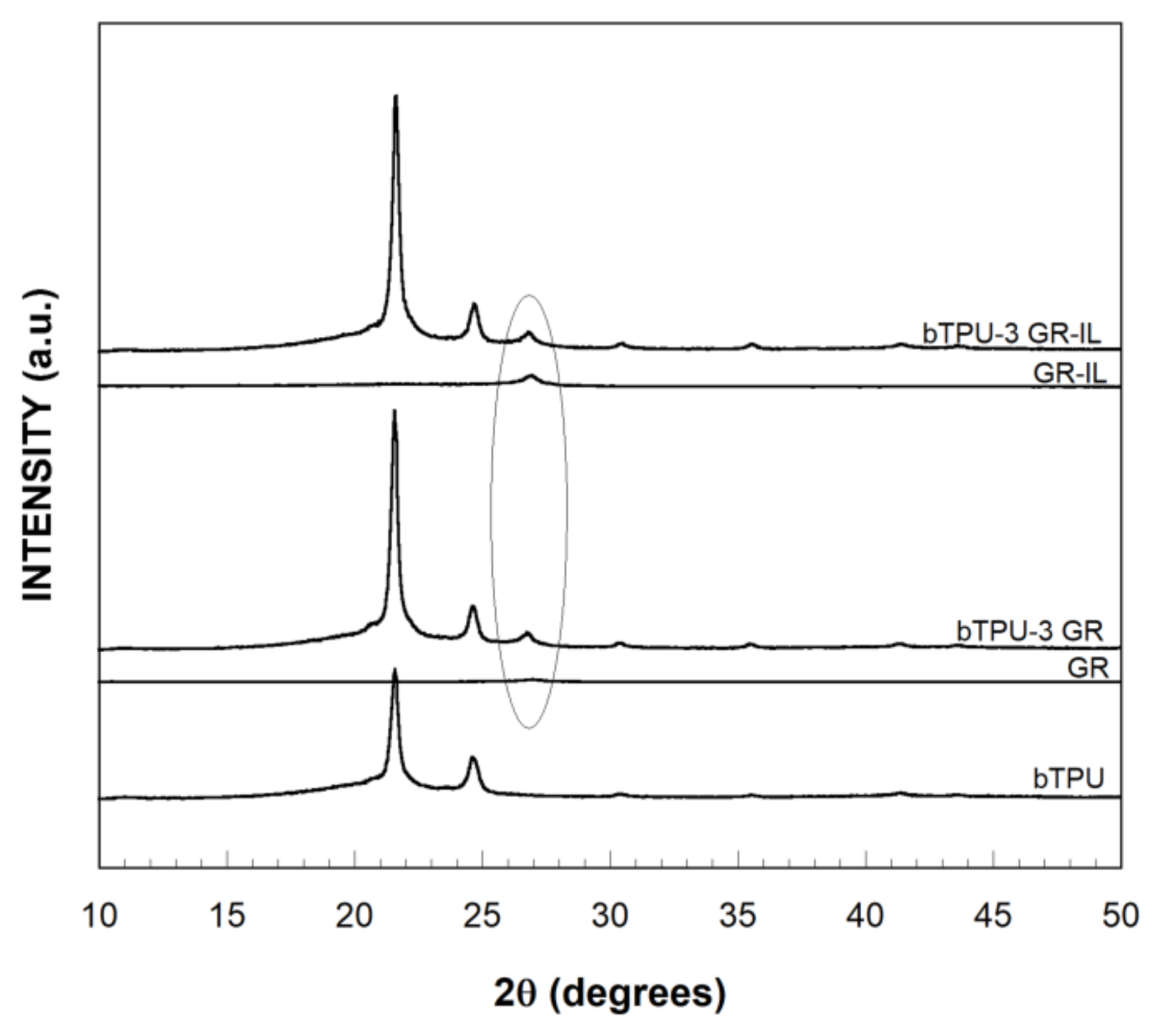

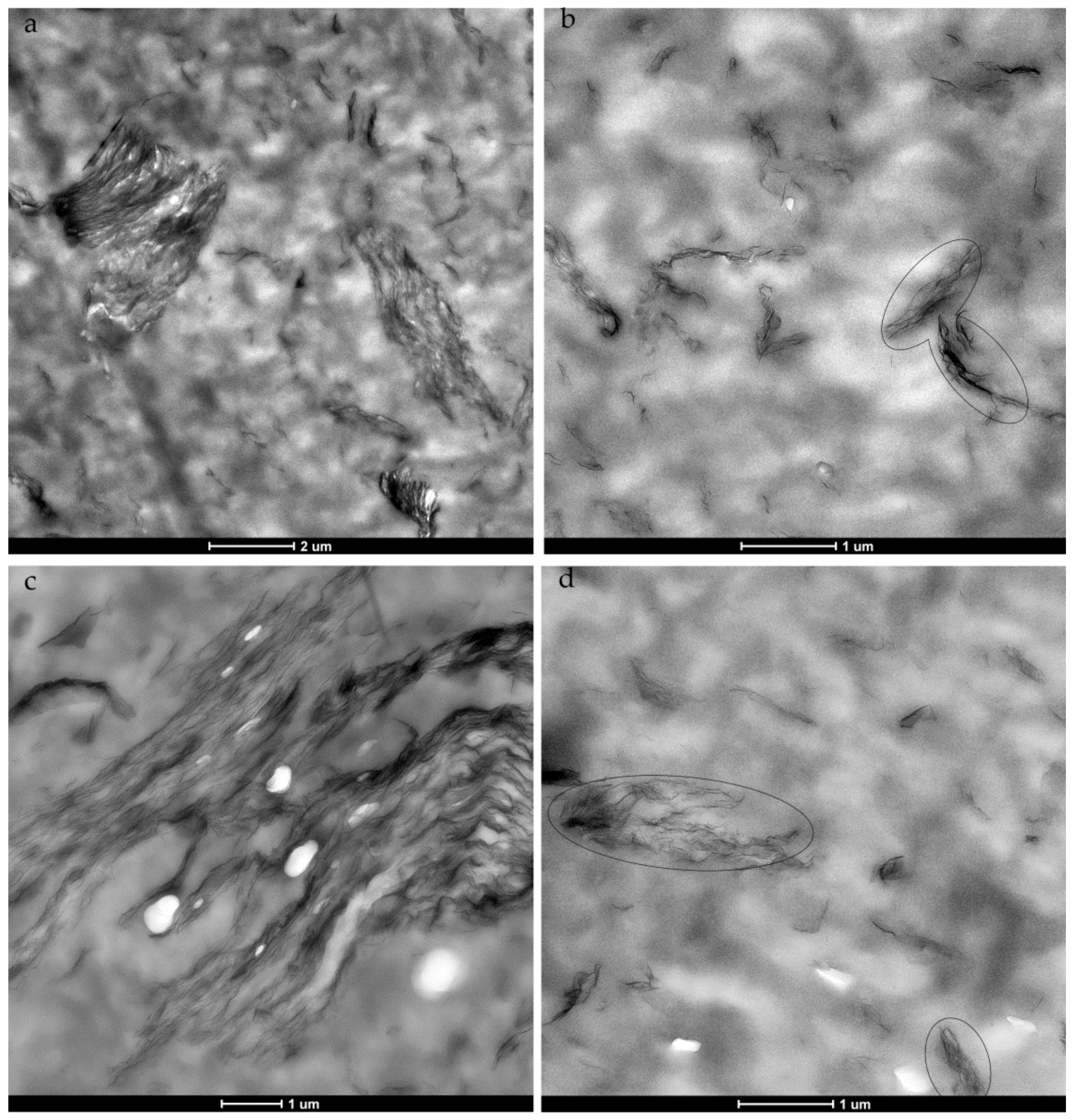

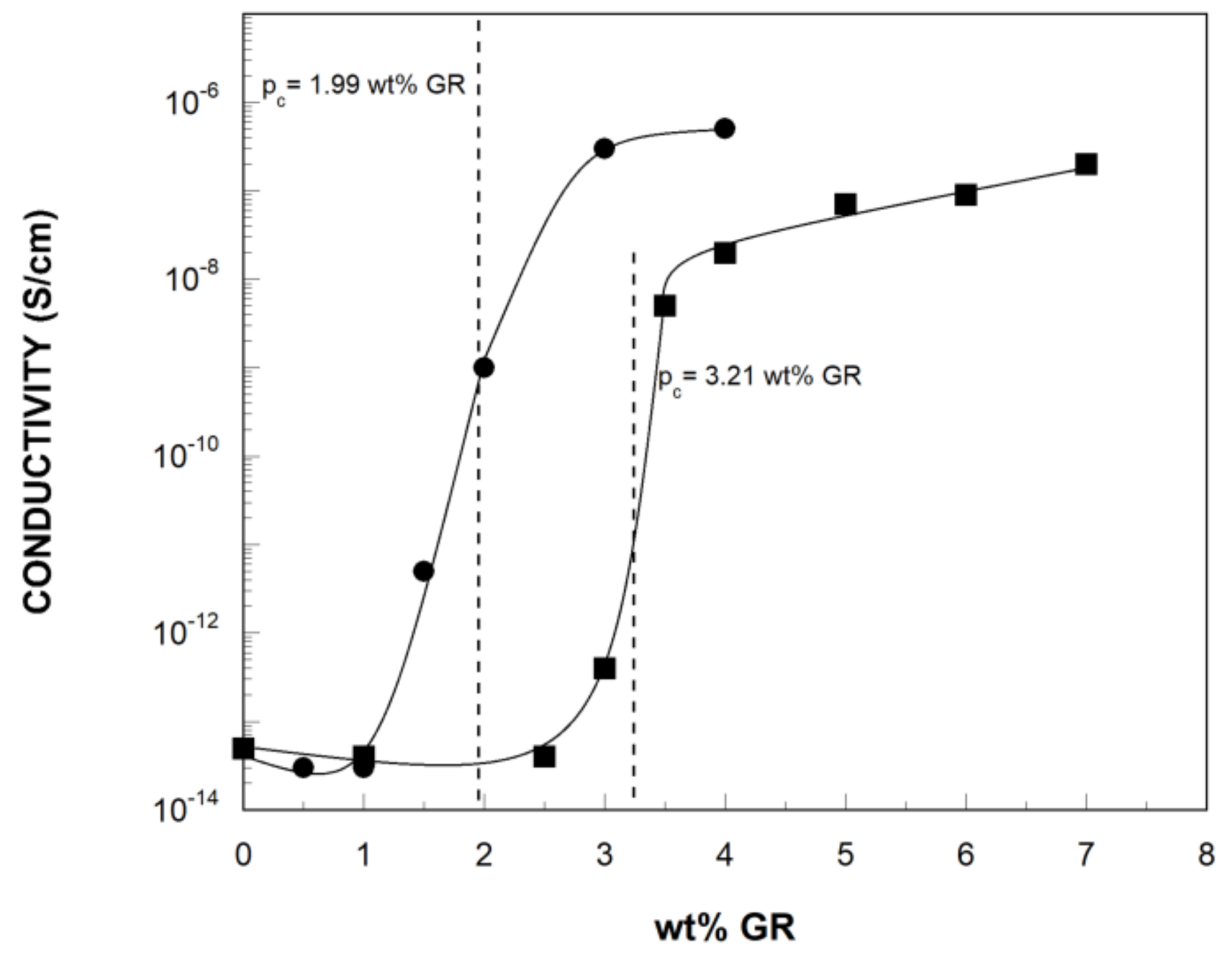

3. Results and Discussion

3.1. Nanostructure

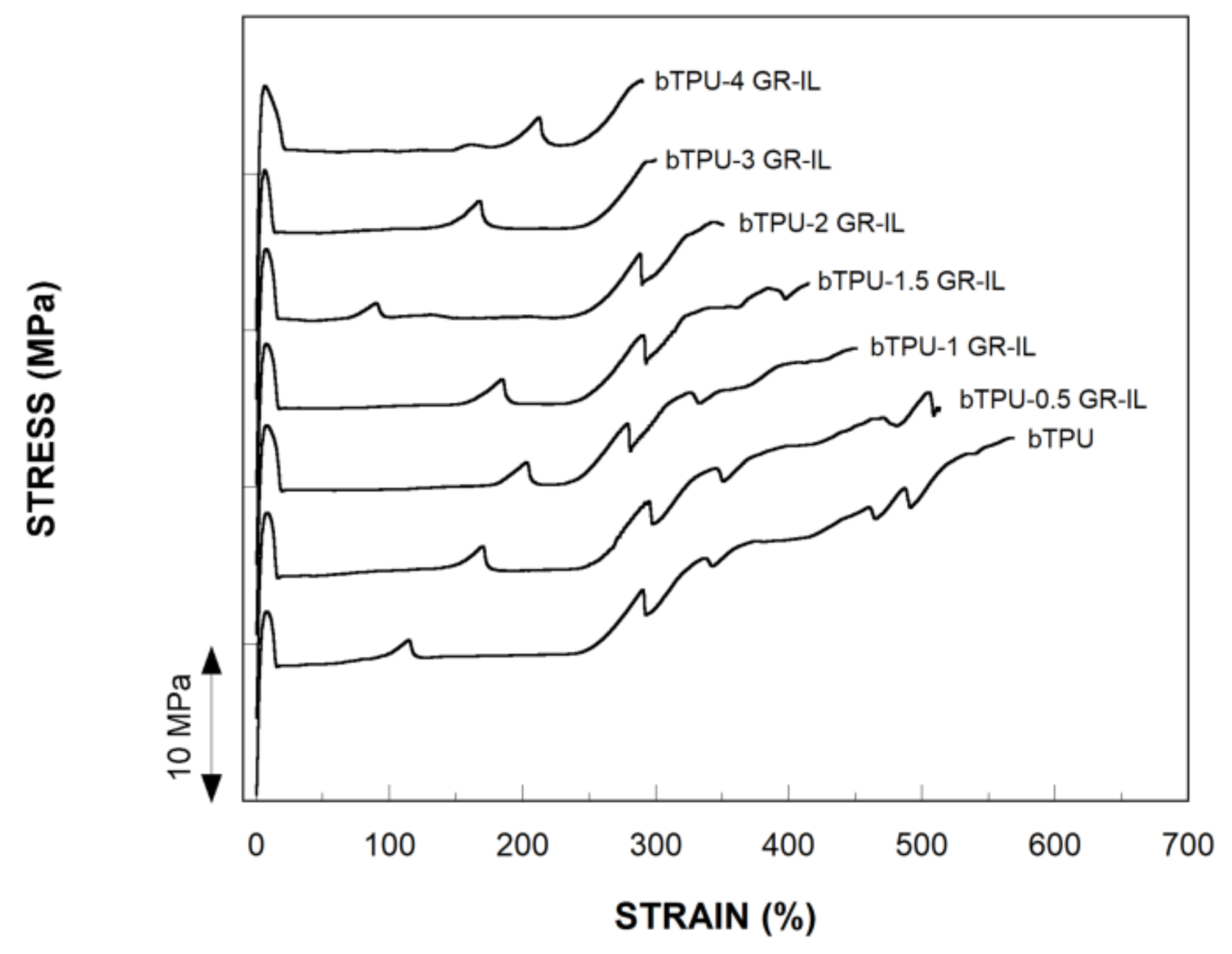

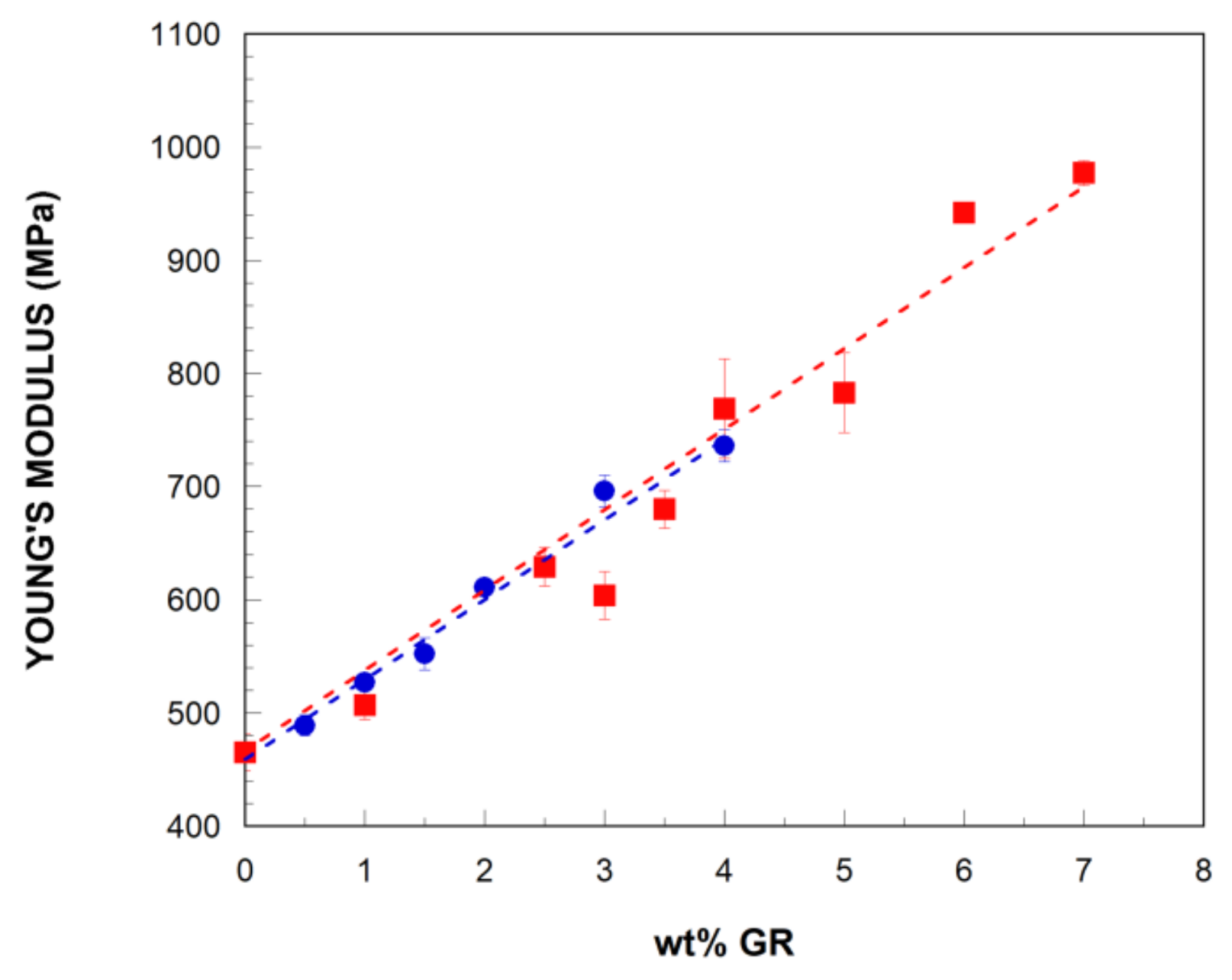

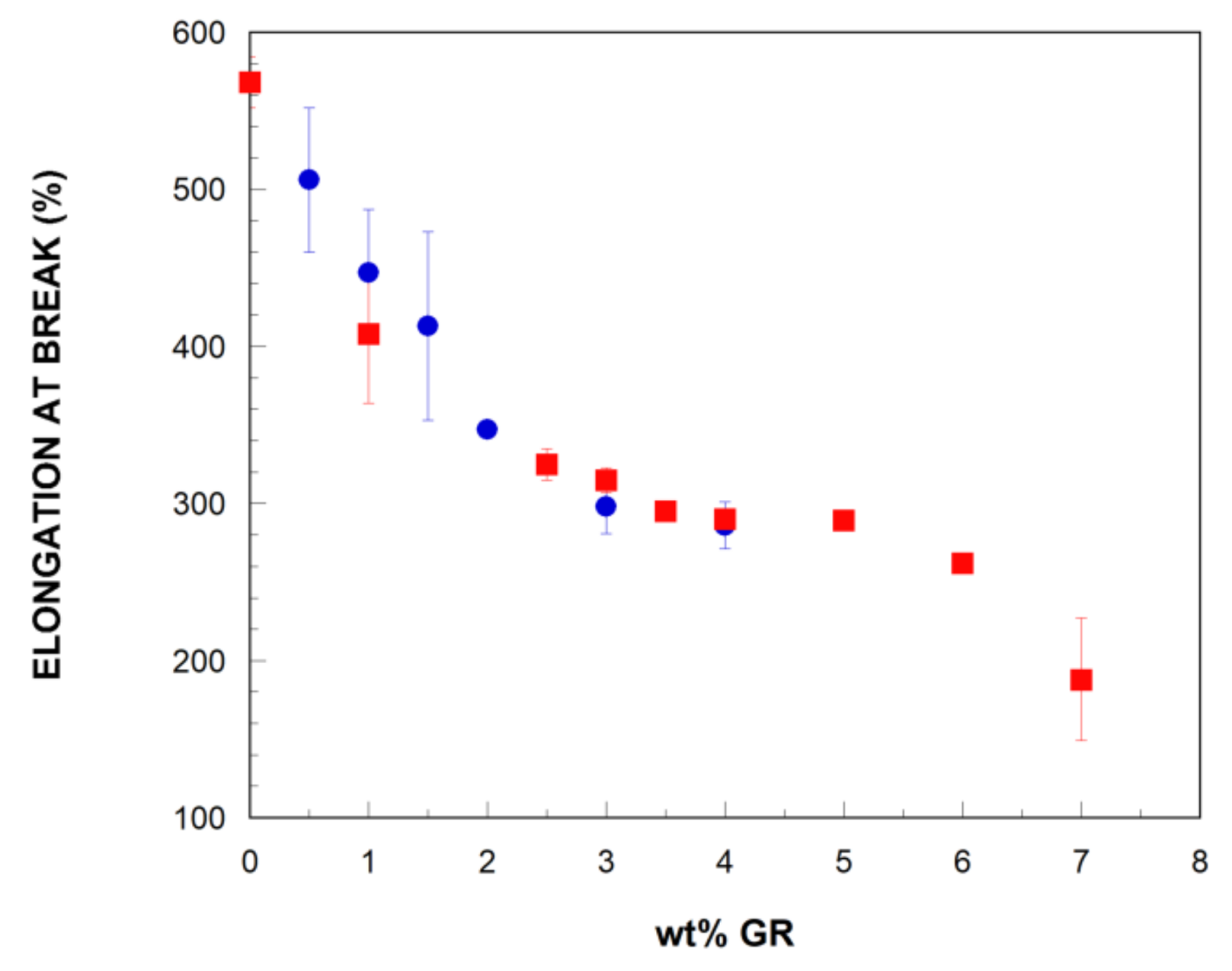

3.2. Mechanical Properties

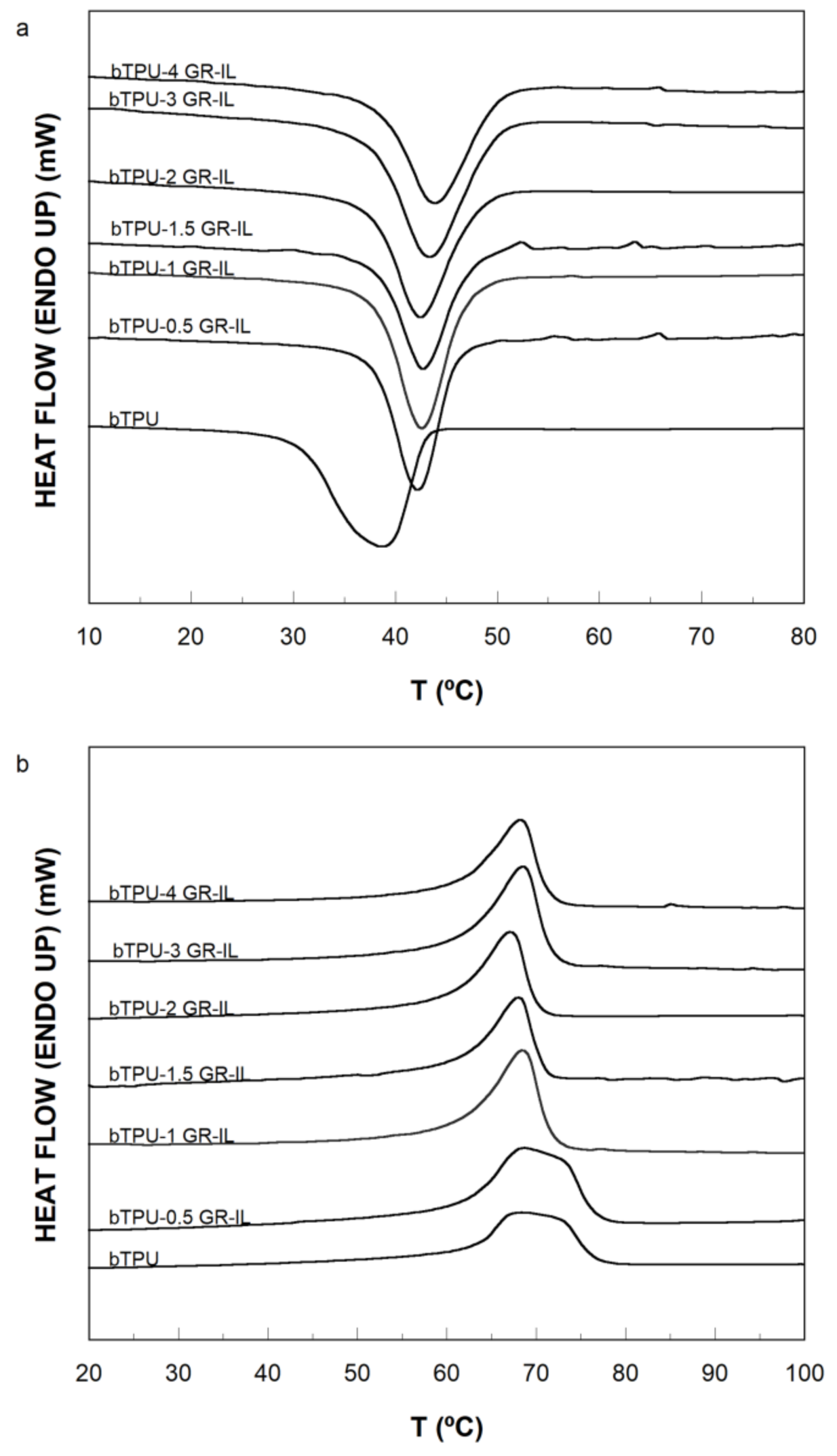

3.3. Thermal Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Mayoral, B.; Harkin-Jones, E.; Khanam, P.N.; AlMaadeed, M.A.; Ouederni, M.; Hamilton, A.R.; Sun, D. Melt processing and characterization of polyamide 6/graphene nanoplatelet composites. RSC Adv. 2015, 5, 52395–52409. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Pan, Q.; Shim, E.; Pourdeyhimi, B.; Gao, W. Nylon-graphene composite nonwovens as monolithic conductive or capacitive fabrics. ACS Appl. Mater. Interfaces 2017, 9, 8308–8316. [Google Scholar] [CrossRef] [PubMed]

- Pan, Q.; Shim, E.; Pourdeyhimi, B.; Gao, W. Highly conductive polypropylene-graphene nonwoven composite via interface engineering. Langmuir 2017, 33, 7452–7458. [Google Scholar] [CrossRef] [PubMed]

- Phiri, J.; Gane, P.; Maloney, T.C. General overview of graphene: Production, properties and application in polymer composites. Mater. Sci. Eng. B 2017, 215, 9–28. [Google Scholar] [CrossRef]

- Atif, R.; Inam, F. Reasons and remedies for the agglomeration of multilayered graphene and carbon nanotubes in polymers. Beilstein J. Nanotechnol. 2016, 7, 1174–1196. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Gui, H.; Wang, X.; Hu, Y.; Ding, Y. Improved dielectric properties of nanocomposites based on polyvinylidene fluoride and ionic liquid-functionalized graphene. Compos. Sci. Technol. 2015, 117, 282–288. [Google Scholar] [CrossRef]

- Yin, B.; Zhang, X.; Zhang, X.; Wang, J.; Wen, Y.; Jia, H.; Ji, Q.; Ding, L. Ionic liquid functionalized graphene oxide for enhancement of styrene-butadiene rubber nanocomposites. Polym. Adv. Technol. 2017, 28, 293–302. [Google Scholar] [CrossRef]

- Gui, H.; Xu, P.; Hu, Y.; Wang, J.; Yang, X.; Bahader, A.; Ding, Y. Synergistic effect of graphene and an ionic liquid containing phosphonium on the thermal stability and flame retardancy of polylactide. RSC Adv. 2015, 5, 27814–27822. [Google Scholar] [CrossRef]

- Ma, W.-S.; Wu, L.; Yang, F.; Wang, S.-F. Non-covalently modified reduced graphene oxide/polyurethane nanocomposites with good mechanical and thermal properties. J. Mater. Sci. 2014, 49, 562–571. [Google Scholar] [CrossRef]

- Wang, L.; Wang, W.; Fan, P.; Zhou, M.; Yang, J.; Chen, F.; Zhong, M. Ionic liquid modified graphene/poly(vinyl alcohol) composite with enhanced properties. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Wan, Z.; Zhao, L.; He, H. Electrical conductivity and mechanical properties of ionic liquid modified shear exfoliation graphene/CO-PA nanocomposites at extremely low graphene loading. Polym. Compos. 2017, 38, E277–E284. [Google Scholar] [CrossRef]

- Liu, N.; Luo, F.; Wu, H.; Liu, Y.; Zhang, C.; Chen, J. One-step ionic-liquid-assisted electrochemical synthesis of ionic-liquid-functionalized graphene sheets directly from graphite. Adv. Funct. Mater. 2008, 18, 1518–1525. [Google Scholar] [CrossRef]

- Yang, Y.-K.; He, C.-E.; Peng, R.-G.; Baji, A.; Du, X.-S.; Huang, Y.-L.; Xie, X.-L.; Mai, Y.-W. Non-covalently modified graphene sheets by imidazolium ionic liquids for multifunctional polymer nanocomposites. J. Mater. Chem. 2012, 22, 5666–5675. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Tayfun, U.; Dogan, M.; Bayramli, E. Effect of surface modification of rice straw on mechanical and flow properties of TPU-based green composites. Polym. Compos. 2016, 37, 1596–1602. [Google Scholar] [CrossRef]

- Verma, M.; Chauhan, S.S.; Dhawan, S.K.; Choudhary, V. Graphene nanoplatelets/carbon nanotubes/polyurethane composites as efficient shield against electromagnetic polluting radiations. Compos. Part B 2017, 120, 118–127. [Google Scholar] [CrossRef]

- Cataldi, P.; Ceseracciu, L.; Marras, S.; Athanassiou, A.; Bayer, I.S. Electrical conductivity enhancement in thermoplastic polyurethane-graphene nanoplatelet composites by stretch-release cycles. Appl. Phys. Lett. 2017, 110, 121904. [Google Scholar] [CrossRef]

- Jan, R.; Habib, A.; Akram, M.A.; Ahmad, I.; Shah, A.; Sadiq, M.; Hussain, A. Flexible, thin films of graphene-polymer composites for EMI shielding. Mater. Res. Express 2017, 4, 035605. [Google Scholar] [CrossRef]

- Li, Y.; Gao, F.; Xue, Z.; Luan, Y.; Yan, X.; Guo, Z.; Wang, Z. Synergistic effect of different graphene-CNT heterostructures on mechanical and self-healing properties of thermoplastic polyurethane composites. Mater. Des. 2018, 137, 438–445. [Google Scholar] [CrossRef]

- Chen, K.; Tian, Q.; Tian, C.; Yan, G.; Cao, F.; Liang, S.; Wang, X. Mechanical reinforcement in thermoplastic polyurethane nanocomposite incorporated with polydopamine functionalized graphene nanoplatelet. Ind. Eng. Chem. Res. 2017, 56, 11827–11838. [Google Scholar] [CrossRef]

- Bera, M.; Maji, P.K. Effect of structural disparity of graphene-based materials on thermo-mechanical and surface properties of thermoplastic polyurethane nanocomposites. Polymer 2017, 119, 118–133. [Google Scholar] [CrossRef]

- Roy, S.; Srivastava, S.K.; Pionteck, J.; Mittal, V. Mechanically and thermally enhanced multiwalled carbon nanotube-graphene hybrid filled thermoplastic polyurethane nanocomposites. Macromol. Mater. Eng. 2015, 300, 346–357. [Google Scholar] [CrossRef]

- Caradonna, A.; Colucci, G.; Giorcelli, M.; Frache, A.; Badini, C. Thermal behavior of thermoplastic polymer nanocomposites containing graphene nanoplatelets. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Strankowski, M.; Piszczyk, L.; Kosmela, P.; Korzeniewski, P. Morphology and the physical and thermal properties of thermoplastic polyurethane reinforced with thermally reduced graphene oxide. Pol. J. Chem. Technol. 2015, 17, 88–94. [Google Scholar] [CrossRef]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- Yuan, D.; Pedrazzoli, D.; Pircheraghi, G.; Manas-Zloczower, I. Melt compounding of thermoplastic polyurethanes incorporating 1D and 2D carbon nanofillers. Polym.-Plast. Technol. Eng. 2017, 56, 732–743. [Google Scholar] [CrossRef]

- Piana, F.; Pionteck, J. Effect of the melt processing conditions on the conductive paths formation in thermoplastic polyurethane/expanded graphite (TPU/EG) composites. Compos. Sci. Technol. 2013, 80, 39–46. [Google Scholar] [CrossRef]

- Yuan, D.; Pedrazzoli, D.; Manas-Zloczower, I. Synergistic effects in thermoplastic polyurethanes incorporating hybrid carbon nanofillers. Int. Polym. Process. 2016, 31, 554–561. [Google Scholar] [CrossRef]

- Razeghi, M.; Pircheraghi, G. TPU/graphene nanocomposites: Effect of graphene functionality on the morphology of separated hard domains in thermoplastic polyurethane. Polymer 2018, 148, 169–180. [Google Scholar] [CrossRef]

- Gomez, J.; Recio, I.; Navas, A.; Villaro, E.; Galindo, B.; Ortega-Murguialday, A. Processing influence on dielectric, mechanical, and electrical properties of reduced graphene oxide-TPU nanocomposites. J. Appl. Polym. Sci. 2019, 136. [Google Scholar] [CrossRef]

- Strankowski, M.; Korzeniewski, P.; Strankowska, J.; Anu, A.S.; Thomas, S. Morphology, mechanical and thermal properties of thermoplastic polyurethane containing reduced graphene oxide and graphene nanoplatelets. Materials 2018, 11, 82. [Google Scholar] [CrossRef] [PubMed]

- Inuwa, I.M.; Hassan, A.; Samsudin, S.A.; Haafiz, M.K.M.; Jawaid, M.; Majeed, K.; Abdul Razak, N.C. Characterization and mechanical properties of exfoliated graphite nanoplatelets reinforced polyethylene terephthalate/polypropylene composites. J. Appl. Polym. Sci. 2014, 131, 40582. [Google Scholar] [CrossRef]

- Istrate, O.M.; Paton, K.R.; Khan, U.; O’Neill, A.; Bell, A.P.; Coleman, J.N. Reinforcement in melt-processed polymer-graphene composites at extremely low graphene loading level. Carbon 2014, 78, 243–249. [Google Scholar] [CrossRef]

- Gandini, A. The irruption of polymers from renewable resources on the scene of macromolecular science and technology. Green Chem. 2011, 13, 1061–1083. [Google Scholar] [CrossRef]

- Sinha Ray, S. Environmentally Fribendly Polymer Nanocomposites: Types, Processing and Properties; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Babb, D.A. Polyurethanes from renewable resources. Adv. Polym. Sci. 2012, 245, 315–360. [Google Scholar]

- Niaounakis, M. Biopolymers: Reuse, Recycling and Disposal; William Andrew Publishing: Norwich, NY, USA, 2013. [Google Scholar]

- Pour, R.H.; Hassan, A.; Soheilmoghaddam, M.; Bidsorkhi, H.C. Mechanical, thermal, and morphological properties of graphene reinforced polycarbonate/acrylonitrile butadiene styrene nanocomposites. Polym. Compos. 2016, 37, 1633–1640. [Google Scholar] [CrossRef]

- Sullivan, E.M.; Oh, Y.J.; Gerhardt, R.A.; Wang, B.; Kalaitzidou, K. Understanding the effect of polymer crystallinity on the electrical conductivity of exfoliated graphite nanoplatelet/polylactic acid composite films. J. Polym. Res. 2014, 21, 1–9. [Google Scholar] [CrossRef]

- El Achaby, M.; Arrakhiz, F.-E.; Vaudreuil, S.; El Kacem Qaiss, A.; Bousmina, M.; Fassi-Fehri, O. Mechanical, thermal, and rheological properties of graphene-based polypropylene nanocomposites prepared by melt mixing. Polym. Compos. 2012, 33, 733–744. [Google Scholar] [CrossRef]

- Shen, M.-Y.; Chang, T.-Y.; Hsieh, T.-H.; Li, Y.-L.; Chiang, C.-L.; Yang, H.; Yip, M.-C. Mechanical properties and tensile fatigue of graphene nanoplatelets reinforced polymer nanocomposites. J. Nanomater. 2013, 2013, 565401. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Wan Yunus, W.M.Z.; Hussein, M.Z.; Loo, Y.Y. Effect of graphene nanoplatelets as nanofiller in plasticized poly(lactic acid) nanocomposites–Thermal properties and mechanical properties. J. Therm. Anal. Calorim. 2014, 118, 1551–1559. [Google Scholar] [CrossRef]

- Fu, X.; Yao, C.; Yang, G. Recent advances in graphene/polyamide 6 composites: A review. RSC Adv. 2015, 5, 61688–61702. [Google Scholar] [CrossRef]

- Inuwa, I.M.; Hassan, A.; Samsudin, S.A.; Mohamad Kassim, M.H.; Jawaid, M. Mechanical and thermal properties of exfoliated graphite nanoplatelets reinforced polyethylene terephthalate/polypropylene composites. Polym. Compos. 2014, 35, 2029–2035. [Google Scholar] [CrossRef]

- Mittal, V.; Chaudhry, A.U.; Luckachan, G.E. Biopolymer–Thermally reduced graphene nanocomposites: Structural characterization and properties. Mater. Chem. Phys. 2014, 147, 319–332. [Google Scholar] [CrossRef]

- Mittal, V.; Chaudhry, A.U. Polymer–graphene nanocomposites: Effect of polymer matrix and filler amount on properties. Macromol. Mater. Eng. 2015, 300, 510–521. [Google Scholar] [CrossRef]

- Jin, J.; Rafiq, R.; Gill, Y.Q.; Song, M. Preparation and characterization of high performance of graphene/nylon nanocomposites. Eur. Polym. J. 2013, 49, 2617–2626. [Google Scholar] [CrossRef]

- Stauffer, D.; Aharony, A. Introduction in Percolation Theory; Taylor and Francis: London, UK, 1994. [Google Scholar]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. A new compounding method for exfoliated graphite-polypropylene nanocomposites with enhanced flexural properties and lower percolation threshold. Compos. Sci. Technol. 2007, 67, 2045–2051. [Google Scholar] [CrossRef]

- Kumari Pallathadka, P.; Koh, X.Q.; Khatta, A.; Luckachan, G.E.; Mittal, V. Characteristics of biodegradable poly(butylene succinate) nanocomposites with thermally reduced graphene nanosheets. Polym. Compos. 2017, 38, E42–E48. [Google Scholar] [CrossRef]

- Oyarzabal, A.; Cristiano-Tassi, A.; Laredo, E.; Newman, D.; Bello, A.; Etxeberria, A.; Eguiazabal, J.I.; Zubitur, M.; Mugica, A.; Mueller, A.J. Dielectric, mechanical and transport properties of bisphenol a polycarbonate/graphene nanocomposites prepared by melt blending. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Zhou, S.; Hrymak, A.; Kamal, M. Electrical and morphological properties of microinjection molded polypropylene/carbon nanocomposites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Aranburu, N.; Eguiazabal, J.I. Electrically conductive multi-walled carbon nanotube-reinforced amorphous polyamide nanocomposites. Polym. Compos. 2014, 35, 587–595. [Google Scholar] [CrossRef]

- Rynkowska, E.; Fatyeyeva, K.; Kujawa, J.; Dzieszkowski, K.; Wolan, A.; Kujawski, W. The effect of reactive ionic liquid or plasticizer incorporation on the physicochemical and transport properties of cellulose acetate propionate-based membranes. Polymers 2018, 10, 86. [Google Scholar] [CrossRef]

- Chen, G.; Chen, N.; Li, L.; Wang, Q.; Duan, W. Ionic liquid modified poly(vinyl alcohol) with improved thermal processability and excellent electrical conductivity. Ind. Eng. Chem. Res. 2018, 57, 5472–5481. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hussein, M.Z. Poly(lactic acid)/poly(ethylene glycol) polymer nanocomposites: Effects of graphene nanoplatelets. Polymers 2014, 6, 93–104. [Google Scholar] [CrossRef]

- Yang, X.; Li, L.; Shang, S.; Tao, X.-M. Synthesis and characterization of layer-aligned poly(vinyl alcohol)/graphene nanocomposites. Polymer 2010, 51, 3431–3435. [Google Scholar] [CrossRef]

- Cai, D.; Song, M. A simple route to enhance the interface between graphite oxide nanoplatelets and a semi-crystalline polymer for stress transfer. Nanotechnology 2009, 2, 315708. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Li, Y.; Dai, K.; Zheng, G.; Liu, C.; Shen, C.; Yan, X.; Guo, J.; Guo, Z. Electrically conductive thermoplastic elastomer nanocomposites at ultralow graphene loading levels for strain sensor applications. J. Mater. Chem. C 2016, 4, 157–166. [Google Scholar] [CrossRef]

- Marini, J.; Pollet, E.; Averous, L.; Bretas, R.E.S. Elaboration and properties of novel biobased nanocomposites with halloysite nanotubes and thermoplastic polyurethane from dimerized fatty acids. Polymer 2014, 55, 5226–5234. [Google Scholar] [CrossRef]

| Composition | Nanofiller wt% | GR wt% |

|---|---|---|

| bTPU-0.5 GR-IL | 1 | 0.5 |

| bTPU-1 GR-IL | 2 | 1 |

| bTPU-1.5 GR-IL | 3 | 1.5 |

| bTPU-2 GR-IL | 4 | 2 |

| bTPU-3 GR-IL | 6 | 3 |

| bTPU-4 GR-IL | 8 | 4 |

| bTPU-1 GR | 1 | 1 |

| bTPU-2.5 GR | 2.5 | 2.5 |

| bTPU-3 GR | 3 | 3 |

| bTPU-3.5 GR | 3.5 | 3.5 |

| bTPU-4 GR | 4 | 4 |

| bTPU-5 GR | 5 | 5 |

| bTPU-6 GR | 6 | 6 |

| bTPU-7 GR | 7 | 7 |

| Composition | Young’s Modulus (MPa) (±10 MPa) | Elongation at Break (%) (±20%) | Tensile Strength (MPa) (±0.5 MPa) | Yield Strength (MPa) (±0.5 MPa) |

|---|---|---|---|---|

| bTPU | 460 | 560 | 24.0 | 12.5 |

| bTPU-0.5 GR-IL | 490 | 500 | 20.5 | 13.5 |

| bTPU-1 GR-IL | 530 | 440 | 18.5 | 14.0 |

| bTPU-1.5 GR-IL | 550 | 420 | 18.0 | 14.0 |

| bTPU-2 GR-IL | 610 | 340 | 16.5 | 14.5 |

| bTPU-3 GR-IL | 700 | 300 | 15.0 | 15.0 |

| bTPU-4 GR-IL | 740 | 280 | 14.5 | 15.5 |

| bTPU-1 GR | 510 | 400 | 18.0 | 14.0 |

| bTPU-2.5 GR | 630 | 320 | 16.5 | 14.0 |

| bTPU-3 GR | 600 | 320 | 16.0 | 14.0 |

| bTPU-3.5 GR | 680 | 300 | 16.0 | 14.5 |

| bTPU-4 GR | 770 | 280 | 17.0 | 16.5 |

| bTPU-5 GR | 780 | 280 | 17.0 | 17.0 |

| bTPU-6 GR | 940 | 260 | 15.5 | 18.0 |

| bTPU-7 GR | 980 | 180 | 16.0 | 18.5 |

| Composition | Tc (°C) a (±0.5 °C) | Tm (°C) a (±0.5 °C) | ΔHm (J/g) a (±5 J/g) | Tg (°C) b (±0.5 °C) |

|---|---|---|---|---|

| bTPU | 38.5 | 64.0–74.0 | 70 | −16.0 |

| bTPU-0.5 GR-IL | 42.0 | 68.5 | 70 | −16.0 |

| bTPU-1 GR-IL | 42.5 | 69.0 | 70 | −15.5 |

| bTPU-1.5 GR-IL | 42.5 | 68.0 | 70 | −15.5 |

| bTPU-2 GR-IL | 42.5 | 67.0 | 70 | −15.5 |

| bTPU-3 GR-IL | 43.5 | 68.0 | 70 | −15.0 |

| bTPU-4 GR-IL | 44.0 | 68.5 | 70 | −15.0 |

| bTPU-1 GR | 42.0 | 66.5 | 75 | −15.0 |

| bTPU-2.5 GR | 40.5 | 66.0 | 75 | −15.0 |

| bTPU-3 GR | 44.5 | 66.5 | 70 | −15.0 |

| bTPU-3.5 GR | 43.5 | 67.5 | 70 | −14.5 |

| bTPU-4 GR | 44.0 | 67.5 | 75 | −15.0 |

| bTPU-5 GR | 43.5 | 68.0 | 75 | −16.0 |

| bTPU-6 GR | 44.0 | 66.0 | 75 | −15.0 |

| bTPU-7 GR | 44.0 | 68.0 | 75 | −14.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aranburu, N.; Otaegi, I.; Guerrica-Echevarria, G. Using an Ionic Liquid to Reduce the Electrical Percolation Threshold in Biobased Thermoplastic Polyurethane/Graphene Nanocomposites. Polymers 2019, 11, 435. https://doi.org/10.3390/polym11030435

Aranburu N, Otaegi I, Guerrica-Echevarria G. Using an Ionic Liquid to Reduce the Electrical Percolation Threshold in Biobased Thermoplastic Polyurethane/Graphene Nanocomposites. Polymers. 2019; 11(3):435. https://doi.org/10.3390/polym11030435

Chicago/Turabian StyleAranburu, Nora, Itziar Otaegi, and Gonzalo Guerrica-Echevarria. 2019. "Using an Ionic Liquid to Reduce the Electrical Percolation Threshold in Biobased Thermoplastic Polyurethane/Graphene Nanocomposites" Polymers 11, no. 3: 435. https://doi.org/10.3390/polym11030435

APA StyleAranburu, N., Otaegi, I., & Guerrica-Echevarria, G. (2019). Using an Ionic Liquid to Reduce the Electrical Percolation Threshold in Biobased Thermoplastic Polyurethane/Graphene Nanocomposites. Polymers, 11(3), 435. https://doi.org/10.3390/polym11030435