Indentation Size Effect in Pressure-Sensitive Polymer Based on A Criterion for Description of Yield Differential Effects and Shear Transformation-Mediated Plasticity

Abstract

1. Introduction

2. Experiment Procedure

2.1. Materials and Specimens

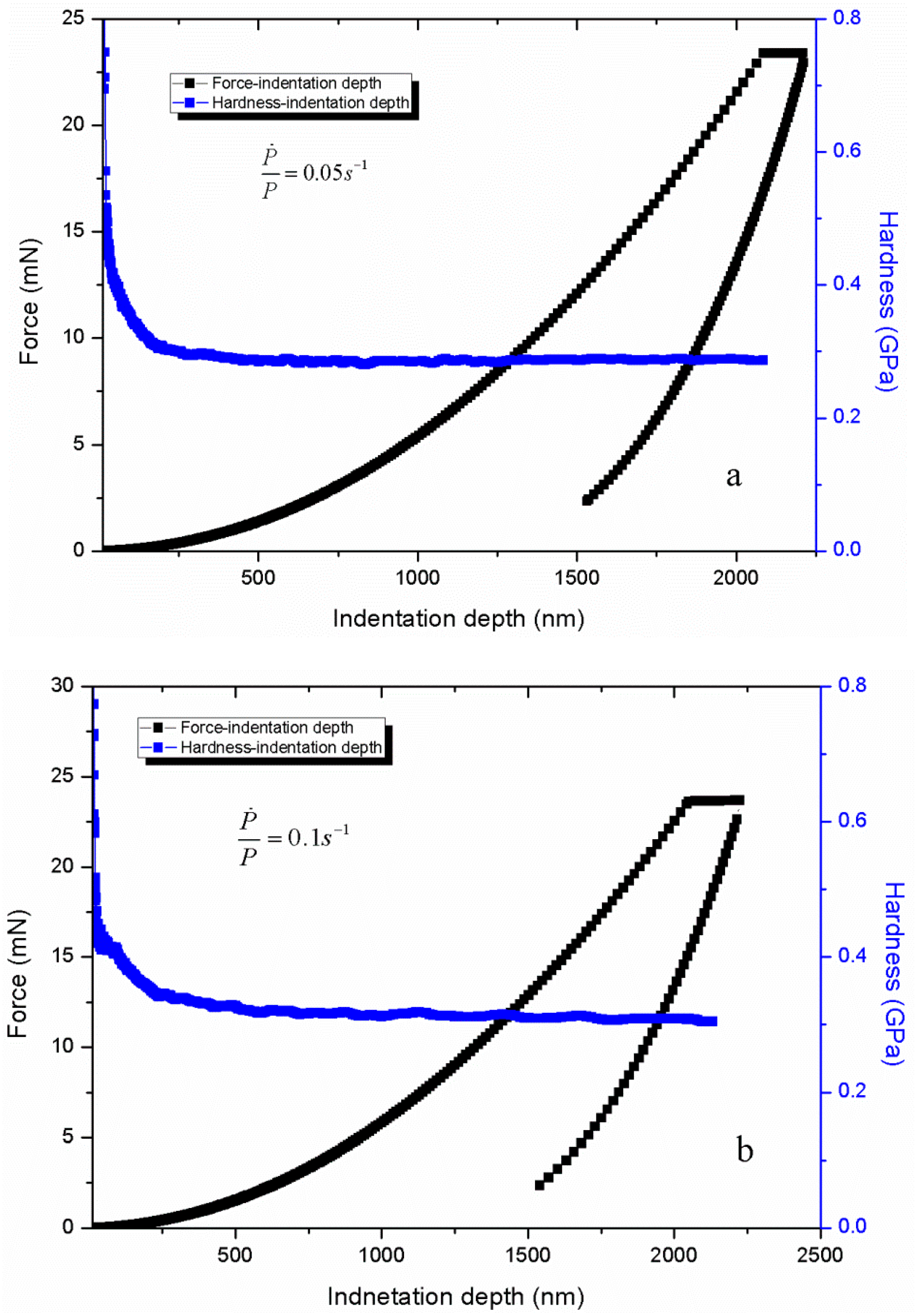

2.2. Nanoindentation Tests

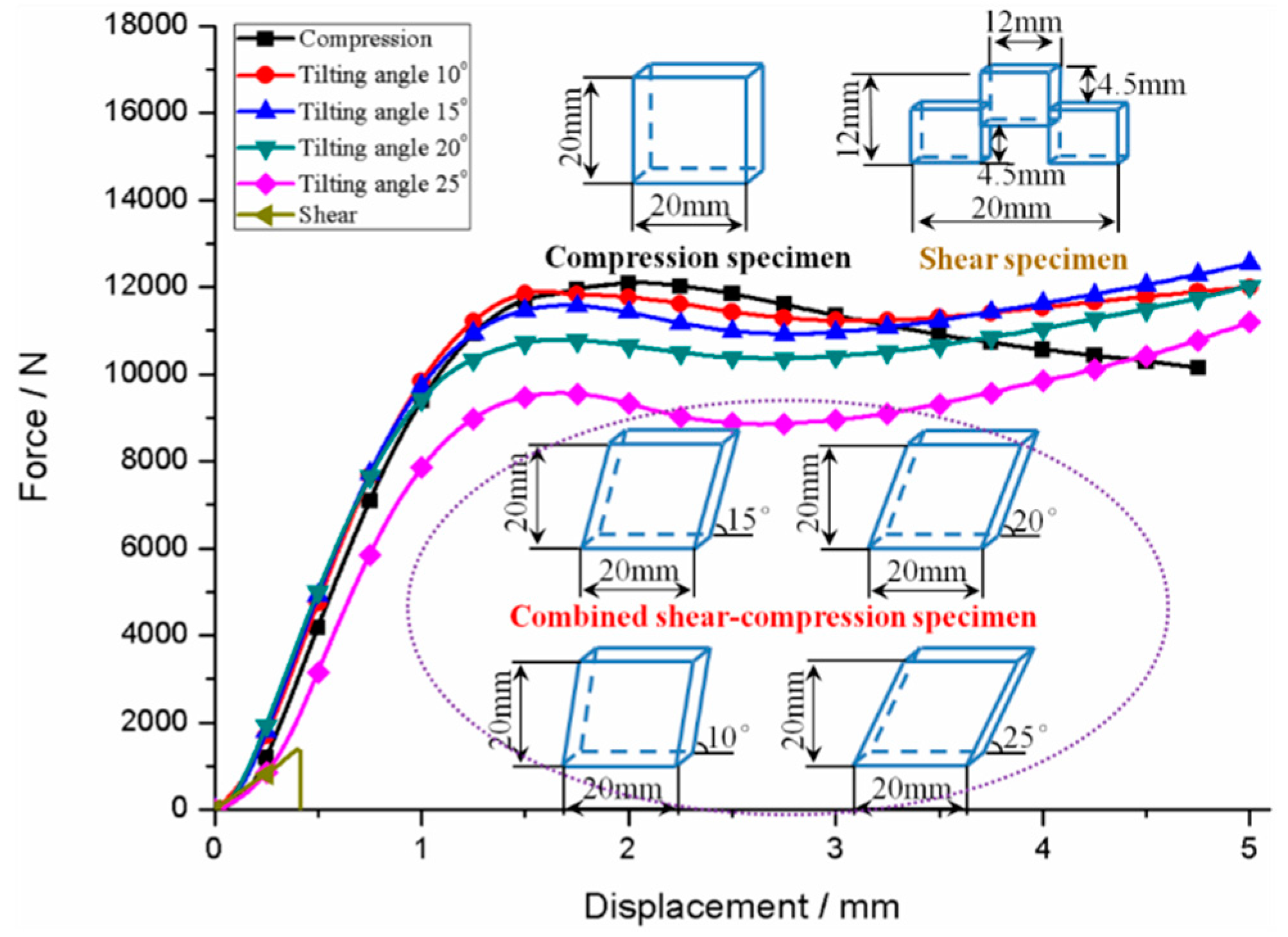

2.3. Combined Shear-Compression Tests

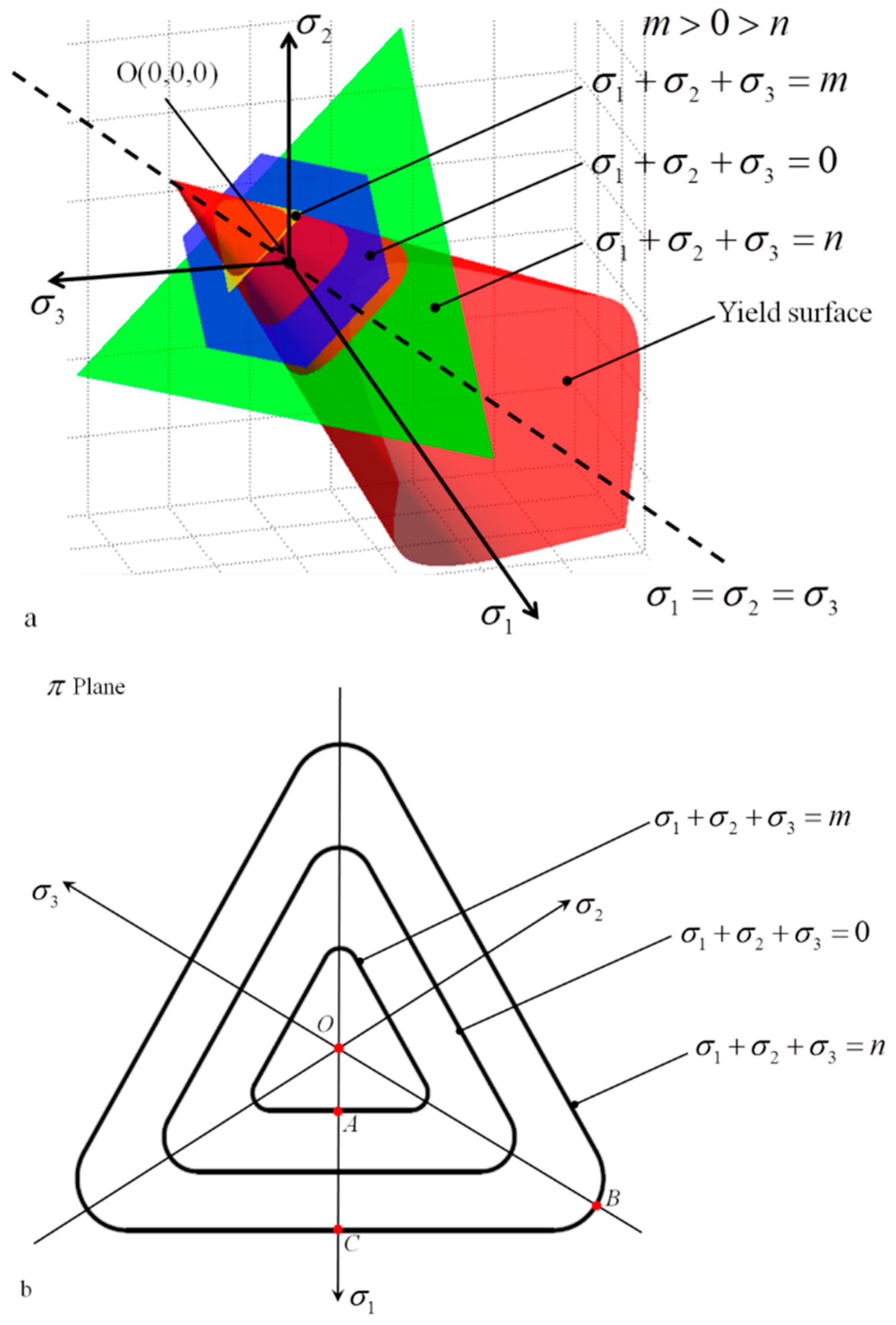

3. Theory

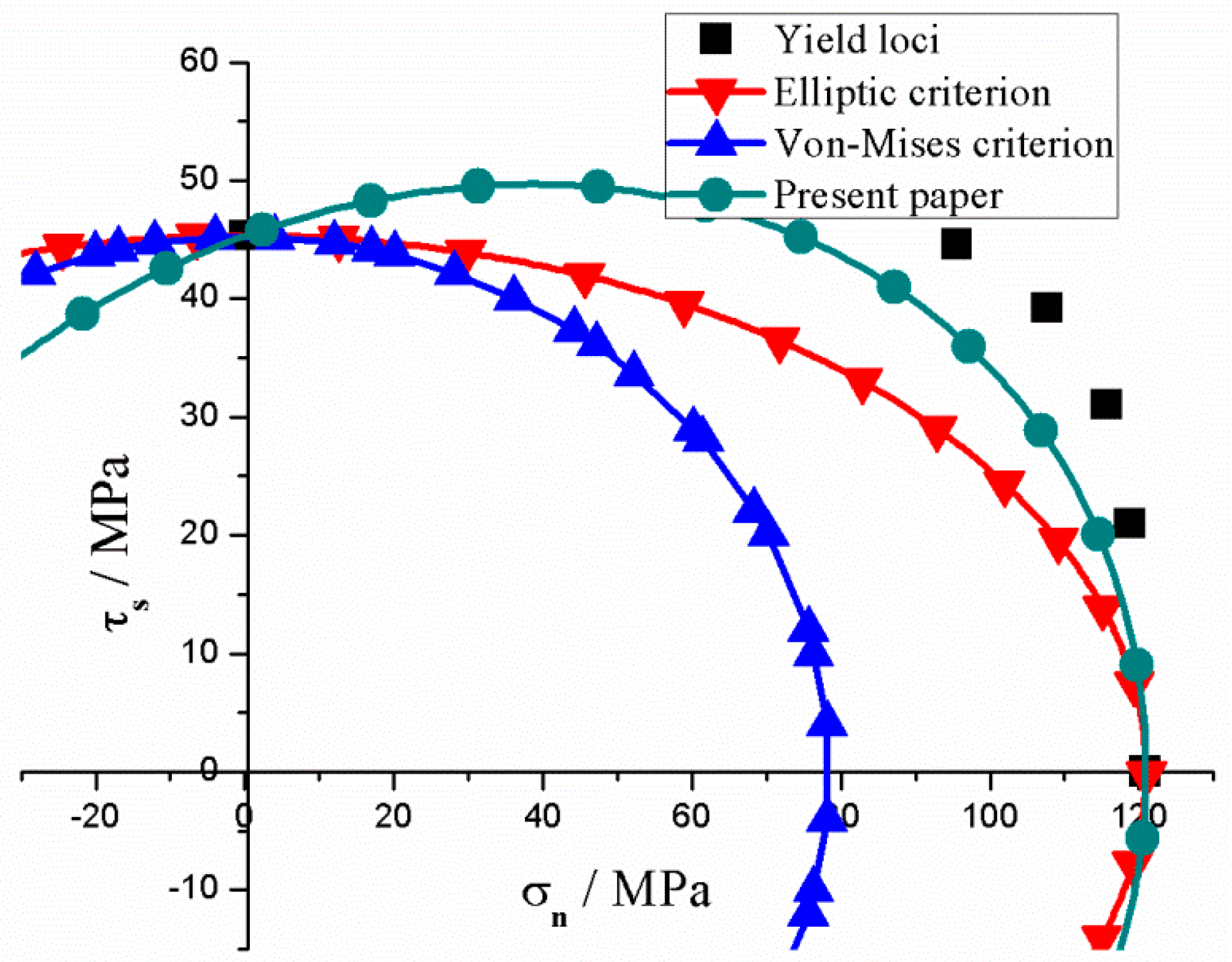

3.1. Yielding of PMMA

3.2. Size-Dependent Hardness

4. Results and Discussion

4.1. Yield Loci of PMMA

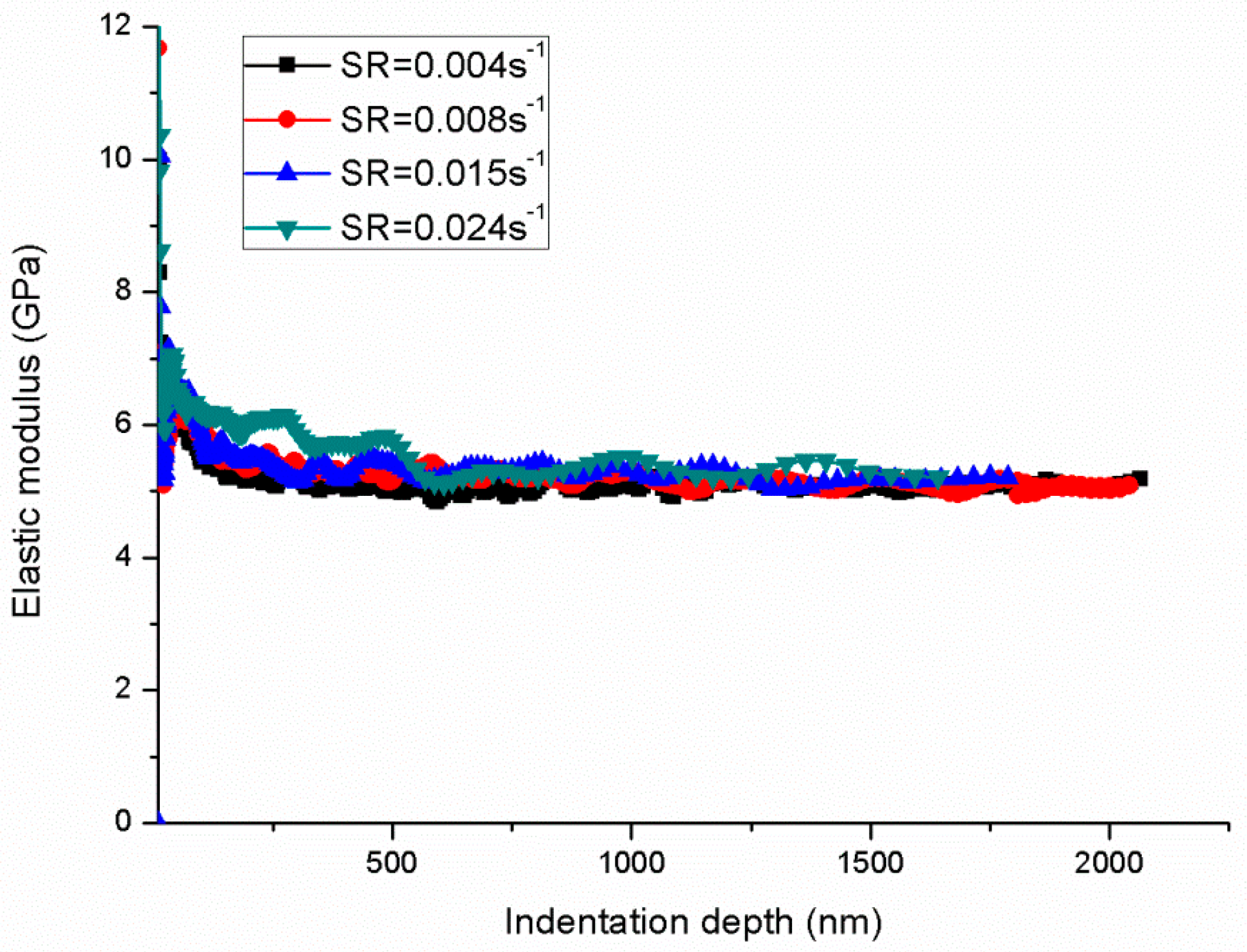

4.2. Nanoindentation Measurements of PMMA

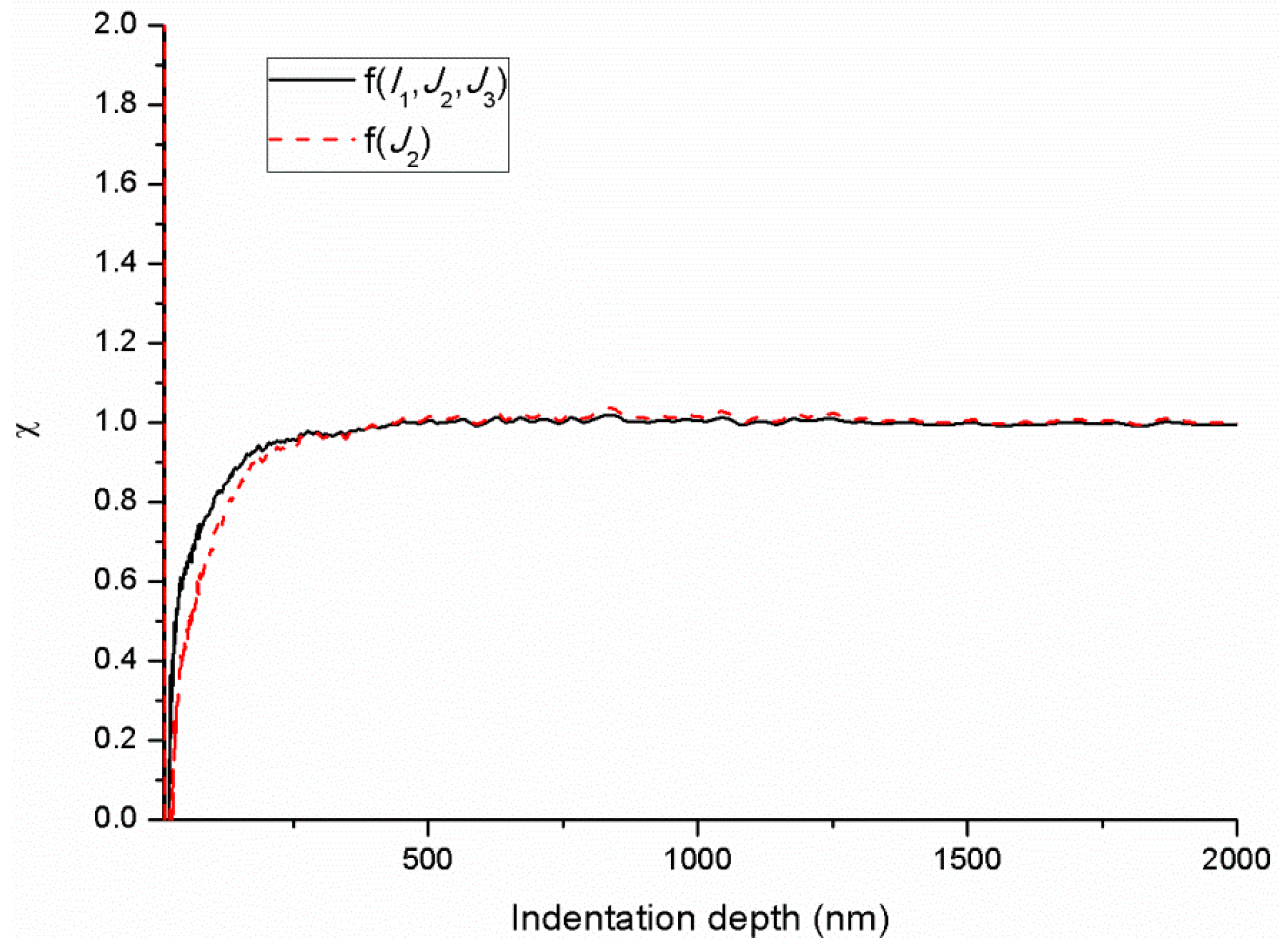

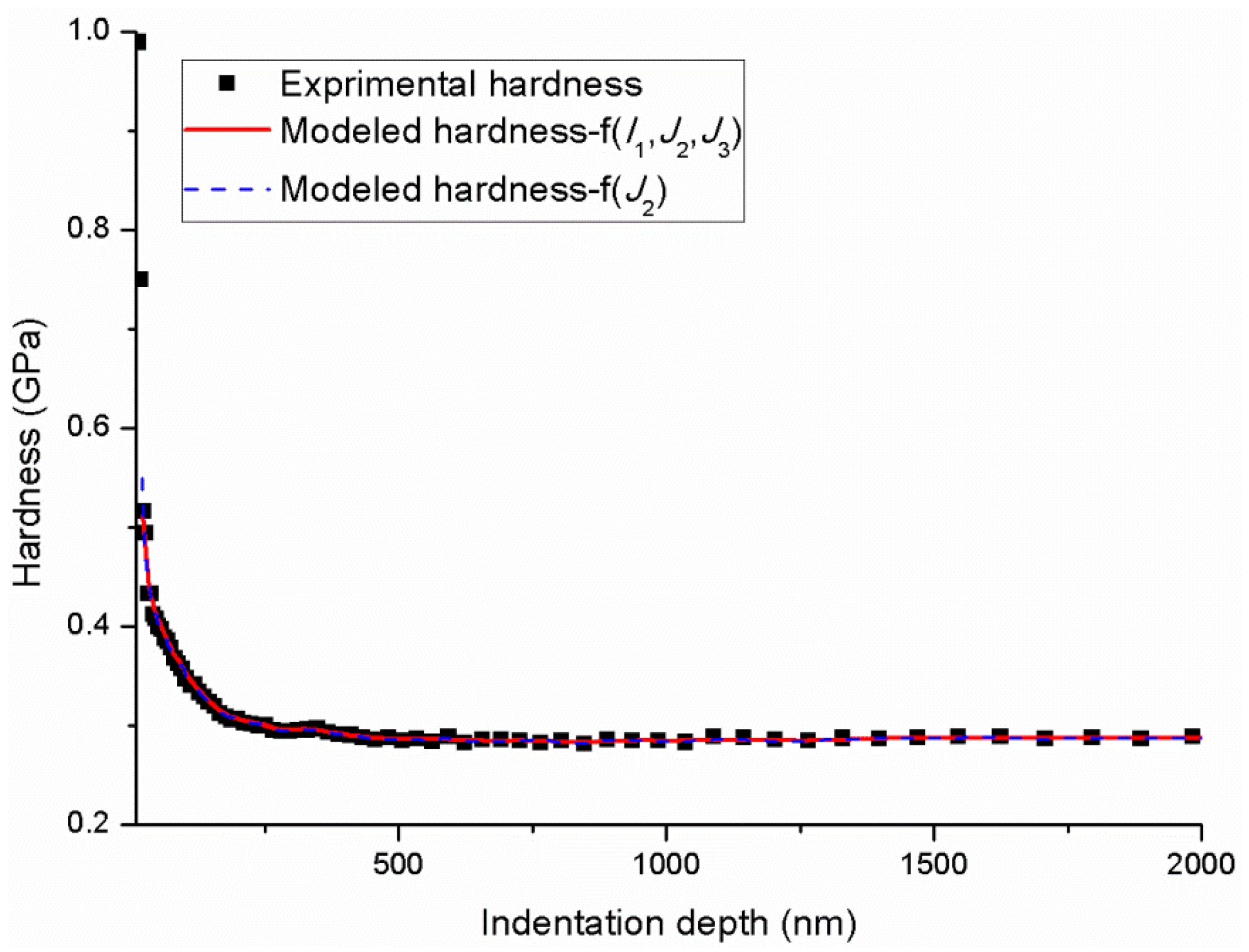

4.3. Comparison Between the Yield Models

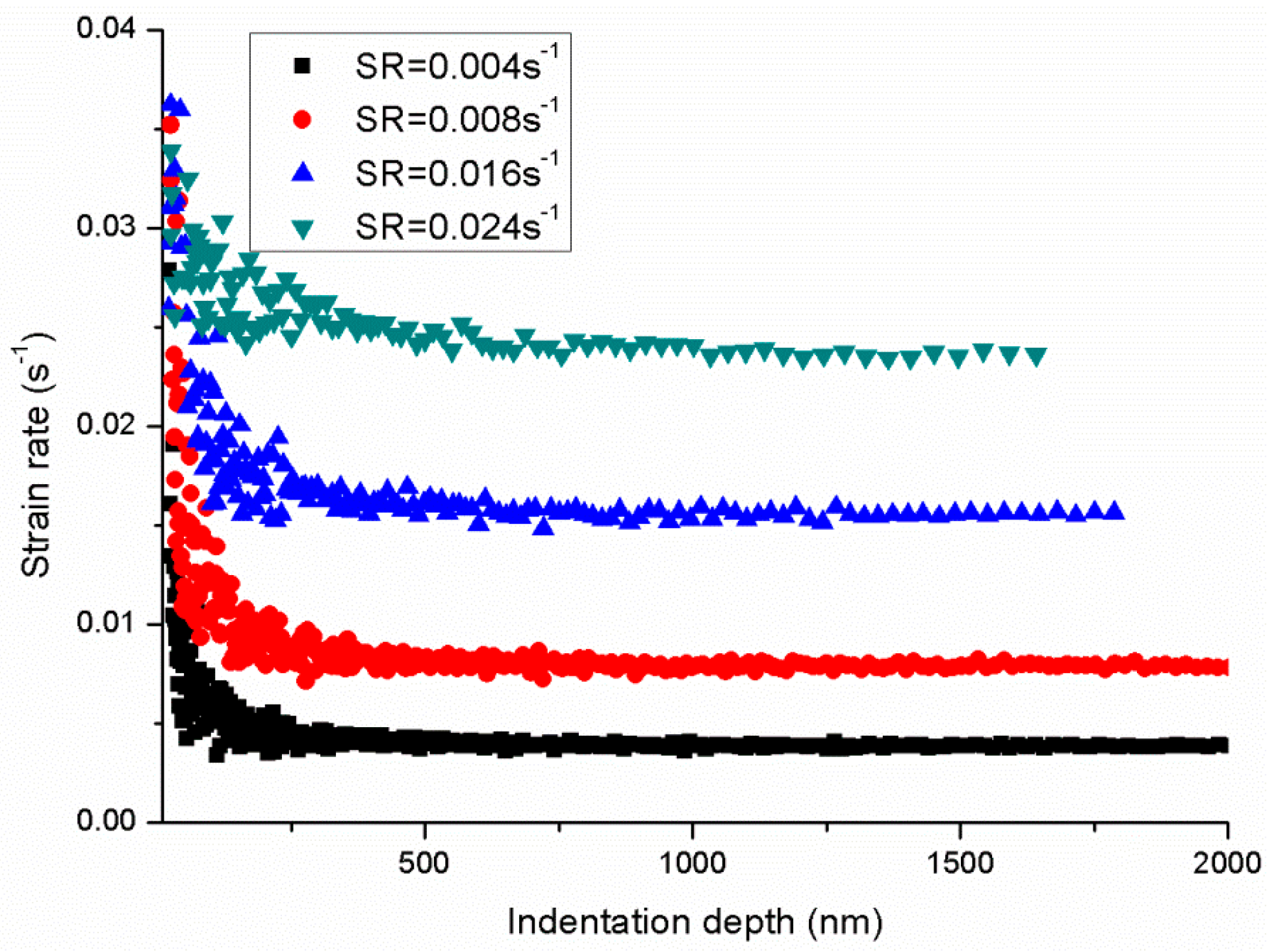

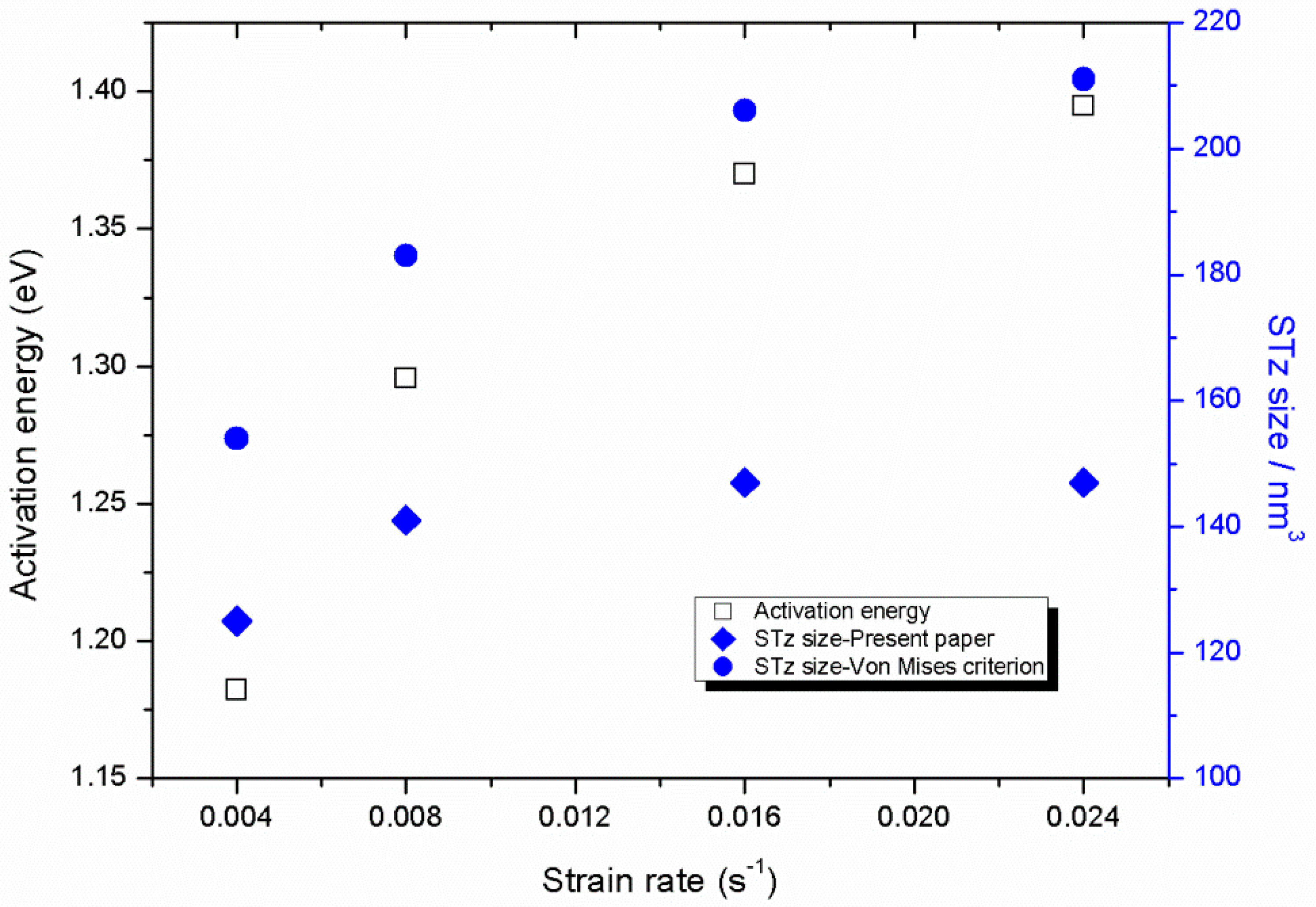

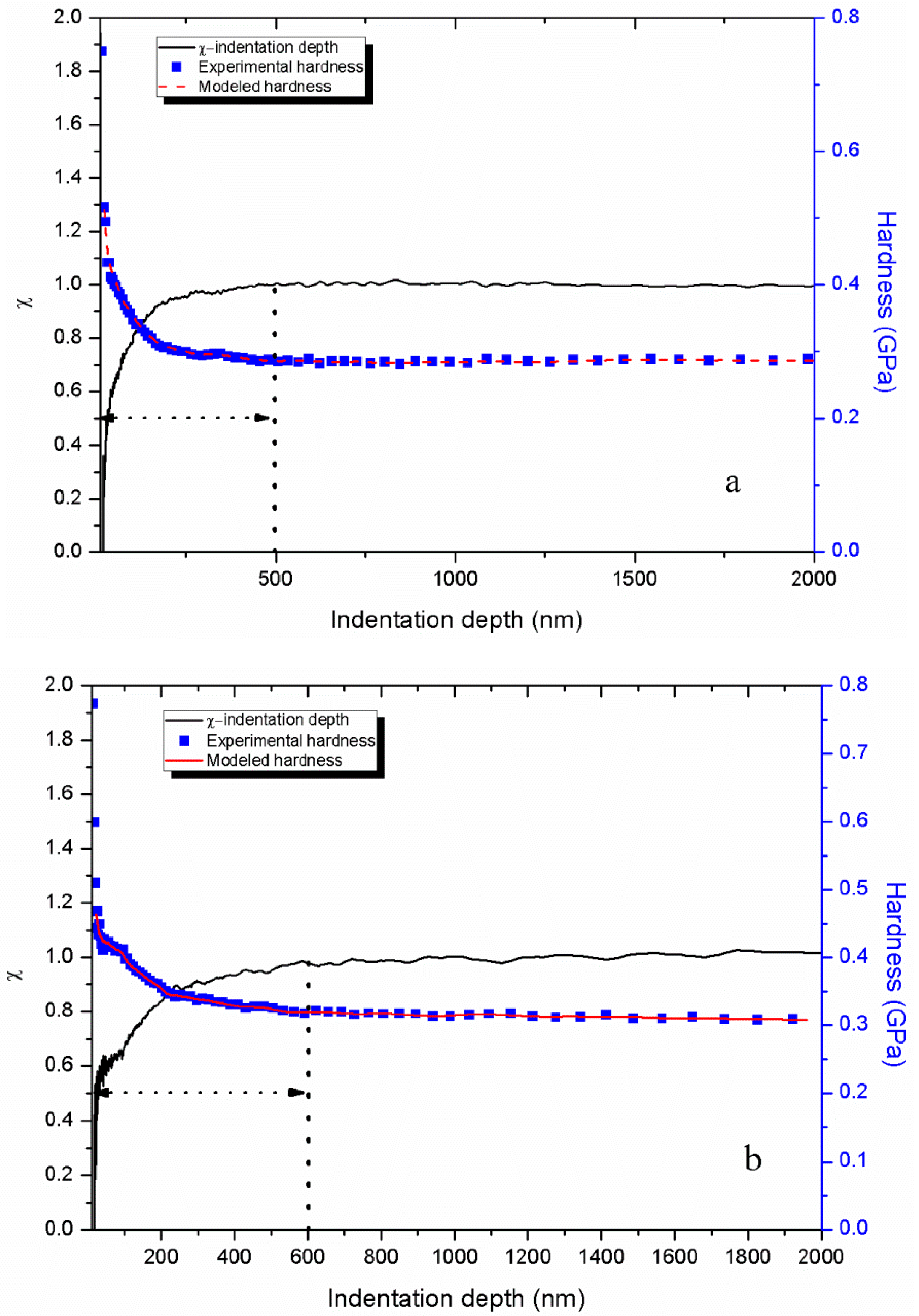

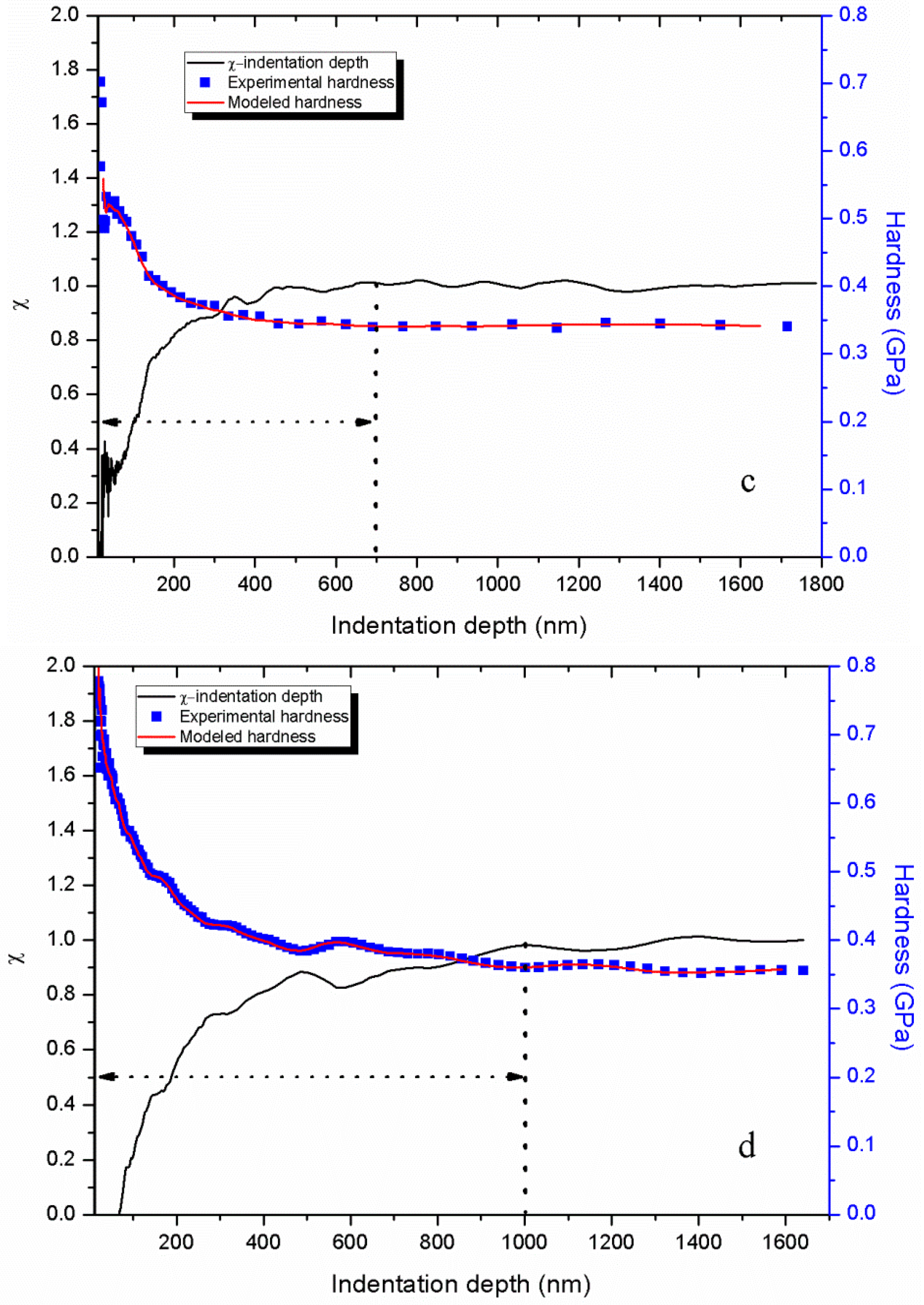

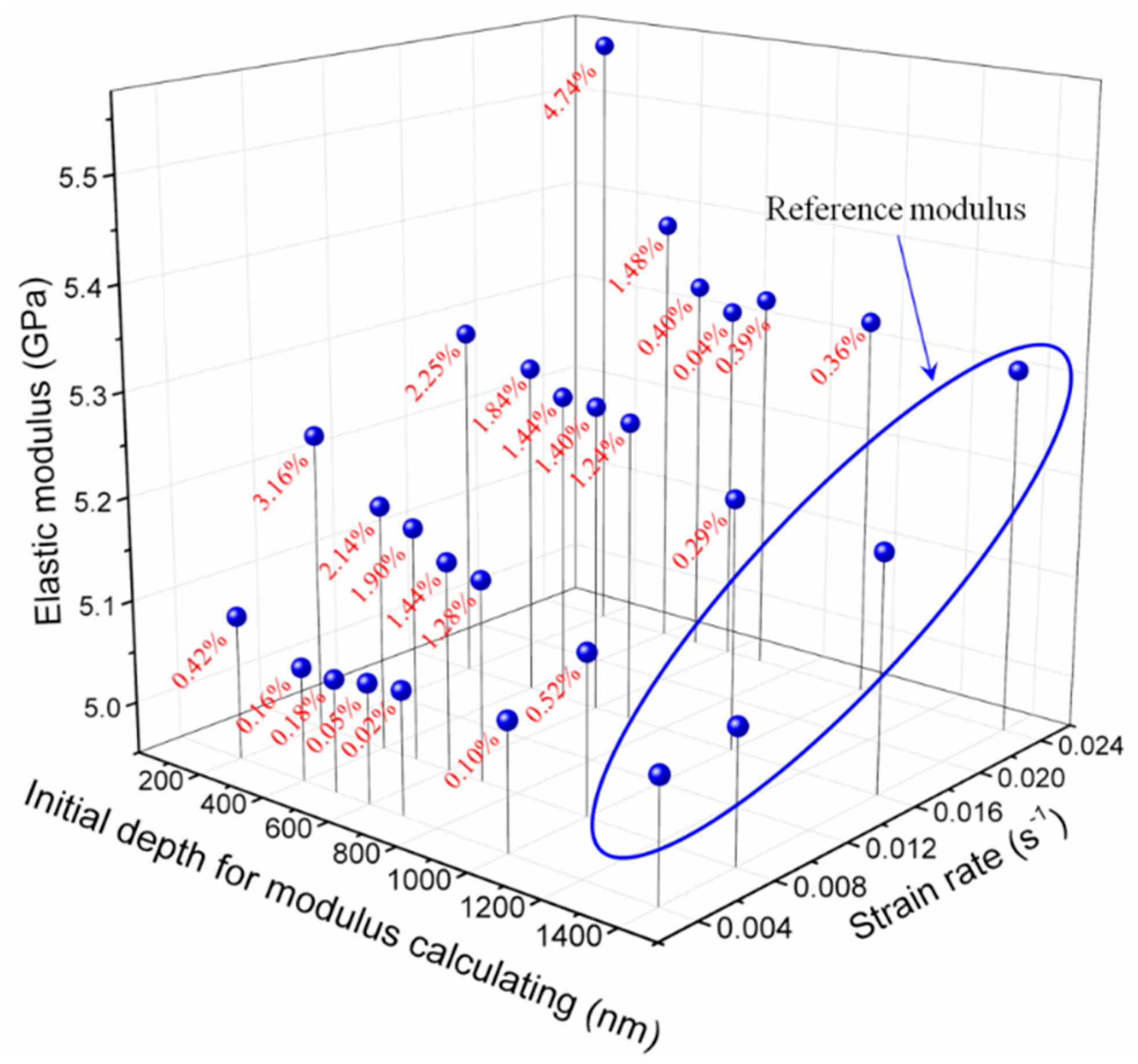

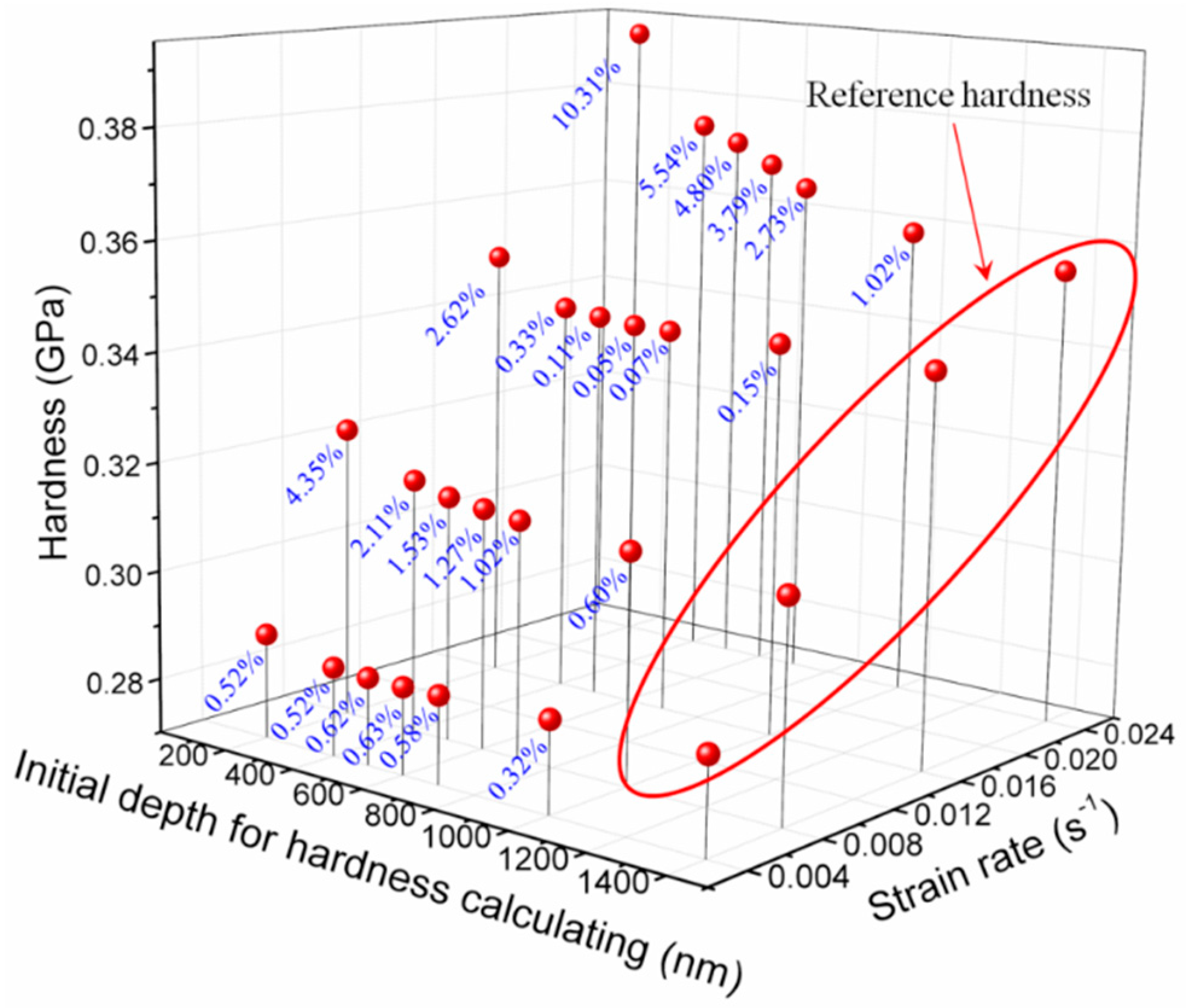

4.4. Influence of Strain Rate on PMMA Indentation Size Effects

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Malekmotiei, L.; Samadi-Dooki, A.; Voyiadjis, G. Nanoindentation Study of Yielding and Plasticity of Poly(methylmethacrylate). Macromolecules 2015, 48, 5348–5357. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Wang, Z.; Wu, G.; Liu, Z.; Shu, X. Quasi-static failure behaviour of PMMA under combined shear−compression loading. Polym. Test. 2015, 42, 181–184. [Google Scholar] [CrossRef]

- Zhou, Z.; Su, B.; Wang, Z.; Li, Z.; Shu, X.; Zhao, L. Shear–compression failure behavior of PMMA at different loading rates. Mater. Lett. 2013, 109, 151–153. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Wang, Z.; Wu, G.; Shu, X.; Liu, Z. Effects of strain rate on PMMA failure behavior. Appl. Phys. A 2016, 122. [Google Scholar] [CrossRef]

- Wu, H.; Ma, G.; Xia, Y. Experimental study of tensile properties of PMMA at intermediate strain rate. Mater. Lett. 2004, 58, 3681–3685. [Google Scholar] [CrossRef]

- Forquin, P.; Nasraoui, M.; Rusinek, A.; Siad, L. Experimental study of the confined behaviour of PMMA under quasi-static and dynamic loadings. Int. J. Impact Eng. 2012, 41, 46–57. [Google Scholar] [CrossRef]

- Hodzic, A.; Stachurski, Z.; Kim, J. Nano-indentation of polymer–glass interfaces Part I. Experimental and mechanical analysis. Polymer 2000, 41, 6895–6905. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Liu, Z.; Xiao, G.; Yuan, G.; Shu, X. Sensitivity of PMMA nanoindentation measurements to strain rate. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Chen, W.; Lu, F.; Cheng, M. Tension and compression tests of two polymers under quasi-static and dynamic loading. Polym. Test. 2002, 21, 113–121. [Google Scholar] [CrossRef]

- Prasad, K.E. Pressure sensitive flow and constraint factor in amorphous materials below glass transition. J. Mater. Res. 2009, 24, 890–897. [Google Scholar] [CrossRef]

- Schuh, C.; Hufnagel, T.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067. [Google Scholar] [CrossRef]

- Oleinik, E. Distortional Plasticity of Organic Glassy Polymers. In High Performance Polymers; Baer, E., Moet, A., Eds.; Hanser: New York, NY, USA, 1991; pp. 79–102. [Google Scholar]

- Oleinik, E.; Salamatina, S.R.O. Evolution in concepts concerning the mechanism of plasticity in solid polymers after the 1950s. Polym. Sci. Ser. A 2007, 49, 1302–1327. [Google Scholar] [CrossRef]

- Farrokh, B.; Khan, A. A strain rate dependent yield criterion for isotropic polymers: Low to high rates of loading. Eur. J. Mech. Solid. 2010, 29, 274–282. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Qiu, J.; Wang, Z.; Zhao, D.; Shu, X.; Yan, S. Investigation on the yield behavior of AZ91 magnesium alloy. J. Alloy. Compd. 2018, 738, 79–88. [Google Scholar] [CrossRef]

- Dorogoy, A.; Rittel, D. A numerical study of the applicability of the shear compression specimen to parabolic hardening materials. Exp. Mech. 2006, 46, 355–366. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, W.; Zhang, S.; Du, H.; Mu, Y.; Li, G. Multiaxial creep of frozen loess. Mech. Mater. 2016, 95, 172–191. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Shu, X.; Wang, Z.; Wu, G.; Zhao, L. Investigation on the yield behaviour and macroscopic phenomenological constitutive law of PA66. Polym. Test. 2018, 69, 563–582. [Google Scholar] [CrossRef]

- Nie, X.; Chen, W.; Sun, X.; Templeton, D. Dynamic failure of borosilicate glass under compression/shear loading experiments. J. Am. Ceram. Soc. 2007, 90, 2556–2562. [Google Scholar] [CrossRef]

- Hou, B.; Ono, A.; Abdennadher, S.; Pattofatto, S.; Li, Y.; Zhao, H. Impact behavior of honeycombs under combined shear-compression. Part I Exp. Int. J. Solids Struct. 2011, 48, 687–697. [Google Scholar] [CrossRef]

- Hou, B.; Pattofatto, S.; Li, Y.; Zhao, H. Impact behavior of honeycombs under combined shear-compression. Part II Anal. Int. J. Solid Struct. 2011, 48, 698–705. [Google Scholar] [CrossRef]

- Lee, H.; Ko, S.; Han, J.; Park, H.; Hwang, W. Novel analysis for nanoindentation size effect using strain gradient plasticity. Scr. Mater. 2005, 53, 1135–1139. [Google Scholar] [CrossRef]

- Fleck, N.; Muller, G.; Ashby, M.; Hutchinson, J. Strain gradient plasticity: Theory and experiment. Acta Met. Mater. 1994, 42, 475. [Google Scholar] [CrossRef]

- Stolken, J.; Evans, A. Micro bend test for measuring the plasticity length scale. Acta Mater. 1998, 46, 509. [Google Scholar] [CrossRef]

- Zhu, T.; Bushby, A.; Dunstan, D.J. Size effect in the initiation of plasticity for ceramics in nanoindentation. J. Mech. Phys. Solids 2008, 56, 1170–1185. [Google Scholar] [CrossRef]

- Pharr, G.; Herbert, E.; Gao, Y. The indentation size effect: A critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 2010, 40, 271–292. [Google Scholar] [CrossRef]

- Han, C. Influence of the molecular structure on indentation size effect in polymers. Mater. Sci. Eng. 2010, 527, 619–624. [Google Scholar] [CrossRef]

- Prasitthipayong, A.; Vachhani, S.; Tumey, S.; Minor, A.; Hosemann, P. Indentation size effect in unirradiated and ion-irradiated 800H steel at high temperatures. Acta Mater. 2018, 144, 896–904. [Google Scholar] [CrossRef]

- Voyiadjis, G.; Samadi-Dooki, A.; Malekmotiei, L. Nanoindentation of high performance semicrystalline polymers: A case study on PEEK. Polym. Test. 2017, 61, 57–64. [Google Scholar] [CrossRef]

- Nix, W.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solid 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Lam, D.; Chong, A. Indentation model and strain gradient plasticity law for glassy polymers. J. Mater. Res. 1999, 14, 3784–3788. [Google Scholar] [CrossRef]

- Voyiadjis, G.; Malekmotiei, L.; Samadi-Dooki, A. Indentation size effect in amorphous polymers based on shear transformation mediated plasticity. Polymer 2018, 137, 72–81. [Google Scholar] [CrossRef]

- Oyen, M. Sensitivity of polymer nanoindentation creep measurements to experimental variables. Acta Mater. 2007, 55, 3633–3639. [Google Scholar] [CrossRef]

- Tsui, T.; Oliver, W.; Pharr, G. Influences of stress on the measurement of mechanical properties using nanoindentation: Part I. Experimental studies in an aluminum alloy. J. Mater. Res. 1996, 11, 752–759. [Google Scholar] [CrossRef]

- Poisl, W.; Oliver, W.; Fabes, B. The relationship between indentation and uniaxial creep in amorphous selenium. J. Mater. Res. 1995, 10, 2024–2032. [Google Scholar] [CrossRef]

- Schuh, C.; Nieh, T. A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 2003, 51, 87–99. [Google Scholar] [CrossRef]

- Schuh, C.; Lund, A.; Nieh, T. New regime of homogeneous flow in the deformation map of metallic glasses: Elevated temperature nanoindentation experiments and mechanistic modeling. Acta Mater. 2004, 52, 5879–5891. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Shu, X.; Wang, Z.; Wu, G.; Zhao, L. Experimental investigation on the yield loci of PA66. Polym. Test. 2016, 51, 148–150. [Google Scholar] [CrossRef]

- Li, H.; Hu, X.; Yang, H.; Li, L. Anisotropic and asymmetrical yielding and its distorted evolution: Modeling and applications. Int. J. Plast. 2016, 82, 127–158. [Google Scholar] [CrossRef]

- Ghorbel, E. A viscoplastic constitutive model for polymeric materials. Int. J. Plast. 2008, 24, 2032–2058. [Google Scholar] [CrossRef]

- Qiu, J.; Jin, T.; Su, B.; Shu, X.; Li, Z. Experimental investigation on the yield behavior of PMMA. Polym. Bull. 2018, 75. [Google Scholar] [CrossRef]

- Cazacu, O.; Barlat, F. A criterion for description of anisotropy and yield differential effects in pressure-insensitive metals. Int. J. Plast. 2004, 20, 2027–2045. [Google Scholar] [CrossRef]

- Pugno, N. A general shape/size-effect law for nanoindentation. Acta Mater. 2007, 55, 1947–1953. [Google Scholar] [CrossRef]

- Ma, Y.; Ye, J.; Peng, G.; Wen, D.; Zhang, T. Nanoindentation study of size effect on shear transformation zone size in a Ni–Nb metallic glass. Mater. Sci. Eng. A 2015, 627, 153–160. [Google Scholar] [CrossRef]

- Spaepen, F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Met. 1977, 25, 407–415. [Google Scholar] [CrossRef]

- Argon, A. Plastic deformation in metallic glasses. Acta Met. 1979, 27, 47–58. [Google Scholar] [CrossRef]

- Argon, A.; Bessonov, M. Plastic deformation in polyimides, with new implications on the theory of plastic deformation of glassy polymers. Philos. Mag. 1977, 35, 917–933. [Google Scholar] [CrossRef]

- Argon, A. The Physics of Deformation and Fracture of Polymers; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

| Stress Component | Compression (MPa) | Combined Shear-Compression (MPa) | Shear (MPa) | |||

|---|---|---|---|---|---|---|

| 10° | 15° | 20° | 25° | |||

| −120.92 | −118.85 | −115.72 | −107.70 | −95.61 | – | |

| – | 20.96 | 30.01 | 39.20 | 44.58 | 45.31 | |

| – | 3.59 | 7.78 | 12.76 | 17.56 | 45.31 | |

| – | – | – | – | – | – | |

| −120.92 | −122.44 | −123.50 | −120.46 | −113.17 | 45.31 | |

| 40.31 | 43.20 | 46.36 | 48.66 | 49.43 | 45.31 | |

| 40.31 | 39.62 | 38.57 | 35.90 | 31.87 | 0 | |

| −80.61 | −82.82 | −84.93 | −84.56 | −81.30 | −45.31 | |

| −120.92 | −118.85 | −115.72 | −107.7 | −95.61 | 0 | |

| 69.81 | 71.75 | 73.65 | 73.50 | 70.95 | 45.31 | |

| −50.78 | −52.14 | −53.35 | −52.86 | −50.41 | 0 | |

| Strain Rate /s−1 | STz-Size | STz-Size | Activation Energy /eV |

|---|---|---|---|

| 0.004 | 154 | 125 | 1.182 |

| 0.008 | 183 | 141 | 1.295 |

| 0.016 | 206 | 147 | 1.370 |

| 0.024 | 211 | 147 | 1.395 |

| Depth Range/Nm | Elastic Modulus/GPa | Hardness/GPa | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.004 s−1 | 0.008 s−1 | 0.016 s−1 | 0.024 s−1 | 0.004 s−1 | 0.008 s−1 | 0.016 s−1 | 0.024 s−1 | |

| 200–2000 | 5.090 | 5.240 | 5.298 | 5.558 | 0.289 | 0.324 | 0.351 | 0.392 |

| 400–2000 | 5.060 | 5.188 | 5.277 | 5.385 | 0.286 | 0.317 | 0.343 | 0.375 |

| 500–2000 | 5.059 | 5.175 | 5.257 | 5.327 | 0.286 | 0.351 | 0.343 | 0.372 |

| 600–2000 | 5.066 | 5.152 | 5.254 | 5.308 | 0.286 | 0.314 | 0.342 | 0.368 |

| 700–2000 | 5.070 | 5.145 | 5.246 | 5.327 | 0.286 | 0.313 | 0.342 | 0.365 |

| 1000–2000 | 5.073 | 5.105 | 5.197 | 5.325 | 0.287 | 0.312 | 0.342 | 0.359 |

| 1400–2000 | 5.068 | 5.079 | 5.182 | 5.306 | 0.288 | 0.310 | 0.342 | 0.355 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, H.; Jin, T.; Lv, L.; Ai, Q. Indentation Size Effect in Pressure-Sensitive Polymer Based on A Criterion for Description of Yield Differential Effects and Shear Transformation-Mediated Plasticity. Polymers 2019, 11, 412. https://doi.org/10.3390/polym11030412

Lin H, Jin T, Lv L, Ai Q. Indentation Size Effect in Pressure-Sensitive Polymer Based on A Criterion for Description of Yield Differential Effects and Shear Transformation-Mediated Plasticity. Polymers. 2019; 11(3):412. https://doi.org/10.3390/polym11030412

Chicago/Turabian StyleLin, Hui, Tao Jin, Lin Lv, and Qinglin Ai. 2019. "Indentation Size Effect in Pressure-Sensitive Polymer Based on A Criterion for Description of Yield Differential Effects and Shear Transformation-Mediated Plasticity" Polymers 11, no. 3: 412. https://doi.org/10.3390/polym11030412

APA StyleLin, H., Jin, T., Lv, L., & Ai, Q. (2019). Indentation Size Effect in Pressure-Sensitive Polymer Based on A Criterion for Description of Yield Differential Effects and Shear Transformation-Mediated Plasticity. Polymers, 11(3), 412. https://doi.org/10.3390/polym11030412